Patents

Literature

71results about How to "Play a leading role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

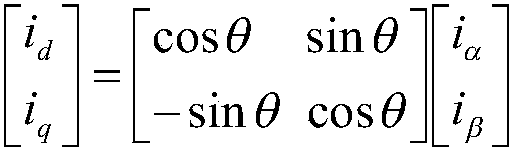

Sliding-mode variable structure control method of variable exponential coefficient reaching law of permanent magnet synchronous motor

InactiveCN106549616AIncrease approach speedReduce buffetingElectronic commutation motor controlAC motor controlState variableControl system

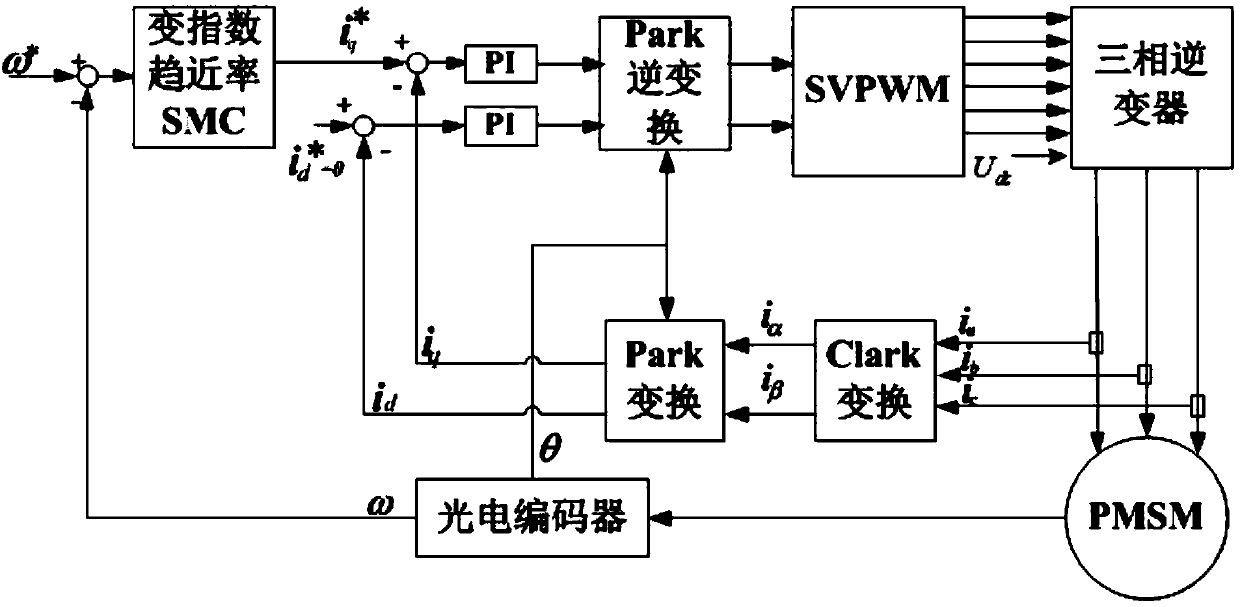

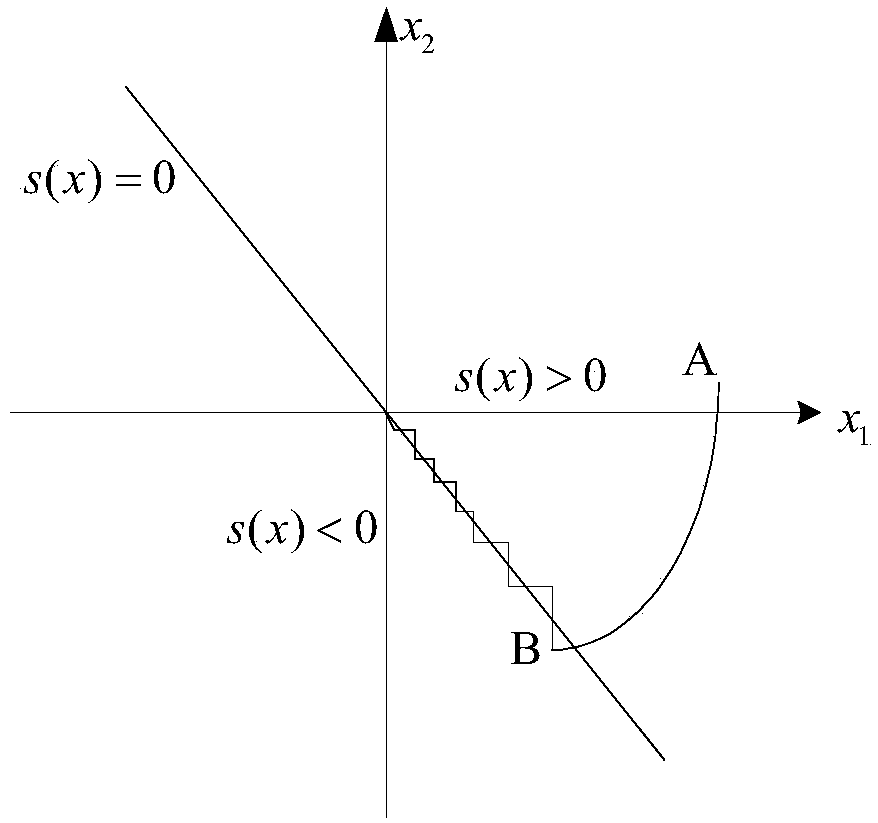

The invention discloses a sliding-mode variable structure control method of a variable exponential coefficient reaching law of a permanent magnet synchronous motor. The method comprises the following steps: aiming at the requirements of a control system of a high-performance permanent magnet synchronous motor, a variable exponential function term formula is introduced on the basis of a conventional exponential reaching law; the formula takes a first-order norm of systematic state variables as an exponent of exponential functions, adaptively adjusts the reaching speed of a variable exponent term and a variable speed term according to the distance between the system and a sliding-mode surface, and is helpful to increase the dynamic response speed of the system; the systematic state variables are associated by taking the first-order norm of the systematic state variables as the exponent of the functions; and an s function is introduced to replace a symbolic function for further suppressing system chattering. Therefore, the sliding-mode variable structure control method of the permanent magnet synchronous motor using the variable exponential coefficient reaching law is provided. Compared with an integral-type sliding-mode variable structure control method, the method disclosed by the invention can be used for effectively increasing the dynamic characteristics and steady state characteristics of the system as well as increasing the robustness of the system.

Owner:JIANGSU UNIV

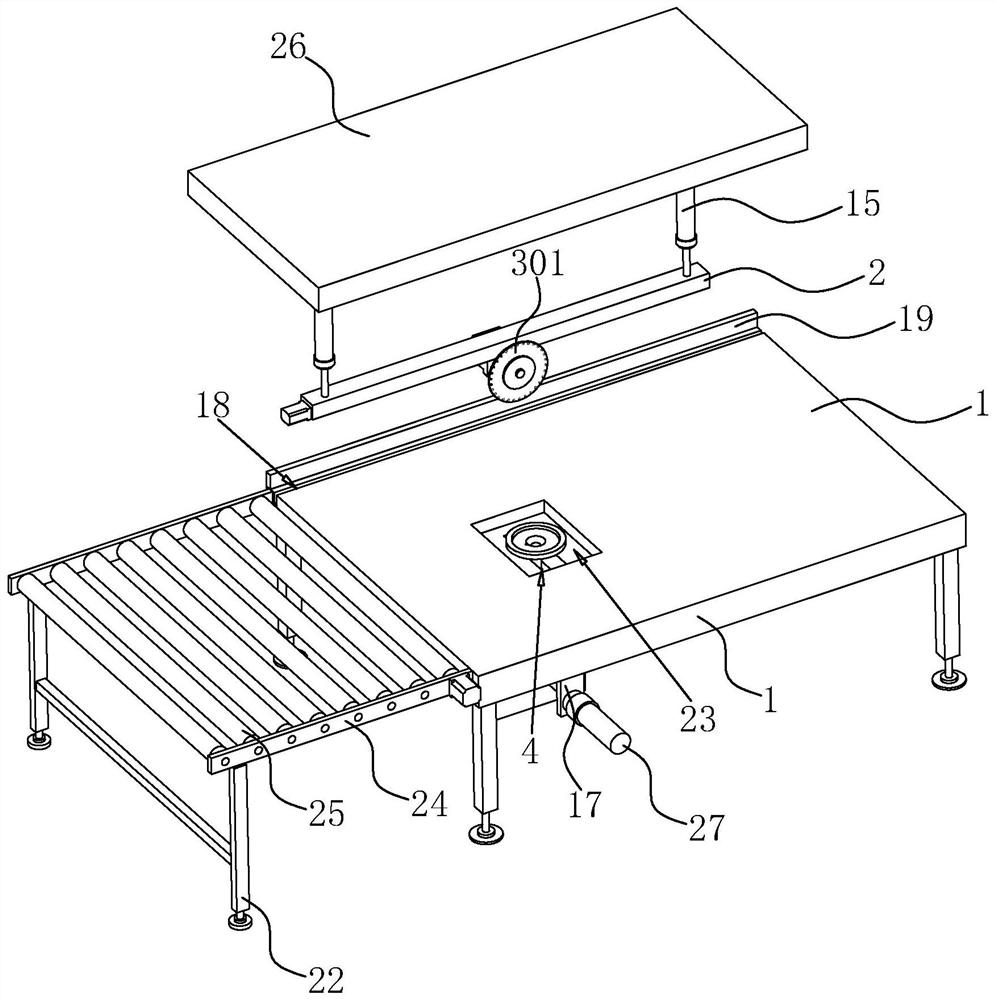

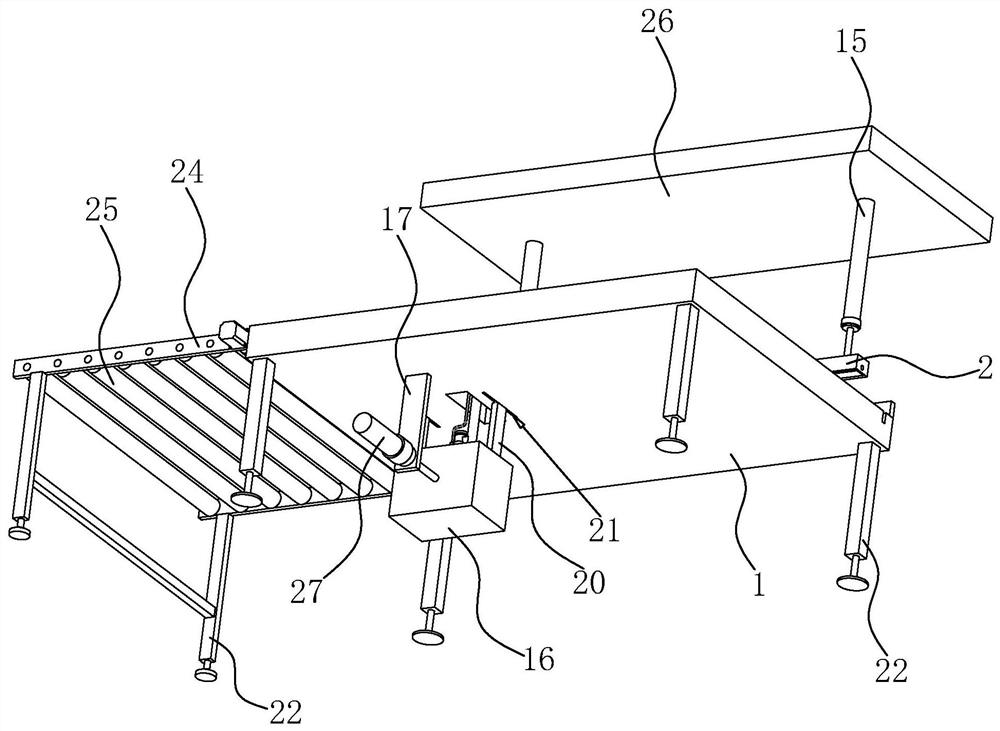

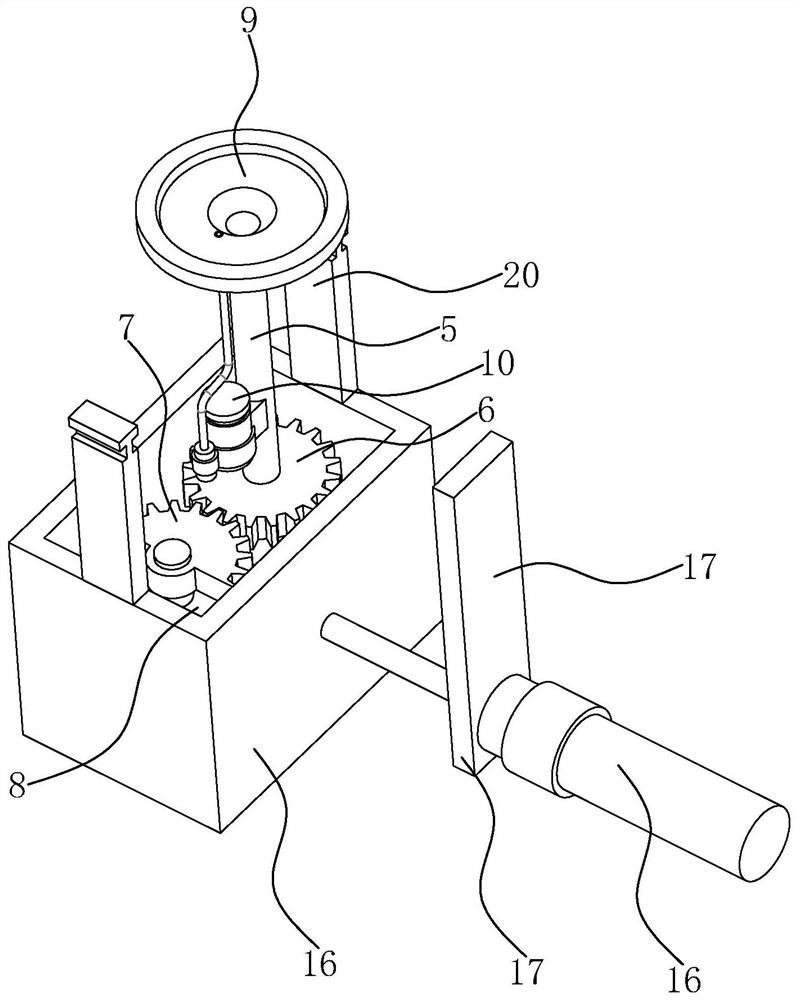

Testing machine for adjusting durability of car steering column

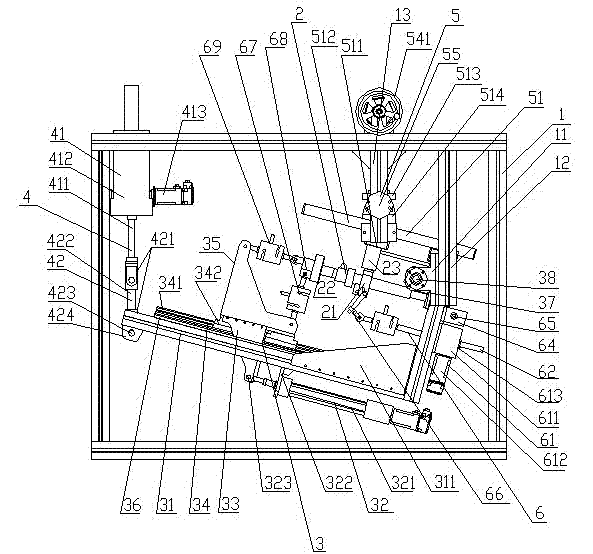

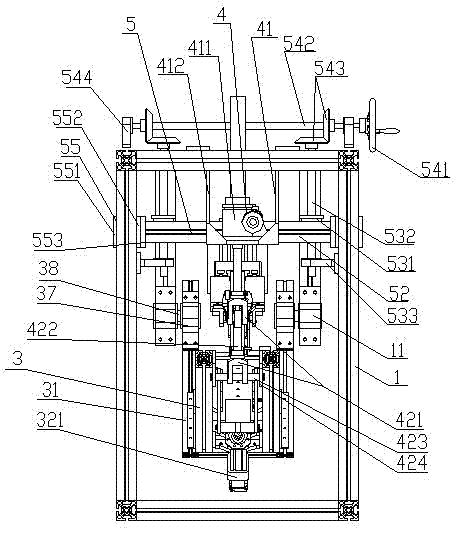

InactiveCN103207072ASolve the technical defects that cannot accurately simulate the operation of the steering wheel by peopleGuaranteed accuracyMachine part testingSteering columnData acquisition

The invention provides a testing machine for adjusting the durability of a car steering column. The testing machine comprises a column clamping apparatus and is configured with a data acquisition and processing system. The column clamping apparatus enables a tested steering column to be mounted according to a real car position and can clamp the steering columns of different models for testing. An axial adjusting apparatus drives a piston rod of the tested steering column to stretch and retract under the traction of an electric cylinder and simulates axial adjustment of the steering column. A radial adjusting apparatus simulates radial adjustment of the tested steering column under the traction of an elevator. An unlocking apparatus simulates unlocking and locking of a user to the steering column. An axial force sensor, a radial force sensor and an unlocking force sensor record measured force of a test. According to the testing machine, the testing method is convenient and efficient, the tested steering column simulates an actual utilization condition accurately for testing, the testing machine suits related ideas about adjusting durability testing of car steering columns, and the accuracy and the stability of the test results are guaranteed.

Owner:SHANGHAI UNIV

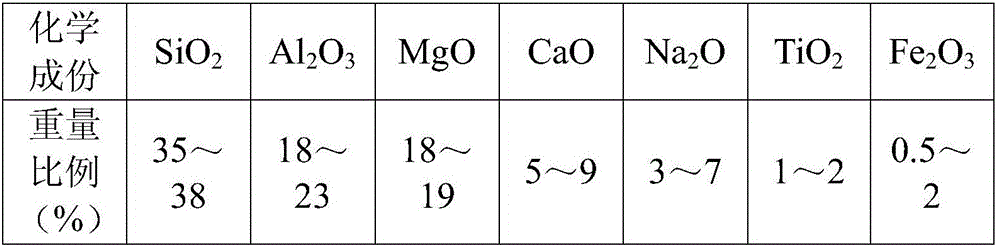

Microcrystalline glass produced from fly ash through all-electric melting calendaring process and production method thereof

ActiveCN105924014AMaintain healthTurn waste into treasureGlass rolling apparatusSlagGreen manufacturing

The invention discloses a microcrystalline glass produced from fly ash through an all-electric melting calendaring process, and a production method thereof. The microcrystalline glass is prepared from 320 to 350 parts by weight of fly ash used as a main raw material and accessory materials consisting of 98 to 115 parts by weight of light-burnt magnesia, 55 to 66 parts by weight of ground calcium carbonate, 42 to 44 parts of sodium carbonate and 2 to 3.5 parts by weight of titanium dioxide by using the all-electric melting calendaring process. The production method mainly comprises the following steps: mixing and melting of the raw materials; calendaring and molding; annealing; nucleation and crystallization; and surface treatment. The production method provided by the invention can consume a great amount of slag waste, turn the waste into the valuable, improve the environment and promote economic development; the production method also realizes green manufacturing, broadens the application space of the calendared microcrystalline glass as a base material and guides consumers to carry out green consumption; and the production method increases the varieties of microcrystalline glass products, improves market competitiveness of microcrystalline glass products and maximally meets consumption demands of different industries and different populations.

Owner:四川一名微晶科技股份有限公司

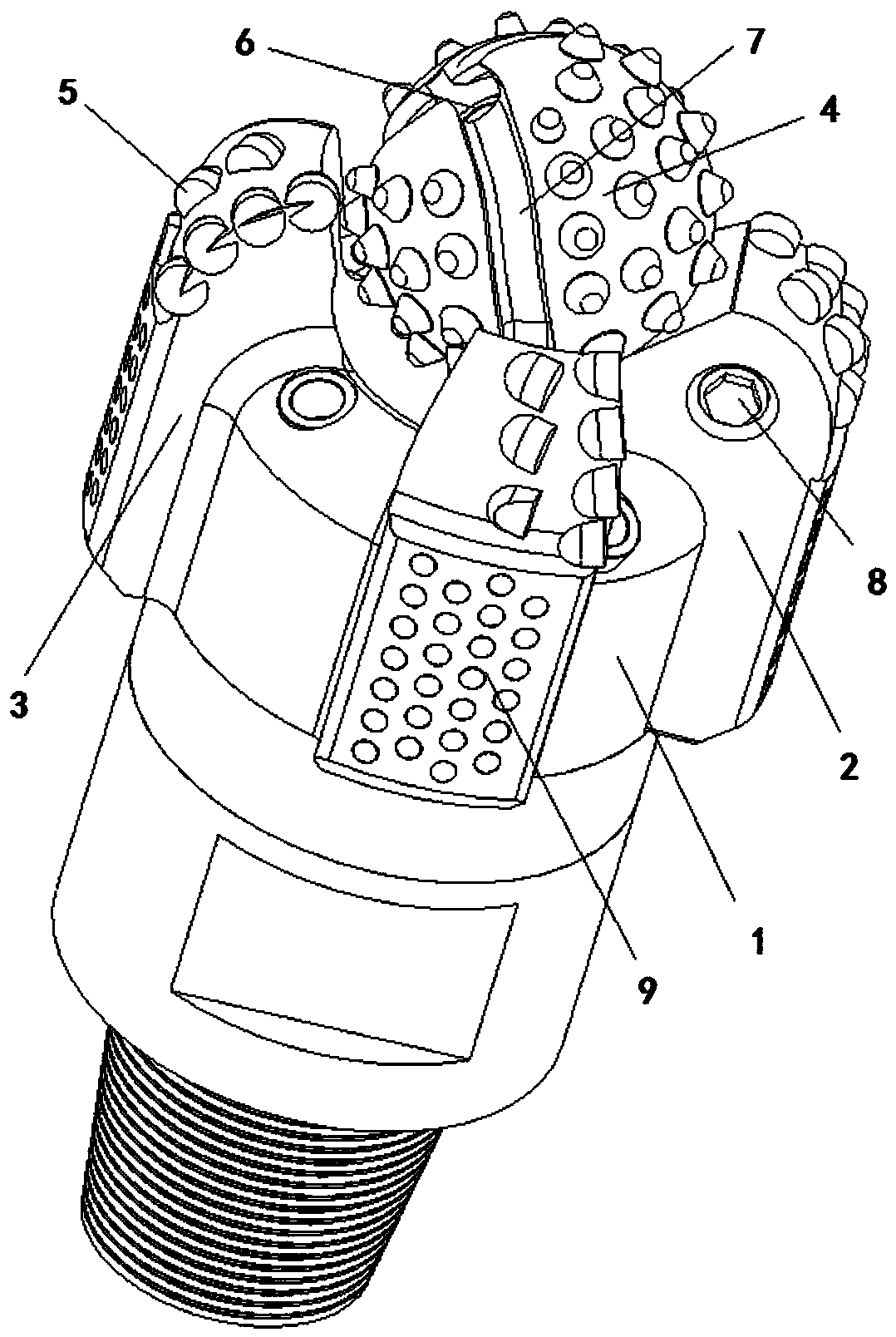

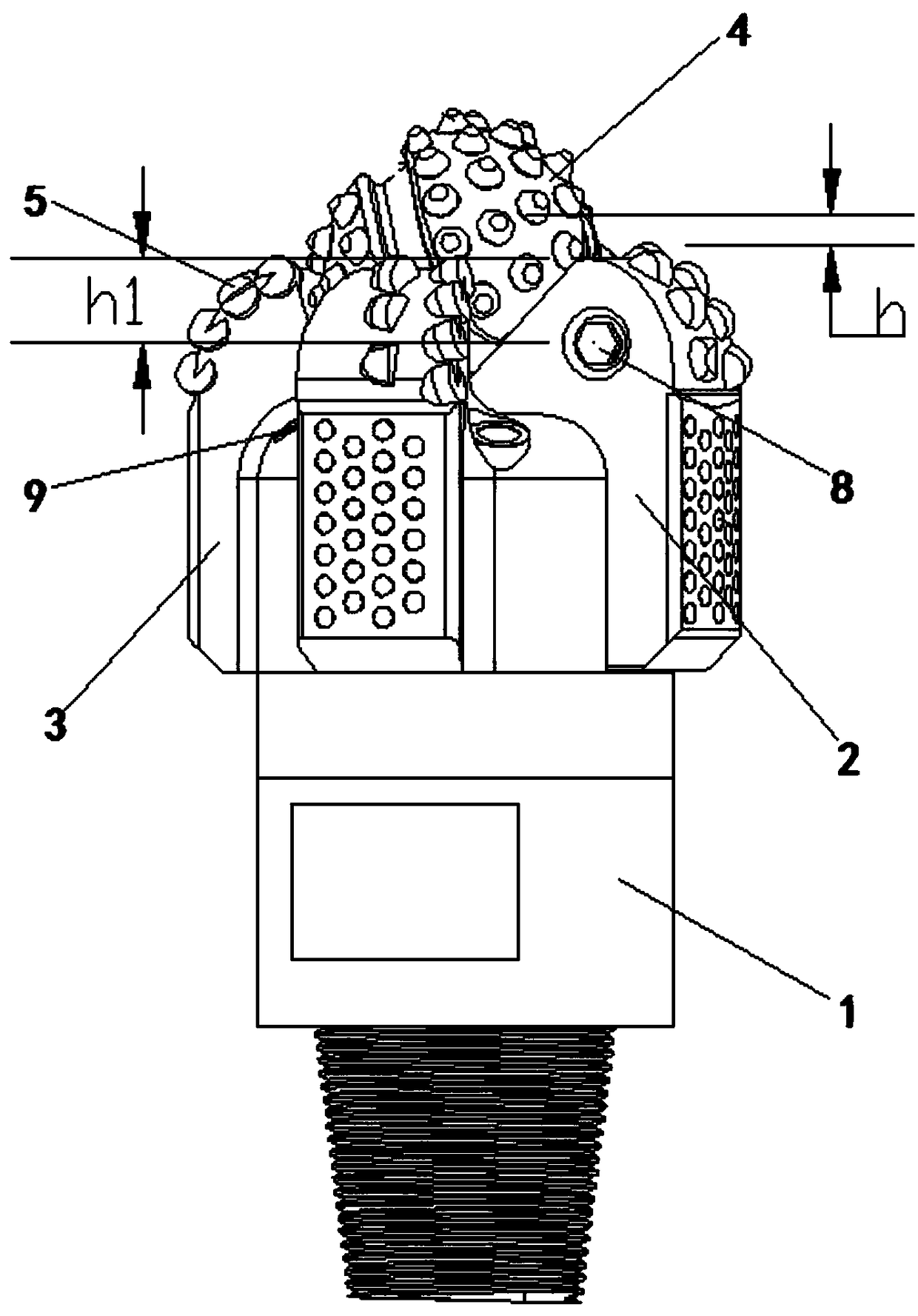

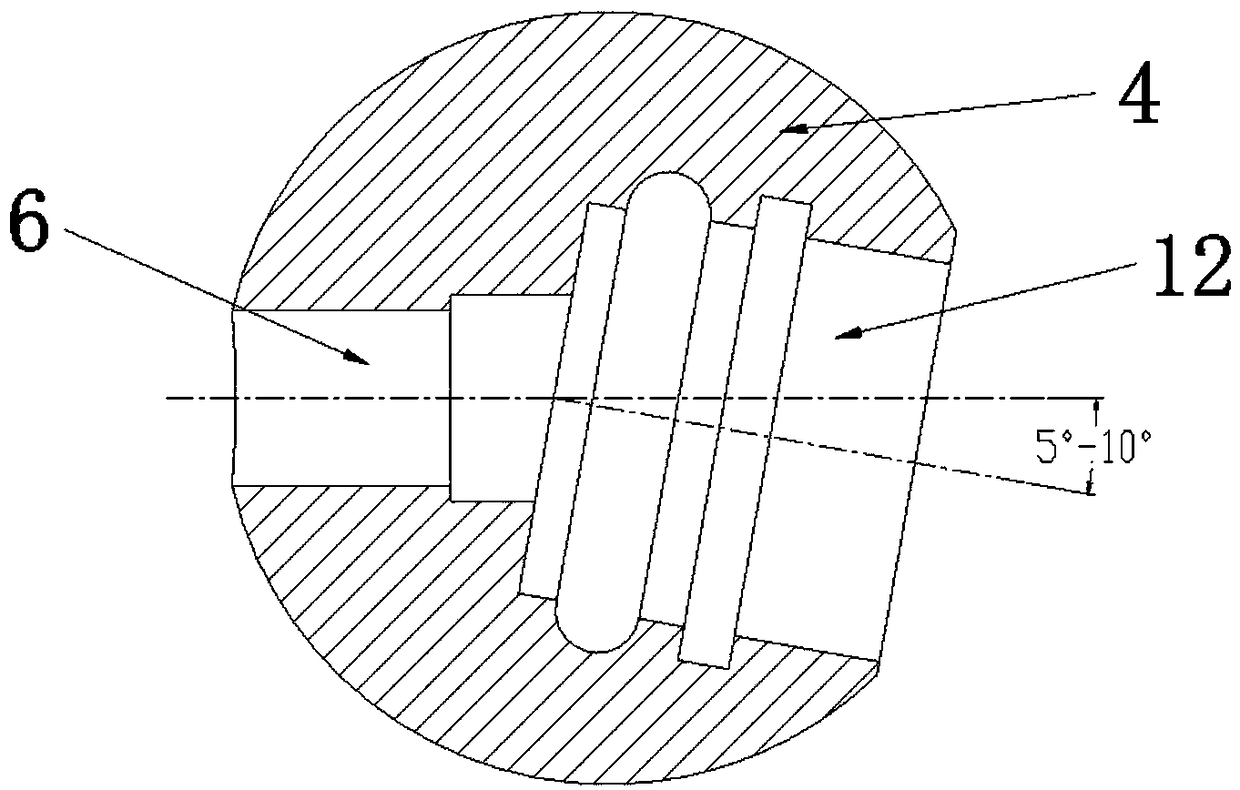

Novel pdc and roller cone composite drill bit

The invention discloses a novel pdc and roller cone composite drill bit. The novel pdc and roller cone composite drill bit comprises a drill bit body, a roller cone palm, a cutting blade, and a spherical roller cone. The spherical roller cone is installed the roller cone palm. The outer sides of the roller cone palm and the cutting blade are provided with pdc cutting teeth and fixed on the drill bit body. The spherical roller cone is positioned above the drill bit body, and a center line of the spherical roller cone is coincided with an axis of the drill bit body. A vertical distance between asphere center position of the spherical roller cone and a highest point of the cutting blade is within a range of 18-29 mm. The side face of the roller cone palm is provided with an oil storage seal.According to the related novel composite drill bit, in a drilling process, a bit pressure is shared by the pdc cutting teeth and the roller cone together, a pressure applied to each tooth is reduced,the wear-resistant capacity of the drill bit is improved, thereby the service life of the whole drill bit is prolonged. In addition, because a position of the oil storage seal is closer to the top ofthe drill bit, a sensitivity of a drill bit lubricating system for sensing a bottom hole pressure is improved, and the drill bit is positioned in the better lubricating environment, so the service life of the drill bit is improved.

Owner:SOUTHWEST PETROLEUM UNIV

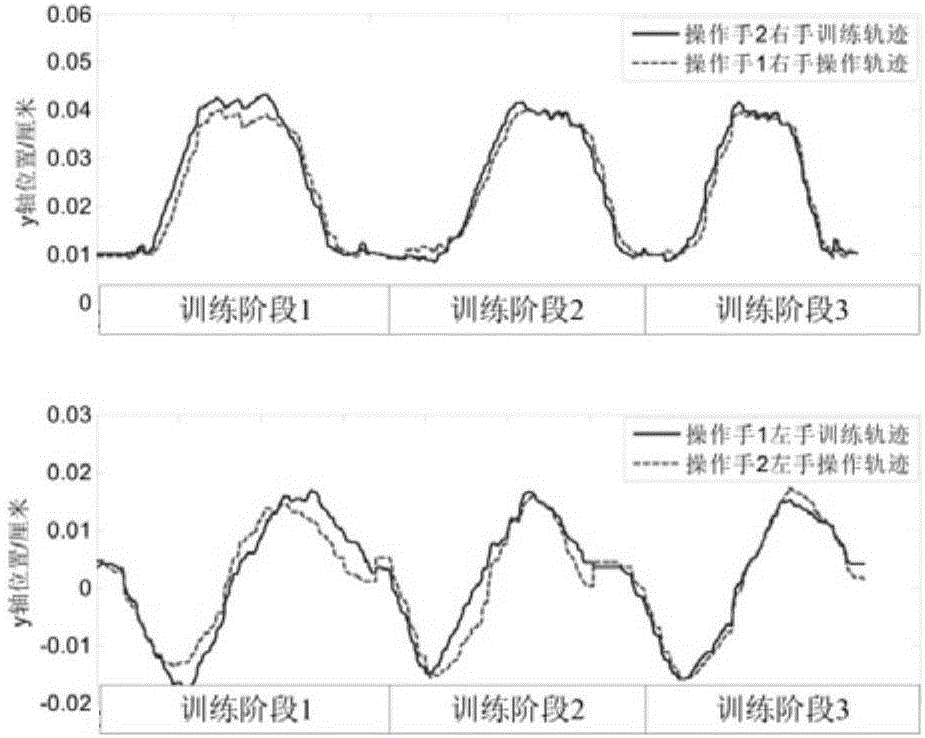

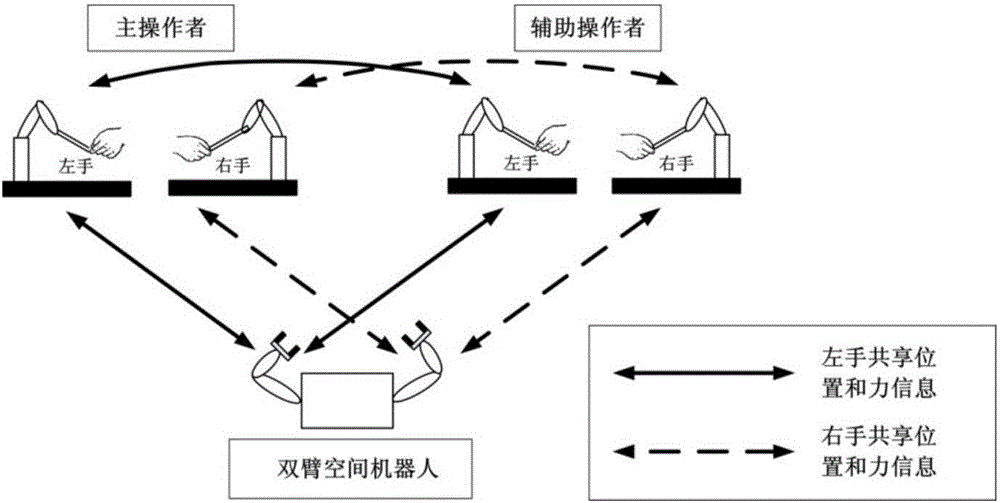

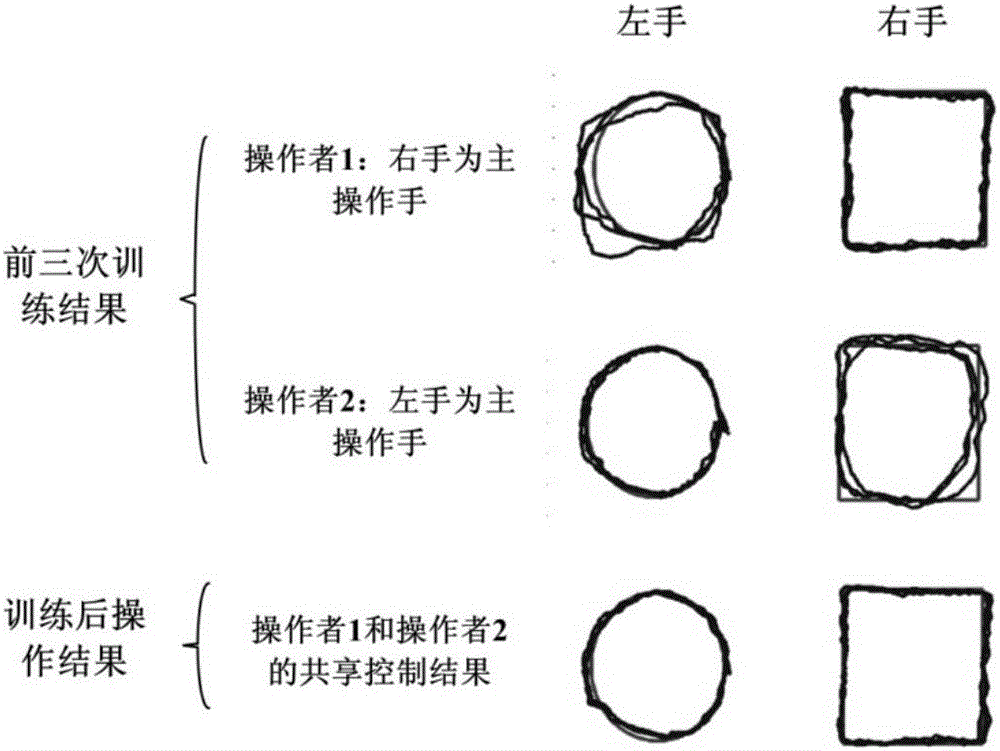

Dual-arm robot teleoperation control system shared by two persons

ActiveCN105965507AAchieve circumventionRealize fine teleoperationProgramme-controlled manipulatorControl systemManipulator

The invention discloses a dual-arm robot teleoperation control system shared by two persons. By establishing a double-hand sharing operating module, operation mapping between both hands of two main hands and a robot is achieved; and then a main manipulator and an auxiliary manipulator are divided, and a main operating arm and an auxiliary operating arm are distinguished in the operating process of the main manipulator, so that operation assisting of the main manipulator is achieved. Meanwhile, the situations such as collision and misoperation of the auxiliary operating arm in the operating process of the main manipulator can be avoided, and thus barrier avoidance and double-hand fine teleoperation are achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Layered tuberization potato cultivation method

InactiveCN104303771AAvoid exposurePrevent intrusionCultivating equipmentsPlant cultivationEngineeringSolanum tuberosum

The invention discloses a layered tuberization potato cultivation method characterized by micro-ridging film laminating, repeated earthing-up and high yield, and aims at solving the problems of low yield, high green potato rate and poor commodity in existing potato production. The method comprises the following steps of A, seeding potatoes at appropriate time, wherein the potatoes are seeded in the first ten-day period of April of a normal year in a region of which the altitude is below 1,800m according to the regional climate characteristics, are appropriately seeded in the last ten-day period of the April in a region of which the altitude is 1,800-2,300m, and are appropriately seeded in the first ten-day period and the middle ten-day period of May in a region of which the altitude is above 2,300m; performing scribing according to 1.1m in the seeding process, trenching two sides of a middle line, and performing two-line seeding, wherein the line spacing is 25-30cm, the row spacing is 22-25cm, and bud eyes face upwards; performing micro-ridging film laminating cultivation in the seeding process, wherein the height of each ridge is 5-8cm; B, performing repeated earthing-up and layered tuberization. The method has the advantages that by virtue of the repeated earthing-up, tuberization over a film and tuberization below the film can be realized, exposure of stolon is prevented, the top end of the stolon is urged to be expanded in soil to form a tuber, two to three additional potatoes can be obtained for a single plant, the green potato rate is remarkably reduced, and the large potato rate and the commodity are obviously improved.

Owner:薛龙

Functional health drink

A functional health beer drink is prepared from astragalus, kudzuvine root, medlar, winged euony twigs and ptunella spike which function as medicines and food at the same time. The drink has functions of nourishing both qi and blood, clearing away heat and toxic materials, promoting the production of body fluid to quench thirst, nourishing the liver and the kidney, clearing and activating the channels and the collaterals, and promoting the circulation of qi and resolving masses. Regular drinking of the drink can regulate chronic diseases, improve microcirculation, and enhance metabolic function of body. The drink is an ideal edible functional health drink which has good healthcare and prophylaxis and treatment effects for people with diabetic complications, hyperlipemia, hypertension and cardiovascular and cerebrovascular diseases.

Owner:侯长平

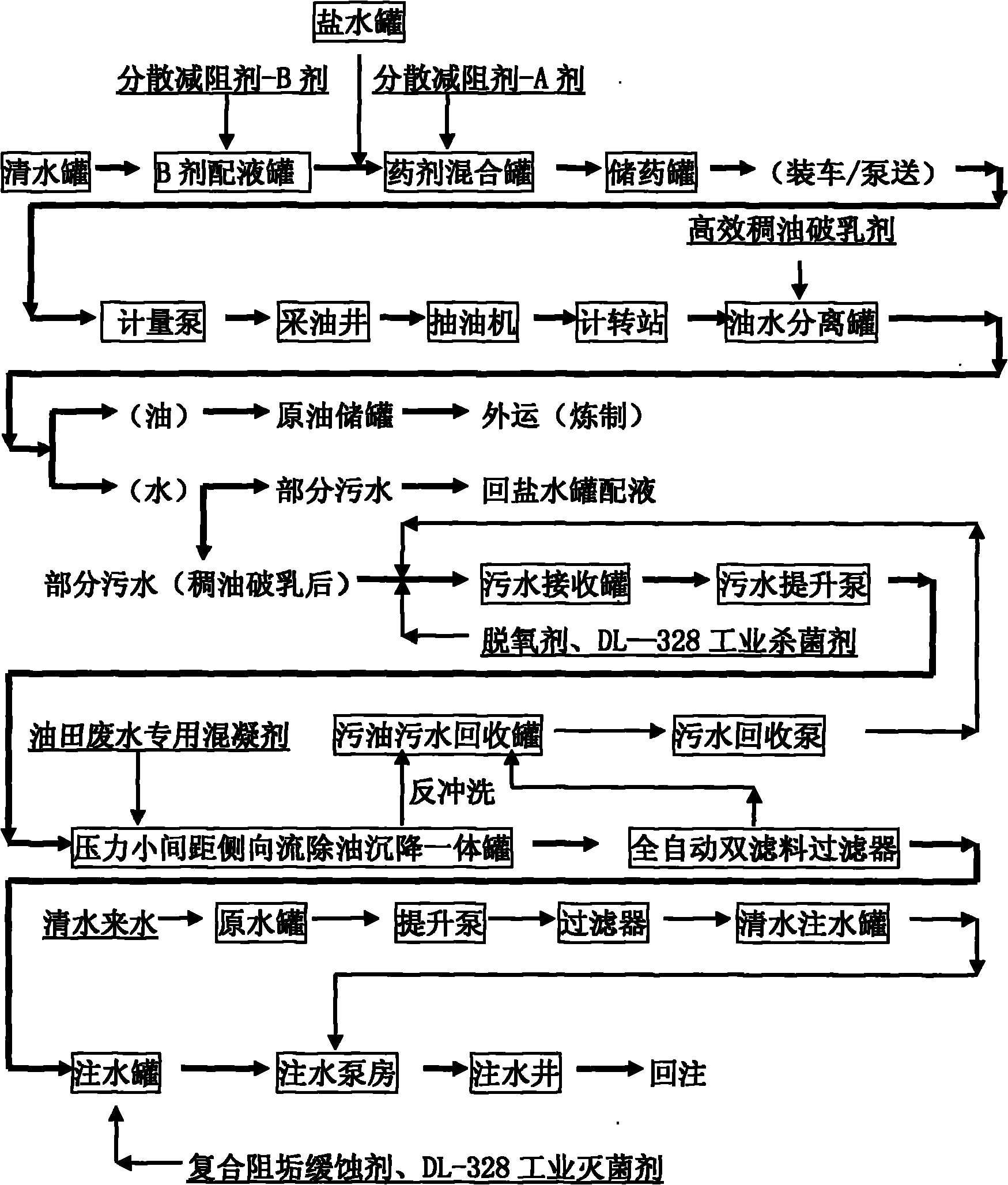

Novel integration technique for improving recovery ratio of thick oil with high thickness and low yield

ActiveCN101852073AEORImprove applicabilityDewatering/demulsification with chemical meansFluid removalChemistryIntegrated technology

The invention provides a novel integration technique for improving a recovery ratio of thick oil with high thickness and low yield. The technique comprises the following steps of: extracting the thick oil: preparing a thick oil dispersing drag reducer into 1 percent aqueous solution serving as a sample a and 0.125 percent aqueous solution serving as a sample b, mixing 1,900-2,500 milligrams / liter of sample a and 230-280 milligrams / liter of sample b uniformly, and injecting the mixture in a well by using a casing, mixing medicaments on the pump with the thick oil to form an oil-in-water emulsion, lifting the emulsion to the mouth of the well by an oil pumping unit, and feeding the emulsion in an oil-water separating tank through a pipeline; breaking the emulsion and separating water from oil: adding a corresponding amount of efficient thick oil demulsifier continuously to prepare 1 percent aqueous solution while the thick oil enters the oil-water separating tank, wherein the adding amount is 90-110 milligrams / liter, and the reaction time is more than 2 hours, namely, oil-water separated sewage is to be treated; treating and recycling the sewage: pumping the sewage in the tank, adding a special coagulant to prepare 2 percent solution, wherein the adding amount is 80-120 milligrams / liter, adding a composite anti-incrustation corrosion inhibitor simultaneously to prepare 2 percent aqueous solution, wherein the adding amount is 48-53 milligrams / liter; adding a DL-328 industrial sterilant to prepare 5 percent aqueous solution, wherein the adding amount is 85-115 milligrams / liter, and blending with clear water, and injecting in the stratum to retain the pressure balance of the stratum.

Owner:XINJIANG DELAND

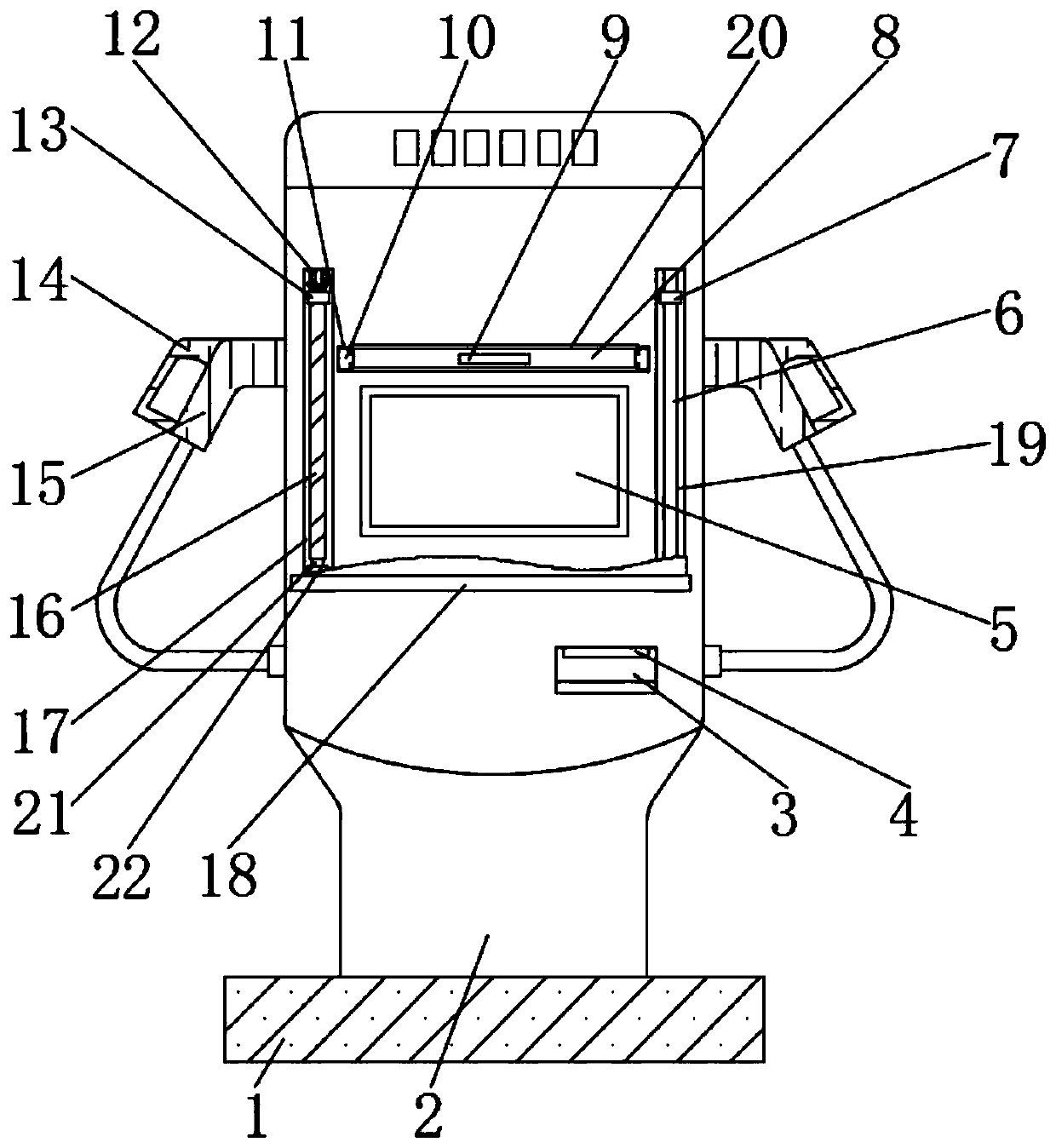

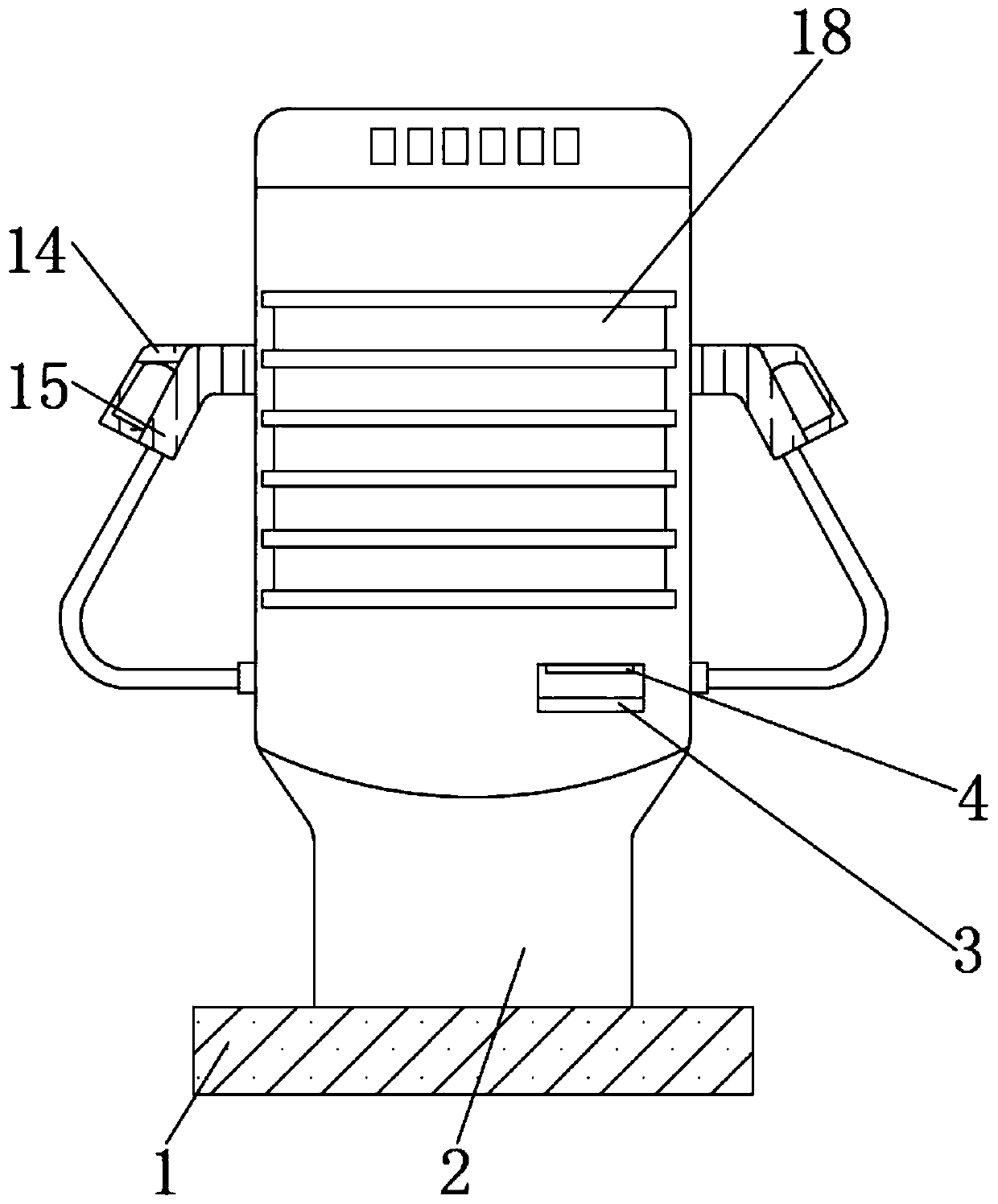

Charging pile with concealed display screen and use method

InactiveCN110605989AAvoid reflective situationsImplement overlay hidingCharging stationsElectric vehicle charging technologyEngineering

The invention belongs to the technical field of charging piles and in particular relates to a charging pile with a concealed display screen. The charging pile with the concealed display screen comprises a base; a charging pile body is fixedly connected with the top of the base; a first groove and a second groove are formed in the front surface of the charging pile body; a motor is fixedly connected to the top of the internal wall of the first groove; a screw rod is fixedly connected to an output shaft of the motor; and a rotating shaft is fixedly connected to one end of the screw rod. According to the charging pile with the concealed display screen, the screw rod can be driven to rotate through the working of the motor; through rotating of the screw rod, a screw rod sleeve drives a telescopic door to expand and retract up and down under the cooperation of a sliding rod and a sliding sleeve; and as the device adopts the motor, the screw rod, the screw rod sleeve, the sliding rod, the sliding sleeve and the telescopic door, the display screen is covered and concealed, and the purpose of protecting the display screen is achieved; by arranging a first slide groove, a second slide groove, a slide block and a light shielding plate, the light reflecting situation generated during the using of the display screen is avoided, and the whole charging pile with the concealed display screenhas the advantages of reasonable structure, simple operation and high practicability.

Owner:SUZHOU QC TECH

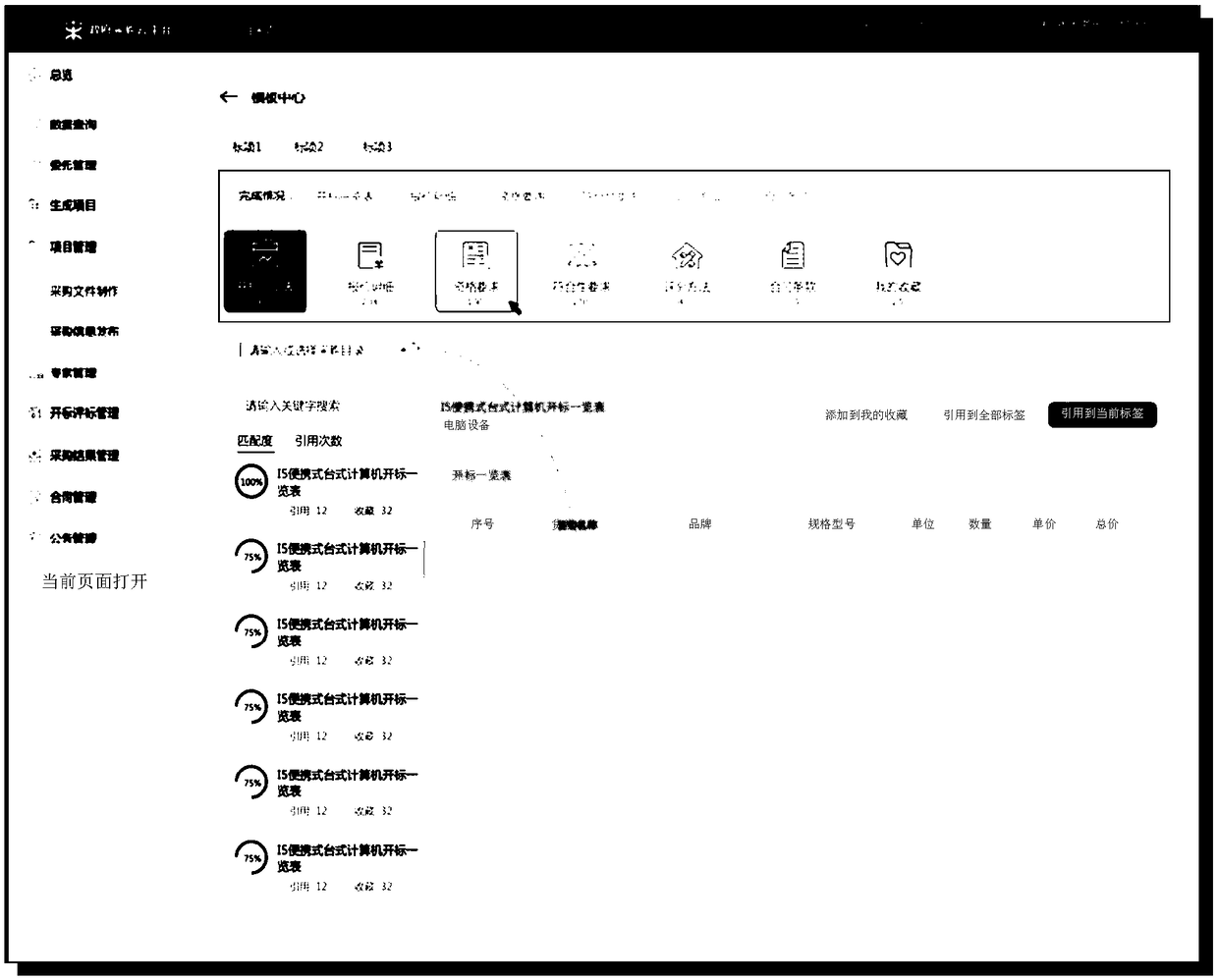

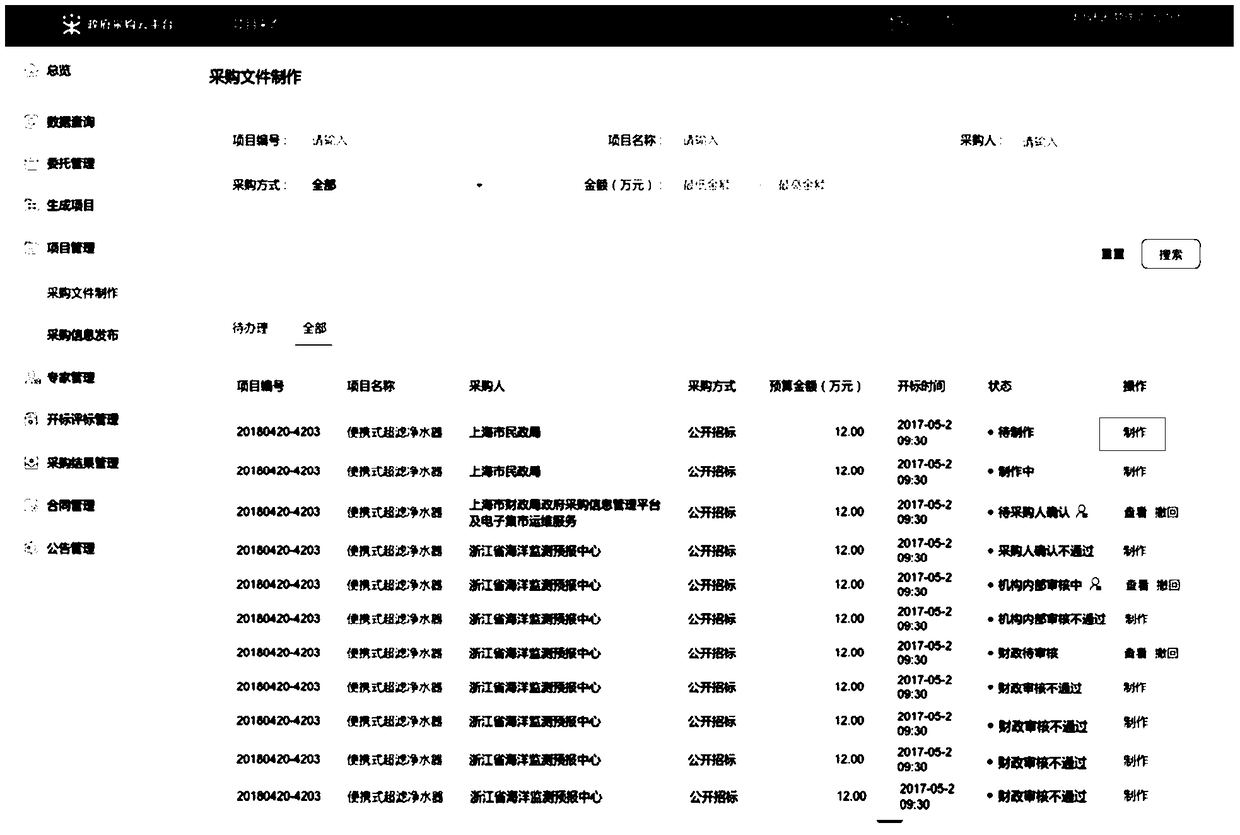

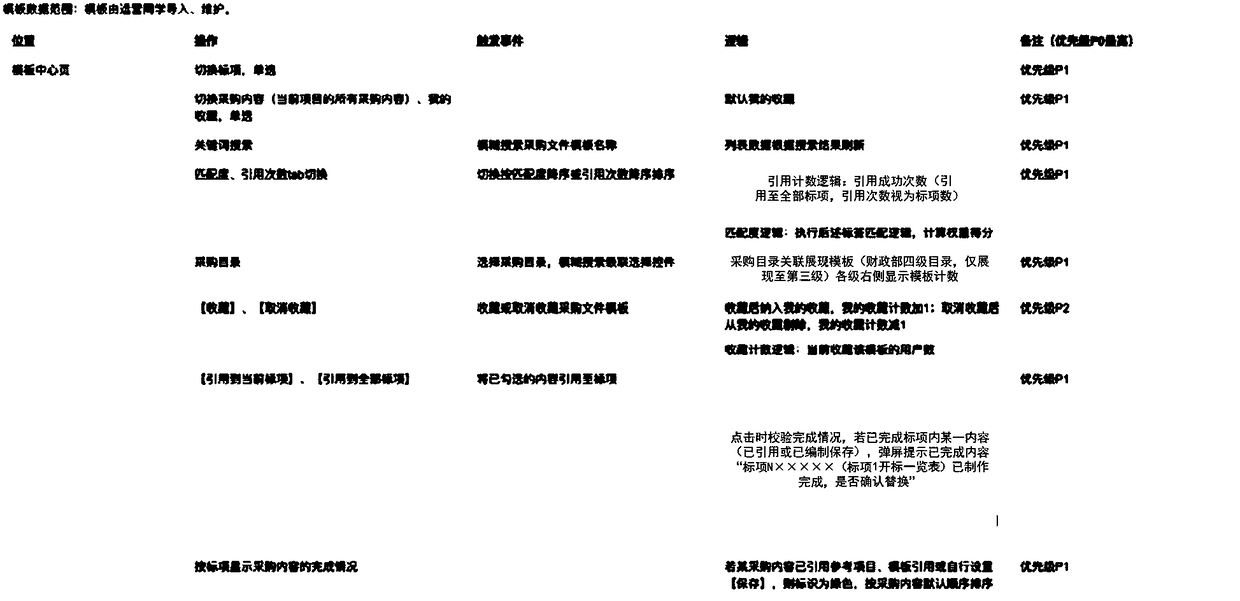

Method, device, computing device and storage medium for obtaining file template

PendingCN109299445AReduce difficultyShorten the timeNatural language data processingSpecial data processing applicationsTemplate libraryDatabase

The invention provides a method, a device, a computing device and a storage medium for obtaining a file template, wherein the method for obtaining the file template comprises the following steps: obtaining at least one attribute tag of a file to be made, wherein the attribute tag is an item attribute tag and / or a content attribute tag; the at least one attribute tag is matched with a template tagin a template library, and a template of a recommendation file is obtained according to the matched template, wherein the template library stores a template and a corresponding template tag.

Owner:政采云有限公司

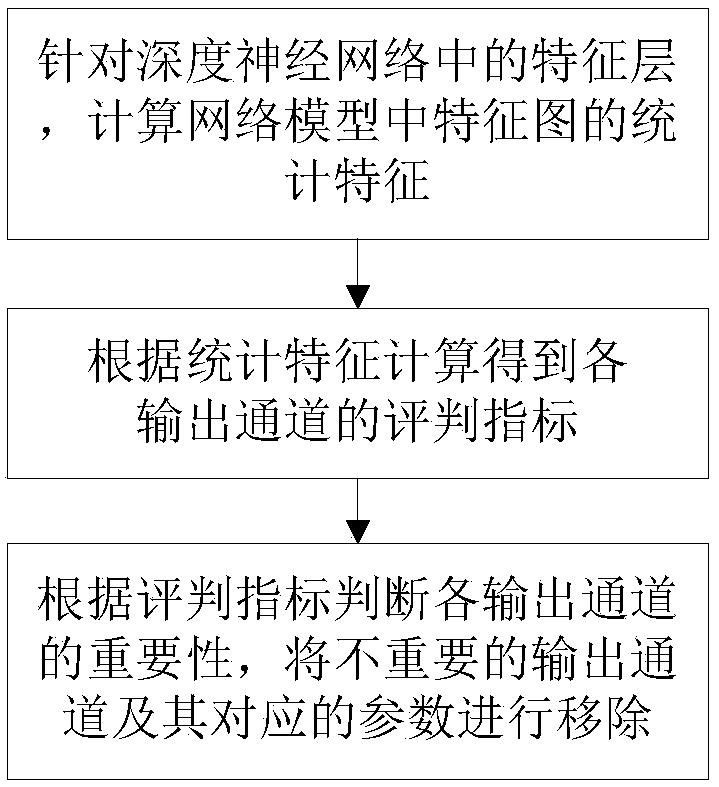

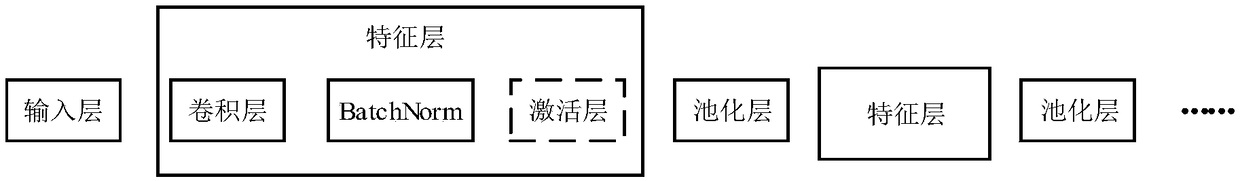

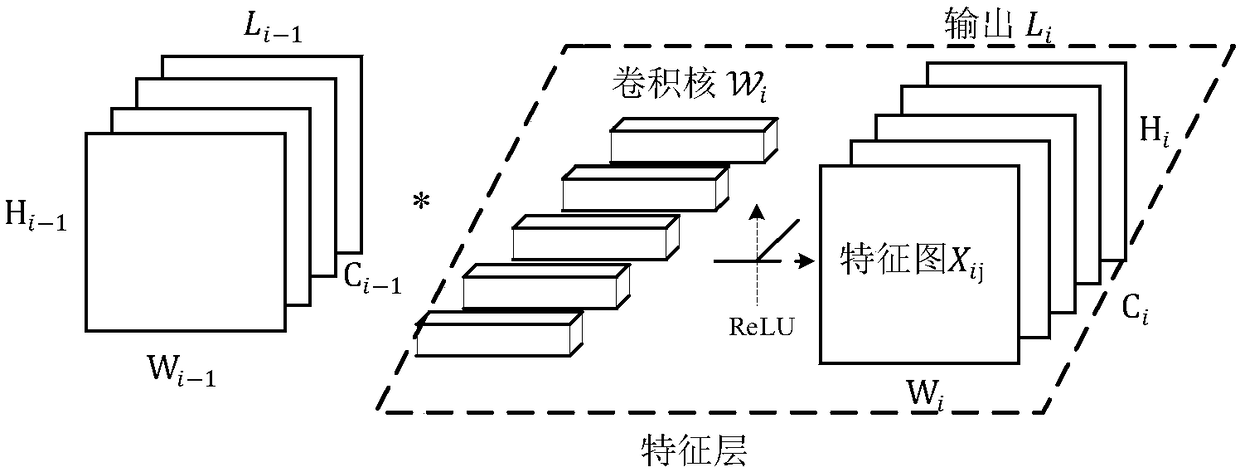

A depth neural network model clipping method based on statistical feature of feature graph

PendingCN109472352AIncrease training speedReduce the number of weightsNeural architecturesNeural learning methodsNerve networkNetwork model

The invention discloses a depth neural network model cutting method based on the statistical characteristics of a characteristic map. The method comprises the following steps: step 1, aiming at the characteristic layer in the depth neural network model, calculating the statistical characteristics of the characteristic map corresponding to each output channel; The characteristic layer consists of convolution layer and activation layer, or of convolution layer, normalization layer and activation layer. 2, accord to that statistical characteristics of the characteristic map correspond to each output channel in the characteristic layer, calculating evaluation indexes of each output channel in the characteristic lay; 3, judging that importance of each output channel in the characteristic layeraccord to the evaluation index, and removing the unimportant output channels and the corresponding parameter. The invention can effectively reduce the dimension of the neural network characteristic layer, improve the operation efficiency of the network model, reduce the network scale, and has little influence on the accuracy.

Owner:XIANGTAN UNIV

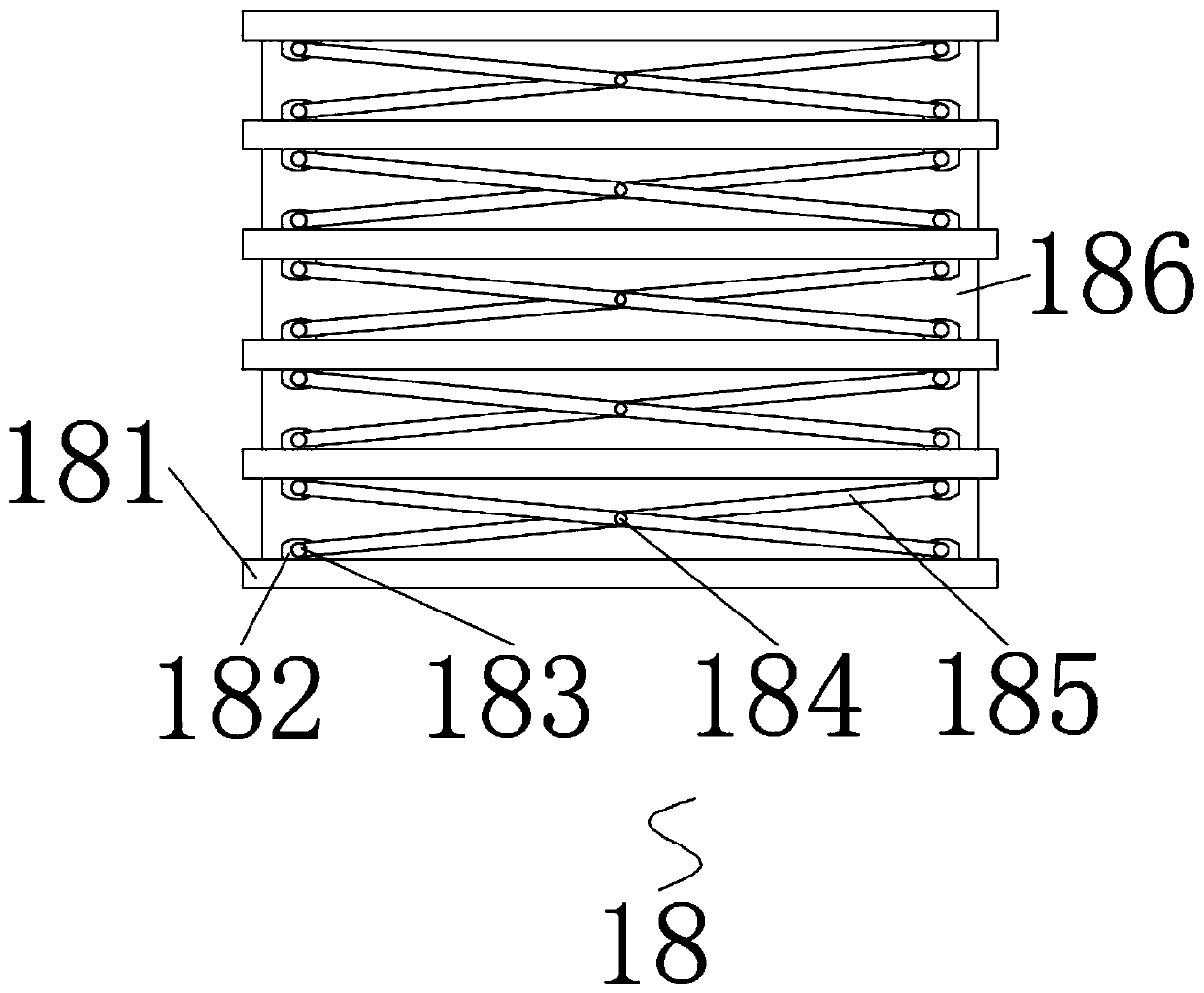

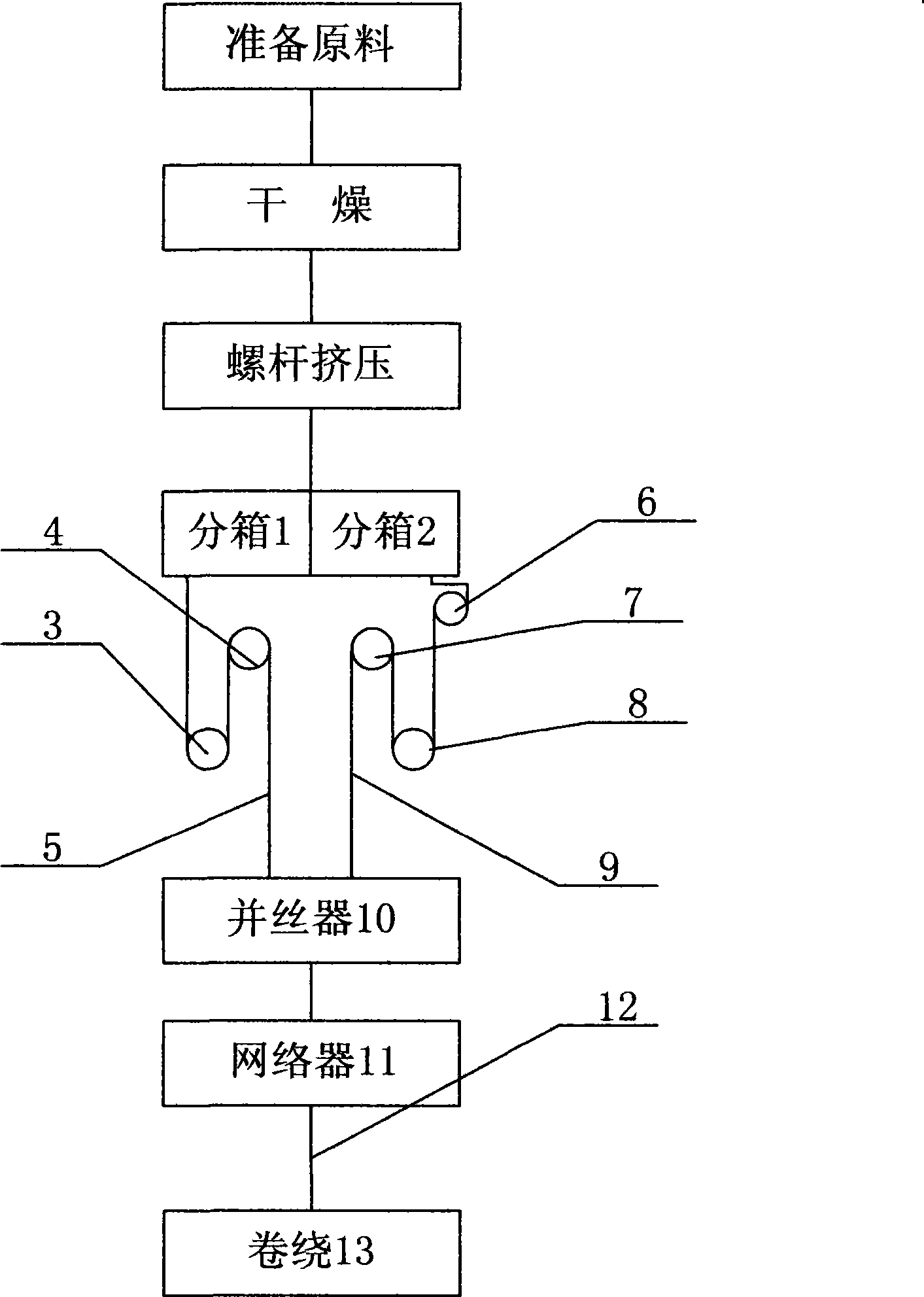

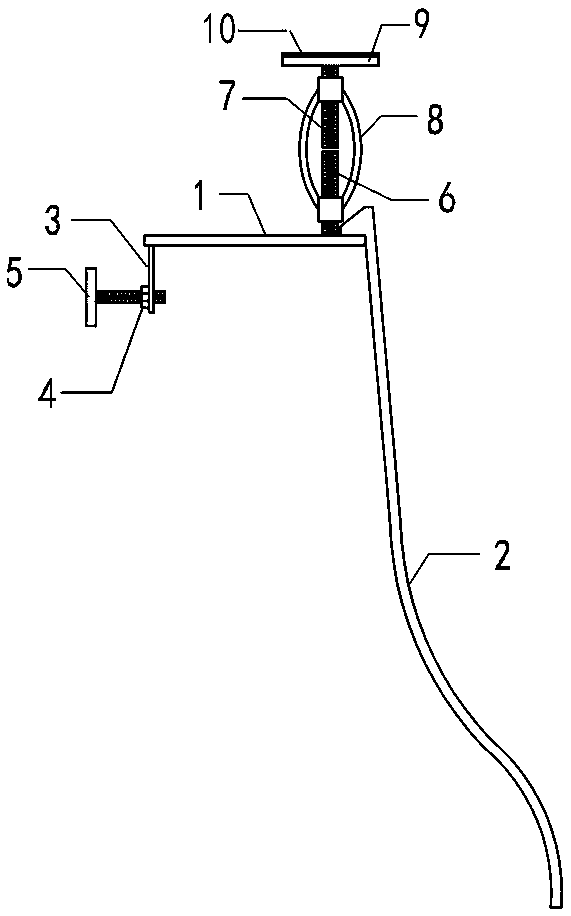

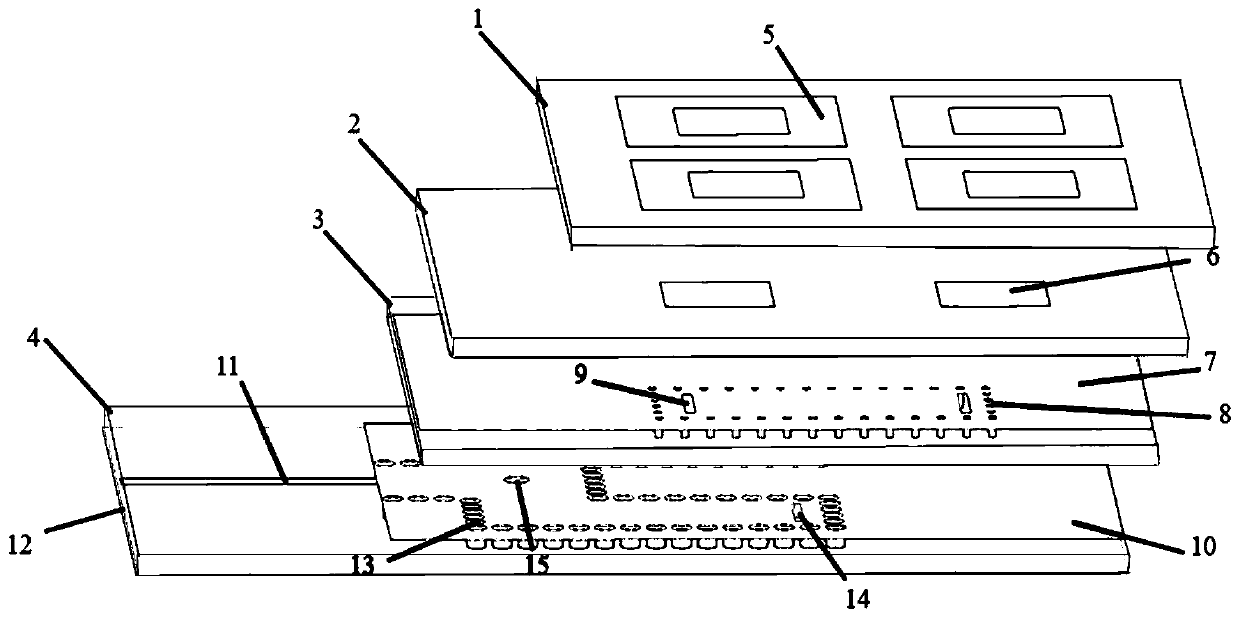

Special composite fiber spinning and winding device by differential-shrinkage differential one-step method

InactiveCN101545163AImprove manufacturing levelSave resourcesTextiles and paperHeat conductingEngineering

The invention relates to a special composite fiber spinning and winding device by a differential-shrinkage differential one-step method, which comprises the following specific processes: preparing raw materials; drying the raw materials, heating and drying the raw material by a heater and wind power so as to remove the moisture; performing screw extrusion; processing the raw materials passing through a separating box (1) by a lower heat conducting roller (3) and an upper heat conducing roller (4) to obtain F threads (5); processing the raw materials passing through a separating box (2) by a thread guide (6), an upper thread guiding roller (7) and a lower thread guiding roller (8) to obtain P threads (9); and putting the threads into a doubling machine (10) and processing the same by an interlacer (11) to obtain composite threads (12), and finally obtaining differential-shrinkage threads (14) after winding (13). The special composite fiber spinning and winding device adopts a one-step method to process composite fibers which are formed through one step, saves a great deal of investment, reduces the production occupied space, reduces the processing cost and improves the production benefit.

Owner:XUZHOU SILK FIBER TECH

Field mounting method for test chamber

InactiveCN105171347AAvoid difficultiesPlay a leading roleWelding/cutting auxillary devicesAuxillary welding devicesTest chamberPhysics

The invention relates to a field mounting method for a test chamber. The field mounting method comprises the following steps: requiring boards; blanking the boards; carrying out edge planning on the boards; welding and joining the boards; rolling the boards into a winding drum; longitudinally welding the winding drum to form drum sections; carrying out roundness correction on the drum sections; carrying out gas cutting on the drum sections; fitting up and welding the drum sections; cutting the drum sections into parts; carrying out field welding on the parts; and carrying assembly welding on an enclosure and the drum sections. The field mounting method solves the problem that a large container is difficult to transport, guarantees the field mounting coaxiality, adopts split transportation and field welding, utilizes a tool to support welding, and guarantees that the roundness of a drum body reaches standard requirements.

Owner:SHENYANG AEROSPACE XINGUANG PRESSURE VESSEL

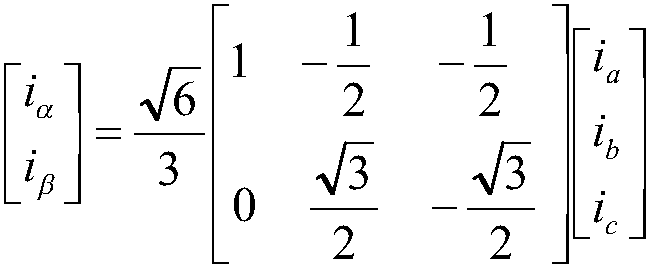

Sliding mode variable structure control method with variable exponent coefficient reaching law sliding mode for permanent magnet synchronous motor

InactiveCN106549616BIncrease approach speedReduce buffetingElectronic commutation motor controlAC motor controlState variableControl system

The invention discloses a sliding-mode variable structure control method of a variable exponential coefficient reaching law of a permanent magnet synchronous motor. The method comprises the following steps: aiming at the requirements of a control system of a high-performance permanent magnet synchronous motor, a variable exponential function term formula is introduced on the basis of a conventional exponential reaching law; the formula takes a first-order norm of systematic state variables as an exponent of exponential functions, adaptively adjusts the reaching speed of a variable exponent term and a variable speed term according to the distance between the system and a sliding-mode surface, and is helpful to increase the dynamic response speed of the system; the systematic state variables are associated by taking the first-order norm of the systematic state variables as the exponent of the functions; and an s function is introduced to replace a symbolic function for further suppressing system chattering. Therefore, the sliding-mode variable structure control method of the permanent magnet synchronous motor using the variable exponential coefficient reaching law is provided. Compared with an integral-type sliding-mode variable structure control method, the method disclosed by the invention can be used for effectively increasing the dynamic characteristics and steady state characteristics of the system as well as increasing the robustness of the system.

Owner:JIANGSU UNIV

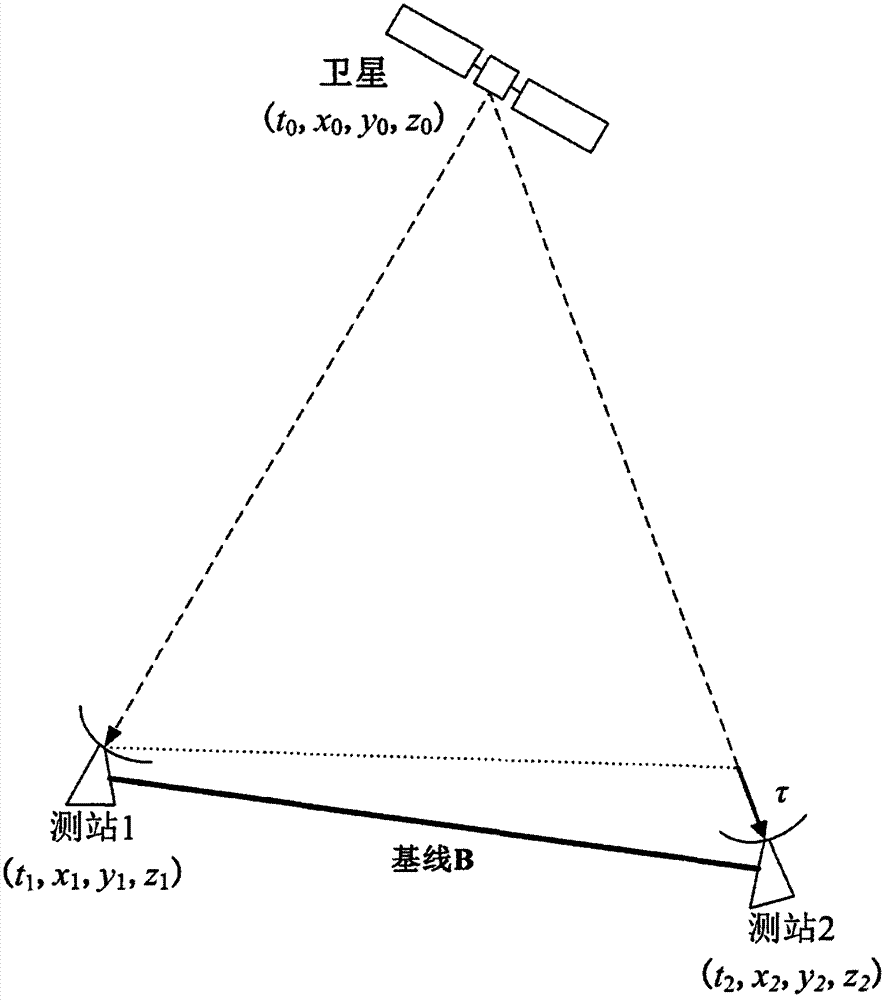

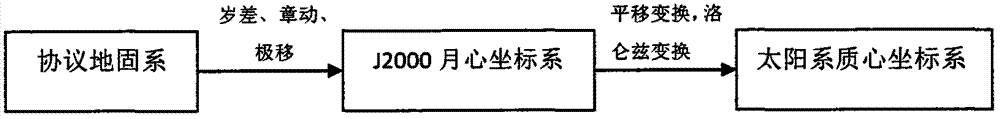

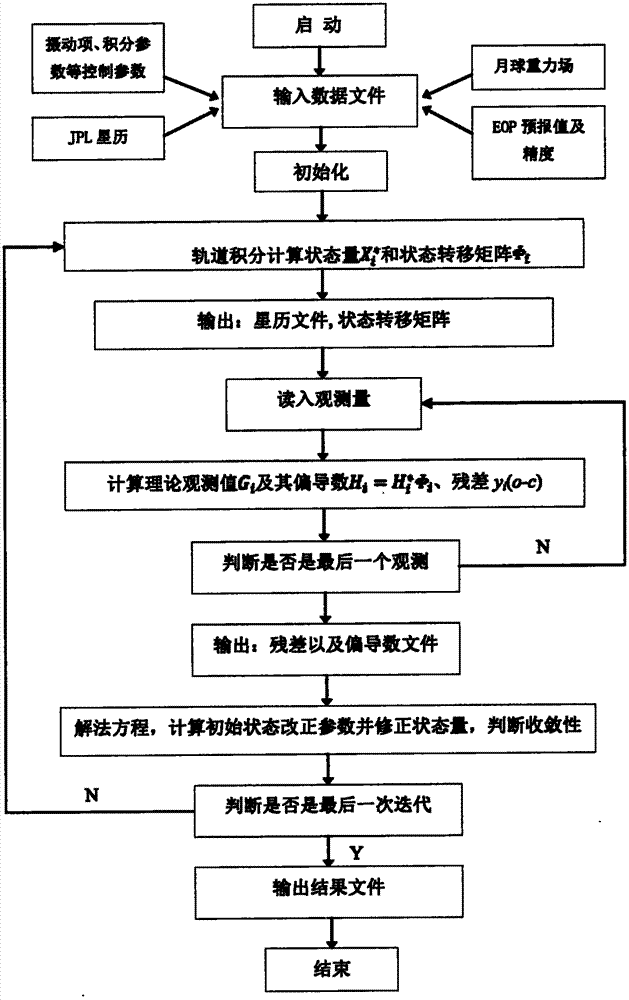

Precise orbit determination method for lunar probe

ActiveCN104713561AImproved prior accuracyHigh positioning accuracyInstruments for comonautical navigationObservation dataOrbit determination

The invention discloses a precise orbit determination method for a lunar probe. An observation model and a dynamical model are organically combined, and therefore the parameters of the dynamical model are introduced into a combination model; different reference systems related by the combination model are unified, so that the connection parameters of the reference systems are introduced into the combination model. Thus, a new module for simultaneously improving the connection parameters of the reference system related by the combination model, the initial state parameters of the probe and the perturbation model parameters of dynamical orbit determination of a flight phase of the probe is established, the prior precision of the parameters can be improved by the model and observation data, and the orbit determination precision of the lunar probe is improved.

Owner:WUHAN UNIV

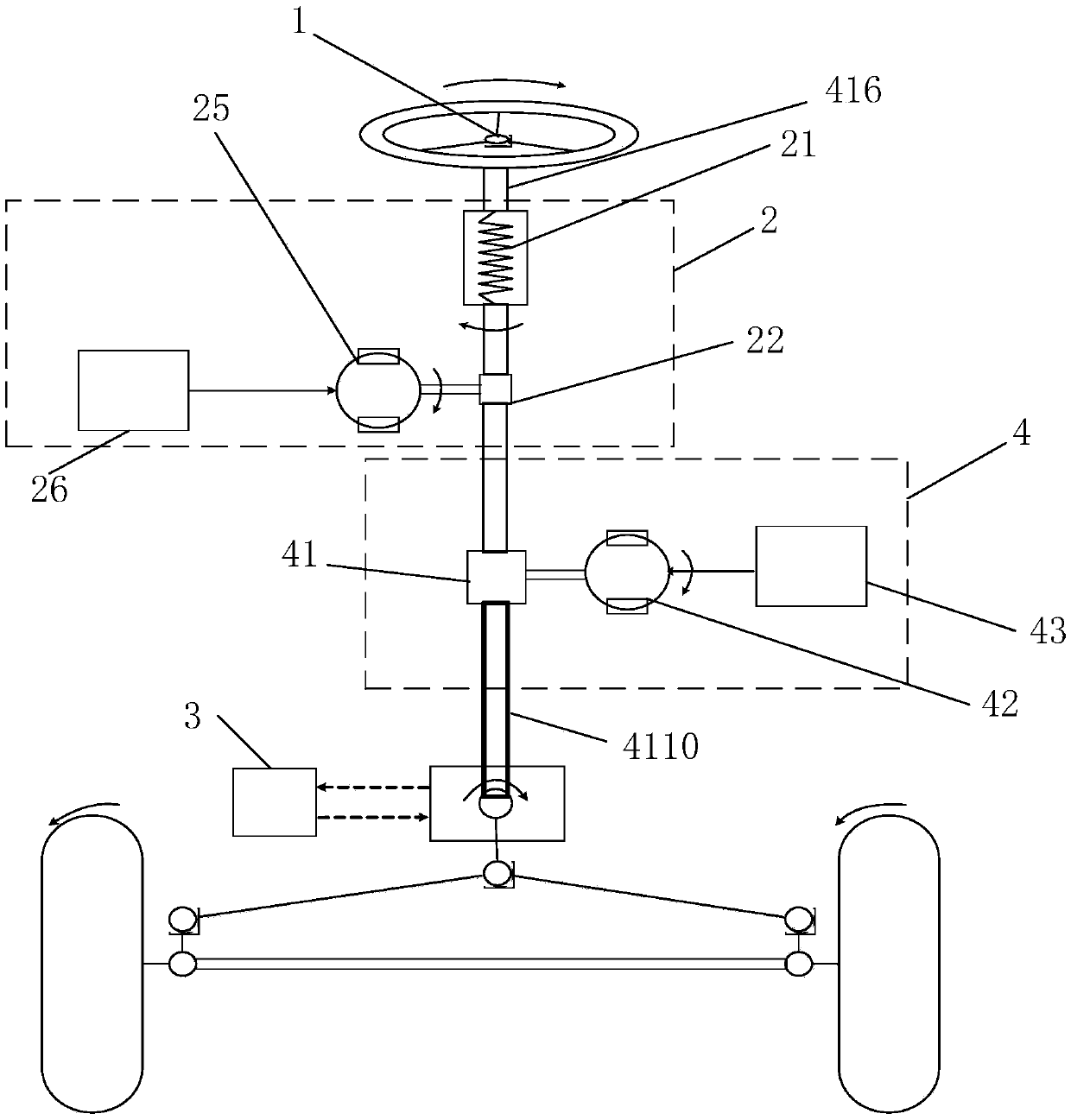

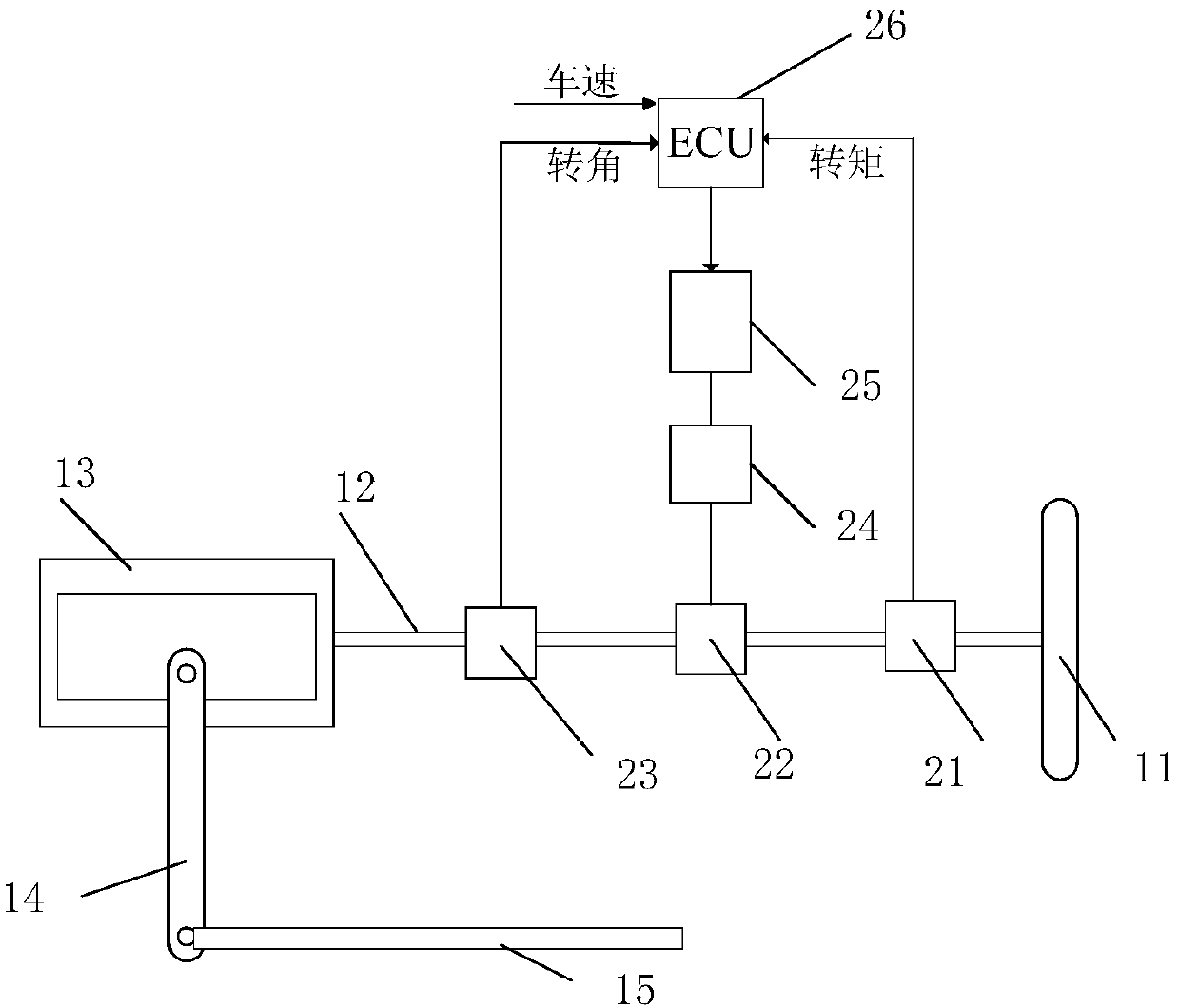

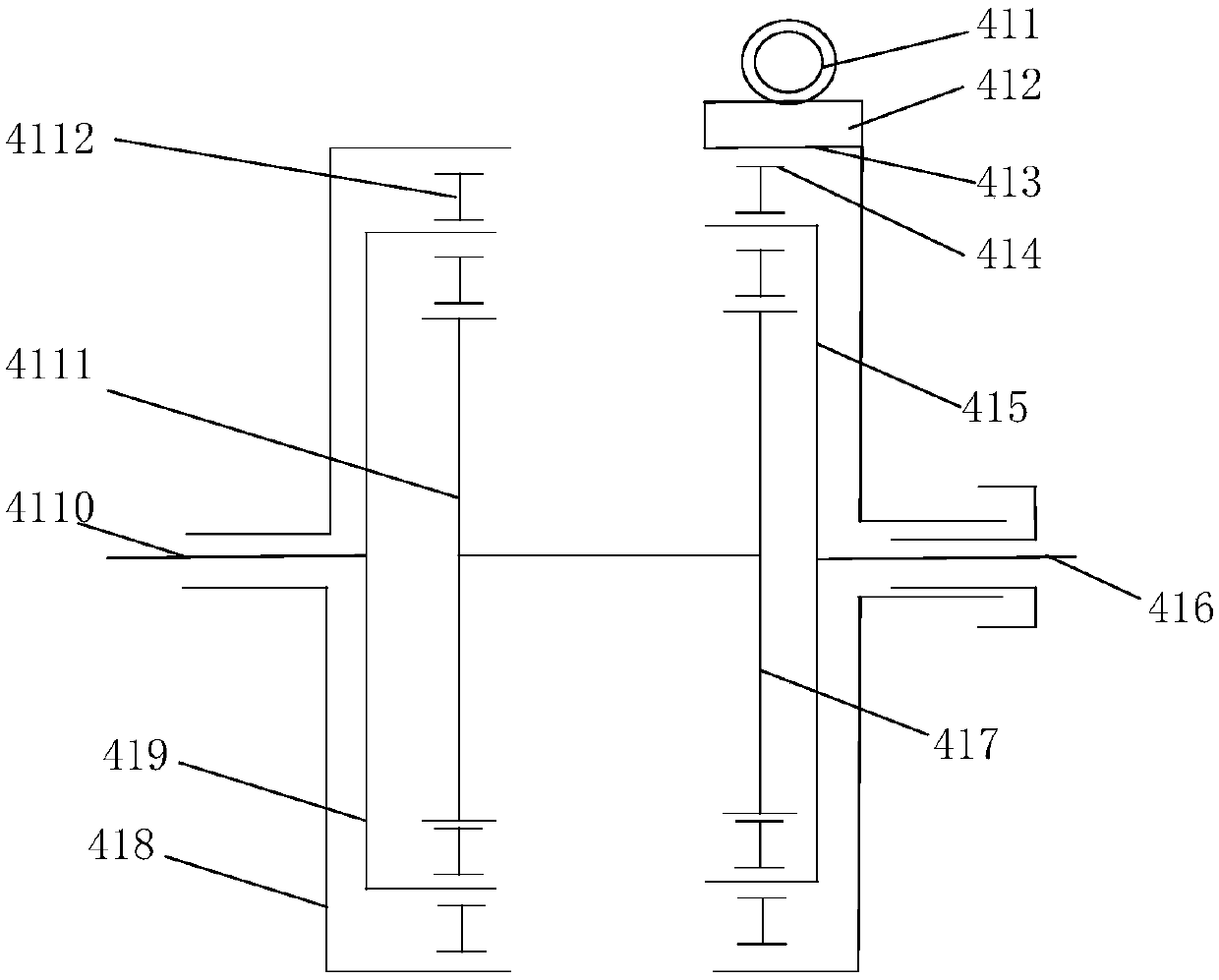

Active electro-hydraulic coupling steering system and vehicle

ActiveCN110962919APlay a leading roleEfficient use ofMechanical steering gearsFluid steeringElectric power steeringSteering wheel

The invention relates to the technical field of vehicle steering control, in particular to an active electro-hydraulic coupling steering system and a vehicle. The steering system comprises a mechanical steering mechanism, an electric power steering mechanism, a variable transmission ratio mechanism and a hydraulic power steering mechanism. The mechanical steering mechanism comprises a steering input shaft connected with a steering wheel and a steering output shaft used for driving a vehicle to turn. The steering input shaft is connected with the input end of the variable transmission ratio mechanism. The output end of the variable transmission ratio mechanism is connected with the steering output shaft. The output end of the electric power steering mechanism is in transmission connection with the steering input shaft. The output end of the hydraulic power steering mechanism is in transmission connection with the steering output shaft. The electric power steering mechanism is arranged between the steering wheel and the variable transmission ratio mechanism. The assisting power borne by the electric power steering mechanism is the ratio of the steering aligning torque to the steeringtransmission ratio, and becomes smaller through the filtering of the variable transmission ratio, such that the assisting power borne by the electric power steering mechanism is reduced. Thus, the size of equipment in the electric power steering mechanism does not need to be designed to be very large, and space can be effectively saved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

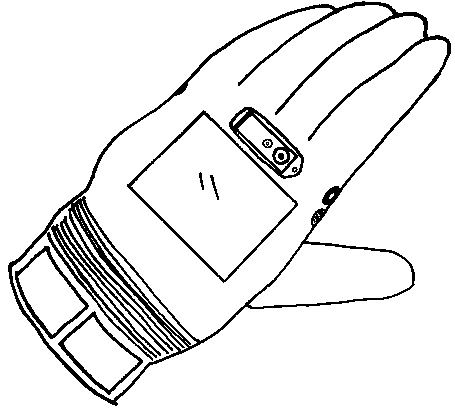

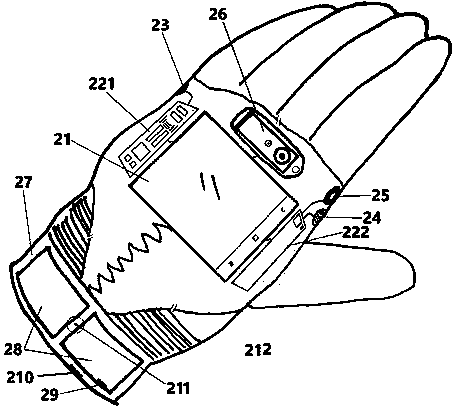

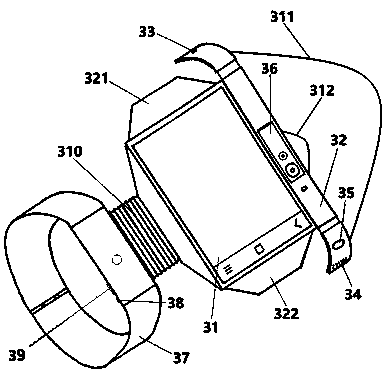

Communication device

The invention provides an intelligent communication device worn on the back of the hand. The communication device is a mobile phone of which the structure and appearance are changed for adapting to wearing. The intelligent communication device is suitable for use in movement, and the functions of an intelligent wearable device are combined. The main engine of the device adopts the design of separable modules, and the modules are mutually connected by flexible conductors, so that the main engine is light and thin and is suitable for wearable use. The voice tube and microphones extending to twosides of the palm solve the communication problem, and the operation of answering the phone can be completed by touching a nearby function button by a single thumb. A built-in wrist module sensor at the rear end is equivalent to a smart bracelet in direct connection with the mobile phone, namely the effect of fixing the main engine is achieved, the third-party transmission of Bluetooth is saved, the screen of the device is larger than a smart switch, the device is convenient to operate, and the shooting problem of the device is solved by a popping-up camera. Therefore, the communication devicedisclosed by the invention is perfect to carry and use in the movement.

Owner:葛培新

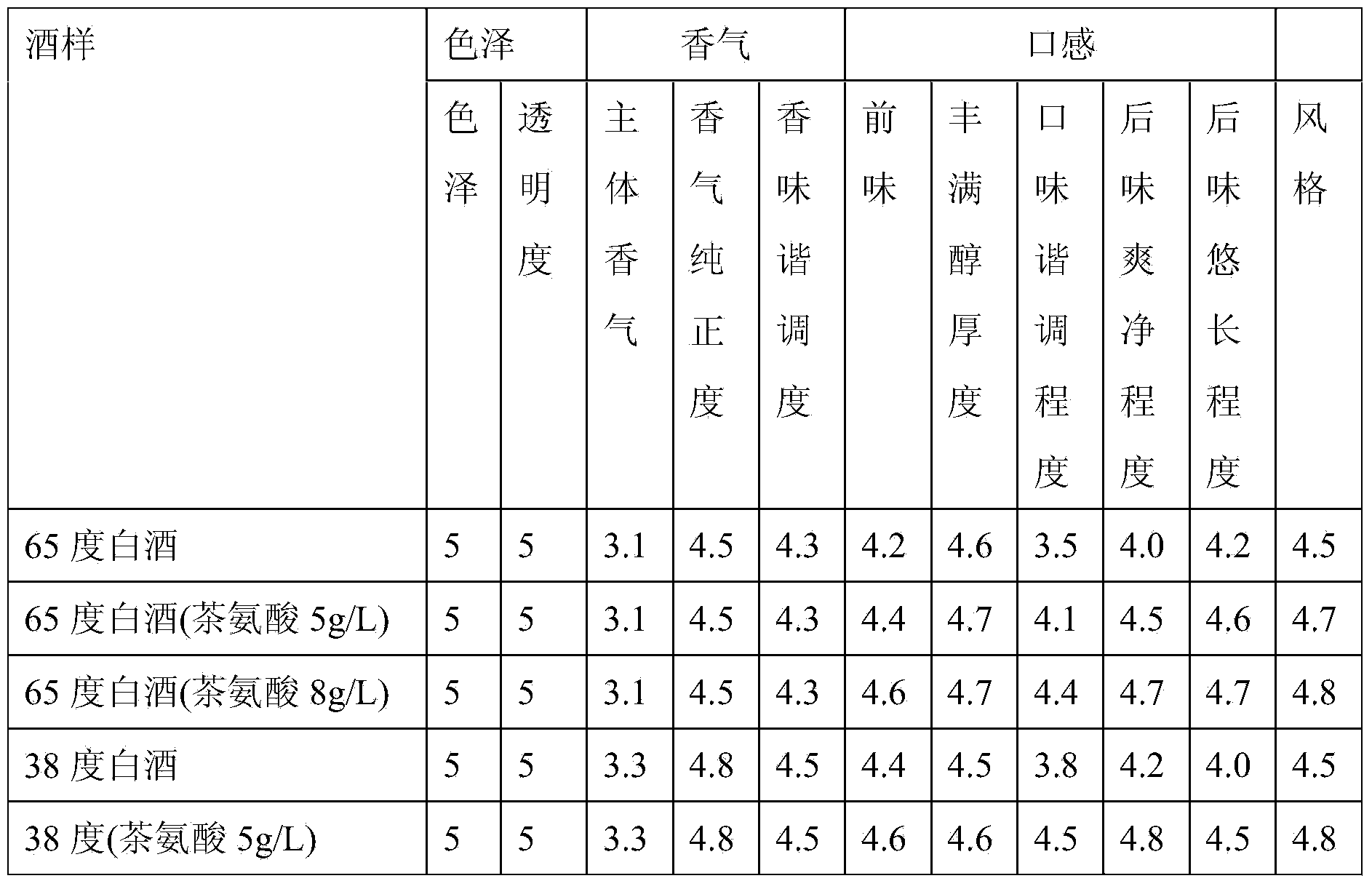

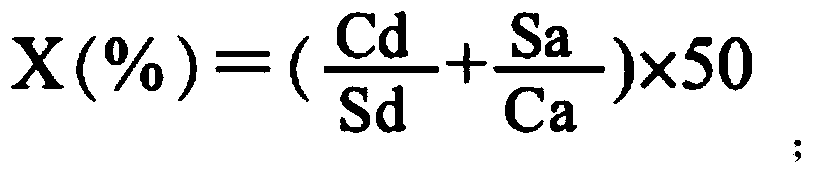

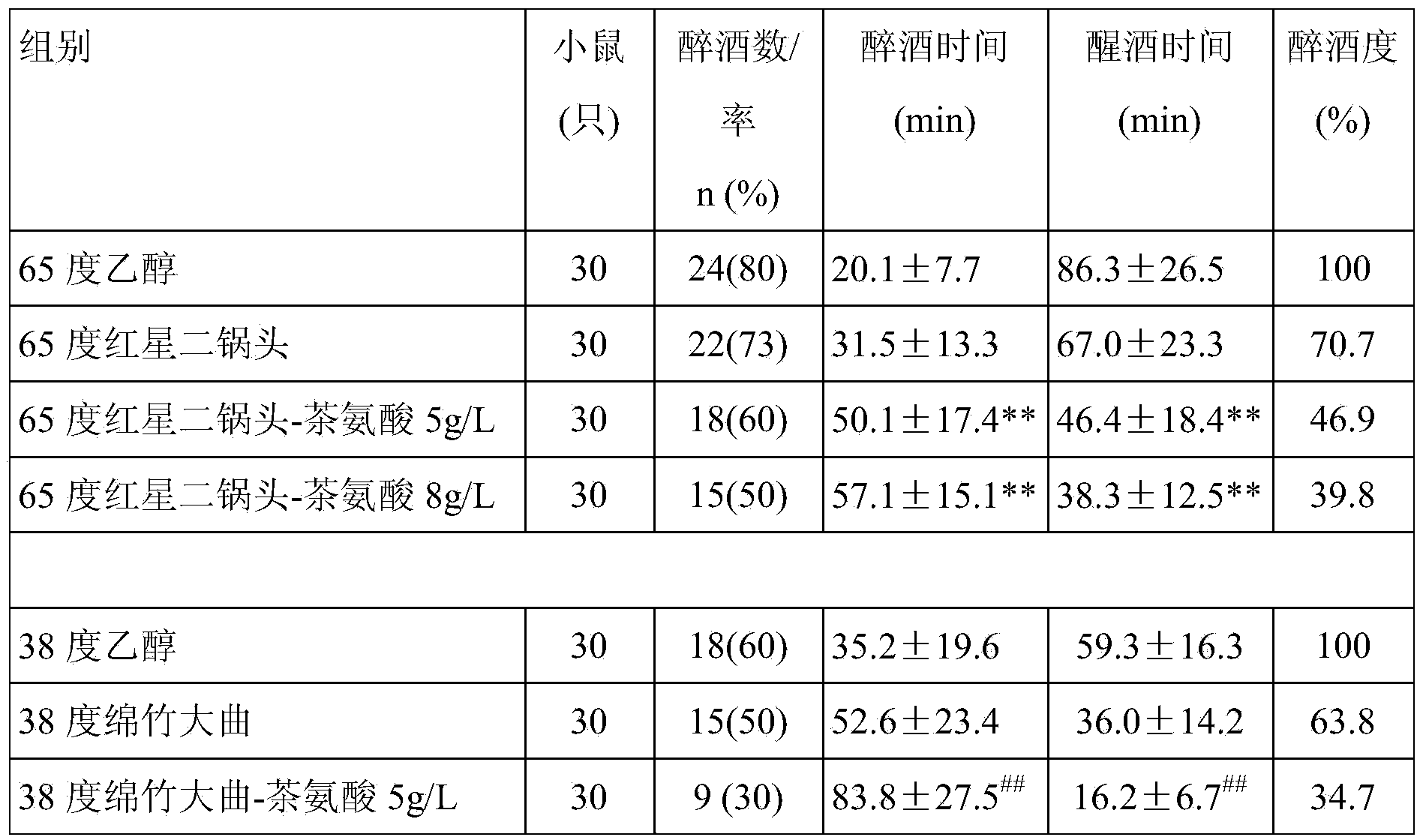

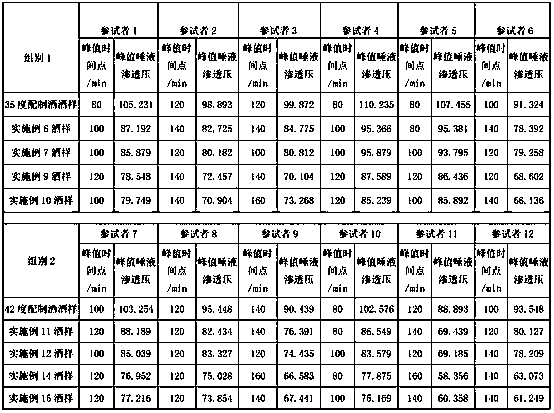

Preparation method of white spirit having low degree of drunkenness

InactiveCN103937651ANo effect on styleGreat tasteAlcoholic beverage preparationL-theanineWhite spirit

The invention discloses a preparation method of a white spirit having low degree of drunkenness. The preparation method comprises the steps of adding L-theanine to the white spirit, and mixing evenly to obtain the white spirit having a low degree of drunkenness; the content of the L-theanine in the white spirit having a low degree of drunkenness is 0.5-20g / L. The white spirit having a low degree of drunkenness prepared by the method has the characteristics of reduced degree of drunkenness and improved quality of white spirit.

Owner:ZHEJIANG FORESTRY UNIVERSITY

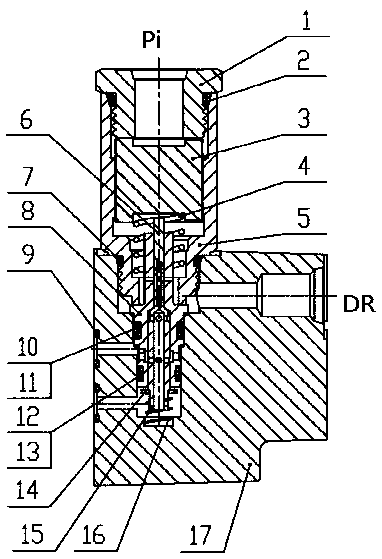

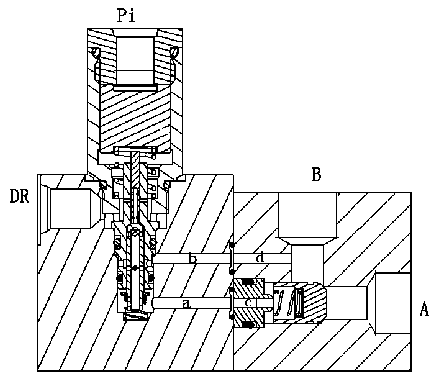

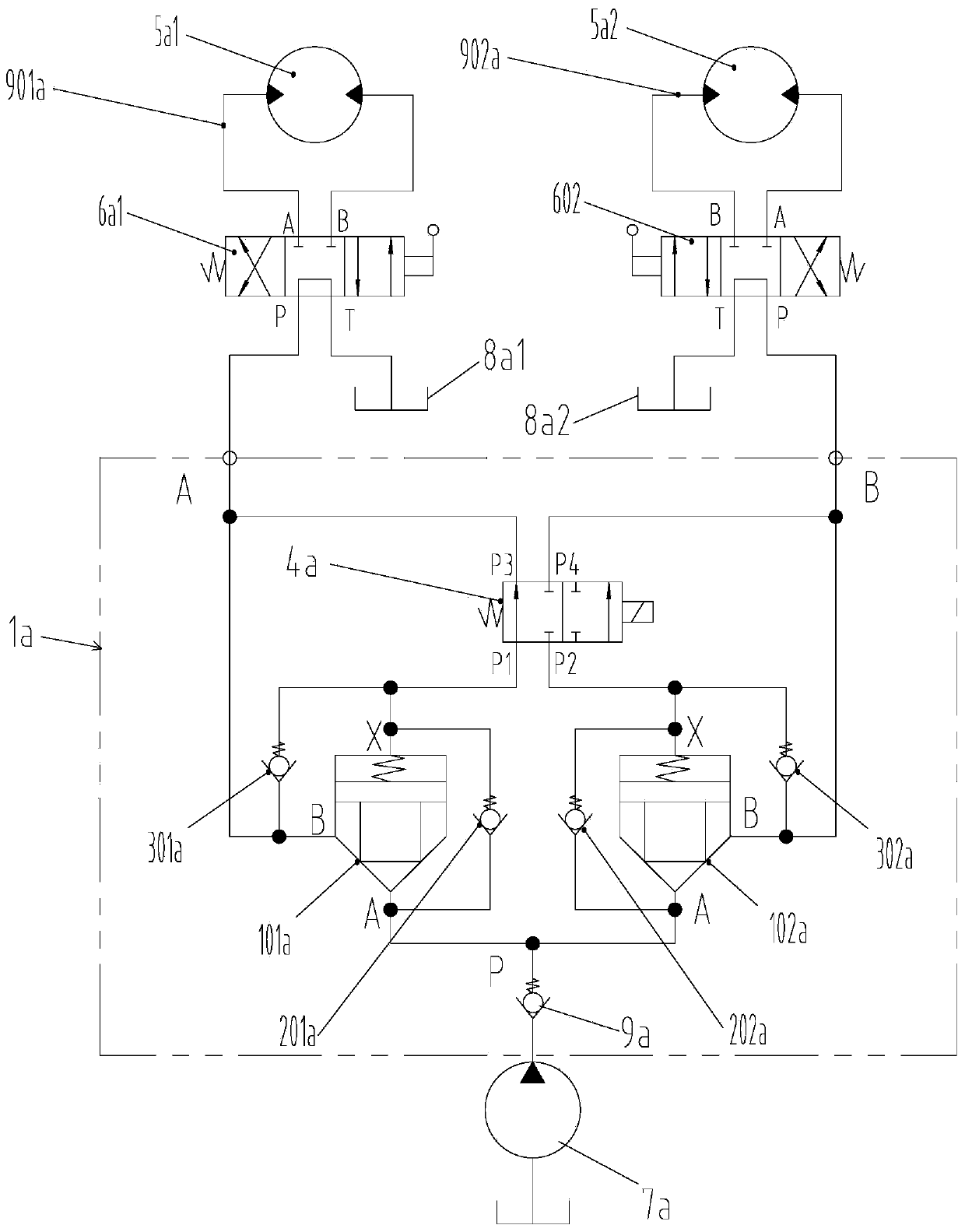

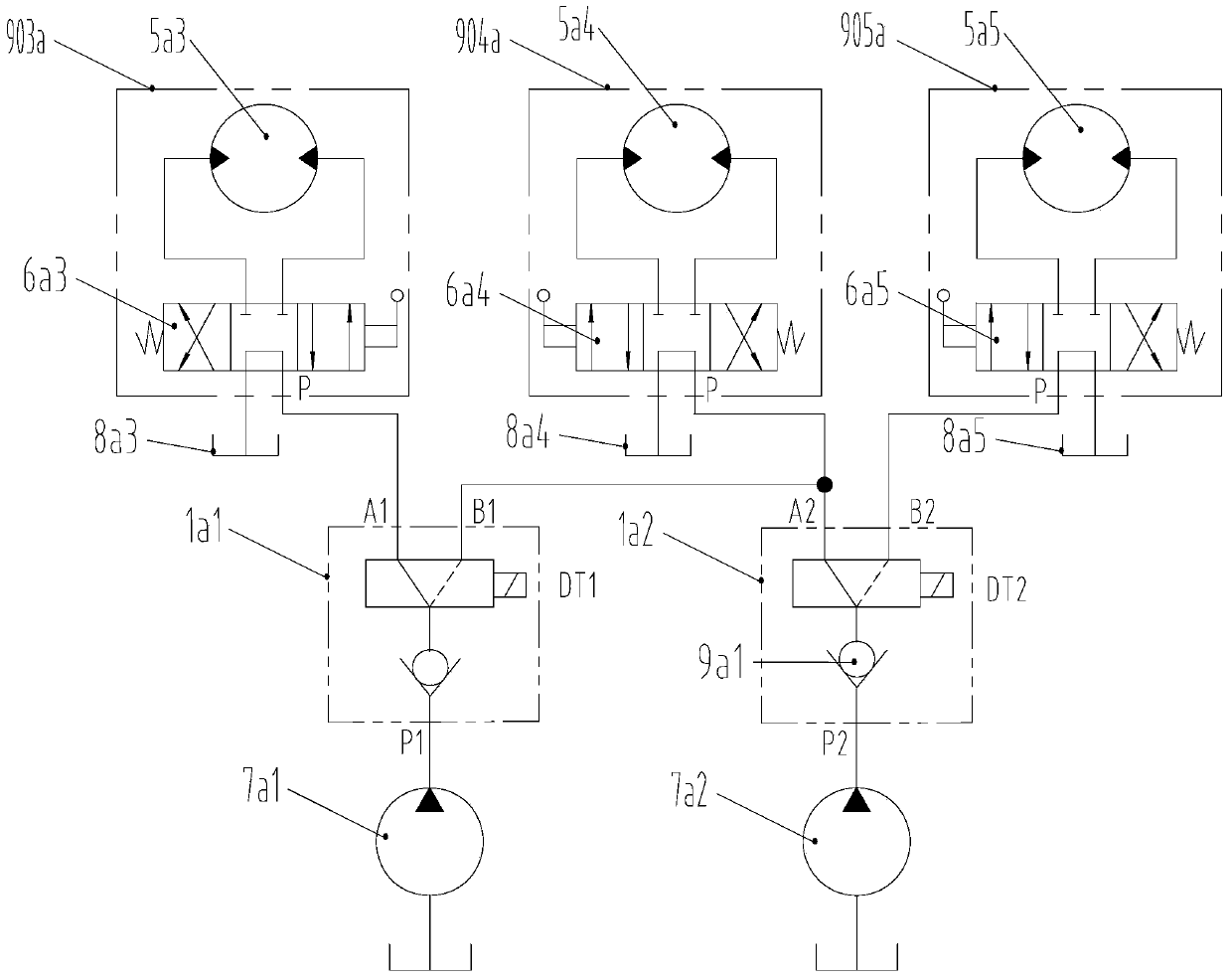

Hydraulically controlled two-way reversing valve, load holding module and load holding system

PendingCN110230618AEasy to operateReduce loadServomotor componentsMultiple way valvesFuel tankEngineering

The invention provides a hydraulically controlled two-way reversing valve, a load holding module and a load holding system and belongs to the technical field of hydraulic systems of engineering machinery. An oil port A of a multitandem valve is connected to an oil duct A of the load holding module; an oil duct B of the load holding module is connected to a large cavity of an oil cylinder of a movable arm, an oil duct DR of the load holding module is connected to an oil tank, and an oil duct Pi of the load holding module is connected to a descending position pilot pressure oil duct of the multitandem valve; and a small cavity of the oil cylinder of the movable arm is connected to an oil port B1 of the multitandem valve. As the area ratio of a cap nut gasket and a pilot valve element in thehydraulically controlled two-way reversing valve can reach 1: 64, the hydraulically controlled two-way reversing valve is simple and convenient to operate. By means of a holding function of a holdingvalve, an inner revealing amount can be controlled at zero, so that the load can be held in a constant position rather than be decreased along with change of time; a pilot effect is exerted to the holding valve through the hydraulically controlled two-way reversing valve, so that a small cone valve element acts frequently under a pilot pressure without phenomena such as breakage.

Owner:XCMG CONSTR MACHINERY

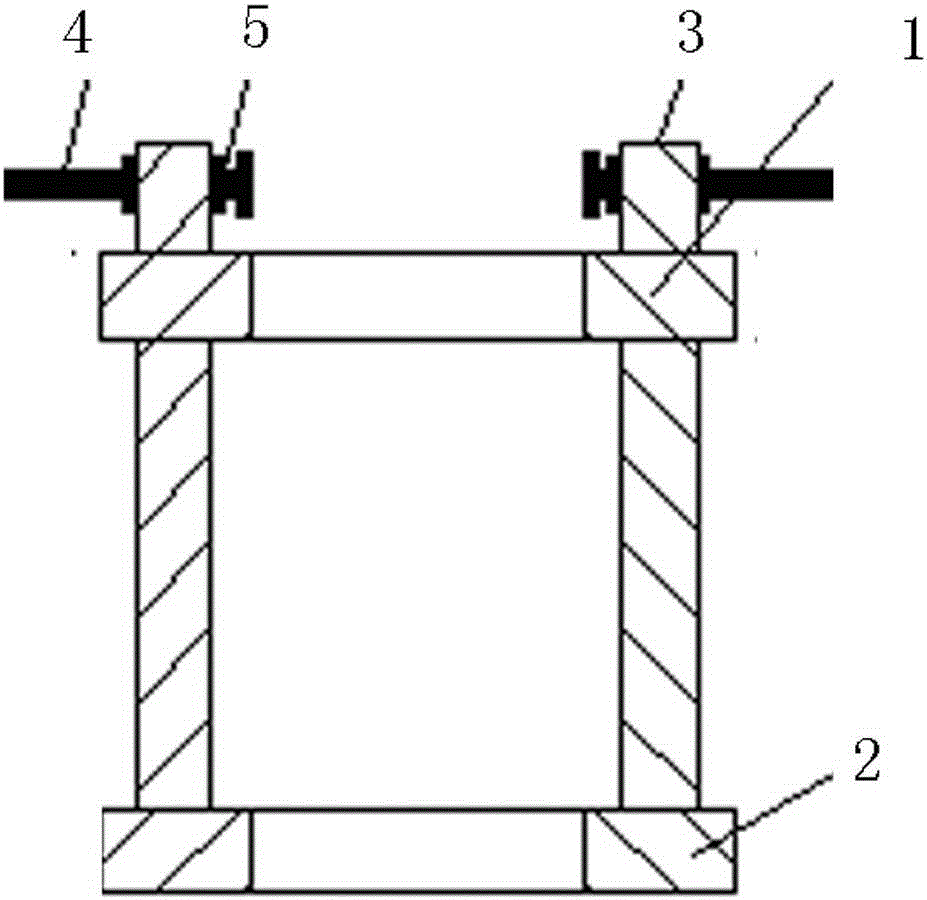

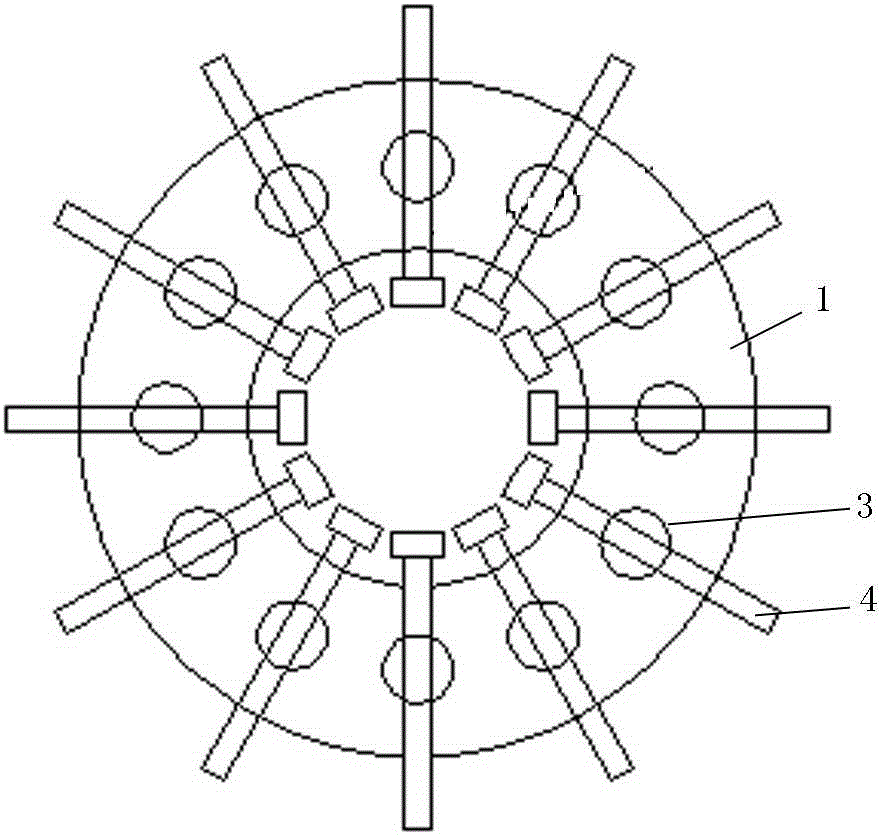

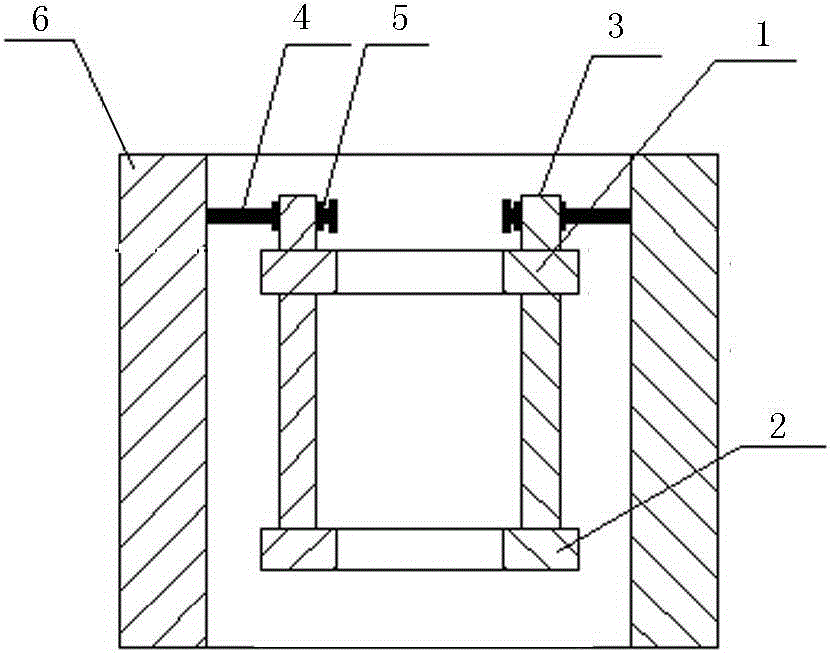

Shaping clamp for repairing of surfaces of concrete guard bars and repairing method of shaping clamp

ActiveCN108086174AGuaranteed service lifeGuaranteed construction effectClimate change adaptationBridge erection/assemblyJackscrewEngineering

The invention provides a shaping clamp for repairing of the surfaces of concrete guard bars and a repairing method of the shaping clamp, and relates to the field of bridge construction. The shaping clamp comprises a rectangular supporting plate, a stopping lever, a clamping piece and a jacking piece, wherein the stopping lever is connected to the edge of the outer side of the supporting plate; theclamping piece is connected to the bottom surface of the inner side of the supporting plate; and the jacking piece is connected to the top surface of the outer side of the supporting plate. The clamping piece comprises a clamping plate, nuts and jackscrews, the clamping plate is perpendicularly connected to the edge of the inner side of the supporting plate, the nuts and the jackscrews are horizontally welded to the bottom of the top plate at intervals, screw holes are horizontally formed in the bottom of the clamping plate at intervals and correspond to welding positions of the nuts, and thejackscrews successively penetrate through the nuts and the screw holes. The problem that templates need to be erected during repairing of the surfaces of existing concrete guard bars, construction isheavy and complicated, and construction of urban roads with narrow space and operation at night are not facilitated are solved, and meanwhile, the problem that the straightness and the flatness of the surfaces of anti-collision guard bars are low is solved.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP

Original soil afforesting method of moderate and severe saline and alkaline land

ActiveCN102763557BLow costQuick resultsClimate change adaptationAfforestationAlkali soilEcological environment

Owner:山东三益园林绿化有限公司

Health-care functional type beer drink

The invention relates to a health-care functional type beer drink, which is prepared from the following homologous food medicaments: Yunnan rhodiola, cassia seed, honeysuckle flower, negundo chastetree extracting solution, negundo chastetree honey, Chinese wolfberry and red jujube. The drink has the effects of strengthening the spleen and nourishing the stomach, soothing the sinews and quickening the blood, nourishing liver and kidney, clearing heat and resolving toxin, supplementing qi and blood, diminishing inflammation and benefiting gallbladder, moistening the intestine and freeing the stool, improving eyesight and enhancing immunity. The beer drink can regulate chronic diseases and promote health and longevity after being taken for a long time. The beer drink has the advantages of comfortable mouthfeel, reduction in blood fat and balanced nutrient and contribution to absorbing nutrient, which is an ideal edible healthy drink.

Owner:张振菲

Edge trimmer for insulation board production

InactiveCN112917551AHave the effect of trimmingReduce manpower lossMetal working apparatusStructural engineeringMechanical engineering

The invention relates to an edge trimmer for insulation board production. The edge trimmer comprises a mounting plate, wherein a connecting plate is arranged above the mounting plate, and an edge trimming device for trimming an insulation board is arranged on the connecting plate; and a strip-shaped hole is formed in the upper surface of the mounting plate, a rotating assembly is arranged in the strip-shaped hole, and the rotating assembly is used for rotating the heat preservation plate placed on the upper surface of the mounting plate so that different edges of the heat preservation plate can rotate to the position above the edge trimming device. The edge trimmer has the effect that the four edges of the insulation board can be conveniently subjected to edge trimming treatment.

Owner:四川世茂新材料有限公司

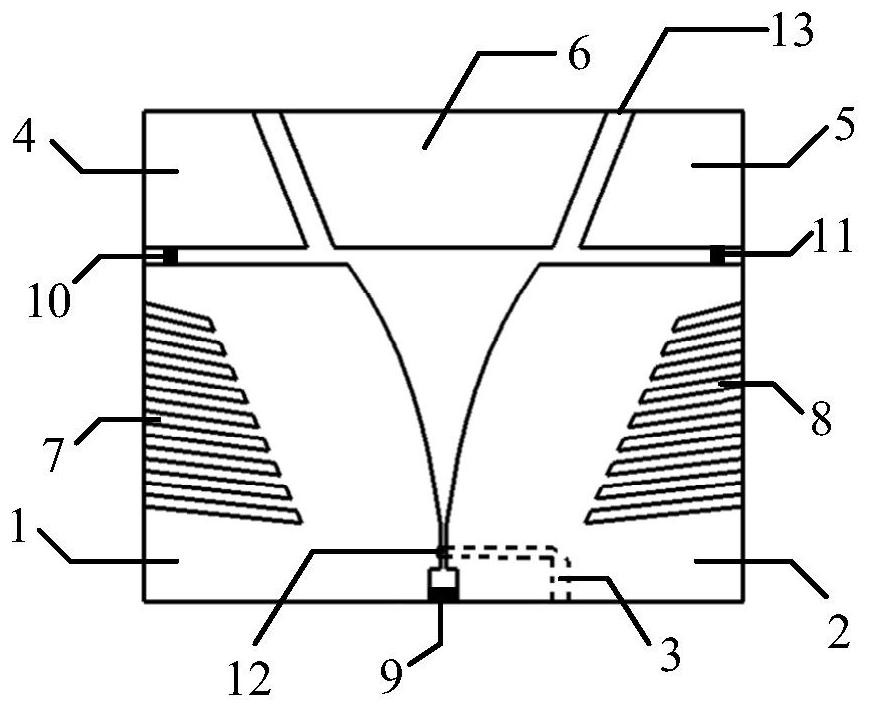

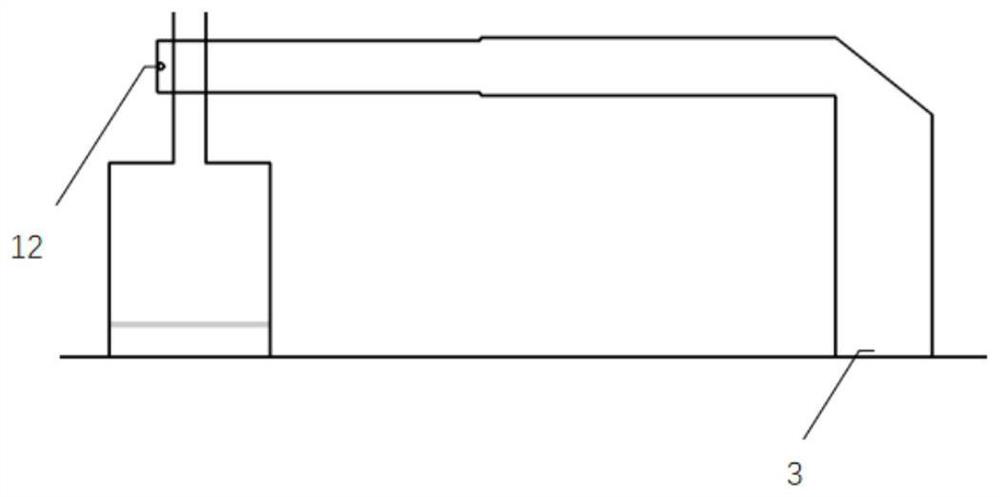

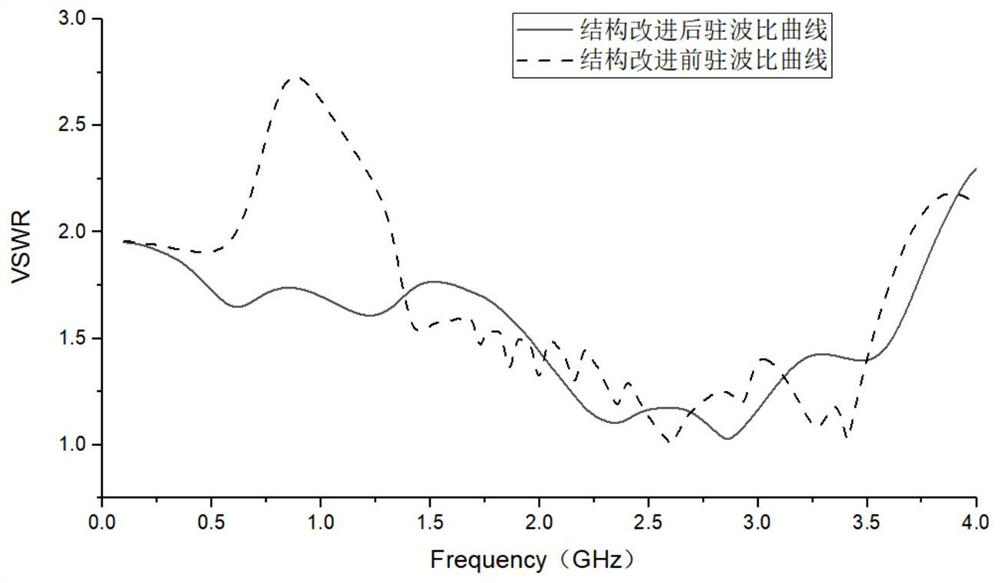

Broadband miniaturized Vivaldi antenna for discharge detection

PendingCN114069240AWith broadbandWith miniaturizationSlot antennasSubstantially flat resonant elementsDielectric plateMiniaturization

The invention discloses a broadband miniaturized Vivaldi antenna for discharge detection, and relates to the technical field of antennas. The antenna comprises a first radiation patch antenna and a second radiation patch antenna. The first radiation patch antenna is provided with a first gradual change gap. The second radiation patch antenna is provided with a second gradual change gap. The first radiation patch antenna and the second radiation patch antenna have the same structure, are symmetrically arranged on the front surface of the dielectric plate, and are electrically connected through the first loading resistor. According to the Vivaldi antenna, the structure is effectively improved, the Vivaldi antenna has the advantages of being wide in frequency band, small in size, simple in structure and low in manufacturing cost, and the dielectric lens is further arranged, so that the radiation performance of the antenna in the wide frequency band is more stable. The invention provides a comprehensive thought for designing a broadband, miniaturized and high-gain antenna.

Owner:SOUTHWEST JIAOTONG UNIV

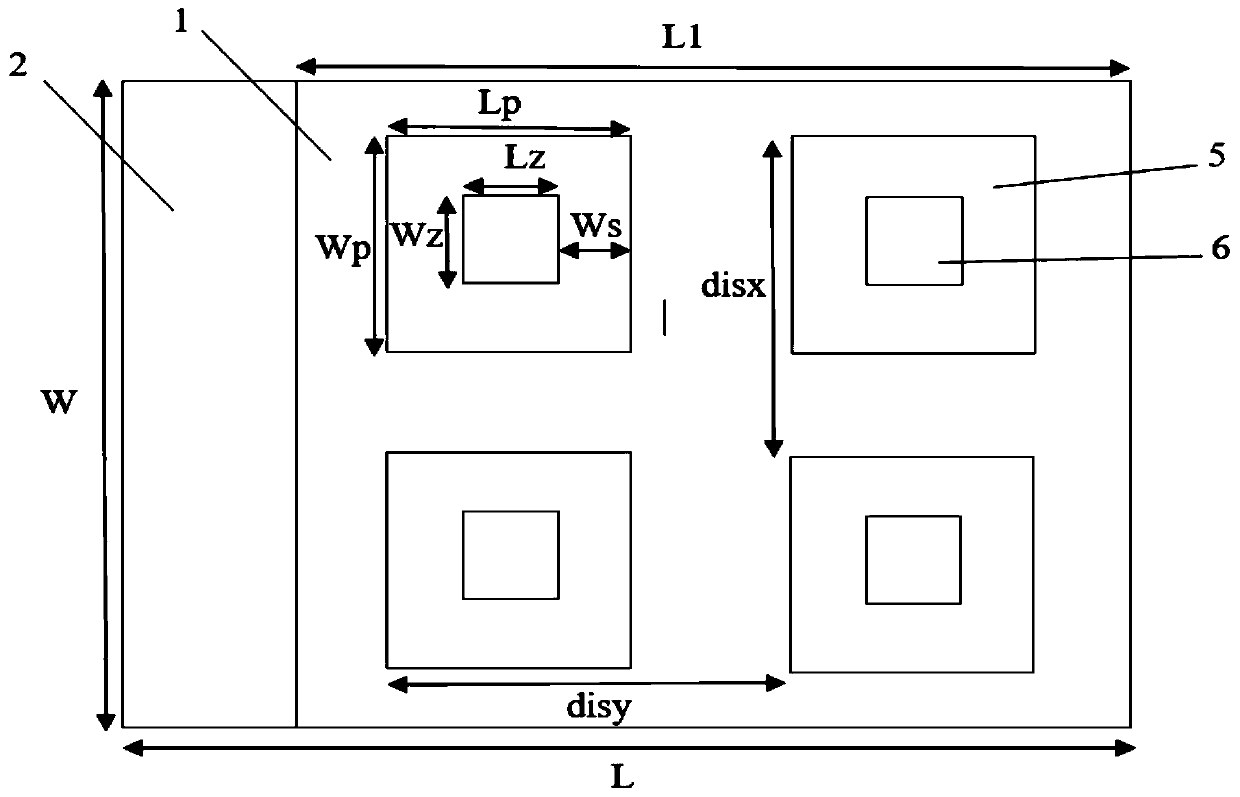

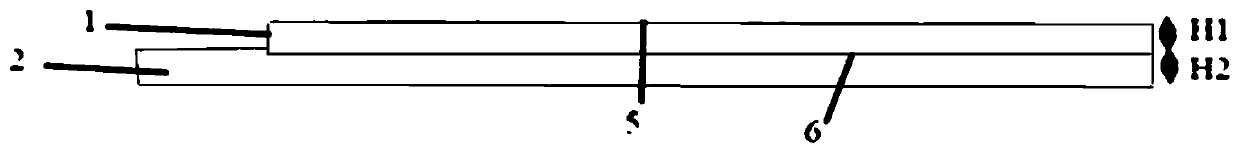

Parasitic patch array antenna substrate integrated waveguide feed

ActiveCN111244624AHigh gainHigh bandwidthAntenna arraysRadiating elements structural formsPatch arrayDielectric plate

The invention discloses a parasitic patch array antenna with substrate integrated waveguide feed. The parasitic patch array comprises a first dielectric plate, a second dielectric plate, a third dielectric plate and a fourth dielectric plate. The parasitic patch array is characterized in that the first dielectric plate is positioned above the second dielectric plate; the second dielectric plate ispositioned above the third dielectric plate; and the third dielectric plate is positioned above the fourth dielectric plate. The first dielectric plate is provided with an annular patch; the second dielectric plate is provided with a main radiation patch; metal through hole structures on the third dielectric plate and the fourth dielectric plate form a one-to-four substrate integrated waveguide feed network, and feed is carried out on the main radiation patch through a gap in the third dielectric plate. The annular patch plays a guiding role, and the substrate integrated waveguide feed network plays a role in reducing feed loss. The array antenna overcomes the defects of large feed loss and low gain of a microstrip patch array antenna, has the advantages of low profile, small size and easiness in planar circuit integration, and can be used for low-profile terahertz or millimeter wave communication.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for planting ginseng industrially by large cylinders

InactiveCN108184591AAvoid destructionSolve production constraints that cannot be reusedBio-organic fraction processingExcrement fertilisersSeeds sourceGreenhouse

The invention relates to the field of planting of traditional Chinese medicinal materials, and provides a method for planting ginseng industrially by large cylinders. Cylinder ginseng is obtained by amethod for planting ginseng, in the method, excellent wild ginseng seeds are screened out, the cylinder ginseng is planted in planting regions, courtyards, greenhouses and the like which are suitablefor growth of ginseng in northern China by common fired tile cylinders by prepared ginseng planting nutrient soil according to analysis and research on soil samples in a plurality of wild ginseng growth regions. The method comprises the following steps: (1) environment selection, (2) erection of an arch-shaped shed, (3) preparation of ginseng planting cylinders, (4) site leveling, (5) sterilizingand loading of nutrient soil, (6) site cylinder placement, (7) seed source selection, (8) seed germination accelerating treatment, (9) seed sowing, (10) growth period management, (11) disease prevention, (12) period of dormancy management, (13) ginseng root harvesting, (14) ginseng root processing, and (15) box packing and storage and the like. By the technical method for planting ginseng industrially by large cylinders, wild ginseng products with high economic benefit and high quality can be produced.

Owner:吉林紫鑫红石种养殖有限公司

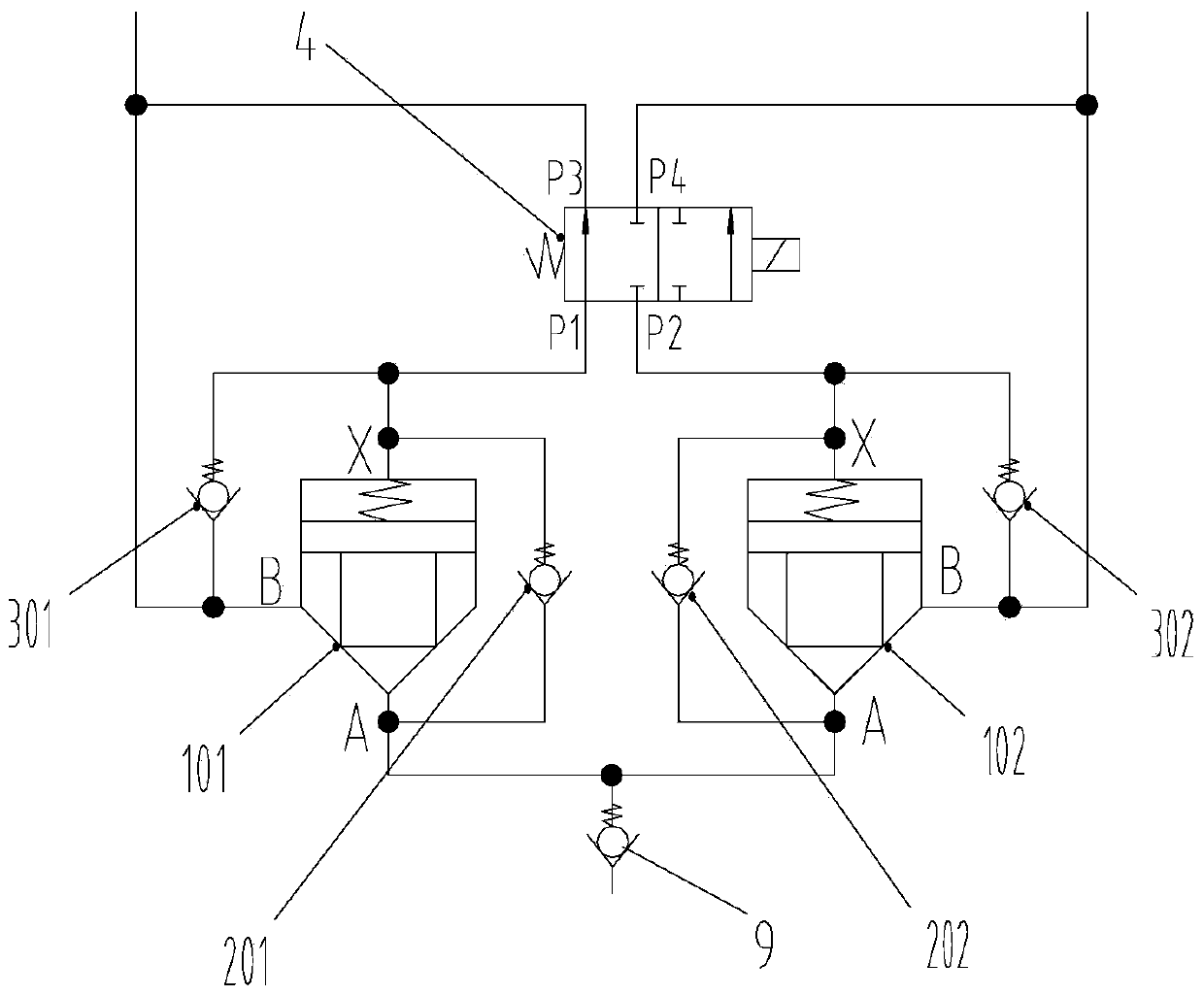

Electrohydraulic control reserving valve and electrohydraulic control system

ActiveCN104214157ALarge circulation capacityPlay a leading roleServomotor componentsServomotorsControl systemControl engineering

The invention discloses an electrohydraulic control reversing valve and an electrohydraulic control system and belongs to the field of hydraulic valves. The electrohydraulic control reserving valve comprises a first cartridge valve, a second cartridge valve and a two-position four-way electromagnetic directional valve, wherein a port A of the first cartridge valve is communicated with a port A of the second cartridge valve; a port X of the first cartridge valve is communicated with a port P1 of the two-position four-way electromagnetic directional valve; a port X of the second cartridge valve is communicated with a port P2 of the two-position four-way electromagnetic directional valve; a port P3 of the two-position four-way electromagnetic directional valve and a port B of the first cartridge valve are communicated with a first actuating mechanism; the two-position four-way electromagnetic directional valve is communicated with the first actuating mechanism; a port B of the two-position four-way electromagnetic directional valve is communicated with a second actuating mechanism. The electrohydraulic control system comprises the electrohydraulic control reversing valve, a hydraulic pump and an actuating mechanism, wherein the electrohydraulic control reversing valve comprises the cartridge valves and the two-position four-way electromagnetic directional valve, so that the electrohydraulic control reversing valve has relatively high flow capacity.

Owner:WUHAN MARINE MACHINERY PLANT

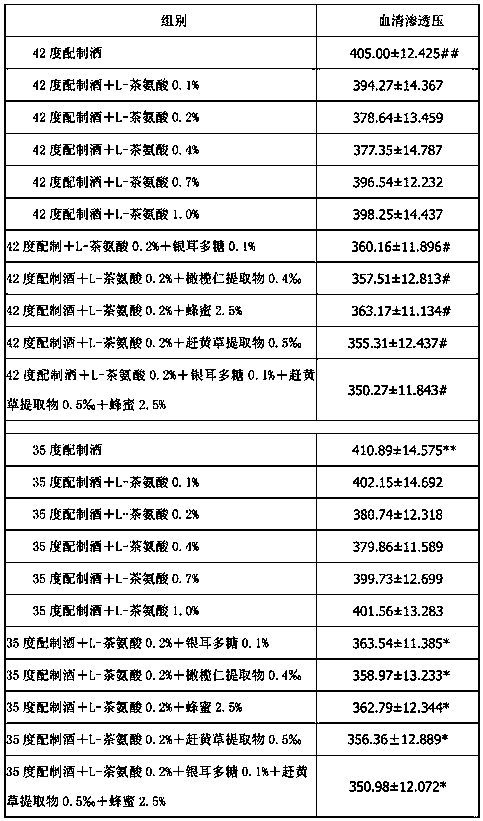

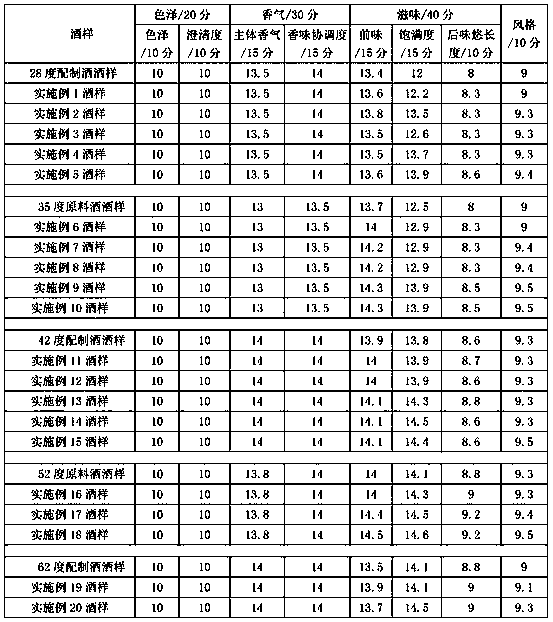

Low-mouth-dryness compound wine

InactiveCN108795674AReduce mouth dryness after drinkingPlay a leading roleOrganic active ingredientsDigestive systemExperimental researchTremella

The invention discloses low-mouth-dryness compound wine, the low-mouth-dryness compound wine has the advantages that L-theanine is added into a wine body appropriately, or compositions comprising theL-theanine and one or more of tremella polysaccharide, olive kernel extract, penthorum chinense pursh herb extract and honey are added into the wine body appropriately to reduce the mouth dryness of the wine body; the comfort level of drinkers after drinking is improved, and quality of the wine is improved; additives in the wine are the L-theanine or the compositions comprising the L-theanine andone or more of the tremella polysaccharide, the olive kernel extract, the penthorum chinense pursh herb extract and the honey, which meet corresponding national quality standards; corresponding reviewby professional judges and animal experimental researches are completed, and results show that the mouth dryness of the wine can be reduced no matter whether the L-theanine is added or the compositions comprising the L-theanine and other plant extract are added, so that the obvious positive effect on quality improvement of the compound wine is achieved, and the compound wine plays a leading rolein safety healthy development of the wine industry.

Owner:JING BRAND

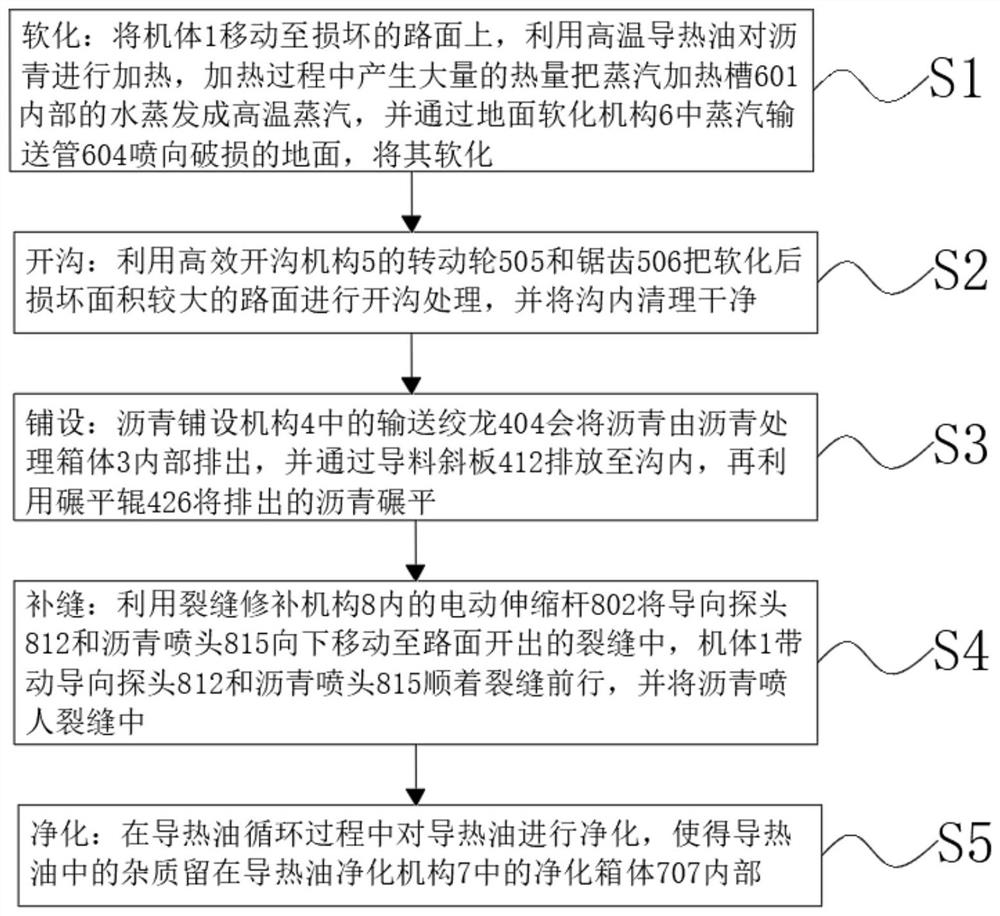

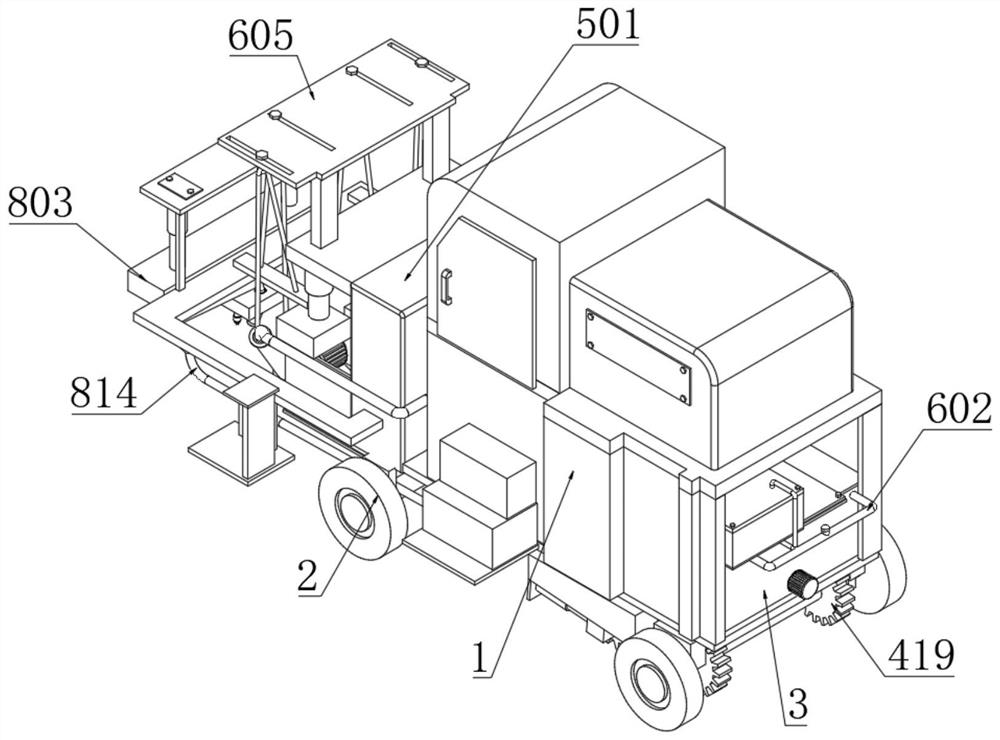

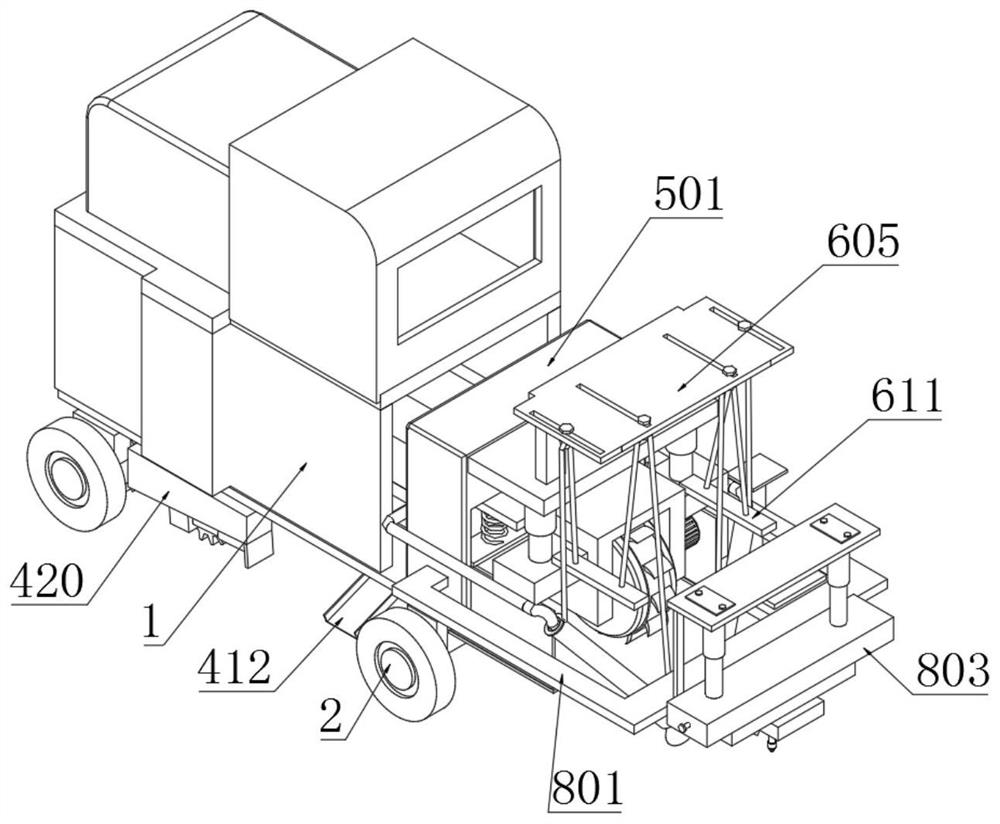

Repairing method based on highway maintenance management

InactiveCN114059430AScientific and reasonable structureEasy to useRoads maintainenceCircular discThermodynamics

Owner:韦海强

Early maturing culture method of corn

InactiveCN106856961APromote growthAvoid damagePlant cultivationCultivating equipmentsAgricultural scienceSheet mulching

The invention relates to the field of agricultural planting, and provides an early maturing culture method of corn. The method comprises the steps that seeds are sowed in a planting field, and a hole is arranged above the sowed seeds. The hole is covered with a mulching film. After seeds sprout, holes are punched in the surface of the mulching film, and seedlings can pass through the film holes to keep growing. The method can make fresh edible corn on the market around 10 days earlier, which effectively increases farmers' income and ensures green safety production. The method is capable of making effects of cold protection, seedling protection and soil moisture conservation, and has the advantages of low cost, advance, practicality and strong operability, thereby facilitating the technical extension and radiation and playing a role of driving effect.

Owner:ZHANGYE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com