Patents

Literature

174 results about "Epoxy matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

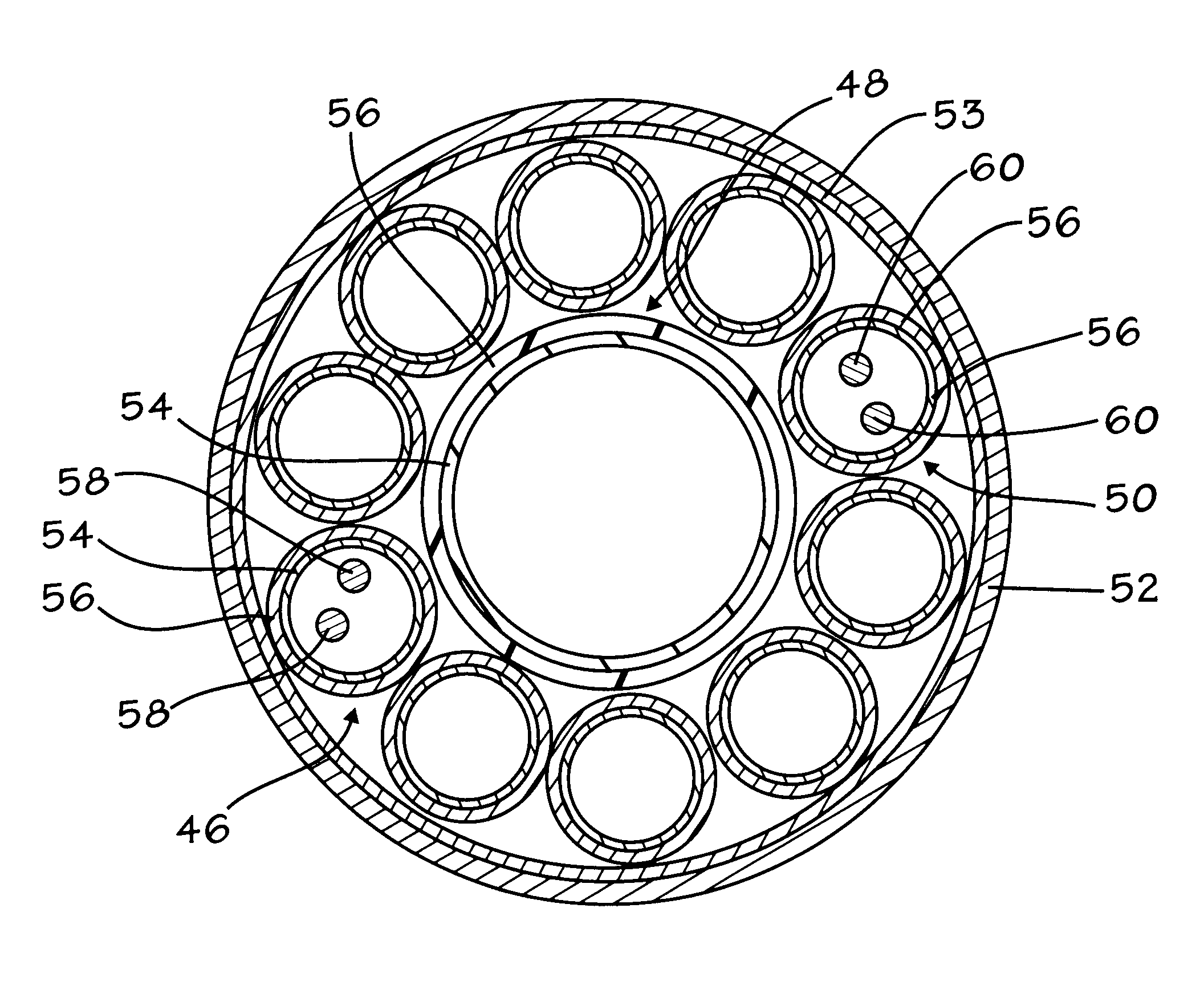

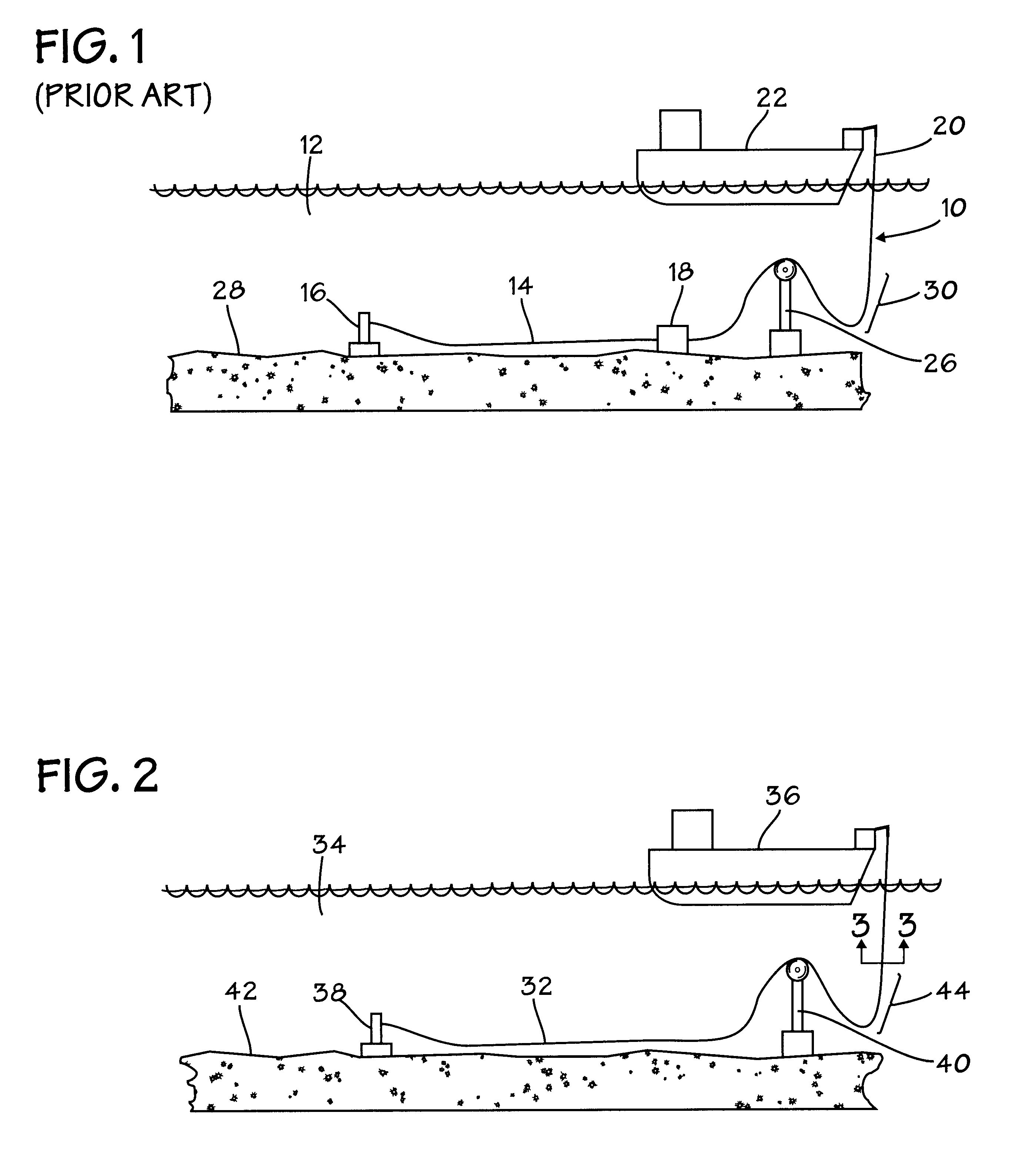

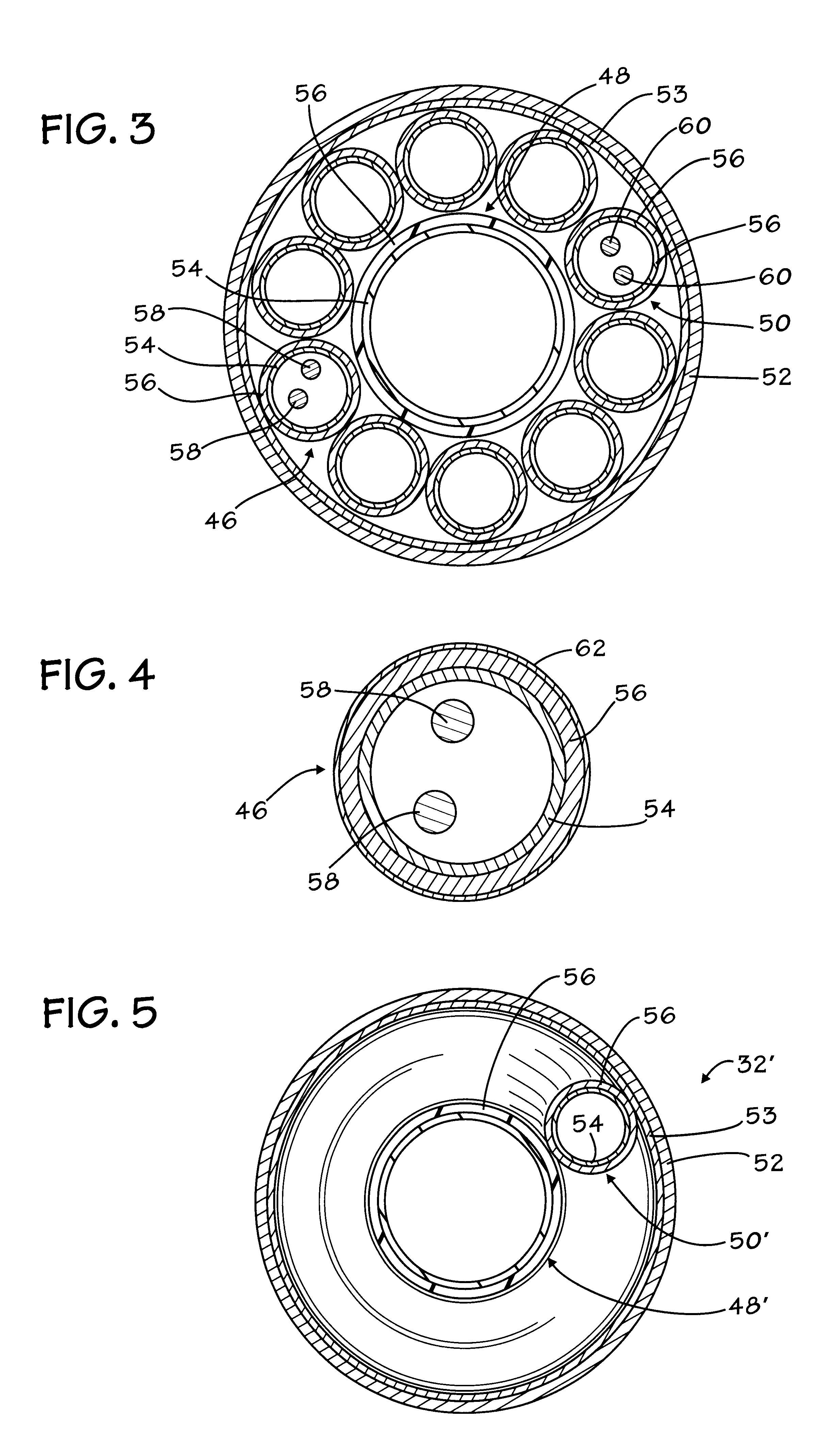

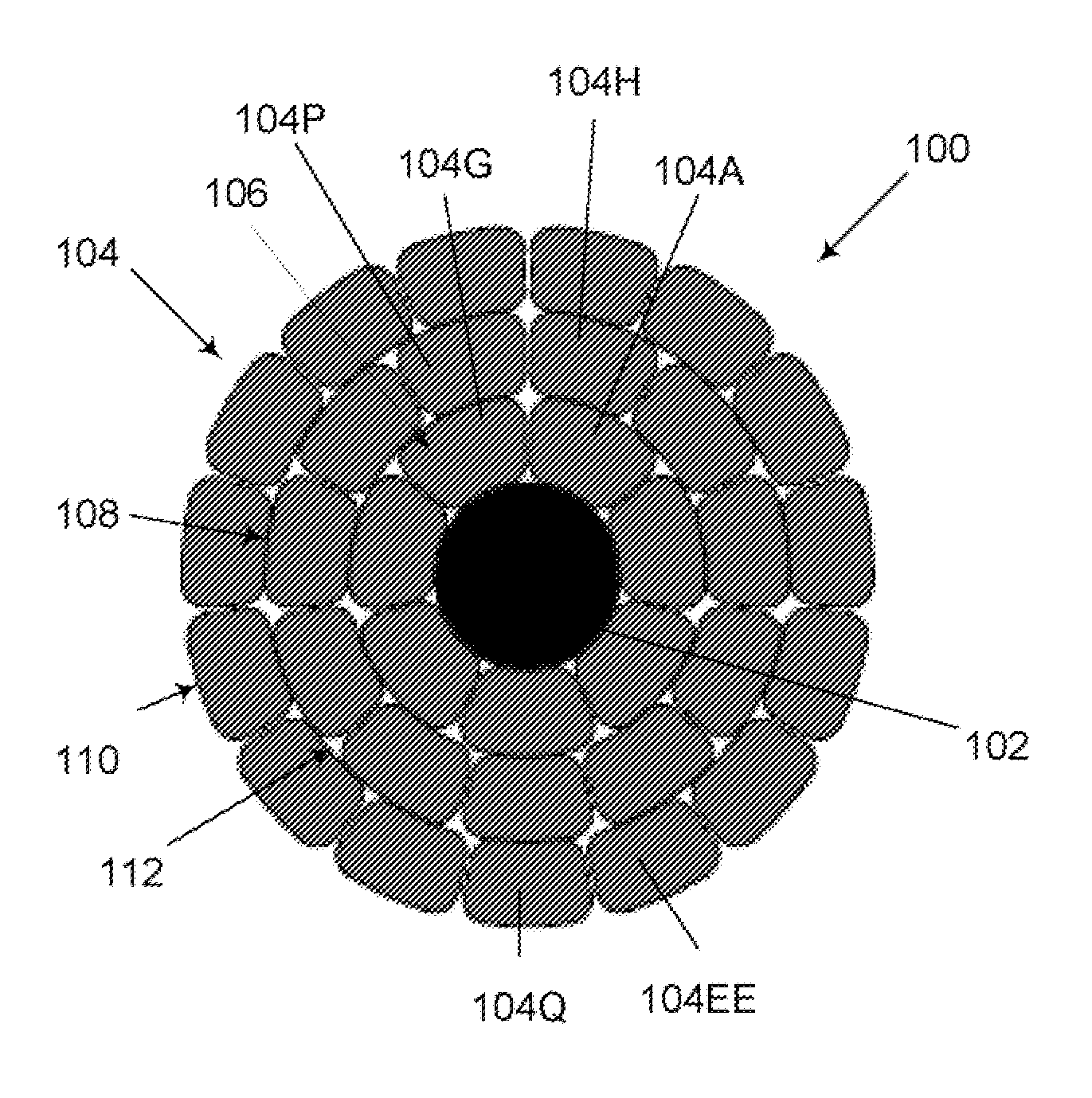

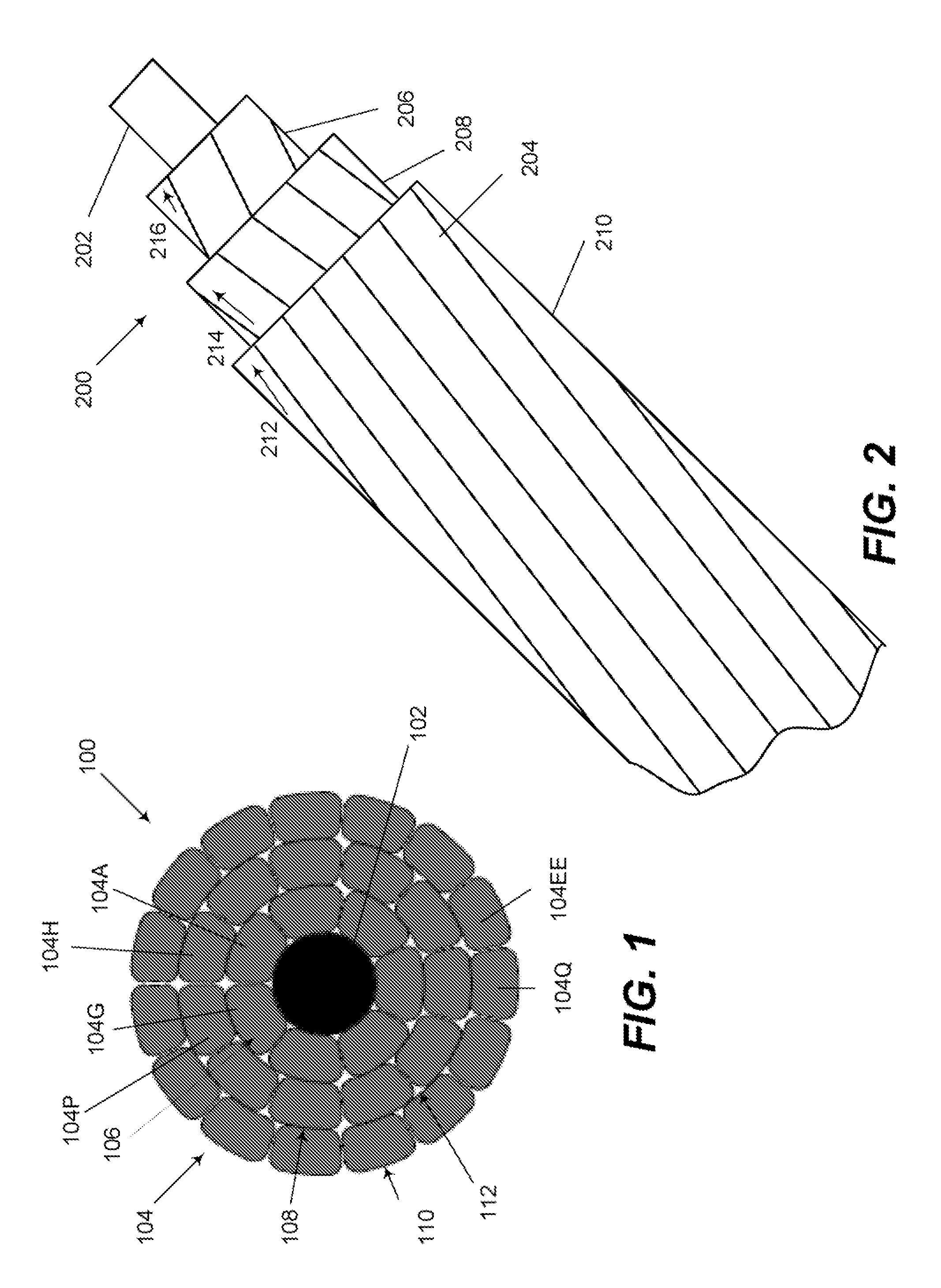

Marine umbilical

Various embodiments of an umbilical are provided. In one aspect, an umbilical is provided that includes a first tube, a second tube positioned in the first tube and a plurality of third tubes positioned in the first tube. Each of the plurality of third tubes has an inner polymer sleeve and an outer sleeve of carbon fibers in an epoxy matrix positioned around the polymer sleeve. The composite tubes yield a lighter umbilical that is easier to handle than a comparably sized conventional umbilical incorporating steel inner tubing and is more tolerant of dynamic bending and hydrostatic pressure loading.

Owner:MARINE INNOVATIONS

High-temperature-resistant modified polyfunctional epoxy matrix resin for advanced composite material and preparation thereof

The invention relates to high-temperature-resistant modified polyfunctional epoxy matrix resin for an advanced composite material. The resin comprises tetramaleimide resin, carboxy terminated nitrile rubber, polyfunctional epoxy resin, a curing agent and an organic solvent. A preparation method comprises the following steps of: adding the tetramaleimide resin, the carboxy terminated nitrile rubber and the polyfunctional epoxy resin into a reaction kettle and reacting at the temperature of 110 DEG C for one hour; adding the organic solvent and dissolving under stirring to obtain a component A;mixing the curing agent and the organic solvent and dissolving under stirring to obtain a component B; and mixing the component A and the component B and uniformly stirring during use. The high-temperature-resistant modified polyfunctional epoxy matrix resin provided by the invention has the advantages of high room temperature tensile shear strength, high heat resistance, wide application prospect in the fields such as electronics, micro-electronics, printed circuit boards (PCB), motors, aerospace and the like, simple preparation process, low cost and contribution to realizing industrial production.

Owner:DONGHUA UNIV +1

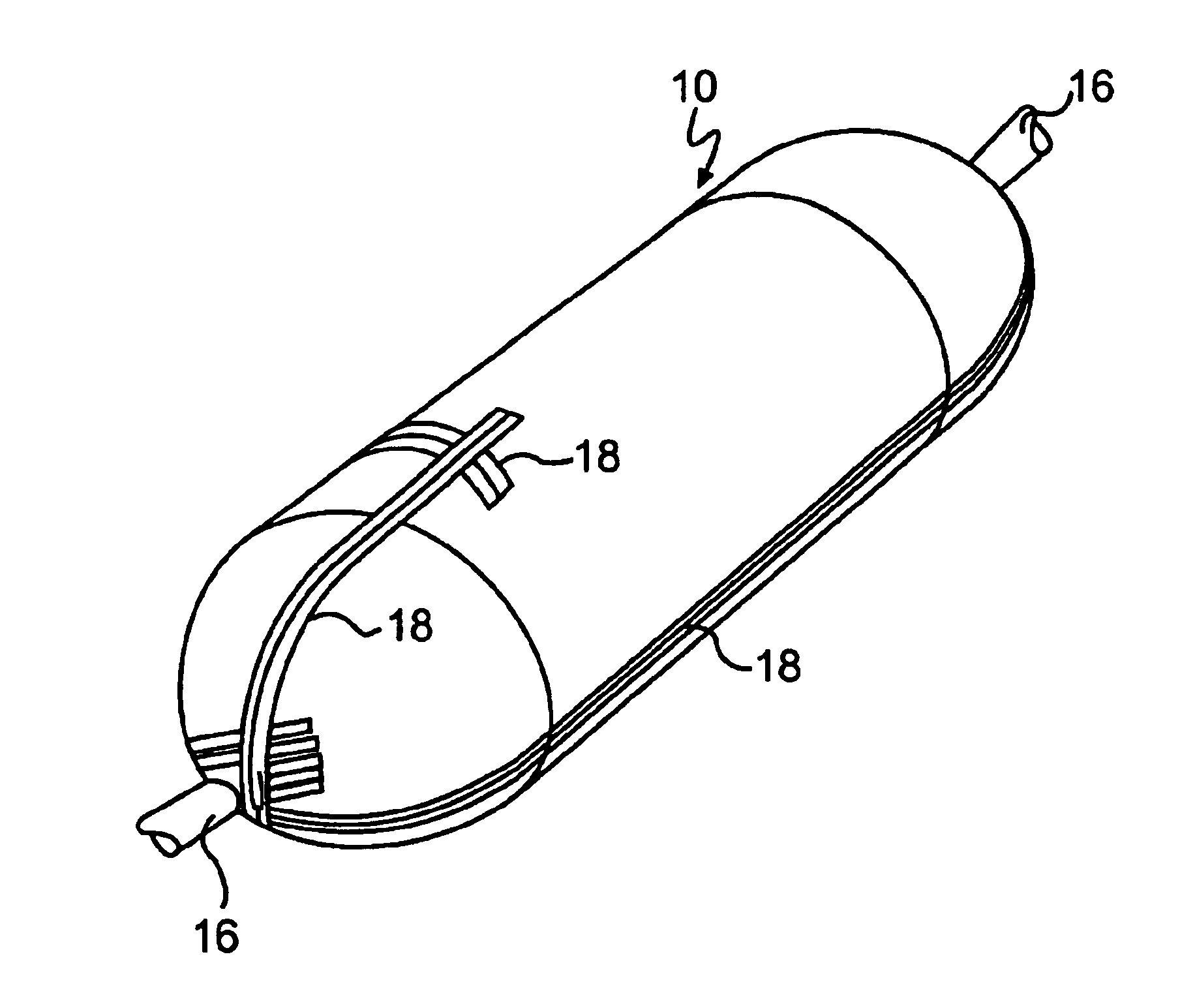

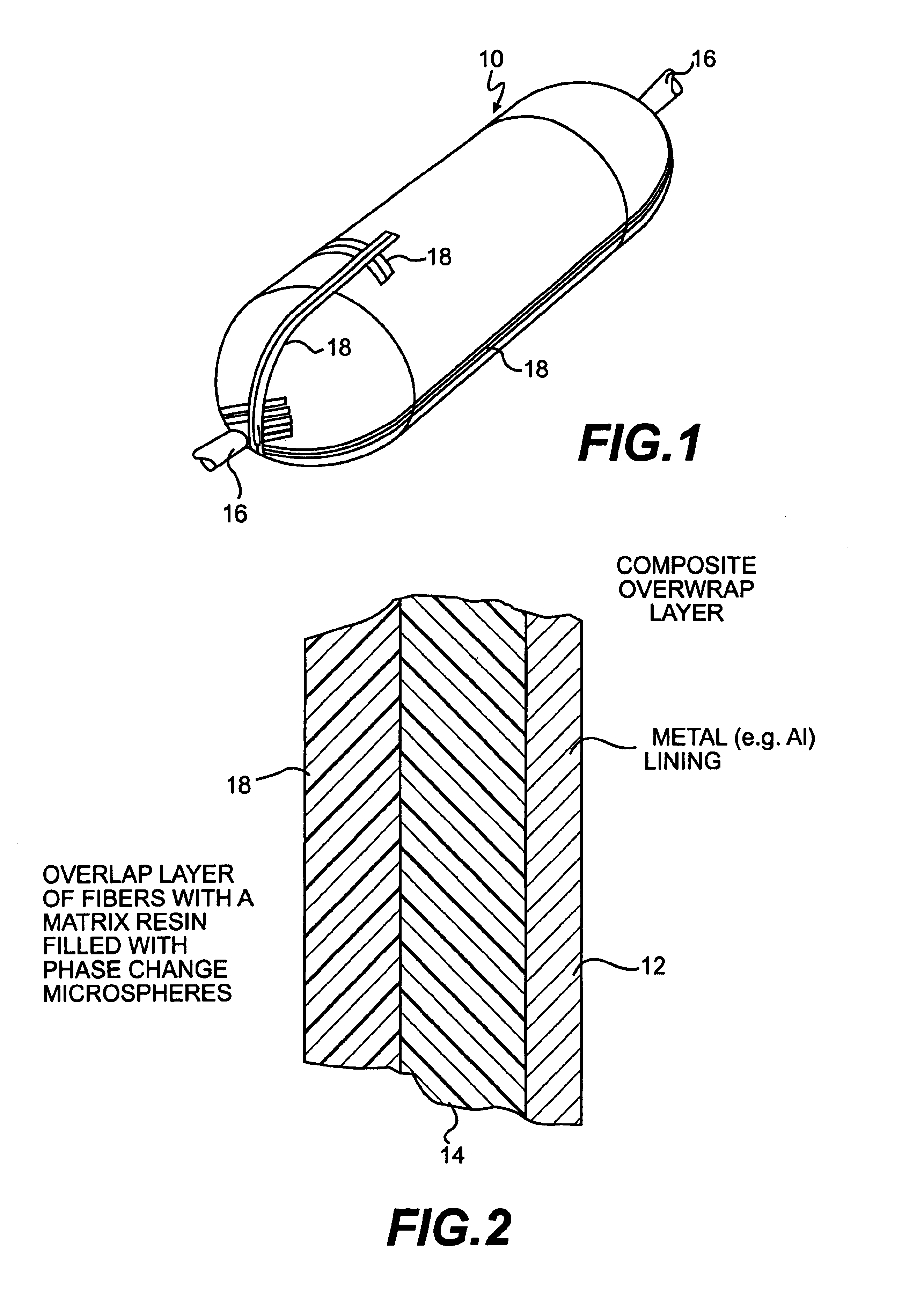

Pressure vessel with impact and fire resistant coating and method of making same

InactiveUS6953129B2Light weightIncrease heatGas handling applicationsLarge containersMicrosphereShock resistance

An impact and fire resistant coating laminate is provided which serves as an outer protective coating for a pressure vessel such as a composite overwrapped vessel with a metal lining. The laminate comprises a plurality of fibers (e.g., jute twine or other, stronger fibers) which are wound around the pressure vessel and an epoxy matrix resin for the fibers. The epoxy matrix resin including a plurality of microspheres containing a temperature responsive phase change material which changes phase in response to exposure thereof to a predetermined temperature increase so as to afford increased insulation and heat absorption.

Owner:NASA

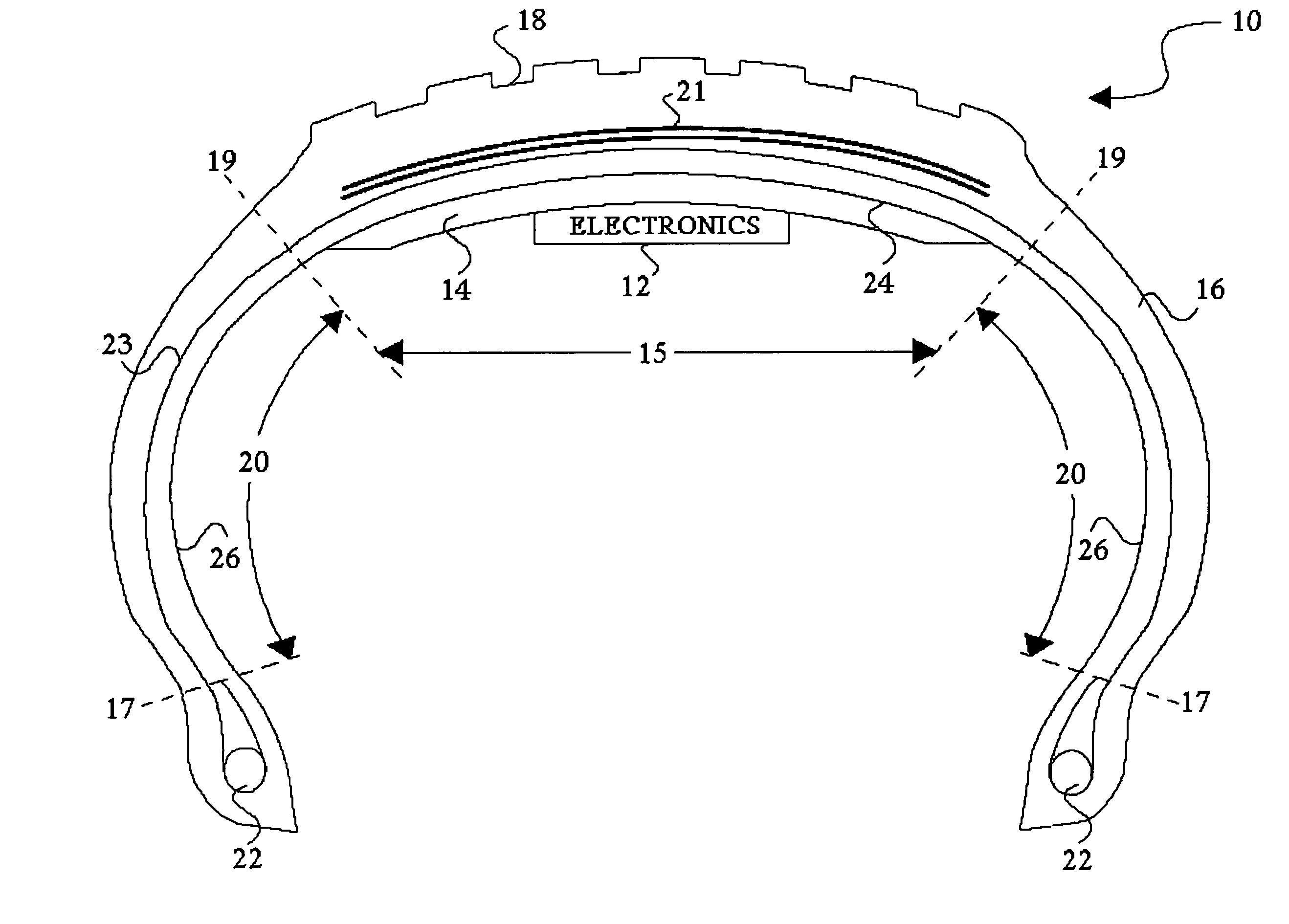

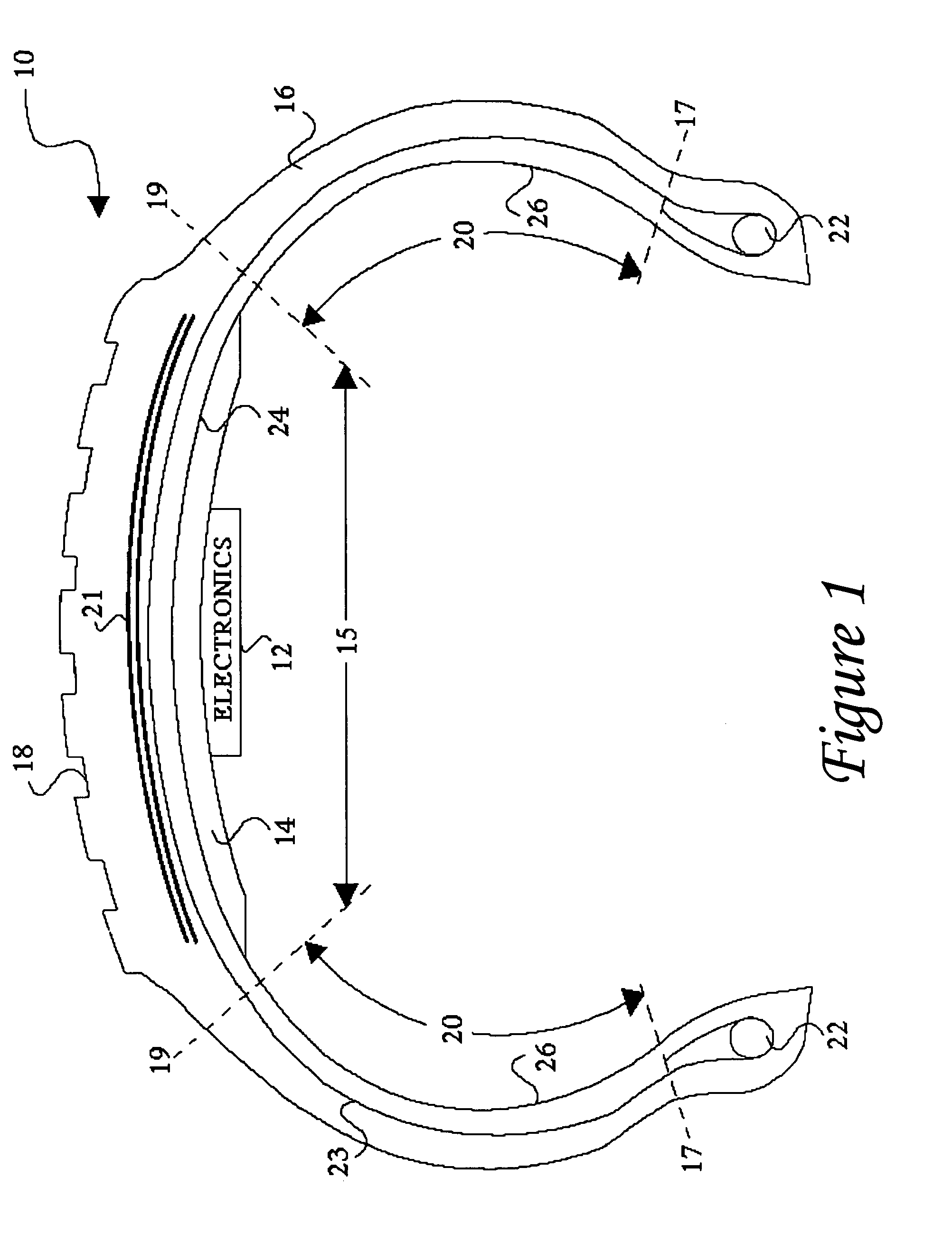

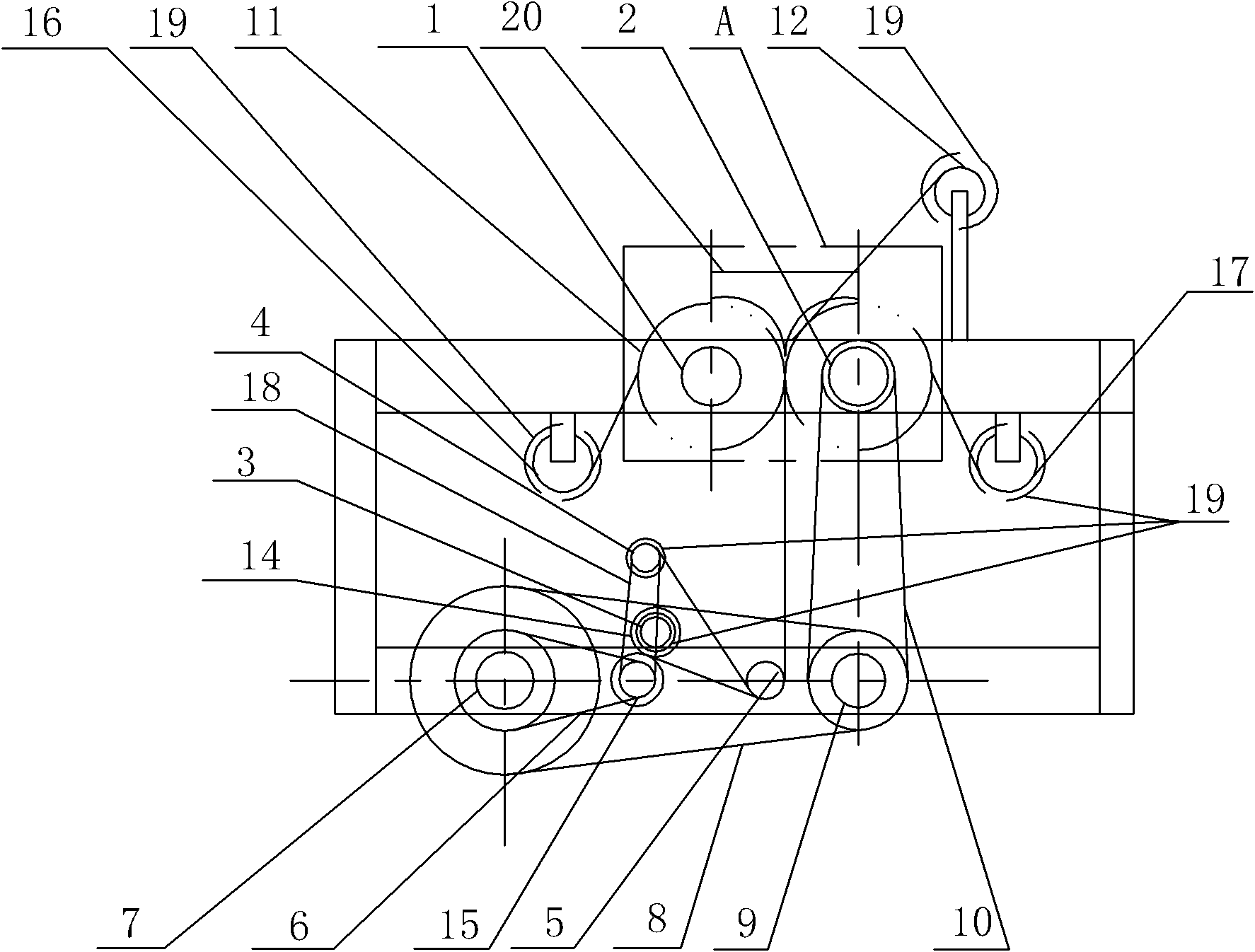

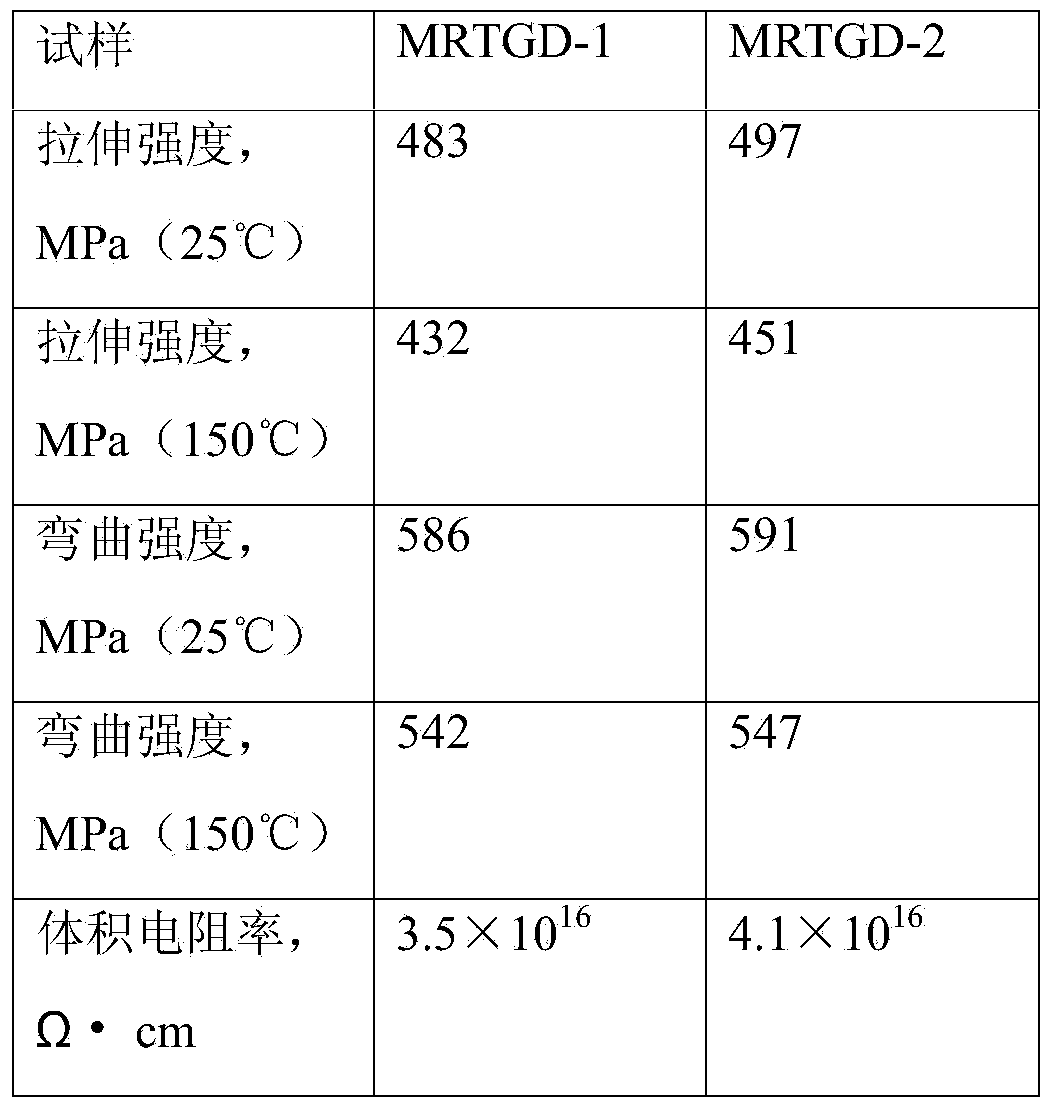

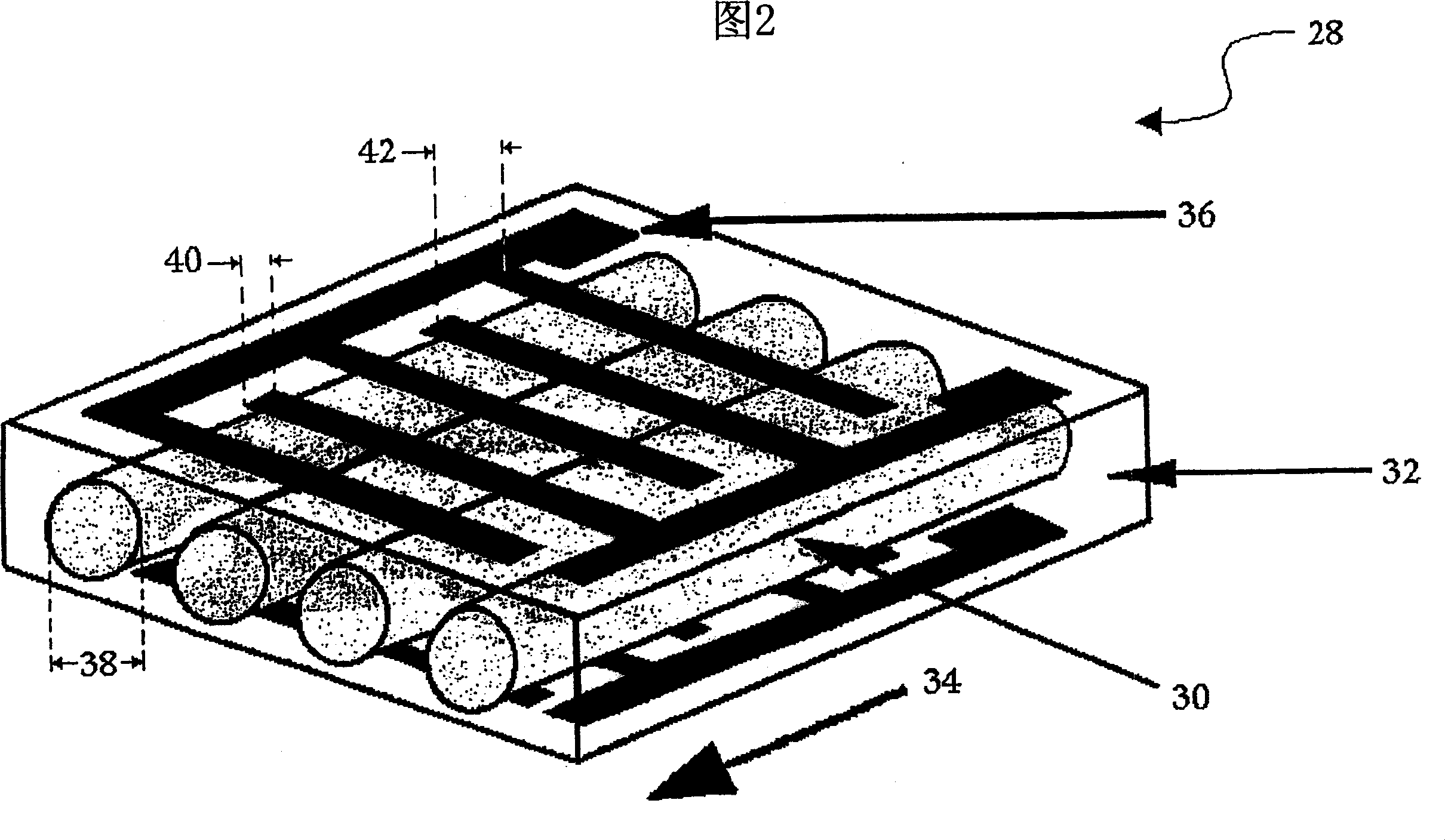

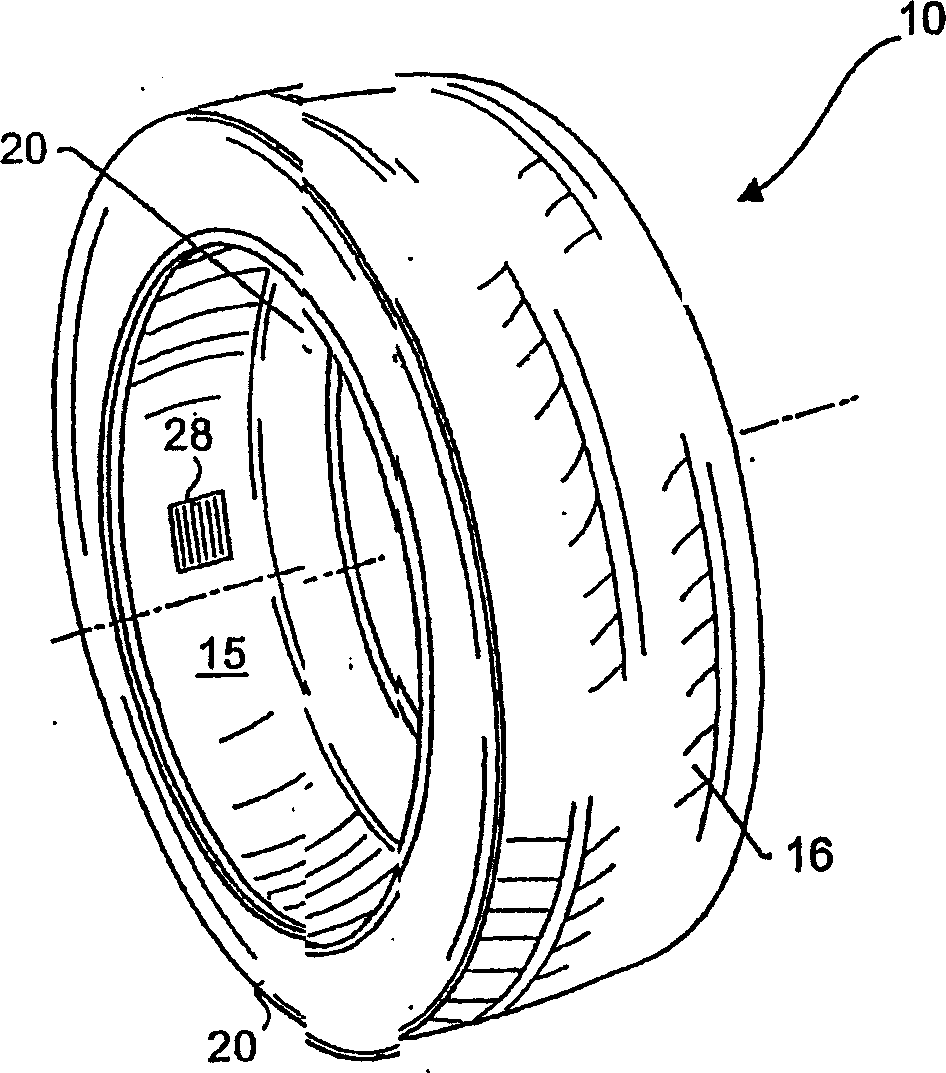

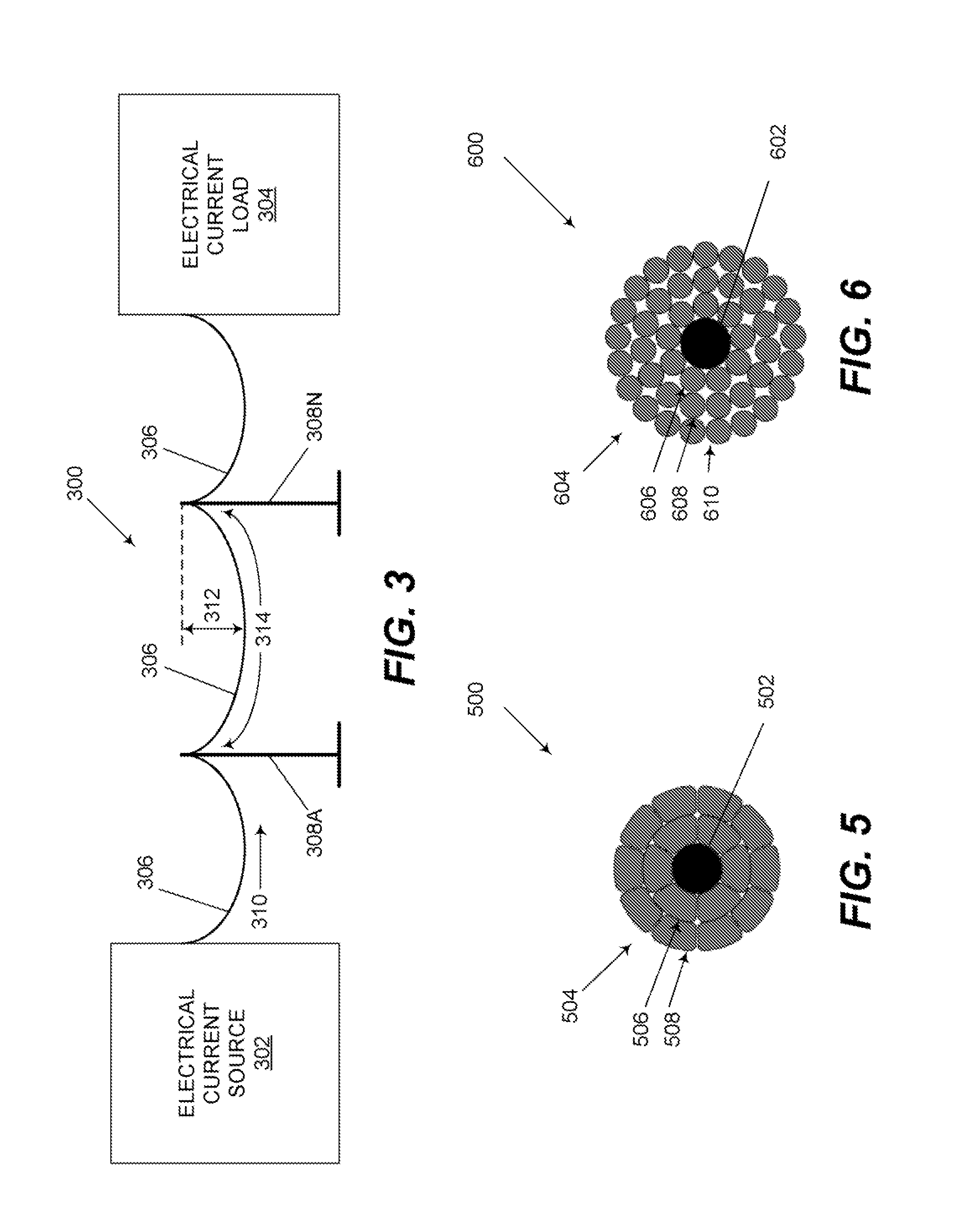

System and method for generating electric power from a rotating tire's mechanical energy

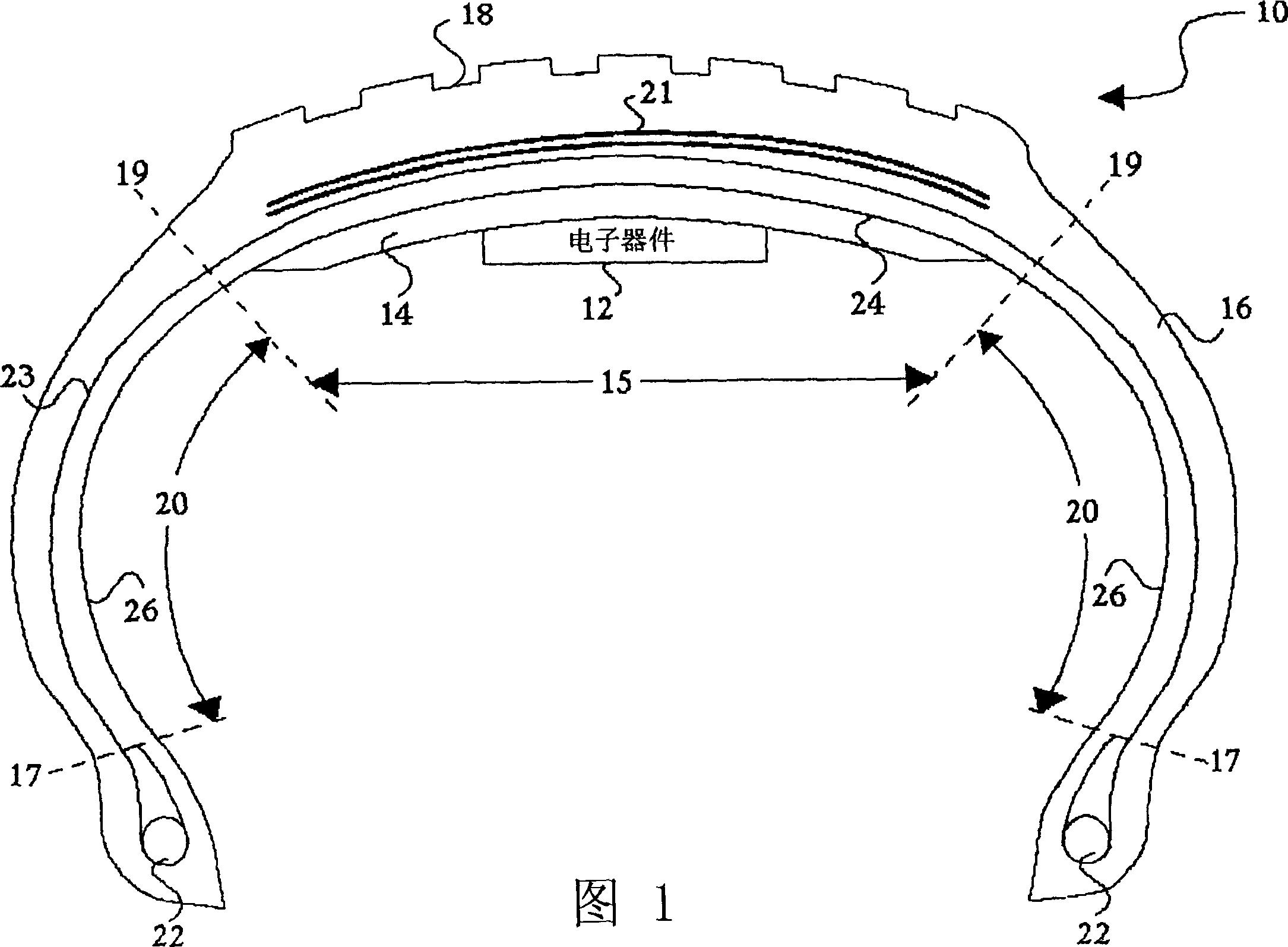

InactiveUS7096727B2Reduce amountFunction increaseAuxillary drivesBatteries circuit arrangementsElectric power systemMechanical energy

A tire assembly with integrated power generation features includes one or more piezoelectric devices and power conditioning modules. Piezoelectric devices may include a plurality of piezoelectric fibers embedded in a generally unidirectional fashion within an epoxy matrix, a piezoceramic wafer provided on a substrate and substantially surrounded by a protective casing, or a piezoceramic unimorph structure adhered with a thermoplastic polyimide to respective top and bottom conductive layers. Each piezoelectric device may include multiple piezoelectric elements connected in series and / or parallel arrangements, configured with respective poling directions in opposing or in-phase arrangements and / or configured in d33 or d31 displacement modes. Piezoelectric devices are preferably mounted within a tire or wheel assembly such that electric charge is generated therein as the wheel assembly moves along a ground surface and is subsequently stored in one or more energy storage devices. Stored energy may then be used to power electronics such as a tire monitoring system that wirelessly transmits such information as tire pressure, temperature and identification variables to a remote receiver location.

Owner:MICHELIN RECH & TECH SA

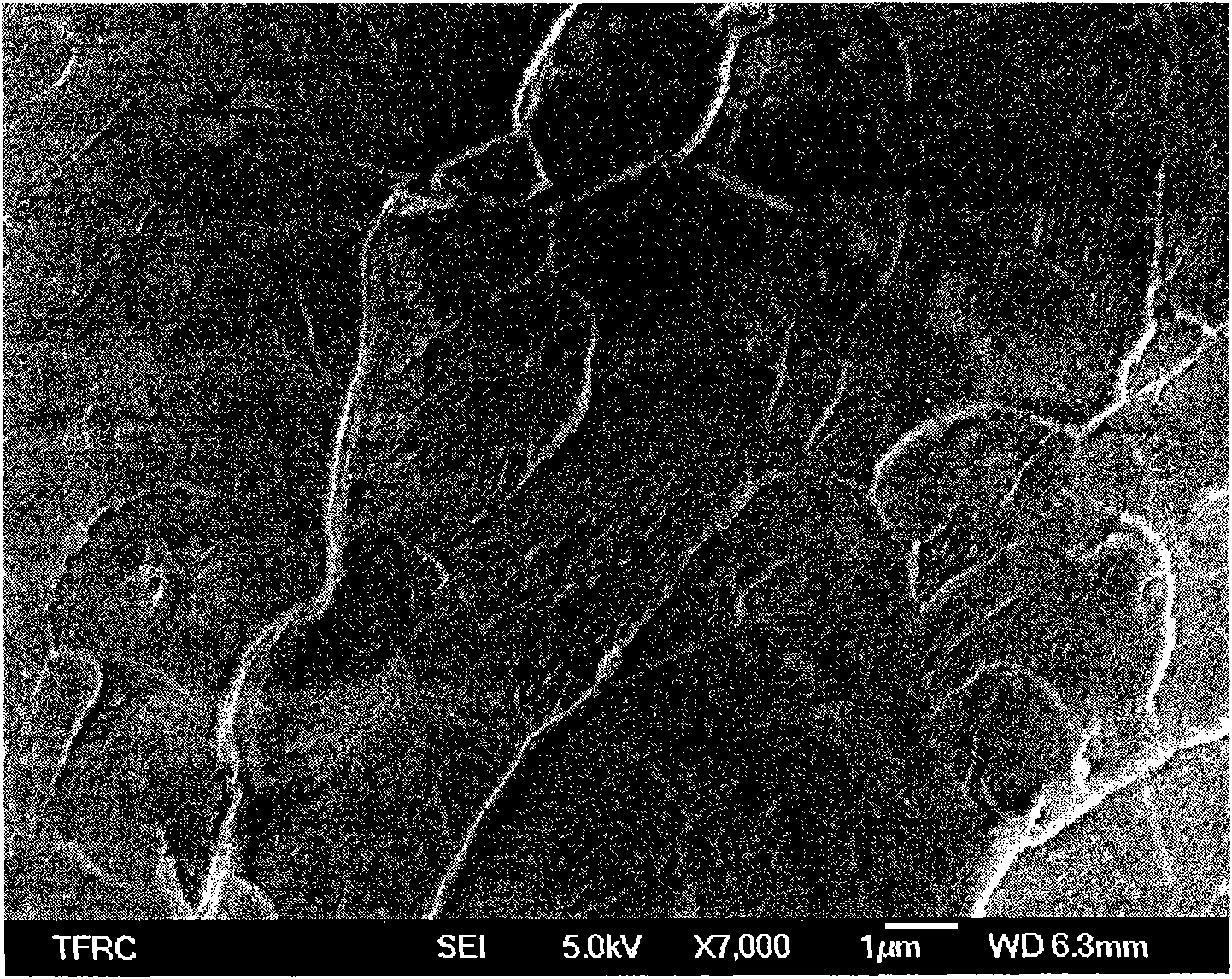

Super hybrid carbon nano material modified carbon fiber/epoxy matrix composite material and preparation method thereof

InactiveCN103552325AImproved interlaminar shear performanceThe interface is firmly bondedSynthetic resin layered productsModified carbonResin matrix

The invention relates to a super hybrid carbon nano material modified carbon fiber / epoxy matrix composite material and a preparation method thereof. The composite material an epoxy resin matrix material and an inorganic nano filler which is uniformly dispersed in the epoxy resin matrix material, wherein the composite nano inorganic filler is composed of graphene and carbon nanotubes. The excellent mechanical properties of the graphene and carbon nanotubes and the active functional groups on the surface are utilized to effectively enhance the mechanical properties of the epoxy resin matrix and the interface bonding strength between the matrix and the carbon fibers. The prepared composite material has excellent interlaminar shear property, and the interlaminar shear strength is enhanced from 50 MPa to 68 MPa.

Owner:JIAXING UNIV

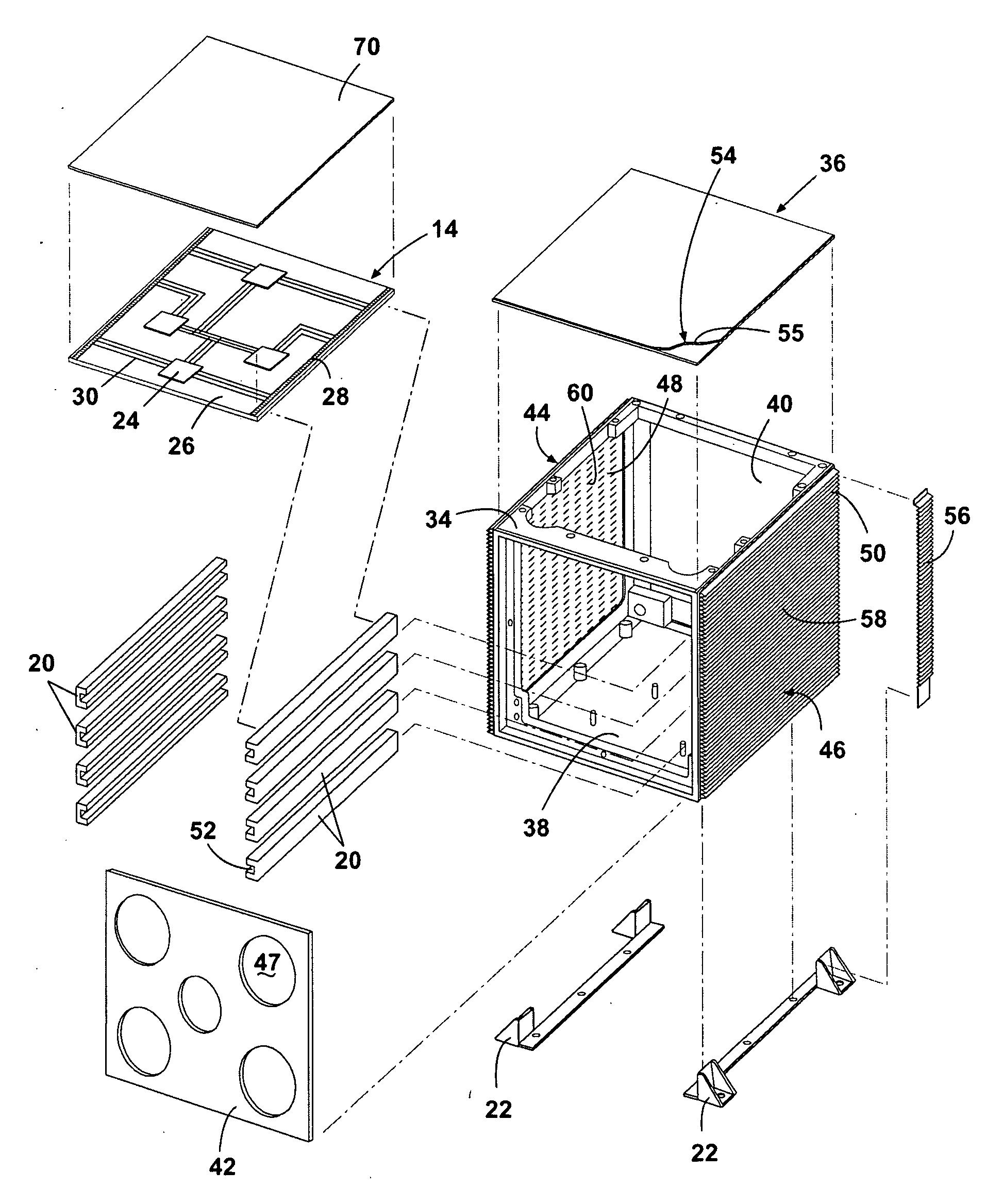

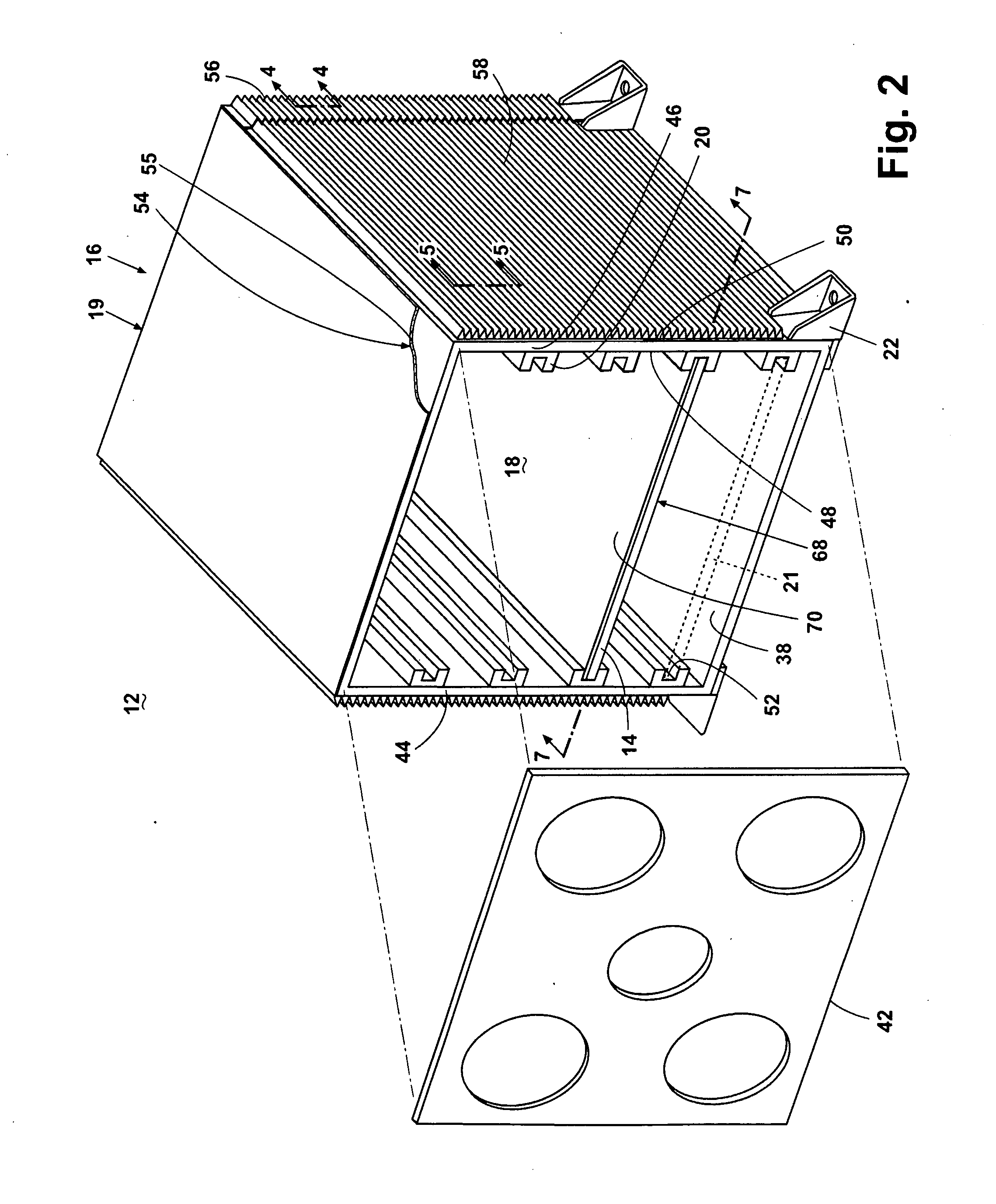

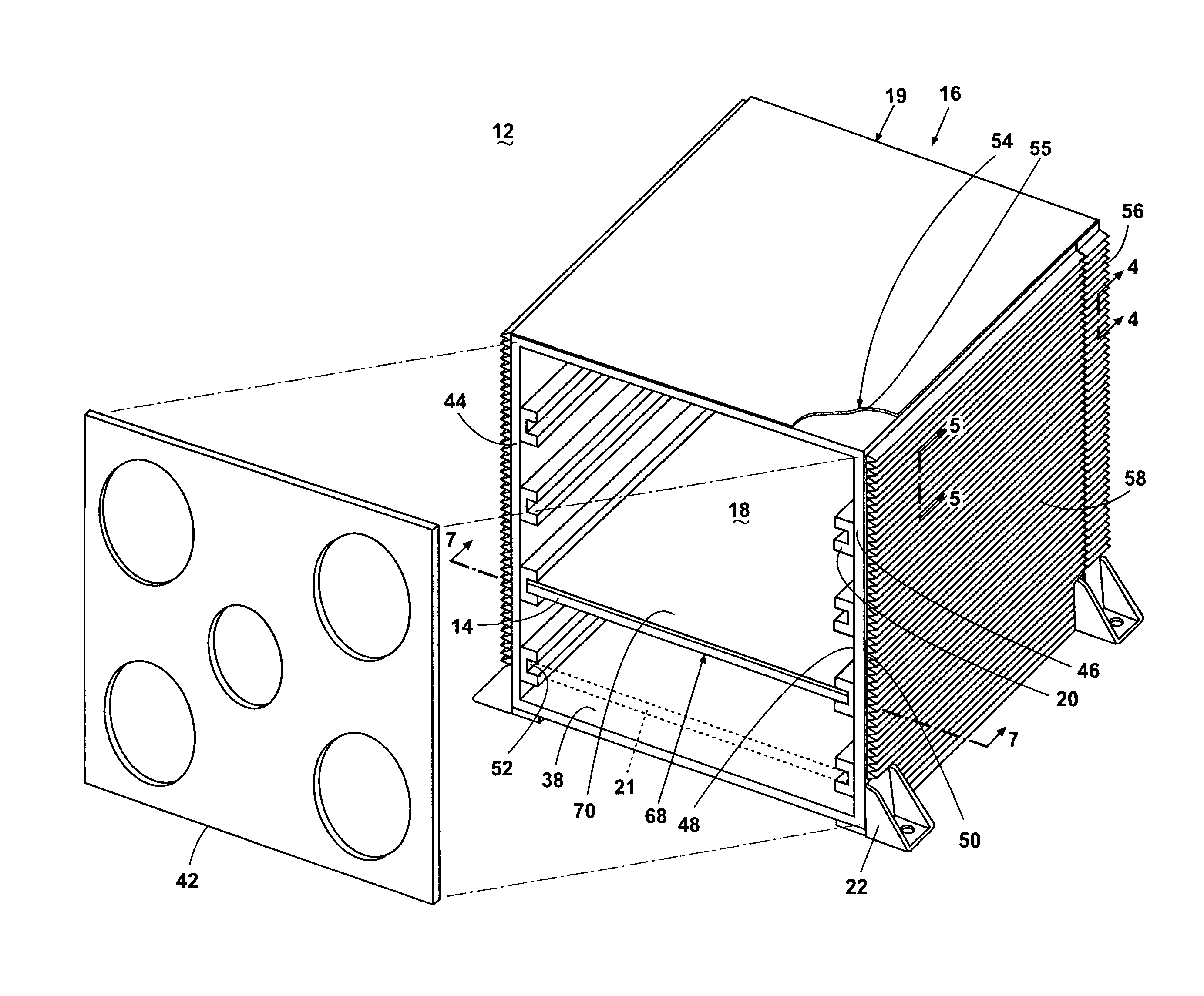

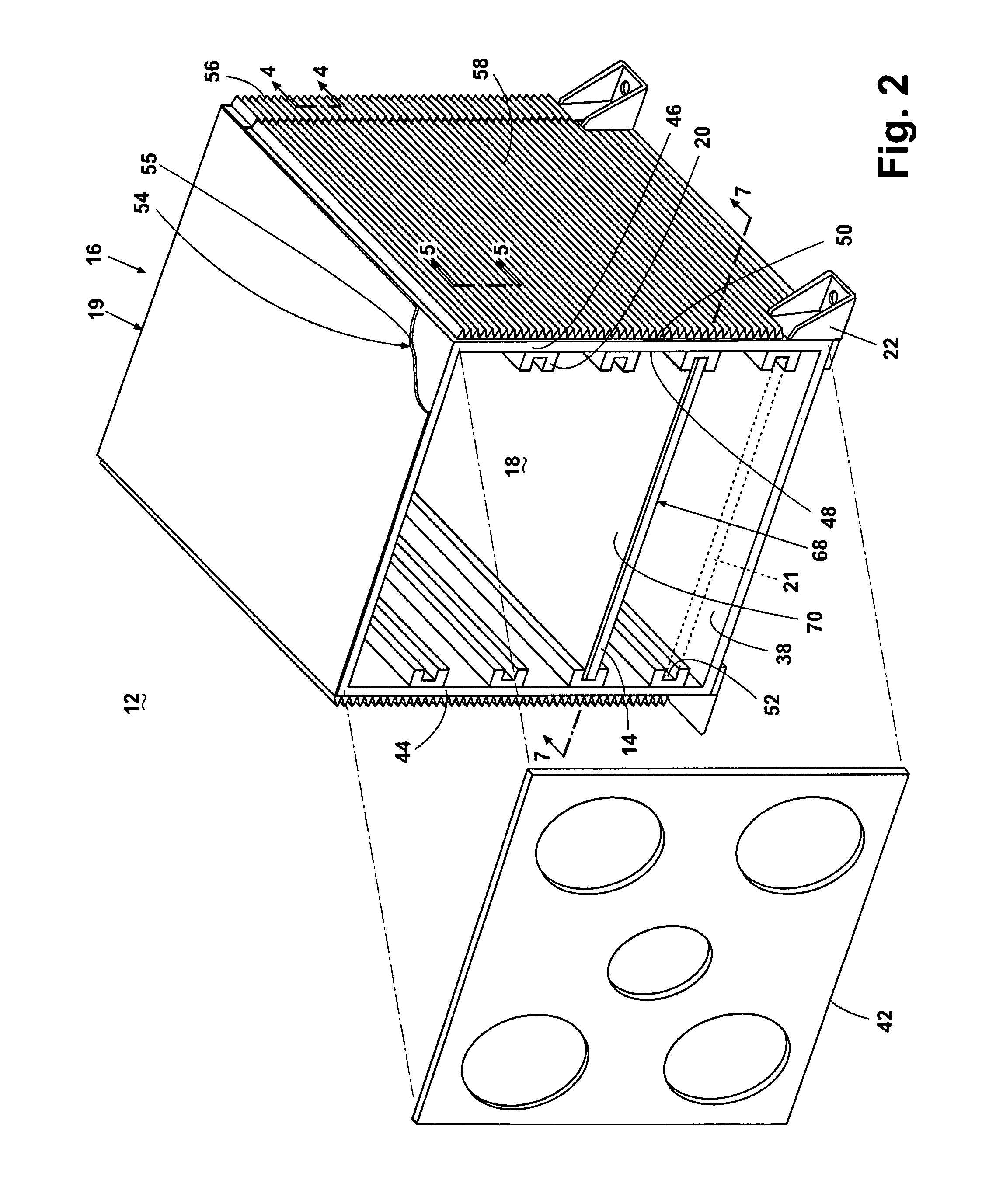

Avionics Chassis

ActiveUS20100321892A1Clamping/extracting meansCooling/ventilation/heating modificationsAviationCarbon fibers

Owner:GENERAL ELECTRIC CO

Preparation method of graphene/nano silver epoxy conductive adhesive

ActiveCN102153976AImprove electrical performanceEvenly dispersedEpoxy resin adhesivesElectrically-conducting adhesivesOrganic solventEpoxy matrix

The invention discloses a preparation method of a graphene / nano silver epoxy conductive adhesive, which comprises the following steps: (1) mixing graphite, promoter and organic solvent, then carrying out ultrasonic treatment at 20-50 DEG C for 3-6 hours, standing for 12 hours, centrifuging, and distilling; (2) dissolving epoxy resin and precursor in organic solvent, stirring at 20-50 DEG C for 5-30 minutes, adding a graphene solution to continue reacting for 10-40 minutes, distilling, and carrying out ultrasonic treatment for 5-20 minutes; and (3) adding silver sheets into the graphene-nano silver epoxy resin compound, and carrying out ultrasonic treatment to react at 20-60 DEG C for 30-120 minutes so as to obtain the graphene / nano silver epoxy conductive adhesive. The graphene / nano silver epoxy conductive adhesive disclosed by the invention ensures that the graphene-nano silver compound can be uniformly dispersed in the epoxy matrix, and avoids the problem that the prepared graphene conglobates when the epoxy resin is added, thereby being beneficial to realizing the low-temperature sintering of the nano silver and improving the conductivity and adhesive strength of the conductiveadhesive.

Owner:SOUTH CHINA UNIV OF TECH

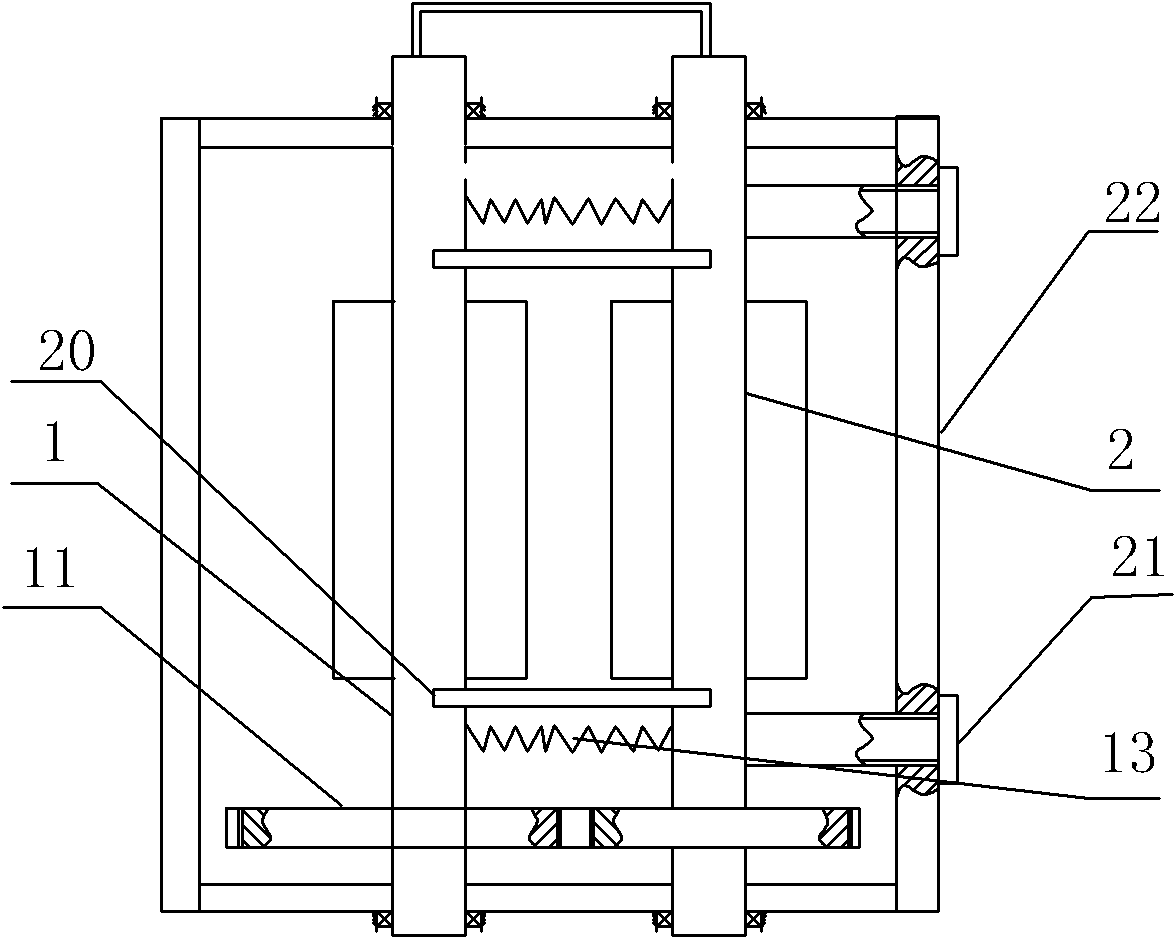

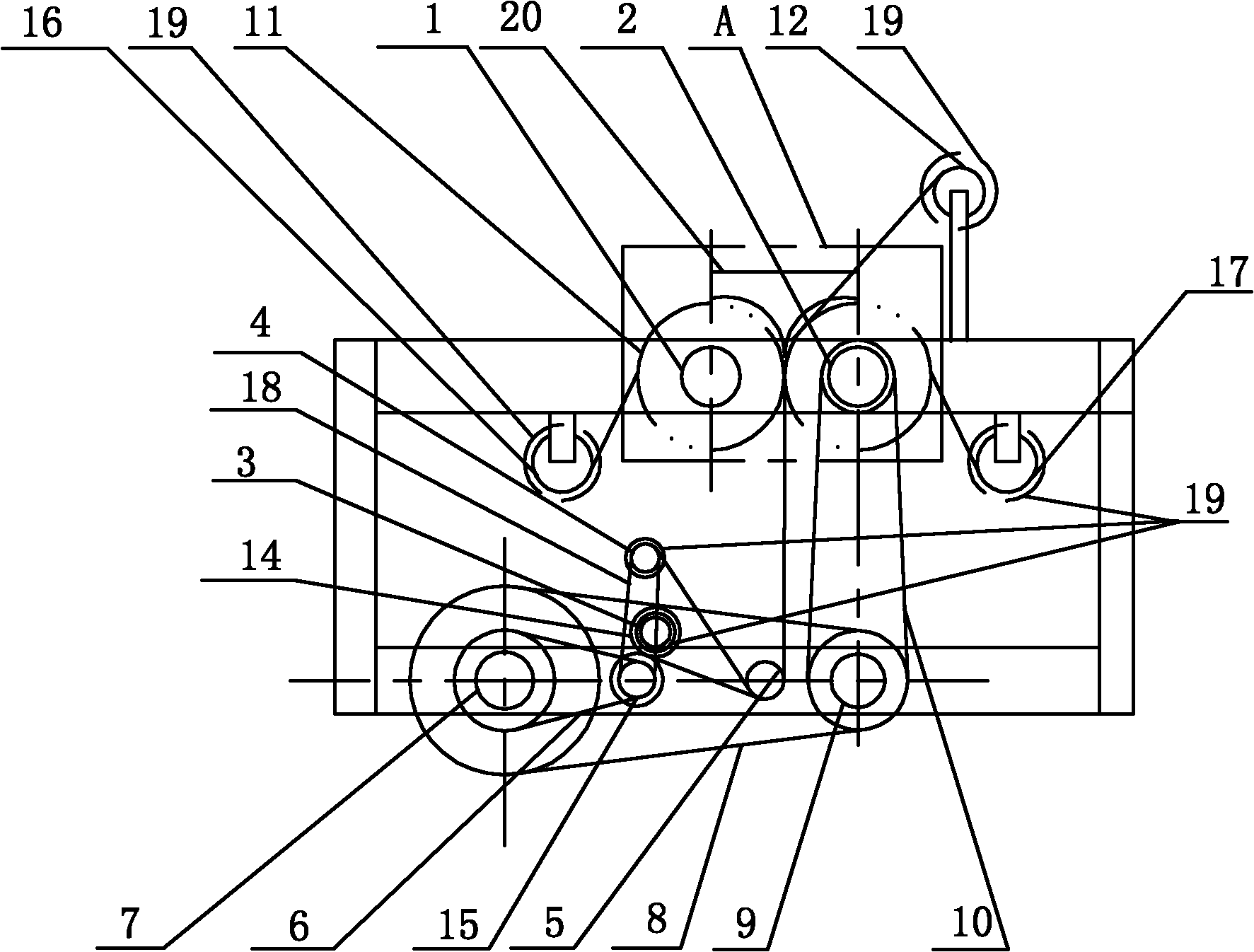

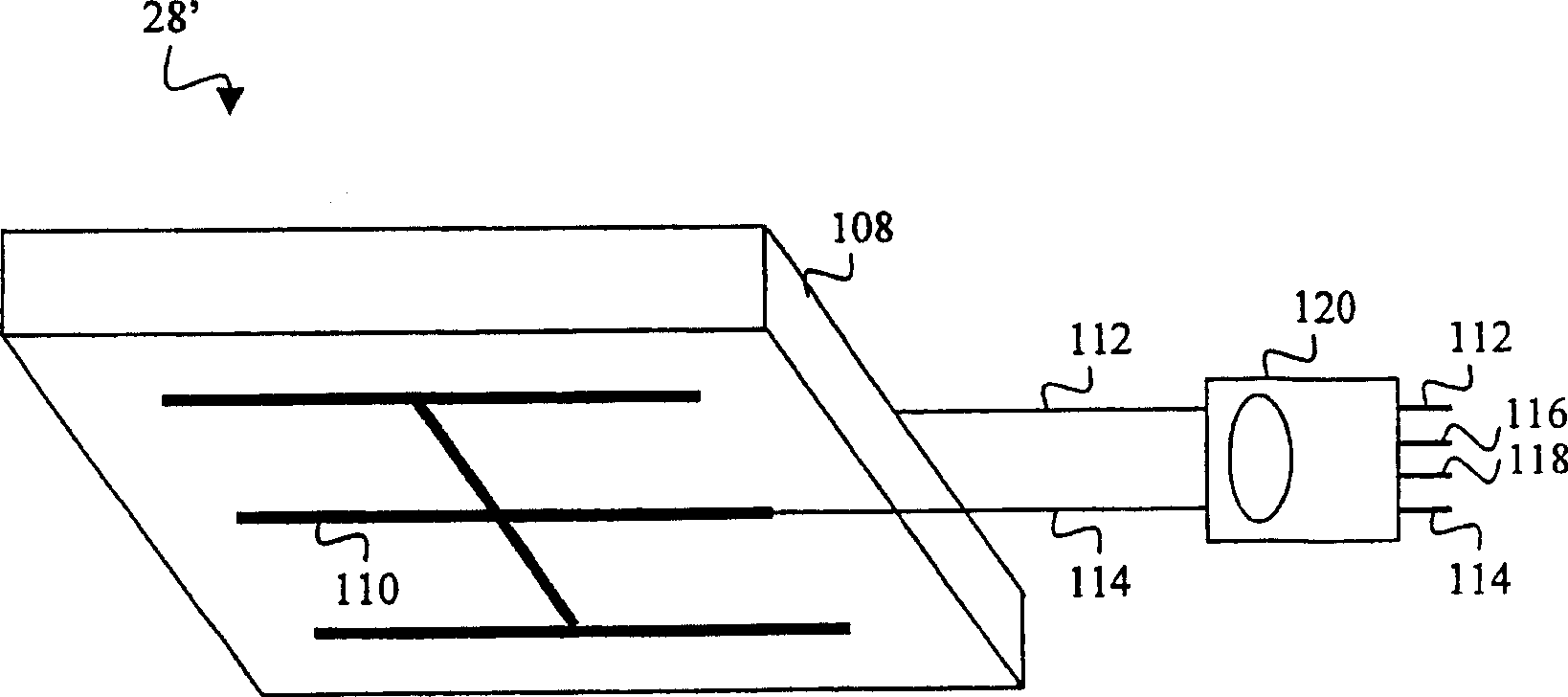

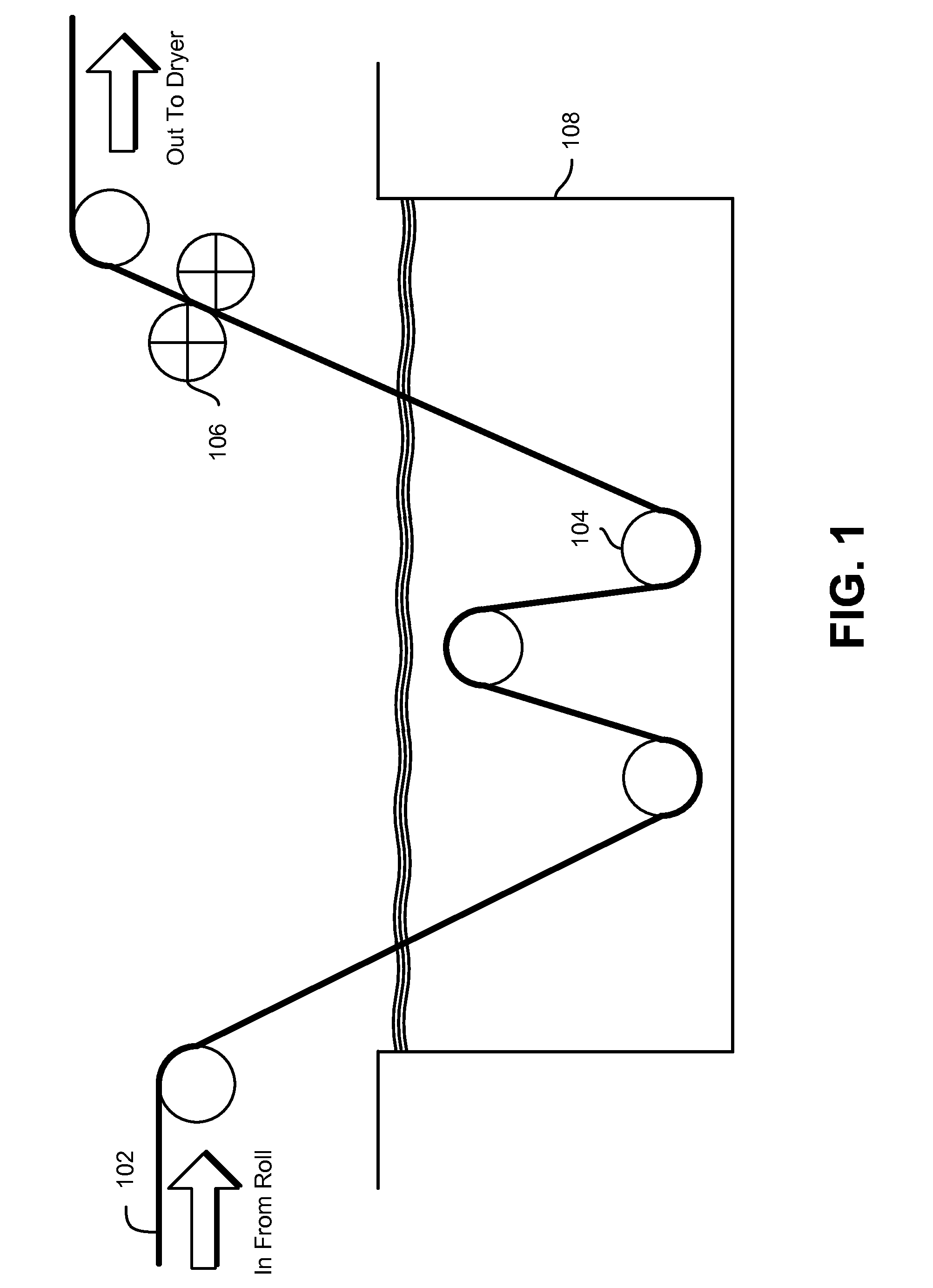

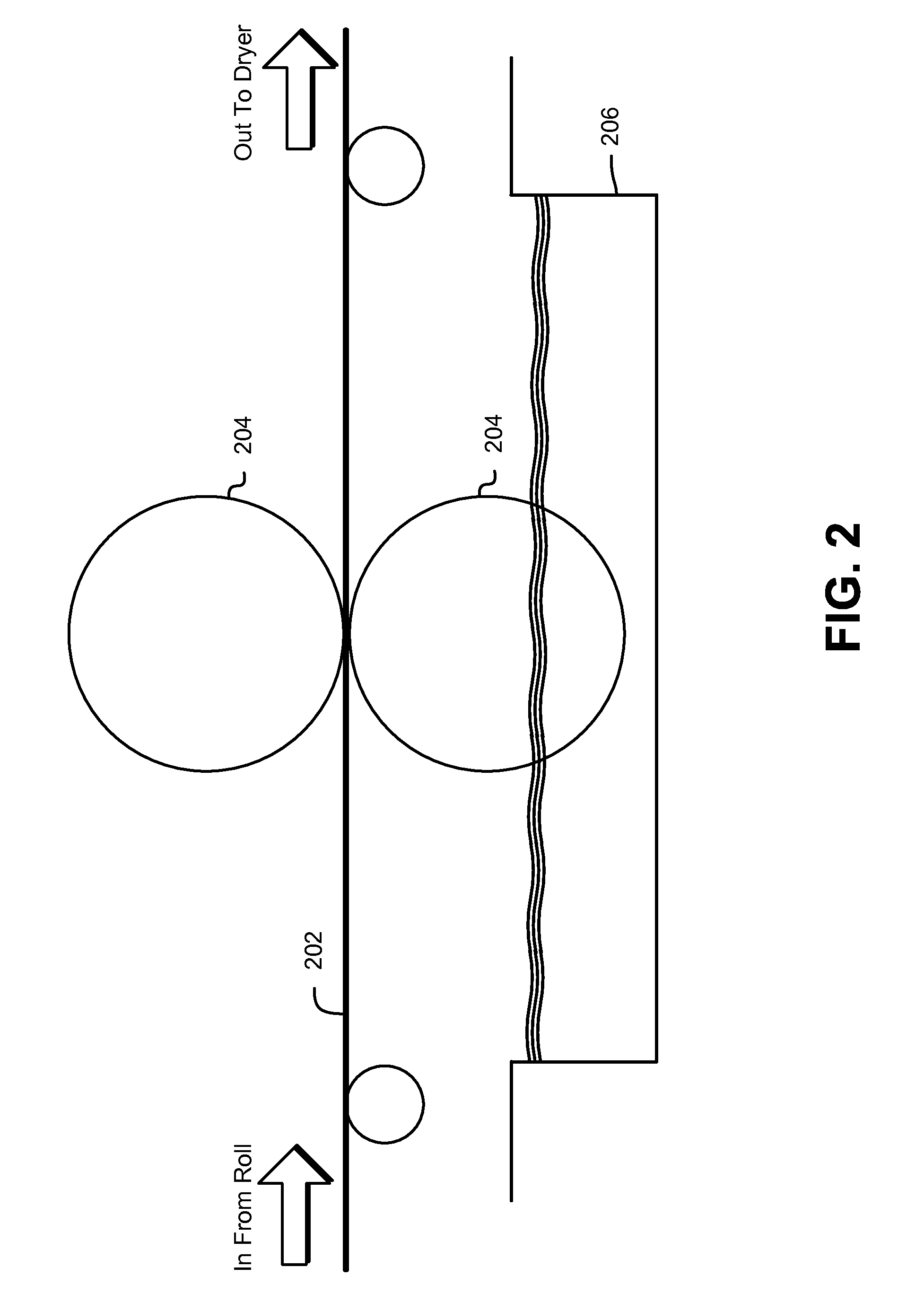

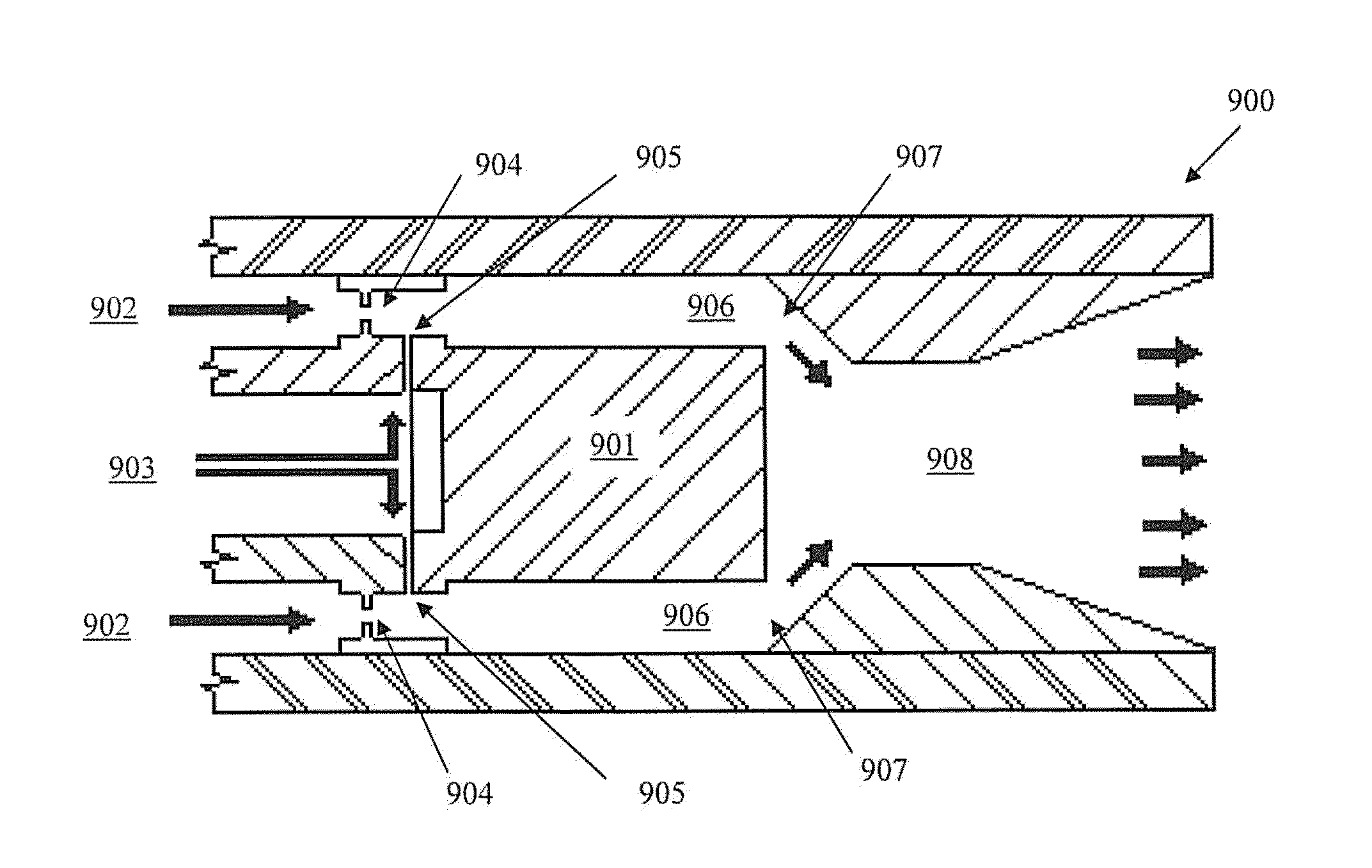

Epoxy matrix resin and prepreg and preparation method thereof and device for preparation thereof

The invention discloses an epoxy matrix resin, a prepreg, a preparation method of the prepreg and a device for preparation of the prepreg, in order to solve the problem of poor performance of an epoxy matrix resin curing substance caused by uneven toughening phase state even no phase separation in the traditional epoxy matrix resin curing product, the problem of complex technique of the traditional preparation method of the prepreg and relatively imprecise control on the resin content in the prepreg, and the problem of high manufacturing cost of the traditional device for preparing the prepreg. The epoxy matrix resin is prepared from a phenolic epoxy resin, a bisphenol A epoxy resin, a core shell polymer, a curing agent and a curing accelerator; the prepreg is prepared from the epoxy matrix resin and fiber woven cloth; and the prepreg is prepared through the device for producing the prepreg by a heat fusion method. After and before the resin is cured, the toughening phase state is not changed and is uniformly dispersed; and the toughening phase state effect is good and stable. The mechanical property of the composite material obtained by curing with the prepreg is high.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

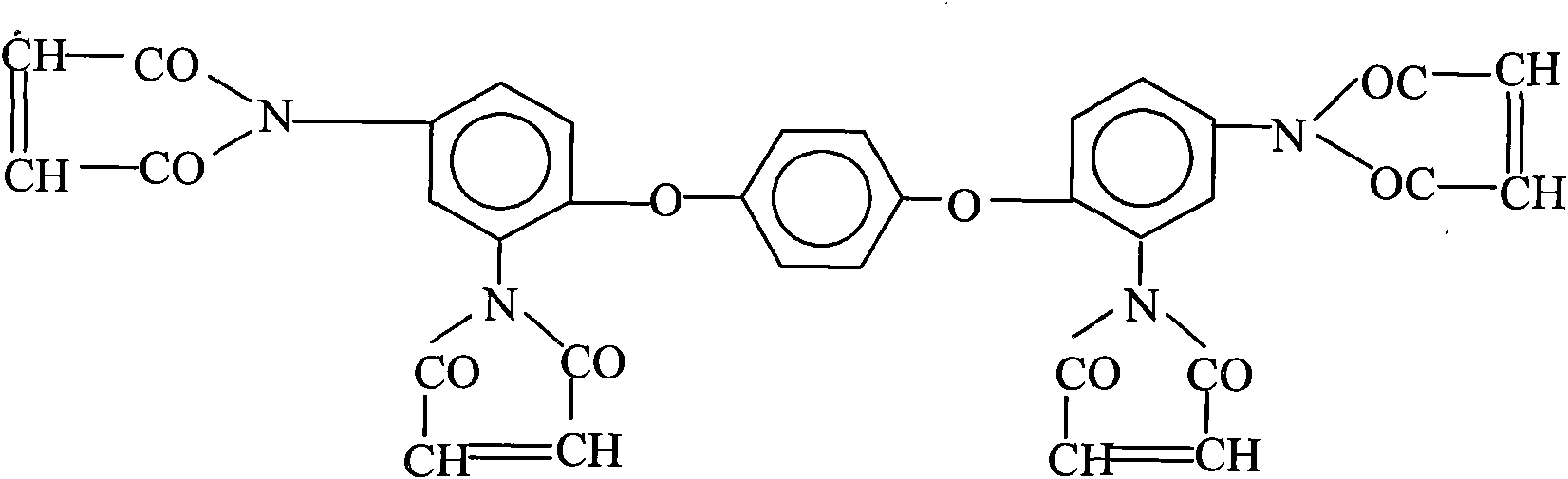

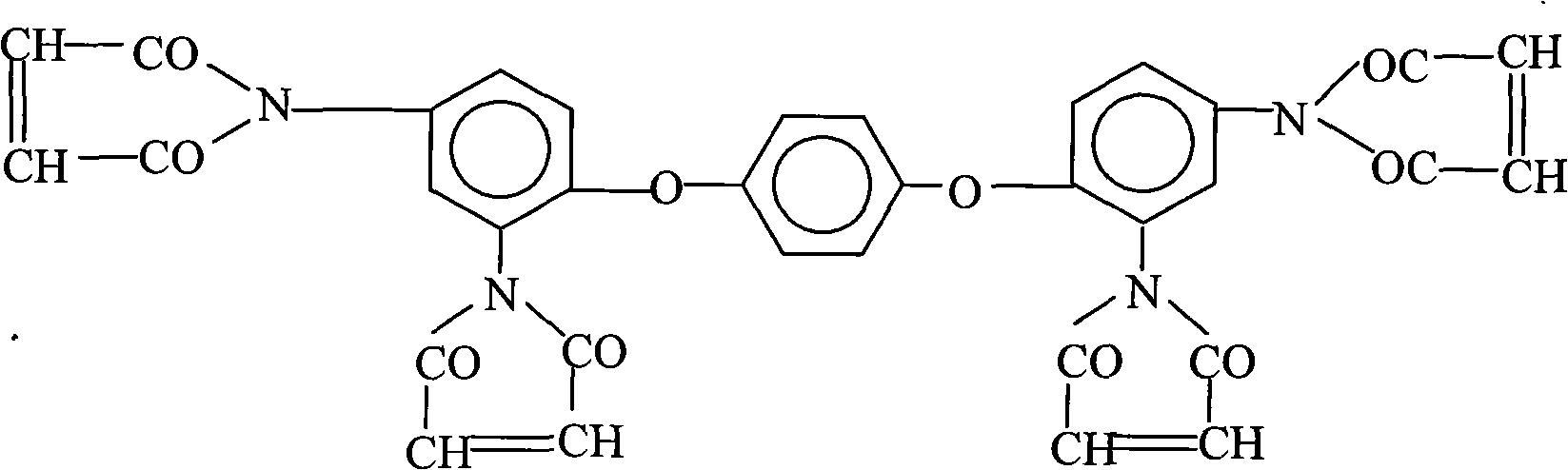

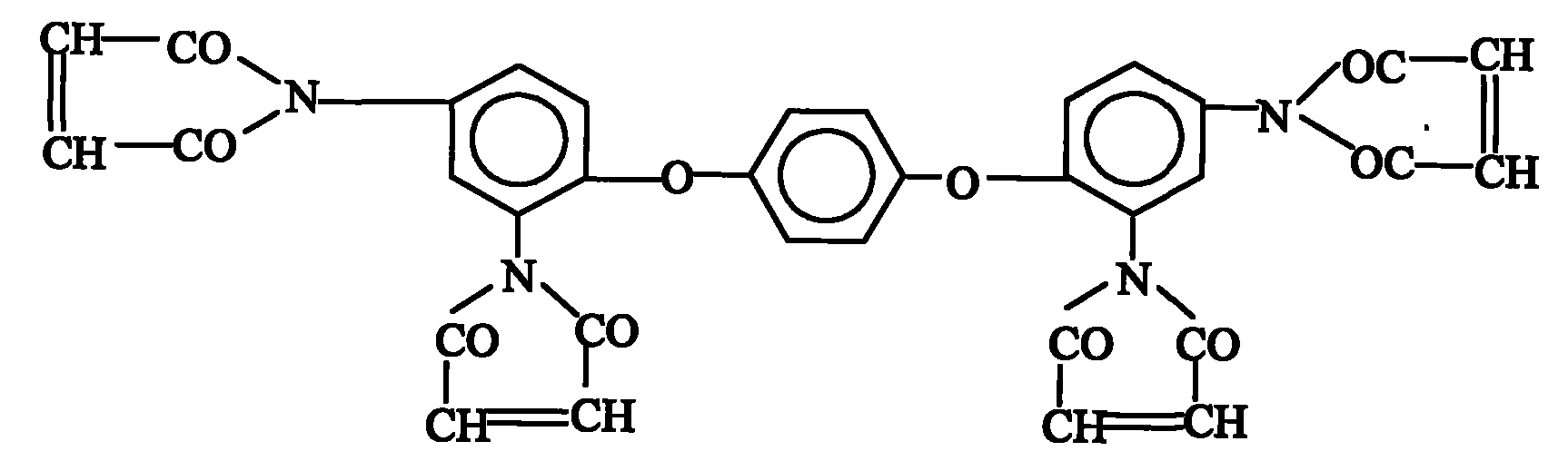

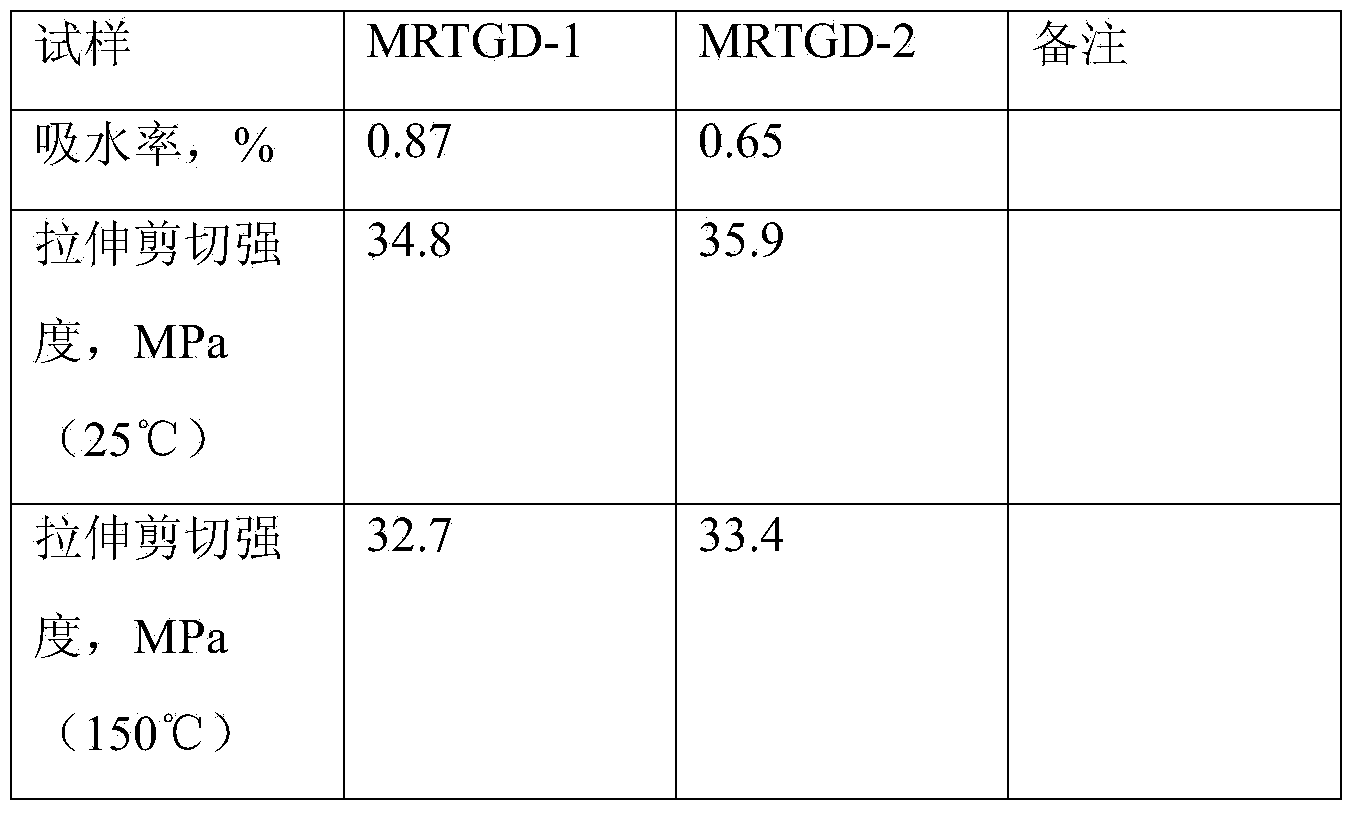

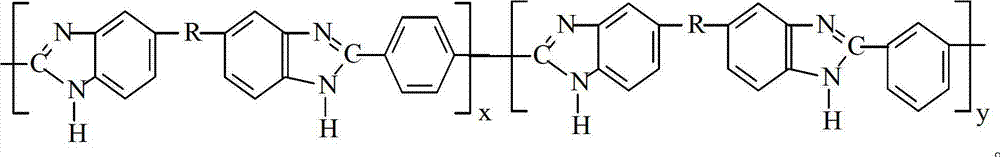

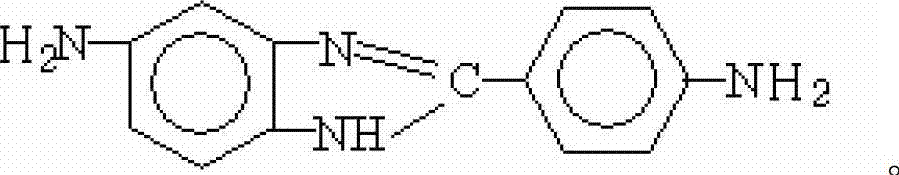

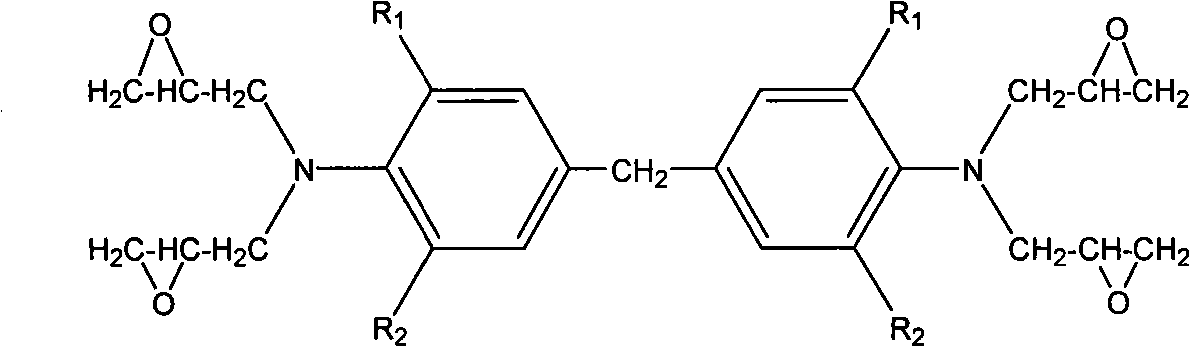

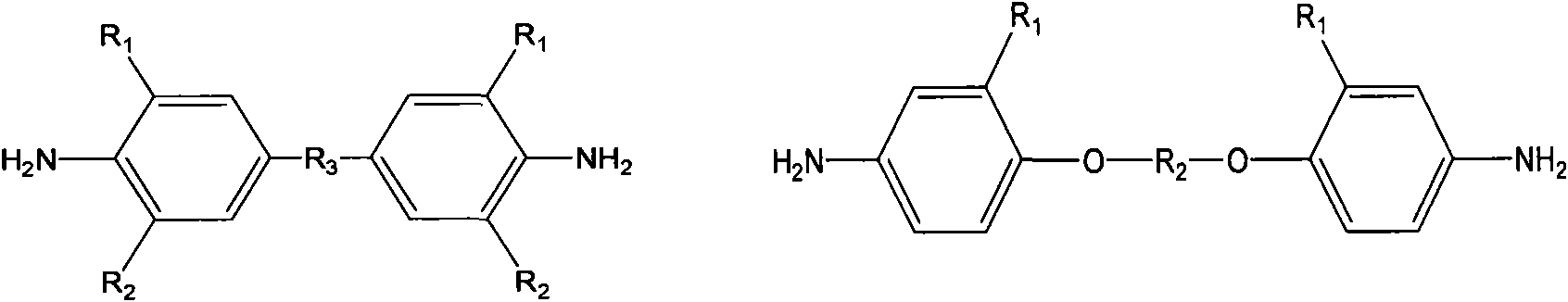

TGDADPE type epoxy matrix resin for advanced composite material and preparation method thereof

InactiveCN103483553AConvenient sourceSimple preparation processSynthetic resin layered productsGlass fiberDiaminodiphenyl ether

The invention relates to a TGDADPE type epoxy matrix resin for an advanced composite material and a preparation method of the TGDADPE type epoxy matrix resin for the advanced composite material. The TGDADPE type epoxy matrix resin for the advanced composite material is prepared from N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, aromatic diamine, aromatic binary anhydride, a curing agent and organic solvent, wherein the mass ratio of the N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin, the aromatic diamine, the aromatic binary anhydride, the curing agent and the organic solvent is 100:5-10:10-20:1-5:80-200. The preparation method of the TGDADPE type epoxy matrix resin is simple in operation technology, the prepared matrix resin is excellent in overall performance and good in wettability to glass fiber, carbon fiber, quartz fiber, basalt fiber and aramid fiber and can be used for preparing the advanced composite material good in overall performance, and the preparation method of the TGDADPE type epoxy matrix resin is suitable for industrial production and has broad application prospects.

Owner:DONGHUA UNIV +1

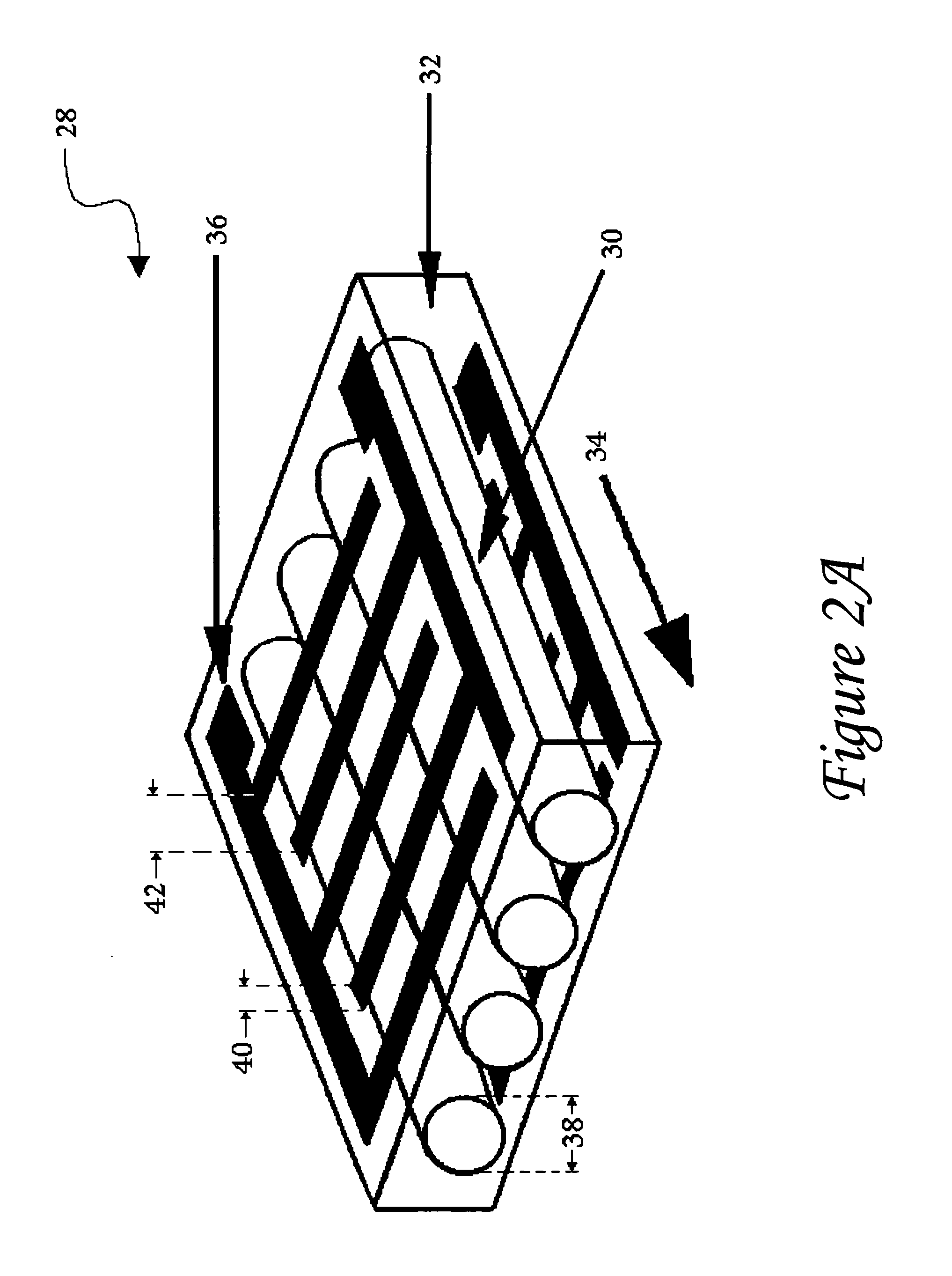

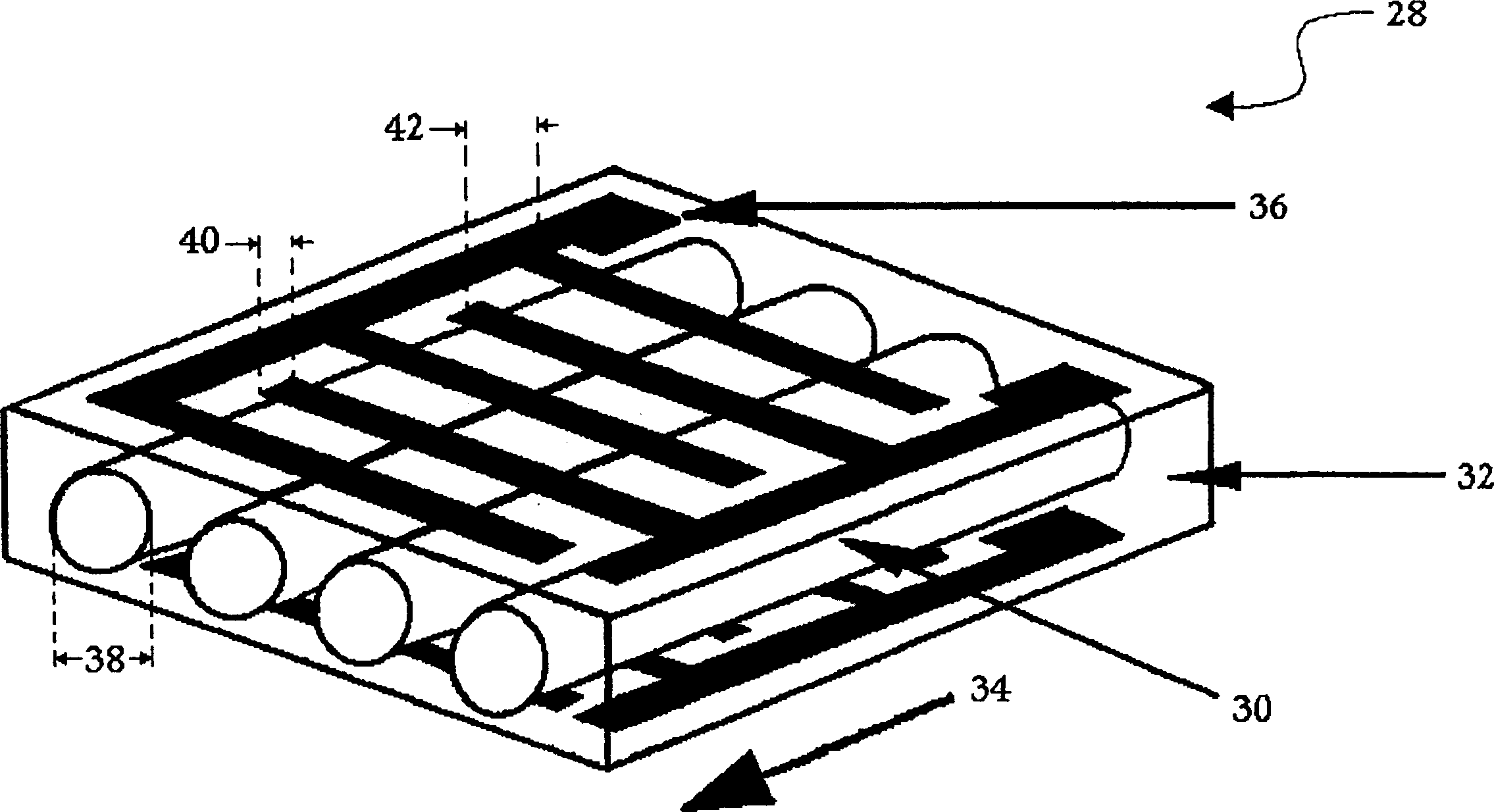

System for generating electric power from a rotating tire's mechanical energy using reinforced piezoelectric materials

InactiveCN1549776AEliminate difficultiesReduce in quantityAuxillary drivesInflated body pressure measurementCapacitanceElectrical battery

A system for generating electric power from a rotating tire's mechanical energy has a piezoelectric structure and an energy storage device. The structure comprises a plurality of piezoelectric fibers embedded in a generally unidirectional fashion in an epoxy matrix. The structure is mounted on a support substrate for distributing mechanical strain in the piezoelectric structure uniformly. The structure is mounted within a tire for generating electric charge as the wheel moves along a ground surface. Electrode within the piezoelectric structure is coupled to a power module to rectify the electric current and store it in a storage device, f. ex. an electrolytic capacitor or a rechargeable battery. A regulated voltage source receives the generated and stored energy to power various electronic systems integrated in the tire or wheel. A tire monitoring system with wireless transmission of tire pressure, temperature, identification information to a remote receiver.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Micron-nano modified epoxy matrix temperature resisting, heat conducting and insulating composite and preparation method thereof

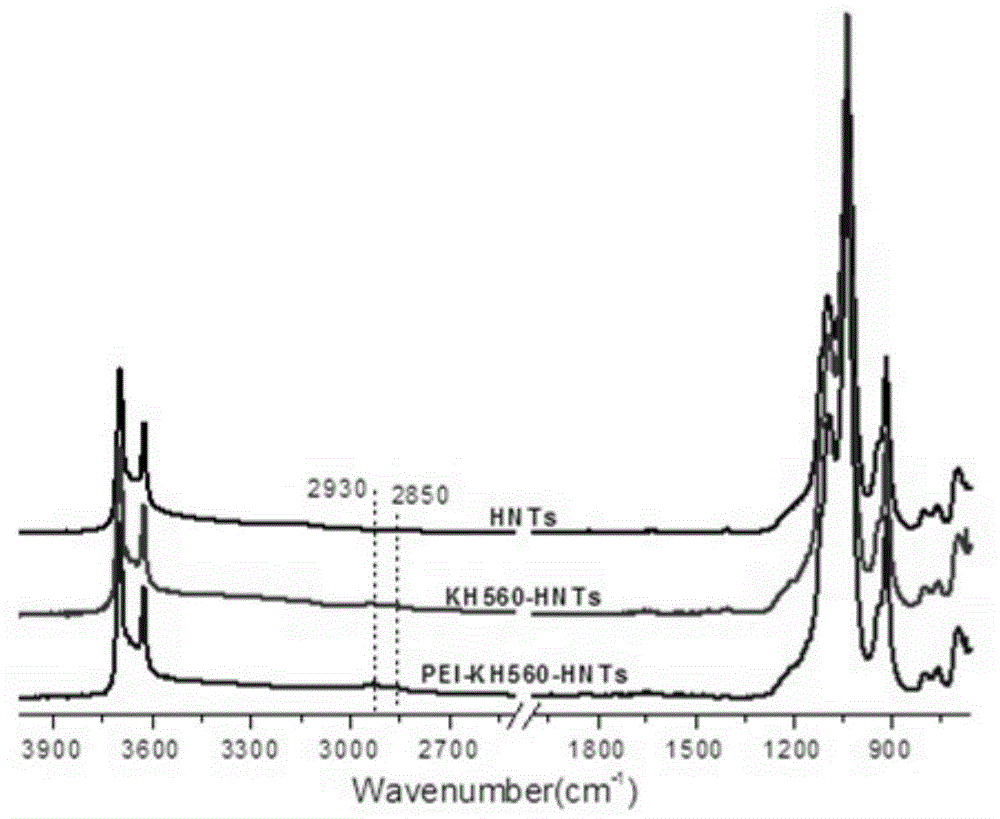

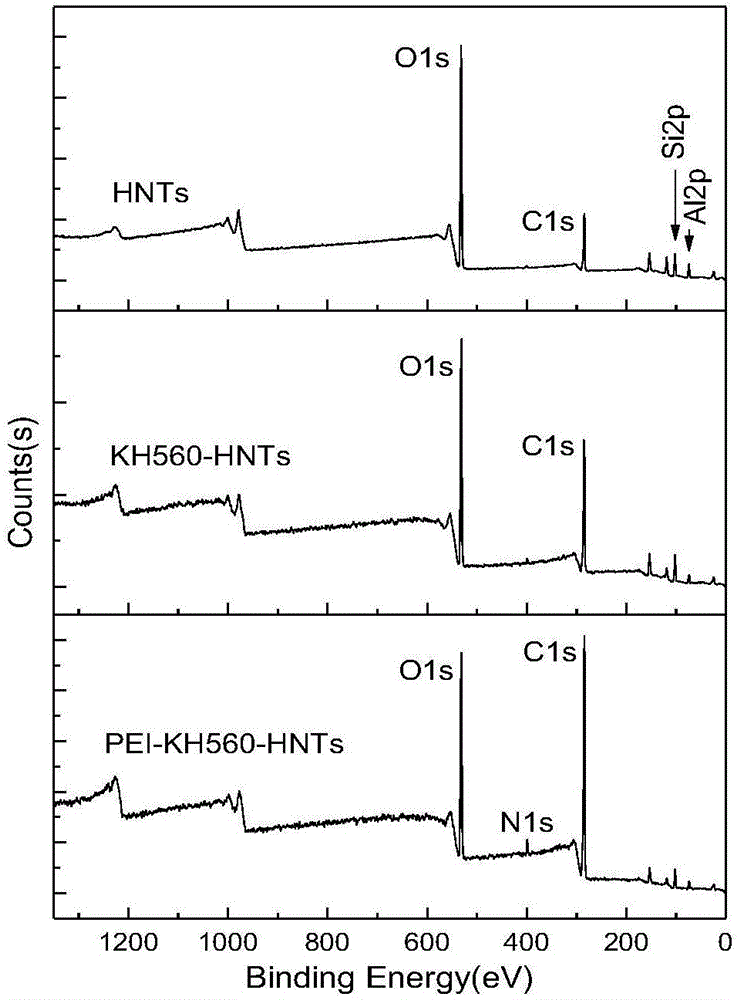

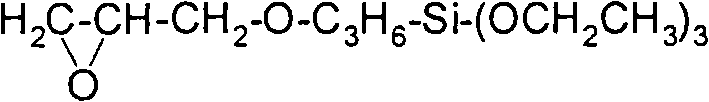

InactiveCN105860437AGuaranteed reliabilityImprove temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesMicro nanoSilanes

The invention provides a micron-nano modified epoxy matrix temperature resisting, heat conducting and insulating composite. The composite is prepared from, by weight, 30% to 60% of epoxy resin, 5% to 30% of polyfunctional group resin, 20% to 50% of epoxy hardener, 2% to 5% of epoxy toughening agent, 0.25% to 0.75% of curing accelerator, 5% to 15% of micron heat conducting filler, 1% to 3% of nano heat conducting filler and 1% to 2.5% of silane type coupling agent. According to the micro-nano modified epoxy matrix temperature resisting, heat conducting and insulating composite and a preparation method thereof, the polyfunctional group resin and the heat conducting filler are adopted for modifying a foundational epoxy system, so that the temperature resisting performance and heat conducting performance of the composite are greatly improved.

Owner:XIAN SITAN ENVIRONMENT TECH CO LTD

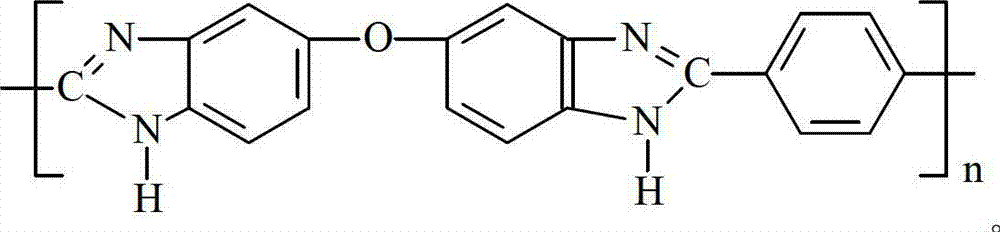

Benzimidazole-epoxy matrix resin and preparation method thereof

The invention relates to benzimidazole-epoxy matrix resin and a preparation method thereof. The resin consists of an A component and a B component. The preparation method comprises the following steps of (1) putting N,N,N',N'-tetraglycidyl-2,2-di-[4-(4-amino phenoxyl) phenyl] propane and 2-(4-amino phenyl)-5-amino benzimidazole into a reaction kettle, heating and raising the temperature to 70-80 DEG C, stirring and reacting for 15min-30min, adding a reactive diluent and an organic solvent, stirring uniformly, obtaining the A component, (2) mixing a curing agent with the organic solvent, stirring and dissolving uniformly, obtaining the B component, and (3) mixing the A component with the B component and stirring uniformly in a use process. The preparation method is simple; and the obtained matrix resin is excellent in comprehensive performance, can be applied to glass fiber or carbon fiber reinforced advanced composites, and can also be applied to adhesive agents of substrates such as metal, glass and ceramics.

Owner:DONGHUA UNIV +1

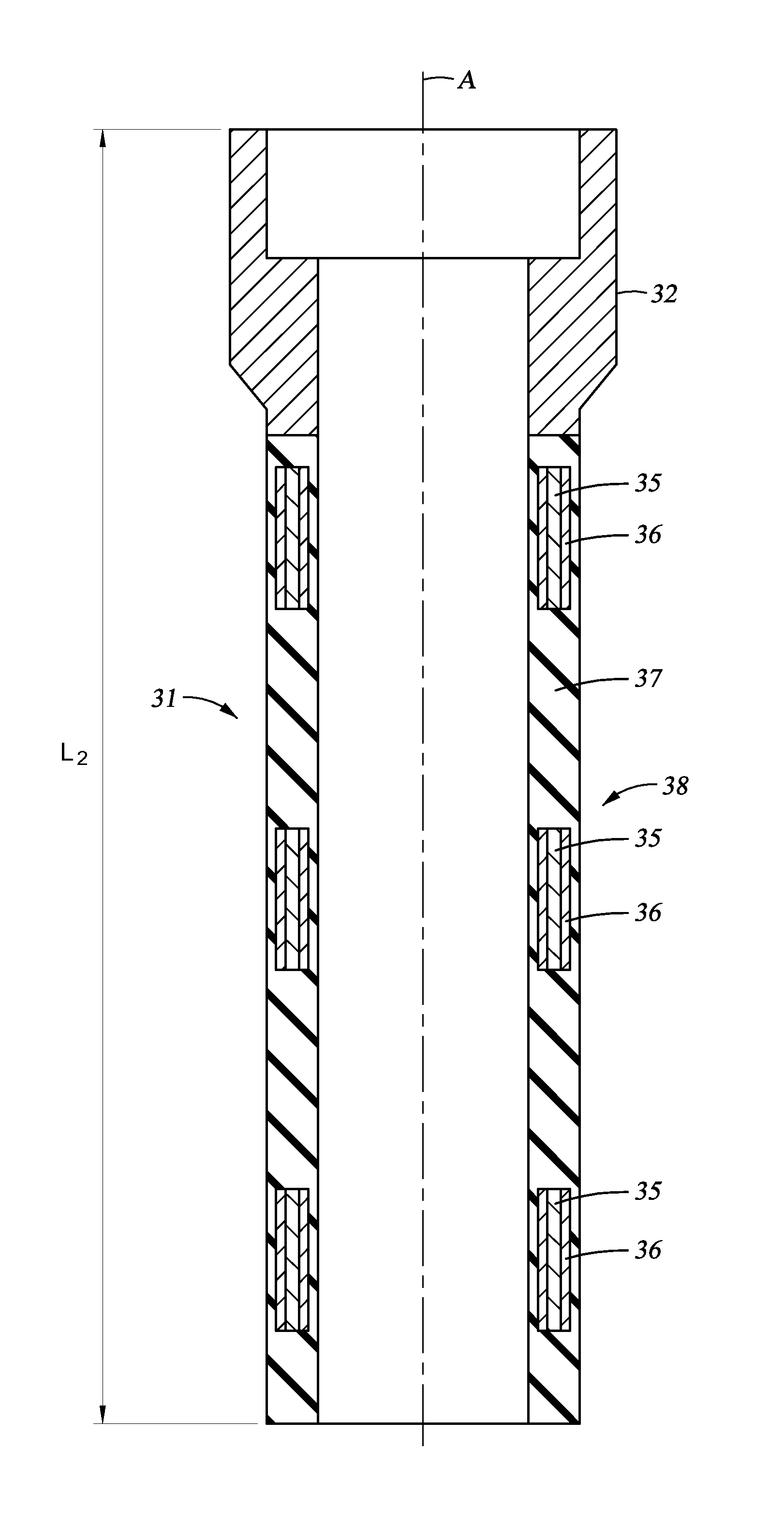

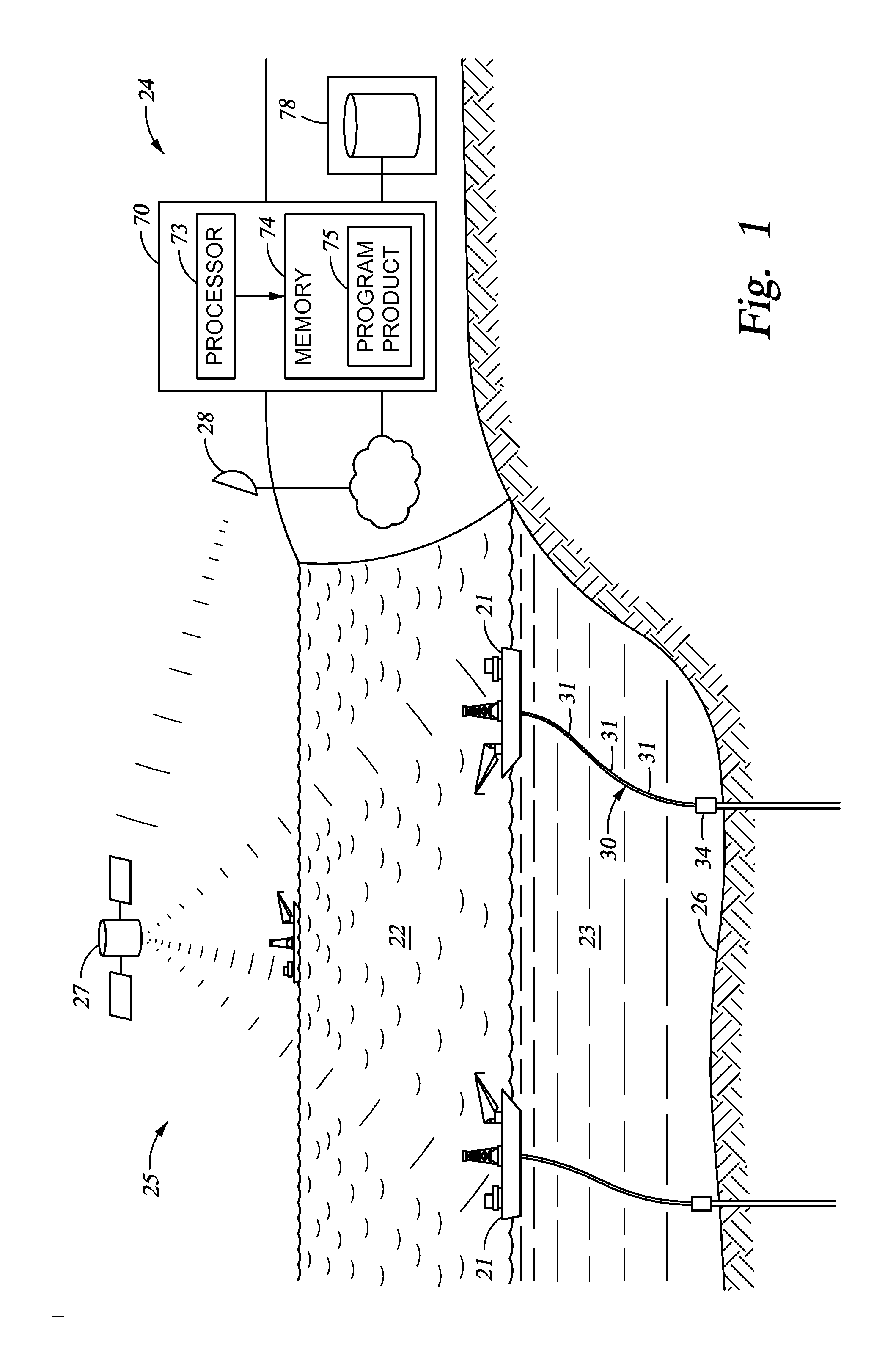

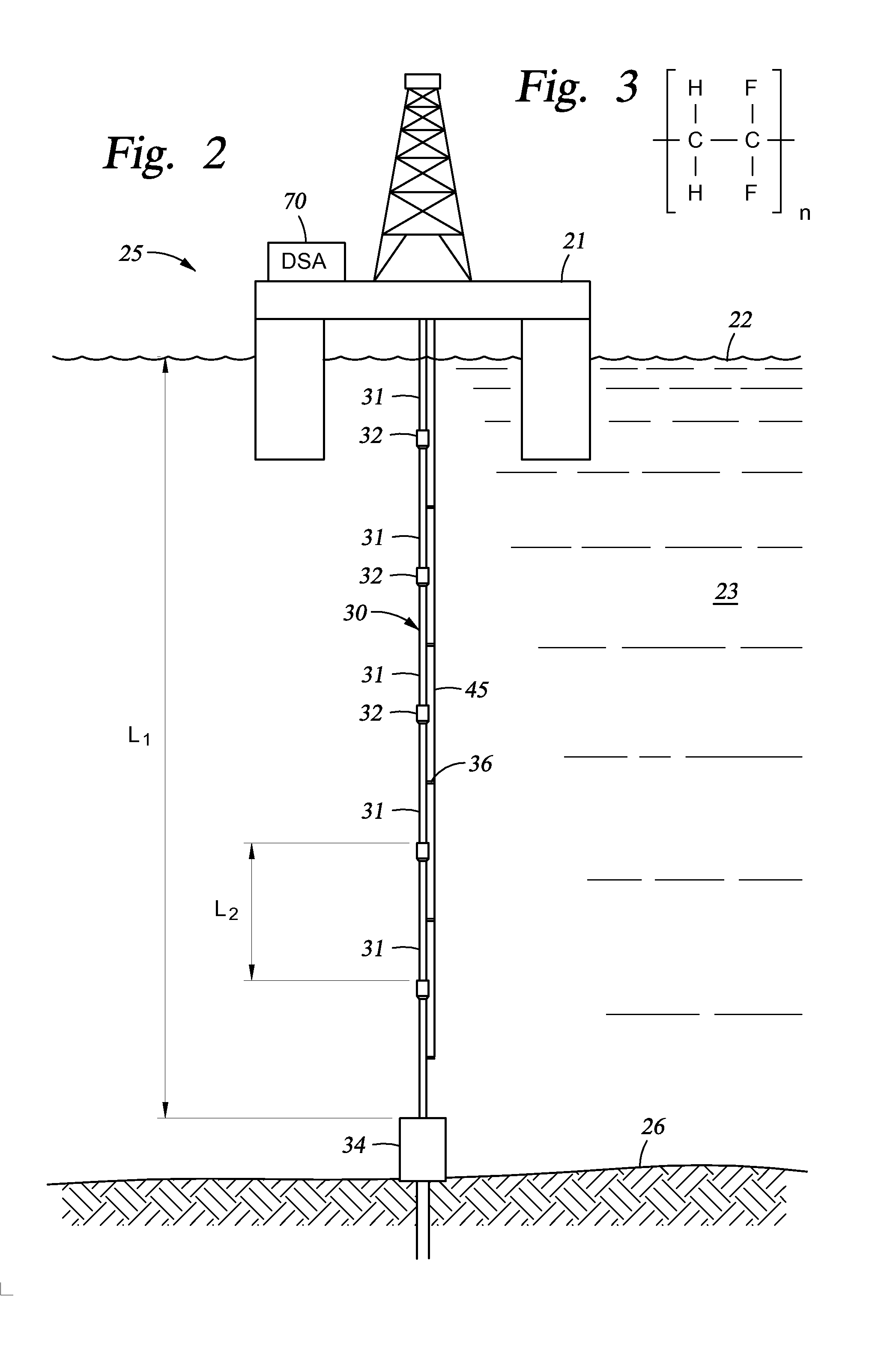

Marine composite riser for structrual health monitoring using piezoelectricity

InactiveUS20120031620A1Increase the areaEasy to detectDrilling rodsConstructionsSilver inkStructural health monitoring

A structural health monitoring system for a marine composite riser string is provided. Each riser pipe section includes a cylindrical form having an axis and also a carbon epoxy matrix. A sensor is associated with (e.g., embedded in) and substantially circumscribes the riser pipe section. The sensor includes a PolyVinyliDene Fluoride laminate and electrodes (e.g., conductive silver ink coating) so that the sensor generates electricity at the electrodes responsive to mechanical stresses and strains of the riser section, including vibrations. The system can also include a data acquisition system and digital signal analyzer to analyze signals responsive to the generated electricity at the electrodes of sensors and to provide health monitoring and damage detection for the marine riser pipe string, including impact damage and fatigue crack initiation. The system can further include a subsurface energy storage device and a plurality subsurface microelectromechanical devices coupled to the subsurface energy storage device.

Owner:VETCO GRAY

Aluminum Alloy Conductor Composite Reinforced for High Voltage Overhead Power Lines

InactiveUS20120170900A1Non-insulated conductorsLine/current collector detailsElectrical conductorCarbon fibers

Embodiments of the invention relate to aluminum alloy conductor composite reinforced for high voltage overhead power lines and associated methods of use and manufacture. In one embodiment, a transmission cable can be provided. The transmission cable can include a core including at least one of: a composite core, a plurality of fibers in a matrix of one or more materials, or a set of carbon fibers embedded in an epoxy matrix; and a plurality of wires wrapped around the core, wherein the wires comprise at least one of the following: aluminum 6201 T83 alloy, aluminum 6201 T81 alloy, aluminum 1350-H19 alloy, or a heat resistant aluminum-zirconium alloy; wherein the transmission cable has a low sag characteristic.

Owner:GENERAL CABLE TECH CORP

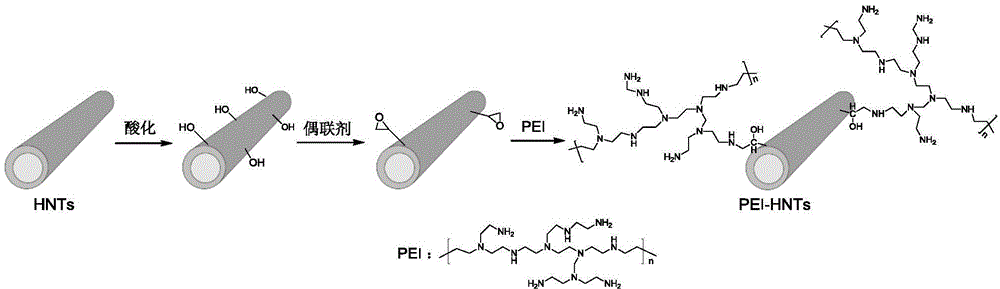

Halloysite nanotube / epoxy nanocomposite

The present invention relates to the field of nano-composite materials, and specifically relates to a halloysite nanotube / epoxy nanocomposite. The halloysite nanotube is a branched polymine grafted halloysite nanotube; the branched polymine grafted weight halloysite nanotube and epoxy resin are in the weight ratio of 0.2-20:100, preferably 0.5-5:100. The hyperbranched polymine is grafted onto epoxidized HNTs, so that the branched structure has rich amino groups to generate stronger chemical bonds or hydrogen bonds between the halloysite nanotube and an epoxy matrix and to enhance the interface effect. The prepared modified halloysite nanotube can effectively improve the impact resistance of epoxy resin and reduce brittle fracture of epoxy resin, and has broad application prospects in the fields of automotive, electronics, functional materials and aerospace.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

System and method for generating electric power from a rotating tire's mechanical energy

InactiveCN1699084AAvoid complexityReduce signal hardwareAuxillary drivesElectrical storage systemElectric power systemMechanical energy

A tire assembly with integrated power generation features includes one or more piezoelectric devices and power conditioning modules. Piezoelectric devices may include a plurality of piezoelectric fibers embedded in a generally unidirectional fashion within an epoxy matrix, a piezoceramic wafer provided on a substrate and substantially surrounded by a protective casing, or a piezoceramic unimorph structure adhered with a thermoplastic polyimide to respective top and bottom conductive layers. Each piezoelectric device may include multiple piezoelectric elements connected in series and / or parallel arrangements, configured with respective poling directions in opposing or in-phase arrangements and / or configured in d33 or d31 displacement modes. Piezoelectric devices are preferably mounted within a tire or wheel assembly such that electric charge is generated therein as the wheel assembly moves along a ground surface and is subsequently stored in one or more energy storage devices. Stored energy may then be used to power electronics such as a tire monitoring system that wirelessly transmits such information as tire pressure, temperature and identification variables to a remote receiver location.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

High-temperature resistant and high-toughness epoxy matrix resin as well as preparation method and application thereof

The invention discloses high-temperature resistant and high-toughness epoxy matrix resin as well as a preparation method and an application thereof. The epoxy matrix resin is prepared from the following components by weight portion: 100 portions of epoxy resin, 20-60 portions of curing agent, 0.5-5.0 portions of curing accelerator and 5-50 portions of thermoplastic resin. The epoxy matrix resin has the glass-transition temperature of 210-235 DEG C, the tensile strength of 80-86MPa, the elongation at break of 3.0-3.3% and the tensile elastic module of 3.2-3.5GPa. The epoxy matrix resin can meet the requirement of carbon fiber solvent for preimpregnation process and hot-melt preimpregnation process, and after being cured by a proper process, the epoxy matrix resin has excellent comprehensive performance and particularly high-temperature resistance and high toughness, thereby being used for preparing high-performance composite material used in the aerospace field and meeting the requirement of the high technology field represented by the aerospace field.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Avionics chassis

Owner:GENERAL ELECTRIC CO

Low dielectric-epoxy resin/mesoporous molecular sieve hybrid material and preparation method thereof

InactiveCN101638505AEvenly dispersedLow dielectric constantPlastic/resin/waxes insulatorsDielectricMolecular sieve

The invention belongs to the field of organic / inorganic hybrid materials and discloses a low dielectric-epoxy resin / mesoporous molecular sieve hybrid material and a preparation method thereof. The hybrid material comprises the following components in portion by weight: epoxy resin prepolymer 70-91.2, mesoporous molecular sieves 0.1-12 and curing agent 8.8-25. The epoxy resin hybrid material containing mesoporous molecular sieves of the invention has a dielectric constant which is reduced by 0.1 to 0.9 at 100kHz compared with that of pure epoxy resin at 100kHz and retains the original excellentperformance of epoxy matrix resin at the same time. According to the preparation method of the invention, the mesoporous molecular sieves uniformly disperse in the resin and form an excellent boundary structure, and the obtained hybrid material has a low dielectric constant and an excellent thermal mechanical property and can be used in the fields of printed circuit boards, electronic package andthe like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

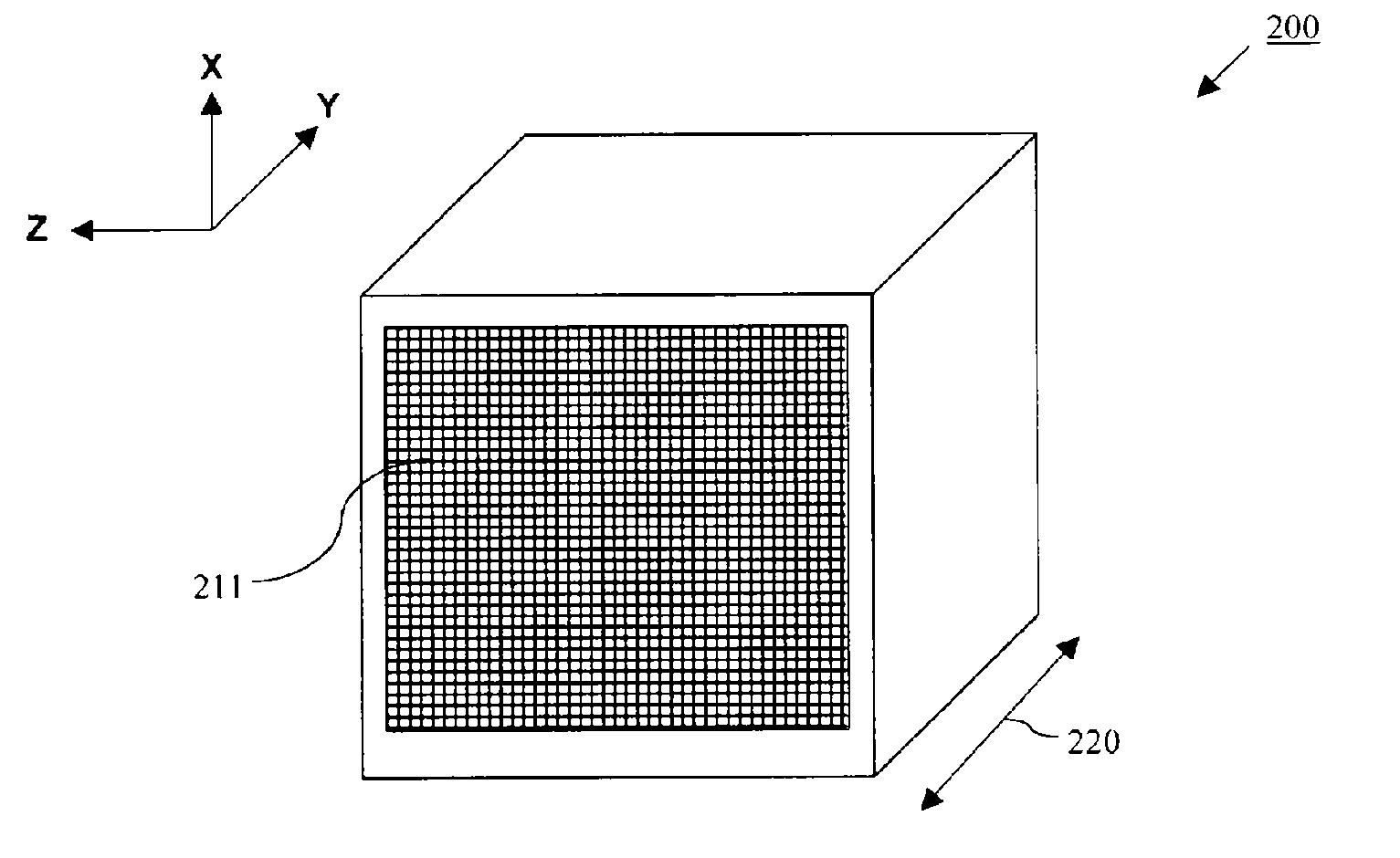

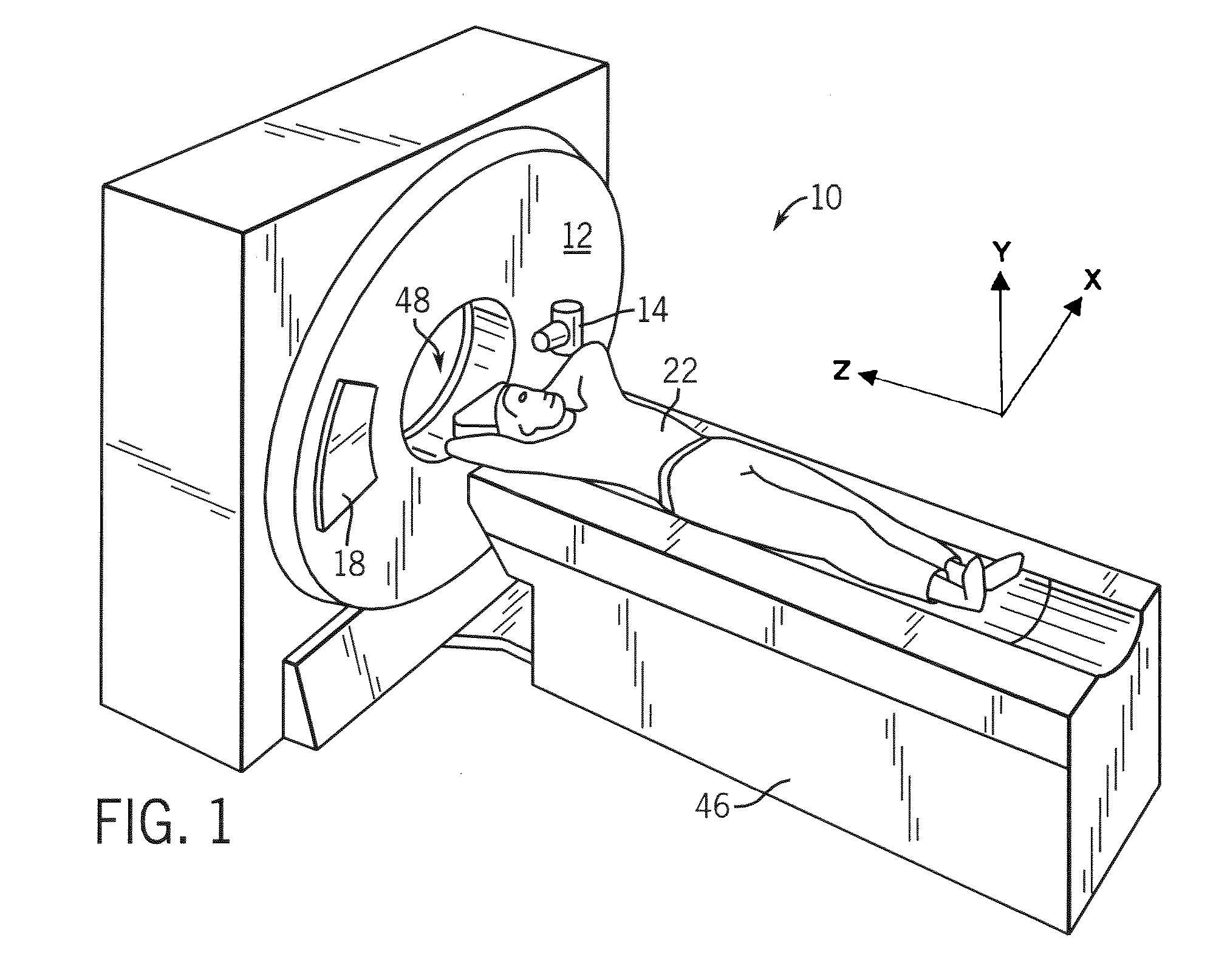

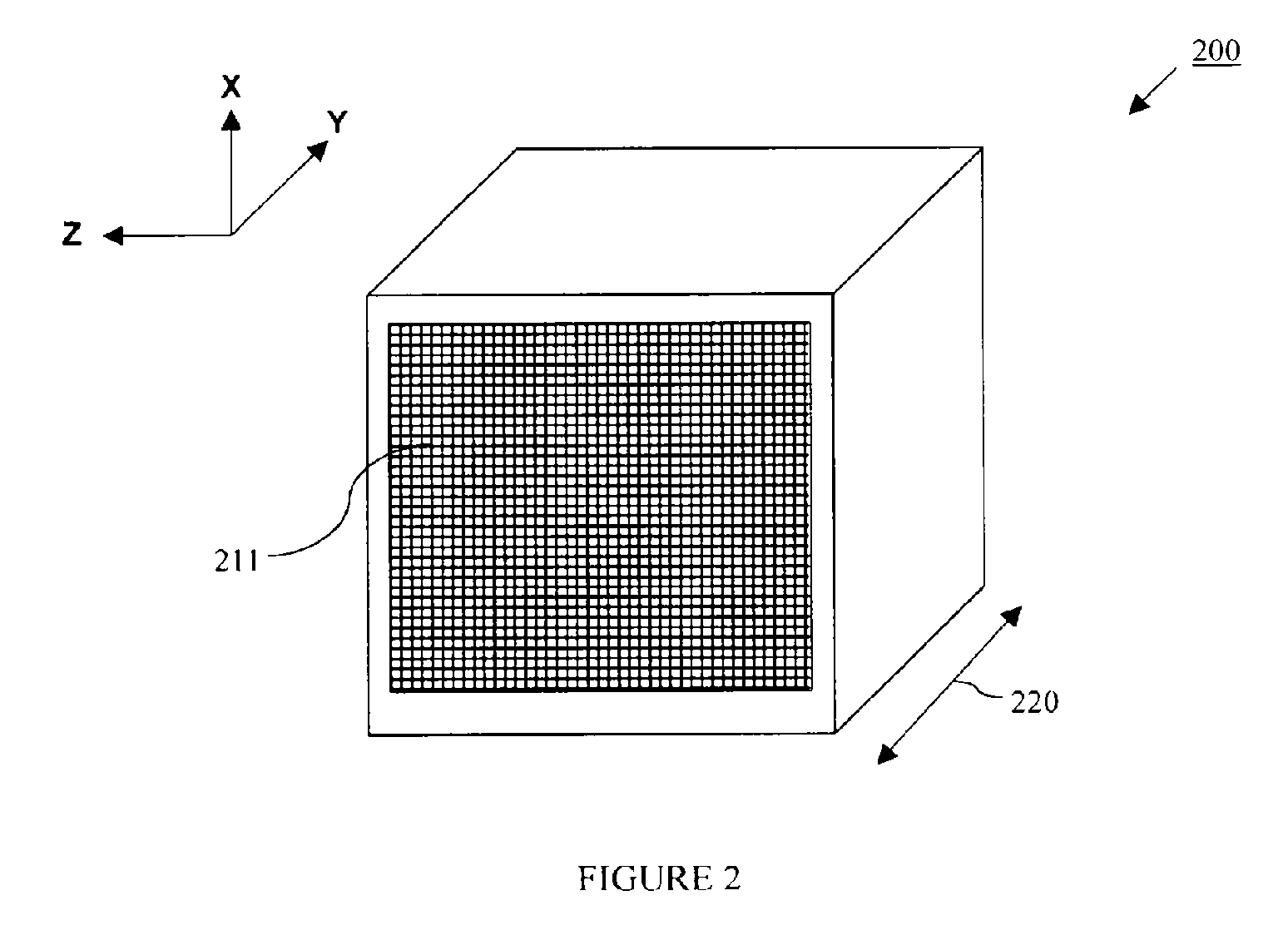

Cast collimators for ct detectors and methods of making same

InactiveUS20070064876A1Reduce X-ray doseLarge atomic numberMaterial analysis using wave/particle radiationHandling using diaphragms/collimetersHigh densityRadiology

Cast collimators for use in CT imaging systems are described, as are methods of making them. Such collimators may comprise pre-patient collimators, pre-patient filter / collimator assemblies, and / or post-patient collimators. The filters and / or collimators may be made of any suitable high-density, high atomic number material such as lead, a lead alloy, tantalum, tungsten, tungsten suspended in an epoxy matrix, tungsten suspended in a slurry, or the like. Embodiments of these collimators comprise specially-designed channels and vanes that allow them to be precision cast to the necessary degree of accuracy. These channels and vanes are preferably tapered. These collimators and filter / collimator assemblies help minimize the x-ray dose to the patient by minimizing the scattered radiation creation mechanism and by collimating out much of the scattered radiation that would otherwise be subjected to the patient. These collimators may be cast as either single piece structures, or multiple pieces that can be operatively connected together.

Owner:GENERAL ELECTRIC CO

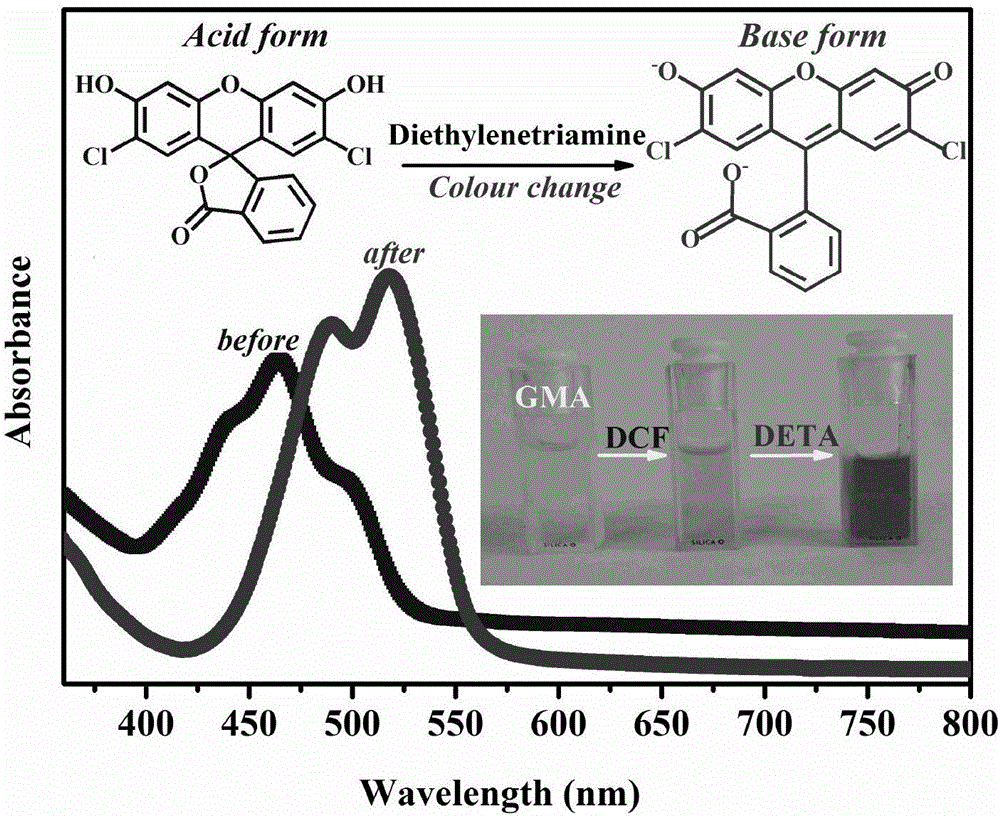

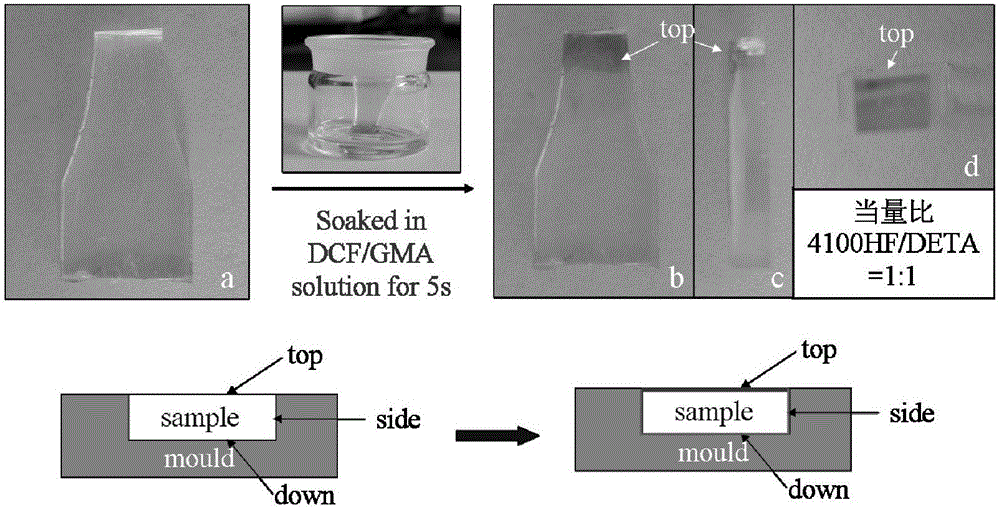

Microcapsule with damage hinting and repairing functions and application thereof in epoxy coating

InactiveCN106118367AChange color quicklyObvious discolorationPolyurea/polyurethane coatingsMicroballoon preparationFluorescenceEpoxy matrix

The invention provides a microcapsule. The microcapsule is of a double-layered structure. The material of an inner capsule wall is polyurethane resin. The material of an outer capsule wall is urea resin. A fluorescent pigment and an epoxy reparation agent are wrapped in the capsule walls. The microcapsule created by the invention has good compatibility with an epoxy matrix. The microcapsule is fractured under the effect of external stress to release reparation monomers for reparation, and meanwhile, the positions and conditions of damage occurring parts can be hinted through colour changes.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

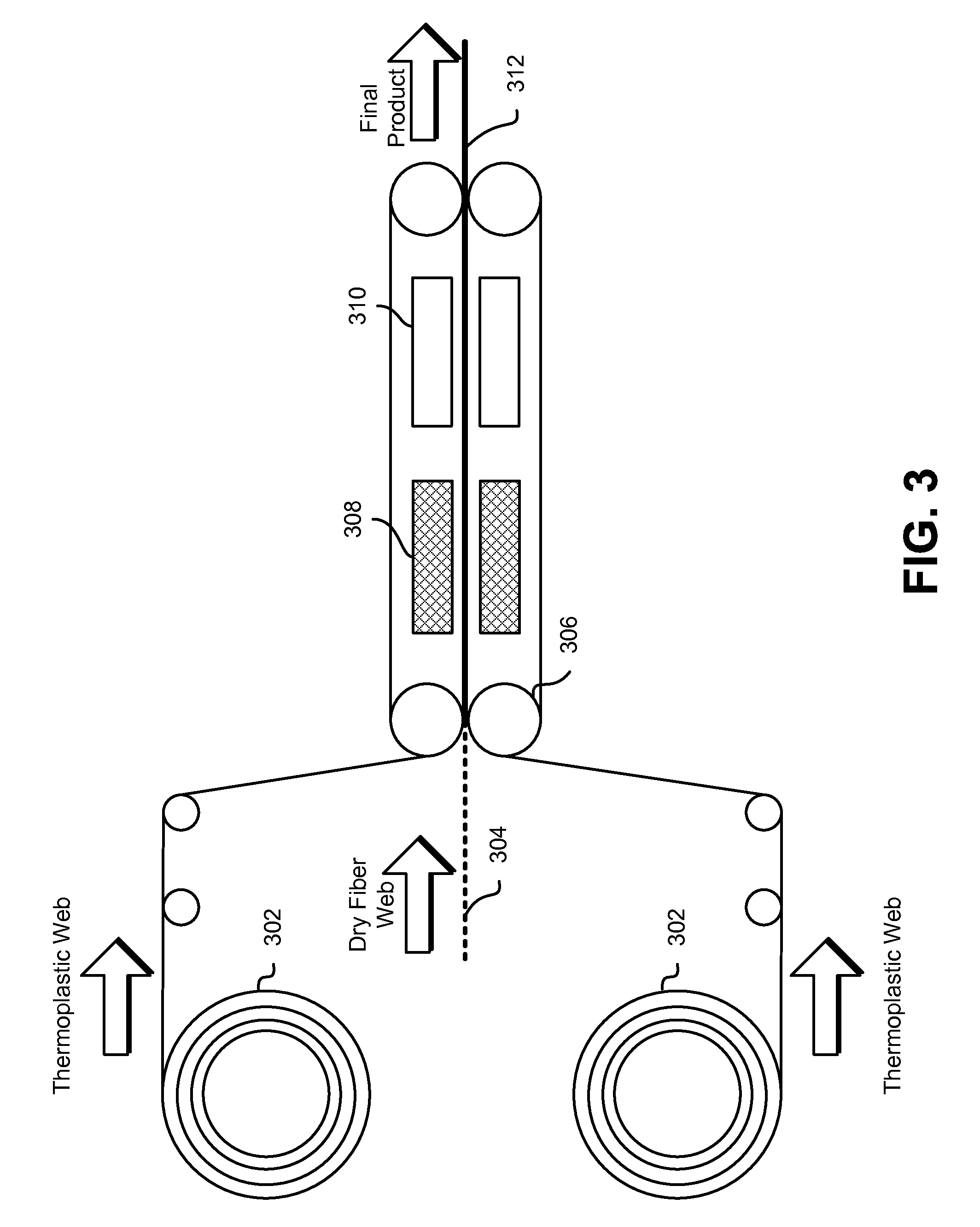

Flexible fiber-reinforced composite material

ActiveUS20150174885A1Lamination ancillary operationsLayered product treatmentPercent elongationFiber-reinforced composite

A flexible fiber-reinforced composite material is manufactured by impregnating a fiber reinforcement material with a non-epoxy matrix material. Subsequently, the impregnated fiber reinforcement material is dried and cured, resulting in a flexible fiber-reinforced composite material that exhibits a tensile modulus between 10 MPa and 42 MPa at 20 percent elongation.

Owner:CARBITEX INC

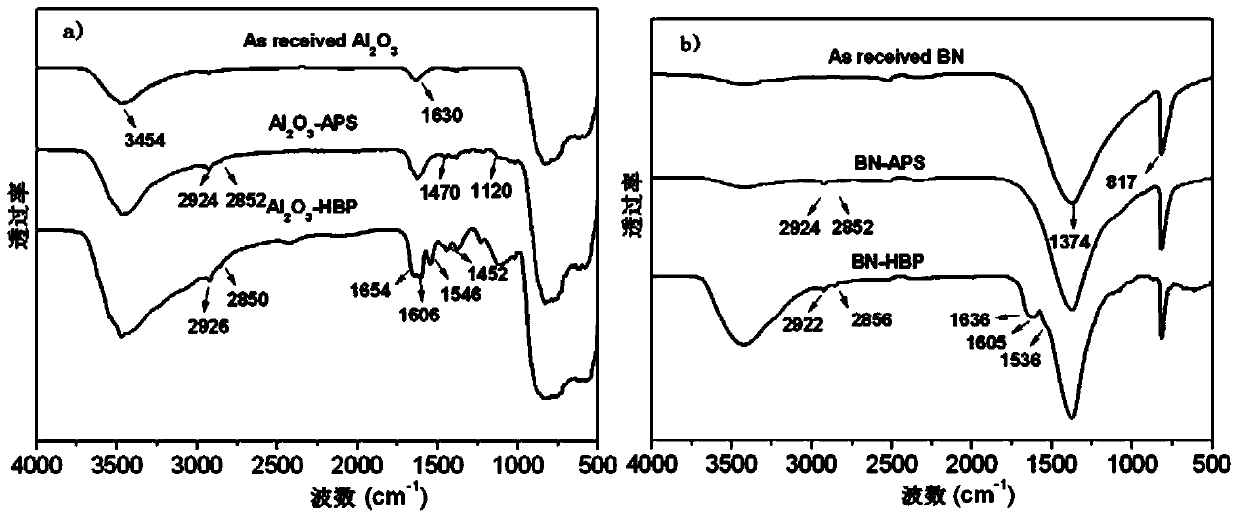

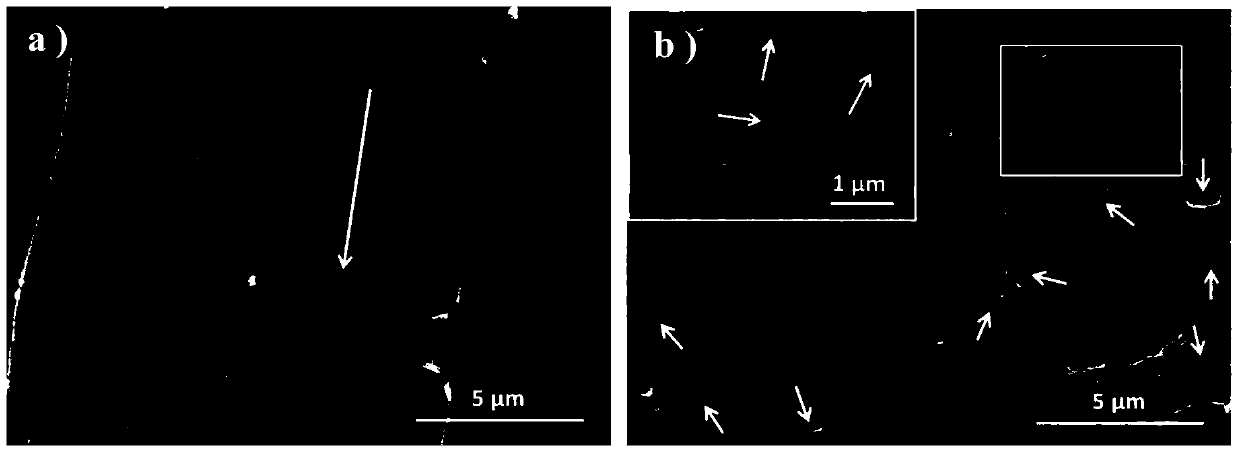

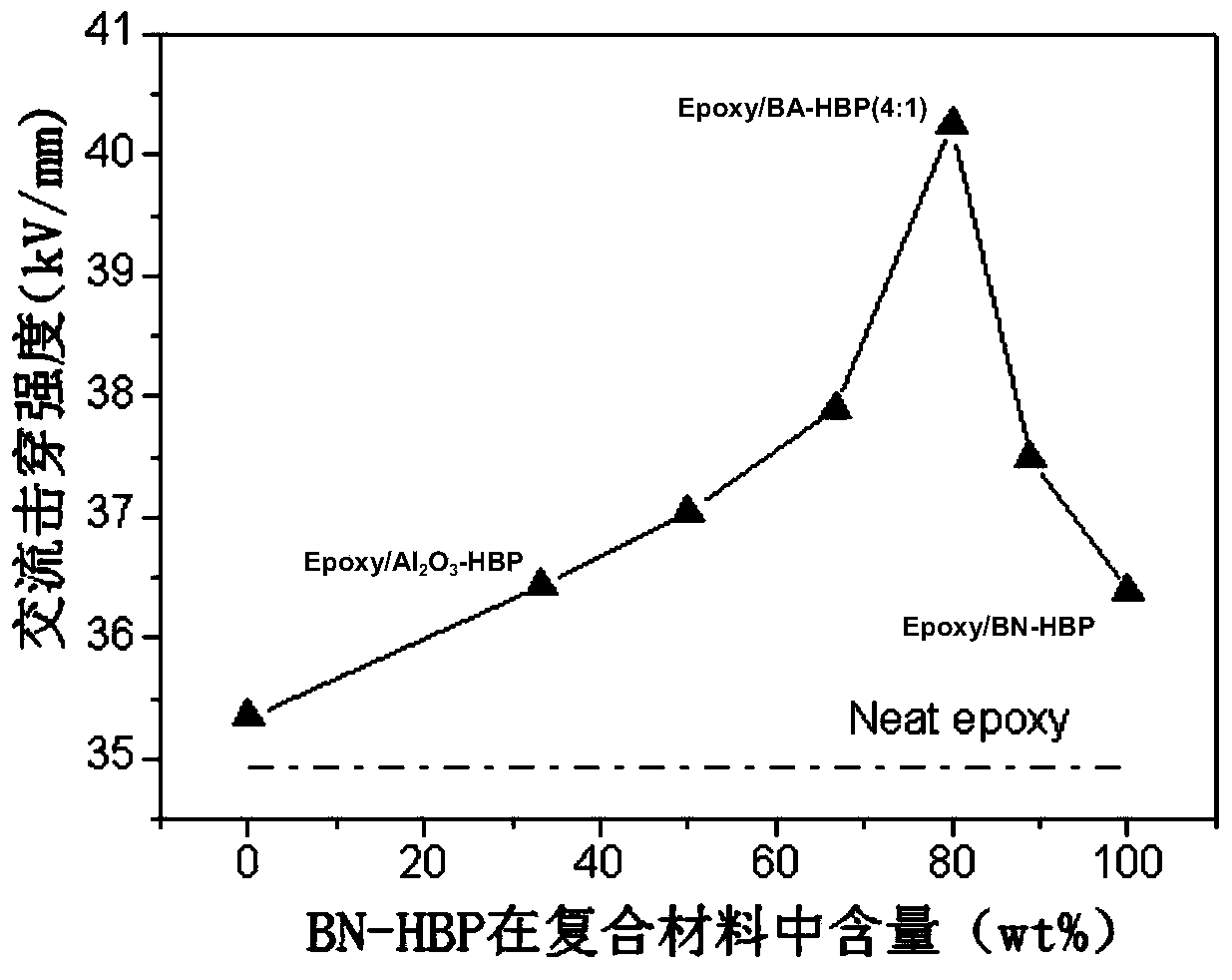

Preparation method of modified compound filler filled breakdown-resisting epoxy composite

The invention relates to a preparation method of a modified compound filler filled breakdown-resisting epoxy composite. The preparation method comprises the following steps: through the modification of a silane coupling agent gamma-APS, amino groups are introduced on the surfaces of Al2O3 and h-BN; hyperwheworries branched polymers (HBP) are grafted on the surfaces of the primarily modified fillers through taking the grafted amino groups as active sites to obtain a modified filler Al2O3-HBP and a modified filler BN-HBP; the two modified fillers are fully mixed with an epoxy resin matrix in different proportions; the epoxy composite is prepared through a two-step stepped heating and curing method. The alternating-current breakdown strength of the prepared epoxy composite shows the obvious cooperative behavior, the system breakdown strength can be regulated through changing the proportion of the fillers; when the BN-HBP accounts for 80 wt% of the compound filler, the performance of the BN-HBP is optimized, only 10 wt% of compound filler is added, and the alternating current strength of the epoxy composite can be improved by 15.7% as compared with that of the epoxy matrix.

Owner:SHANGHAI JIAO TONG UNIV

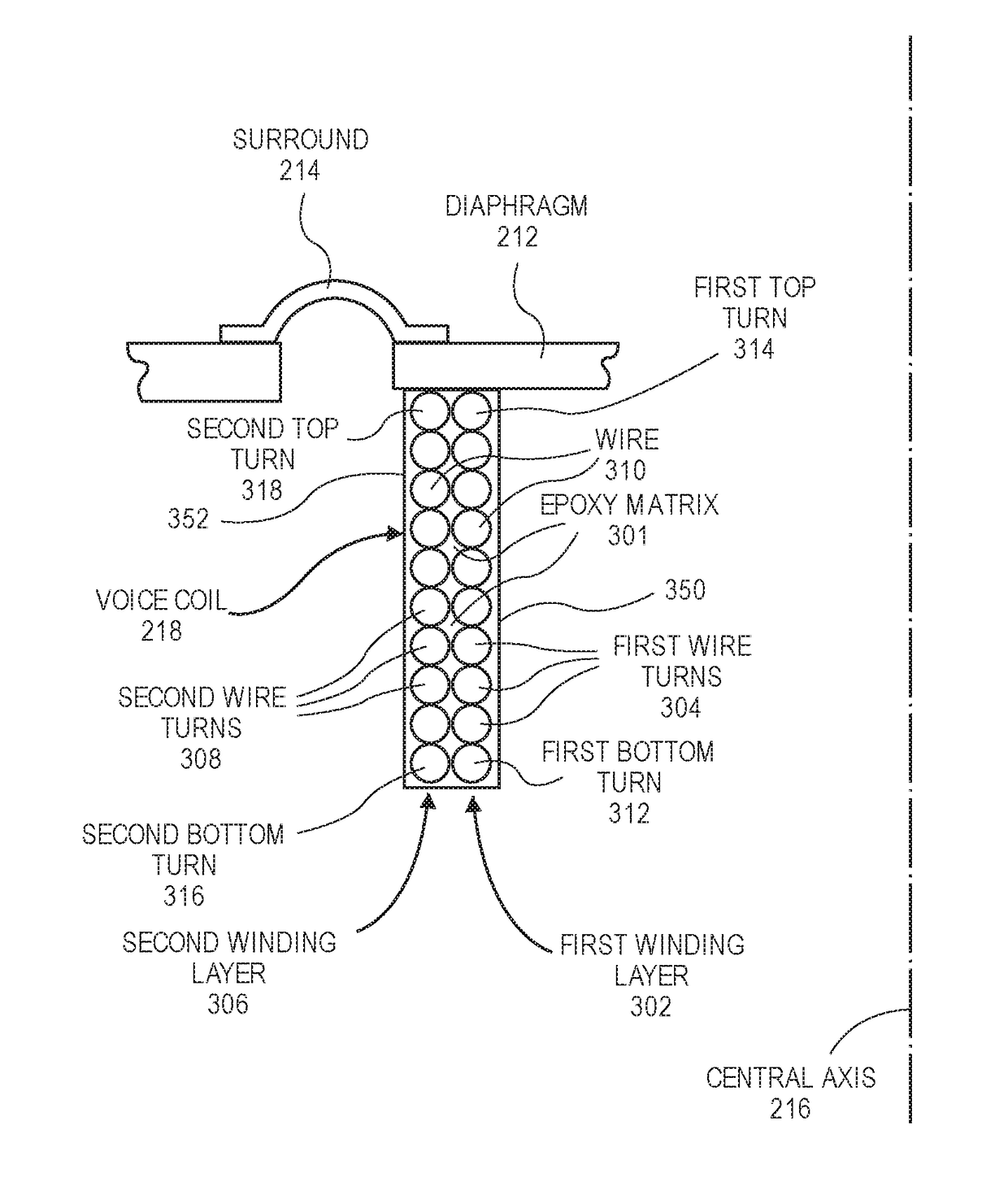

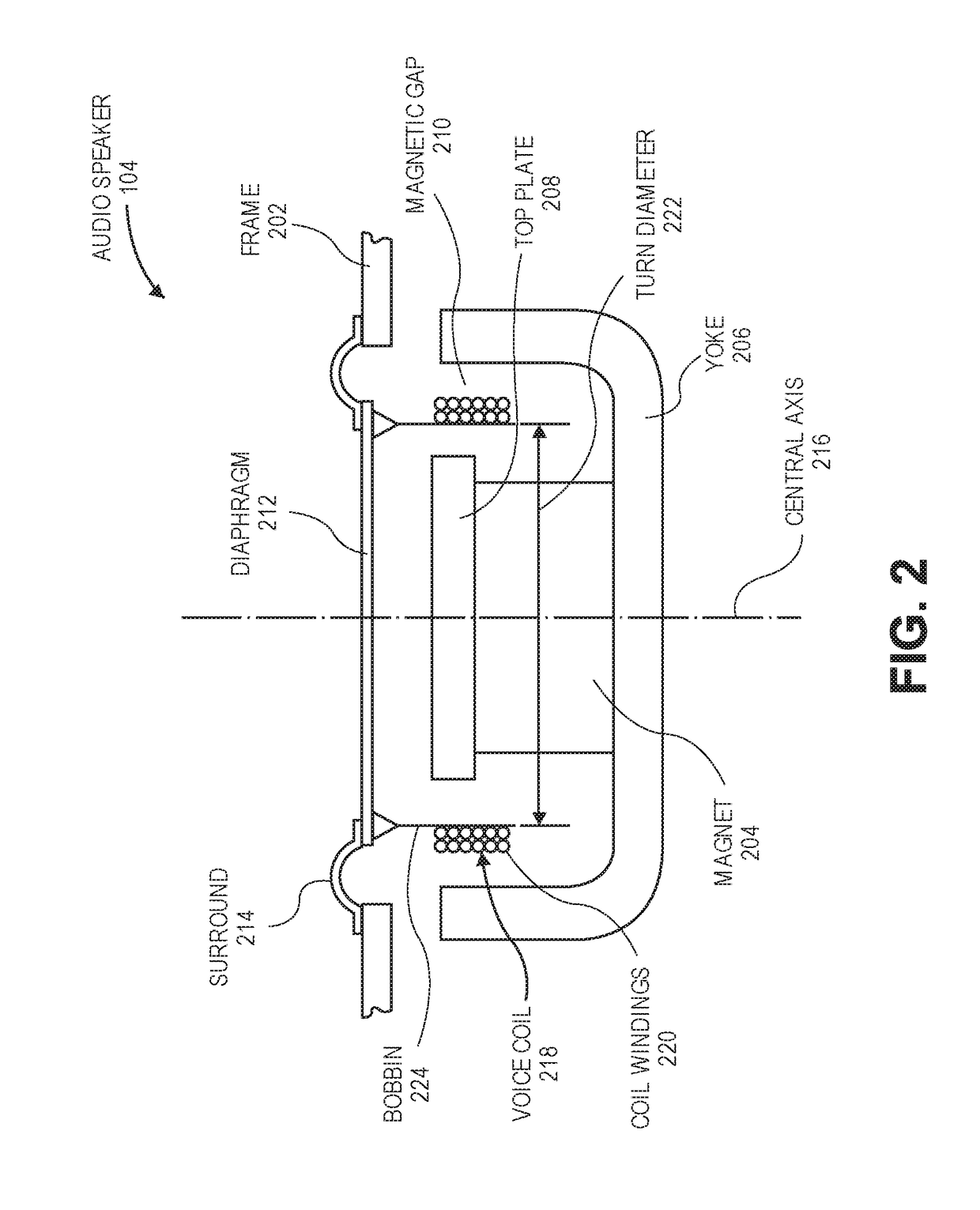

Voice coil having epoxy-bound winding layers

An audio speaker including a bobbin-less voice coil having epoxy-bound winding layers is disclosed. More particularly, a voice coil may include a first winding layer and a second winding layer coaxially arranged about a central axis. The winding layers may include respective wire turns coiled about the central axis in a longitudinal direction. The winding layers may be bound by an epoxy matrix. For example, the epoxy matrix may be disposed radially between the first winding layer and the second winding layer to bond first wire turns to second wire turns, and to bond the winding layers to a speaker diaphragm.

Owner:APPLE INC

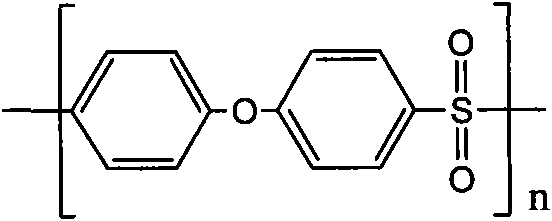

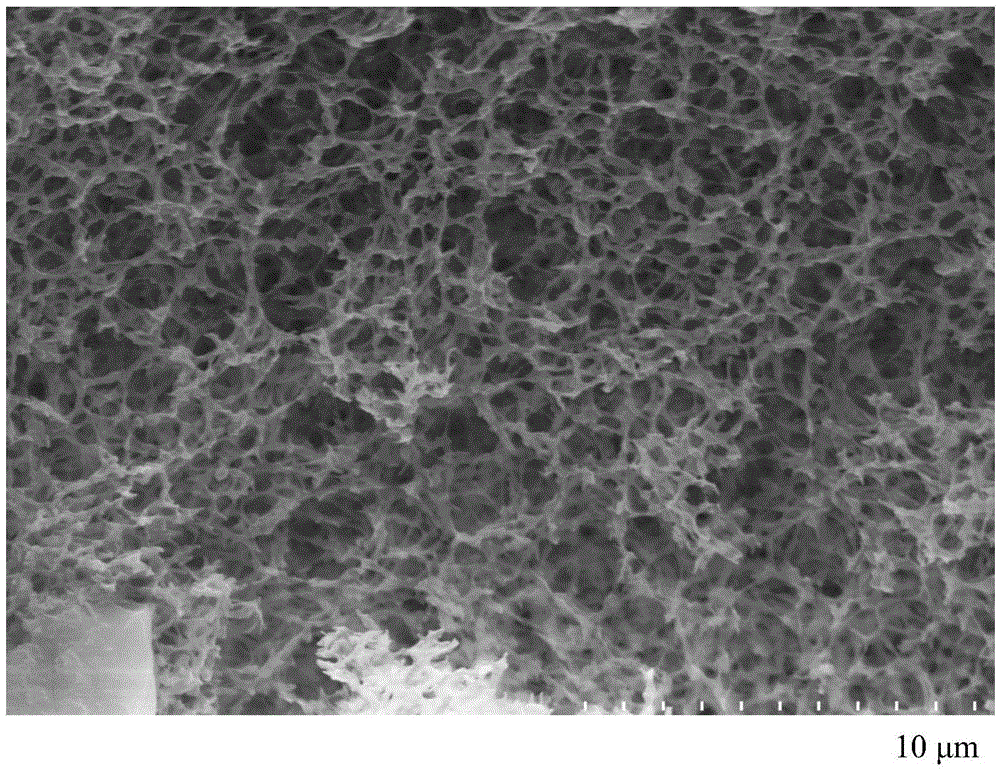

Fast dissolving polyimide powders

ActiveUS20120245239A1Large specific surface areaDissolve fastSynthetic resin layered productsCellulosic plastic layered productsPorosityPolymer science

Polyetherimide particles or powders with a high surface area and high porosity can be prepared by precipitation of polymer solution in hot water or steam without the use of any additives. The particles or powders produced rapidly dissolved in organic solvents as well as epoxy matrices.

Owner:SHPP GLOBAL TECH BV

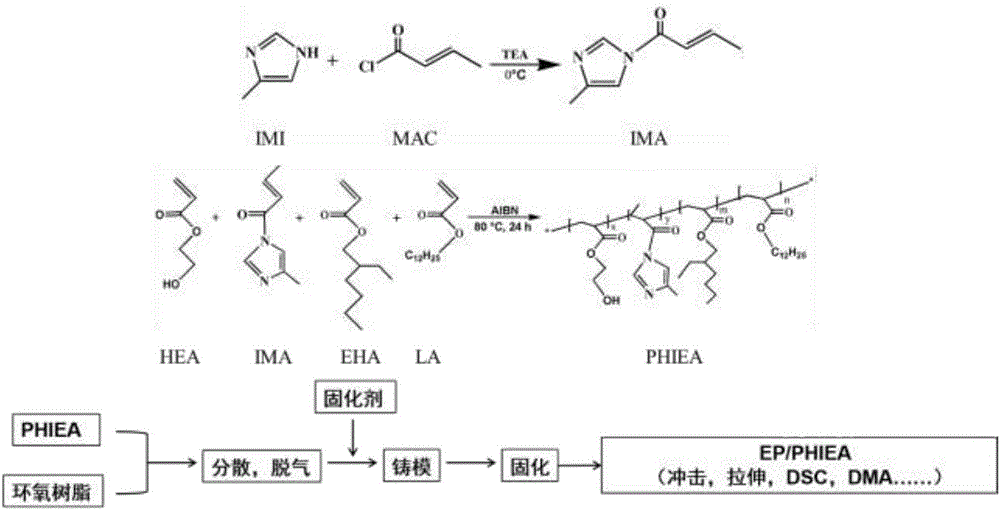

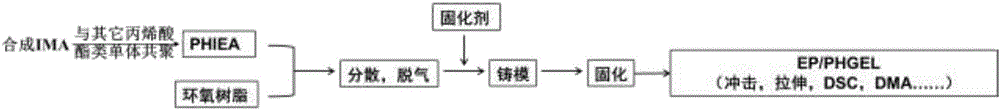

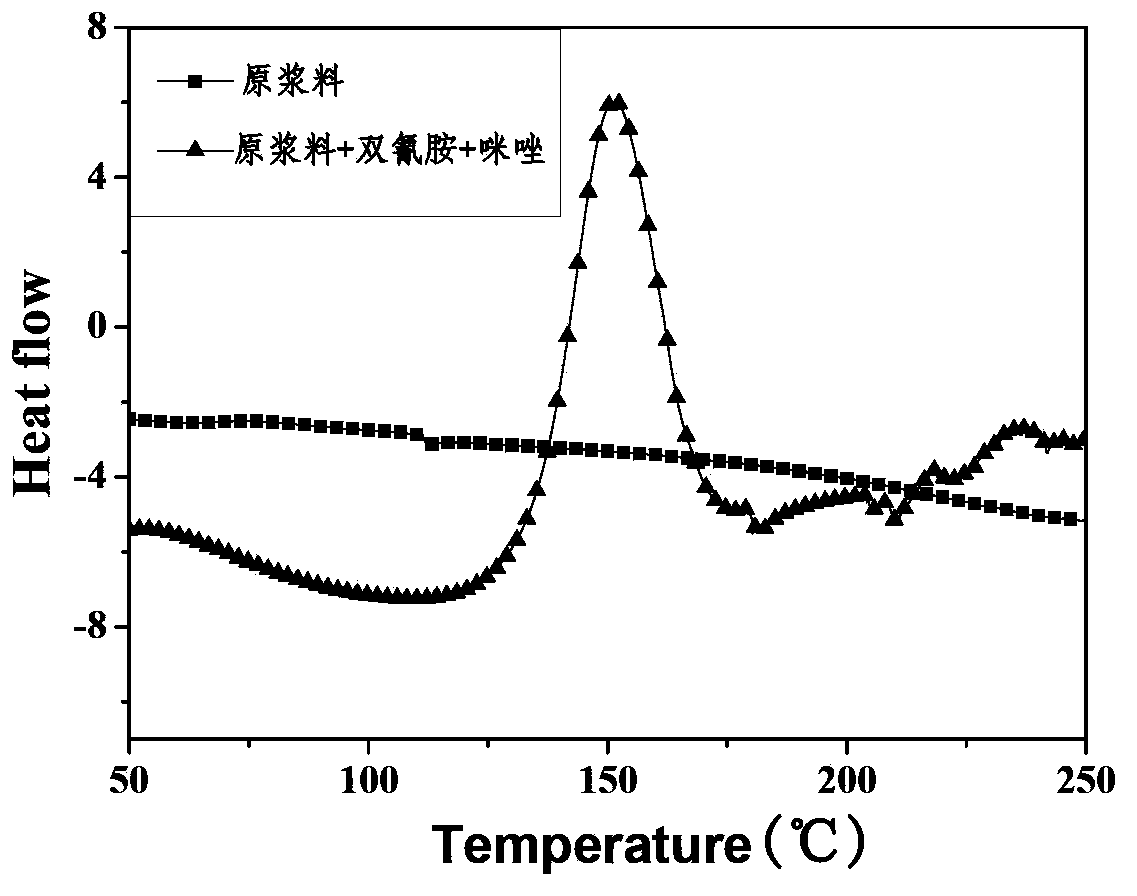

Synthesis of imidazole latent epoxy curing accelerator having toughening effect and application of accelerator in epoxy modification

The invention discloses an acrylate copolymer synthetized through simple free radical polymerization, containing an imidazole ring side group and applied to a latent epoxy curing accelerator to simultaneously toughen epoxy resin. Firstly, imidazole is grafted to a macromolecular chain, the catalytic activity of an imidazole ring can be reduced through a steric effect to achieve the latency purpose; secondly, an acrylate molecular chain participates in formation of an epoxy curing network, microphase separation is formed in an epoxy matrix, and the mechanical property of the epoxy resin is improved. The prepared imidazole latent epoxy curing accelerator having a toughening effect can improve the curing temperature of an imidazole catalyzed DGEBA / MHHPA curing system to about 180 DEG C and has good storage stability at room temperature.

Owner:JIANGNAN UNIV

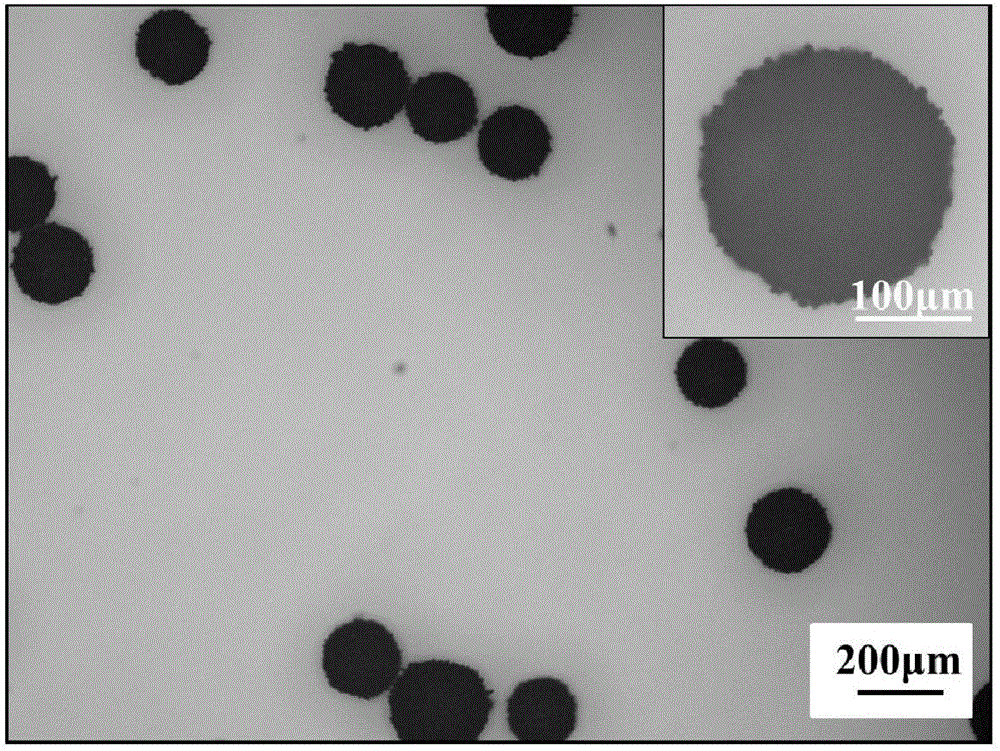

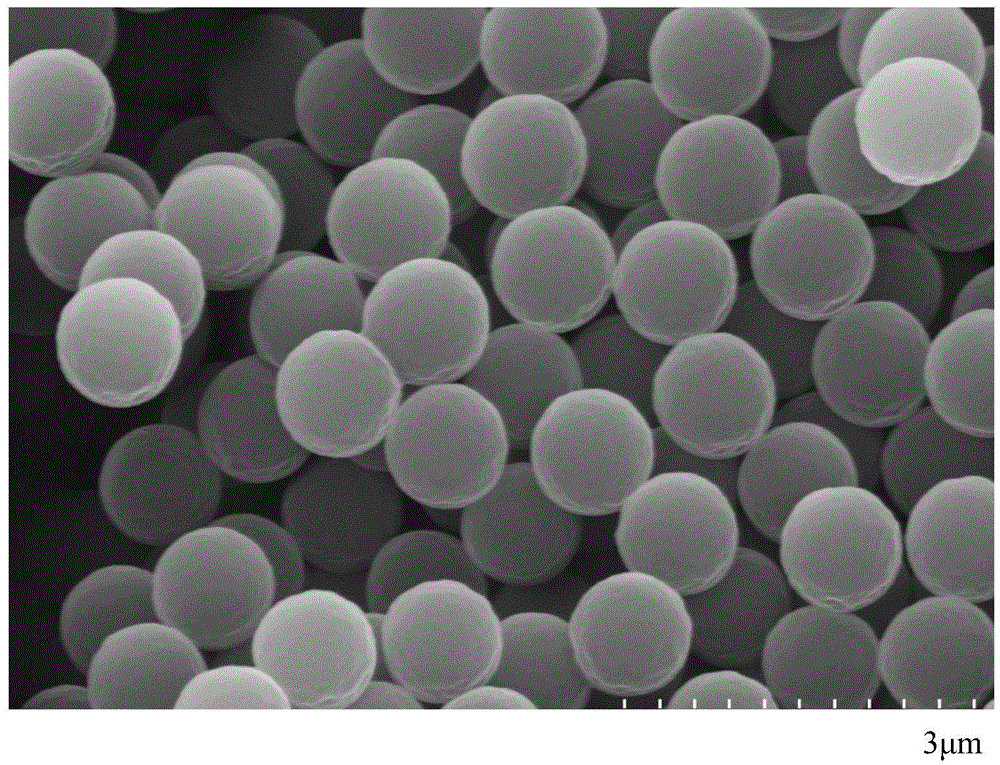

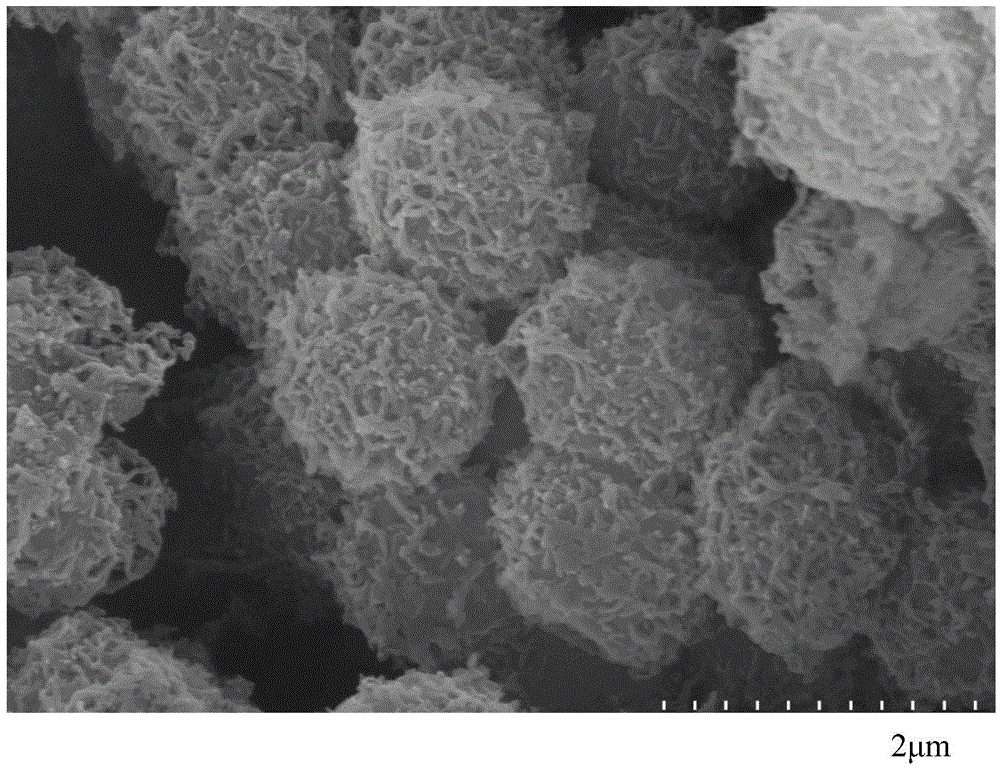

Preparation method of nanopolyaniline-containing compound anti-corrosion coating auxiliary agent

ActiveCN105462336AFirmly attachedGood dispersionAnti-corrosive paintsEpoxy resin coatingsNanowireMicrosphere

The invention discloses a preparation method of a nanopolyaniline-containing compound anti-corrosion coating auxiliary agent, and relates to a polymer nano composite material. Monodisperse micron-graded poly(methyl methacrylate)glycidyl ester microspheres are obtained through dispersion polymerization; under an acid doped environment, aniline monomers are polymerized on the microsphere surface, polyaniline nanowires are loaded on the microspheres, and thus the micron-graded spherical anti-corrosion auxiliary agent is obtained; the auxiliary agent is mixed with epoxy matrix resin and all kinds of solvents for adjusting a coating, the microspheres are dissolved by a solvent, and at the same time, the polyaniline nanowires are dispersed in the coating; phenylamine has less use amount, can be highly dispersed, also has crosslinking functions, has large practical meaning, and has excellent industrialization prospect.

Owner:T&H NOVEL MATERIALS (SUZHOU) CO LTD

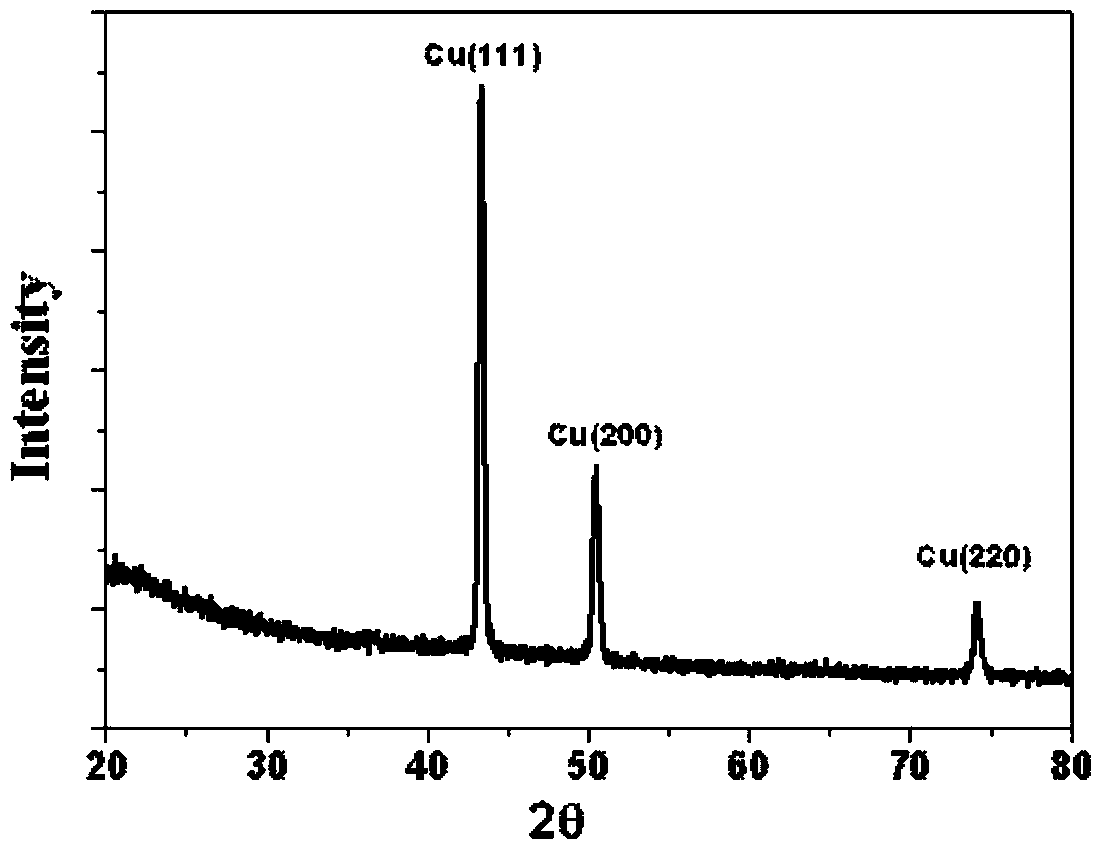

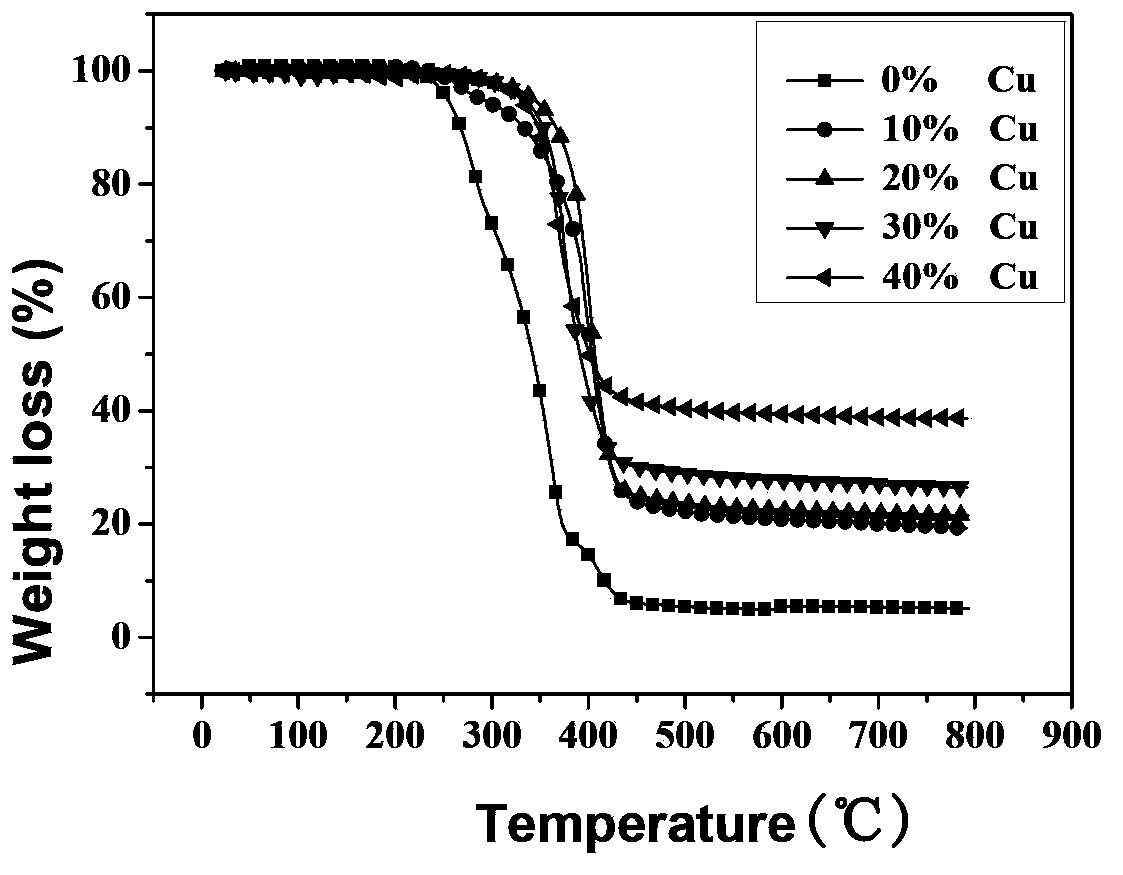

Nano-copper-containing epoxide resin composite material and preparation method thereof

The invention discloses a nano-copper-containing epoxide resin composite material and a preparation method thereof. The preparation method comprises the following steps: sequentially adding a copper precursor, a protective agent, polyalcohol and epoxide resin to a reaction flask, increasing temperature to reaction temperature, and carrying out an in-situ thermal reduction reaction to obtain nano-copper / epoxide composite slurry; and dispersing the nano-copper / epoxide composite slurry into a solvent, adding a solidifying agent, and then solidifying at solidifying temperature to obtain the nano-copper / epoxide resin composite material. Nano-copper granules obtained by utilizing the method are uniformly dispersed in an epoxy matrix, the sizes of the nano-copper granules can be controlled between 50 nanometers and 250 nanometers, the mass fraction of the nano-copper granules can be controlled between 5% and 80%; the prepared slurry is free of impurities in such a way that appropriate precursor, reducing agent and protective agent are selected, and meanwhile, the slurry has good dispersion stability and oxidation stability in the organic solvent. The preparation method disclosed by the invention is simple in process and low in production cost, can be applied to the field of electronic packaging as an embedded type capacitor dielectric material and is suitable for large-scale industrialized production.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

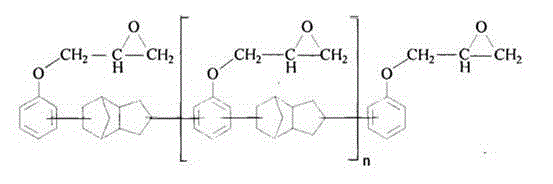

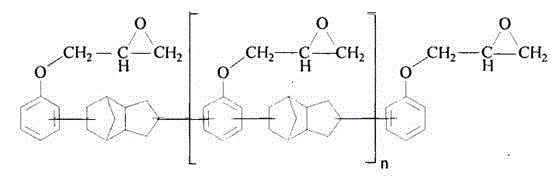

High-performance epoxy resin composition for vacuum infusion molding and preparation method thereof

The invention relates to a high-performance epoxy resin composition for vacuum infusion molding and a preparation method of the epoxy resin composition. The epoxy resin composition is formed by the following components in parts by mass: 100 parts of mixed epoxy resin, 20-60 parts of curing agent, 10-40 parts of diluting agent, 0.5-5.0 parts of accelerating agent, and 0.5-5.0 parts of filling, wherein the epoxy resin comprises an epoxy resin a and an epoxy resin b; the epoxy resin a is a dicyclopentadiene (DCPD) type epoxy resin; and the epoxy resin b is a composition of a glycidyl amine type epoxy resin and a bispheno1-A diglycidyl ether type epoxy resin. The epoxy matrix resin provided by the invention is the composition of the dicyclopentadiene type epoxy resin, the glycidyl amine type epoxy resin and the glycidyl ether type epoxy resin; the obtained composition is characterized by low viscosity, high mechanical property, and good fire resistance; the unchangeable viscosity of enough long time of the composition is conductive to the permeation, the venting and the service life of the resin so that the requirements of molding large parts can be met.

Owner:BLUESTAR BEIJING CHEM MACHINERY

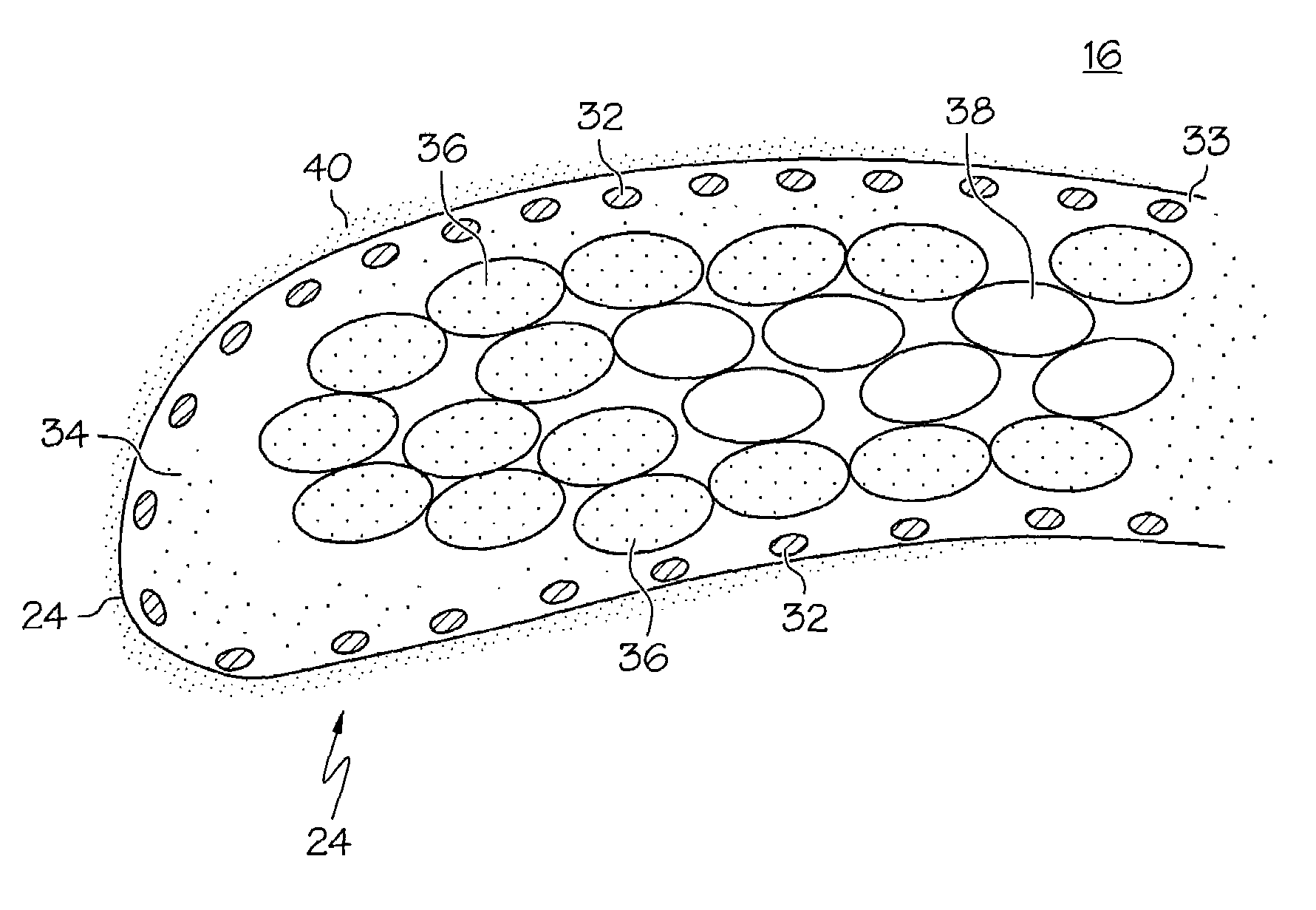

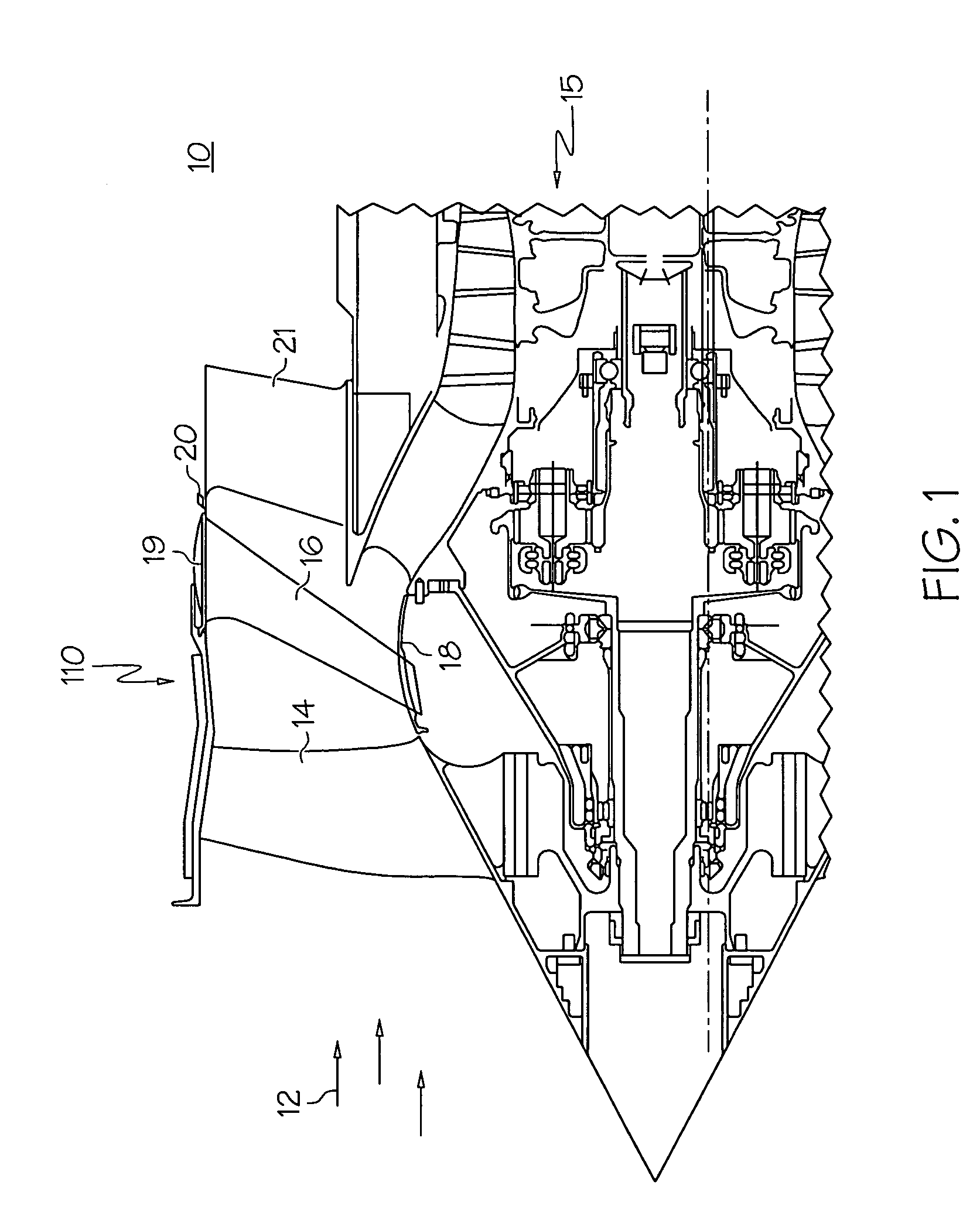

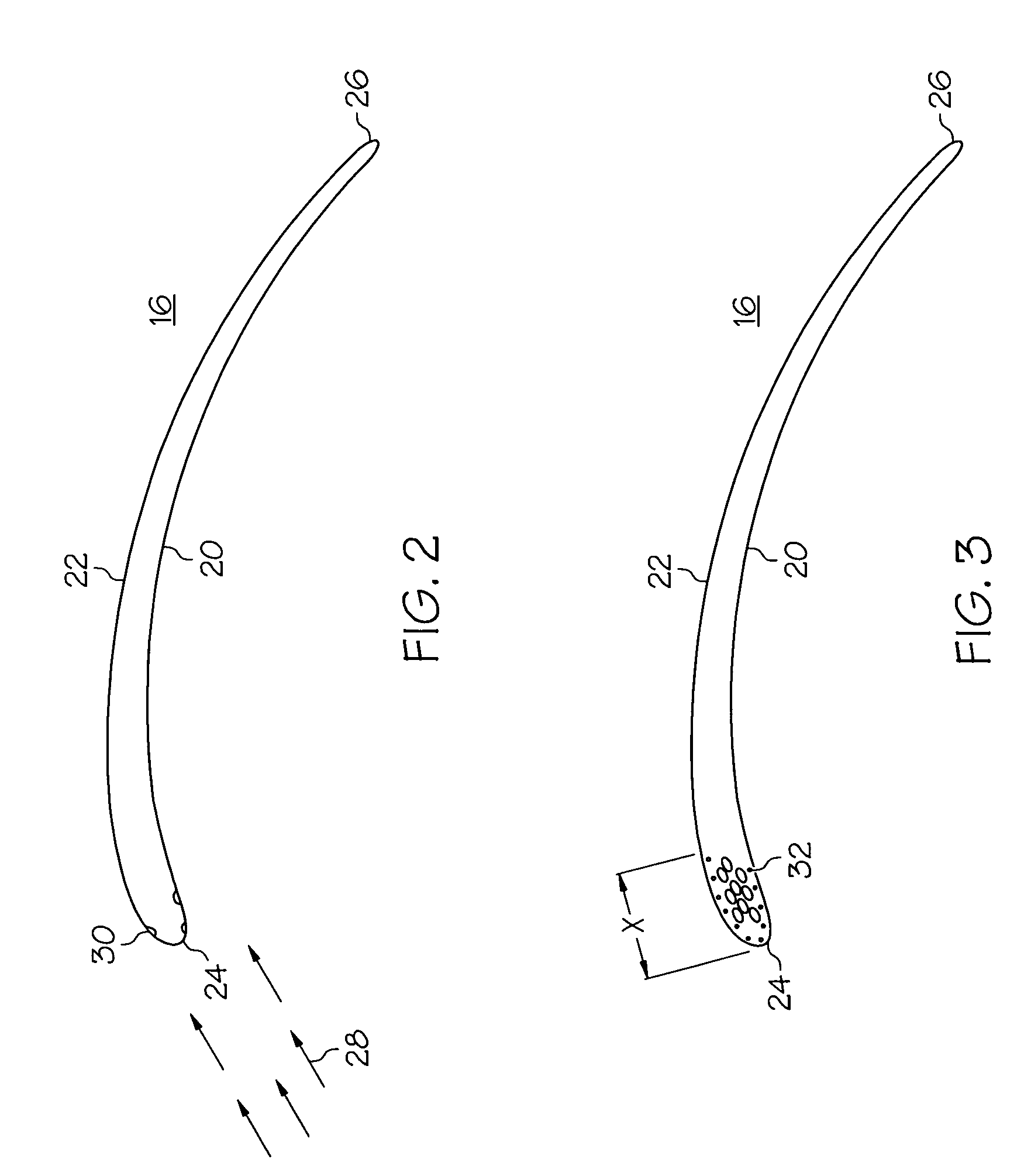

Leading edge erosion protection for composite stator vanes

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com