Shaping clamp for repairing of surfaces of concrete guard bars and repairing method of shaping clamp

A technology for shaping fixtures and surface repair, which is used in bridge maintenance, bridge erection/assembly, bridge reinforcement, etc. It can solve the problems of inconvenient space construction and night work, low straightness and flatness of the surface of the anti-collision guardrail, and complicated construction. , to achieve the effect of ensuring service life, reducing construction costs and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

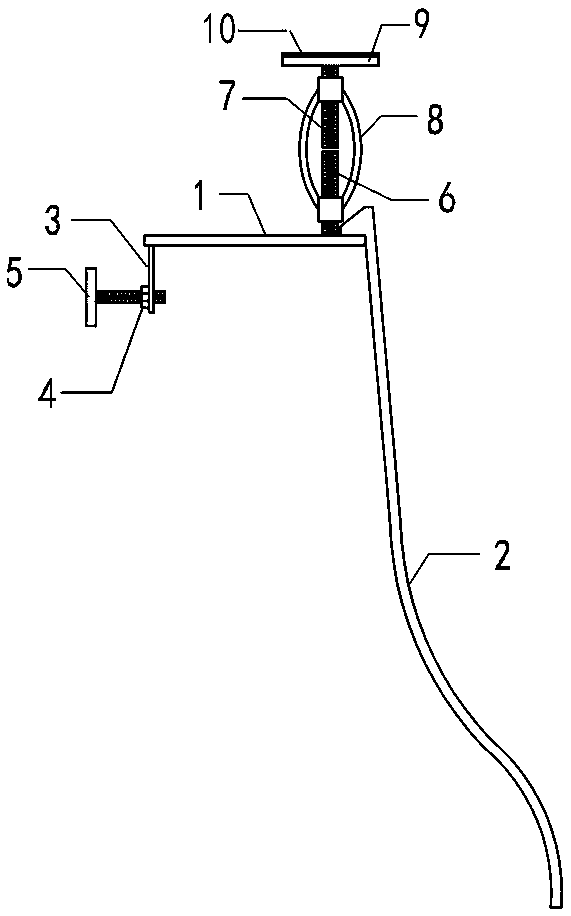

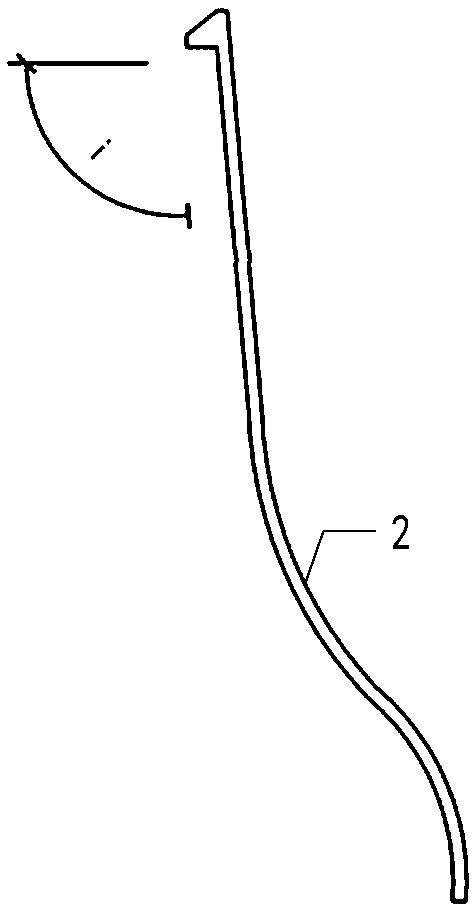

[0050] see example figure 1As shown in the figure, a shaping fixture for repairing the surface of a concrete guardrail and a repairing method thereof, the shaping fixture for repairing the surface of a concrete guardrail comprises a rectangular support plate 1, a blocking rod 2 connected to the outer edge of the support plate 1, a connection The engaging member on the inner bottom surface of the support plate 1 and the top support member connected to the outer top surface of the supporting plate 1; The nut 4 and the top wire 5 welded on the bottom of the top plate at intervals, see Figure 5 As shown, corresponding to the welding position of the nut 4, the bottom of the clamping plate 3 is horizontally spaced with screw holes, and the top wire 5 passes through the screw cap 4 and the screw holes in turn; The first screw 6 on the top surface of the support plate 1, the second screw 7 vertically arranged directly above the first screw 6, the connecting ring 8 sleeved between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com