Patents

Literature

50results about How to "Meet craft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing seamless titanium alloy tube for aircraft engine

The invention discloses a method for preparing a seamless titanium alloy tube for an aircraft engine. The seamless titanium alloy tube for the aircraft engine which meets corresponding requirements is manufactured by improving the technological plasticity of the titanium alloy tube material. The method comprises the following steps of: firstly, smelting a spongy cast ingot to introduce interstitial elements as little as possible; secondly, cogging and forging heated cast ingot at large deformation and repeatedly upsetting and stretching the cast ingot to ensure that as-cast coarse grains are completely crushed and thinned, thermally processing formed tube billet under vacuum to eliminate residual stress produced during tube billet extrusion so as to improve the plasticity of the tube billet; thirdly, cogging and rolling the tube billet at large deformation and further thinning the grains; and finally, annealing at a low temperature after cold rolling of intermediate rolling and finished product rolling to effectively control the coarsening of the grains. Therefore, full recrystallization can be ensured by prolonging the heating time, and mechanical property and processing property required by material consumption of the aircraft engine can be met under the condition that the tube structure is fully recrystallized.

Owner:WESTERN TITANIUM TECH

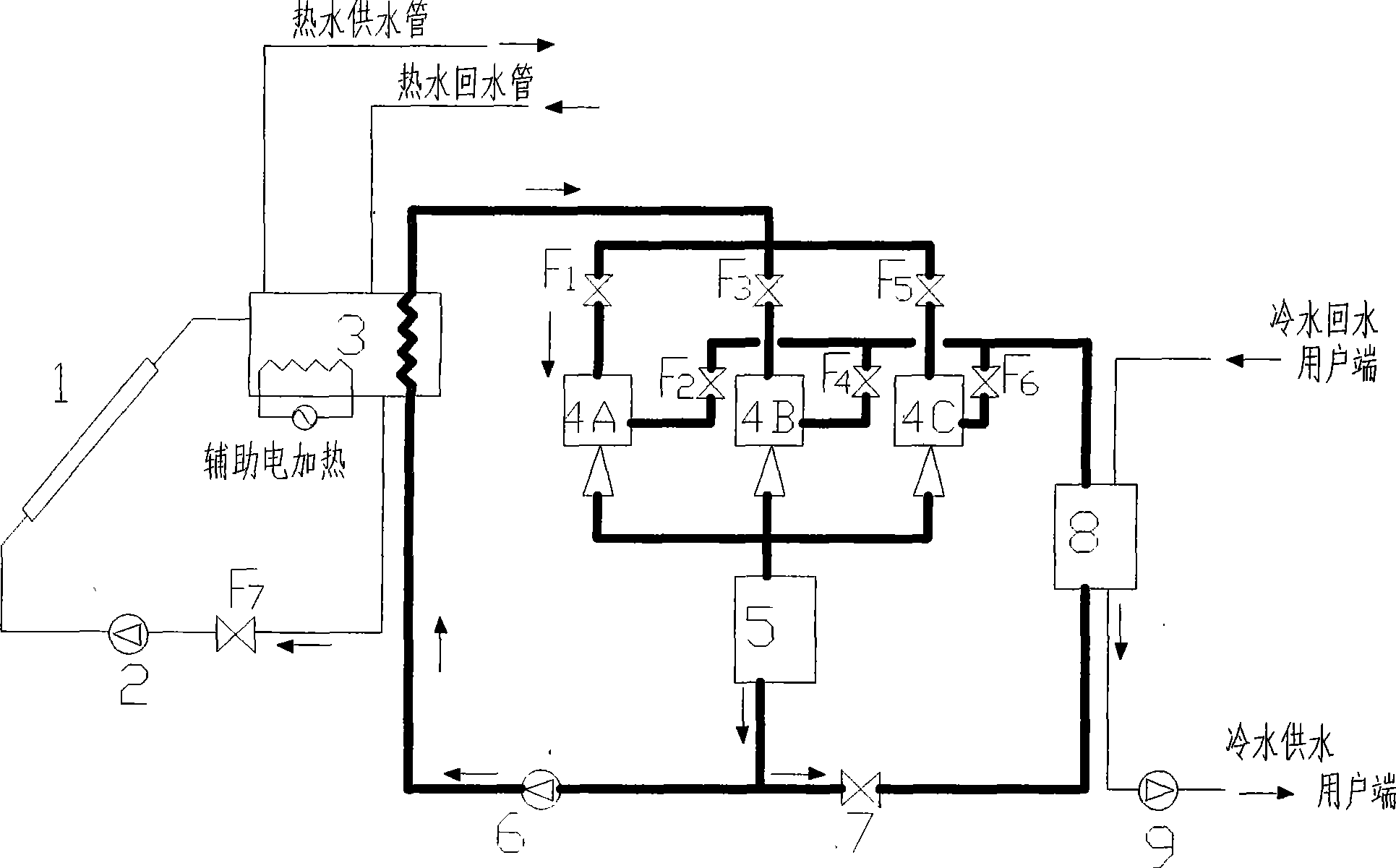

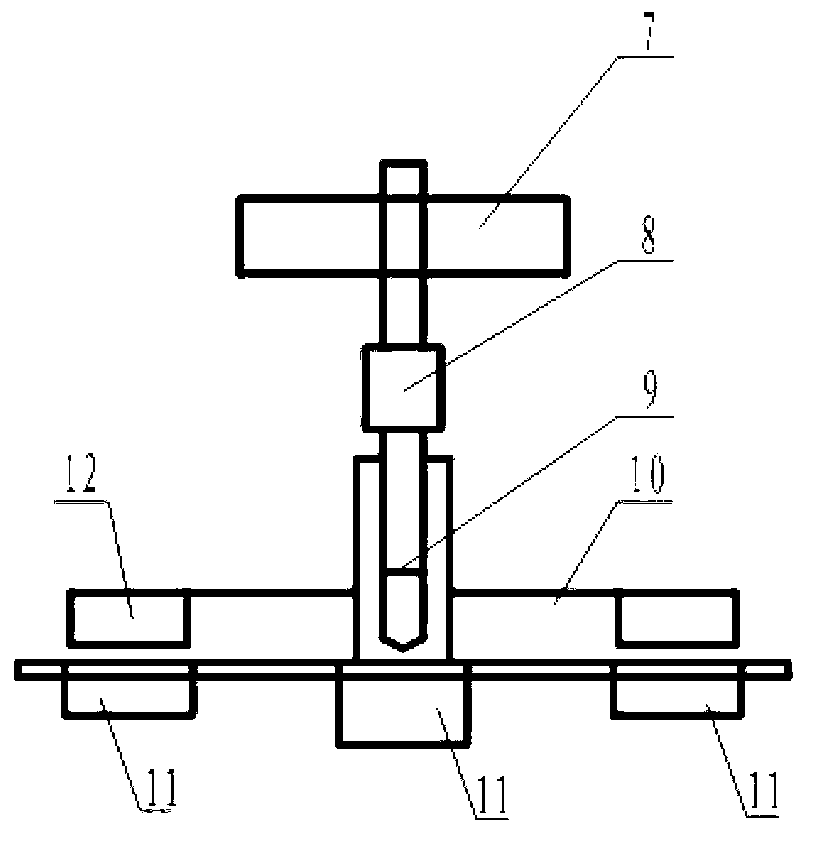

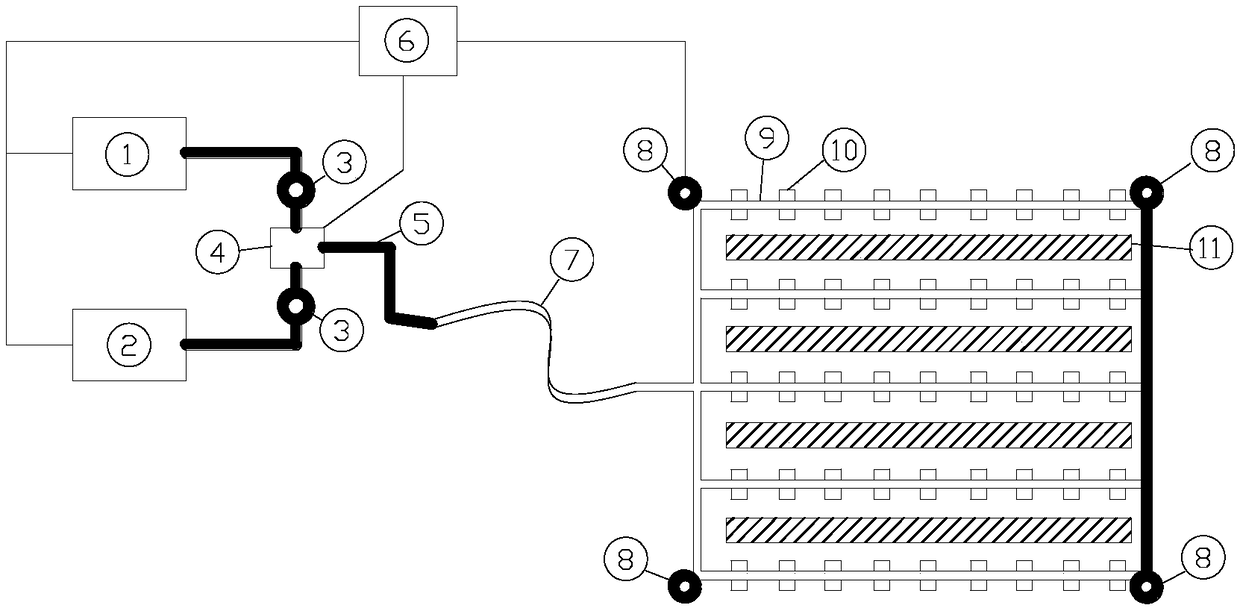

Multi-injector parallel connection type solar injection cooling device

InactiveCN101387457AWide temperature rangeMeet supplySolar heat devicesMachines using refrigerant evaporationCold airConnection type

The invention relates to a multi-ejector parallel type solar ejecting refrigeration unit which utilizes solar energy to supply cold air, which comprises a solar hot-water loop, an ejecting refrigerant loop and an air conditioner water loop. The unit solves the problems that the prior ejecting refrigeration system is only provided with an ejector, the structural dimension of the ejector is fixed and the efficiency of an ejector system is drastically declined directly because operation condition is derivated from design condition. The unit is arranged between a generator and a condenser, and is provided with two or more than two ejectors with different structural dimensions in parallel. The multiple ejectors can meet high-efficiency operation of variable working conditions; and the unit can automatically or manually switch to a proper ejector for working according to solar radiation or weather changing conditions, further ensure that the system operates in refrigeration season with high efficiency, can improve the operation efficiency of the solar ejector system, and realize the aim of supplying the cold air with high efficiency and reasonability, thereby improving the utilization rate of solar energy, saving energy, relieving the pressure of electricity grid at the peak time, and improving the light-heat utilization efficiency.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Pressure casting aluminium aluminium alloy for cylinder of minicar engine

InactiveCN1483847AGood casting process performanceHigh leak inspection pass rateChemical compositionPressure casting

The present invention relates to a mnicar engine cylinder pressure casting aluminium alloy, and its chemical component composition includes (wt%) Cu 1.5-3.0%, Si 10.0-12.0%, Mg 0.15-0.35%, the rest is al and the other is impurity. Said alloy tensile strength Qb is greater than or equal to 300MP. Said alloy has enough strength and rigidity and good size stability. Said alloy can meet the requirements for minicar engine cylinder body high-pressure casting process and mechanical working process.

Owner:重庆长安汽车有限责任公司

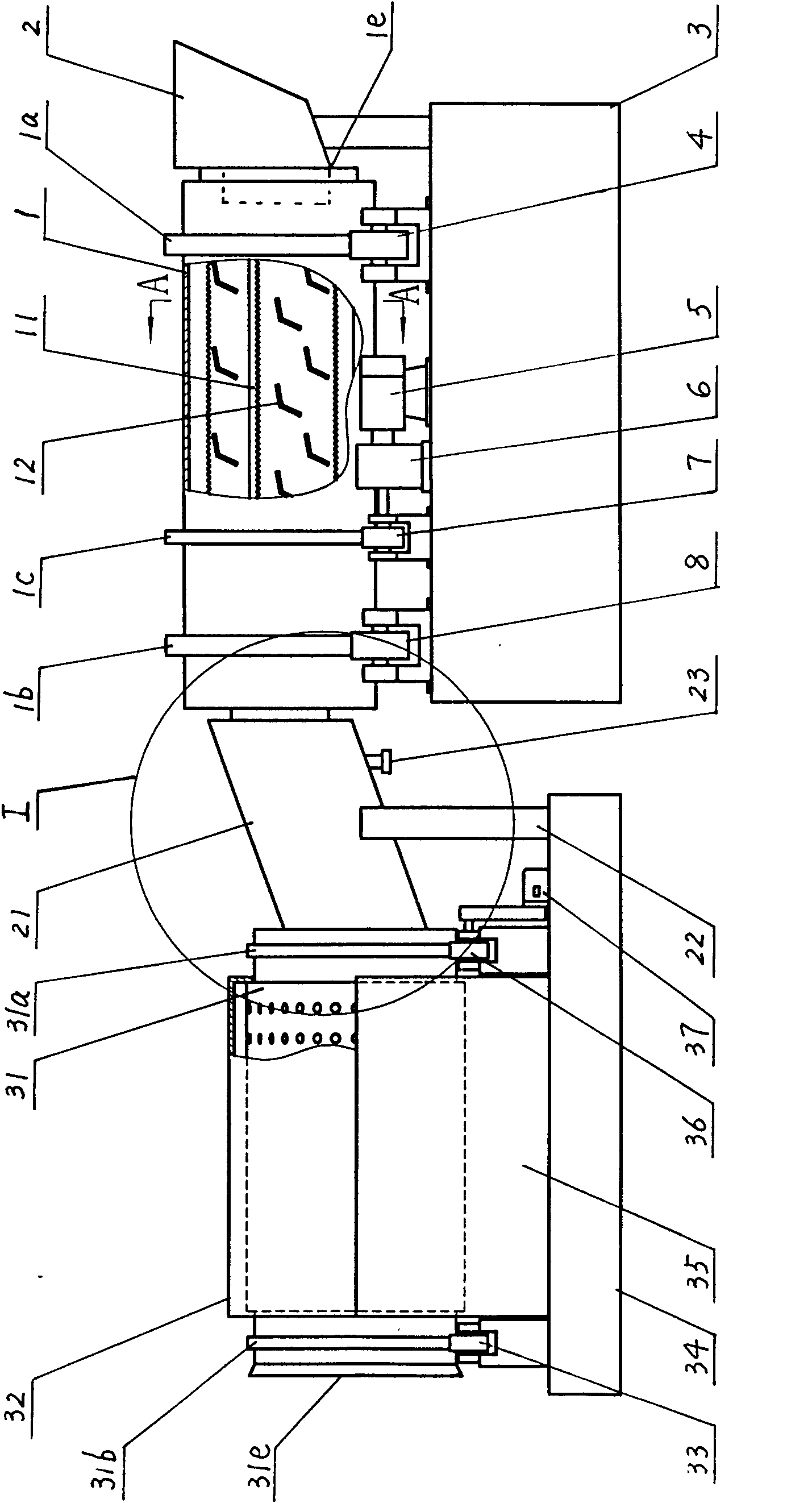

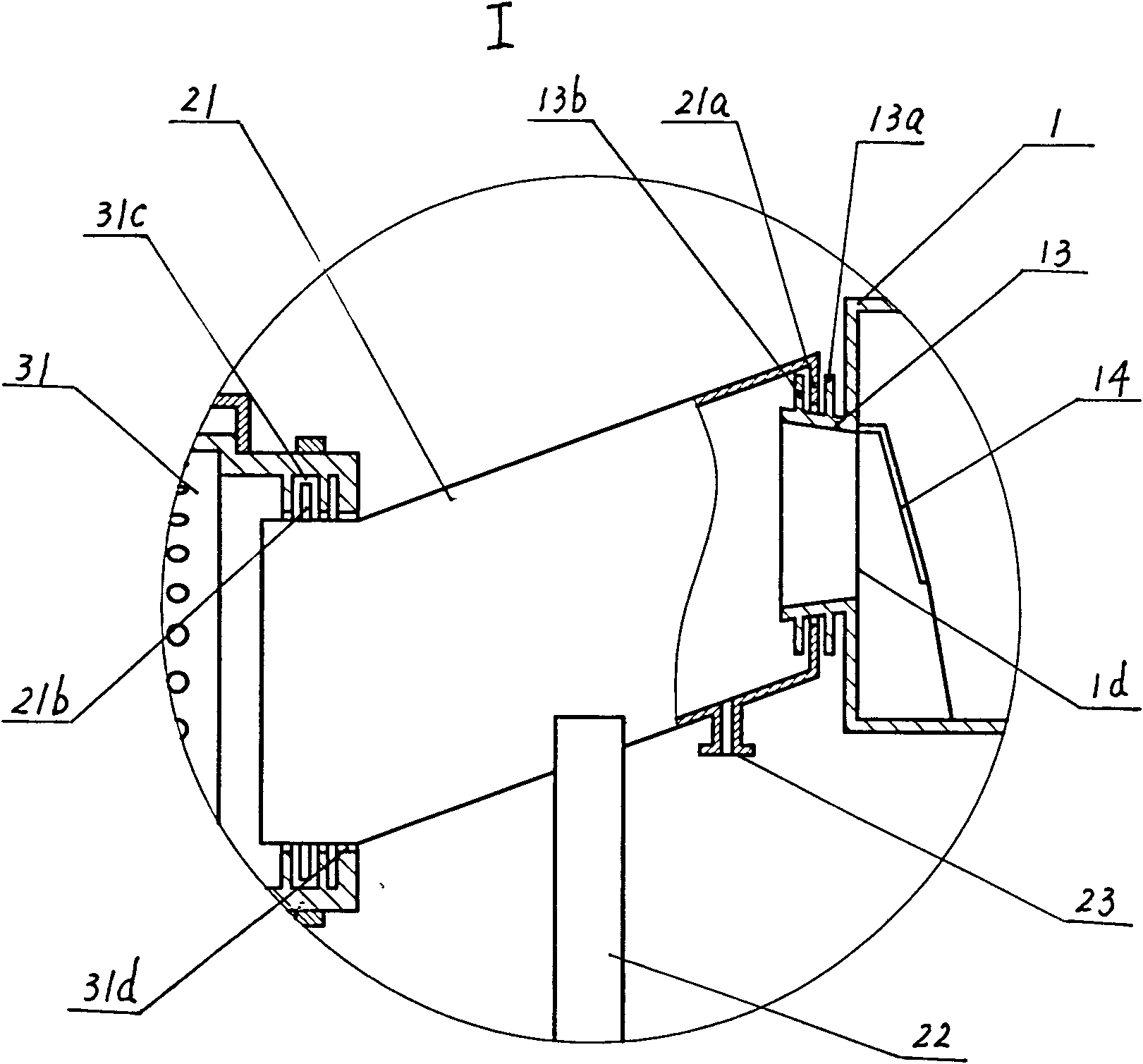

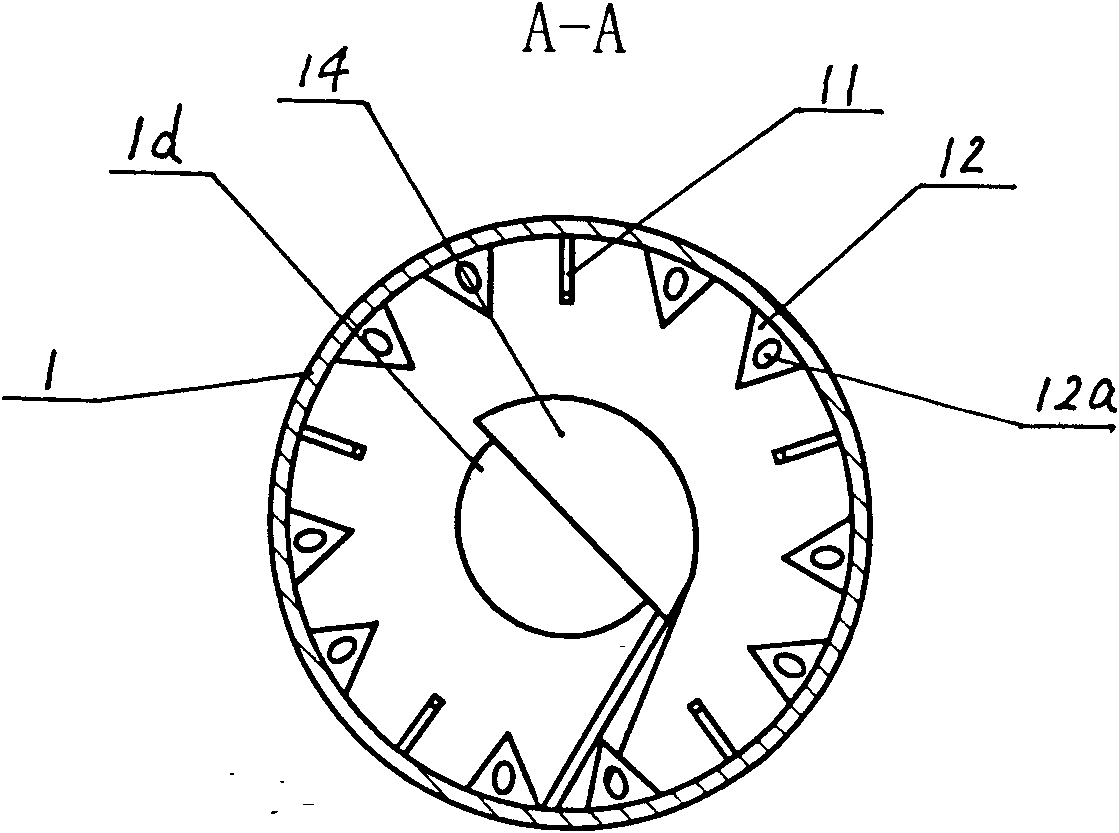

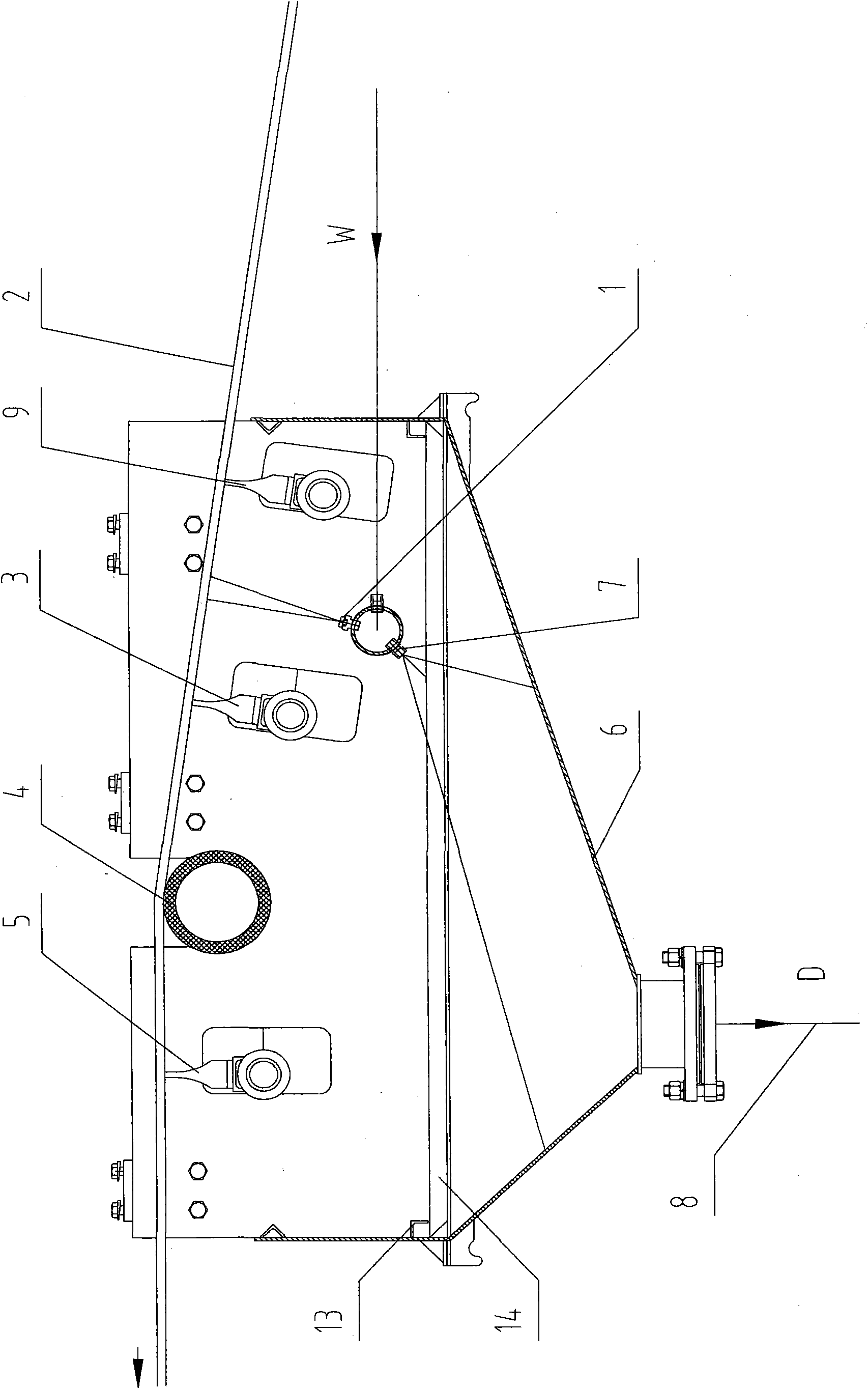

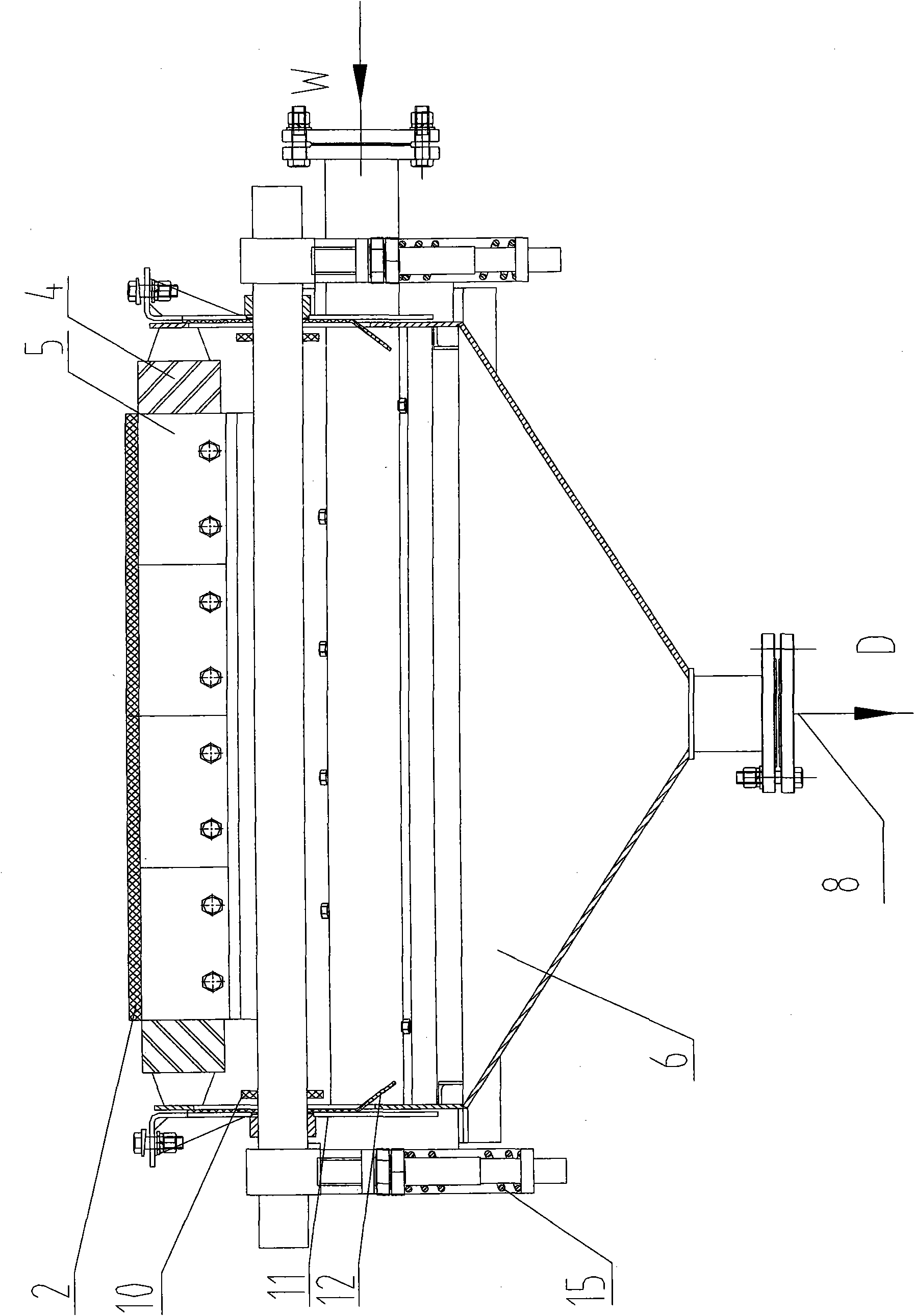

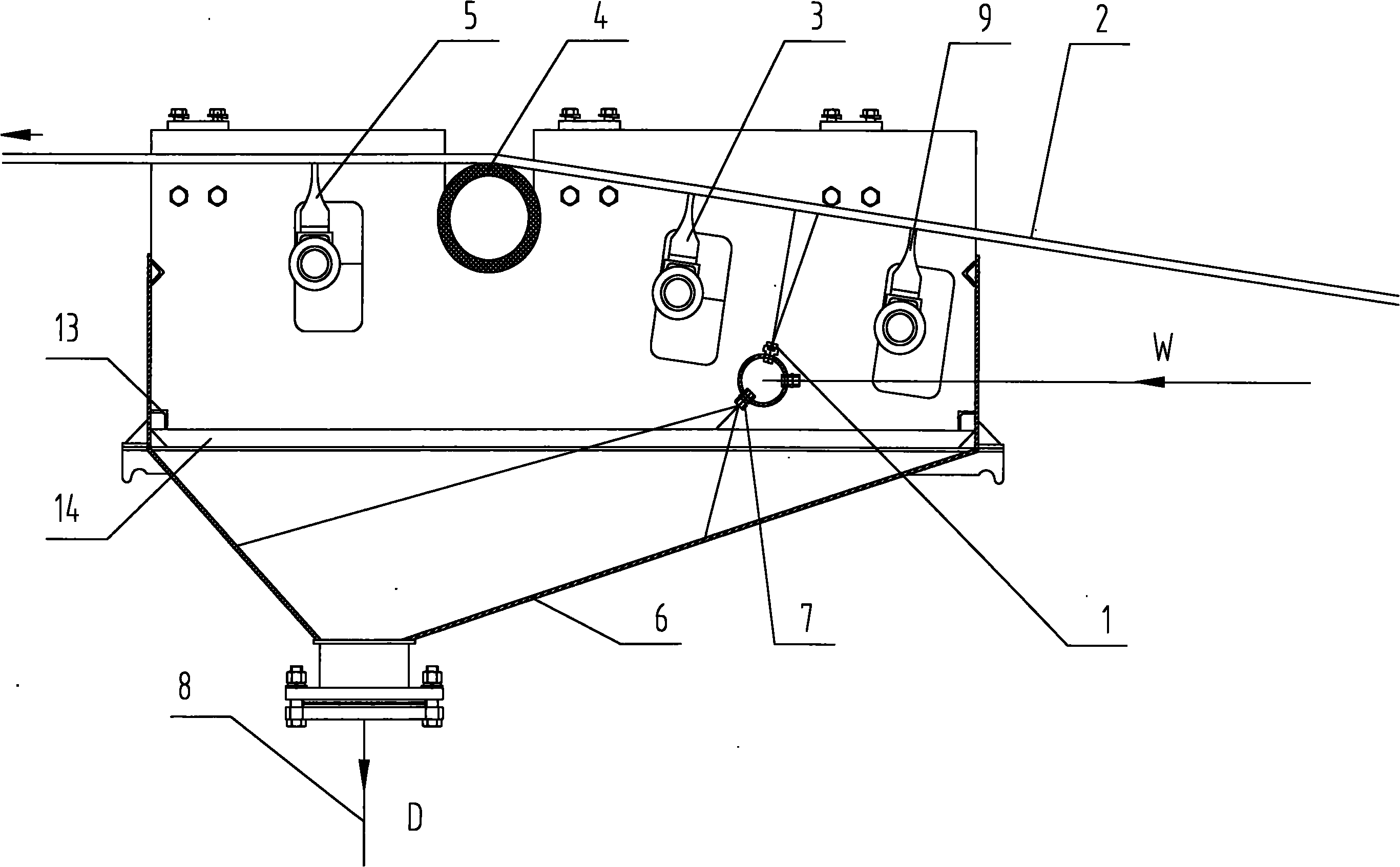

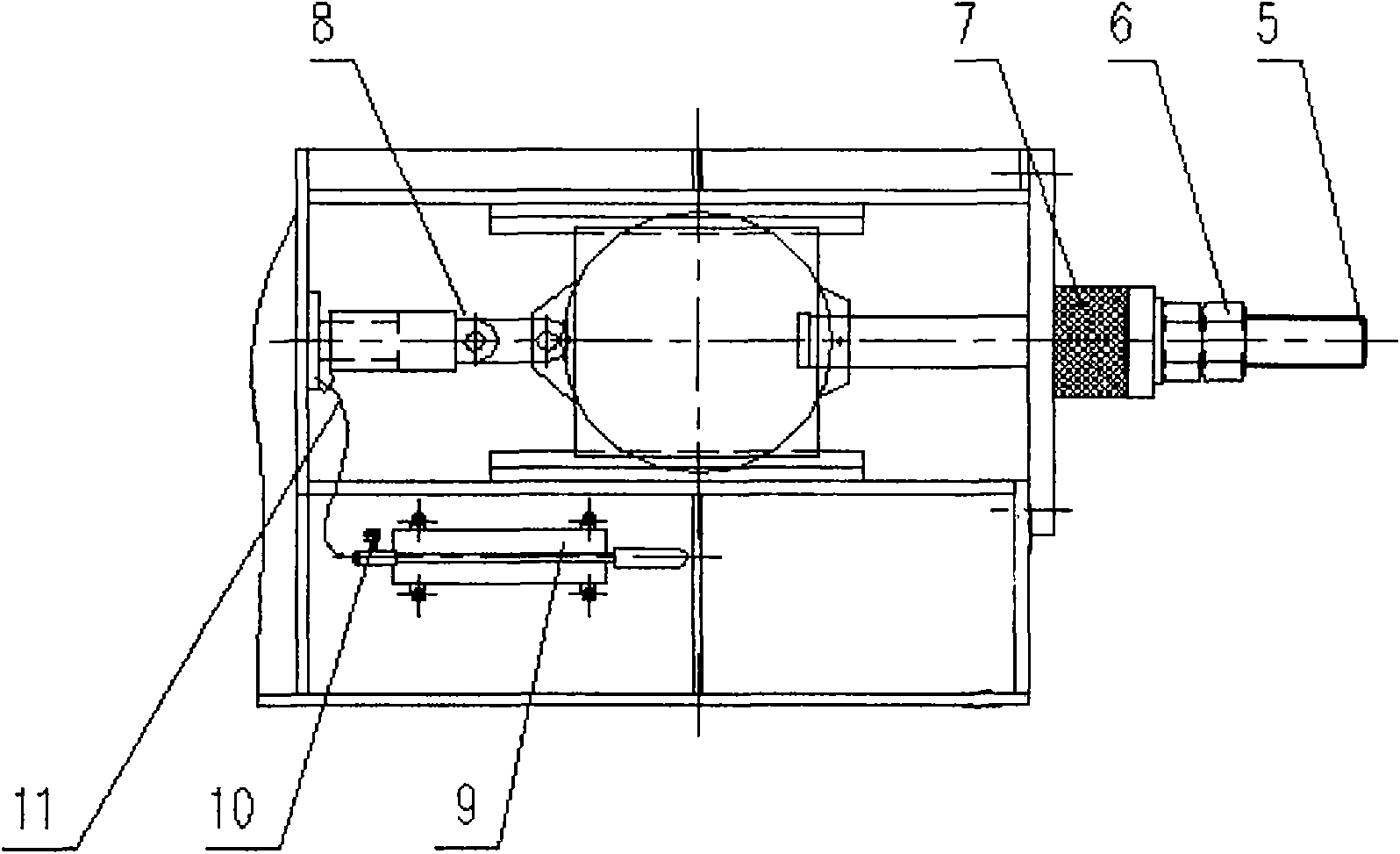

Split type rotary drum pulping device

InactiveCN101671970AGuarantee quality and efficiencyGuaranteed screening efficiencyRaw material divisionPulp and paper industry

The invention discloses a split type rotary drum pulping device comprising a pulping machine and a screening machine. The pulping machine is internally provided with a rotary drum; the inner wall of the rotary drum is connected with a plurality of scratch plates; the screening machine is internally provided with a screen drum; the wall of the screening drum is provided with a plurality of screen holes; a bottom plane of the pulping machine is higher than a bottom plane of the screening machine; a pulp passing drum is arranged between the pulping machine and the screening machine in an inclineway and is fixedly arranged on a base; a left port of the pulp passing drum is arranged on a pulp outlet of the rotary drum and communicated corresponding to the pulp outlet port; a right port of thepulp passing drum is arranged in a pulp inlet of the screen drum and communicated corresponding to the pulp inlet; and the rotary drum is internally connected with a pulp feeding hopper in a shape ofa spoon and the pulp feeding hopper corresponds to the pulp outlet port. The invention can solve the problems that the prior art cannot simultaneously meet the requirements of a pulping process and ascreening process, is easy to cause low pulping quality and screening efficiency and brings great difficulty to processing and manufacturing, hoisting transportation, installation and debugging of theequipment.

Owner:王秉华

Conveyer belt water cleaning system of belt type conveyer

The invention relates to a conveyer belt water cleaning system of a belt type conveyer, which is applied to the industry of belt type conveyers. The whole device comprises a fan nozzle, a conveyer belt surface, a first sweeper, a roller, a spring structure and the like. Water entering into a water feeding tube is sprayed on the conveyer belt surface at fixed angle, fixed flow quantity and fixed pressure to dissolve, peel and remove bonding matters on the conveyer belt surface; the first sweeper is in contact with the conveyer belt surface under certain pressure through the spring structure to scrap the remained dissolved bonding matters and water; the turnabout roller of which the surface is provided with a herringbone grooved rubber surface rotates along with the conveyer belt to roll and press the conveyer belt surface with great pressure so as to extrude and peel residues on the conveyer belt surface in two directions; and a second sweeper is in contact with the conveyer belt surface under certain pressure through the spring structure and is used for completely cleaning the conveyer belt surface. The invention has the advantages of simple structure and good cleaning effect, and can be used for greatly improving of operation efficiency and prolonging the service life of the equipment; and water can be recycled and no sewage is leaked.

Owner:沈阳矿山机械有限公司

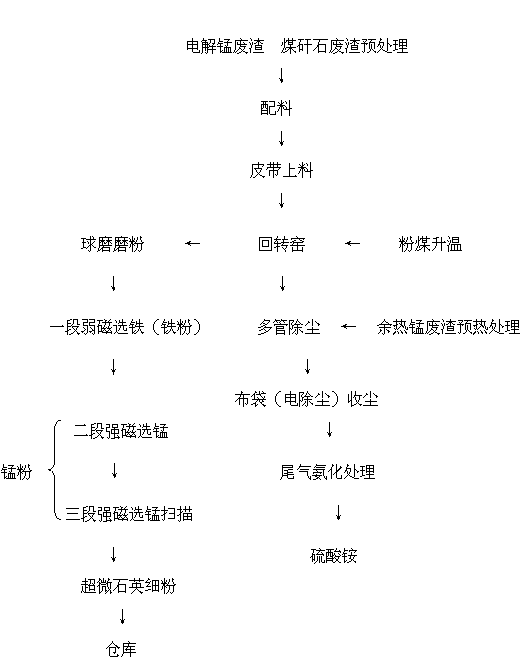

Method for restoring, roasting, purifying, and extracting manganese and iron by utilizing electrolytic manganese slag rotary kiln

The invention discloses a method for restoring, roasting, purifying, and extracting manganese and iron by utilizing an electrolytic manganese slag rotary kiln. The method comprises the following steps of: adding manganese slag and coal gangue slag into a rotary kiln, wherein the adding quantity of the coal gangue slag is 5-10%; carrying out high-temperature roasting under a high-temperature environment inside the rotary kiln and the condition of negative pressure, so that sulphur, ammonia and nitrogen compound is decomposed into gaseous state, feeding the gases into a multi-pipe dedusting and tail gas treatment system to be removed along with the smoke; and carrying out the scavenging processes of ball-milling, first-stage low-intensity magnetic separation, second-stage high-intensity magnetic separation and third-stage high-intensity magnetic separation on the material restored by high temperature of the rotary kiln to obtain an iron product, a manganese product and a novel ultra-fine quartz powder, wherein the iron product is obtained after first-stage low-intensity magnetic separation, the manganese product is obtained after the second-stage high-intensity magnetic separation and third-stage high-intensity magnetic separation, and the final tailing is the ultra-fine quartz powder. The manganese and iron are extracted by the process disclosed by the invention; detrimental impurities are moved; the gas containing sulphur, ammonia and nitrogen is prepared into an ammonium sulfate fertilizer; and the tailing is prepared into the superfine powder as a building material. The afterheat is utilized; the energy is saved, and the environment friendliness is achieved.

Owner:陈建湘

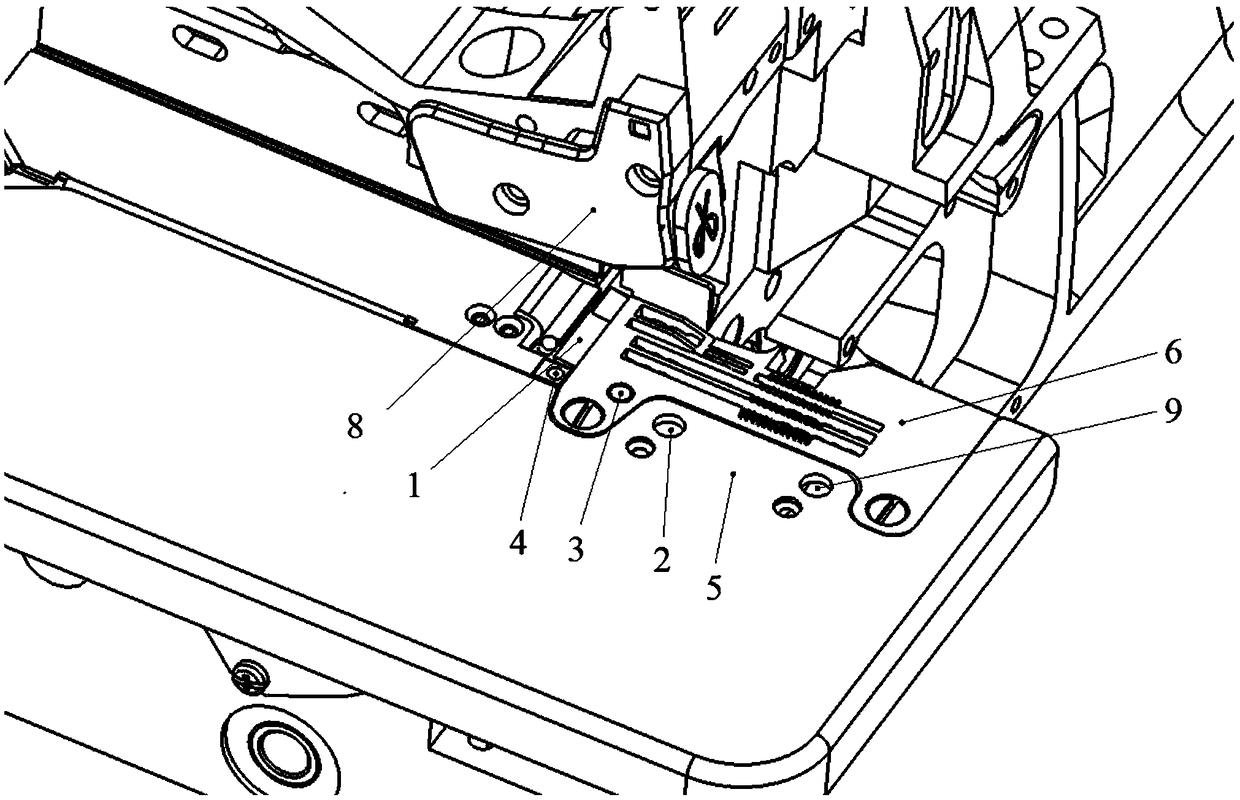

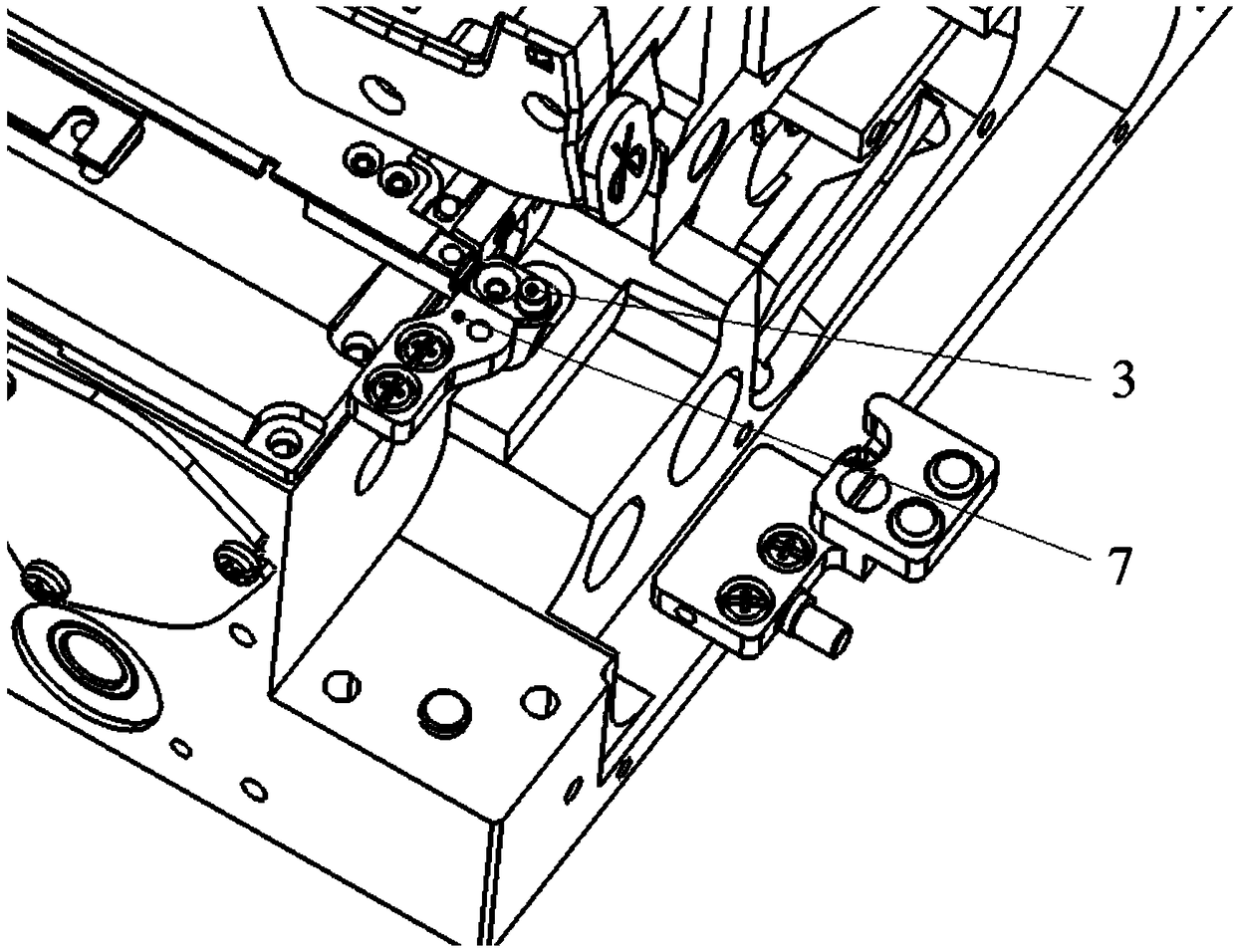

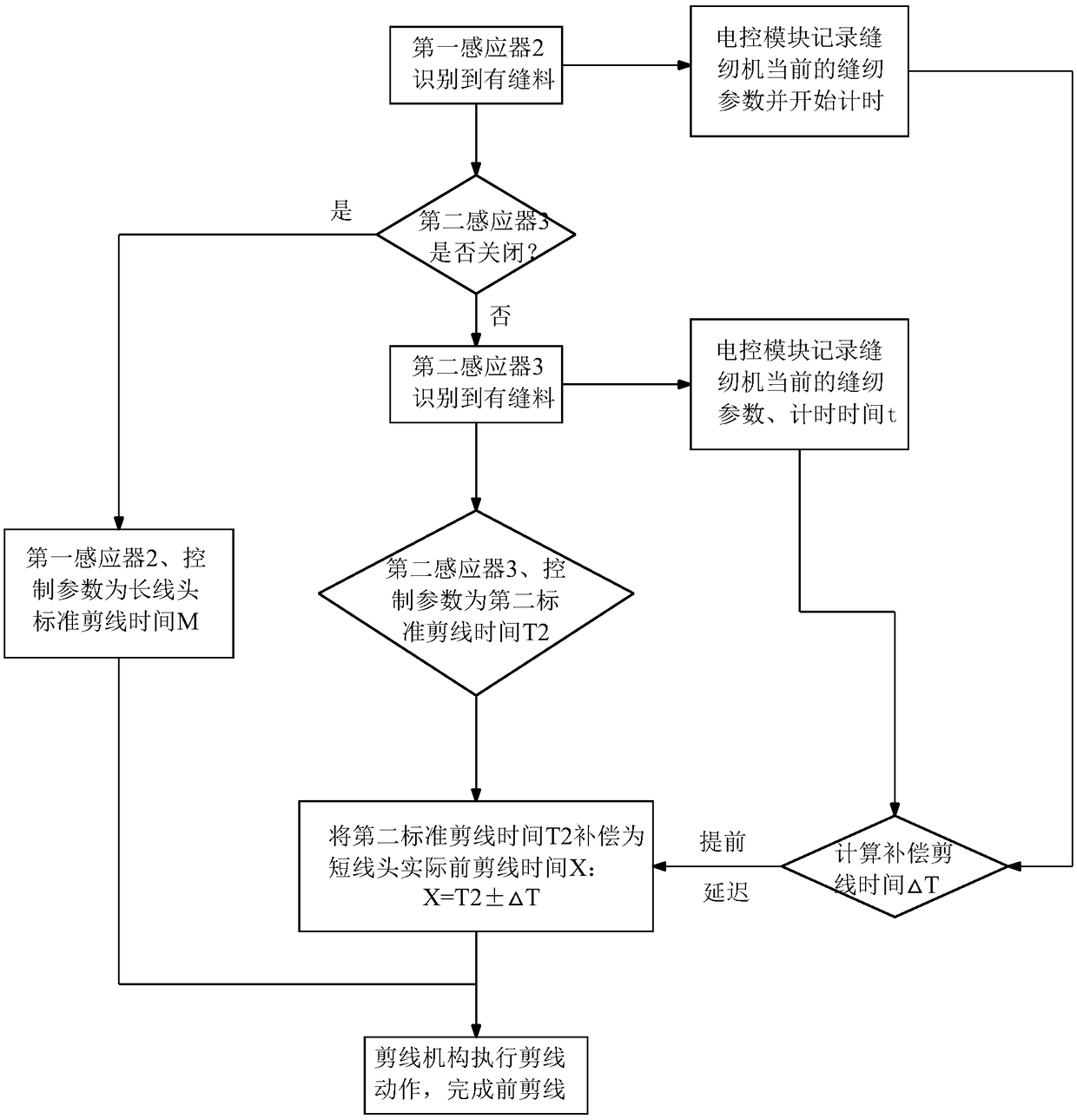

Thread cutting control method and mechanism of sewing machine and overedger

The invention provides a thread cutting control method of a sewing machine. According to the thread cutting control method, a long thread end cutting mode, a short thread end cutting mode and a shortthread end cutting compensation mode are provided; in the long thread end cutting mode, when a detecting sensor detects that the edge of a sewing fabric passes, an electric control module starts timing, and thread cutting is conducted when a standard long thread end cutting time M preset in the electric control module arrives; in the short thread end cutting mode, when the detecting sensor detectsthat the edge of the sewing fabric passes, thread cutting is conducted instantly; in the short thread end cutting compensation mode, the electric control module compensates for the standard short thread end cutting time T into an actual short thread end cutting time X according to current sewing parameters of the sewing machine; when the detecting sensor detects that the edge of the sewing fabricpasses, the electric control module starts timing, and when the actual short thread end cutting time X arrives, thread cutting is conducted. By the adoption of the thread cutting control method of the sewing machine, the effects of long thread end cutting and short thread end cutting can be achieved, and requirements of multiple sewing technologies and specified sewing technologies are met.

Owner:JACK SEWING MASCH CO LTD

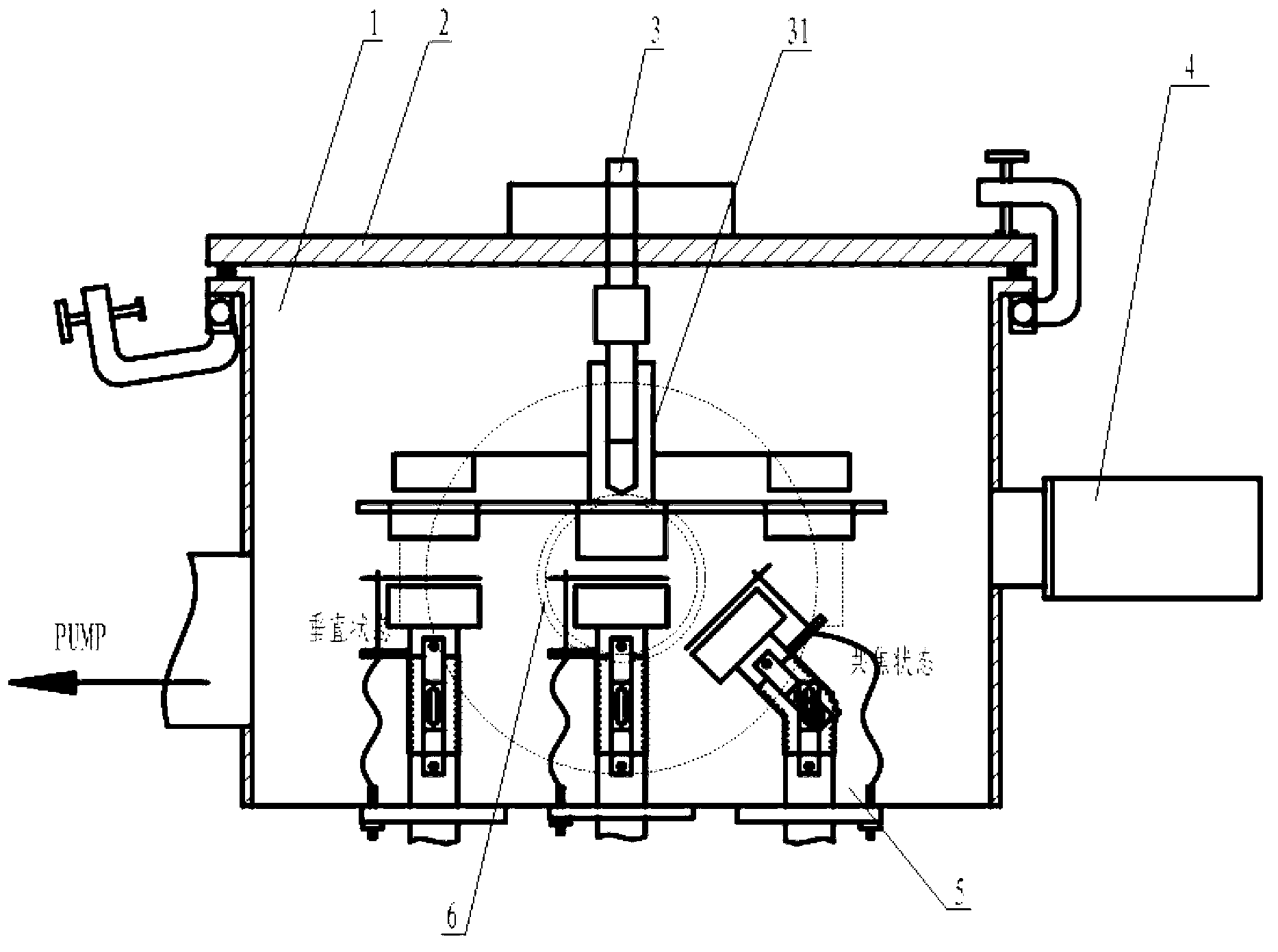

Multifunctional magnetron sputtering film coating device

InactiveCN103290379AEasy to disassemble and maintainAchieve cleaningVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention discloses a multifunctional magnetron sputtering film coating device. The device comprises a vacuum chamber, a top cover, a connecting rod and a substrate frame, wherein the top cover is detachably connected onto the top of the vacuum chamber; the connecting rod is fixedly connected onto the top cover and arranged within the vacuum chamber in a suspension way, the substrate frame is in cup joint with the lower end of the connecting rod in a rotating and lifting way, a plurality of substrate carriers are arranged on the bottom surface of a disc at the bottom of the substrate frame, and heating devices are arranged above the disc and on the positions which correspond to the substrate carriers; a plurality of magnetron sputtering targets arranged on the same periphery are arranged on the position where the bottom of the inner cavity of the vacuum chamber corresponds to the substrate carriers, an inclined angle which is available between the target head arranged at the upper part of each magnetron sputtering target and the main shaft of the vacuum chamber can be adjusted from 0-45 degrees, and a turnover sputtering baffle plate is arranged under the target heads on the magnetron sputtering targets. The device has the characteristics of being compact in structure, high in practicability, and diversified in function, and the requirement for the research of a thin-film technology and a component test by a magnetron sputtering method in the colleges and universities and the scientific research institutions can be met.

Owner:HEFEI LIHENG HYDRAULIC SYST

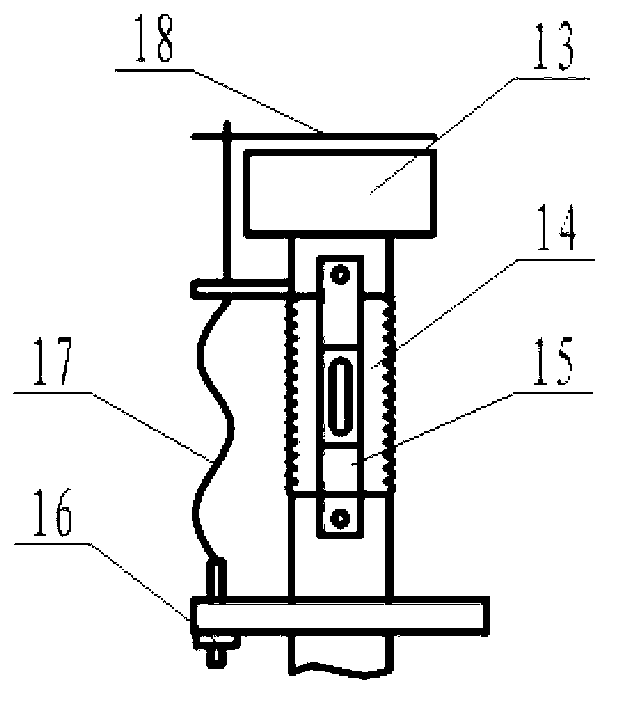

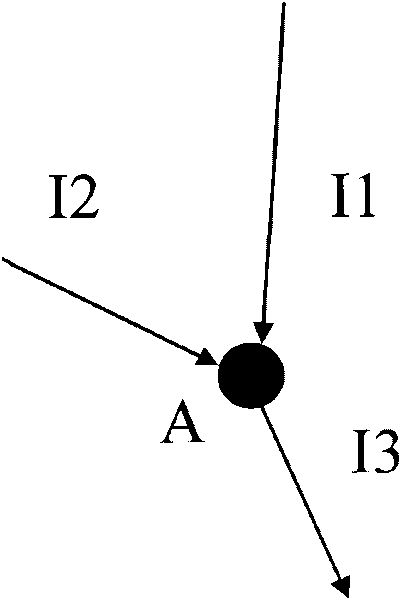

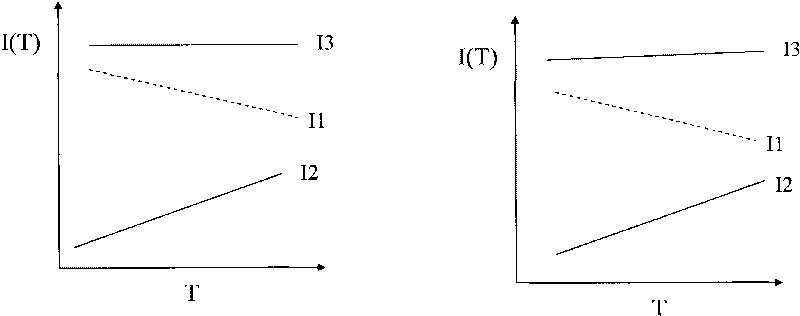

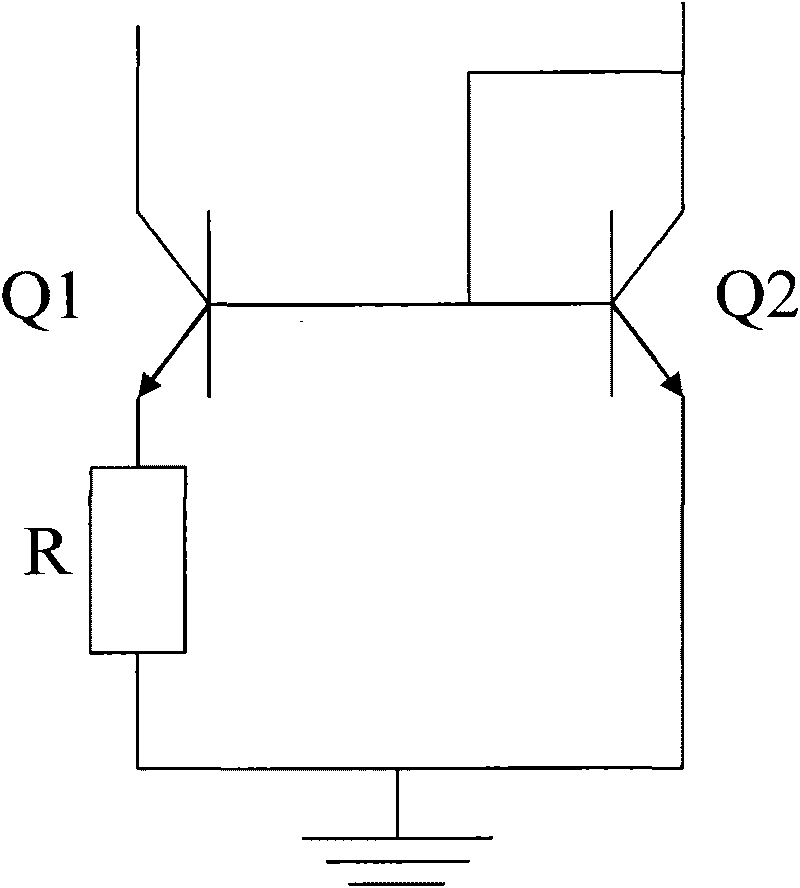

Current generating circuit

ActiveCN101763137AEasy to manageMeet craftElectric variable regulationEngineeringProcess miniaturization

The invention relates to a current generating circuit which comprises a first current generating unit and a second current generating unit, wherein the first current generating unit comprise an MOS transistor working in a subthreshold area, and is used for generating a current in direct proportion with temperature; the second current generating unit comprises an MOS transistor working in a saturation area, and is used for generating a current irrelevant to the temperature; the difference between the current generated by the second current generating unit and the current generated by the first current generating unit is the third current generated by the current generating circuit. The current generating circuit can meet requirements for semiconductor process miniaturization and system simplification.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

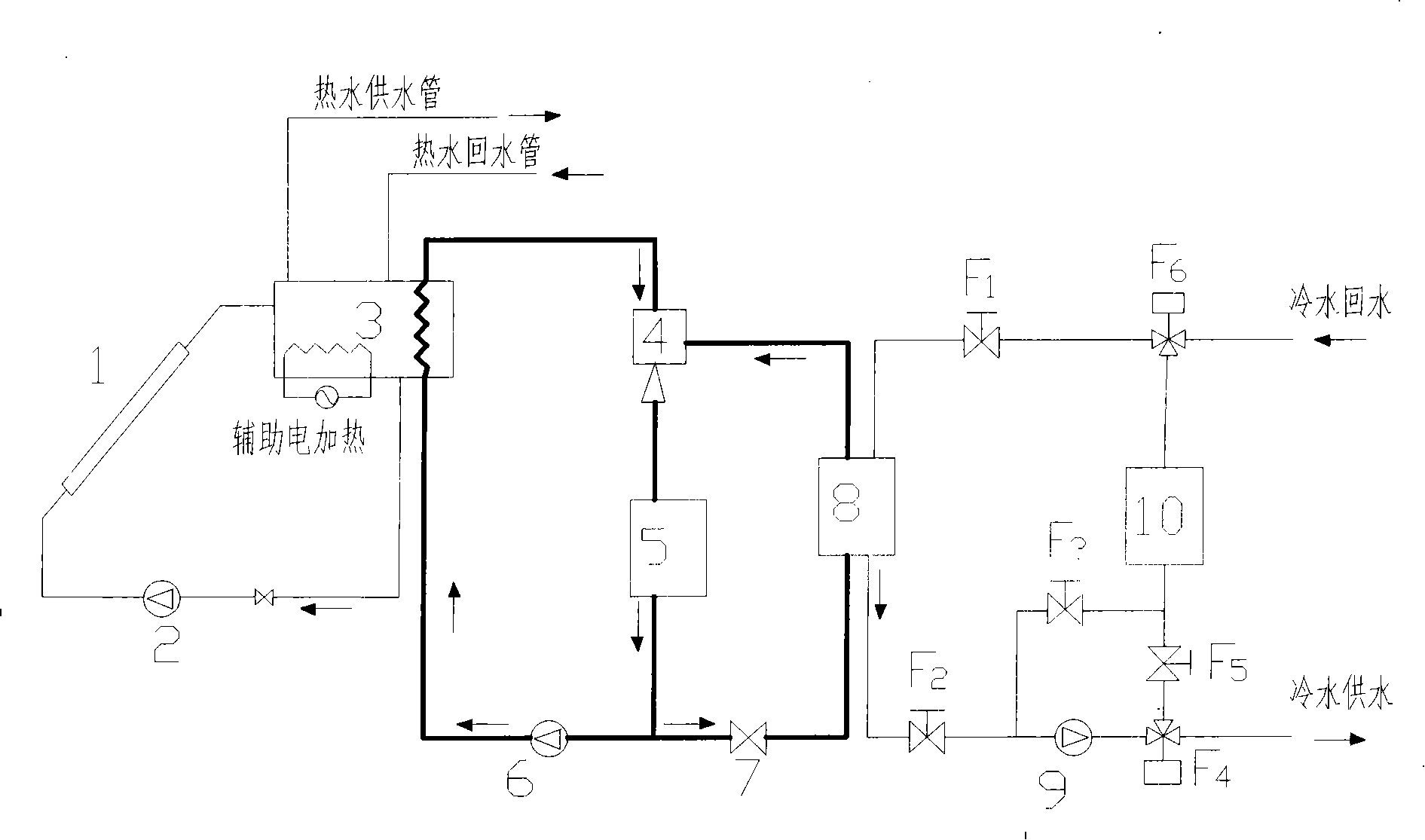

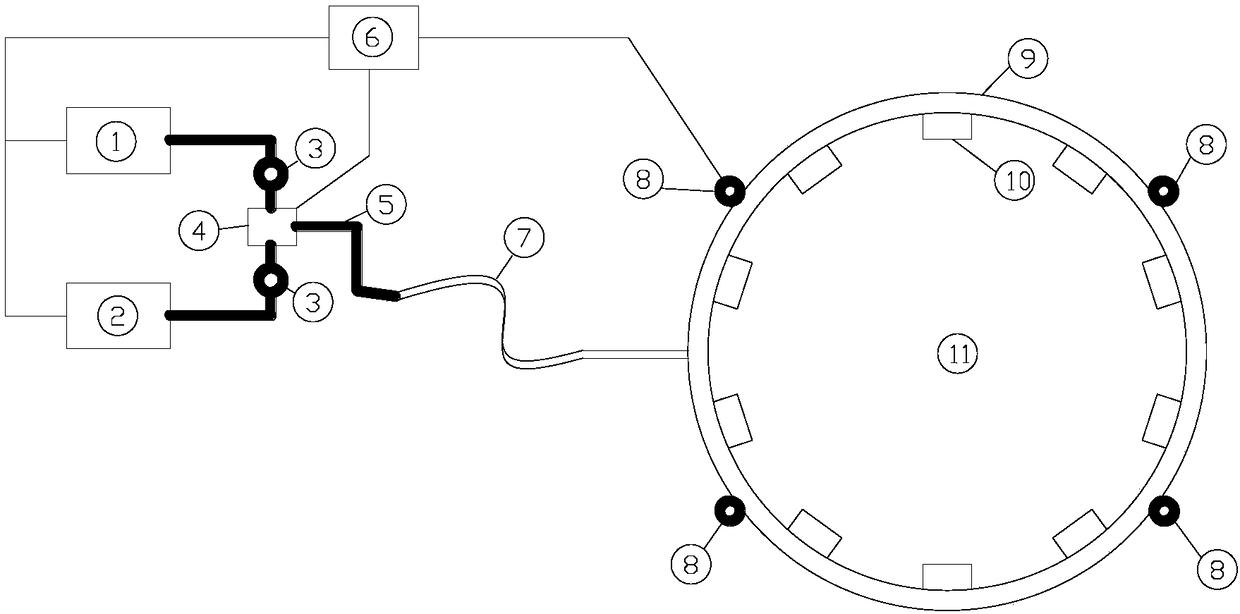

Energy storage type solar injection refrigerating device

InactiveCN101251314AWide temperature rangeMeet supplySolar heat devicesMachines using refrigerant evaporationEngineeringAir conditioning

The invention relates to an energy storage solar ejection refrigeration device by adopting the solar energy to refrigerate, comprising a solar thermal collector, a water pump and a generator which form a circulation loop together with the solar thermal collector, a refrigerating medium circulation loop which exchanges the heat with the generator and consists of an ejector, a condenser and the refrigerating medium which are connected in series, a refrigerating medium circulatory refrigeration loop consisting of a throttling valve, an evaporator, the ejector and the condenser and an air conditioning circulatory refrigeration loop consisting of an air conditioning water pump and the evaporator, wherein, in the air conditioning circulatory refrigeration loop, a cold water loop is provided with a three way valve F6 and a valve F1, a cold water supply pipeline is provided with a valve F2 and a three way valve F4, an ice storage tank is arranged on a pipeline between the three way valve F6 and the three way valve F4, a pipeline between the valve F2 and the three way valve F4 is communicated with the ice storage tank by the valve F3, a pipeline between the ice storage tank and the three way valve F4 is also provided with a valve F5. The solar energy utilization ratio is increased by more than 30 percent, the cooling capacity is increased by more than 20 percent, 'the peak shifting and valley filling' of the solar energy is realized and the electric fence load is lightened.

Owner:ZHONGYUAN ENGINEERING COLLEGE

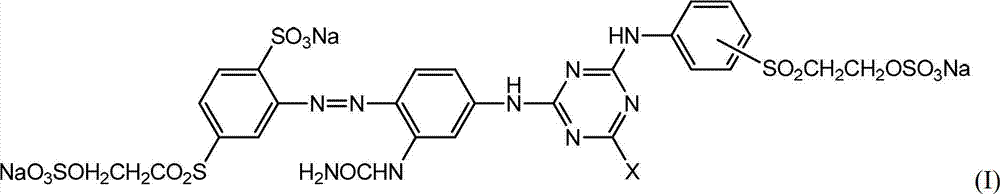

Composite reactive yellow dye and preparation method thereof

The invention discloses a composite reactive yellow dye and a preparation method thereof. The composite reactive yellow dye is shown as a formula (I), wherein X is Cl or F; and vinyl sulfone sulfuric acid ester group is at a meta-position or a para-position of phenyl. The novel composite reactive yellow dye has a red-light yellow dye structure with three reactive groups and is obtained by compounding solutions in proportion and performing standardization and spray-drying. The solubility is high and more than 200g / l, the product is bright-colored, the color fastness is as high as 90 percent, the dyeing buildup is improved, the composite reactive yellow dye can be used for dark color dyeing, reactivity is high, saline-alkaline resistance is good, stability is ensured, and the composite reactive yellow dye is suitable for common dip dyeing, pad dyeing, and pollution-free dyeing and finishing processes such as cold batch dyeing and wet short-steaming dyeing.

Owner:无锡润新染料有限公司

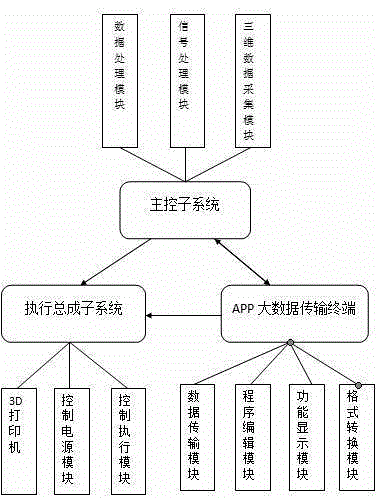

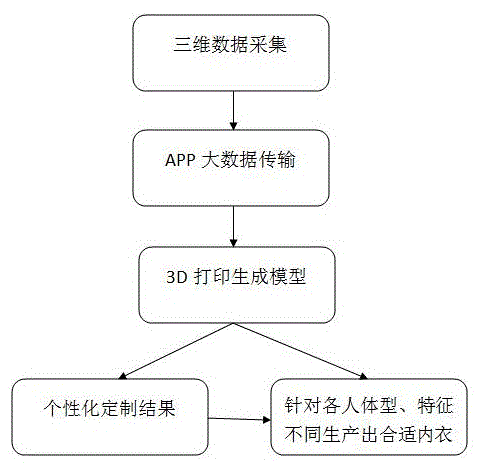

3D printing method based on APP big-data modeling and control system

InactiveCN104991517APlay a protective effectExtend your lifeProgramme controlComputer controlPersonalizationData modeling

A 3D printing method, disclosed in the invention, based on APP big-data modeling enables the 3D printing technology to be reasonably applied in fields comprising underwear design or processing and manufacturing; secondly, for personalized customized products of a large processing difficulty, physical data of printing equipment can be analyzed in advance, and key parameters of a feeding speed, body type data docking, personalized specification data docking, special data and the like of the equipment are judged, so a role in protection for the machine is played, the service life of the machine is prolonged, and processing efficiency and processing precision is improved; and the processing ability is improved, processing is convenient, misoperation and waste are reduced, and working efficiency is improved. A control system provided by the invention improves positioning precision, tracking precision and the comprehensive data processing capability of 3D printing are improved; and full visual positioning and omni-directional three-dimensional type tracking monitoring are reasonably adopted, a humanized operation interface of an APP terminal is improved, parameter setting and data acquisition are effectively achieved, the degree of automation is high, and different-specification and different-dimension processing technology is satisfied in a large scale.

Owner:广东汇星新材料科技股份有限公司

Preparation method of polyvinylidene fluoride

InactiveCN104403033AImprove thermal stabilityEasy to processPolyethylene glycol1,1,2-Trichloroethane

The invention discloses a preparation method of polyvinylidene fluoride. The preparation method comprises the following steps: (1) putting 1.3 parts of hydrogen peroxide and 2.1 parts of inorganic alkali solution by weight in a reaction kettle, uniformly mixing, then putting 8.9 parts of 1,2,2-trifluoro-1,1,2-trichloroethane solvent and 1.3 parts of undecafluoro-hexanoyl fluoride solution by weight, and stirring at 8 DEG C below zero for 35-minute reaction; (2) then introducing 5.5 parts of a polyglycol solution, 83 parts of vinylidene fluoride monomers and 3.1 parts of methylcyclopentane by weight, stirring at 32 DEG C for reaction, and ending the reaction when the pressure is reduced below 0.27 MPa; (3) filtering, washing and drying to obtain powered polyvinylidene fluoride. The prepared polyvinylidene fluoride has good heat stability and machinability, and can meet the production technology such as injection molding, extrusion and film drawing.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

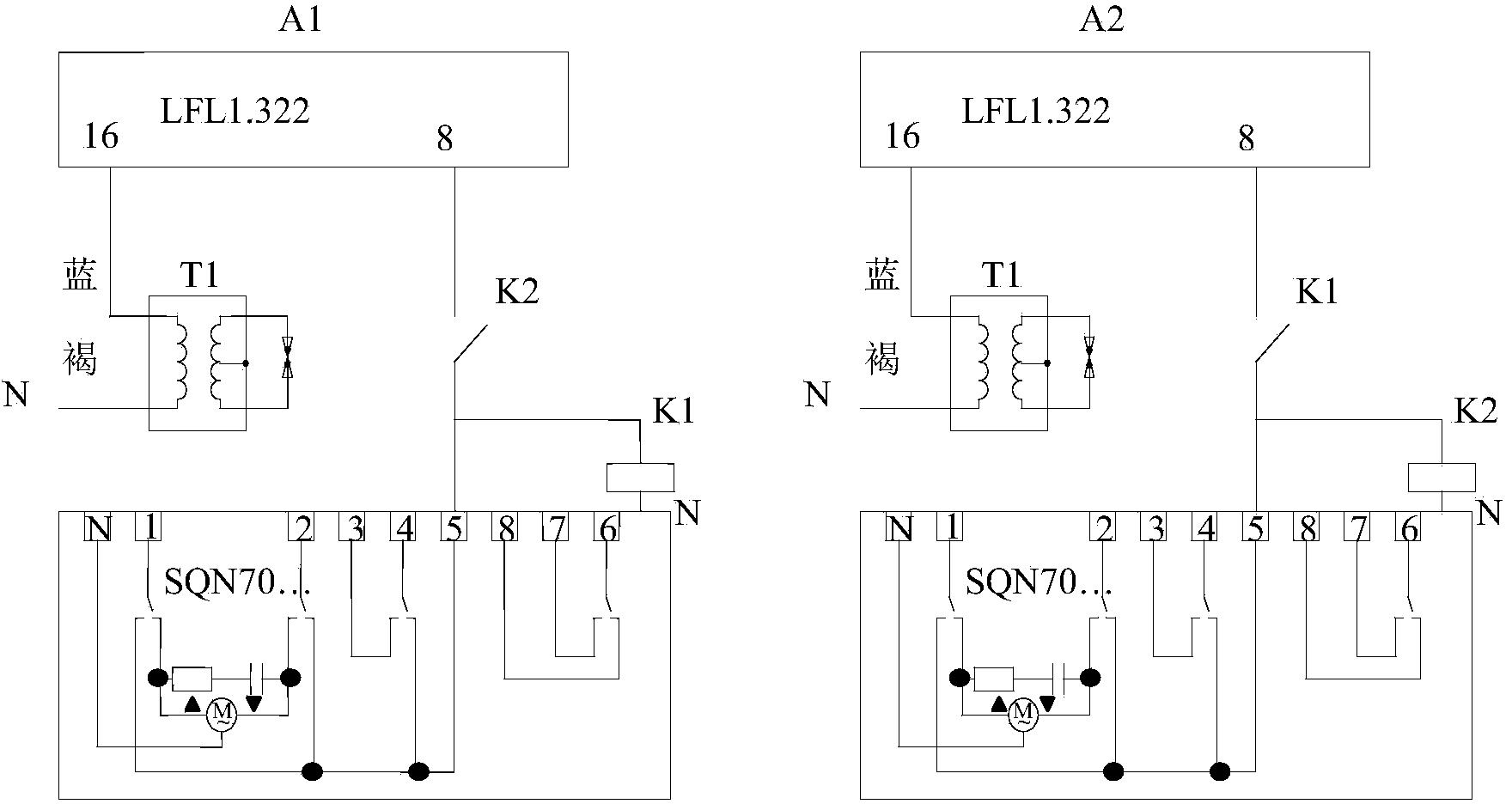

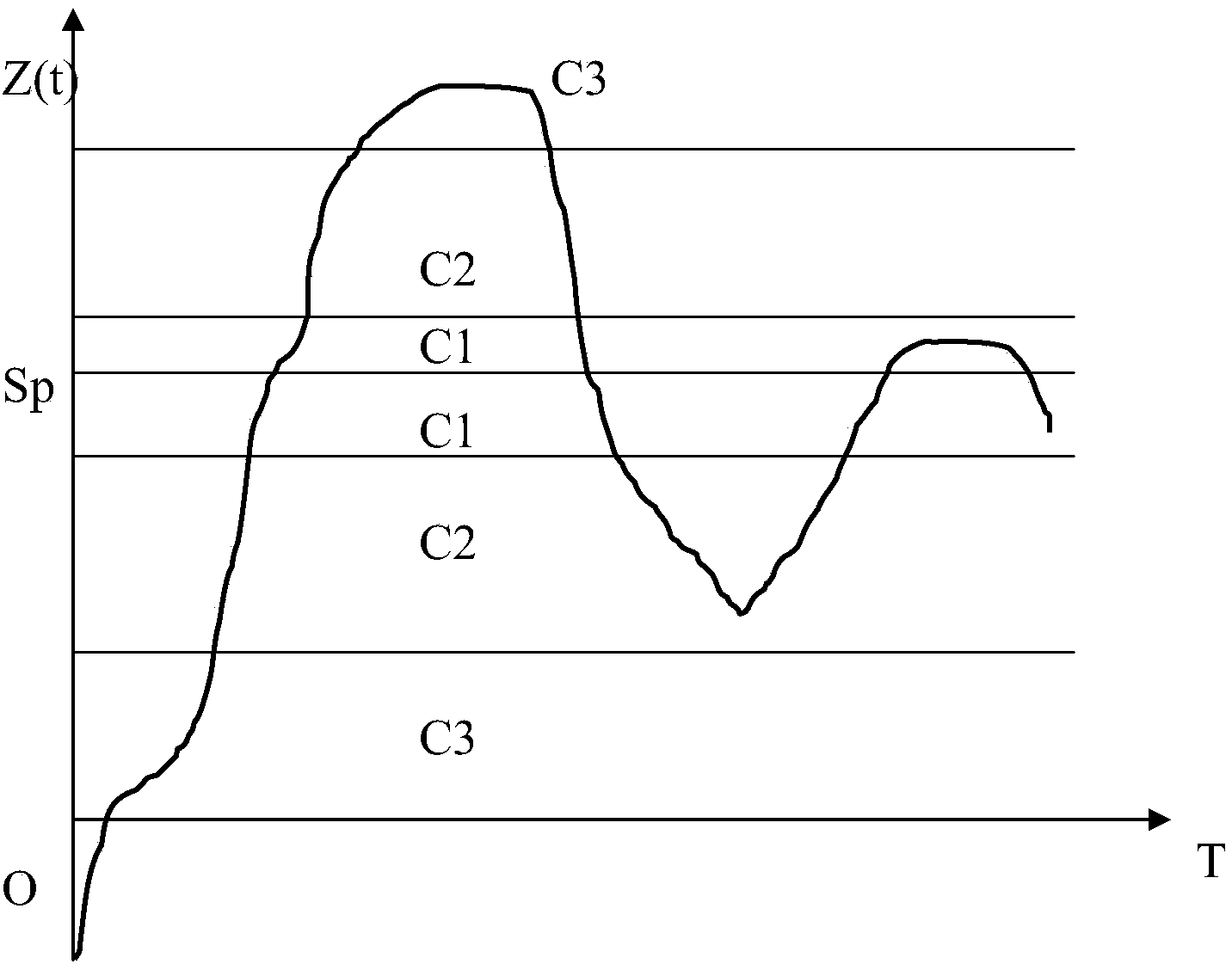

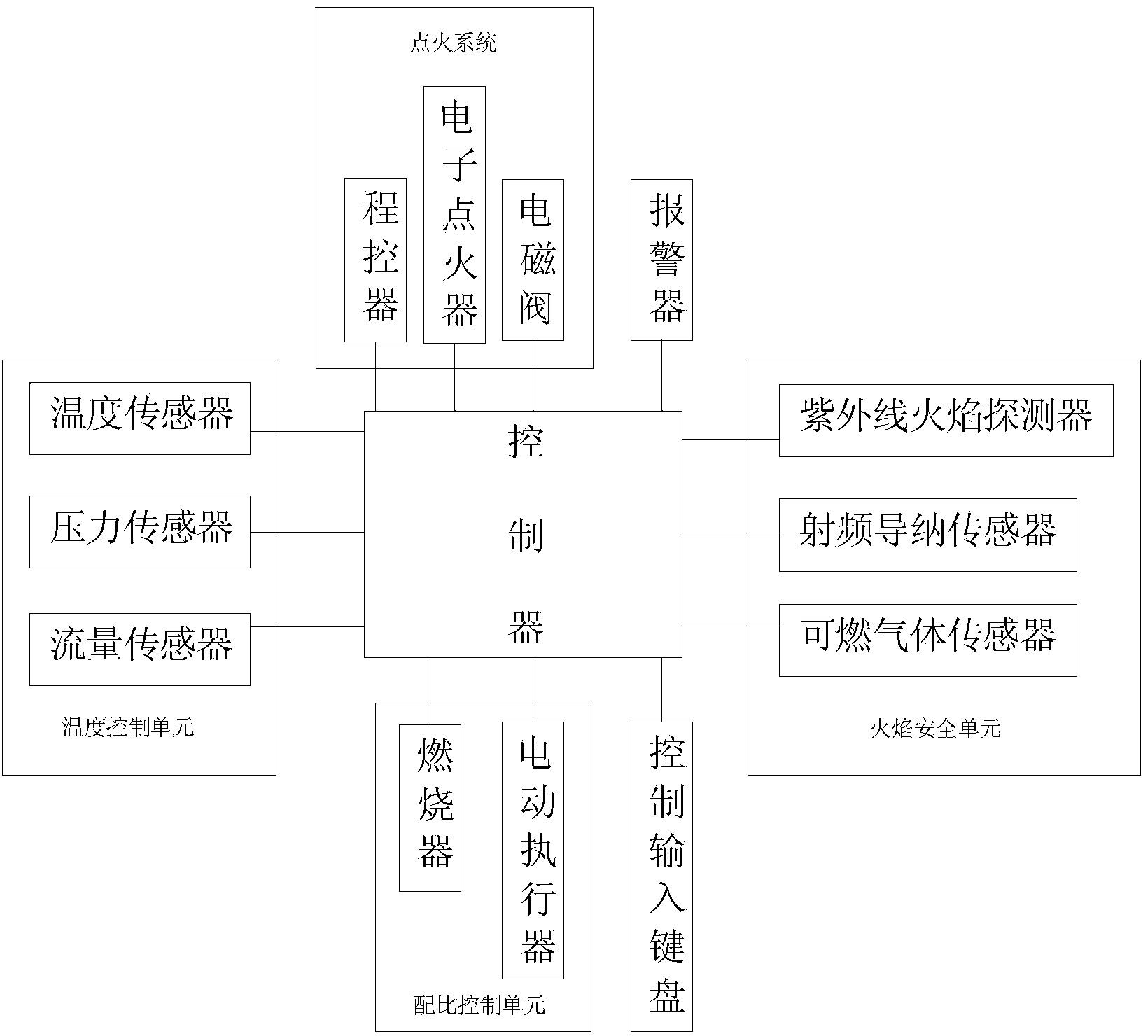

Temperature accurate control device and method of oilfield negative-pressure heating furnace

InactiveCN104390354AExtended service lifeSafe and stable operationStorage heatersLiquid temperatureControl manner

The invention provides a temperature accurate control device of an oilfield negative-pressure heating furnace, aiming to solve the problems of a traditional control manner that the liquid temperature fluctuation in a gathering and transportation process is great, and functions of synchronously starting and stopping, monitoring a flue gas discharging temperature and protecting liquid leakage and gas leakage are lacked, certain potential safety hazards exist and the oilfield output is seriously influenced. The temperature accurate control device comprises a controller, wherein the controller is connected with a temperature control unit, a proportioning control unit, an ignition system and a flame safety unit respectively; the temperature control unit comprises a temperature sensor, a pressure sensor and a flow sensor; the proportioning control unit comprises a combustor and at least one electric actuator mounted on an air door; the ignition system comprises an electronic igniter, a program controller and a solenoid valve mounted in a flue gas pipeline; the flame safety unit comprises an ultraviolet flame detector, a radio frequency admittance sensor and a combustible gas sensor; the controller is connected with an alarm and a control input keyboard respectively. The temperature accurate control device of the oilfield negative-pressure heating furnace is simple to operate, convenient to use and high in practicability.

Owner:PETROCHINA CO LTD +1

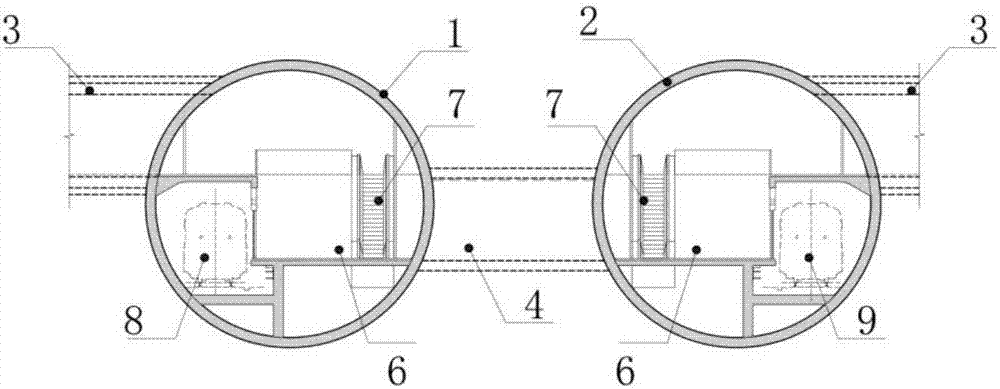

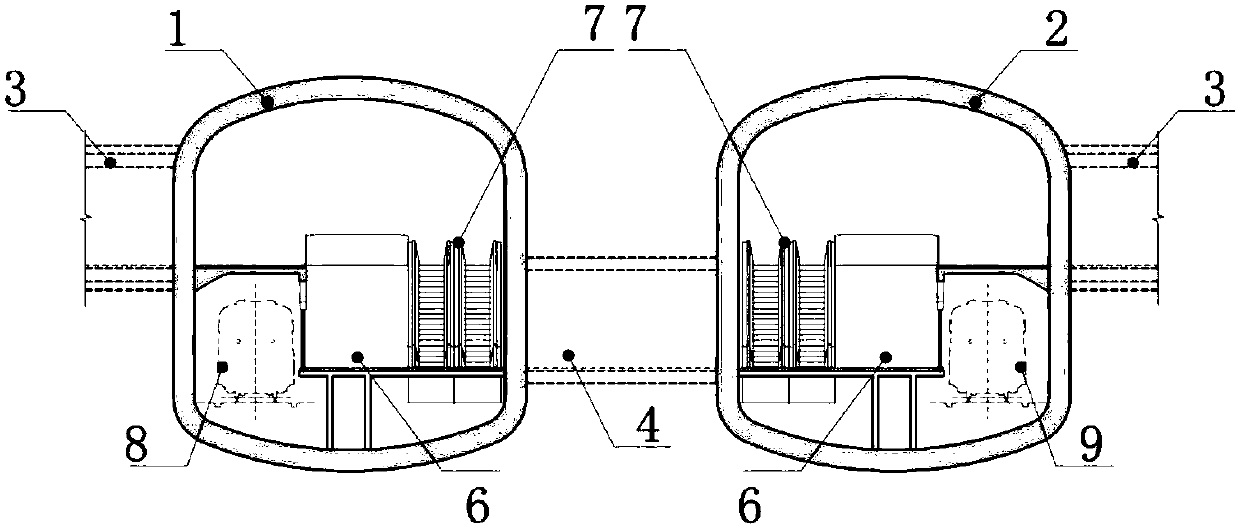

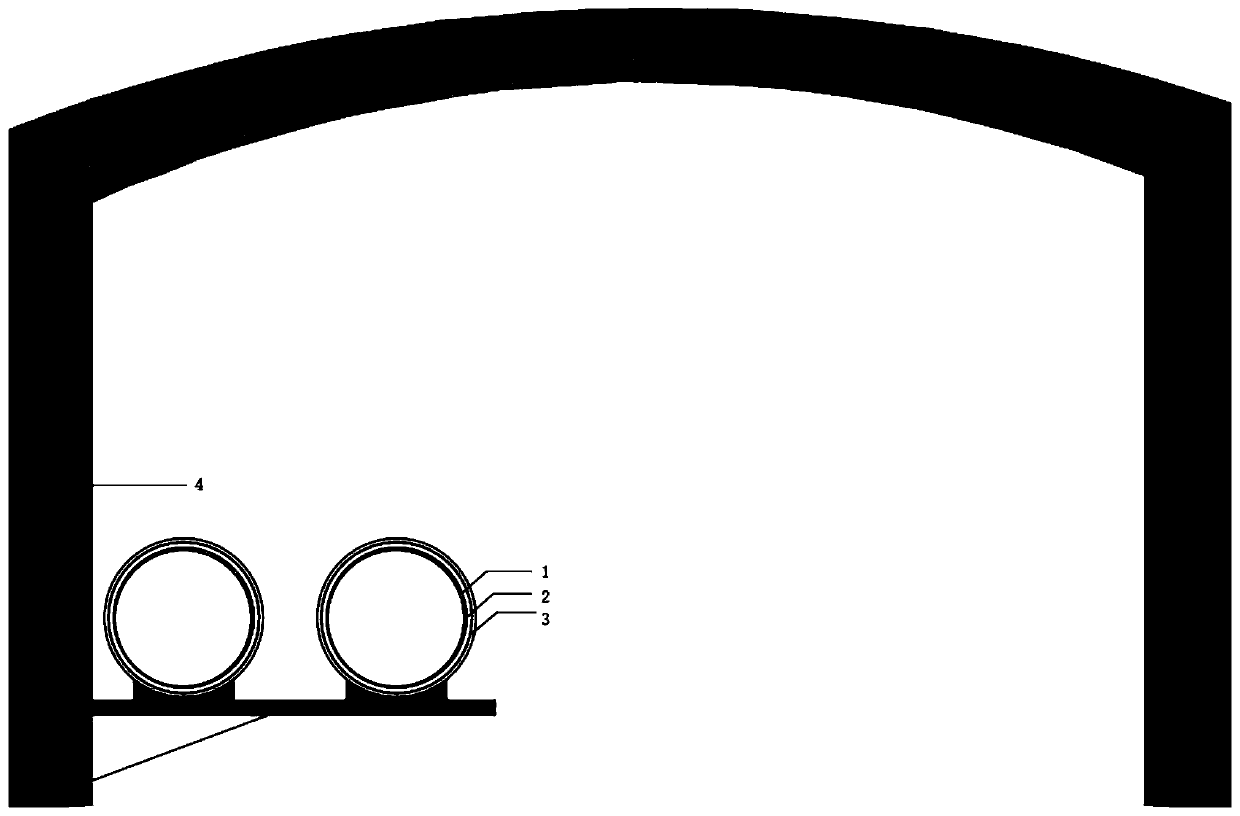

Shield double-layered space combined metro station

PendingCN107460887AMeet craftSatisfy functionArtificial islandsUnderground chambersMetro stationArchitectural engineering

The invention discloses a shield double-layered space combined metro station and relates to the technical field of shield tunnel metro stations. A #1 shield double-layered tunnel communicates with a #2 shield double-layered tunnel through a cross-linking channel; the #1 shield double-layered tunnel and the #2 shield double-layered tunnel are divided into double-layered spaces through middle plates, and a #1 line is arranged in the lower space of the double-layered space of the #1 shield double-layered tunnel; a #2 line is arranged in the lower space of the double-layered space of the #2 shield double-layered tunnel; platforms are arranged on one sides of the #1 line and the #2 line, escalators are arranged on one sides of the platforms, and both the platforms and the escalators are arranged in the upper spaces of the double-layered spaces; and inlet and outlet channels are arranged on one sides of the tops of the #1 shield double-layered tunnel and the #2 shield double-layered tunnel. The shield double-layered space combined metro station can meets the process and function of the station effectively, and meanwhile, is high in engineering exploitativeness, so that the construction risk can be reduced, pipeline migration and modification are reduced, traffic reconciliation is optimized, and the practicality is higher.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

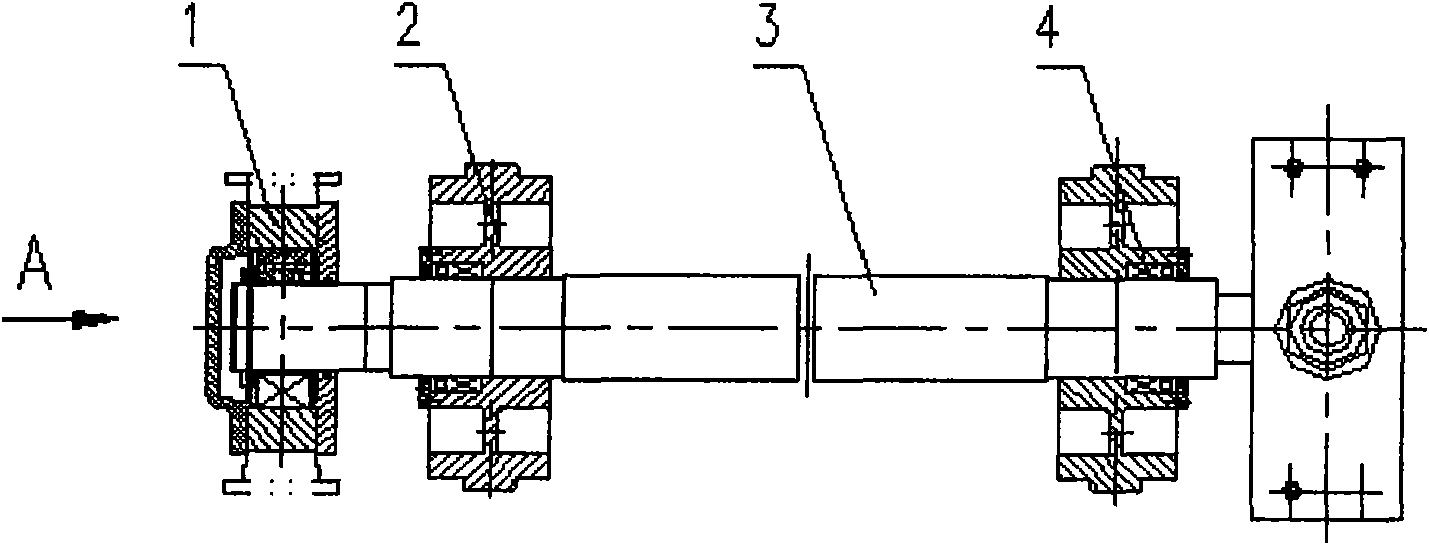

Composite tensioning device

InactiveCN101979286AReduce labor intensityImprove efficiencyConveyorsSafe operationMechanical engineering

The invention discloses a composite tensioning device applied in the heavy plate feeder industry. The whole device consists of a sliding bearing seat, a supporting wheel, a tensioning shaft, an expansion sleeve, a lead screw, a nut, a composite spring, an oil cylinder, a manual oil pump, a pressure gauge and a pipeline, wherein the sliding bearing seat, the supporting wheel and the expansion sleeve are arranged on the tensioning shaft and arranged on a tail rack; the supporting wheel supports a chain on a link plate device; the front of the sliding bearing seat is hinged with the oil cylinder together, a base of the oil cylinder is welded on the tail rack, and the back of the sliding bearing seat is connected with the lead screw; and the lead screw passes through the tail rack and is screwed down through the composite spring and the nut. An operating method for the composite tensioning device comprises that: pressure oil passes through the pipeline, the pressure gauge and the oil cylinder by simultaneous left and right pressing of a handle of the manual oil pump to drive the tensioning shaft, the supporting wheel and the link plate device to move backwards together at the same time of pushing the sliding bearing seat to move backwards on the tail rack, and the nut on the lead screw is screwed down after the chain reaches a certain pre-tensioning force. The device has the advantages of low labor intensity, high strength, long service life of members and reasonable structure, ensures the reliable and safe operation of products, and meets the requirements of process and design aspects.

Owner:沈阳矿山机械有限公司

Casting epoxy resin composition for part repair

The invention relates to a casting epoxy resin composition for part repair, aims at achieving the technical purpose that the requirements of rapid curing at room temperature and excellent properties can be met simultaneously, and belongs to technical field of high-molecular polymers. The composition is characterized in that a preparation method of the composition comprises the steps that 1, preheated bisphenol A type epoxy resin, toughening type epoxy resin and a diluent are added into a reaction kettle in sequence, the temperature inside a stirring tank is maintained to be 50-70 DEG C, a defoamer is added, stirring and defoaming are conducted simultaneously, and a resin mixture is obtained; 2, aliphatic amine is added into another reaction kettle, stirring is started, the temperature inside a tank is maintained to be about 25-40 DEG C, alicyclic amine and an amine type accelerator are added in sequence, mixing and stirring are conducted continuously for 15-30 min, and a curing agent mixture is obtained; 3, the resin mixture and the curing agent mixture are mixed to be uniform according to the ratio of 100:(15-17), and the epoxy resin composition for part repair is obtained. The comprehensive performance of the product is excellent, and the composition has low viscosity and rapid curing speed and can meet curing requirements in different temperature environments.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

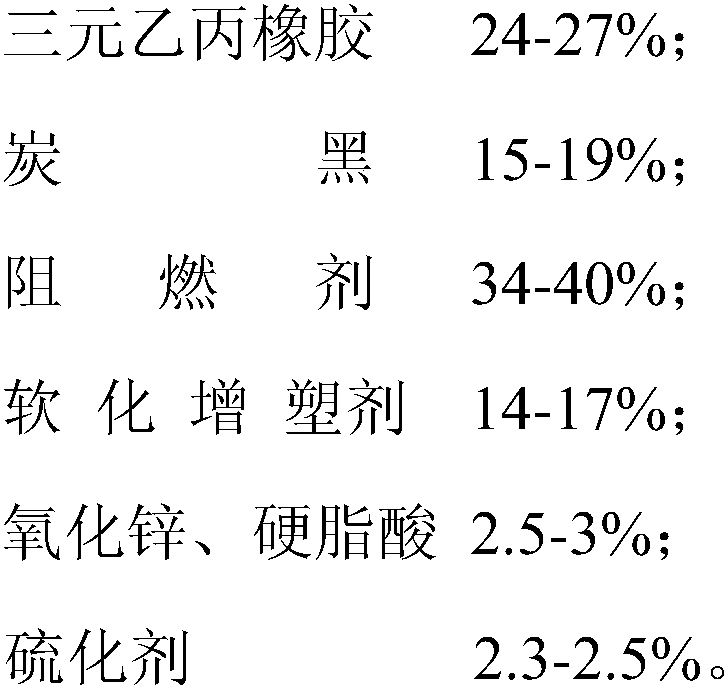

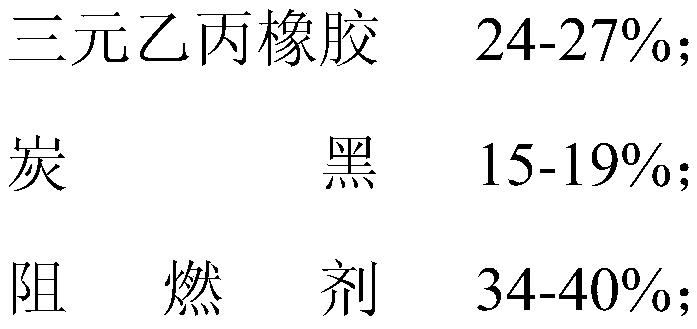

Halogen-free flame-retardant ethylene-propylene-diene monomer rubber for sealing strips, and preparation method thereof

The invention discloses a halogen-free flame-retardant ethylene-propylene-diene monomer rubber for sealing strips. The halogen-free flame-retardant ethylene-propylene-diene monomer rubber for sealingstrips comprises 24-27 wt% of ethylene-propylene-diene monomer rubber, 15-19 wt% of carbon black, 34-40 wt% of a flame retardant, 14-17 wt% of a softening plasticizer, 2.5-3 wt% of an activator and 2.3-2.5 wt% of a vulcanizing agent. The halogen-free flame-retardant ethylene-propylene-diene monomer rubber for sealing strips has the characteristics of high strength, good high-temperature aging resistance and high flame retardancy in a use environment, and also has a long service life.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

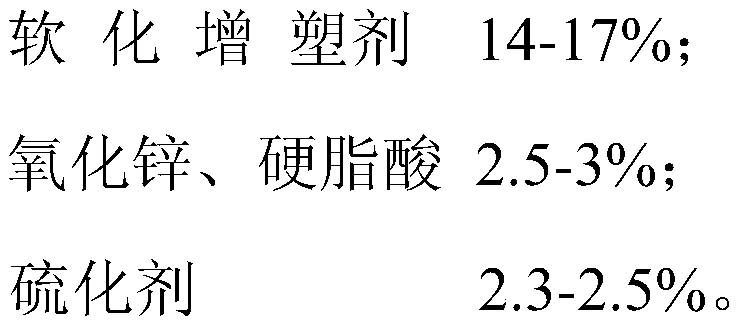

Membrane bioreactor and membrane bioreactor membrane pollution control method and device

ActiveCN108249560ASimple structureEasy to operateSemi-permeable membranesTreatment with anaerobic digestion processesGas compressorEnvironmental engineering

The invention discloses a membrane bioreactor and a membrane bioreactor membrane pollution control device and method. The membrane bioreactor comprises a fluid medium conveying device, an injection device and a movement device, wherein an exhaust port of a gas compressor of the fluid medium conveying device is communicated with an air inlet of a pipeline switching device through a gas conveying pipeline; the gas conveying pipeline is provided with a check valve; a liquid outlet of a liquid pump is communicated with a liquid inlet of the pipeline switching device through a liquid conveying pipeline; the liquid conveying pipeline is provided with a check valve; the injection device comprises an injection pipe and a plurality of nozzles; an inlet of the injection pipe is communicated with anoutlet of the pipeline switching device through a pipeline; each outlet of the injection pipe is provided with one nozzle; the movement device is installed in or out of the MBR (membrane bioreactor);the injection device is arranged on the movement device. According to the membrane bioreactor and the membrane bioreactor membrane pollution control device and method disclosed by the invention, in-situ efficient control on aerobiotic and anaerobic MBR membrane pollution can be met, operation is simple, energy consumption is low, and an application range is wide.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for manufacturing highly heat resistant wide-mouth polyester container

The invention discloses a method for manufacturing a highly heat resistant wide-mouth polyester container, belonging to the manufacturing method of polyester containers. The invention aims at providing a method for manufacturing a polyester container which can satisfy the requirements of hot filling and pasteurization processes. The method comprises material drying, parison pre-manufacturing and blow-forming. The method comprises the following steps: drying the mixed material of a PET resin with intrinsic viscosity of 0.78-0.85dl / g and weight percent of 60-80% and a PENT-8 resin with intrinsicviscosity of 0.78-0.85dl / g and weight percent of 20-40%, and ensuring the water content to be less than or equal to 0.005%; pre-manufacturing the parison according to the injection forming process; carrying out crystallization on the neck of the parison for 30-40s at 170-180 DEG C and setting for 48h at room temperature; and blow-forming the parison according to the blow-forming process, pressurizing and heat setting for 5-20s, cooling and opening molds. Each performance index of the container manufactured by the invention reaches or surpasses the Hot Filled PET Bottle Standard QB / T2665-2004.

Owner:GUIZHOU CHIEN YEH PLASTIC

Preparation process of polyvinylidene fluoride

InactiveCN104497181AImprove thermal stabilityEasy to processDichlorodifluoromethanePolypropylene glycol

The invention discloses a preparation process of polyvinylidene fluoride. The preparation process comprises the following steps of (1) adding 2.1 parts of hydrogen peroxide and 1.8 parts of an inorganic alkaline solution into a reaction kettle, uniformly mixing, then, adding 11.3 parts of a dichlorodifluoromethane solvent and 0.2 part of a perfluorobutanesulforyl fluoride solution, and reacting while stirring at the temperature of 6 DEG C below zero for 30 minutes; (2) introducing 6.7 parts of a polypropylene glycol solution, 72 parts of vinylidene fluoride monomers and 2.5 parts of isopropylcyclopentane, reacting while stirring at the temperature of 35 DEG C, and stopping reacting when the pressure is reduced to be less than 0.21MPa; and (3) filtering, washing and drying to obtain the powdery polyvinylidene fluoride. The polyvinylidene fluoride prepared by using the preparation process is favorable in thermal stability and processability and capable of meeting the requirements of production processes such as injection molding, extrusion and film drawing.

Owner:CHANGSHU LIYUAN MEMBRANE TECH

Submerged arc refining slag and preparation method thereof

InactiveCN102220456AImprove ingredient stabilityHigh yieldProcess efficiency improvementSlagHigh carbon

The invention discloses submerged arc refining slag, which is prepared from the following raw materials in part by weight: 35 to 40 parts of sintered bauxite, 1 to 2 parts of metal aluminum powder, 8 to 12 parts of silicon carbide, 2 to 4 parts of high carbon powder, 40 to 45 parts of limestone, 1 to 3 parts of blast furnace grain slag and 2 to 4 parts of lignin. In the invention, deoxygenation, submerged arc foaming and refining are integrated, production process is simplified, working environment is improved, the stability of ingredients of molten steel is improved, smelting cost is lowered, refining time is reduced, yield of expensive metal is increased, secondary oxidization of molten steel is relieved, the recovery rate of molten steel is increased, arc and noise pollution are reduced and the service life of refractory materials is prolonged.

Owner:ZHENGZHOU DONGSHENG METALLURGY NEW MATERIAL

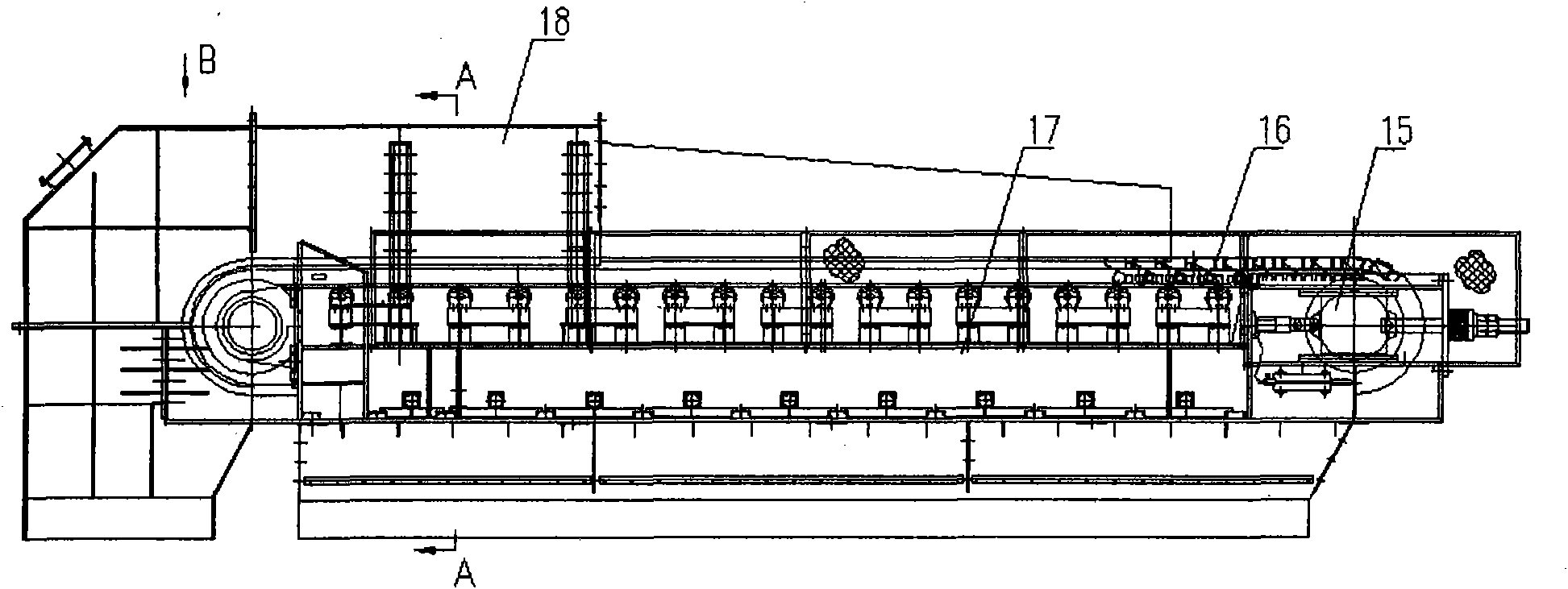

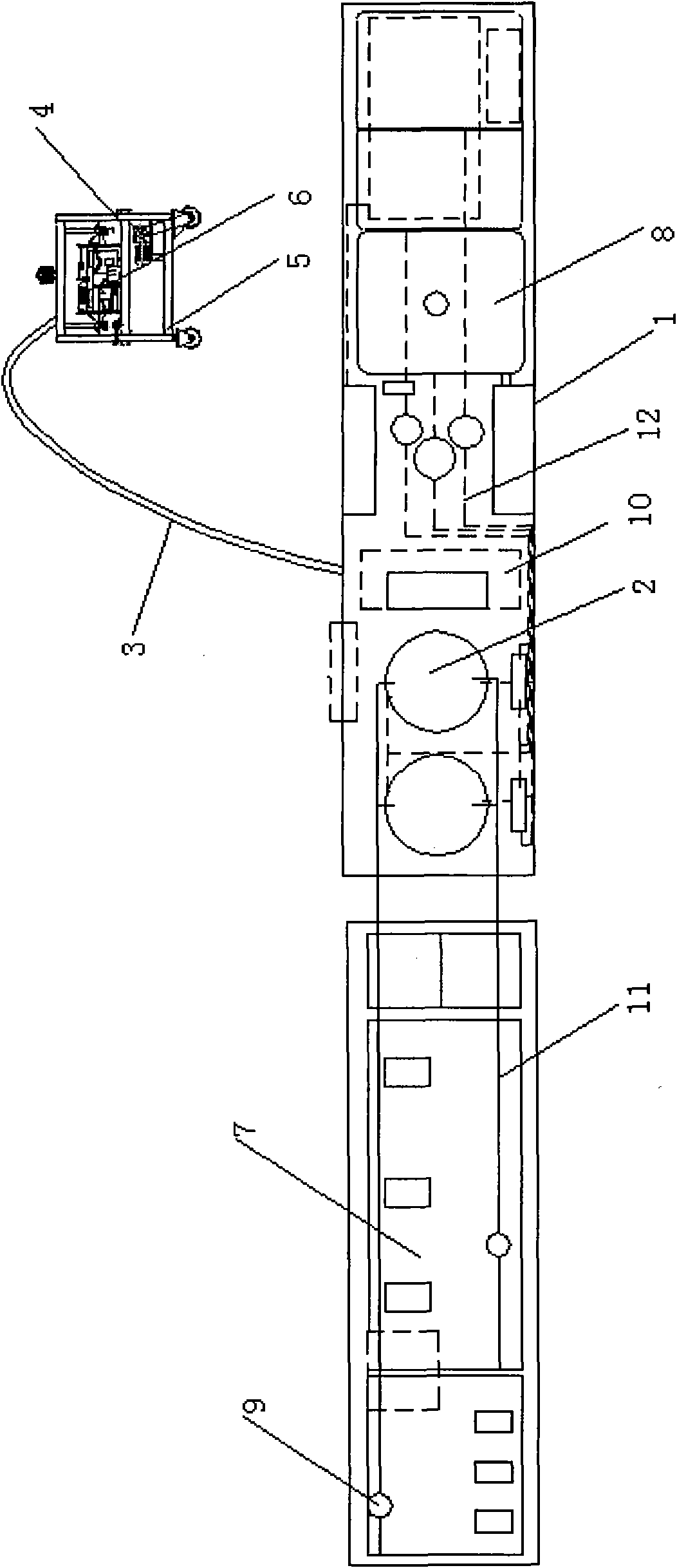

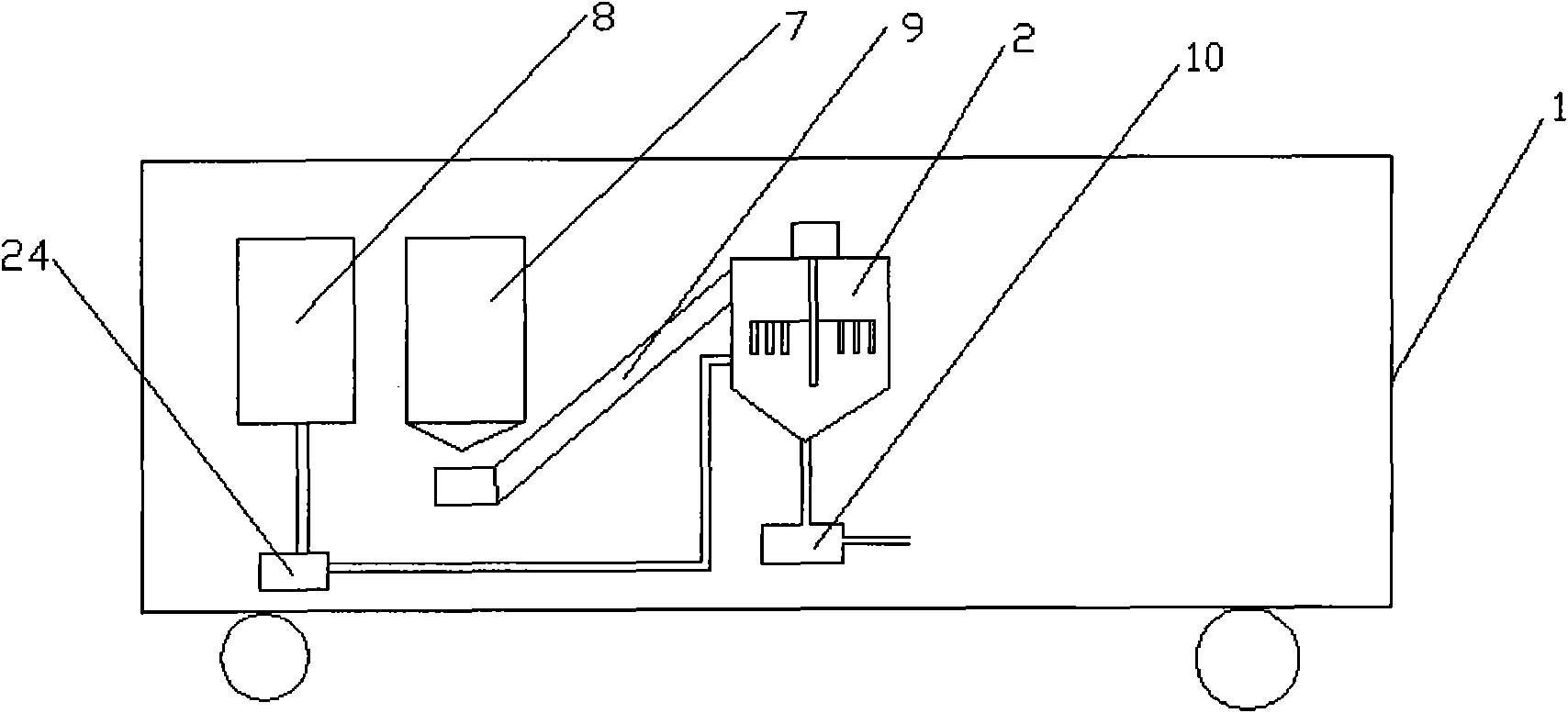

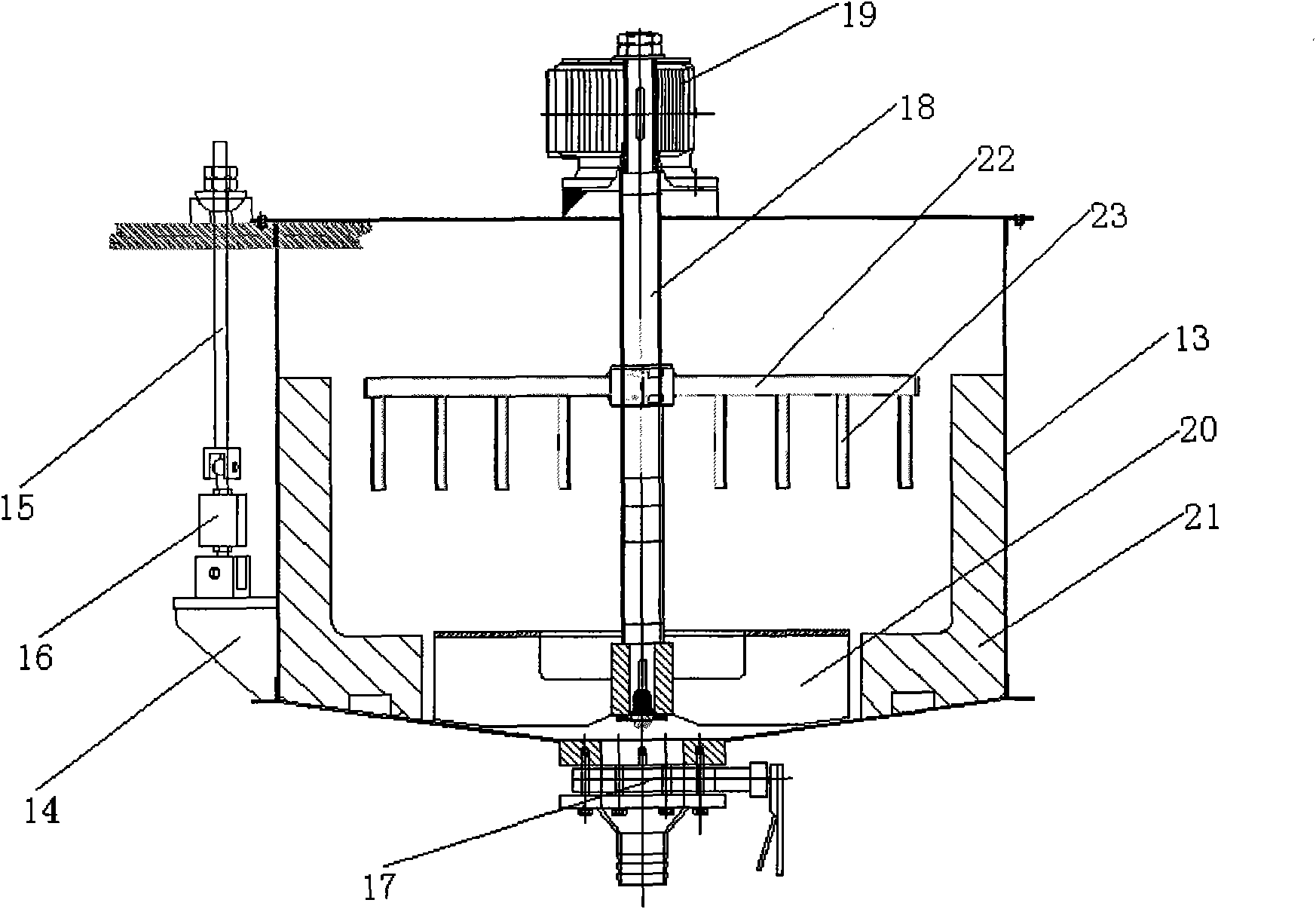

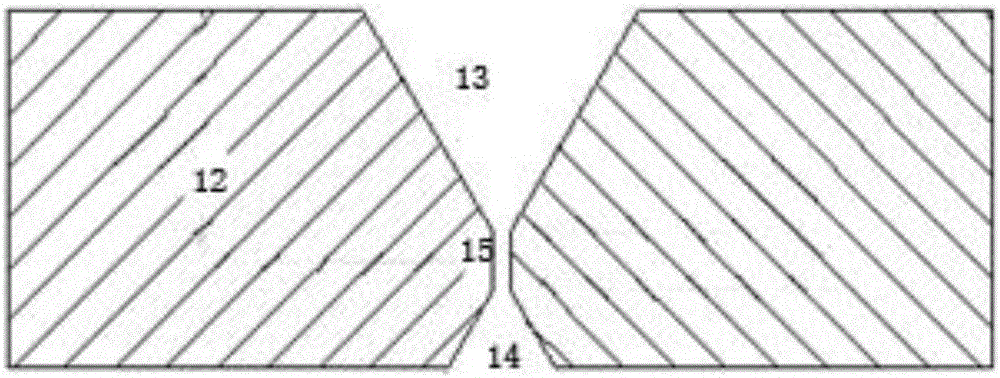

General stirring pumping perfusion vehicle of high and low elasticity model cement emulsified asphalt slurry

InactiveCN101629403AThe docking process is simpleMeet the needs of constructionDischarging apparatusMixing operation control apparatusEngineeringSlurry

The invention discloses a general stirring pumping perfusion vehicle of high and low elasticity model cement emulsified asphalt slurry, comprising an on-vehicle container frame. The on-vehicle container frame is internally provided with a stirring tank which is externally connected with a fluid material and dry material feeding system, and an on-line perfusion trolley is connected out of the stirring tank through a pumping feeding system; the fluid material and dry material feeding system comprises a dry material storage and a fluid material storage; the dry material storage is connected into a cylindrical tank body of the stirring tank through a helical conveyer; the fluid material storage is connected into the cylindrical tank body of the stirring tank through a transfer pipe with a control valve; the pumping feeding system comprises a mortar pump which is respectively connected with a feeding pipeline and a material supply pipeline; a discharge opening with a discharge valve is arranged at the bottom of the stirring tank of the perfusion vehicle; and the discharge valve is externally connected with a discharge pipeline with a manual butterfly valve. The invention adopts the large-volume design, realizes automatic loading and counting, satisfies the construction requirement, ensures even dosing and stirring, saves energy and protects the environment.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Medicinal composition of silibin

InactiveCN1714786AIncrease fat solubilityReduce manufacturing costOrganic active ingredientsMetabolism disorderOrganic solventMedicine

The present invention discloses a kind of medicinal composition containing silibin and its preparation process. Specifically, silibin and phosphatide are dissolved in organic solvent, the solution is heated and refluxed until becoming clear, and the solution is decompression concentrated to certain volume to obtain phosphatide dispersed matter, and the phosphatide dispersed matter is dried to obtain the medicinal composition.

Owner:TIANJIN TASLY PHARMA CO LTD

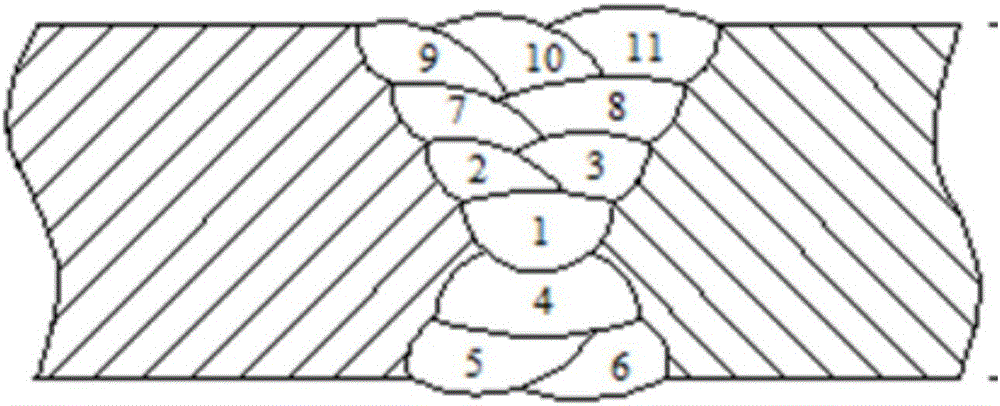

SMAW (shielded metal arc welding) process method for steel plates with 9% of Ni

InactiveCN105643067AQuality improvementQuality assuranceArc welding apparatusMetal working apparatusShielded metal arc weldingButt welding

The invention discloses an SMAW process method for steel plates with 9% of Ni. The process method is characterized in that an alternating current welding machine is adopted as a welding machine, nickel-based welding rods ENiCrFe-9 are adopted as welding rods, the diameter of the welding rods is 3.2 mm, drying treatment is performed before welding, and the welding rods are placed in an insulation barrel after drying to be available for any time; single edge grooves are opened in single edges of two steel plates with 9% of Ni requiring welding correspondingly, blunt edge thickness is reserved, gaps are reserved during opposite point welding assembly of the two steel plate groups with 9% of Ni requiring butt welding, X-shaped grooves are formed, rust, oil contamination and burrs on the surfaces of the grooves and in the vicinity of 20-30 mm are cleaned with a polishing machine and a file before welding, and metal luster is exposed; during welding, one surface with a large groove is welded firstly, turn-over back gouging is performed according to the workpiece deformation condition after 3-5 layers of welding, one surface with a small groove is fully welded by one time, and the other surface is turned to and the large groove is fully welded by one time. According to the SMAW process method for the steel plates with 9% of Ni, the welding process is optimized, and site construction is realized conveniently.

Owner:WUHAN YIYE STEEL STRUCTURE

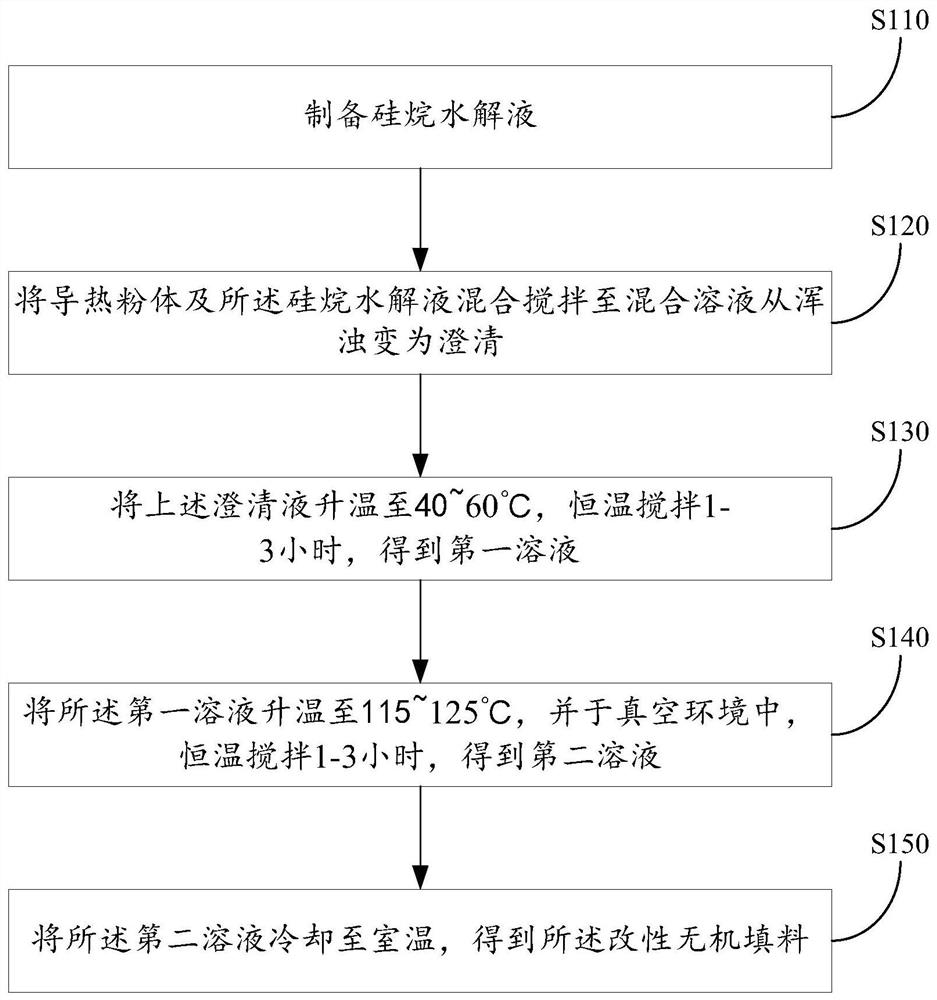

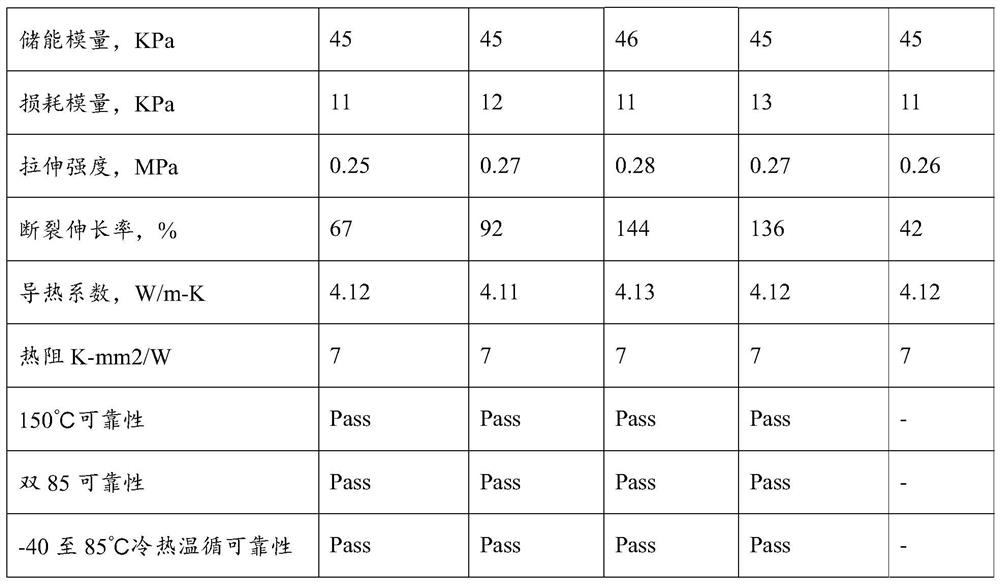

Preparation method of modified inorganic filler, modified inorganic filler and heat-conducting gel

PendingCN113667325AGood flexibilityGood lipophilic and hydrophobicHeat-exchange elementsPigment treatment with organosilicon compoundsHydrolysateResin matrix

The invention provides a preparation method of a modified inorganic filler, which comprises the steps of mixing and stirring heat-conducting powder and the silane hydrolysate until a mixed solution becomes clear from turbid, heating the clear solution to 40-60 DEG C, stirring for 1-3 hours at a constant temperature to obtain a first solution, heating the first solution to 115-125 DEG C, stirring for 1-3 hours at a constant temperature in a vacuum environment, obtaining a second solution, cooling the second solution to the room temperature, and obtaining the modified inorganic filler. According to the preparation method of the modified inorganic filler, through modification of special silane, long-chain functional groups with good compatibility are grafted to the surface of the heat-conducting powder, the modified inorganic filler has more excellent oleophylic and hydrophobic performance and is more tightly combined with a resin matrix, and the flexibility of the material is improved. In addition, the invention also provides a modified inorganic filler and heat-conducting gel.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

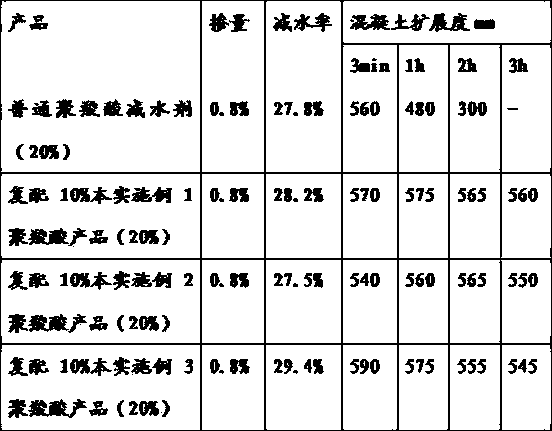

Super-strong slump retaining agent and processing method thereof

ActiveCN103724560AImprovement of the amount of change over timeSatisfy mixing transportationPotassium persulfateHigh intensity

The invention discloses a super-strong slump retaining agent. The super-strong slump retaining agent is composed of following raw materials: a, isopentenol polyoxyethylene ether, b, acrylic acid or methylacrylic acid or a mixture thereof, c, ethyl acrylate or propyl acrylate or a mixture thereof, d, allyl methacrylate, e, ammonium persulfate or potassium persulfate, and f, sodium methallyl sulfonate, wherein the mol ratio of the raw materials is as follows: a:b:c:d:f=1:(1.5-2.5):(1.5-2):(0.05-0.15):(0.3-0.6); the use amount of the e accounts for 0.5%-1.0% of the total weight of a, b and c. According to the slump retaining agent, the initial water-reducing rate is not influenced and the time-dependent change amount of the concrete slump degree is obviously improved; the loss of the slump degree can be not generated in three hours; the requirements of concrete agitating and transporting, pumping, pouring technical processes, and the high-strength requirements can be completely met; the super-strong slump retaining agent has good workability.

Owner:大连市铭源全科技开发有限公司

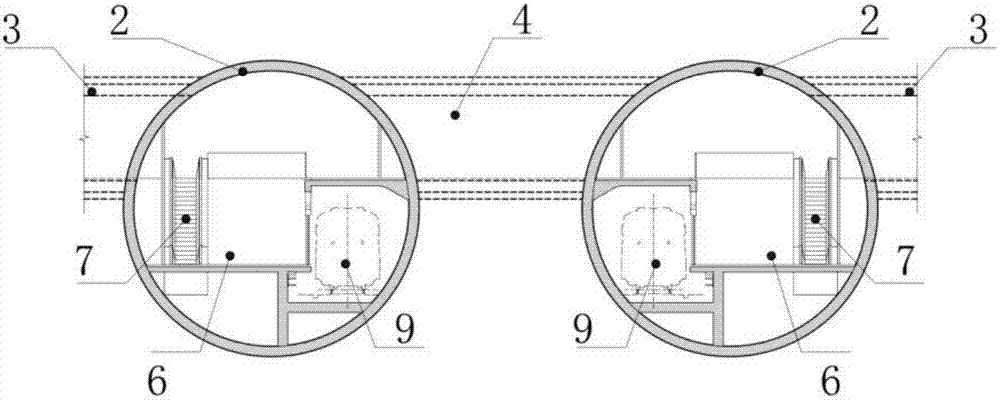

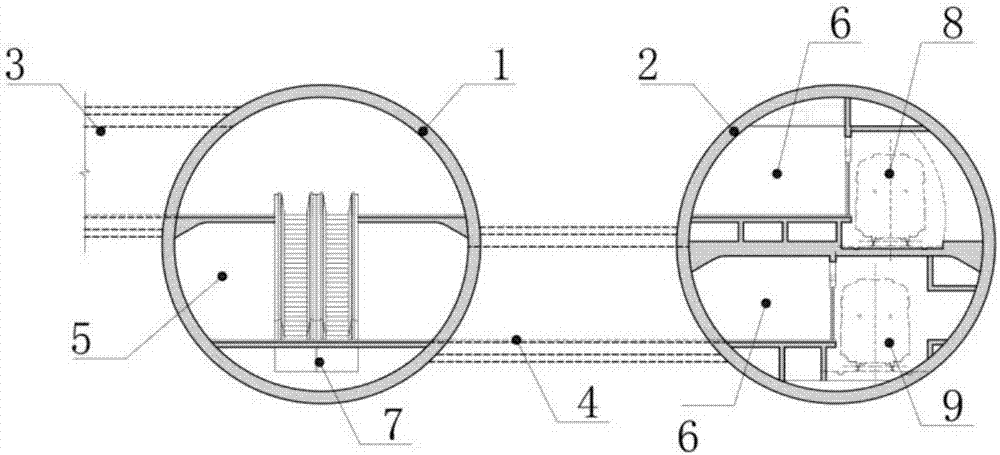

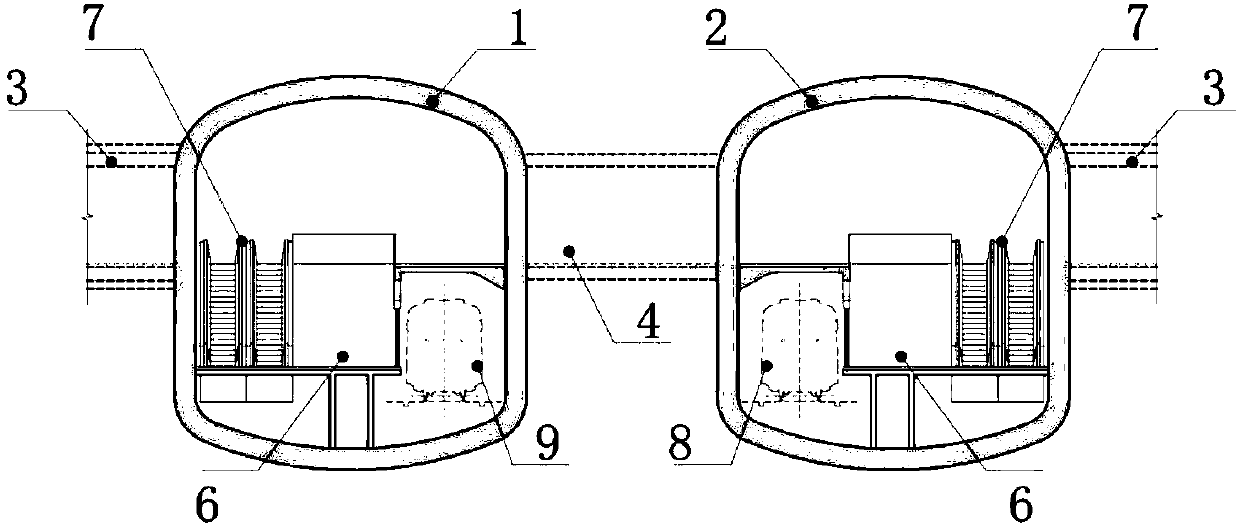

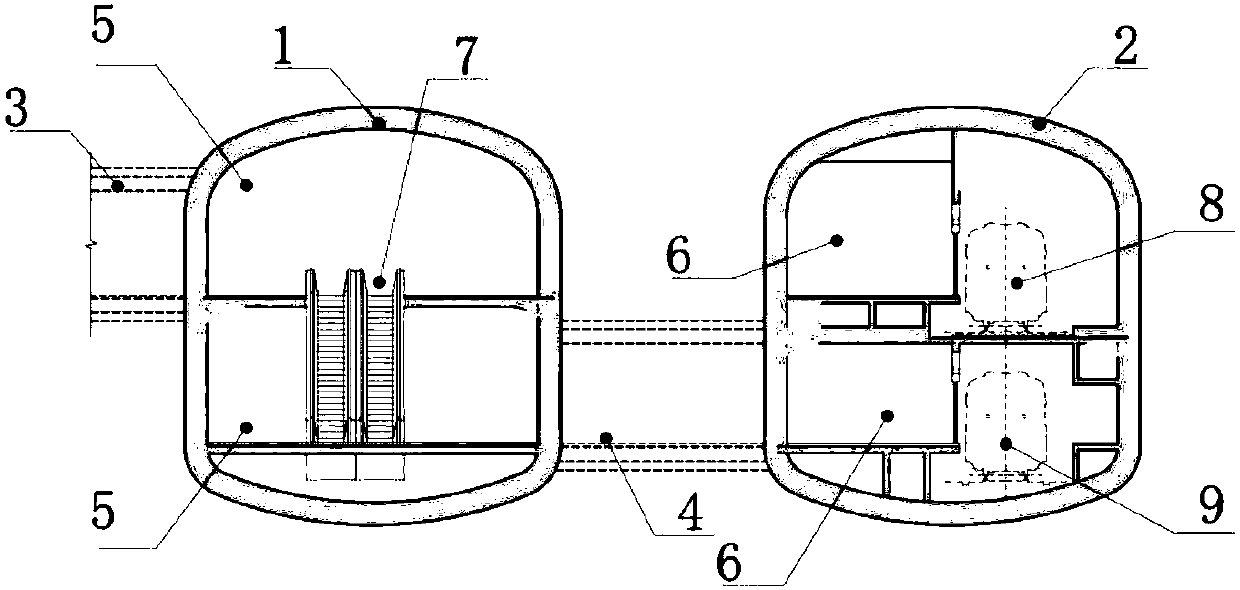

Metro station with double-hole double-layer ejector pipe space combination

PendingCN107559026AMeet craftSatisfy functionUnderground chambersTunnelsMetro stationStructural engineering

The invention discloses a metro station with double-hole double-layer ejector pipe space combination, and relates to the technical field of metro stations. The metro station comprises a first ejectorpipe double-layer tunnel and a second ejector pipe double-layer tunnel which are symmetrically arranged. The first ejector pipe double-layer tunnel communicates with the second ejector pipe double-layer tunnel through a transverse connecting channel. The outer sides of the tops of the first ejector pipe double-layer tunnel and the second ejector pipe double-layer tunnel are each provided with an inlet and outlet channel. Inner spaces of the first ejector pipe double-layer tunnel and the second ejector pipe double-layer tunnel are each divided into an upper layer space and a lower layer space through structural plates. Each upper layer space is internally provided with a platform and an escalator. A first line is arranged in the lower layer space of the first ejector pipe double-layer tunnel, and a second line is arranged in the lower layer space of the second ejector pipe double-layer tunnel. The metro station can effectively meet the station process and function, meanwhile, the project practicability is high, the construction risk can be reduced, pipeline relocation is reduced, traffic reconciliation is optimized, and the practicability is higher.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

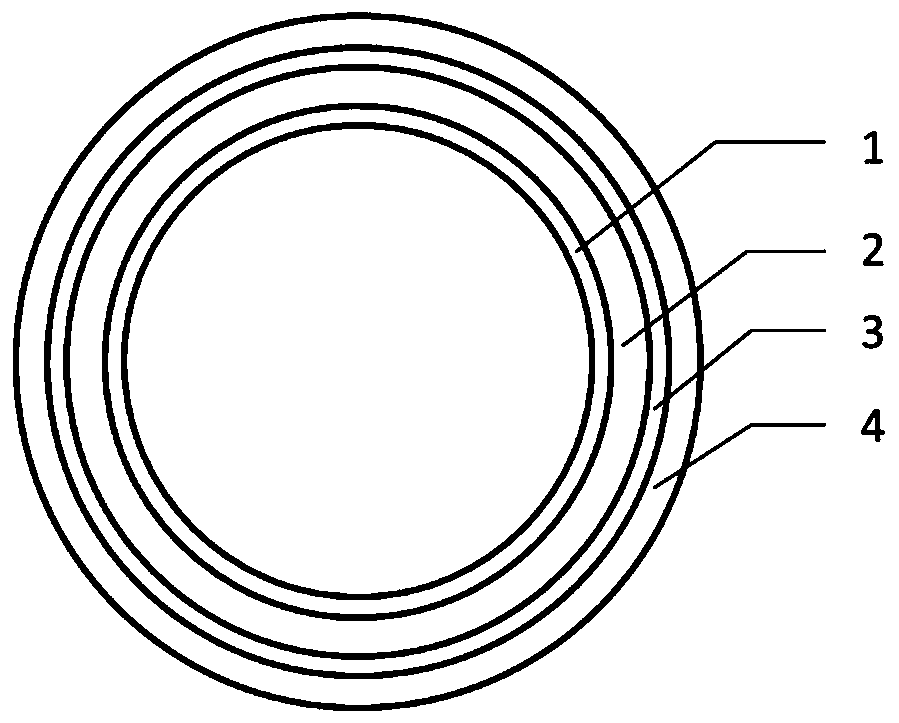

Pipeline suitable for conveying ultralow-temperature medium

PendingCN110513544AMeet craftFulfil requirementsPipeline expansion-compensationThermal insulationInsulation layerInsulation system

The invention discloses a pipeline suitable for conveying an ultralow-temperature medium. The pipeline comprises a pipeline body and a functional layer arranged on the outer surface of the pipeline body; the functional layer is sequentially provided with a heat-insulation system layer and an anti-collision protection outer layer from inside to outside; the heat-insulation system layer comprises acold-insulation material layer and / or a vacuum cold-insulation layer; the cold-insulation material layer is realized in the mode that the pipeline body is directly wrapped with a cold-insulation material; the vacuum cold-insulation layer comprises an inner-wall sleeve and an outer-wall sleeve, two layers of sleeve pipelines are connected through a support, and a vacuum is formed between the two layers of sleeve pipelines; and a concrete sleeve serves as the anti-collision protection outer layer. According to the pipeline, the pipeline body is paved with expansion joints and the cold-insulationto meet process and soil environment requirements, the pressure bearing capacity of the pipeline meets the road requirement, a comprehensive scheme meets the relevant requirements of the burying environment, and the problem that chemical raw materials at the ultralow temperature (minus 162 DEG C) cannot be conveyed in a buried mode can be solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of high-nitrogen-content nitrified bamboo cellulose

The invention relates to a preparation method of high-nitrogen-content nitrified bamboo cellulose, and belongs to the field of nitrocellulose preparation. The method comprises the following steps: half-immersing a pressure-resistant three-opening device filled with nitric acid in a high-precision low-temperature constant-temperature tank, adding acetic anhydride into the nitric acid, stirring, adding a nitrification aid after complete dissolution, heating, and keeping the temperature to obtain a solution A; adding bamboo cellulose into the solution A, stirring for 20-40 minutes, sealing the reaction device, heating to 40-60 DEG C, keeping the temperature for 4-6 hours, filtering, and washing and drying filter residues to obtain a nitrified bamboo cellulose crude product; dissolving the crude product in water, and adding dilute sulfuric acid and a solution B; and filtering and drying to obtain the high-nitrogen-content nitrified bamboo cellulose. The preparation method disclosed by theinvention is simple in process, easily available in raw materials, low in waste acid discharge amount in the production process and suitable for factory operation; and the prepared product has high nitrogen content and meets the process parameter requirements of high-quality smokeless and sulfur-free pyrotechnic composition, propellant and explosive.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com