Flexible manufacturing method of thin-wall complex bent pipes

A flexible manufacturing and pipe bending technology, applied in the field of plastic forming of pipe parts, can solve problems such as difficult thin-wall forming, section distortion, and no suitable manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

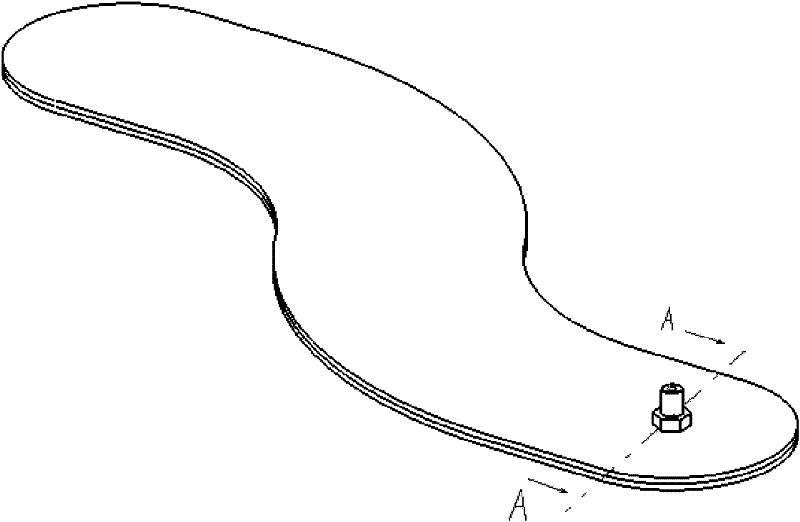

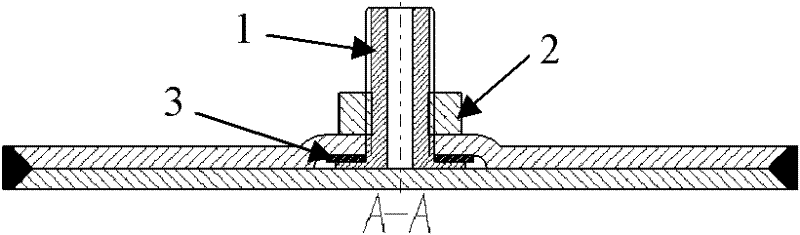

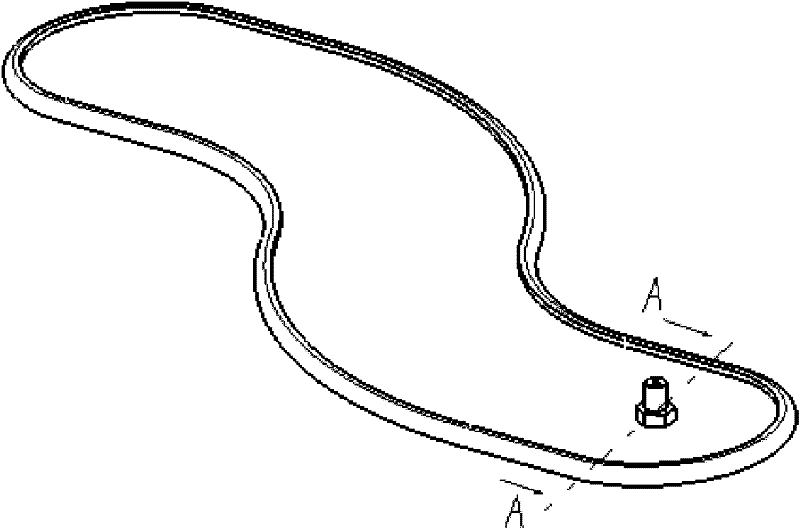

[0029] The specific content and working process of the present invention are further described below in conjunction with the embodiments shown in the accompanying drawings.

[0030] The flexible manufacturing method of a thin-walled complex bend pipe according to the present invention adopts the following specific steps: dividing the bend pipe into two mirror-symmetrical workpieces, calculating the unfolded views of the two workpieces, and reserving appropriate flanges Quantity, welding seam and process supplement area for pressurization, and install pressurizing pipe joint 1 on one of the workpieces. After direct butt welding or flanging welding of the two workpieces, gas or liquid is used to inflate the pipe joint 1. The elbow can be composed of one or more sections, and it can also be a special-shaped pipe or a variable-section pipe, or a pipe with a variable bending radius.

[0031] Divide the elbow into two mirror-symmetrical workpieces, calculate the expansion diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com