Epoxy resin thermally conductive insulating material and preparation method thereof

A heat-conducting insulating material, epoxy resin technology, applied in the direction of plastic/resin/wax insulators, heat exchange materials, organic insulators, etc., can solve problems such as complex preparation process, achieve simple preparation method, reduce material cost, and excellent insulation The effect of performance features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

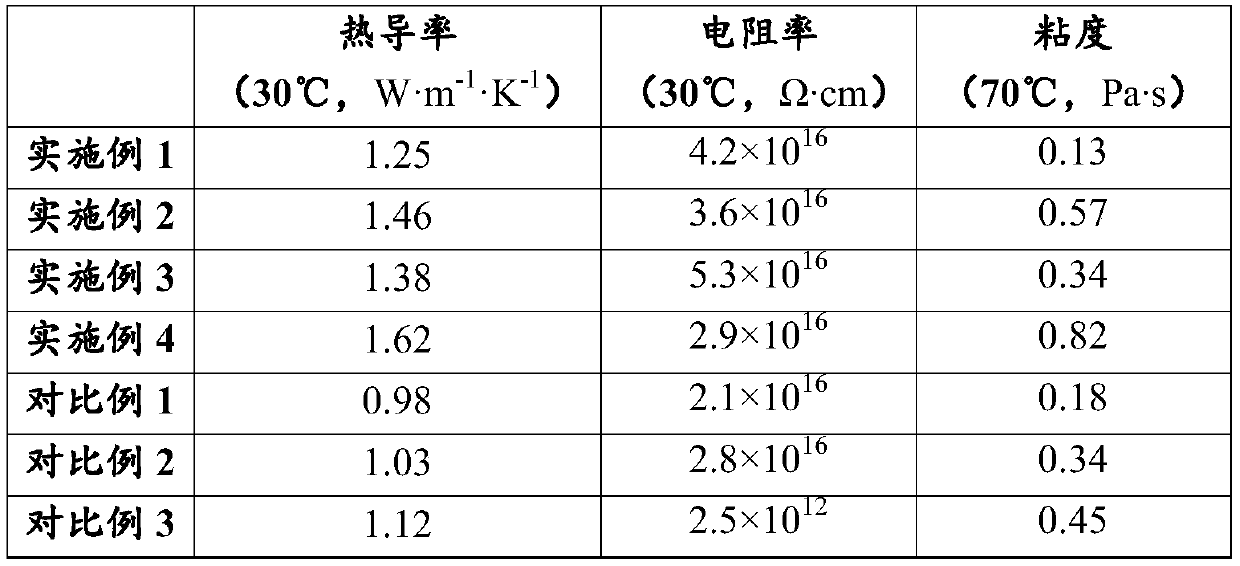

Examples

Embodiment 1

[0035] This embodiment provides an epoxy resin thermally conductive insulating material, the preparation method of which comprises:

[0036] Mix three kinds of fillers with different particle sizes with a total volume fraction of 35% with bisphenol A epoxy matrix and phthalic anhydride curing agent and heat to 50°C under pressure of 1.3×10 4 Vacuum stirring in Pa environment for 20min, then pouring into the mold, heating and curing at 70°C and 120°C successively, the curing time is 2h and 18h respectively. The three fillers are all boron nitride, the average particle size ratio of the three fillers is 4:1.6:0.8 according to the particle size, the particle number ratio is 1:0.9:2.2 according to the particle size, and the largest average particle size The particle size of the filler was 22 μm.

Embodiment 2

[0038]This embodiment provides an epoxy resin thermally conductive insulating material, the preparation method of which comprises:

[0039] Mix three kinds of fillers with different particle sizes with a total volume fraction of 40% with E51 epoxy matrix and hexahydrophthalic anhydride curing agent, heat to 70°C and press at a pressure of 1.8×10 4 Vacuum stirring under Pa environment for 3 hours, then pouring into the mold, heating and curing at 80°C and 130°C successively, the curing time is 1h and 23h respectively. The three fillers are all mixtures of boron nitride, silicon nitride, and silicon oxide at a volume ratio of 1:1:2, and the average particle diameter ratio of the three fillers is arranged as 4:1.656:1.2 according to particle size, and the particle number ratio The particle size arrangement is 0.98:1:2.03, and the particle size of the filler with the largest average particle size is 18 μm.

Embodiment 3

[0041] This embodiment provides an epoxy resin thermally conductive insulating material, and its preparation method includes:

[0042] Mix three kinds of fillers with different particle sizes with a total volume fraction of 37%, mix with bisphenol F epoxy matrix and methyl hexahydrophthalic anhydride curing agent, heat to 120°C and press at a pressure of 1.7×10 4 Vacuum stirring in Pa environment for 10min, then pouring into the mold, heating and curing at 120°C and 180°C successively, the curing time is 2h and 3h respectively. The three fillers are all mixtures of boron nitride, aluminum nitride, and silicon nitride in a mass ratio of 3:5:1, and the average particle diameter ratio of the three fillers is arranged as 4:1.656:0.9 according to particle size, and the particle number ratio The particle size arrangement is 1.05:1:1.96, and the particle size of the filler with the largest average particle size is 11 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com