TGDADPE type epoxy matrix resin for advanced composite material and preparation method thereof

An advanced composite material and epoxy matrix technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the high cost of polyetherimide resin, unfavorable large-scale application, linear expansion The coefficient is small and other problems, and the effect of good comprehensive performance, low cost and convenient operation is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 1000 grams of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin (TGDADPE) and 50 grams of 2,2-bis[4-(4-aminobenzene Oxygen)phenyl]hexafluoropropane was put into the reaction kettle, reacted at 50°C for 30min, cooled to room temperature, and added 2224g of a homogeneous solution of aromatic dibasic acid anhydride, curing agent and organic solvent (200g of 2,2 - bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride, 20 g 2-ethyl-4-methylimidazole, 4 g 2,4-dimethylimidazole, 1000 g N -Methyl-2-pyrrolidone, 500 grams of N,N-dimethylacetamide, 300 grams of dichloromethane, 200 grams of toluene) were stirred and mixed evenly to obtain 3274 grams of TGDADPE type epoxy matrix resin for advanced composite materials. Make MRTGD-1.

Embodiment 2

[0040] 1000 grams of N,N,N',N'-tetraglycidyl-4,4'-diaminodiphenyl ether epoxy resin (TGDADPE), 10 grams of 4,4'-bis(4-aminophenoxy ) diphenyl sulfide and 90 grams of 2,2-bis[4-(2-trifluoromethyl-4-aminophenoxy)phenyl]hexafluoropropane were put into the reaction kettle, and reacted at 90°C for 40 minutes, Cool to room temperature, add a homogeneous solution of 948 grams of aromatic dibasic acid anhydride, curing agent and organic solvent (50 grams of 3,3',4,4'-tetracarboxylic diphenyl ether dianhydride, 50 grams of 2,2-bis [4-(3,4-Dicarboxyphenoxy)phenyl]propane dianhydride, 8 g 2-ethyl-4-methylimidazole, 40 g 2,4-dimethylimidazole, 600 g N-methylimidazole Base-2-pyrrolidone, 150 grams of chloroform, 50 grams of xylene) were stirred and mixed uniformly to obtain 2048 grams of TGDADPE type epoxy matrix resin for advanced composite materials, denoted as MRTGD-2.

Embodiment 3

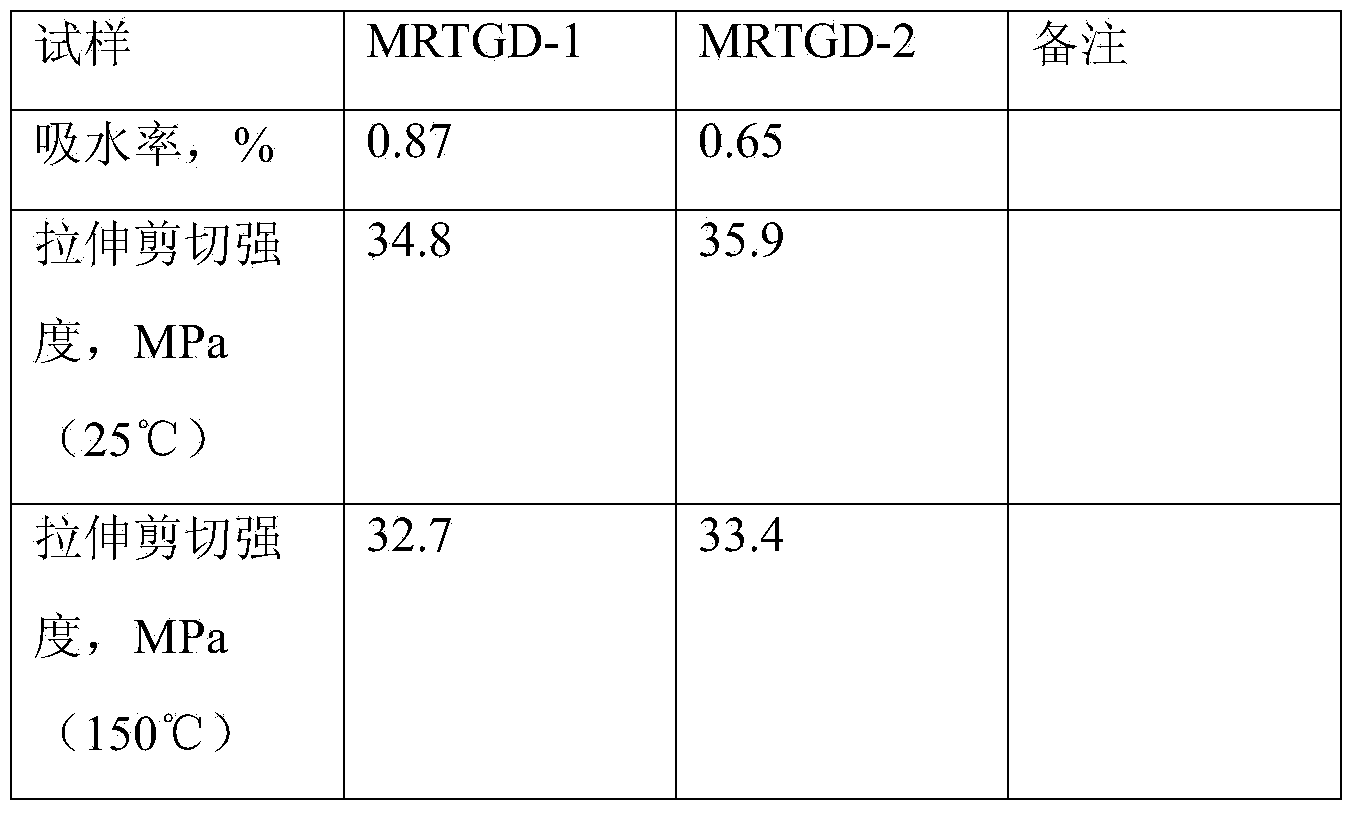

[0042] Take an appropriate amount of TGDADPE type epoxy matrix resin for the advanced composite materials of MRTGD-1 and MRTGD-2 of the above-mentioned embodiment 1 and embodiment 2, and apply them evenly on the standard stainless steel test pieces respectively, and stack them after airing for 1 hour at room temperature , clamped, and put into a blast oven for curing: heat from room temperature to 90°C, hold for 1 hour, continue to heat up to 130°C, hold for 2 hours, continue to heat up to 180°C, hold for 2 hours, and cool to room temperature naturally. The measured tensile shear strengths are shown in Table 1.

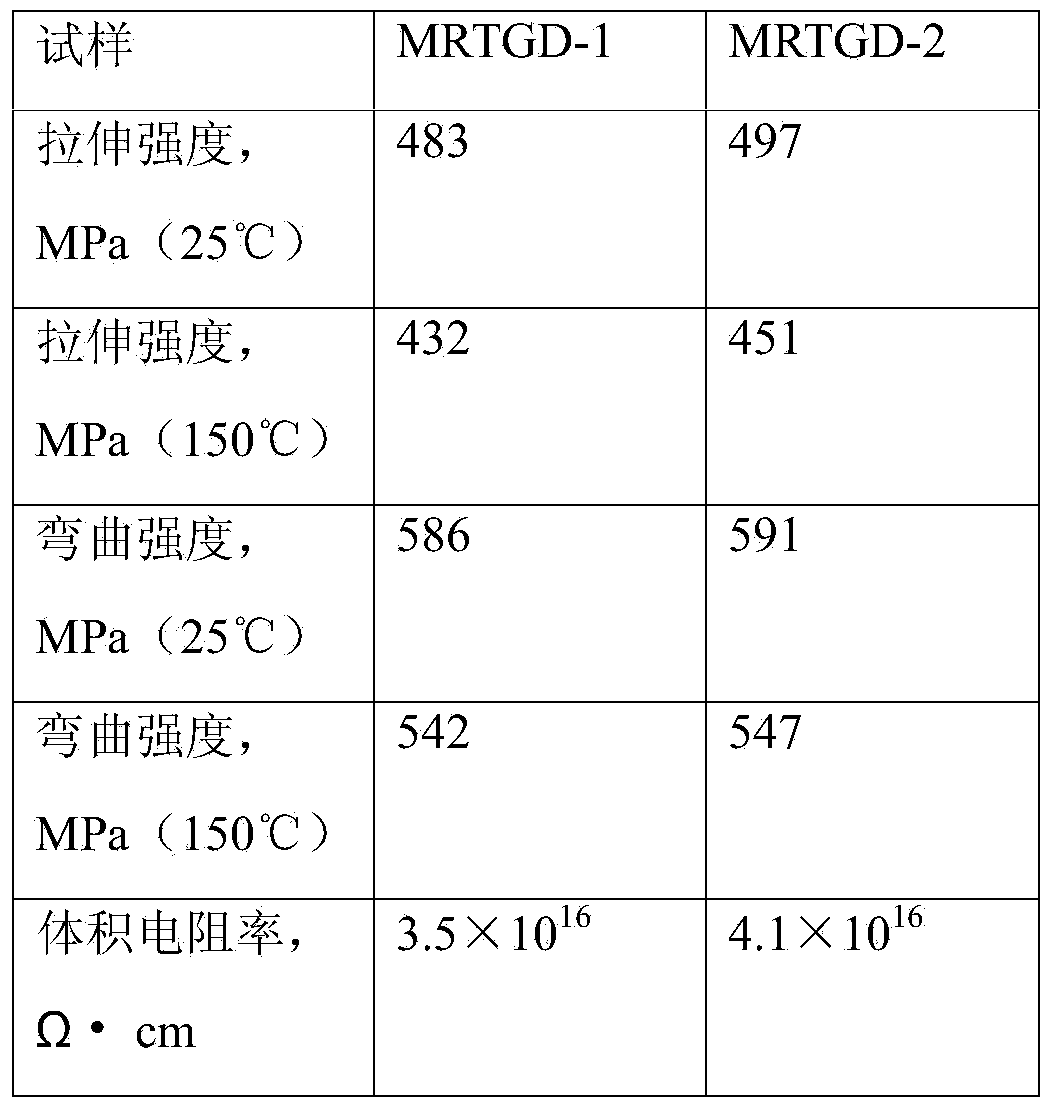

[0043] Take an appropriate amount of TGDADPE epoxy matrix resin for advanced composite materials of MRTGD-1 and MRTGD-2 in the above-mentioned examples 1 and 2, and pour it into a stainless steel disc with a diameter of 10 cm (the disc is coated with a release agent in advance) , Thermal curing: heat from room temperature to 90°C, hold for 1 hour, continue to heat up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com