Preparation method of modified compound filler filled breakdown-resisting epoxy composite

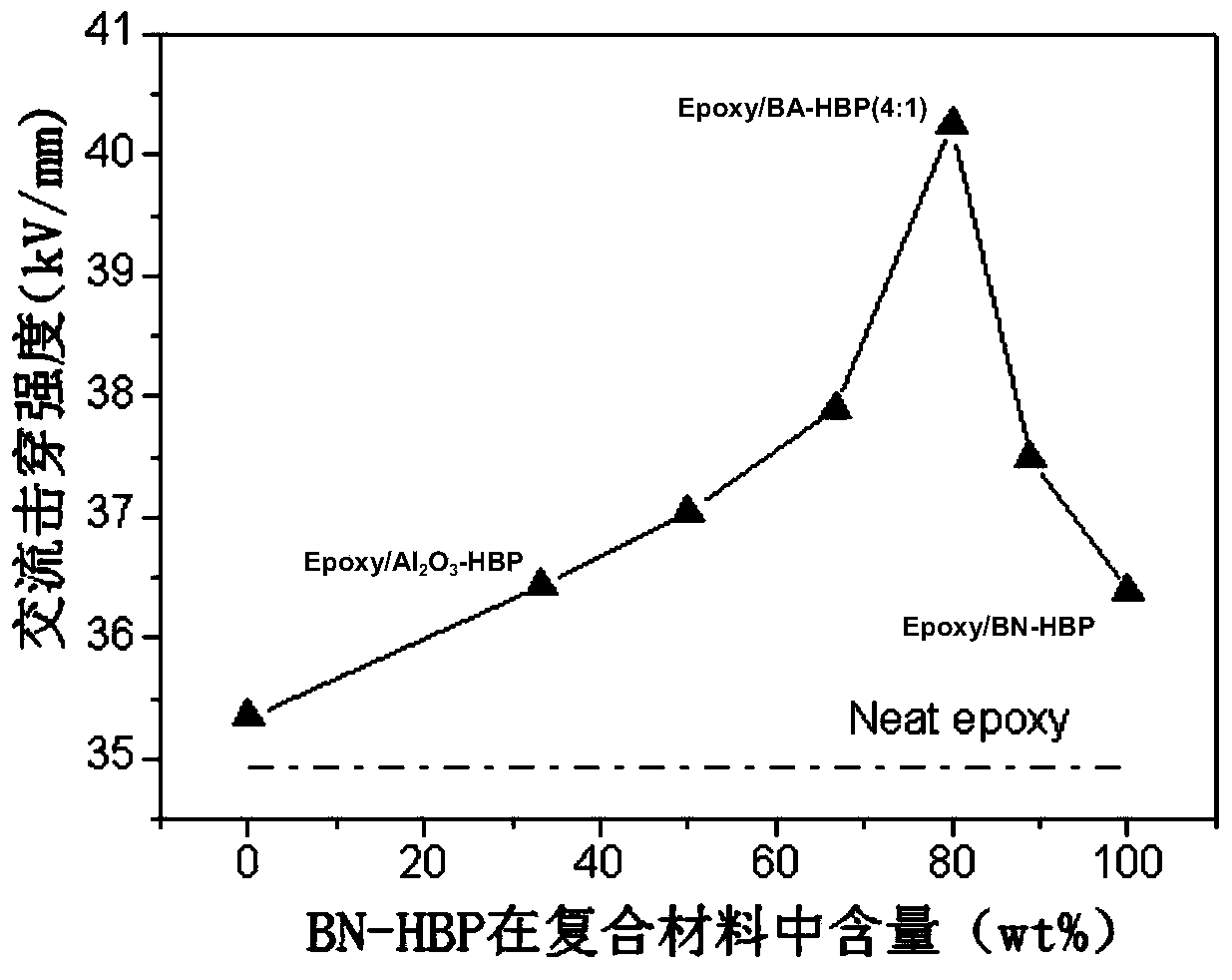

A composite material and breakdown-resistant technology, which is applied in the field of preparation of modified compound filler-filled breakdown-resistant epoxy composite materials, can solve the problems of decreasing breakdown strength, limiting the insulation performance of composite materials, increasing costs, etc., and achieving complete Filler network, shortened mean free path, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment relates to a method for preparing a modified composite filler-filled, breakdown-resistant ternary conductive polymer composite material, which includes the following steps:

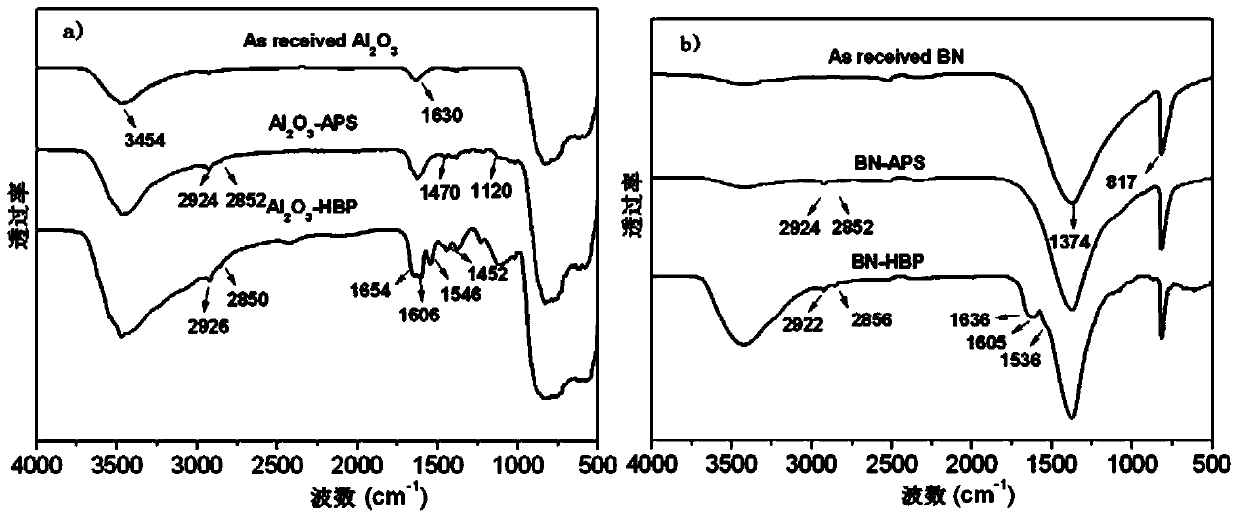

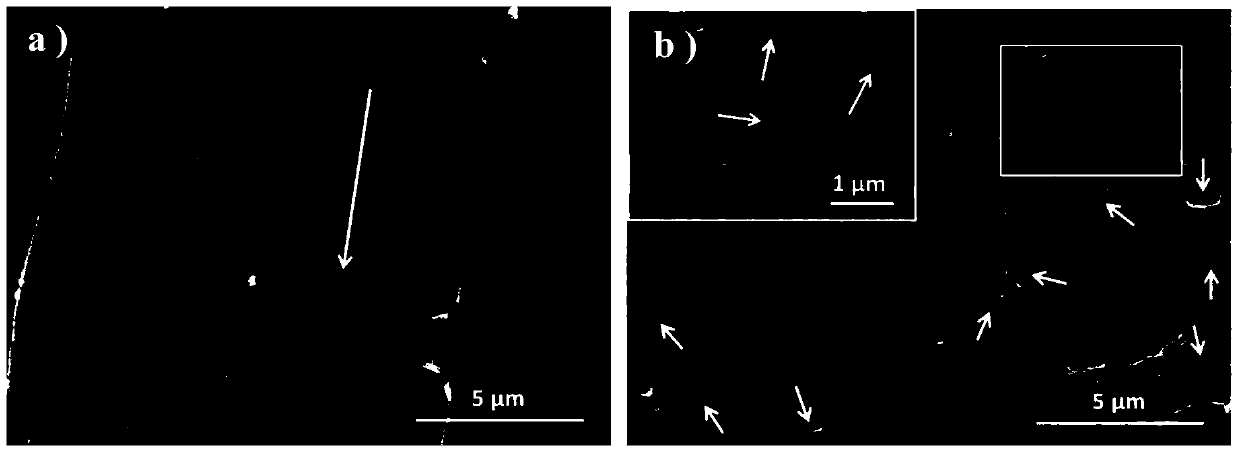

[0034] Step (1), Al 2 o 3 , BN surface grafted γ-aminopropyltriethoxysilane (γ-APS)

[0035] Weigh 2g Al 2 o 3 , fully dispersed in 100mL xylene, then added 1wt% γ-APS and stirred and refluxed for 1h; after the reaction was completed, it was centrifuged at high speed, and the product was washed with xylene for 3 times and vacuum-dried at 50°C for 1d to obtain Al 2 o 3 -APS; BN undergoes two-step pretreatment before grafting silane coupling agent: first, weigh 2g of BN, stir and disperse in 100mL30wt% hydrochloric acid solution, react at 50°C for 1h, filter and wash 3 times with deionized water; Next, add pre-acidified BN to 50mL of 30wt% hydrogen peroxide, react at 50°C for 1h, continue to heat up to 75°C for 1h, and centrifuge the product and dry it in vacuum at 50°C for 1d; ...

Embodiment 2

[0041] This embodiment relates to a method for preparing a modified composite filler-filled, breakdown-resistant ternary conductive polymer composite material, which includes the following steps:

[0042] Step (1), Al 2 o 3 , BN surface grafted γ-aminopropyltriethoxysilane (γ-APS)

[0043] Weigh 5g Al 2 o 3 , fully dispersed in 200mL xylene, then added 2wt% γ-APS and stirred and refluxed for 2h; after the reaction was completed, it was centrifuged at high speed, and the product was washed with xylene for 3 times and vacuum-dried at 50°C for 1d to obtain Al 2 o 3 -APS; BN undergoes two-step pretreatment before grafting silane coupling agent: first, weigh 5g of BN, stir and disperse in 200mL30wt% hydrochloric acid solution, react at 50°C for 1h, filter and wash with deionized water for 3 times; Next, add pre-acidified BN to 100mL of 30wt% hydrogen peroxide, react at 50°C for 1h, continue to heat up to 75°C for 1h, and centrifuge the product and dry it in vacuum at 50°C for ...

Embodiment 3

[0049] This embodiment relates to a method for preparing a modified composite filler-filled, breakdown-resistant ternary conductive polymer composite material, which includes the following steps:

[0050] Step (1), Al 2 o 3 , BN surface grafted γ-aminopropyltriethoxysilane (γ-APS)

[0051] Weigh 2g Al 2 o 3 , fully dispersed in 100mL xylene, then added 1wt% γ-APS and stirred and refluxed for 1h; after the reaction was completed, it was centrifuged at high speed, and the product was washed with xylene for 3 times and vacuum-dried at 50°C for 1d to obtain Al 2 o 3 -APS; BN undergoes two-step pretreatment before grafting silane coupling agent: first, weigh 2g of BN, stir and disperse in 100mL30wt% hydrochloric acid solution, react at 50°C for 1h, filter and wash 3 times with deionized water; Next, add pre-acidified BN to 50mL of 30wt% hydrogen peroxide, react at 50°C for 1h, continue to heat up to 75°C for 1h, and centrifuge the product and dry it in vacuum at 50°C for 1d; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com