General stirring pumping perfusion vehicle of high and low elasticity model cement emulsified asphalt slurry

A cement emulsified asphalt and mixing pump technology, which is applied to cement mixing devices, tank trucks, transport buses, etc., can solve the problems of high labor intensity of workers, affecting construction ability, and numerous construction procedures, so as to be beneficial to environmental protection and reduce labor intensity , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

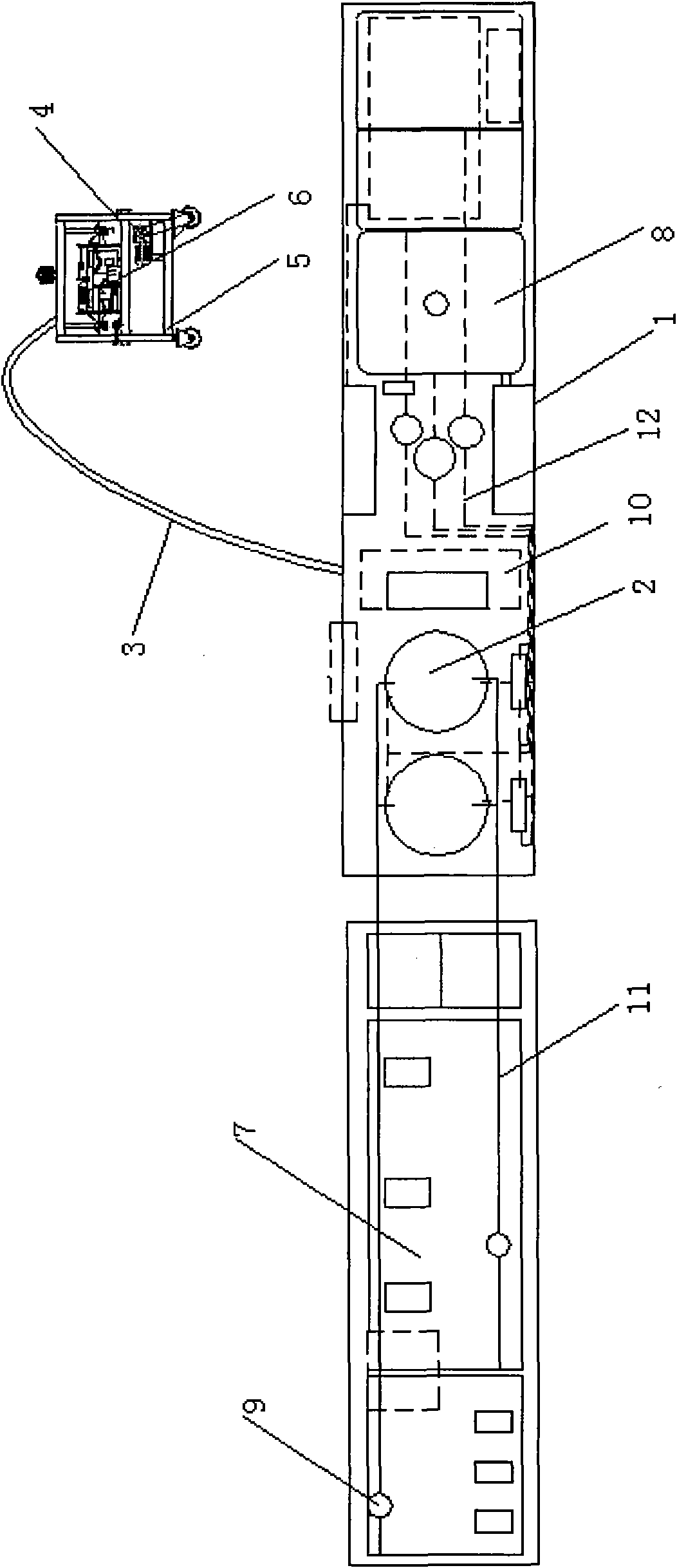

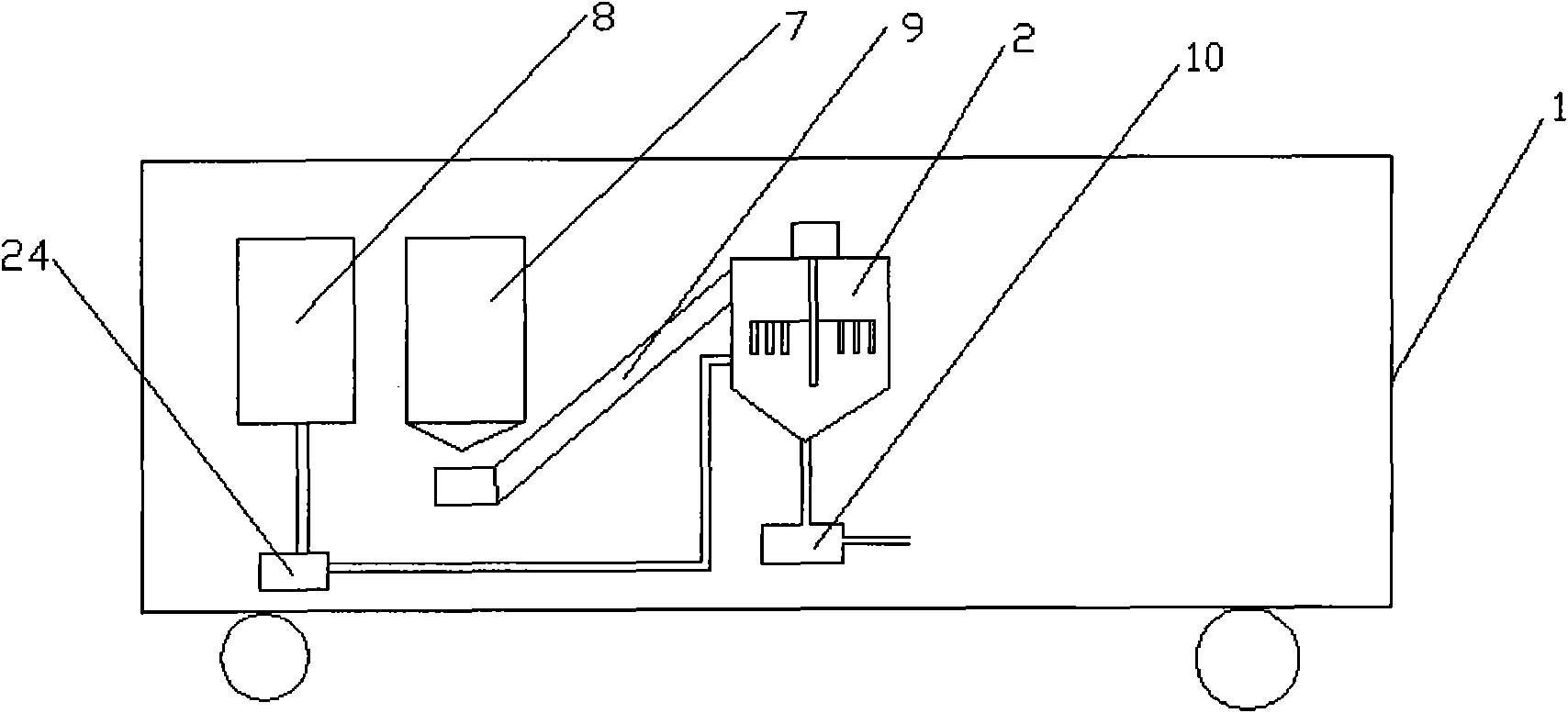

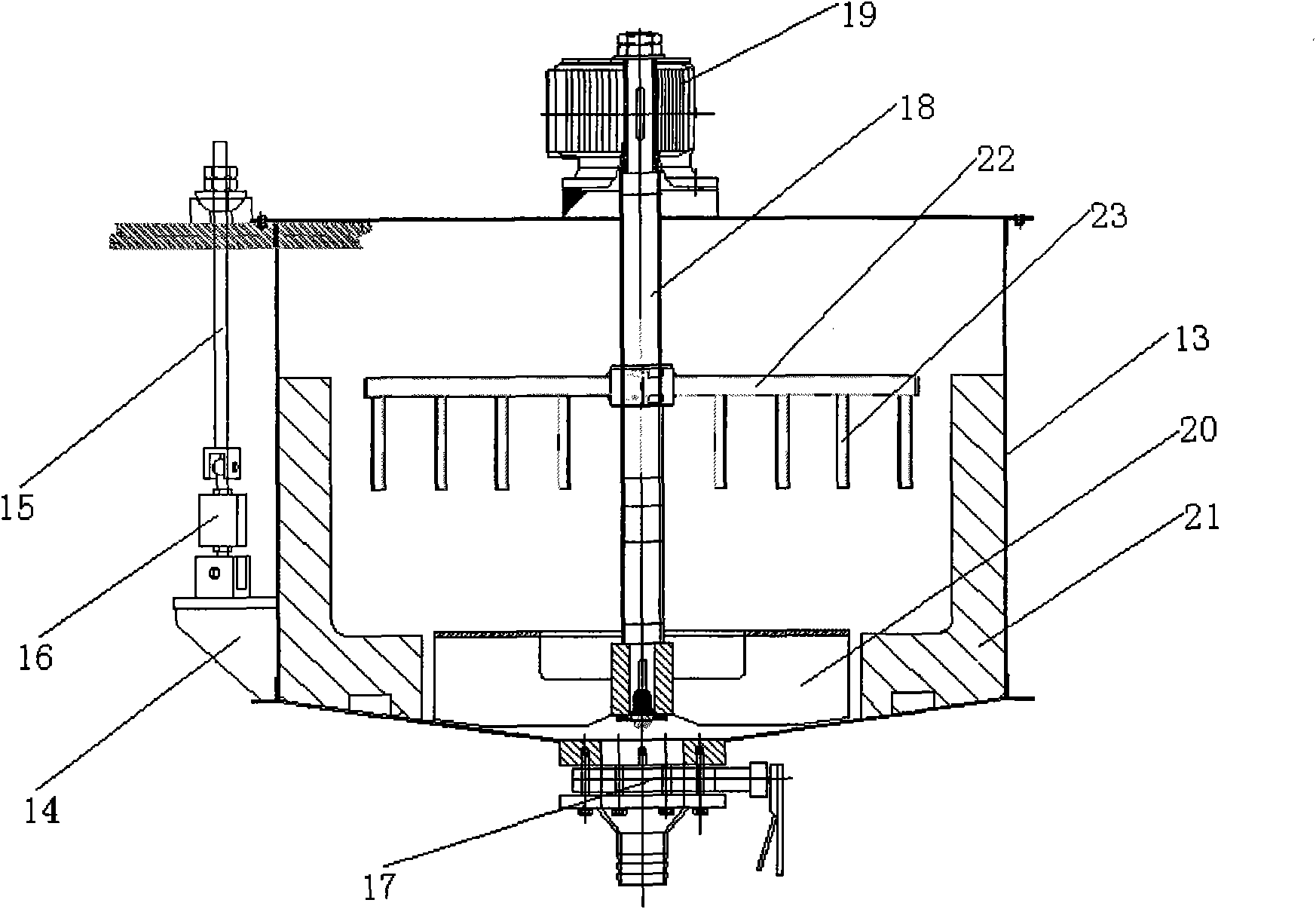

[0017] Referring to the accompanying drawings, the high- and low-elastic-modulus cement-emulsified asphalt mortar universal mixing and pumping pouring vehicle includes a vehicle-mounted container frame 1, a mixing tank 2 is arranged inside the vehicle-mounted container frame 1, and a liquid material supply system 11 is connected to the outside of the mixing tank 2 1. Dry material feeding system 12, the bottom of the mixing tank 2 is connected to the on-line filling trolley 4 through the pumping feeding system 3, and the on-line filling trolley 4 is composed of a traveling frame 5 and a small mixing tank 6 installed on the traveling frame; The mixing tank includes a cylindrical tank body 13 fixedly arranged in the vehicle-mounted container frame 1, at least three lifting lugs 14 are fixedly installed on the outer wall of the cylindrical tank body 13, and a suspender 15 is connected between the lifting lugs 14 and the vehicle-mounted container frame 1 , the lower end of the boom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com