Labeling machine used for installing handle on PET container

A labeling machine and labeling technology, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems of high additional energy consumption, complexity, and high additional investment cost space requirements, and achieve the effect of reducing investment costs and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

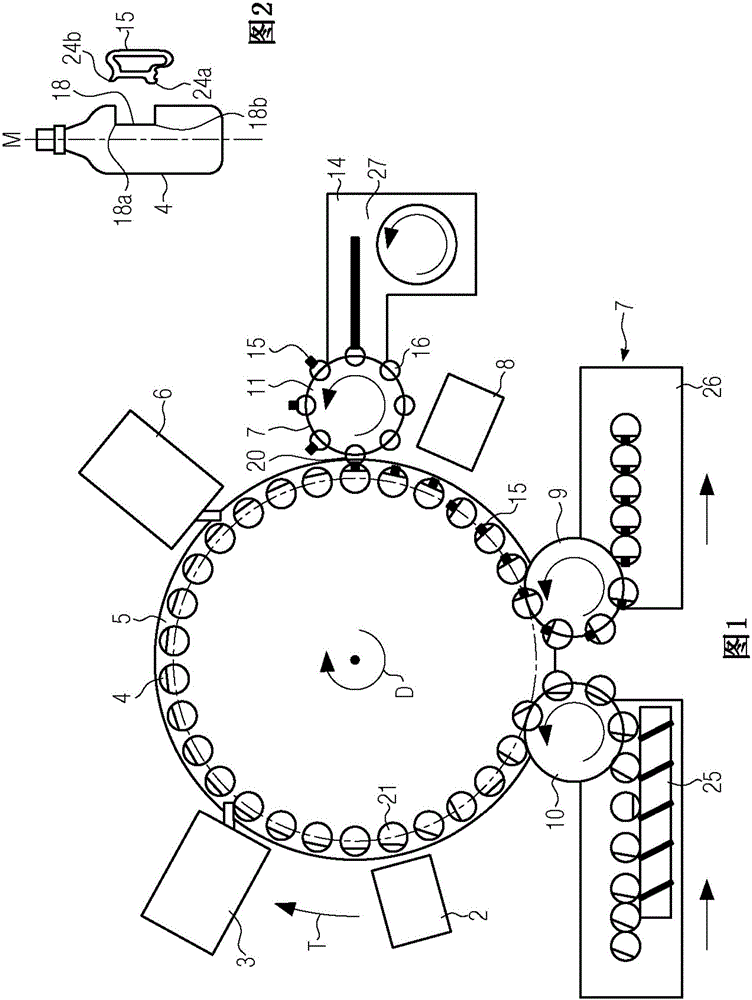

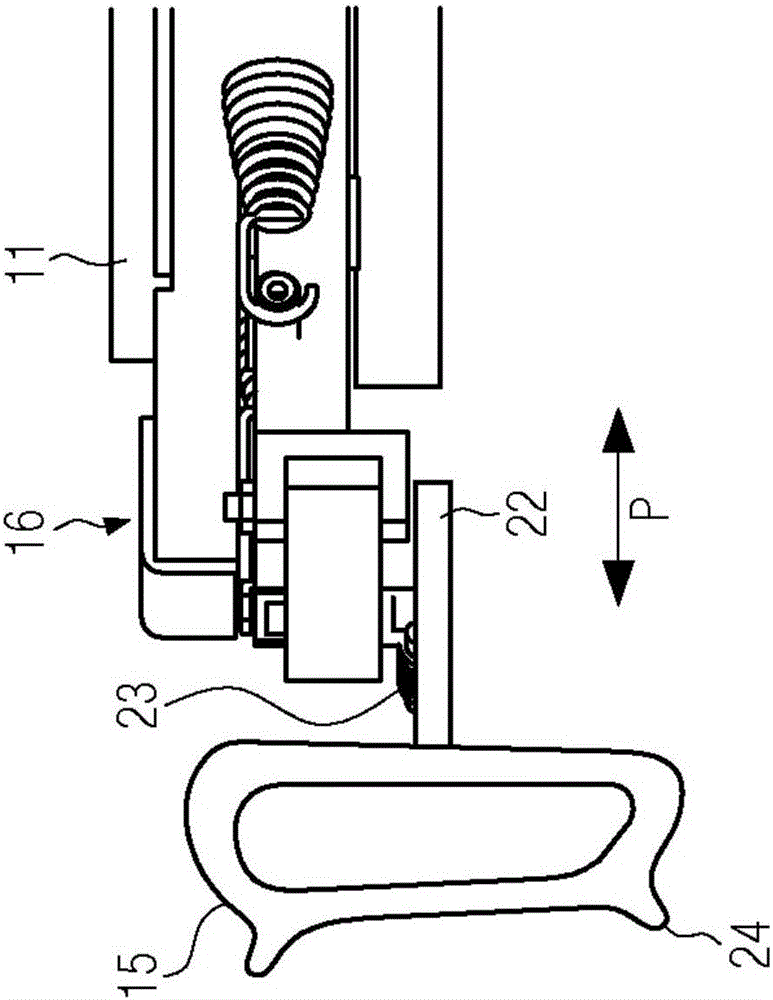

[0028] figure 1 An embodiment of a labeling machine according to the invention is shown. In this exemplary embodiment, the labeling machine is designed as a rotary labeling machine.

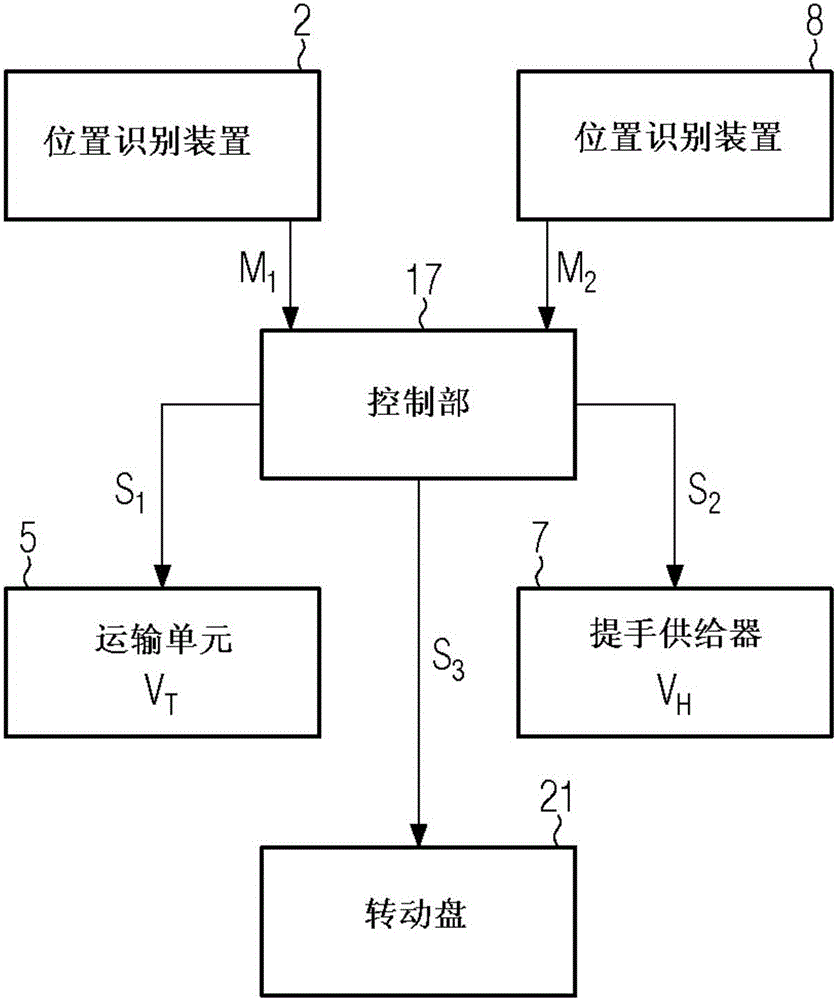

[0029] The labeling machine 1 here has a container infeed 10 in the form of an infeed star wheel, to which, for example, PET containers 4 , here bottles, are conveyed via a one-piece screw 25 . Furthermore, the labeling machine comprises a transport unit in the form of a turntable which, as indicated by the arrow, rotates about a central axis D in the transport direction T. The turntable has a plurality of rotating disks 21 arranged at equal distances on a common circle, on which PET containers are erected and held in a known manner. The turntable 5 also has a delivery star 9 via which the labeled PET containers equipped with handles 15 can be transported to a removal device 26 .

[0030] Finally, the labeling machine 1 has a first position detection device 2 which is able to detect the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com