Sectional type blade of large-scale wind power generator set and connecting method for sectional type blade

A technology of wind turbines and connection methods, which is applied to wind turbine components, wind power generation, wind engines, etc., can solve the problems of blade manufacturing, processing and transportation difficulties, and achieve the effects of low cost, reliable connection and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

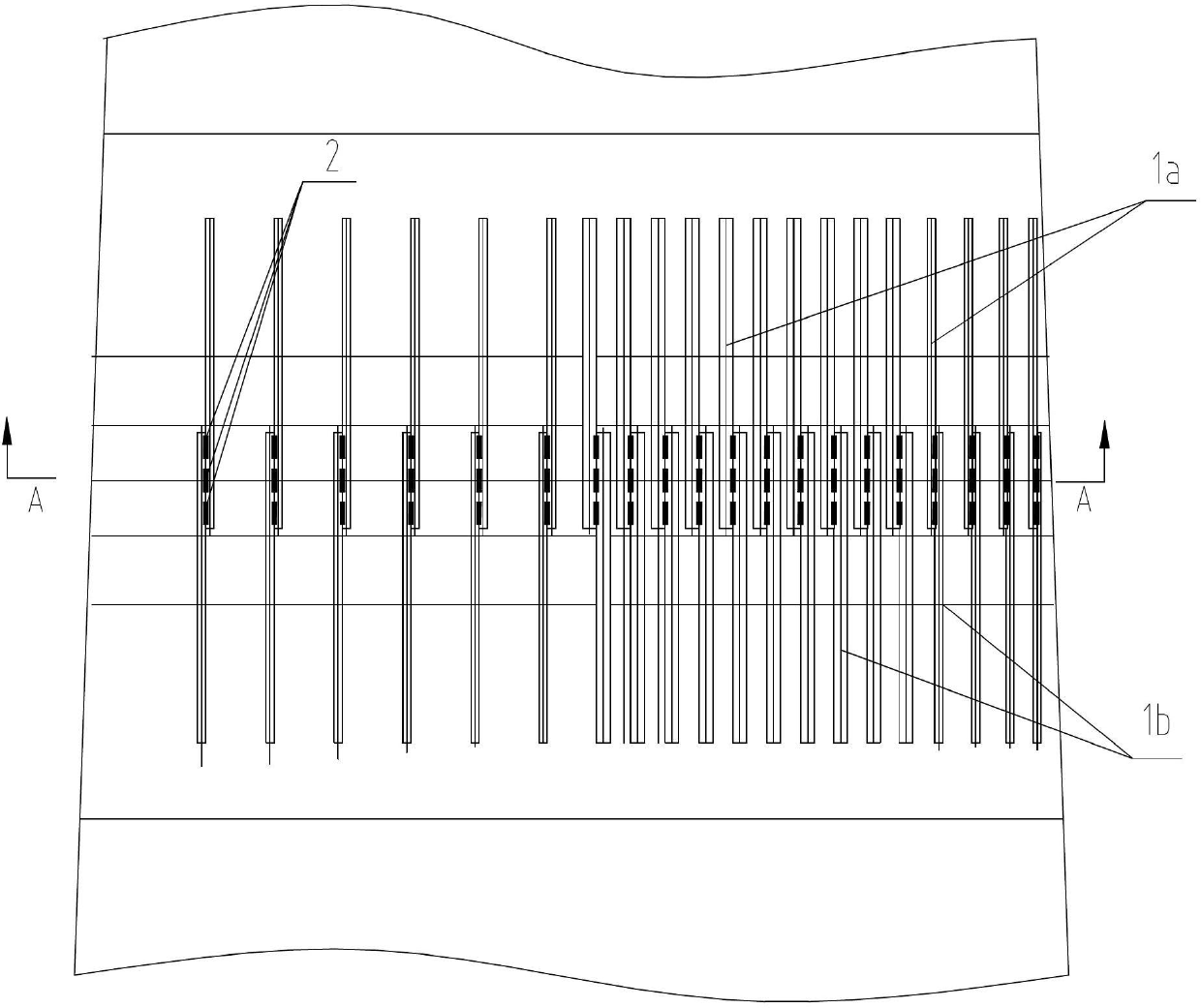

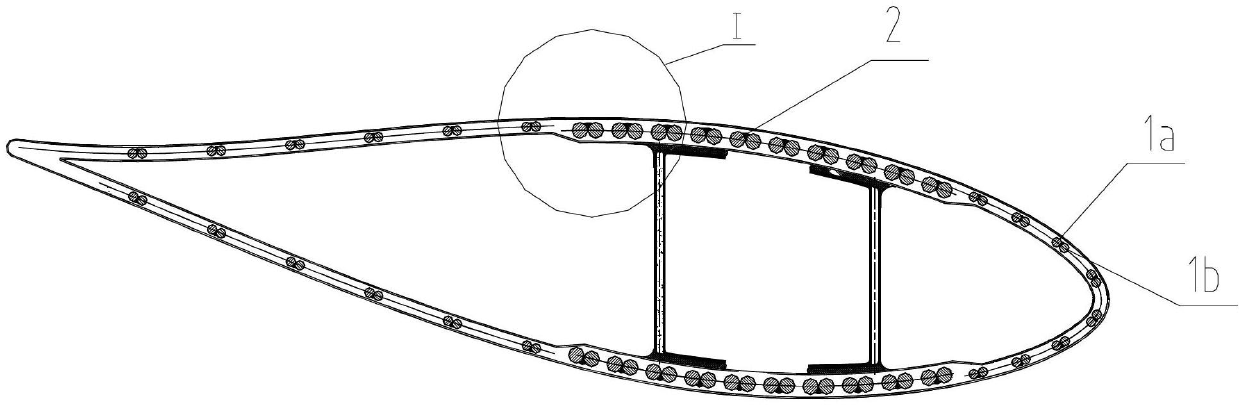

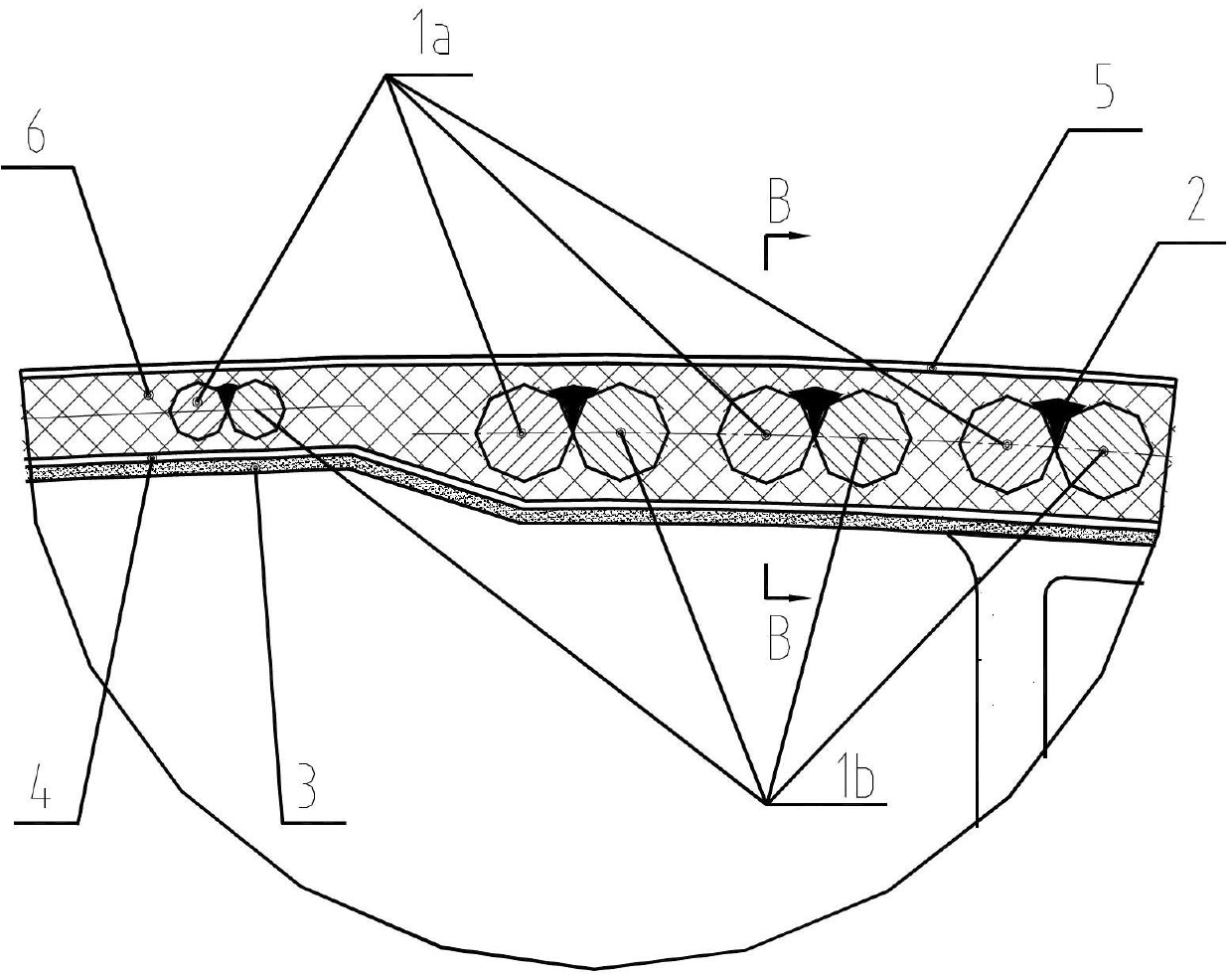

[0033] A segmented blade of a large-scale wind turbine of the present invention, the blade is made into two sections: a blade root section and a blade tip section, such as Figure 1-Figure 4 shown. A set of threaded steel 1a is pre-embedded in the blade shell of the joint of the blade tip section, and a set of threaded steel 1b is pre-embedded in the blade shell of the joint of the blade root section, and part of the length of the threaded steel 1a and 1b is exposed at the same time; each section The joint parts of the steel bars 1a and 1b are connected by lap welded structure, and the weld seam is 2; the inside of the area of the lap welded structure of threaded steel 1a and 1b is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com