Sn-doped high-entropy perovskite oxide ceramic material with high power density, and preparation method thereof

A perovskite oxide, high power density technology, applied in the field of relaxor ferroelectrics, can solve problems such as environmental damage, reduce waste of resources, reduce the steps of removing binders, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

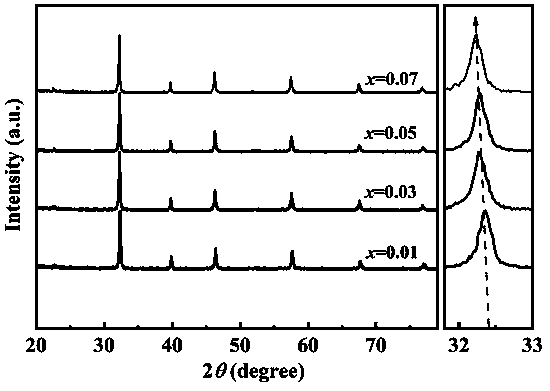

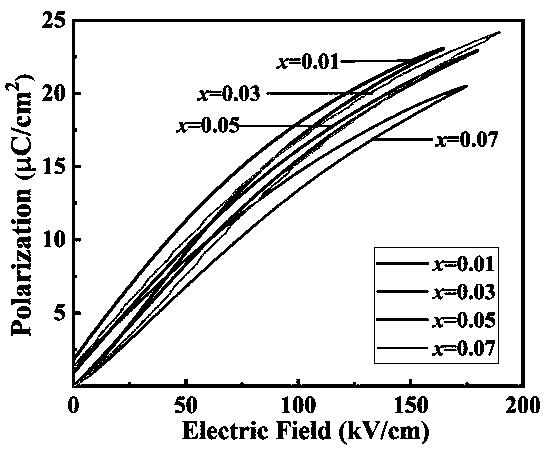

[0029] The chemical formula of this high entropy ceramic material is: (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 1-x sn x o 3 ,in x represents the mole percentage, and x =0.01.

[0030] The above Sn-doped (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 )TiO 3 The preparation method of high entropy ceramic material comprises the following steps:

[0031] (1) According to the chemical formula (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 1-x sn x o 3 ( x =0.01) will analyze pure Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 , SrCO 3 , CaCO 3 、TiO 2 and SnO 2 After preparation, it is uniformly mixed by ball milling, then dried, sieved, and then pre-calcined to obtain a block solid;

[0032] (2) After pulverizing the massive solid, ball milling is carried out again, and the product is sieved to obtain uniform size (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 0.99 sn 0.01 o 3 Powder;

[0033] (3) will get (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 0.99 sn 0.01 o 3 For powde...

Embodiment 2

[0040] The chemical formula of this high entropy ceramic material is: (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 1-x sn x o 3 ,in x represents the mole percentage, and x =0.03.

[0041] The above Sn-doped (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 )TiO 3 The preparation method of high entropy ceramic material comprises the following steps:

[0042] (1) According to the chemical formula (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 1-x sn x o 3 ( x =0.03) will analyze pure Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 , SrCO 3 , CaCO 3 、TiO 2 and SnO 2 After preparation, it is uniformly mixed by ball milling, then dried, sieved, and then pre-calcined to obtain a block solid;

[0043] (2) After pulverizing the massive solid, ball milling is carried out again, and the product is sieved to obtain uniform size (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 0.97 sn 0.03 o 3 Powder;

[0044] (3) will get (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 0.97 sn 0.03 o 3 For powde...

Embodiment 3

[0052] The chemical formula of this high entropy ceramic material is: (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 1-x sn x o 3 ,in x represents the mole percentage, and x =0.05.

[0053] The above Sn-doped (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 )TiO 3 The preparation method of high entropy ceramic material comprises the following steps:

[0054] (1) According to the chemical formula (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 1-x sn x o 3 ( x =0.05) will analyze pure Na 2 CO 3 、Bi 2 o 3 、BaCO 3 , SrCO 3 , CaCO 3 、TiO 2 and SnO 2 After preparation, it is uniformly mixed by ball milling, then dried, sieved, and then pre-calcined to obtain a block solid;

[0055] (2) After pulverizing the massive solid, ball milling is carried out again, and the product is sieved to obtain uniform size (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 0.95 sn 0.05 o 3 Powder;

[0056] (3) will get (Na 0.2 Bi 0.2 Ba 0.2 Sr 0.2 Ca 0.2 ) Ti 0.95 sn 0.05 o 3 For the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com