High-temperature resistant and high-toughness epoxy matrix resin as well as preparation method and application thereof

A technology of epoxy matrix and epoxy resin, which is applied in the field of epoxy matrix resin with high heat resistance and high toughness and its preparation and application, and can solve the problem of poor process performance of matrix resin, poor modification effect, heat resistance of resin system Reduced performance and other issues, to achieve the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

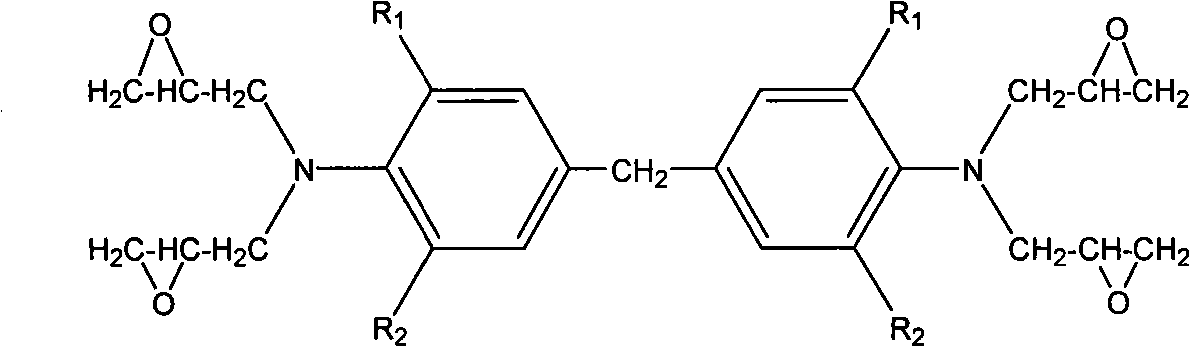

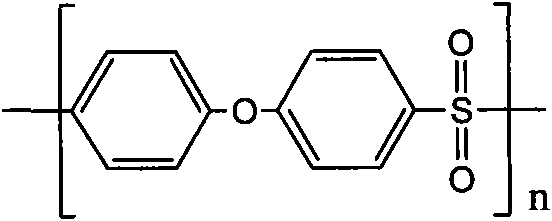

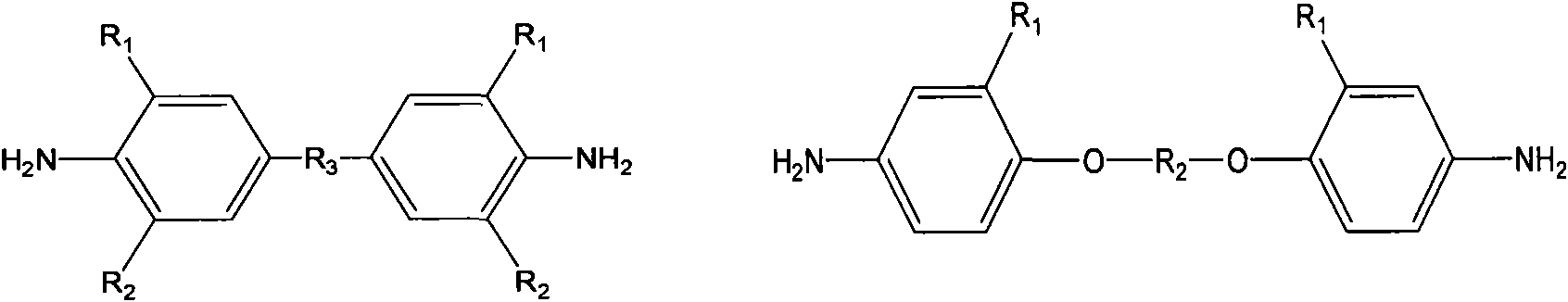

[0052] With 80g TGDDM (compound shown in formula (I), wherein R 1 for H, R 2 Mix H), 20g 1,2-epoxycyclohexane 4,5-diglycidyl dicarboxylate and 15g thermoplastic resin PSF (polymer shown in formula (V), n=1), heat to 150°C and stir To form transparent solution, be cooled to 100 ℃ then, then add 15g DDS (compound shown in formula (II) in described transparent solution, wherein R 1 for H, R 2 for H, R 3 for SO 2 ), 25g 1,4,4-6FAPB (compound shown in formula (III), wherein R 1 for CF 3 , R 2 for ) and 0.5g boron trifluoride-monoethylamine, mixed evenly and then poured and solidified. The curing program was 1 hour at 130°C, 2 hours at 180°C, and 2 hours at 200°C to obtain a cured epoxy matrix resin. DMA method (dynamic thermomechanical analysis) to measure glass transition temperature, using three-point bending loading mode, spline size (18±0.5mm)×(5±0.2mm)×(1.5±0.2mm), frequency 1Hz, heating rate 5 °C / min, the measured glass transition temperature of the epoxy matrix re...

Embodiment 2

[0054] With 70g TGDDM (compound shown in formula (I), wherein R 1 for H, R 2 For H), 30g p-aminophenol epoxy resin and 20g thermoplastic resin PEI (polymer shown in formula (VII), n=10) are mixed, heated to 160 ℃ and stirred to form transparent solution, then cooled to 80 ℃, then Add 20gTMDDM (compound shown in formula (I) in described transparent solution, wherein R 1 for CH 3 , R 2 for CH 3 , R 3 for CH 2 ), 15g DDS (compound shown in formula (II), wherein R 1 for H, R 2 for H, R 3 for SO 2 ) and 1.5g boron trifluoride-monoethylamine, mixed evenly and poured and solidified. The curing program is 130° C. for 2 hours, 170° C. for 3 hours, and 200° C. for 2 hours to obtain a cured epoxy matrix resin. DMA method (dynamic thermomechanical analysis) to measure glass transition temperature, using three-point bending loading mode, spline size (18±0.5mm)×(5±0.2mm)×(1.5±0.2mm), frequency 1Hz, heating rate 5 °C / min, the measured glass transition temperature of the epoxy mat...

Embodiment 3

[0056] With 95g DCTGDDM (compound shown in formula (I), wherein R 1 for Cl, R 2 For H), 5g of bisphenol A epoxy resin and 25g of thermoplastic resin PEK (polymer shown in formula (IV), n=60) are mixed, heated to 110 ° C and stirred until a transparent solution is formed, then cooled to 60 ° C, added 25gDDM (the compound shown in formula (II), wherein R 1 for H, R 2 for H, R 3 for CH 2 ), 20g 1,4,4-APB (compound shown in formula (III), wherein R 1 for H, R 2 for ) and 1.5g ethanedithiol, mixed uniformly and then poured and solidified. The curing program is 130° C. for 2 hours, 150° C. for 4 hours, and 180° C. for 4 hours to obtain a cured epoxy matrix resin. DMA method (dynamic thermomechanical analysis) to measure glass transition temperature, using three-point bending loading mode, spline size (18±0.5mm)×(5±0.2mm)×(1.5±0.2mm), frequency 1Hz, heating rate 5 °C / min, the measured glass transition temperature of the epoxy matrix resin is 210 °C, according to the nationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com