Patents

Literature

203results about How to "Reduce manpower loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

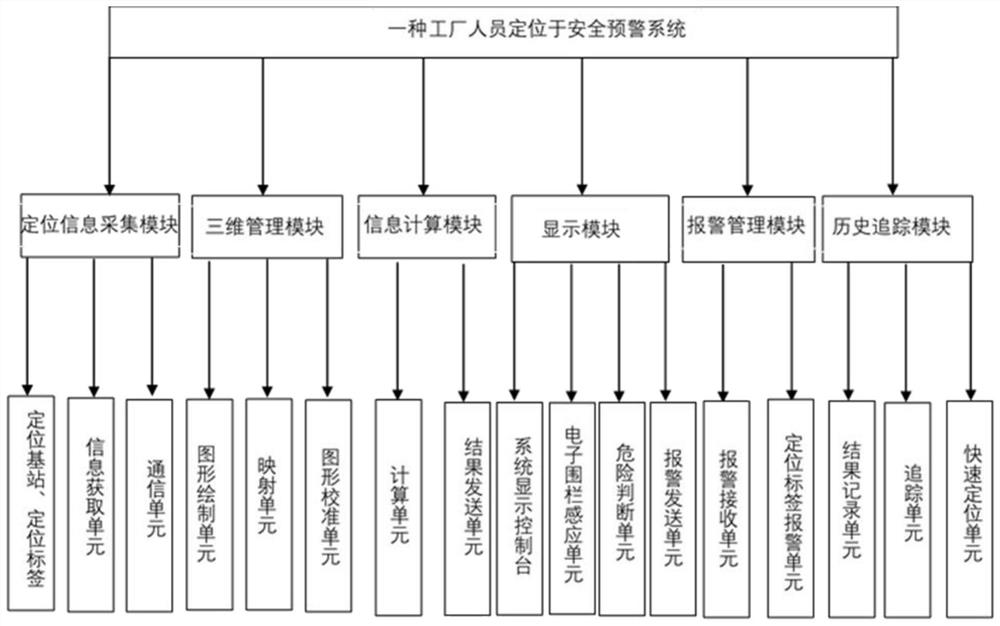

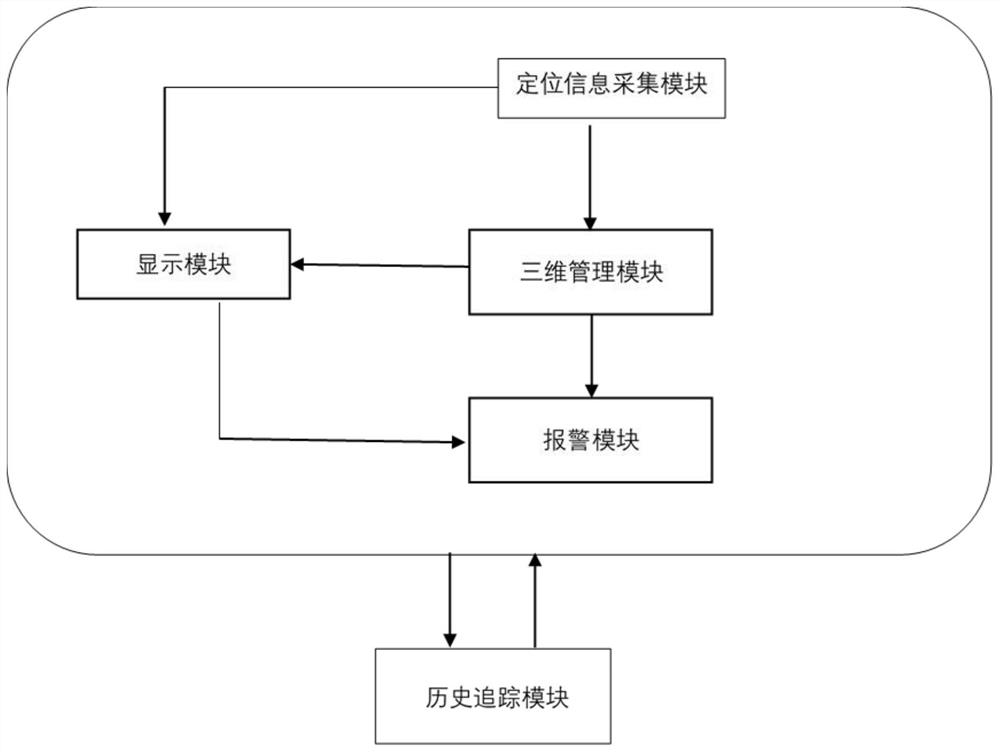

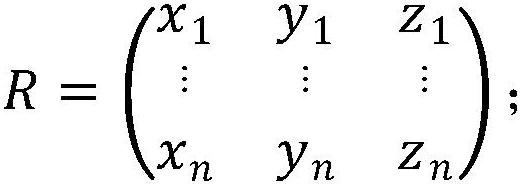

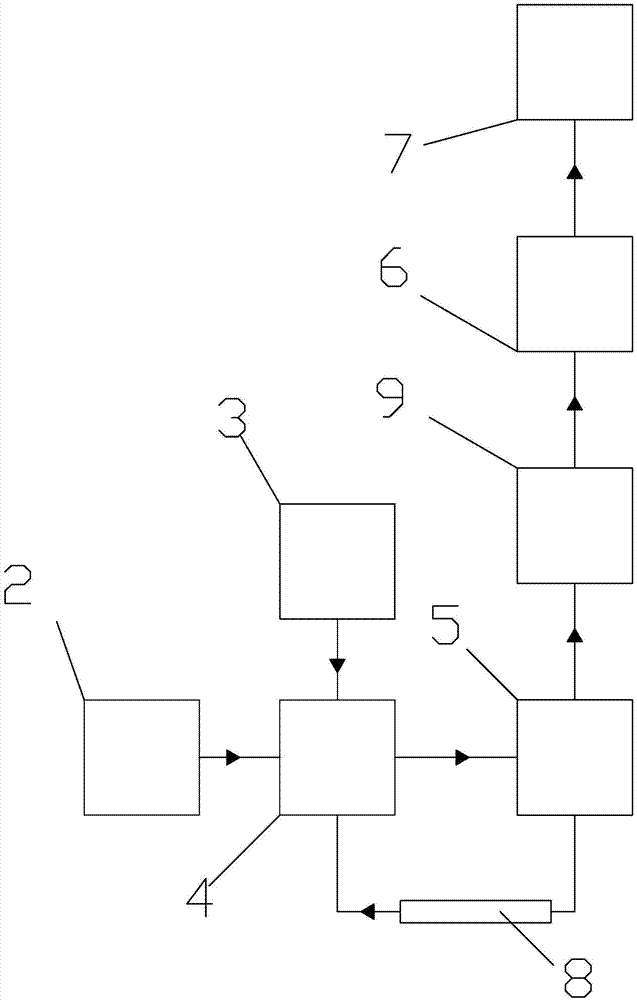

Factory personnel positioning and safety early warning system

PendingCN111811516AImprove accuracyImprove effectivenessNavigational calculation instrumentsAlarmsEarly warning systemEngineering

The invention discloses a factory personnel positioning and safety early warning system. The system comprises a positioning information acquisition module, a three-dimensional management module, an information calculation module, a display module, an alarm management module and a historical tracking module, wherein the positioning information acquisition module is arranged, the position information of the factory personnel can be acquired in real time, the three-dimensional management module and the information calculation module are used, an action path is updated and calculated, the positionis mapped into a coordinate system, accuracy of positioning is improved, the factory personnel safety state calculation result is fed back to the display module in time, the system can master a safety state of the factory personnel at the first time, safety reminding is carried out, effectiveness of safety management is effectively improved, when a safety problem occurs, an alarm can be sent to factory personnel in time, manpower loss is reduced to the minimum, an emergency safety problem can be timely solved, and the utilization rate of various resources in a factory is improved.

Owner:南京和光智能制造研究院有限公司

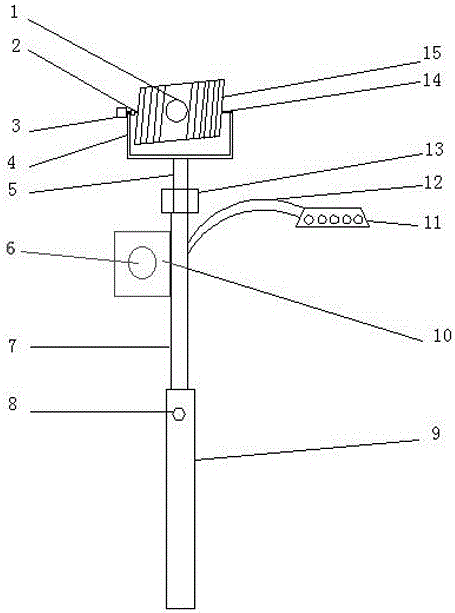

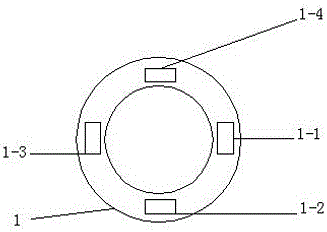

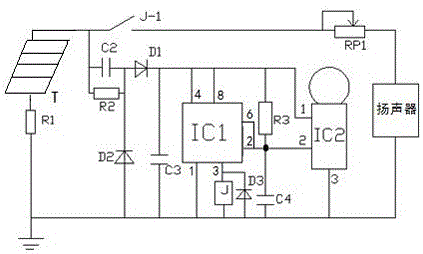

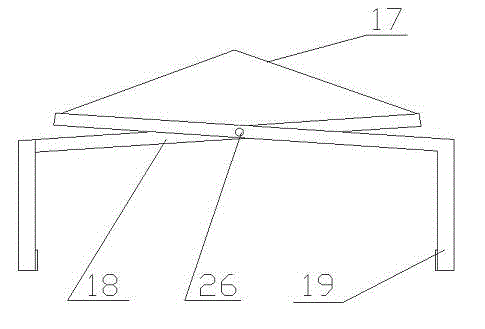

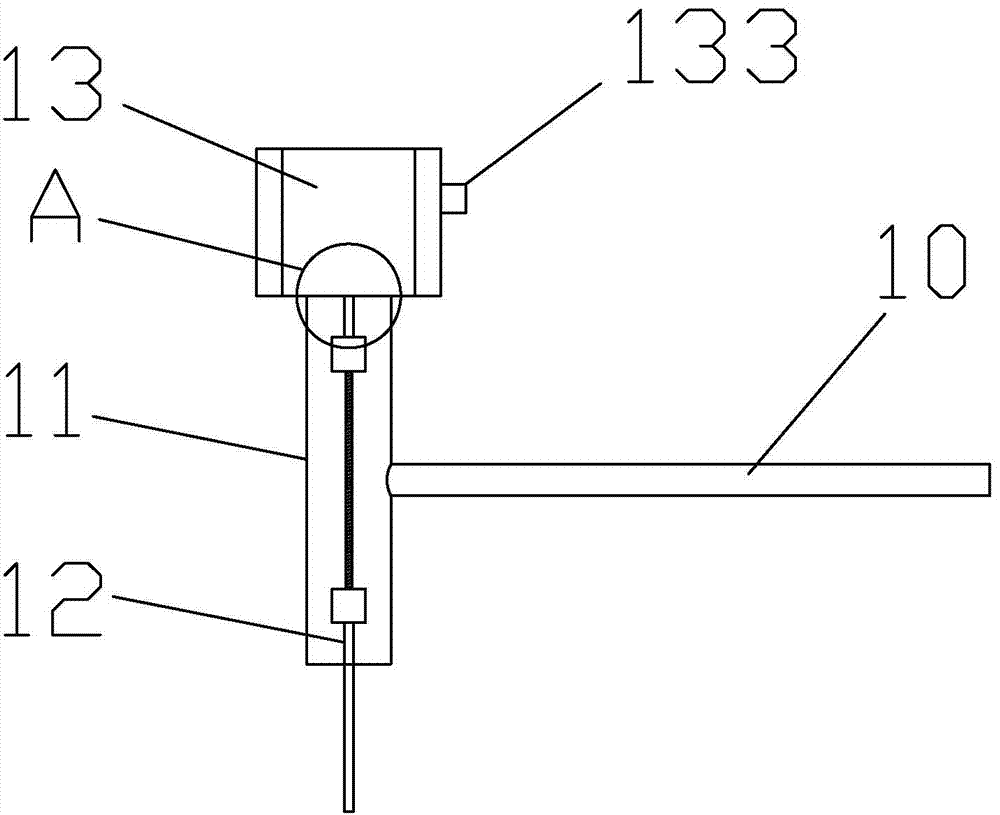

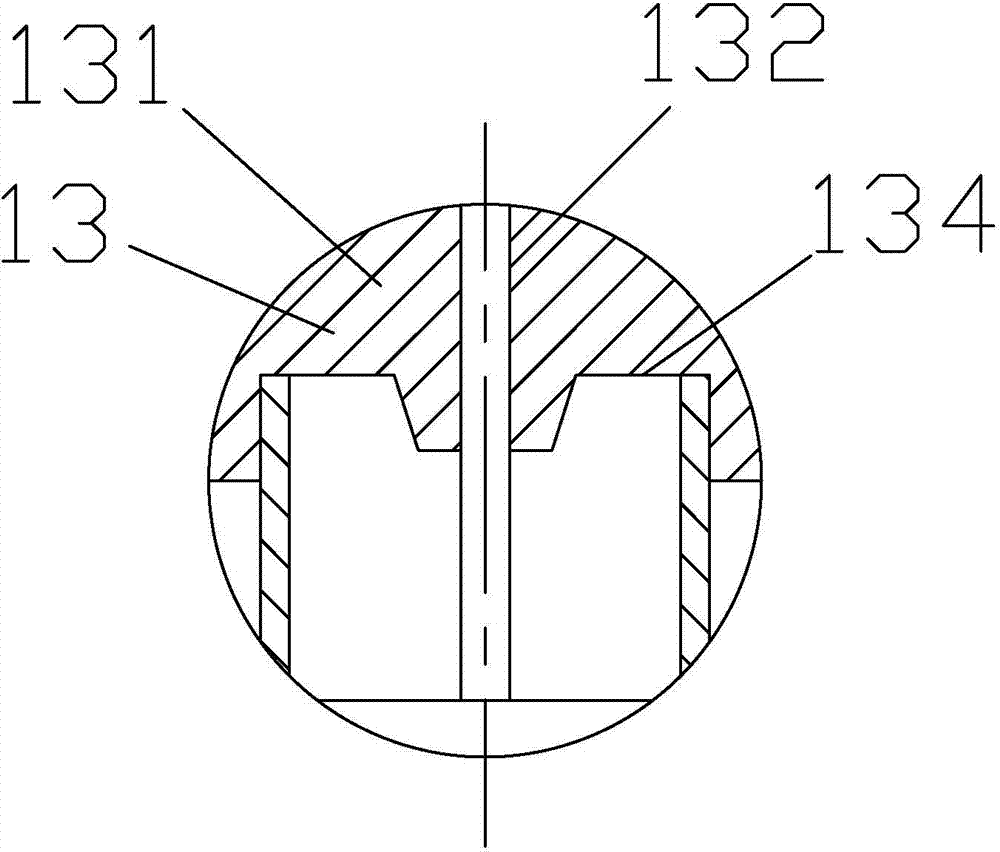

Automatic tracking type solar street lamp

InactiveCN106594659AAvoid affecting workImprove applicabilityPhotovoltaic supportsMechanical apparatusElectrical resistance and conductanceSolar street light

The invention discloses an automatic tracking type solar street lamp which comprises a solar cell panel, a tracking sensor, a rotating frame, a coupler, a transmission rod, a first motor, a second motor, a main shaft, a first lamp pole, a second lamp pole, a rainproof box, a bird repelling device, a lamp frame, an LED lamp and a fastening screw. According to the automatic tracking type solar street lamp, the tracking sensor composed of four photoresistors is adopted, and therefore the deflection angle, namely the azimuth angle of the sun moving from east to west and the sun apparent altitude, namely the altitude angle of the sun can be detected; the first motor and the second motor are used for controlling the direction and the angle of the solar panel so that illumination all day can be sufficiently utilized; the bird repelling device part with a rainproof structure is additionally arranged so that the phenomenon that birds move on the solar panel, and consequently work of the whole device is affected can be prevented, and applicability is improved; and the lamp poles are of adjustable structures, a worker does not need to climb up the lamp poles when parts need to be replaced or the street lamp needs to be repaired, and labor losses are reduced.

Owner:苏晓玲

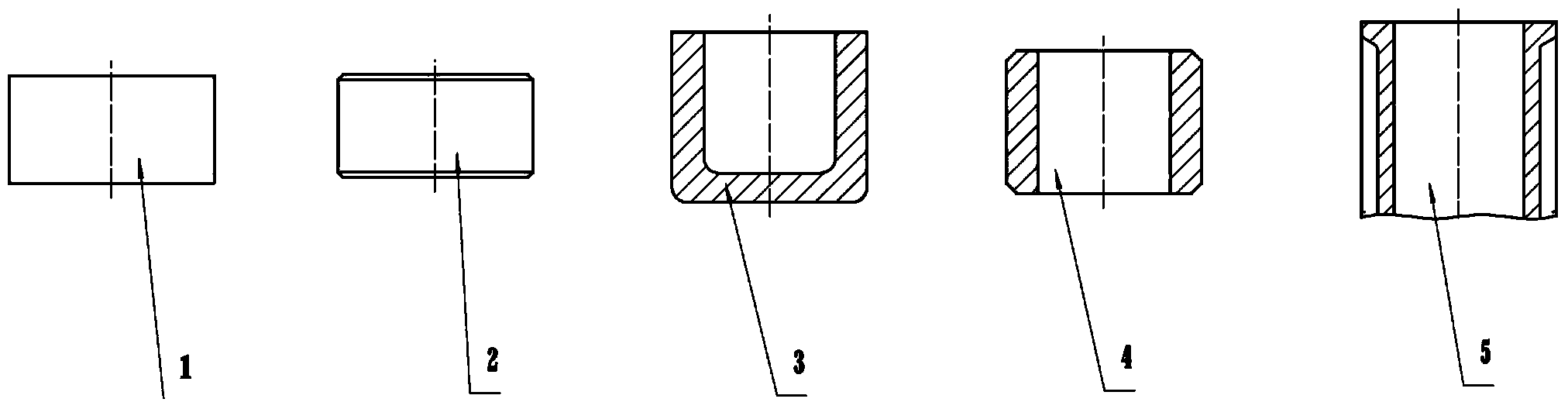

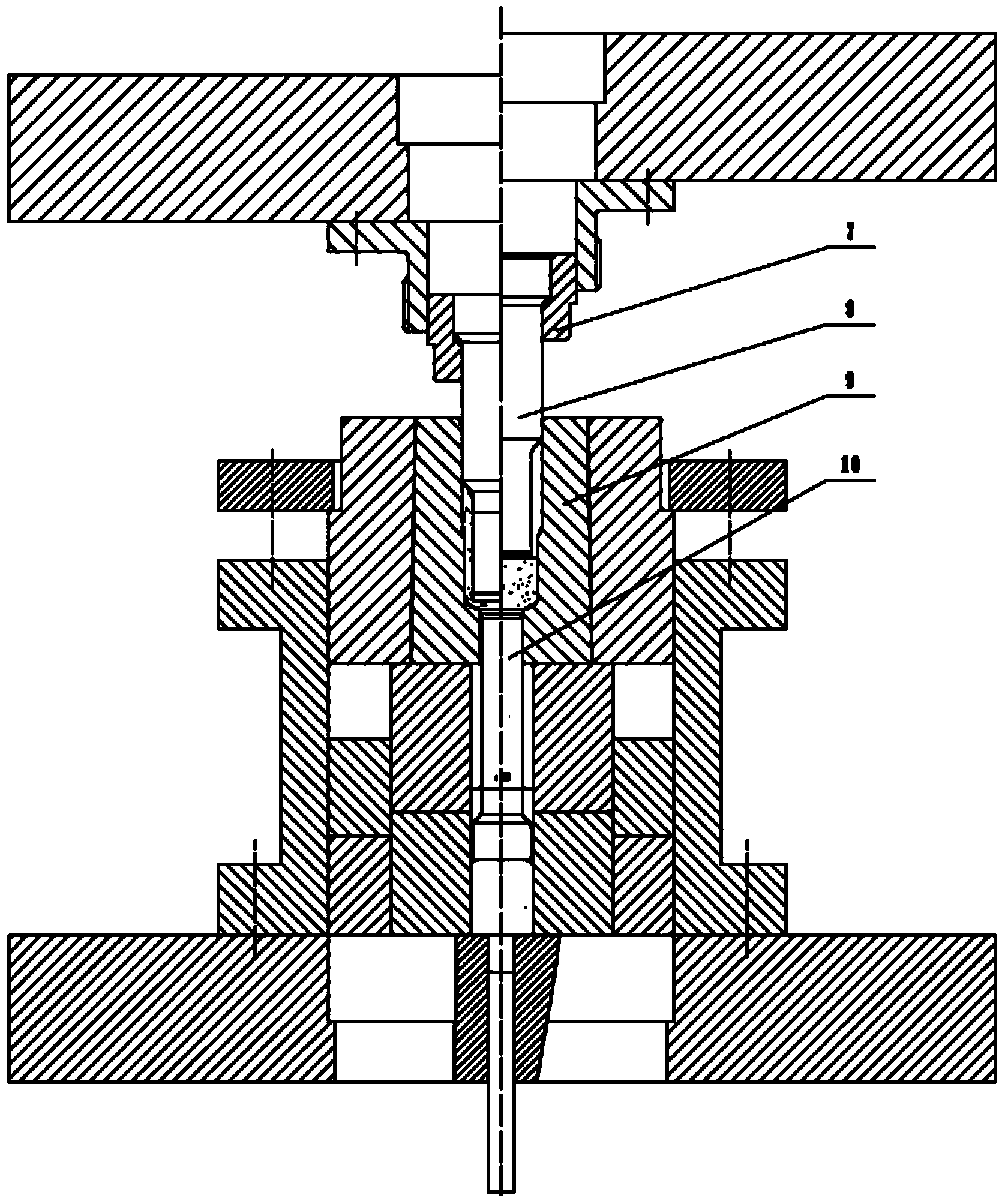

Precision external spline pipe forming method

ActiveCN103934638ASolve the problem of batch processingImprove the finishExtrusion diesEngineeringHardness

The invention provides a precision external spline pipe forming method. The method comprises the steps that hot rolling bars are sawn, spheroidizing annealing is conducted, and bars are formed through cylindrical turning; shot blasting is conducted on the bars, the bars are processed through phosphorus saponification, and workblank is formed; reverse extrusion, radial facing, chamfering, phosphorus saponification processing and external spline forward extrusion are conducted on the workblank, and the external spline pipe is obtained. According to the precision external spline pipe forming method, the precision external spline pipe can be produced through the common hot rolling bars, and the problem that external spline batch machining is difficult for multiple enterprises is solved. The precision external spline pipe formed by the method is compact in internal structure and stable in hardness number, and the surface smooth finish of the external splines is high and can be smaller than or equal to Ra1.6; in addition, the machining cost is low, machining efficiency is high, follow-up cutting machining amount is small, the requirement for batch production can be met, labor loss is saved, and the enterprise cost is reduced.

Owner:JIANGSU SUNWAY PRECISION FORGING

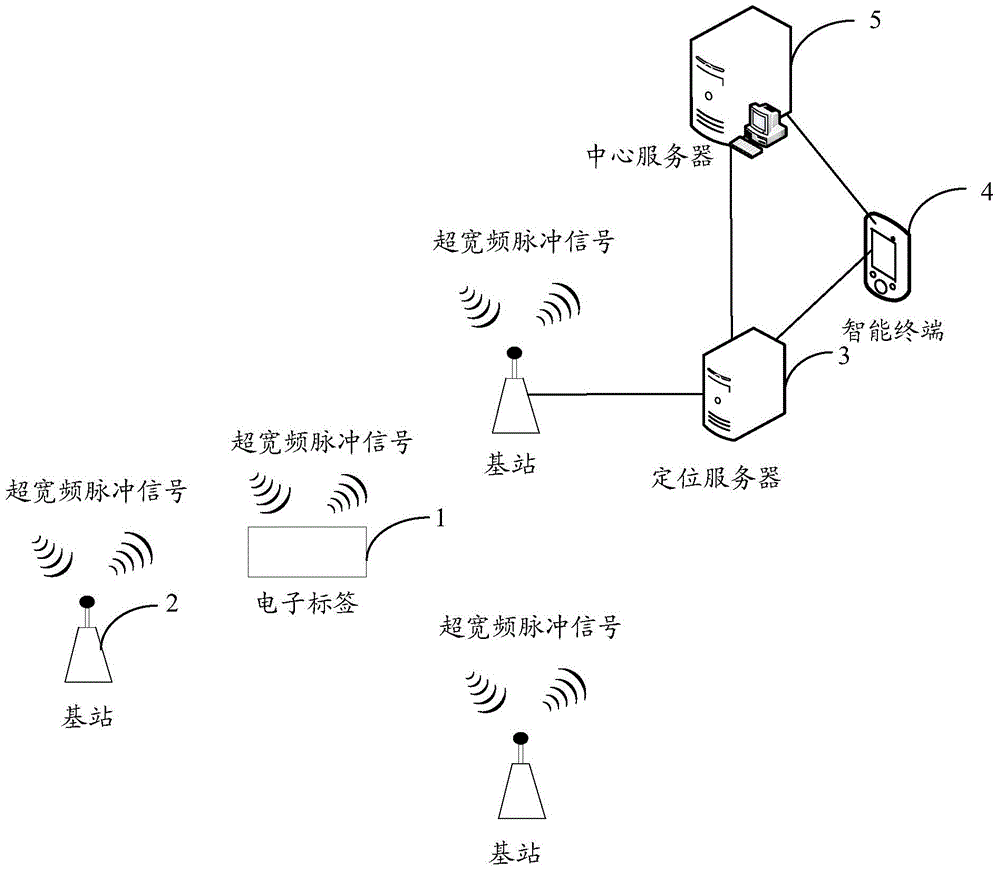

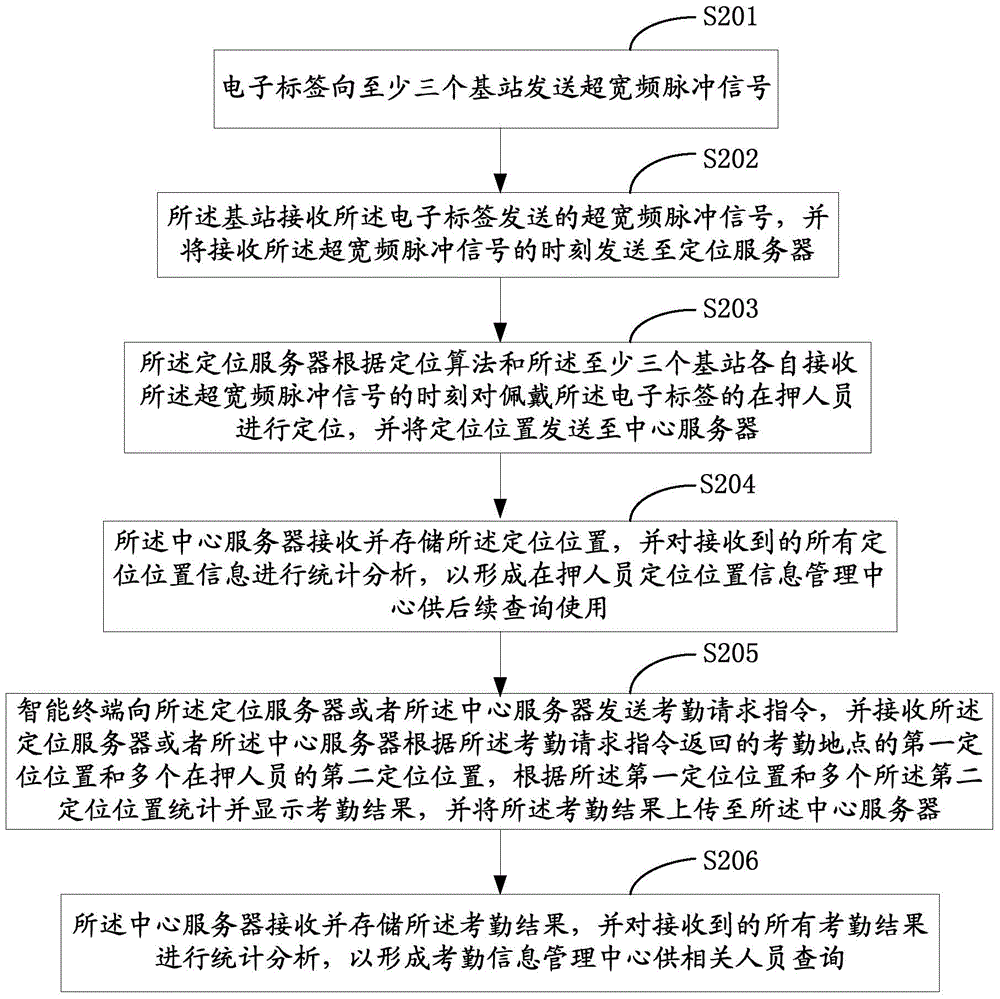

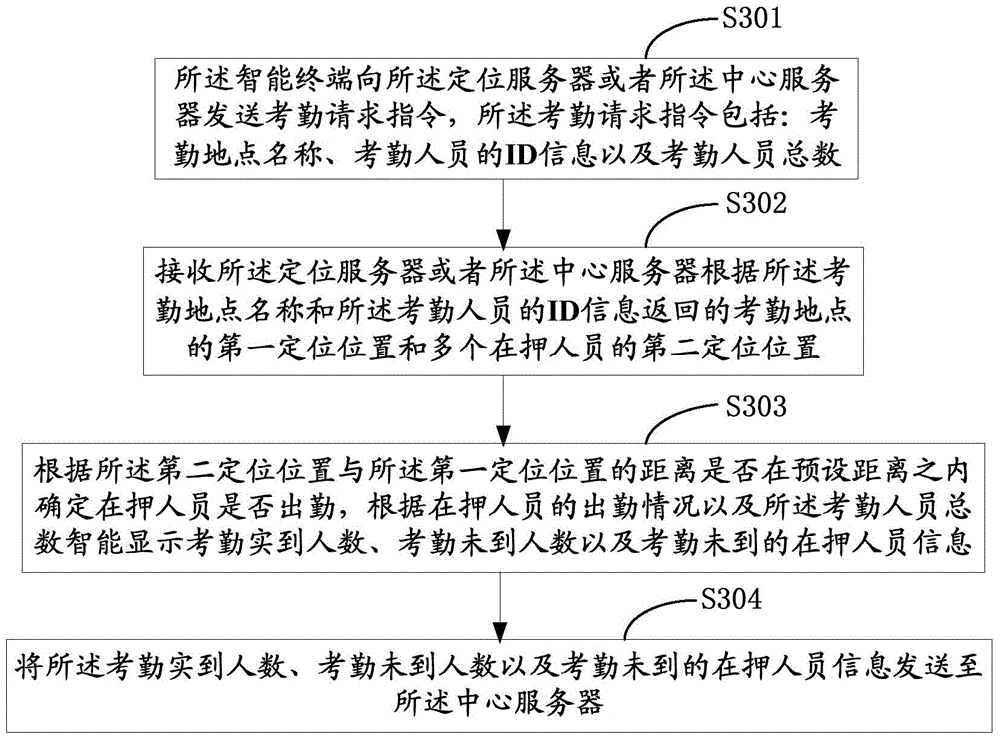

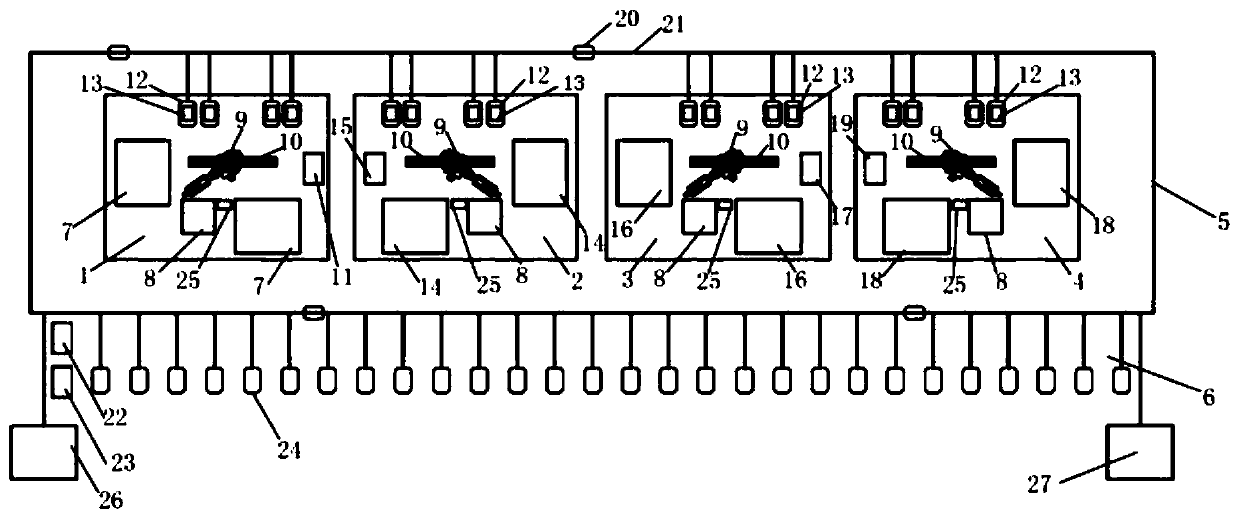

Detainee attendance system and method

ActiveCN105006029AConvenient attendance managementGood assistance in attendance managementRegistering/indicating time of eventsTransmissionUltra-widebandComputer science

The invention provides a detainee attendance system and method. The system comprises electronic tags, base stations, a positioning server, an intelligent terminal and a center server, wherein the electronic tags are used for transmitting ultra-wideband pulse signals to the at least three base stations; the base stations are used for transmitting the moments of receiving the ultra-wideband pulse signals to the positioning server; the positioning server is used for positioning detainees wearing the electronic tags according to a positioning algorithm and the respective moments of receiving the ultra-wideband pulse signals of the base stations and transmitting the positioning positions to the center server; the intelligent terminal is used for obtaining an attendance place and the positioning positions of the detainees from the positioning server or the center server according to an attendance request instruction, obtaining an attendance result according to the positioning positions and uploading the attendance result to the center server; the center server is used for carrying out statistics on the received attendance result to form an attendance information management center for related personnel to inquire. The detainees can be positioned at high accuracy, the positioning stability is enhanced, and the detainee attendance system can well help jailers to carry out attendance management on the detainees.

Owner:SHENZHEN RUNAN SCI & TECH DEVCO

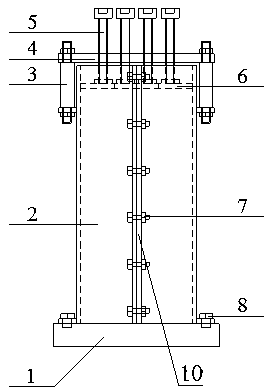

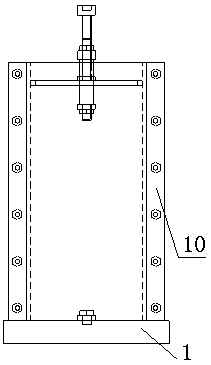

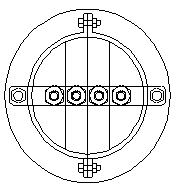

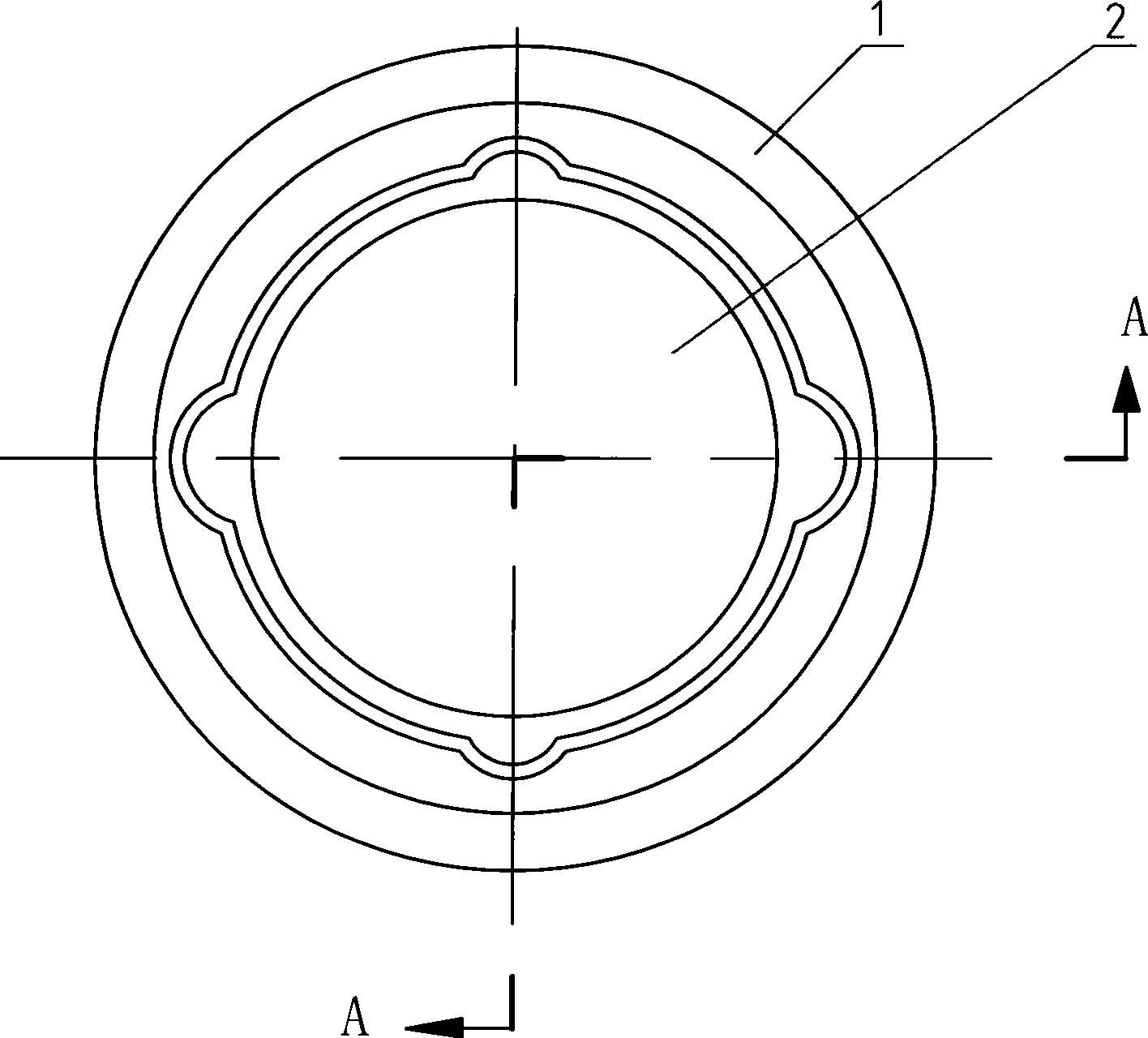

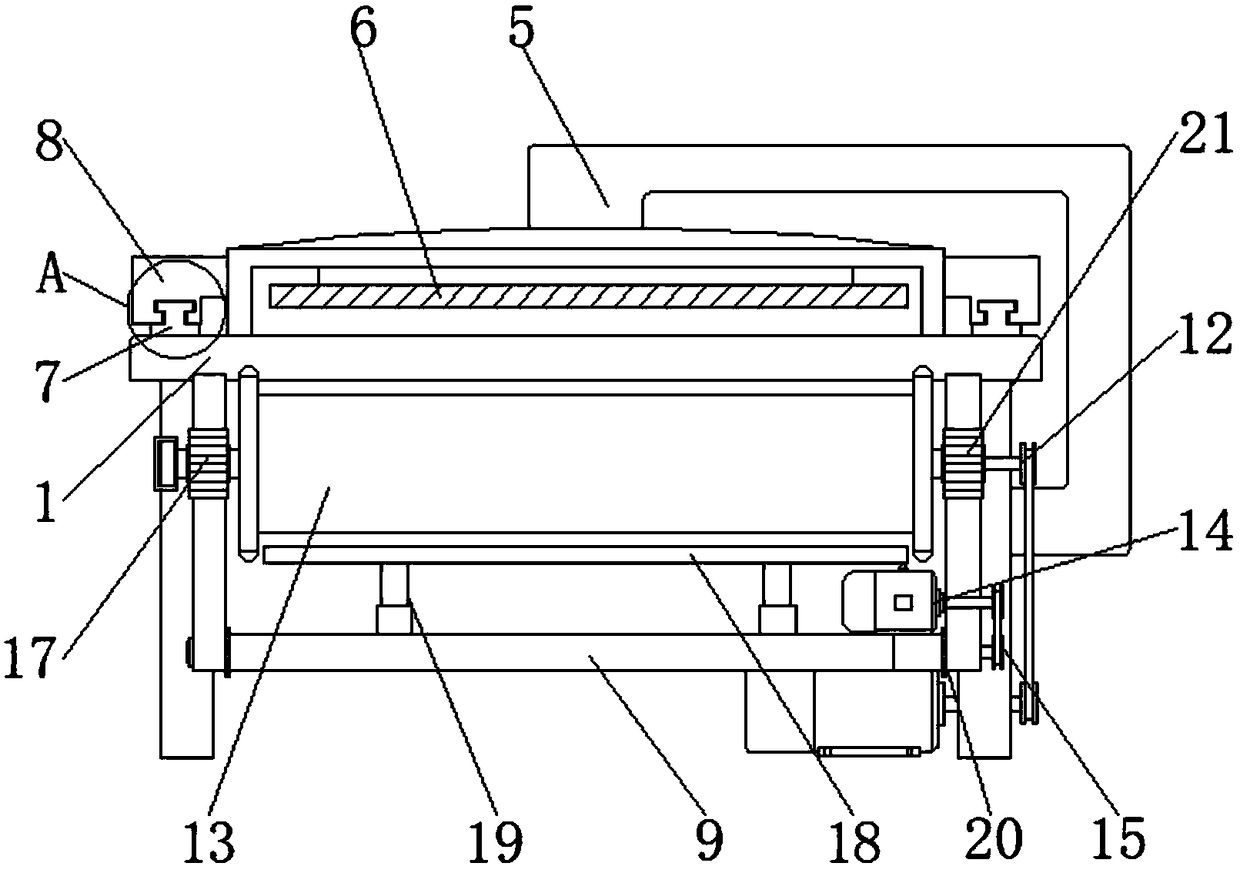

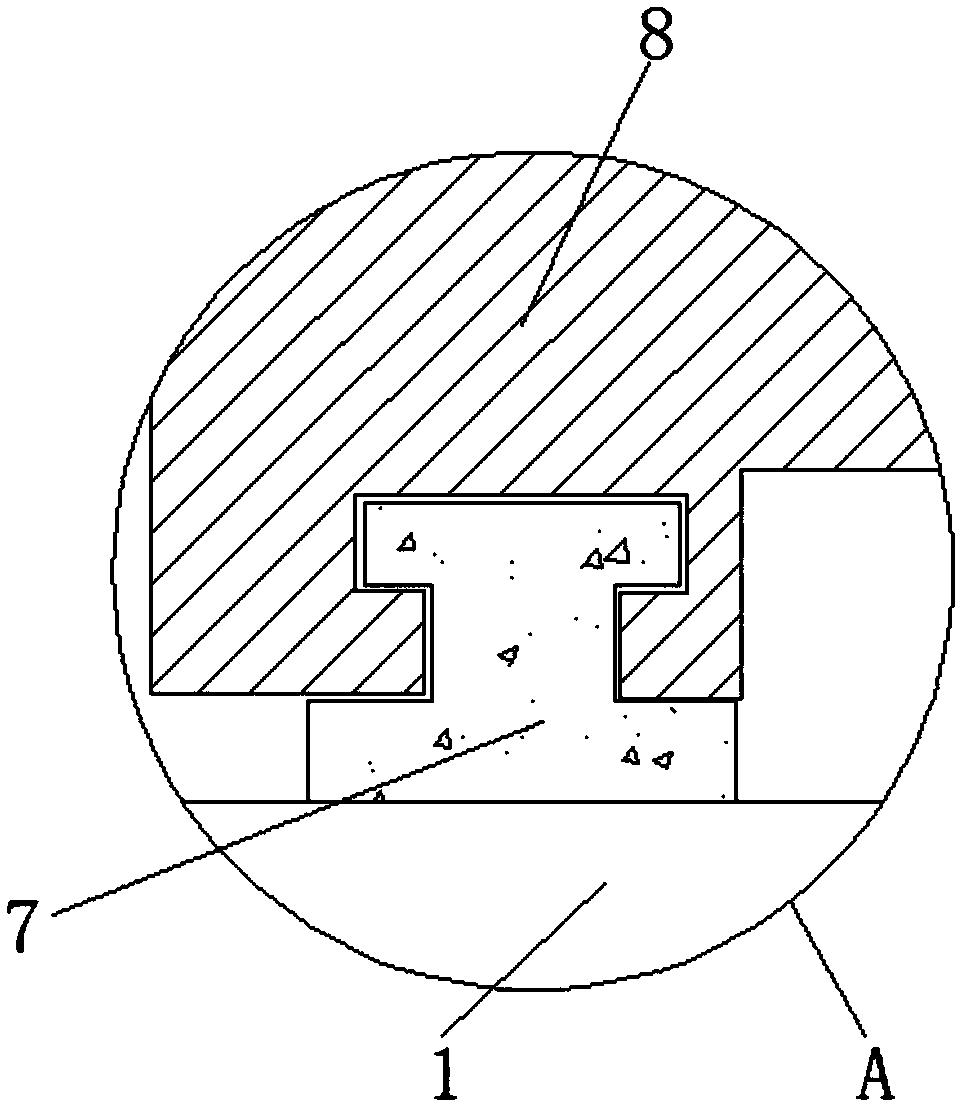

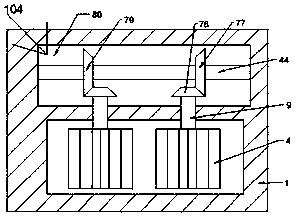

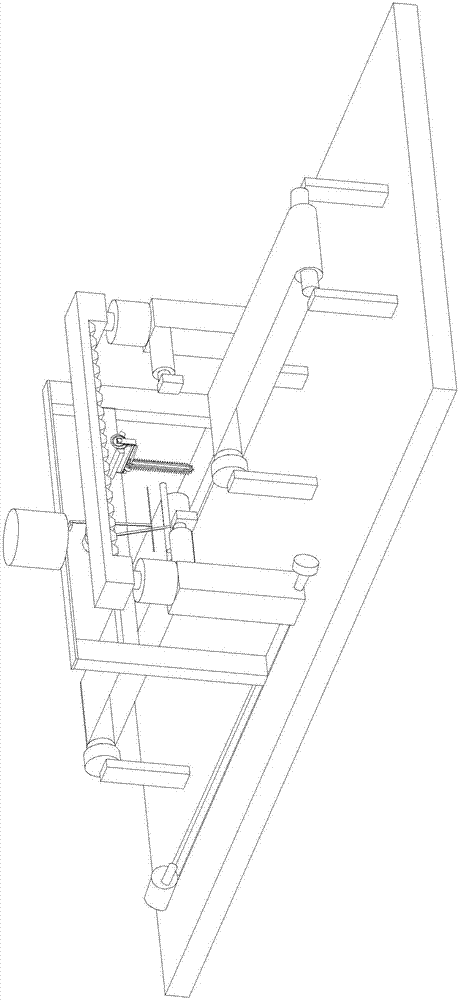

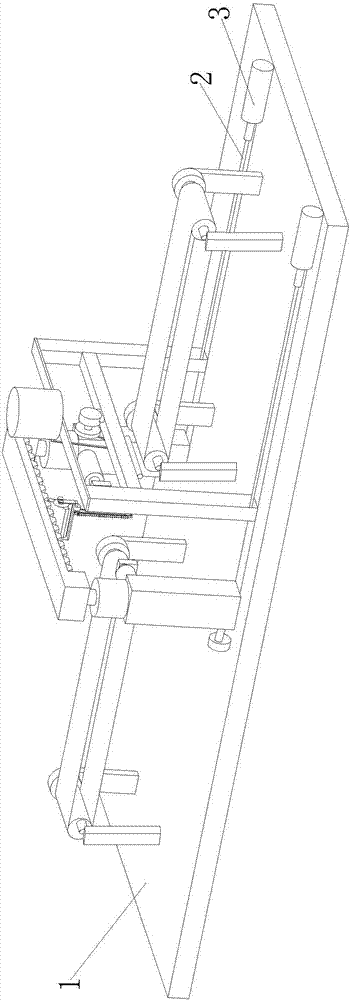

Filling body and surrounding rock composite rock mass routine test sample manufacturing mould and manufacturing method

ActiveCN107255586APerfecting the Research Method of Indoor Mechanics TestAvoid damagePreparing sample for investigationStructure of the EarthTest sample

The invention relates to the field of mine filling body and surrounding rock composite rock mass mechanical property test, in particular to a filling body and surrounding rock composite rock mass routine test sample manufacturing mould and a manufacturing method. A mould plate is mounted on a base; the mould plate consists of two semicircular structures; lugs are connected with a reaction frame through fixing bolts; the reaction frame is arranged above the mould plate; fixing jack screws are mounted on the reaction frame; and an upper pressing plate consists of a plurality of split type structures. The manufacturing method comprises the following steps: determining the numbers of the upper pressing plates which are applied to fixing the upper planes of surrounding rocks and the fixing jack screws which are matched with the upper pressing plates according to the type of the composite rock mass; preparing filling slurry, and casting the filling slurry into circular pore cavities filled with the surrounding rocks; applying the upper pressing plates which are not used in the split structures and the fixing jack screws to enclose a composite rock mass test sample; demoulding after the composite rock mass test sample is placed in a curing room for 24 hours, curing the filling body after the composite rock mass test sample is demoulded; and grinding a cured test sample into a standard test sample. According to the filling body and surrounding rock composite rock mass routine test sample manufacturing mould and the manufacturing method, the damage to a test sample caused by conventional field drilling and cutting sampling is avoided; and the manufacturing cost is reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

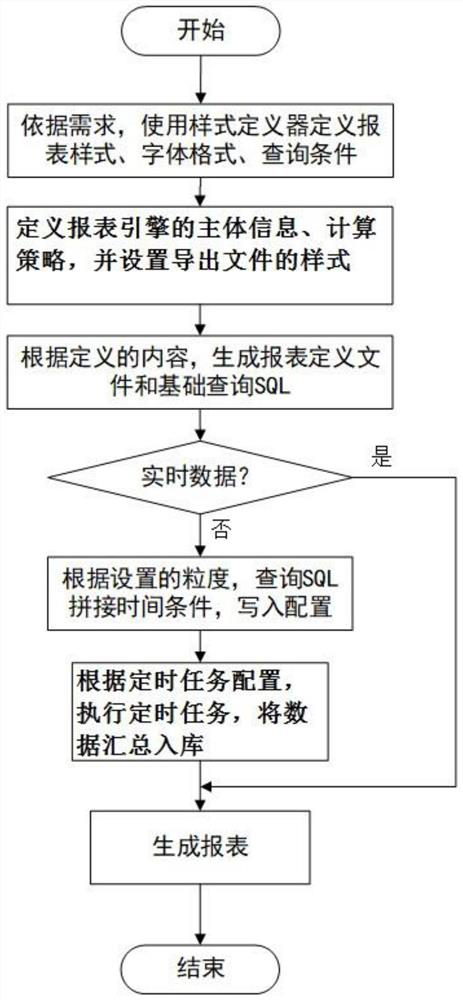

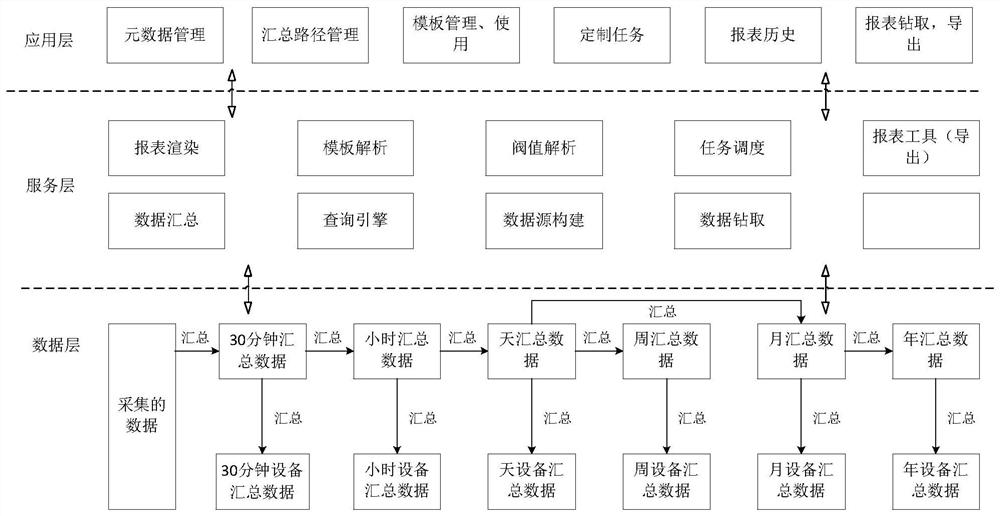

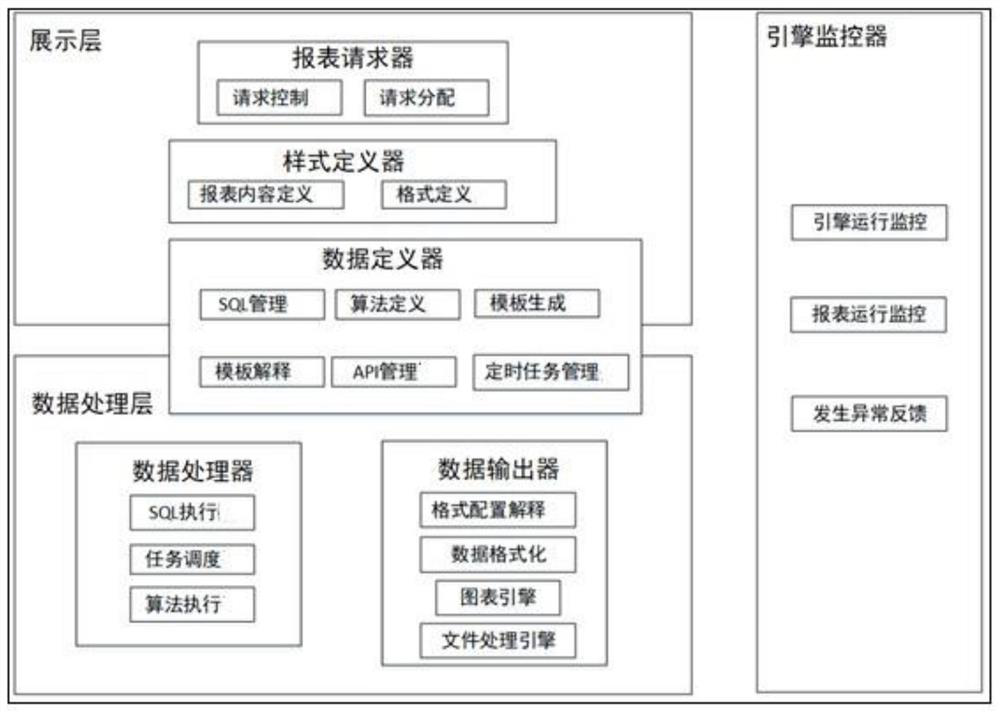

Visual configuration report generation method and system, electronic equipment and storage medium

PendingCN111881192ASimplify the development processReduce interactionDigital data information retrievalNatural language data processingData streamData source

The invention discloses a visual configuration report generation method and system, electronic equipment and a storage medium, belongs to the field of report generation, and aims to solve the technical problem of how to automatically generate reports with different requirements and realize appearance self-design, service logic self-definition and timely feedback when abnormality occurs. Accordingto the adopted technical scheme, the method specifically comprises the following steps that S1, after basic data in a database is processed and subjected to format conversion through a data processinglayer, generating a data stream suitable for interface display and file writing and completing generation of a report; S2, generating an interface style and configuration information of a data sourcein a display layer in a visual configuration mode, and finishing visual display of the report; and S3, decoupling the display layer and the data processing layer, and reserving a fixed interface forinteractive processing, thereby improving the user experience of report generation. The system comprises a report requester, a style defining device, a data defining device, a data processor, a data output device and an engine monitor.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

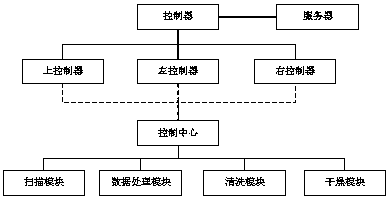

Automobile cleaning system and method

InactiveCN108146394AImprove managementSave manpower and material resourcesVehicle drying apparatusCleaning apparatus for vehicle exteriorsComputer modulePressure sense

The invention relates to the field of automation, in particular to an automobile cleaning system and method. The automobile cleaning system comprises a controller and a server, and the controller andthe server are connected based on an RS-485 network; the controller further comprises a scanning module, a data processing module, a cleaning module, a drying module, a pressure sensing module and a control center, and the control center is electrically connected with the scanning module, the data processing module, a cleaner and the drying module and used for controlling normal operation of eachmodule; and the server is used for receiving cleaning data transmitted by the controller and storing the cleaning data. According to the automobile cleaning system and method, reasonable dispatching is conducted on automatic cleaning of automobiles, so that manpower and material resources are saved; the management intensity of an airport to a cleaning storehouse is strengthened, the manpower lossis reduced, and the management efficiency is improved; and meanwhile, the difficult removing area such as refractory silt can be automatically identified and cleaned, and the cleaning effect is improved.

Owner:防城港市港口区天平电子科技有限公司

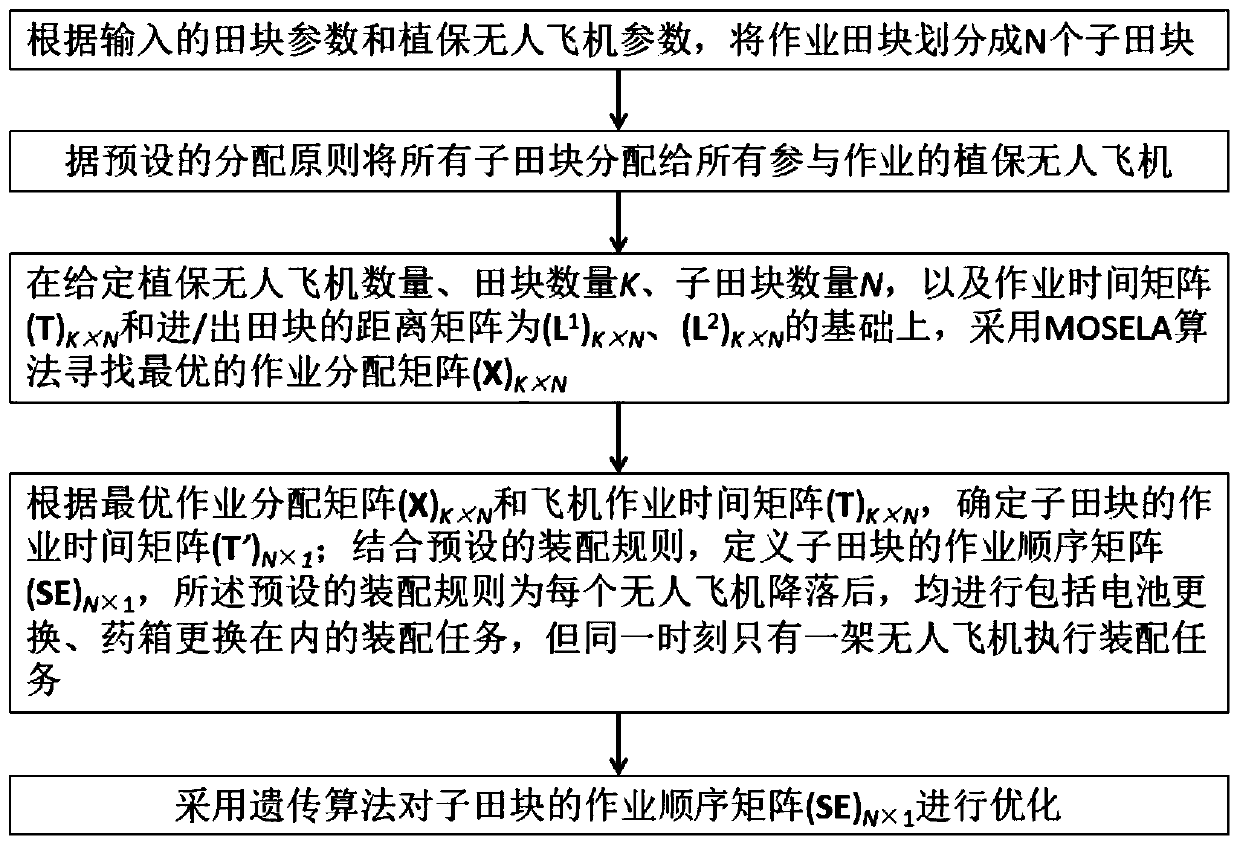

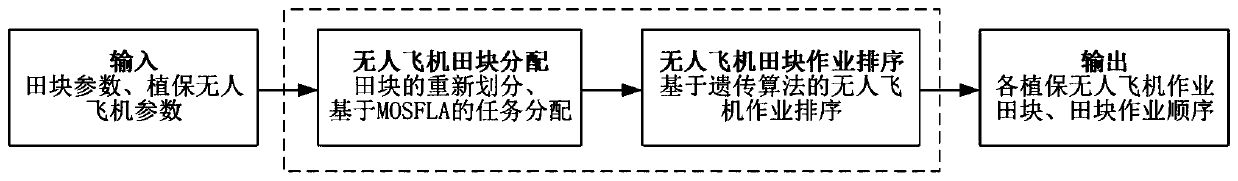

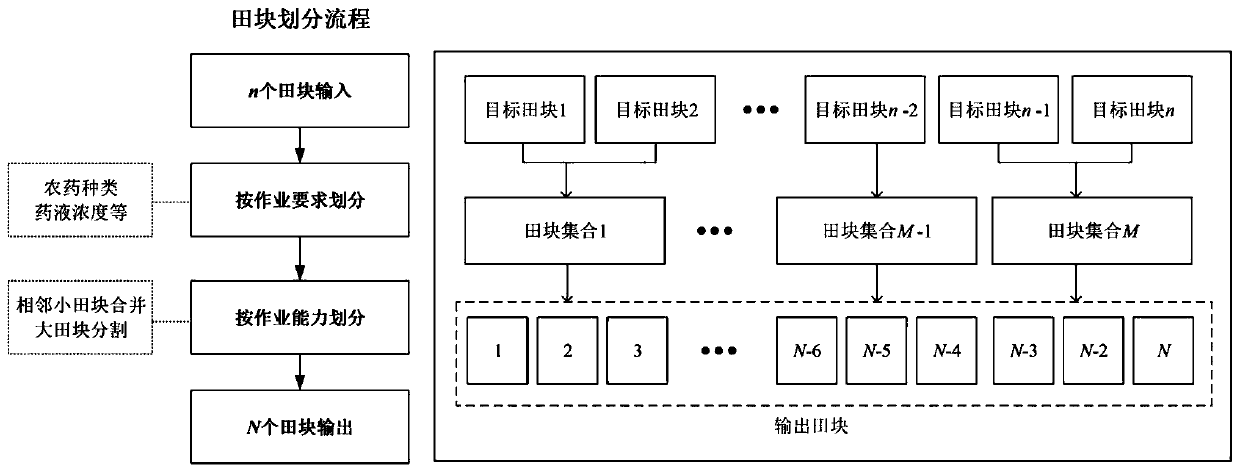

Plant protection unmanned aerial vehicle cluster operation task allocation method and device

ActiveCN111461464AReduce time conflictImprove work efficiencyForecastingResourcesDistribution matrixControl engineering

The invention discloses a plant protection unmanned aerial vehicle cluster operation task allocation method. The method comprises the following steps: dividing an operation field into N sub-fields; distributing all the sub-fields to all the plant protection unmanned aerial vehicles participating in operation according to a preset distribution principle; adopting an MOSELA algorithm to search for an optimal job allocation matrix; according to the optimal operation distribution matrix and the aircraft operation time matrix, determining an operation time matrix of the sub-fields; defining an operation sequence matrix of the sub-fields in combination with a preset assembly rule; and optimizing the operation sequence matrix of the sub-fields by adopting a genetic algorithm. On the basis of guaranteeing full coverage of an air route, the two constraint conditions of time and energy consumption are integrated, the shortest flight distance and optimal time allocation double-layer decision-making method is established, time conflicts are reduced, and the operation efficiency is improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

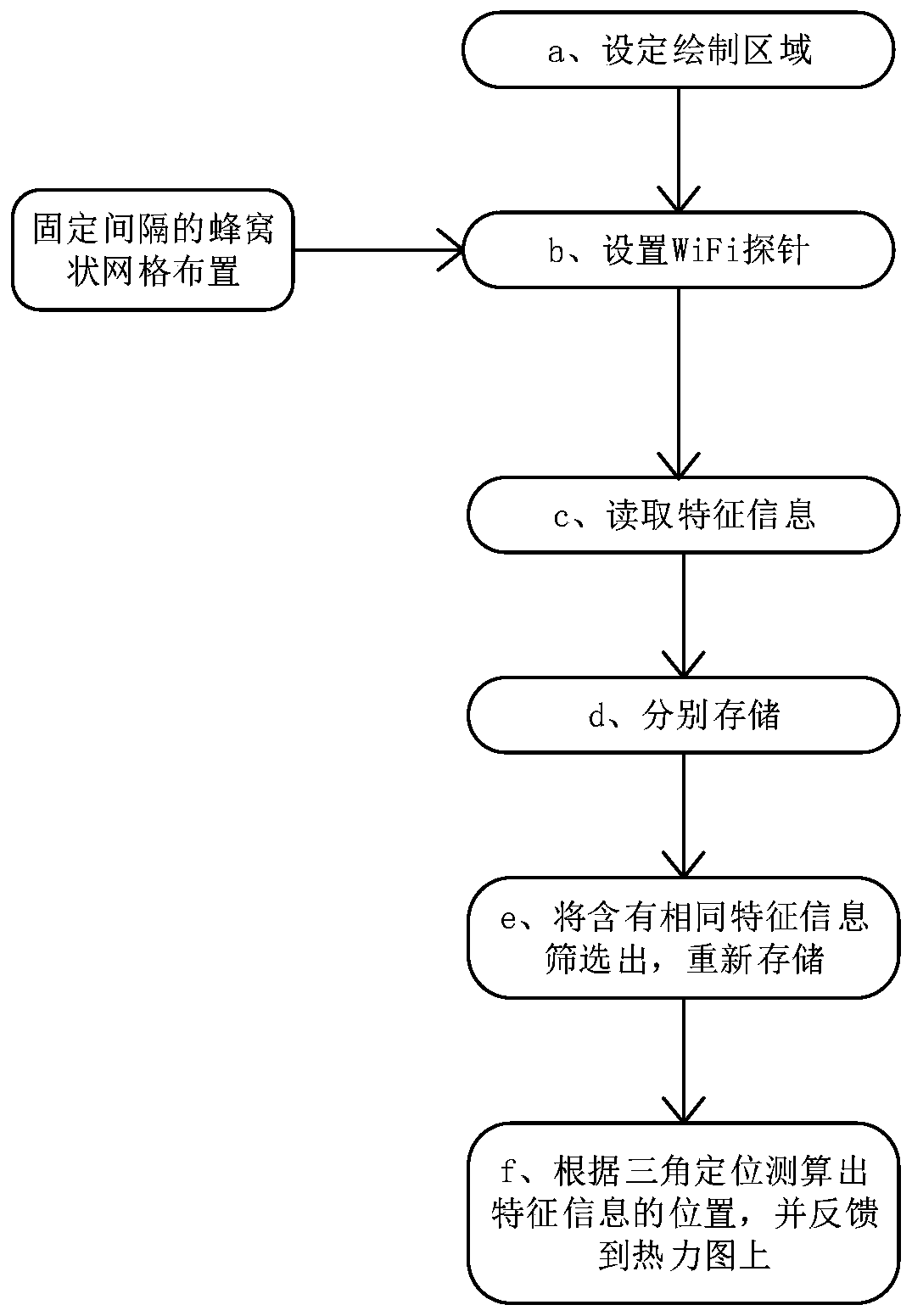

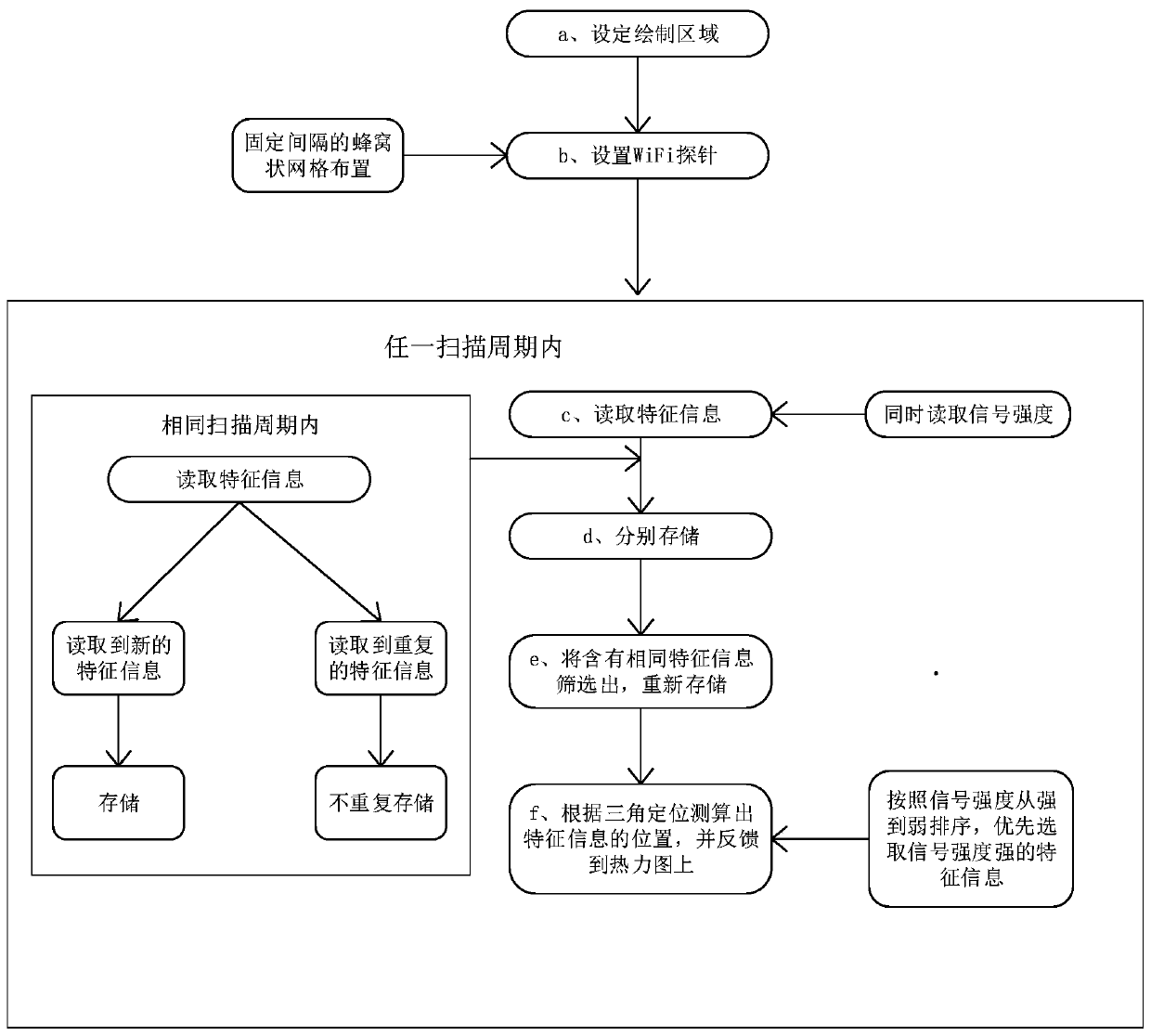

Method for drawing a station riding area personnel distribution thermodynamic diagram

ActiveCN109803230AEasy to controlEasy to judgeLocation information based serviceNetwork data managementComputer scienceThermodynamic diagrams

The problem to be solved by the invention is to provide a method for drawing a personnel distribution thermodynamic diagram in a station riding area, which comprises the following steps: a) setting adrawing area, and arranging a plurality of WiFi probes in the drawing area in a station according to a set interval; B) setting the corresponding position of each WiFi probe on the thermodynamic diagram according to the actual spatial position of the drawing area, and setting an effective scanning area of the WiFi probe; C) reading feature information of the Wifi-containing electronic equipment entering the drawing area; D) sending and storing the feature information read by any WiFi probe into a data server and a feature information address list corresponding to the feature information; E) counting all feature information address lists containing the same feature information by the data server, and forming a feature information-Wifi probe corresponding table information according to the corresponding WiFi probe information; wherein the Wifi probe corresponds to a table; and f) calculating the position of the characteristic information through triangular positioning, and feeding the position back to the thermodynamic diagram The method has the beneficial effects that unnecessary manpower loss is reduced, the working efficiency is improved, and the judgment possibility of risk earlywarning is increased.

Owner:北京万相融通科技股份有限公司

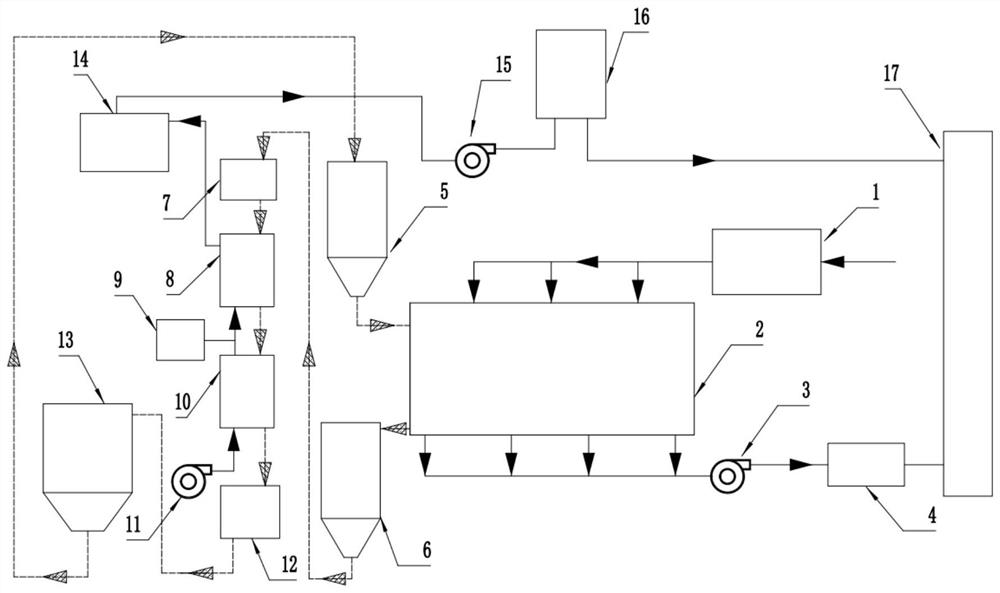

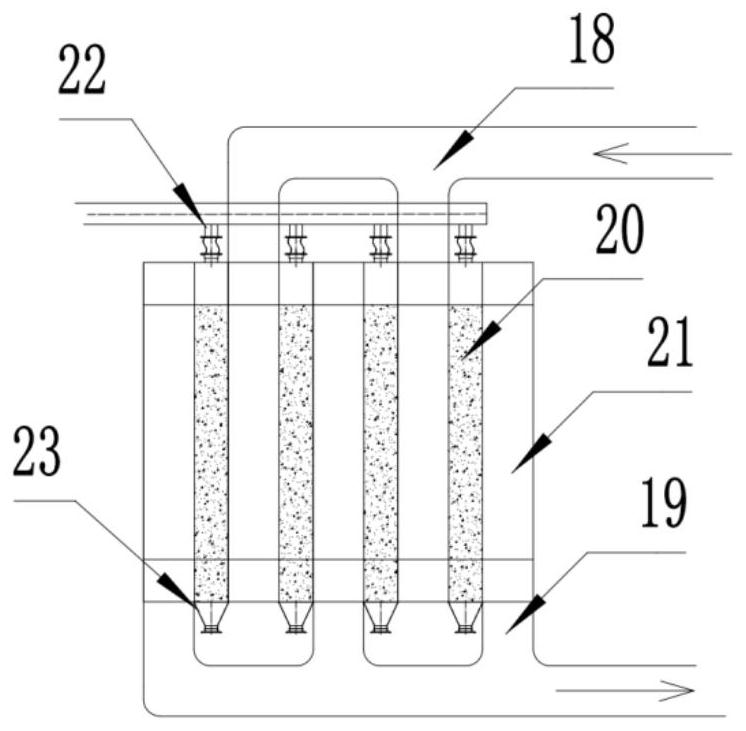

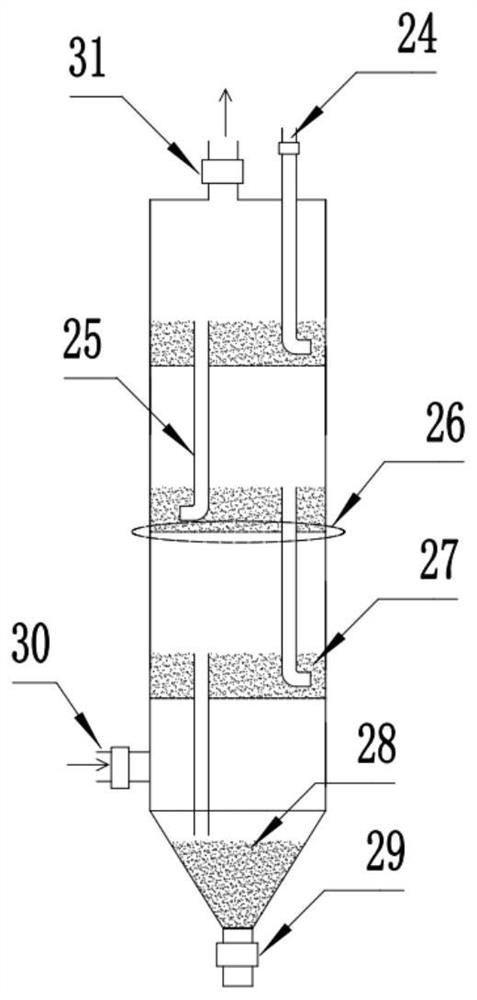

Fluidized bed adsorption-fluidized bed desorption coupled efficient VOCs (volatile organic compounds) treatment system and method

ActiveCN112843988AUniform adsorptionEfficient mass and heat transferGas treatmentDispersed particle separationSorbentDesorption

The invention discloses a fluidized bed adsorption-fluidized bed desorption coupled efficient VOCs treatment system and method, through separation of an adsorption system and a desorption system, online adsorption and desorption of an adsorbent are realized, and the problems of safety and heat conflict caused by sharing one device are solved. The adsorption system adopts a full-automatic feeding and discharging fixed bed, adsorbents are automatically updated, and manpower loss is reduced. By adopting the multi-stage fluidized bed desorption, continuous and uniform high-concentration and small-air-volume desorption gas is formed, the treatment capacity of tail end treatment equipment can be reduced, and the treatment difficulty is reduced. According to the invention, the problems of non-uniform adsorption, incomplete desorption and adsorption and desorption heat conflict of an adsorbent in waste gas treatment are solved, and an efficient, convenient, energy-saving and safe treatment system is provided for treatment of large-air-volume and low-concentration organic waste gas.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

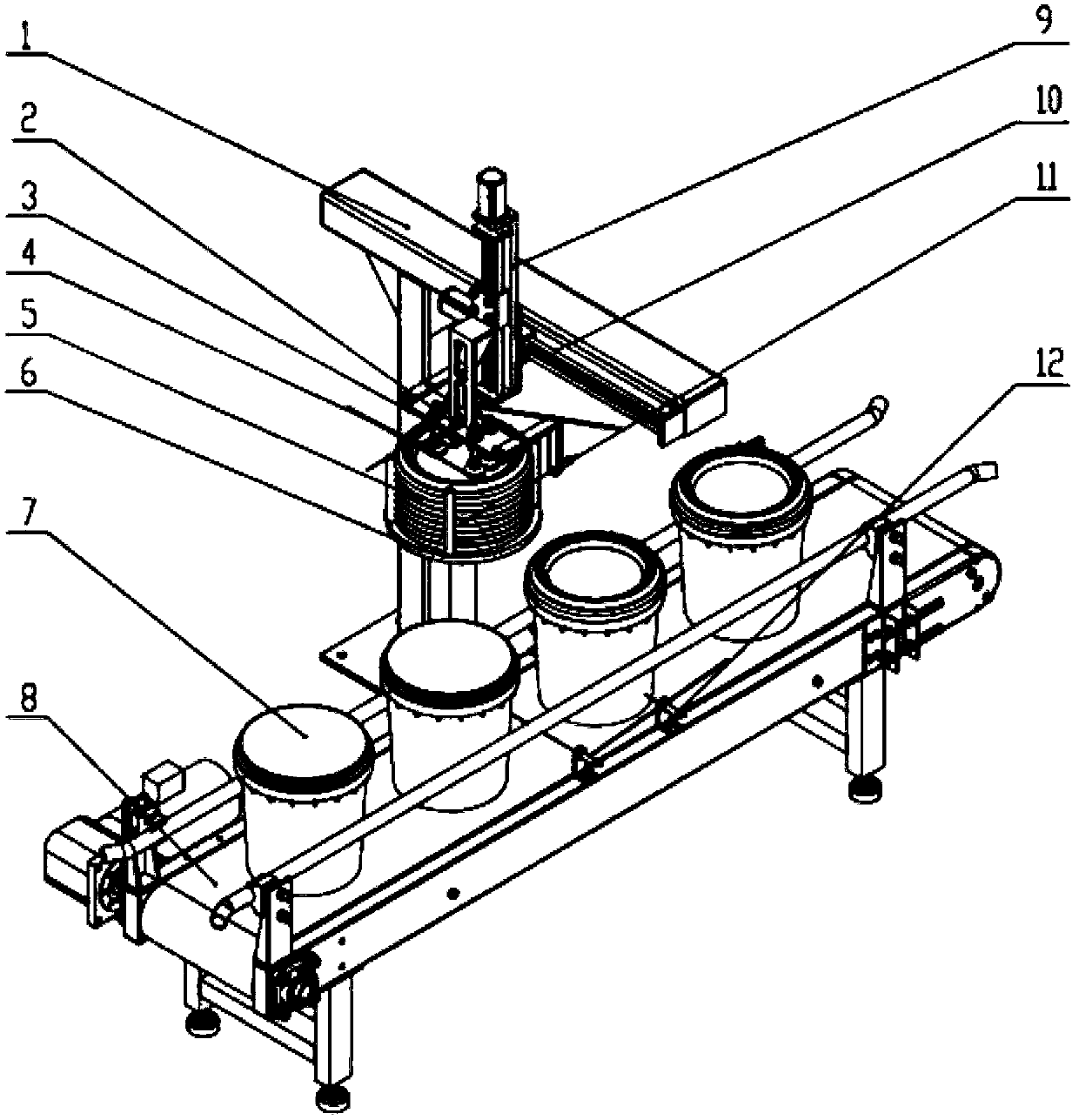

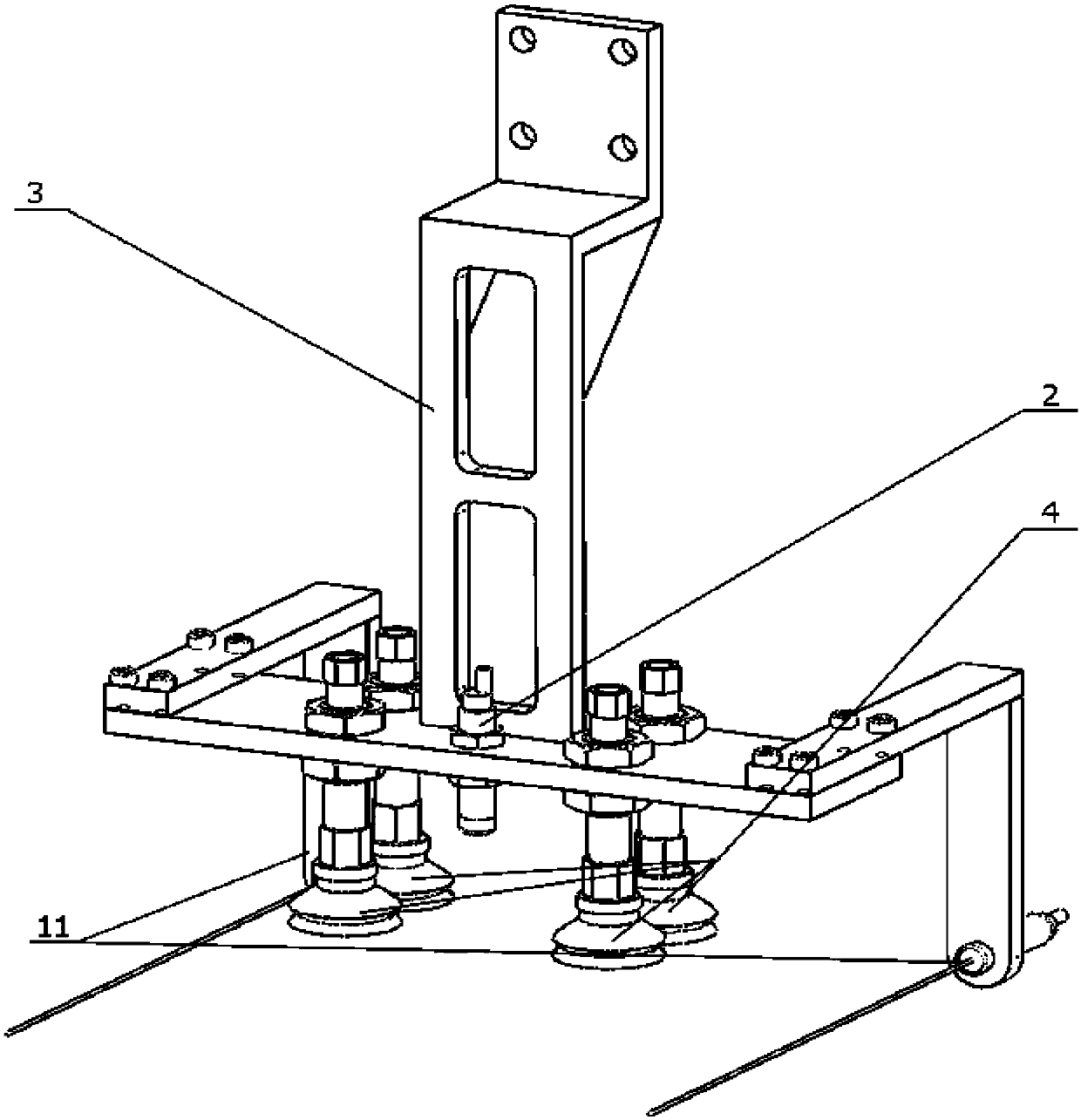

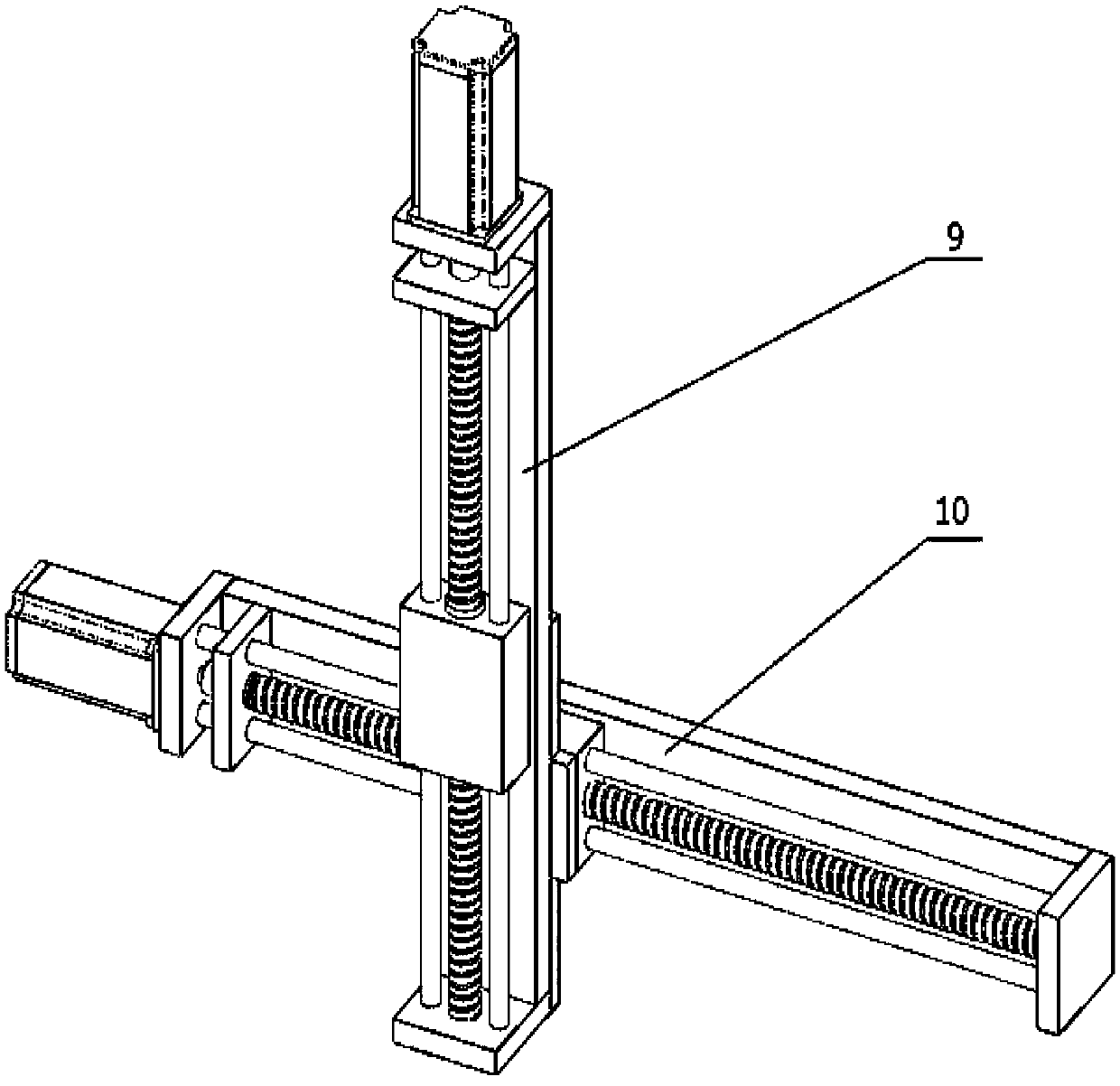

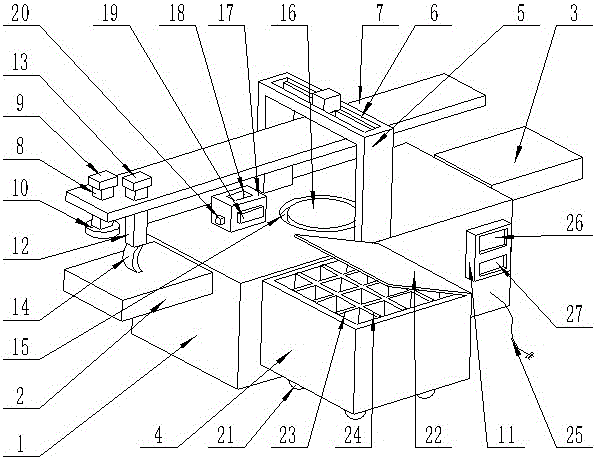

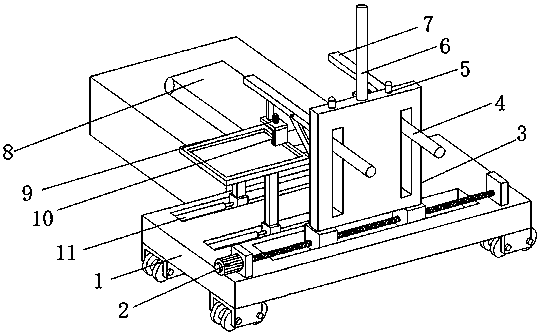

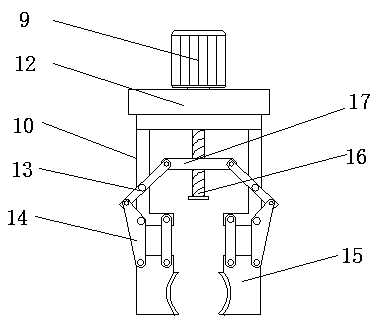

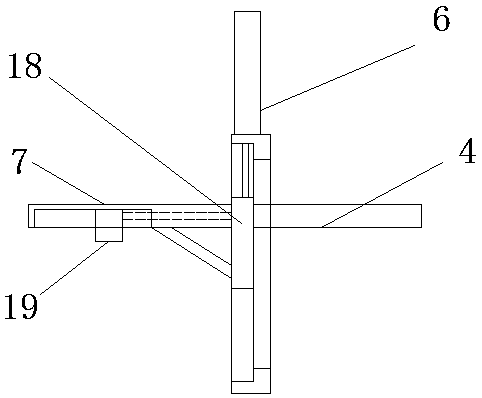

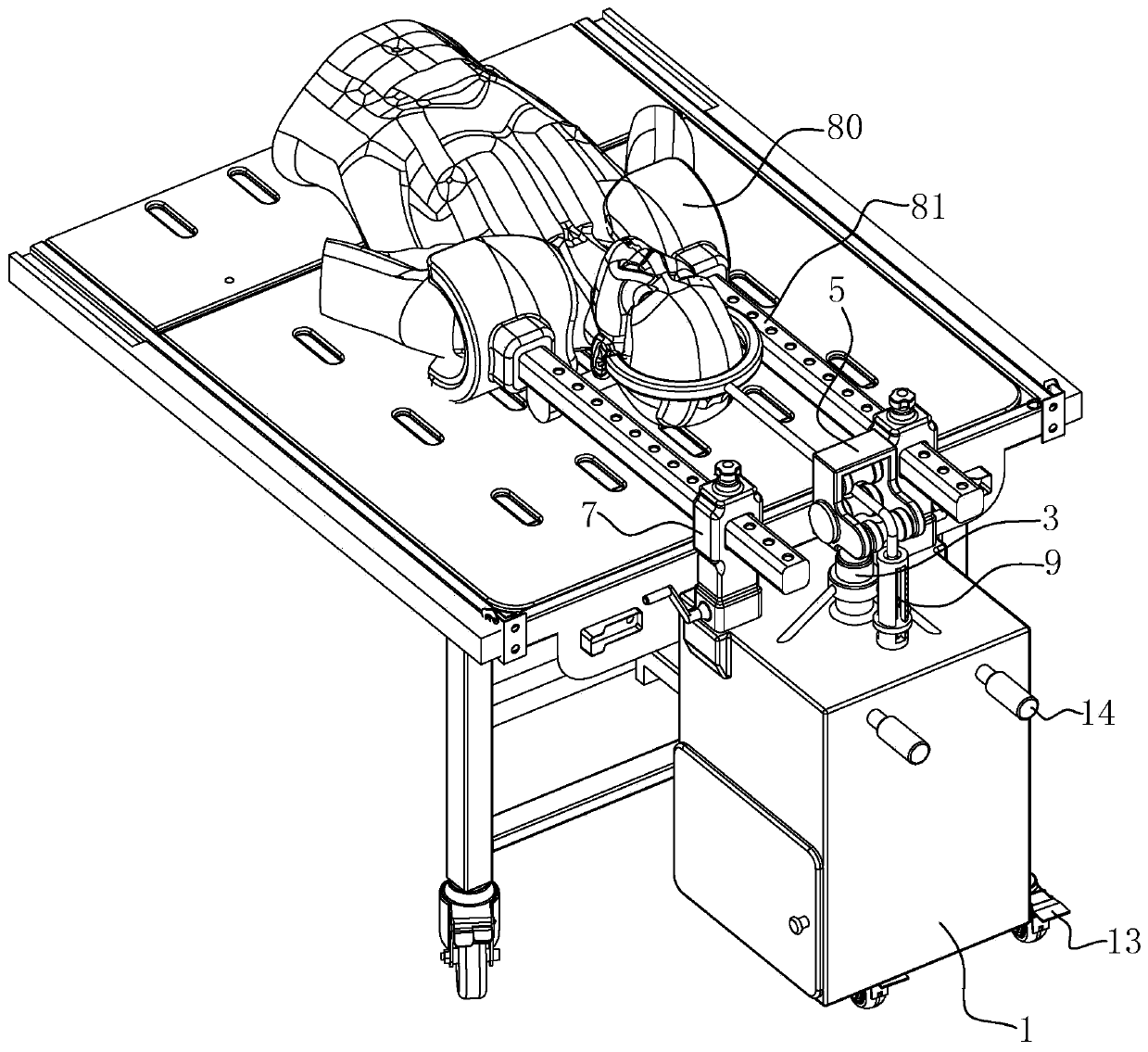

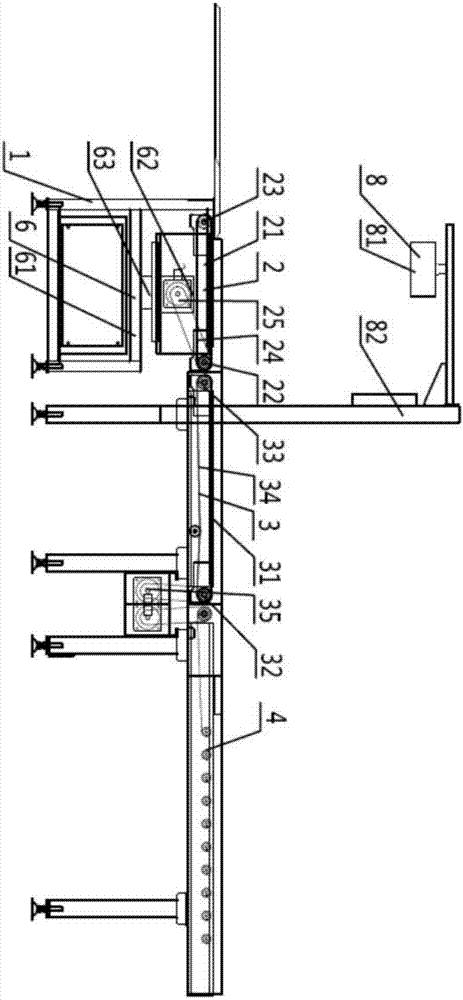

Full-automatic multi-type feeding machine for plastic bucket covers

The invention relates to the technical field of automation, in particular to a full-automatic multi-type feeding machine for plastic bucket covers. The machine comprises a control system and further comprises a plastic bucket conveying platform for conveying plastic buckets; and a sensing device is arranged on the plastic bucket conveying platform. The machine further comprises an adjusting and grasping device matched with the sensing device; and a cover rack for placing the covers is arranged on the adjusting and grasping device. The covers are sucked by the aid of suction cups, and the machine is applicable to different types of covers and has the broad adaptability and flexibility; signal transmission is performed on the positions of the plastic buckets and the covers in real time by the aid of the sensing device and a sensing mechanism, so that working is in real time and is reliable; the position error rate is greatly reduced through two times of position sensing, the working efficiency is improved, and the labor loss is reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE +1

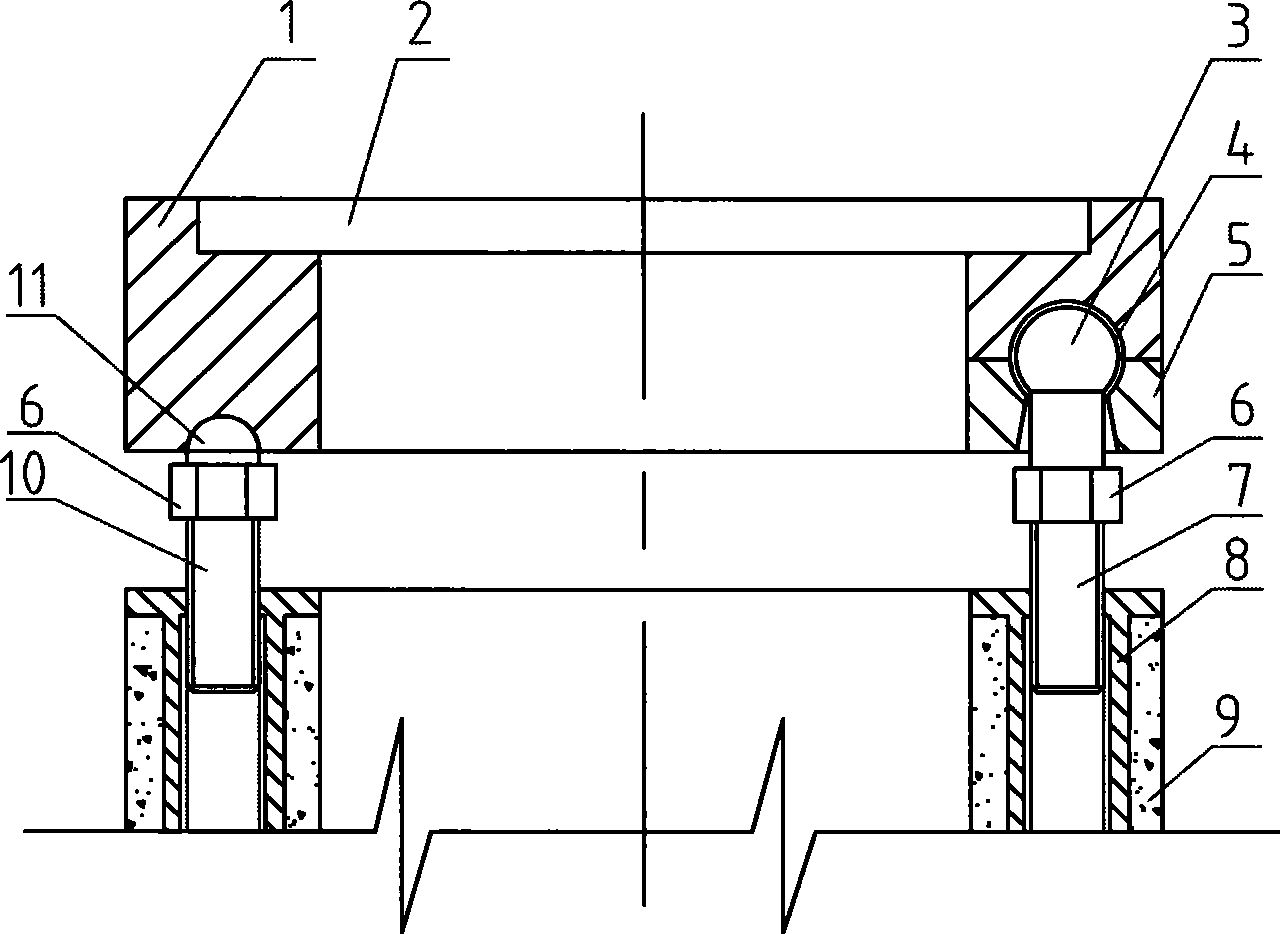

Height-adjustable road manhole

InactiveCN101368392AUniform load bearingAvoid frictionArtificial islandsUnderwater structuresEngineeringWellhead

Owner:彭琦

Sorting device for inferior products with unqualified weights

The invention discloses a sorting device for defective products with unqualified weight, which includes a detection platform and No. 1 conveyor belt and No. 2 conveyor belt arranged at the left and right ends of the detection platform. One side of the detection platform is provided with a storage box for defective products. A detection unit is provided on the platform, and a crossbeam is arranged above the detection platform, and a high-quality product sorting unit is arranged on the crossbeam, and the high-quality product sorting unit is composed of slide rails arranged on the The longitudinal beam inside the slide rail and can move along its length direction, the defective product sorting mechanism and the high-quality product transportation mechanism arranged on the longitudinal beam are jointly constituted. A control cabinet is arranged on one side of the detection table, and the control cabinets are respectively It is electrically connected with the detection unit, No. 1 movable arm, No. 1 hydraulic cylinder, vacuum suction cup and Youpin transportation mechanism. The invention has the advantages of simple structure and strong practicability.

Owner:柏伟伟

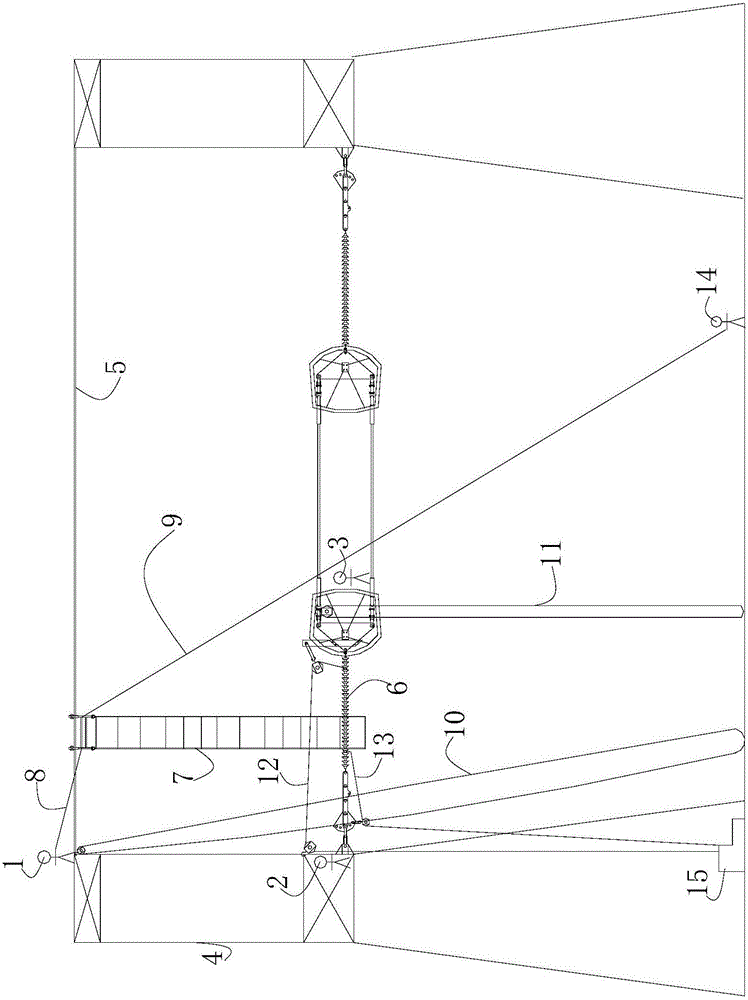

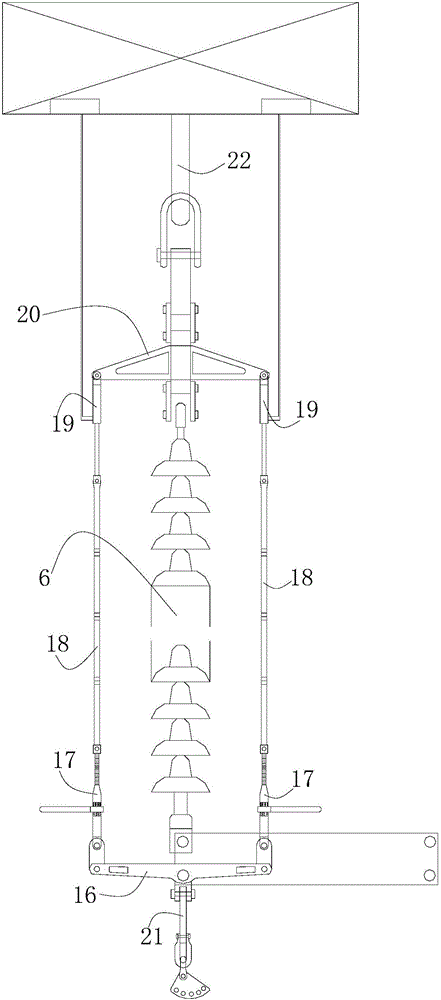

Method for live replacement of +/-500kV DC line strain tower insulator string

ActiveCN105743013AEliminates the possibility of abnormal operationImprove the reliability of safe and stable operationApparatus for overhead lines/cablesEquipotentialEngineering

The invention discloses a method for live replacement of a + / -500kV DC line strain tower insulator string. A third electrician is conveyed to a wire terminal from a tower by cooperation of an insulated flexible ladder and an overhead ground wire pulley; a ground potential is transferred to an equipotential; and meanwhile, tools required for operation are carried, so that the operation process of 'taking out the whole ceramic insulator string to put on the ground in a live manner' can be quickly finished; a guarantee is provided for safe and stable operation of the line; and the process is safe, reliable, time-saving and labor-saving.

Owner:EXTRA HIGH VOLTAGE POWER TRANSMISSION NANJING OF CHINA SOUTHERN POWER GRID

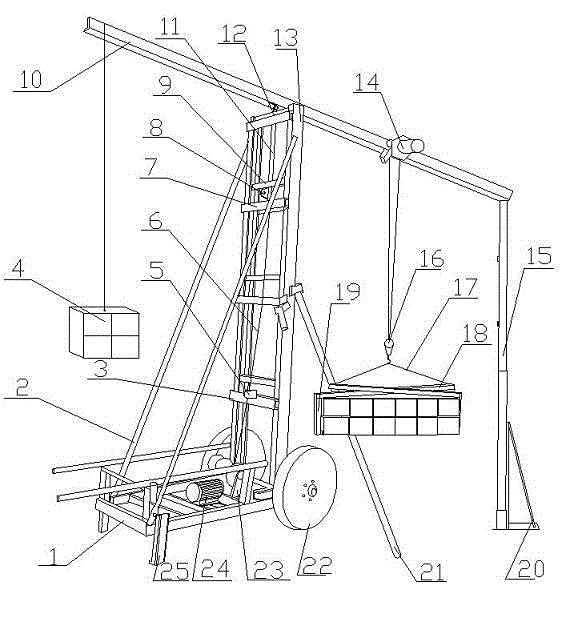

Cement brick loader

The invention discloses a cement brick loader, comprising a triangular support, a lifting mechanism, a suspension rod and a chain hoist, wherein the triangular support comprises a vertical support, a transverse support and two diagonal bracings; the vertical support comprises two vertical rods and a plurality of cross rods; the lifting mechanism comprises a positioning cross rod, an ejector rod, a winch, a steel wire rope and a pulley block, wherein the positioning cross rod is arranged between the two vertical rods and capable of moving along the vertical rod up and down, and also can be positioned on the vertical rod through a pin; the lower end of the ejector rod is connected with the middle part of the positioning cross rod, while the upper end thereof penetrates through the top of the vertical support and in rotational connection with the middle part of the suspension rod through a bearing; the pulley block comprises a fixed pulley and a movable block; the winch is arranged on the transverse support; one end of the steel wire rope is wound around the winch, while the other end thereof is connected with the positioning cross rod round the pulley block; the chain hoist is arranged at one side of the suspension rod; and the chain hoist catches on a cement brick clamp through a lifting hook. The cement brick loader provided by the invention is capable of clamping a plurality of cement bricks simultaneously; and as a result, the traditional manual carrying manner is changed and the labor efficiency is effectively improved.

Owner:零永孝

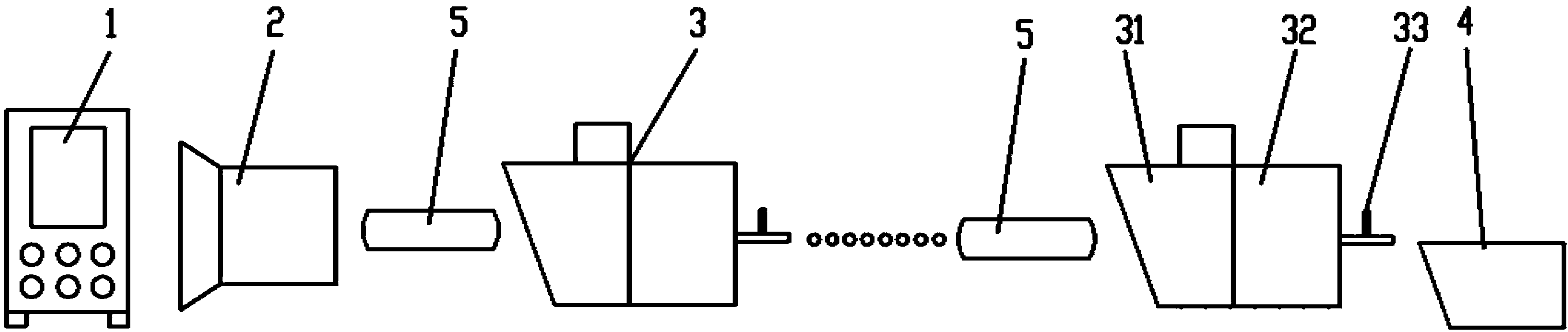

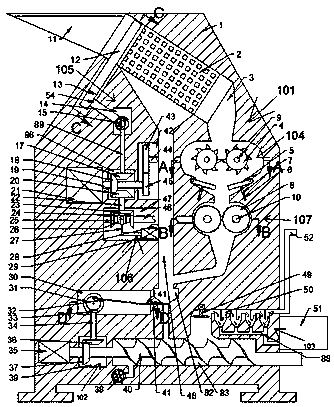

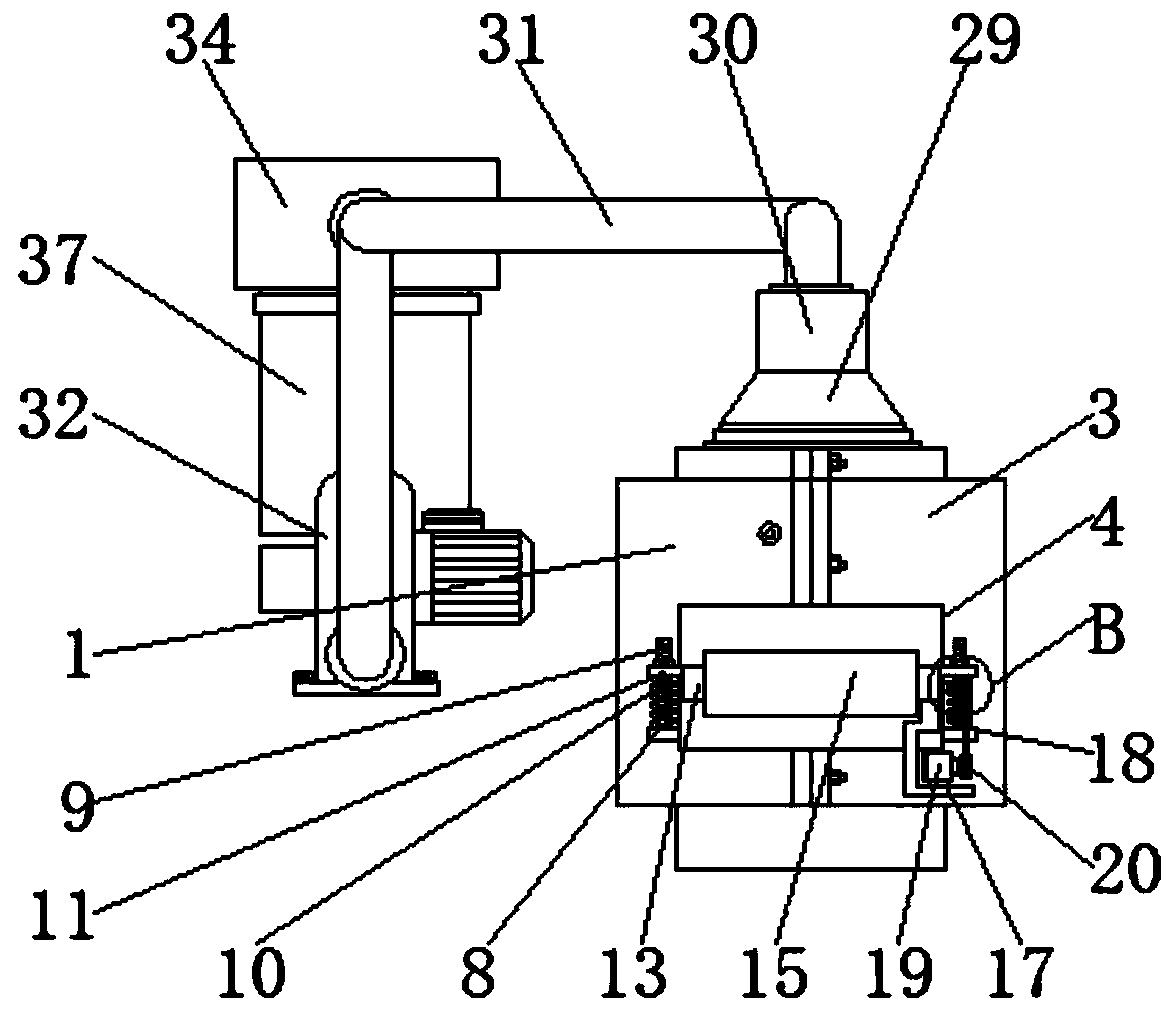

Full-automatic production line for halogen lamp

InactiveCN104505332AReduce manpower lossFast mechanical actionElectrical apparatusProduction lineEngineering

The invention discloses a full-automatic production line for a halogen lamp. The full-automatic production line comprises a lamp filament spot welding unit, a tube connecting unit, a filament inserting unit, a clamping and sealing unit and an exhaust unit, wherein the lamp filament spot welding unit is used for welding a lamp filament, a molybdenum sheet and a lamp pin together; the tube connecting unit is used for connecting a glass tube with an exhaust tube; the filament inserting unit is used for placing a lamp filament assembly into the glass tube; the clamping and sealing unit is used for clamping and sealing lamp pins at the two ends of the glass tube; the exhaust unit is used for filling halogen gas into the clamped and sealed exhaust tube; the output end of the lamp filament spot welding unit and the output end of the tube connecting unit are connected with the filament inserting unit simultaneously; the filament inserting unit is further connected with a plug conveying mechanism for conveying plugs. Each halogen lamp processing unit working separately is connected in series through the filament inserting unit, thereby forming a full-automatic production line. The full-automatic production line has the advantages of avoidance of manual participation, reduction of labor force loss, high mechanical action speed and high production efficiency.

Owner:李洪普

Novel building thermal insulation layer carrying device

InactiveCN107893543AImprove work efficiencySimple designBuilding material handlingBuilding insulationEngineering

The invention discloses a new type of conveying device for building insulation layer, which comprises a base, two fixed blocks are arranged on one side of the upper end of the base, a first drive device is fixed on one side of one of the fixed blocks, and the output of the first drive device The shaft passes through the fixed block and extends to one side of the fixed block. The end of the output shaft of the first driving device is fixed with a first screw rod. The base is provided with a first chute, and the first chute is installed with Two first moving blocks, and the first moving block is set through the first screw rod, the first moving block is provided with a first threaded through hole, and one end of the first screw rod passes through the first threaded through hole and is rotatably connected On one side of the other fixed block, the upper ends of the two first moving blocks are fixed with fixed plates. The invention has advanced design, simple and integrated operation, saves a lot of manpower consumption, has high working efficiency, wide application range, good economic benefits and is suitable for popularization.

Owner:河南伟民装饰工程有限公司

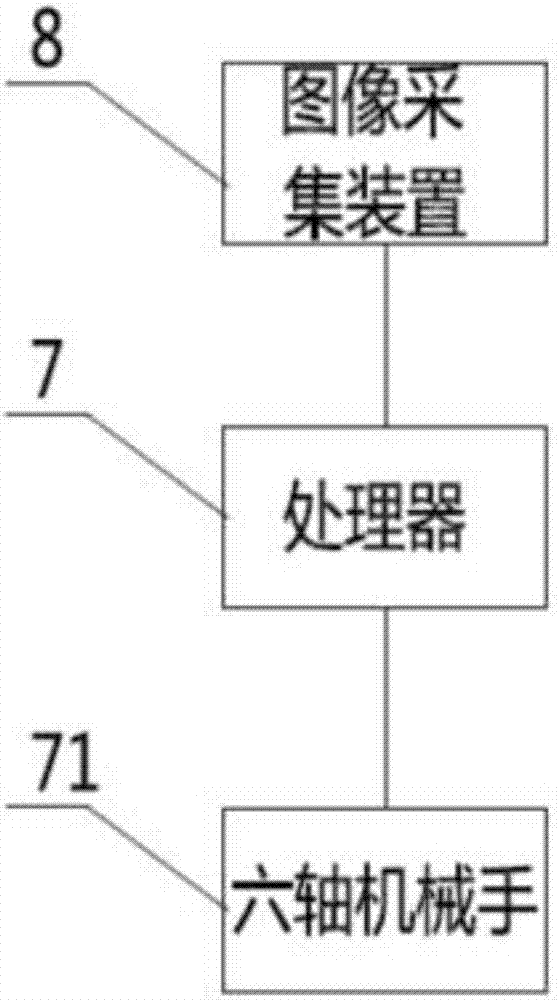

Intelligent machining production line

PendingCN110153729AAchieve connectionReduce manpower lossOther manufacturing equipments/toolsProduction lineControl system

The invention relates to the field of industrial machining, in particular to an intelligent machining production line which comprises an unqualified product frame, a raw material preparation room, a finished product warehouse and a general control system component. The intelligent machining production line further comprises an AGV intelligent trolley distribution unit, a turning processing unit, amilling processing unit, a grinding processing unit, a thread rolling processing unit and a semi-finished product temporary storage unit; and the machining types are classified to form four independent processing units respectively, the processing units are controlled through the general control system component, and the process switching of each production task is completed by guiding an AGV intelligent trolley through instructions of the general control system component. The AGV intelligent trolley serves as a transmission chain on a traditional production line, and finally the AGV intelligent trolley distribution unit and the semi-finished product temporary storage unit form the soft connection of the whole intelligent production line, so that the connection of the processing units isrealized, the processing of each production task is completed, the labor loss is reduced, and the production efficiency is improved.

Owner:安徽天航机电有限公司

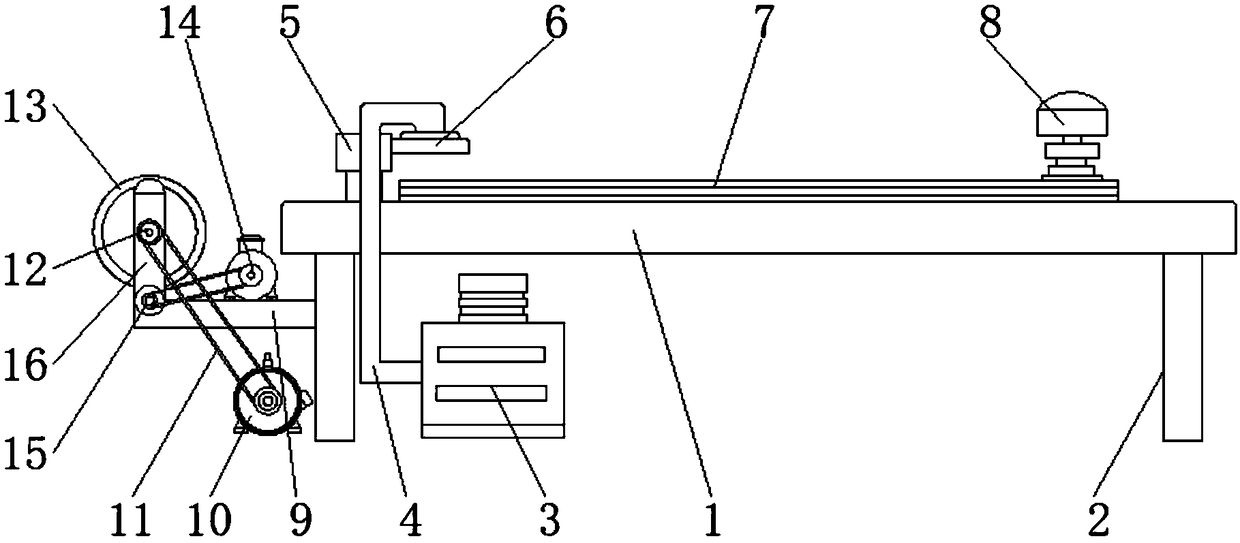

Cutting table with rewinding function

InactiveCN108301183AEasy to cleanEasy to installSevering textilesCleaning using gasesDrive shaftPulp and paper industry

The invention relates to a cutting table with a rewinding function. The cutting table comprises a table top, a sliding rail, connecting frames, a cloth collecting roller, a second motor and a pressureplate, supporting legs are mounted at the lower end of the table top, vacuum cleaners are arranged on the inner sides of the supporting legs, the upper ends of the vacuum cleaners are connected to air suction ports through dust suction pipes, the air suction ports are formed outside a mounting frame, the sliding rail is disposed on the upper surface of the table top, a cutting scissor is mountedon the upper end of the sliding rail, the connecting frames are fixed to the outer sides of the supporting legs, first motors are mounted on the lower ends of the connecting frames, the upper ends ofthe first motors are connected to driven shafts through transmission belts, the driven shafts penetrate through the insides of second bearings, the cloth collecting roller is disposed on the inner side of a support frame, the lower end of the pressure plate is connected to the connecting frames through an adjusting mechanism, and the pressure plate is located below the cloth collecting roller. Theair suction ports are formed in the cutting table with the rewinding function which can conveniently clean rags or thread heads generated by the cutting so that sundries such as the thread heads thelike cannot enter the next process.

Owner:丁志鹏

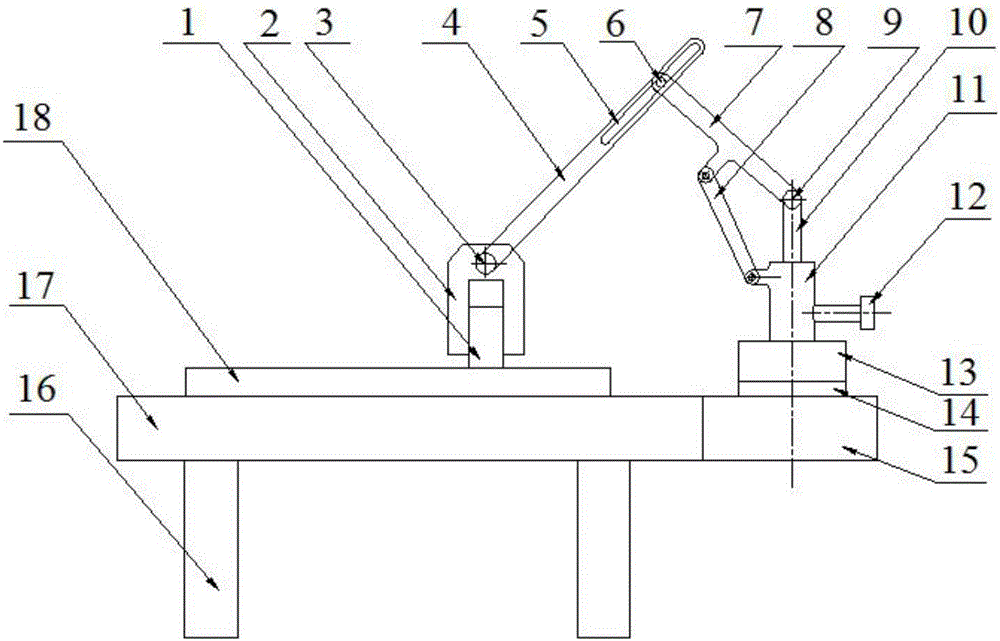

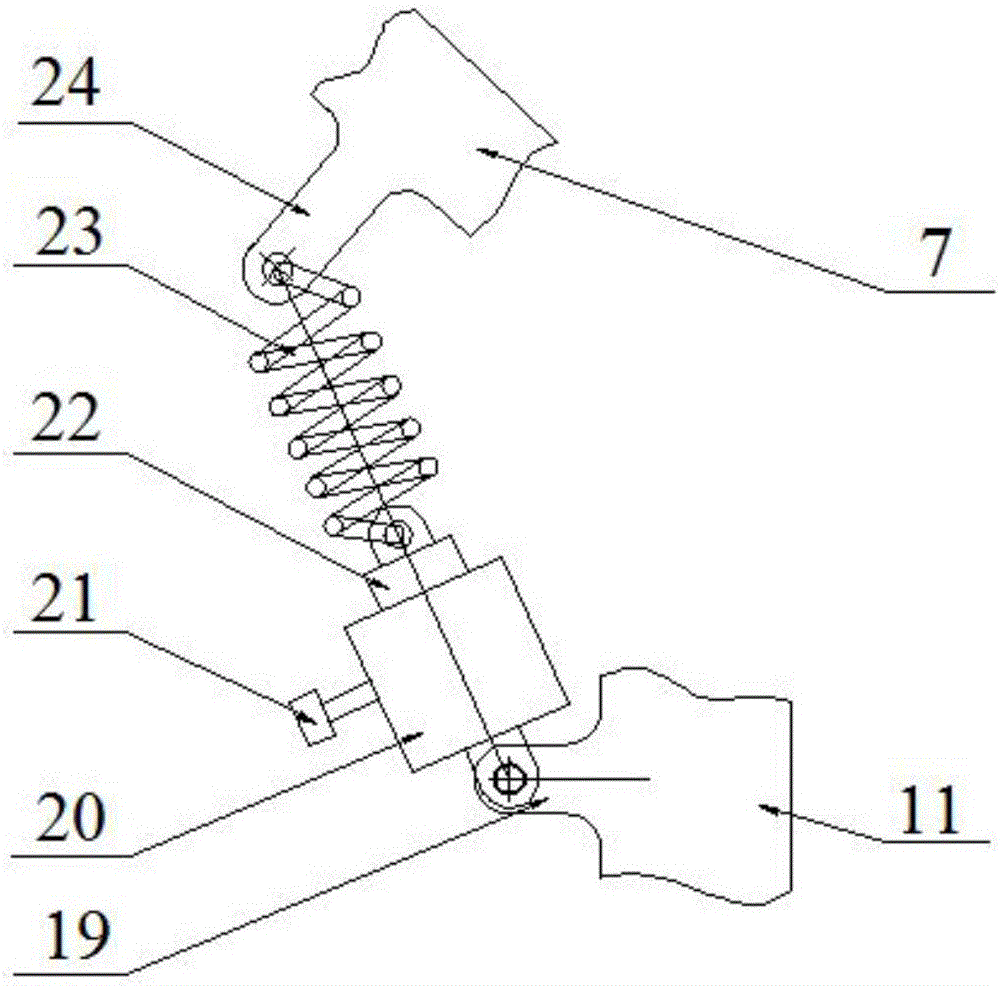

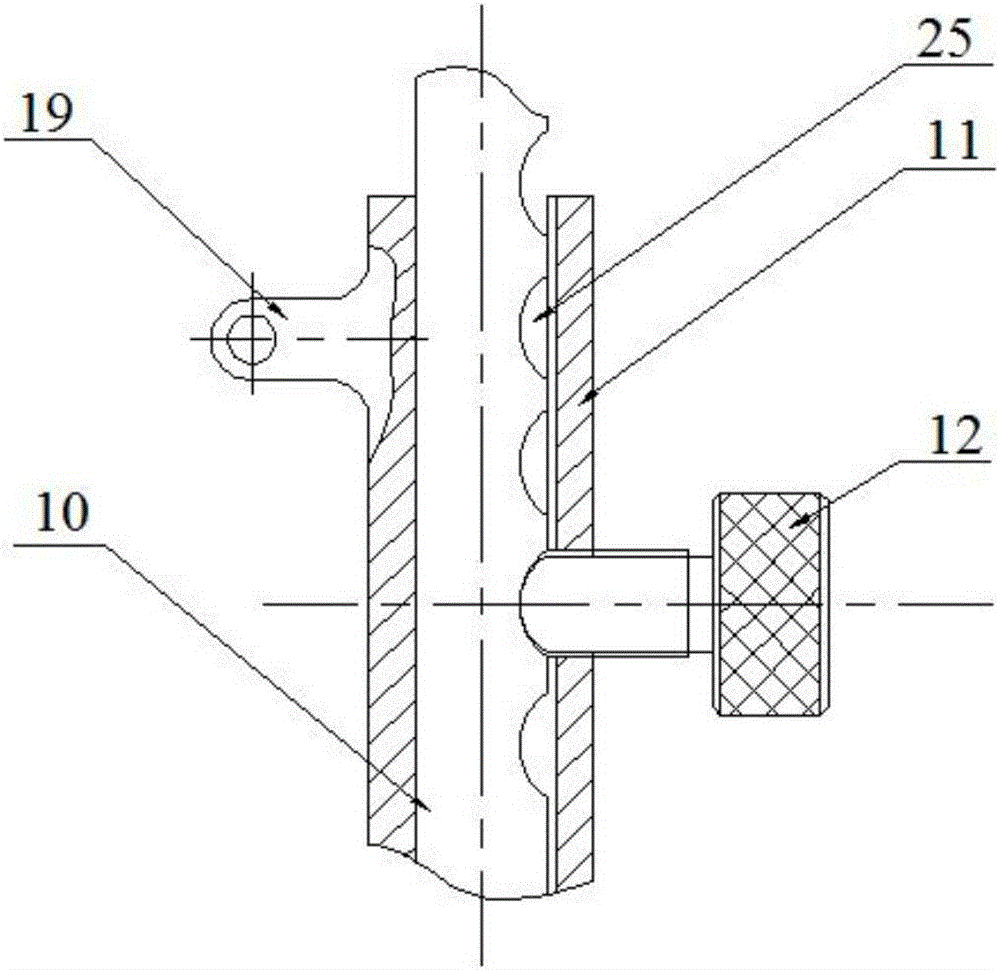

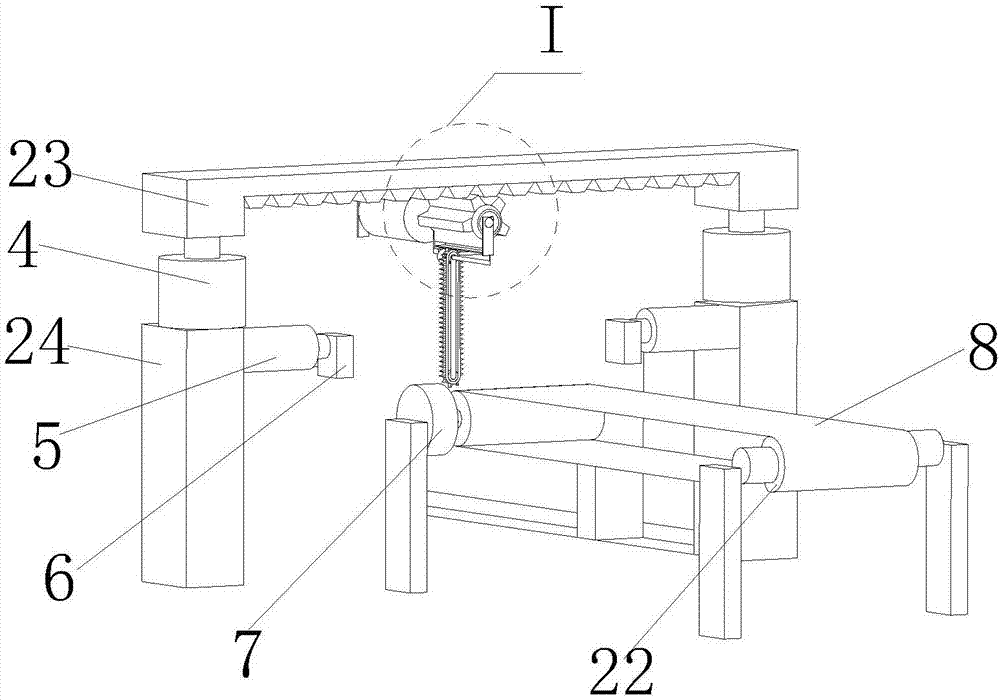

Sample clamping device of polishing machine

ActiveCN106826557ASolving Polishing Quality IssuesReduce manpower lossPolishing machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a sample clamping device of a polishing machine and belongs to the technical field of machinery. A spring telescoping device comprises a telescopic sleeve, a locking screw, a telescopic rod and an adjusting spring, the locking screw is provided with orderly arranged telescopic rod grooves like a tail-section clamping arm, two ends of the adjusting spring are hooked on a lug of a middle-section clamping arm and a telescopic rod hole, a sample is placed on a polishing table, the adjusting spring adjusts lamination force to the sample, one end of the telescopic sleeve is connected with a lug of a clamping table thick casing pipe through a bolt, and the telescopic sleeve is nested in the telescopic rod through the locking screw and can realize telescopic adjustment. The sample clamping device has the benefits as follows: adjusting devices, comprising the spring telescopic device, in three positions of the clamping device are used for regulating the force and direction of the sample.

Owner:江苏维航精仪科技有限公司

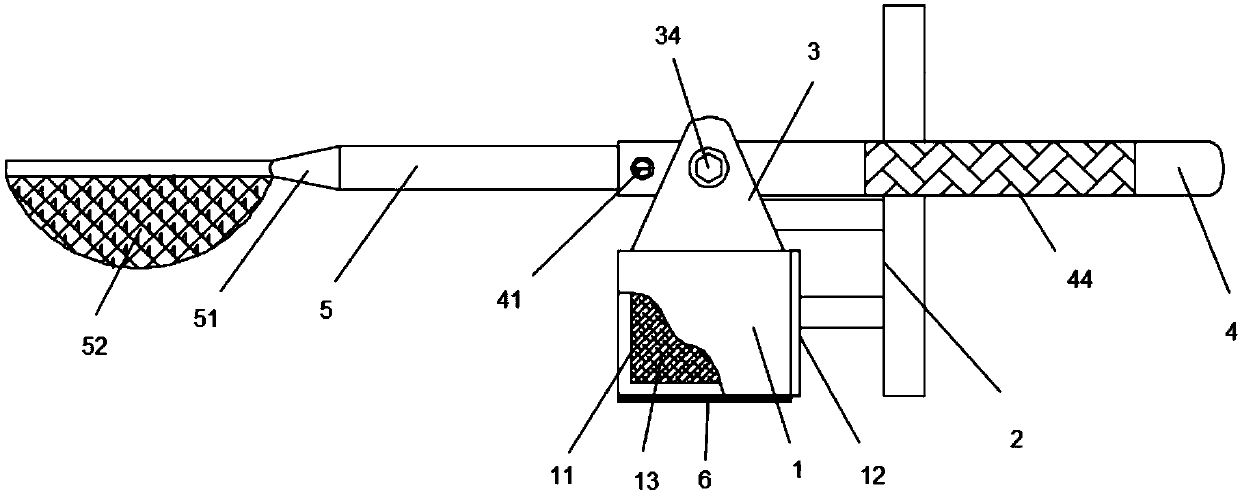

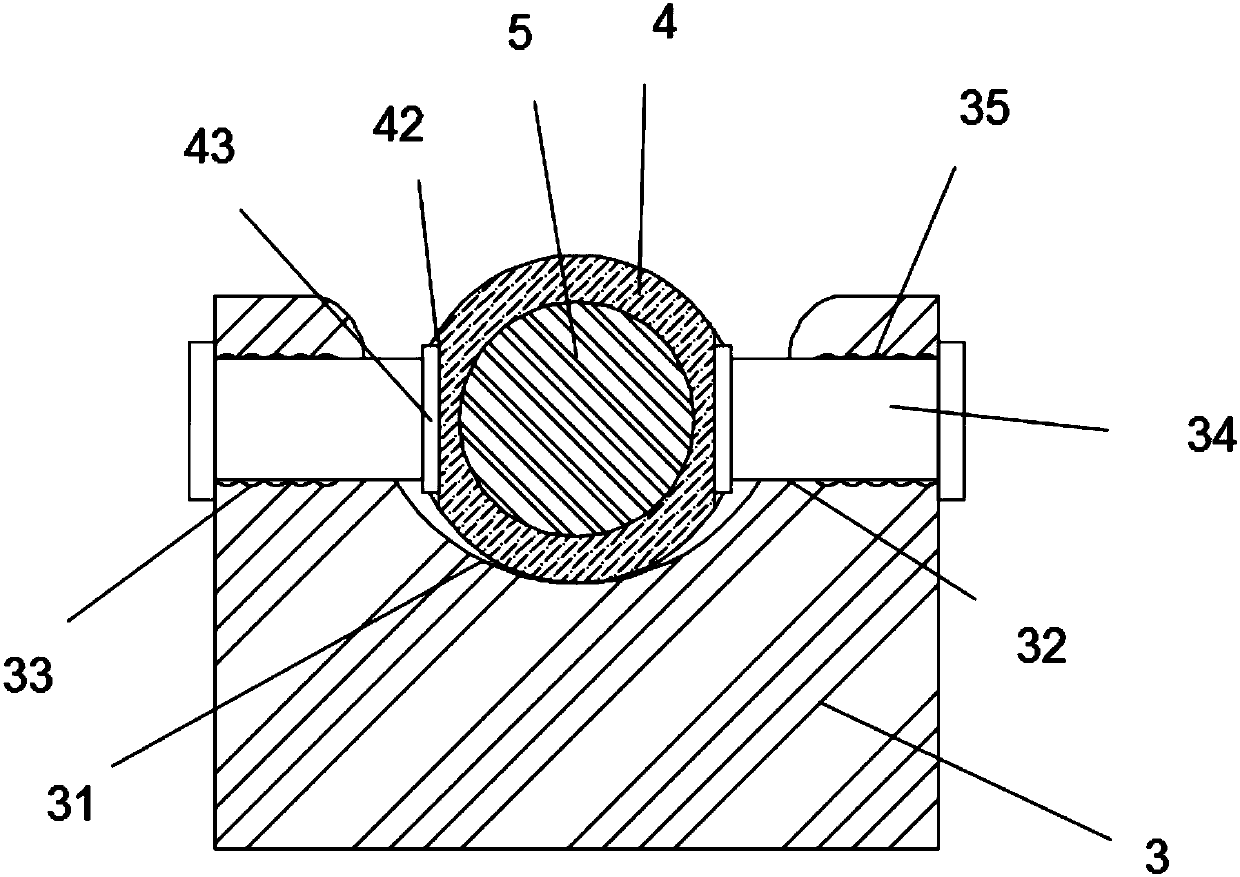

River channel garbage collecting device for environmental protection engineering

The invention discloses a river channel garbage collecting device for environmental protection engineering. According to the river channel garbage collecting device, a seat is fixedly mounted on the rear surface of the base; a bracket is fixedly mounted on the upper surface of the base; a hollow rod is hinged to the inside of the bracket; a telescopic rod is inserted into the left end of the hollow rod; a connecting column is fixedly mounted at the left end of the telescopic rod; a scoop net is fixedly mounted at the left end of the connecting column; and a screw rod is in threaded connectionwith the left side of the outer side wall of the hollow rod. Through the designed river channel garbage collecting device, plastic garbage floating in a river channel can be cleaned up; cleaning staffonly need to salvage the plastic garbage floating along the water flow at a specified position; the river channel garbage collecting device is simple and practical; and the loss of manpower is reduced, the working efficiency is improved, and the environment is better protected.

Owner:成都睿鸿环保科技有限公司

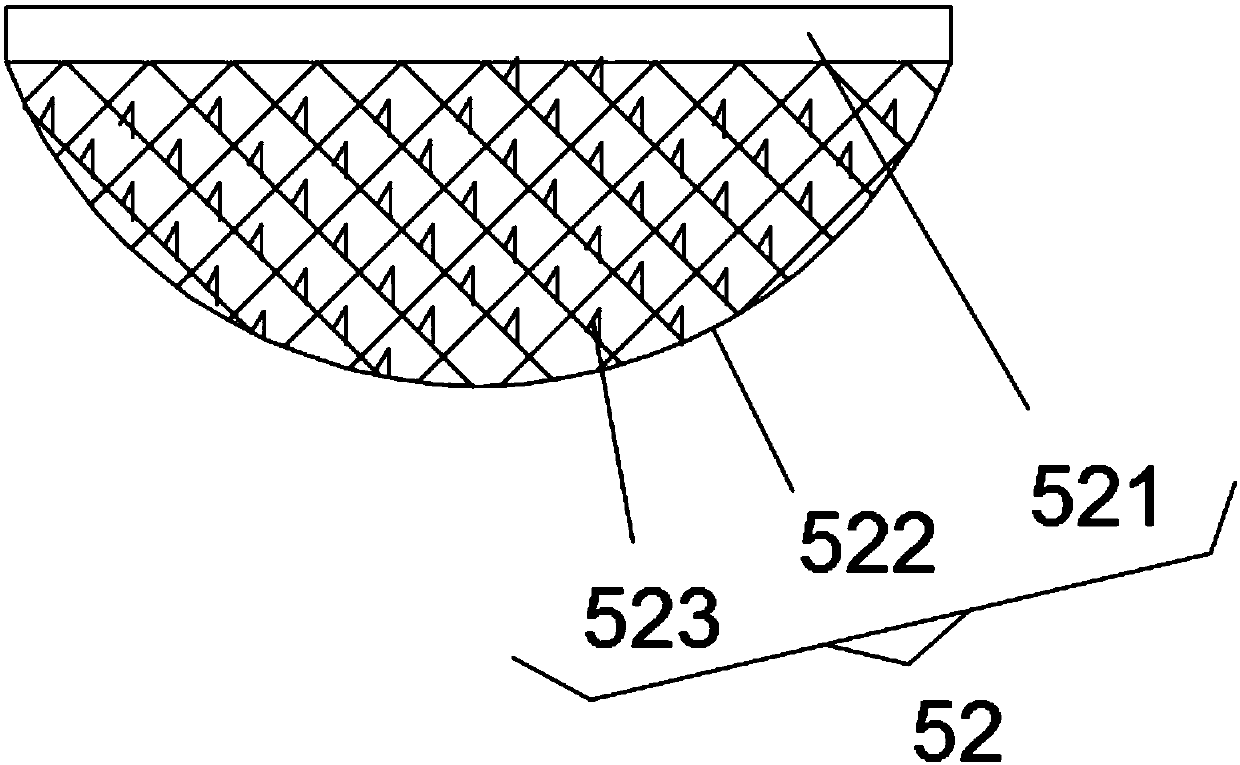

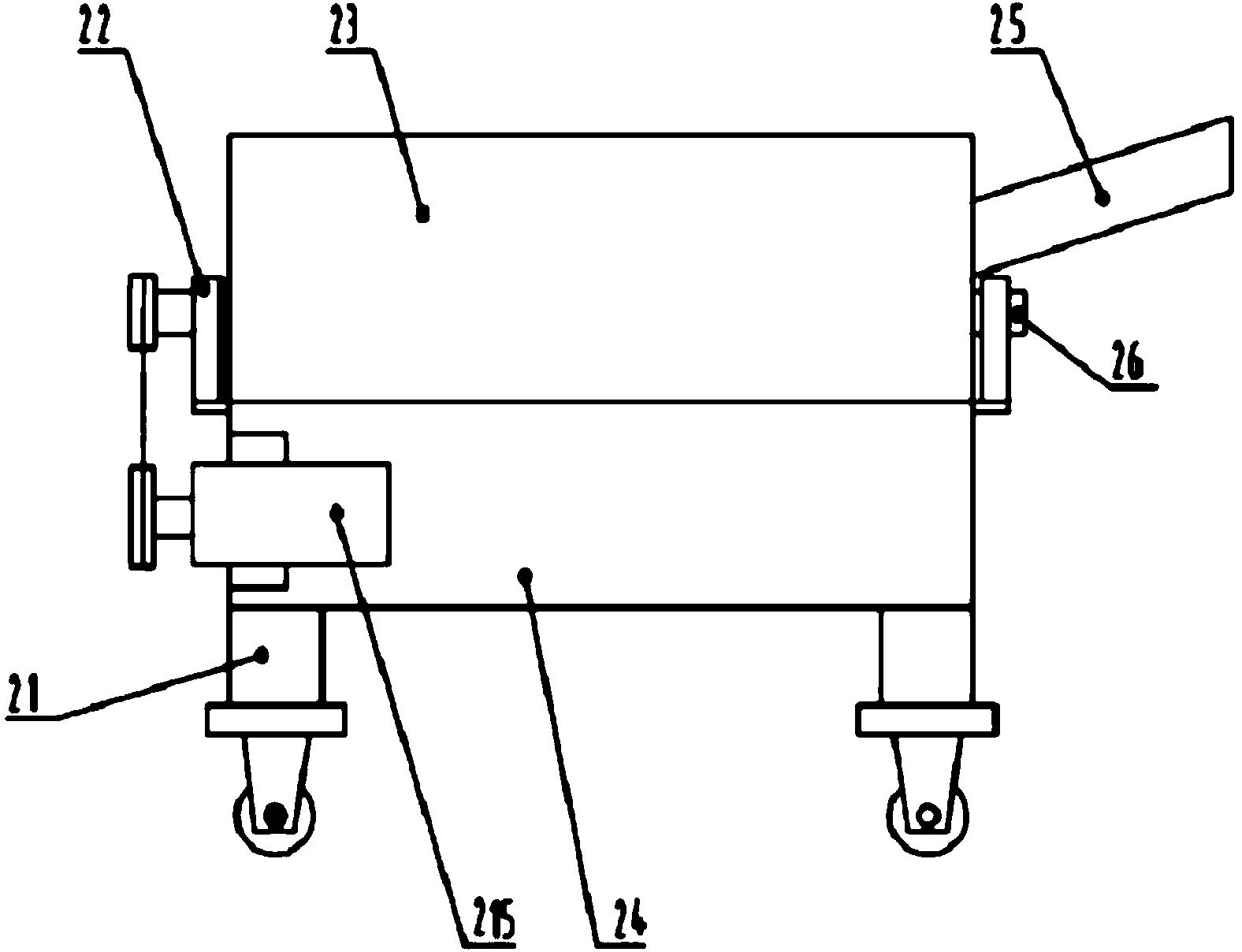

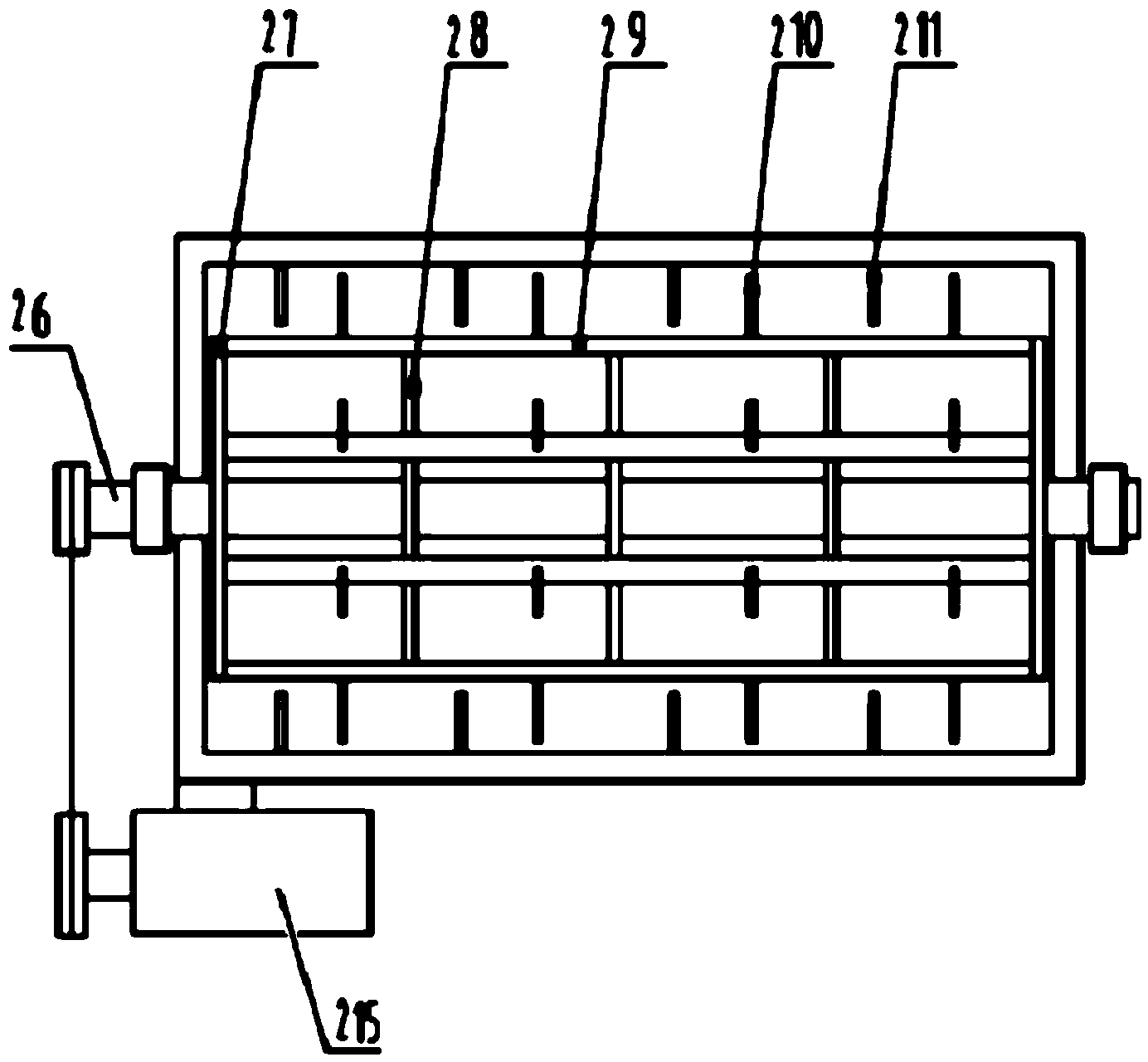

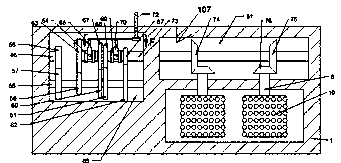

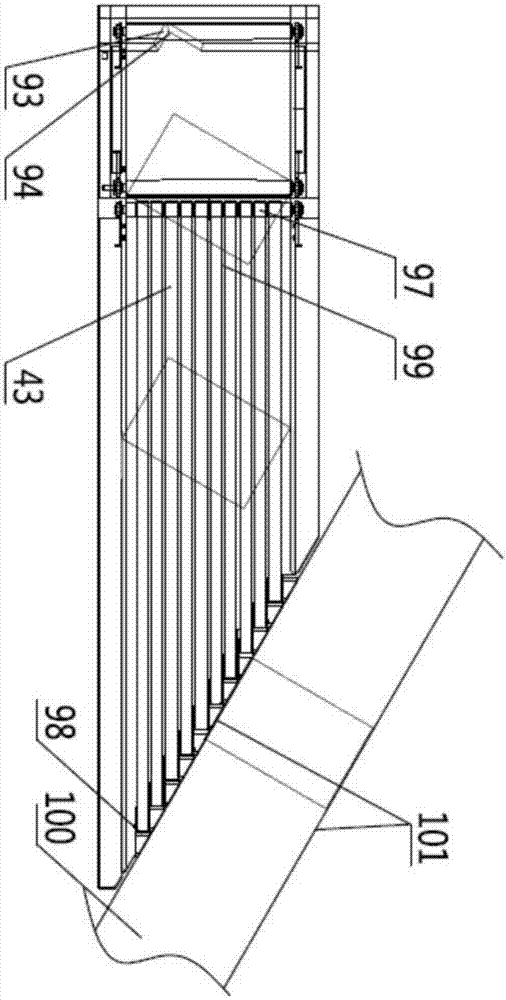

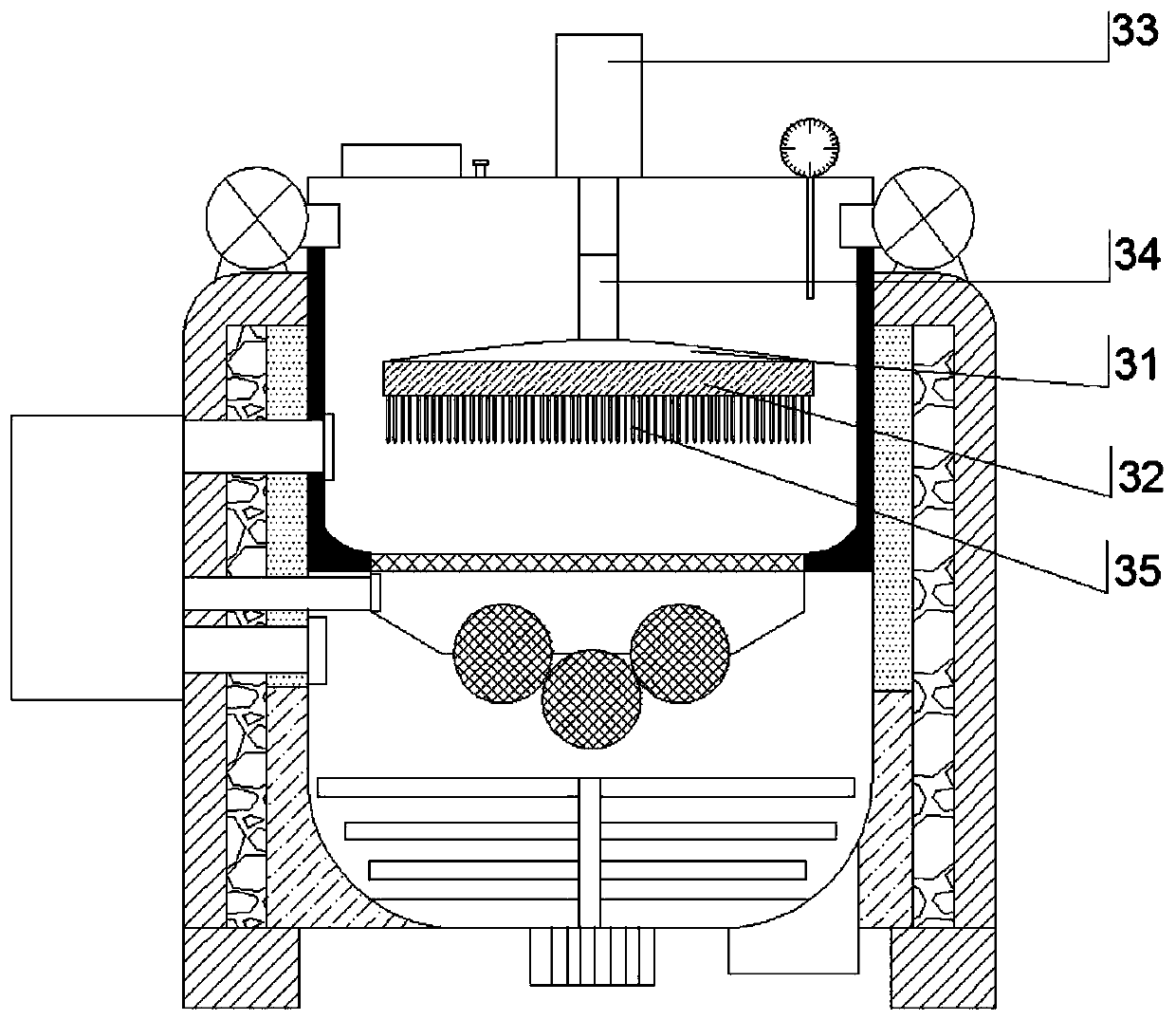

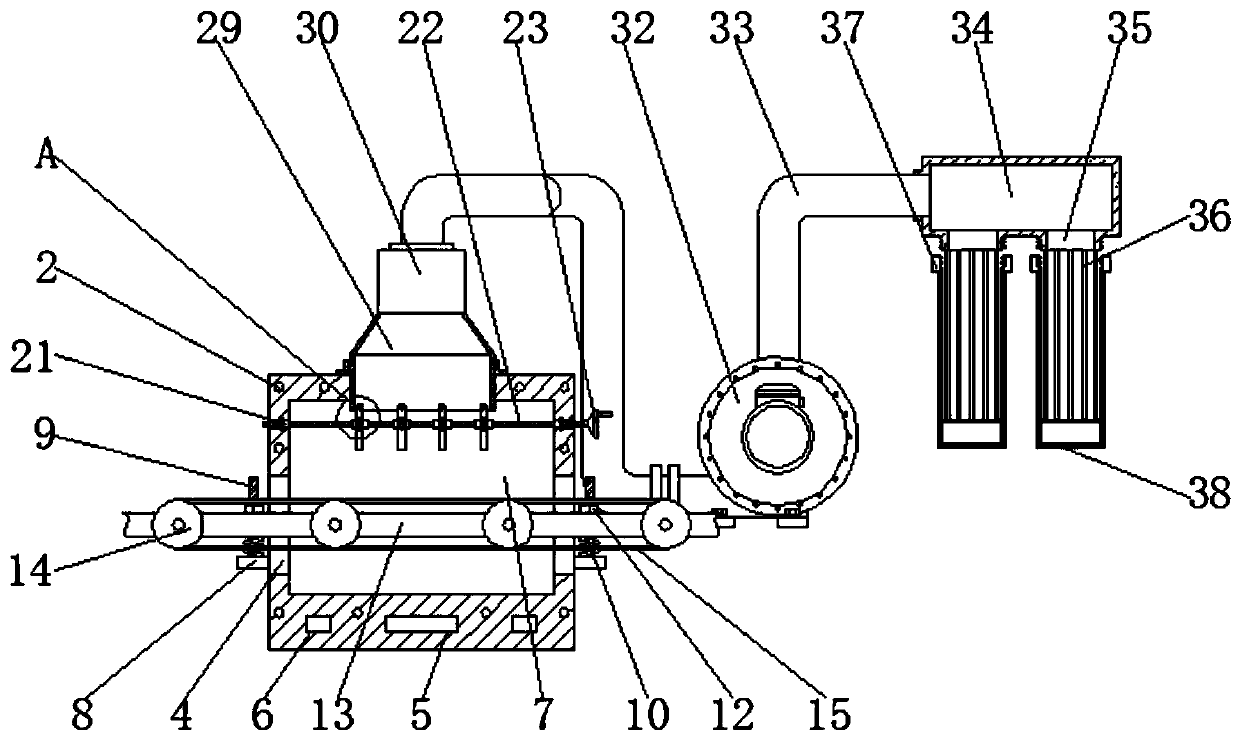

Cashmere opening and carding line production system and process thereof

ActiveCN103451781AImprove carding efficiencyImprove carding qualityContinuous processingFibre feedersAutomatic controlMoisture regain

The invention discloses a cashmere opening and carding line production system, which structurally comprises an industrial control computer, an opener and 8-16 carding machines sequentially, wherein the 8-16 carding machines are connected end to end and are arrayed in sequence, and the industrial control computer is used for monitoring the operation states of the opener and the carding machines in real time and performing automatic control; according to the line production sequence, each carding machine comprises a cashmere feeding mechanism used for conveying and feeding cashmere to a carding host, the carding host used for carrying out carding operation, and a moisture regain mechanism used for carrying out water spray moisture regain operation on carded cashmere sequentially. According to the cashmere opening and carding line production system and the process thereof, when opened and mixed cashmere enters each carding machine sequentially by virtue of conveying flat belts, the arrangement sequence of the carding machines are strictly controlled so as to ensure that the Xth carding machine is always used for carrying out the Xth carding operation, and the opening and carding operation can be efficiently finished. The feed quantity, the carding speed and the moisture regain rate of the carding machines can be automatically adjusted according to different properties of raw materials, and accordingly, the carding efficiency and quality of the cashmere can be improved.

Owner:HONGYE CASHMERE

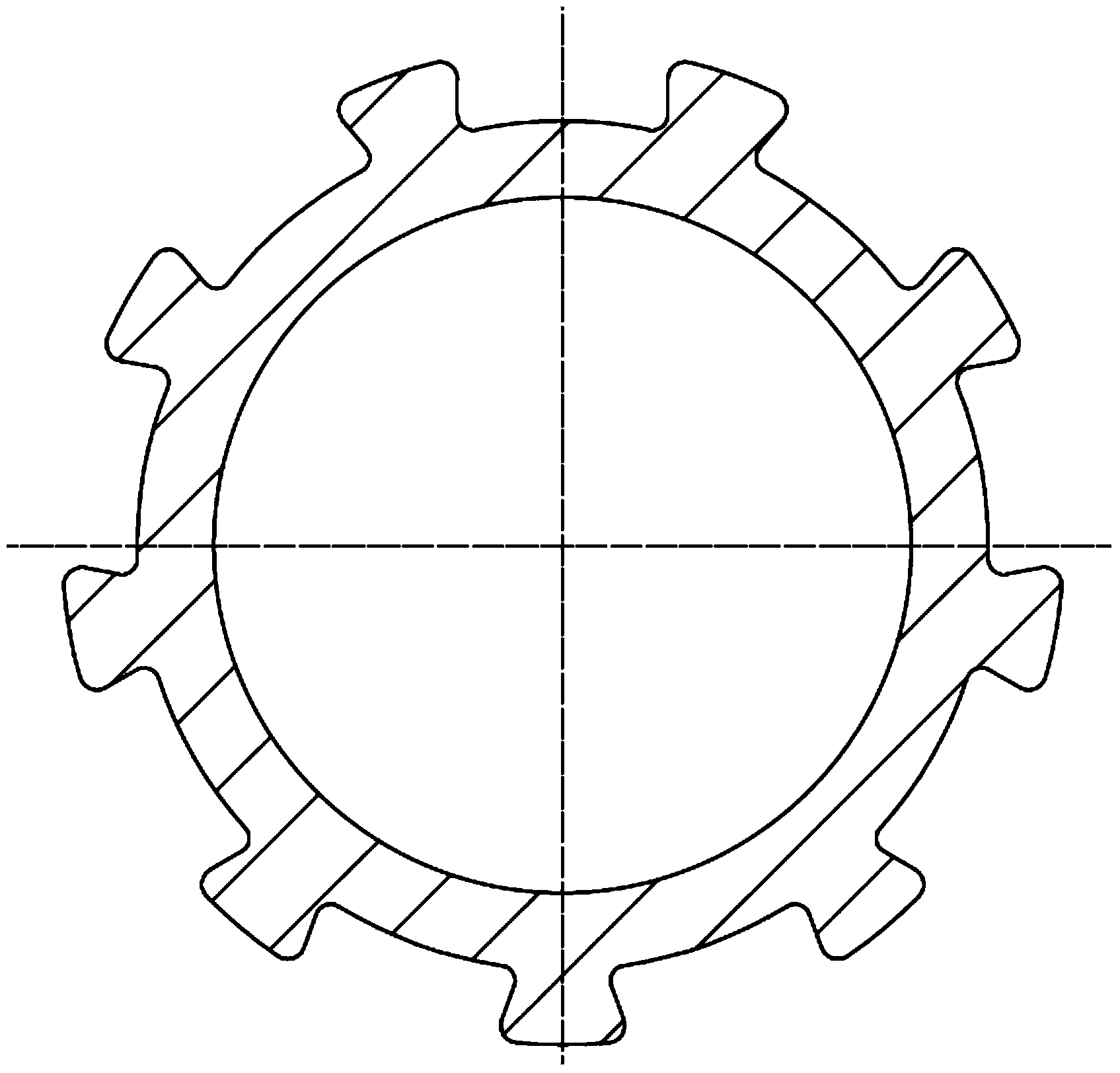

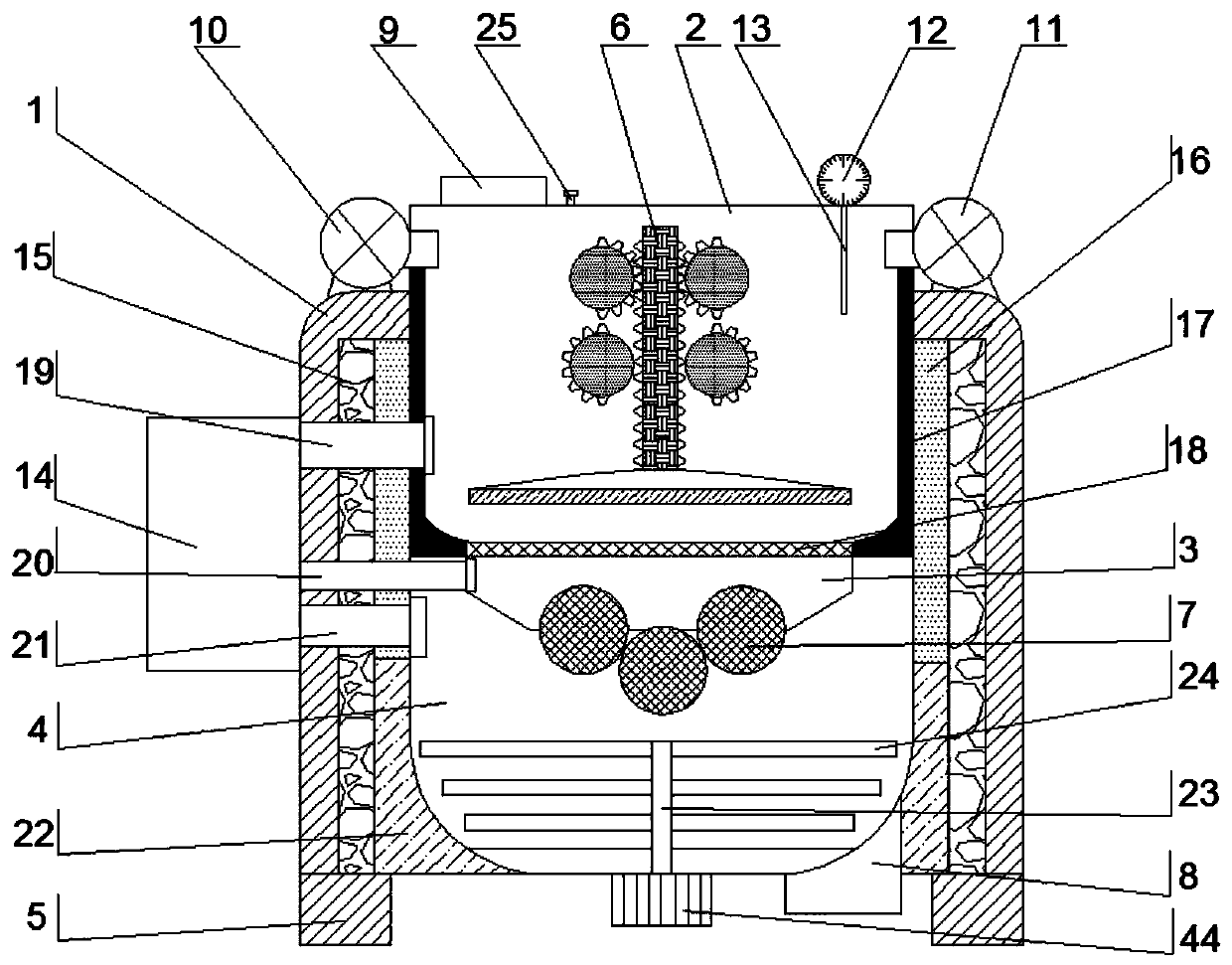

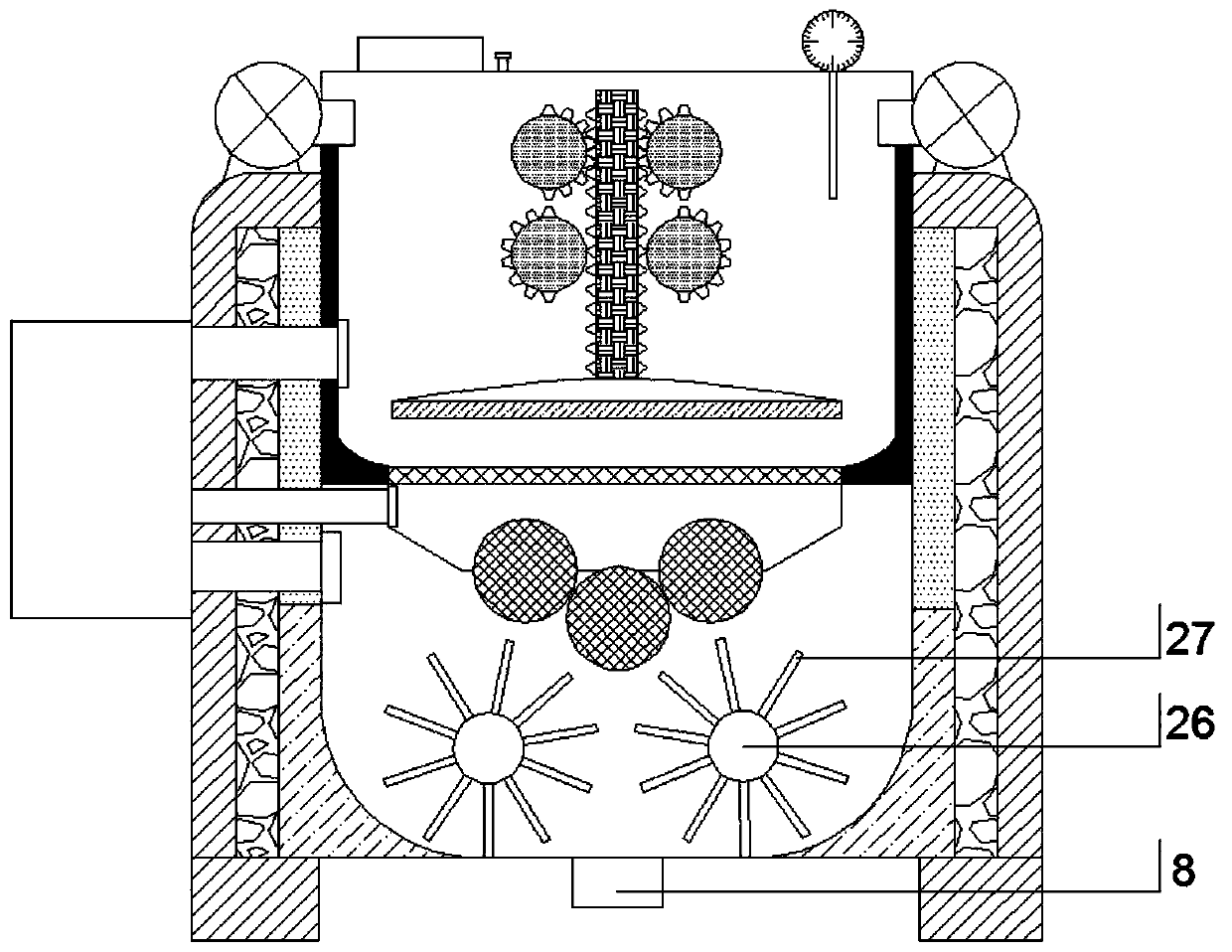

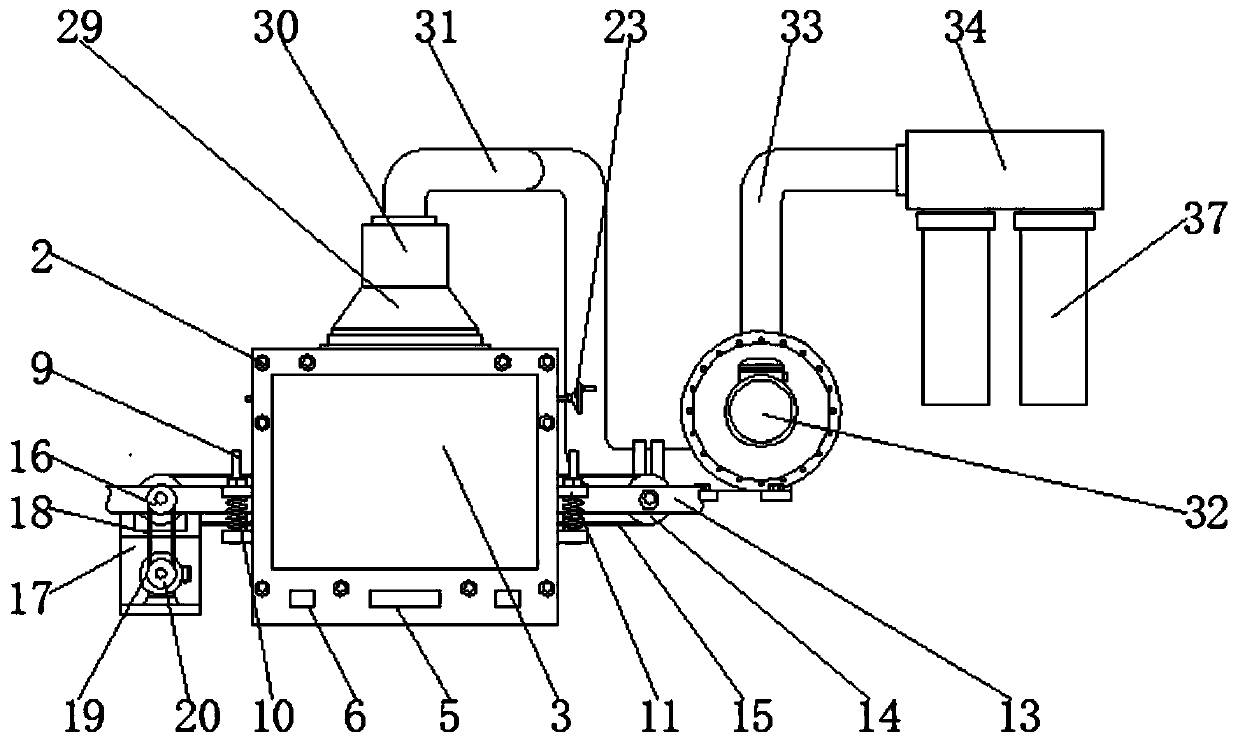

Anti-jamming wheel adjustable gear crusher

ActiveCN111111882AExtended service lifeWill not cause personal safety hazardsDirt cleaningGrain treatmentsGear wheelDust control

The invention discloses an anti-jamming wheel adjustable gear crusher. The anti-jamming wheel adjustable gear crusher comprises a box, an adjustable gear crushing device is arranged in the box, a crushing cavity is formed in the adjustable gear crushing device, a crushing wheel and a grinding wheel are arranged in the crushing cavity, a quantitative transportation device is arranged on the lower side of the adjustable gear crushing device, a motor and a transportation rod are arranged in the quantitative transportation device, a dust removal device is arranged above the transportation rod, anda fan and a filtering cavity are formed in the dust removal device. According to the anti-jamming wheel adjustable gear crusher, the rotating speed and direction of a rotary shat are changed by changing the meshing condition of reversing teeth and reversing gears, so that the grinding wheel changes the rotating speed in the crushing process, and the condition of jamming wheel can further be effectively prevented; and meanwhile, the dust removal device is further arranged in the device, and it is ensured that the damage of personnel safety cannot be caused to personnel due to excessive dust inhalation during construction operation.

Owner:YANGZHOU HENGXING PRECISION MACHINERY

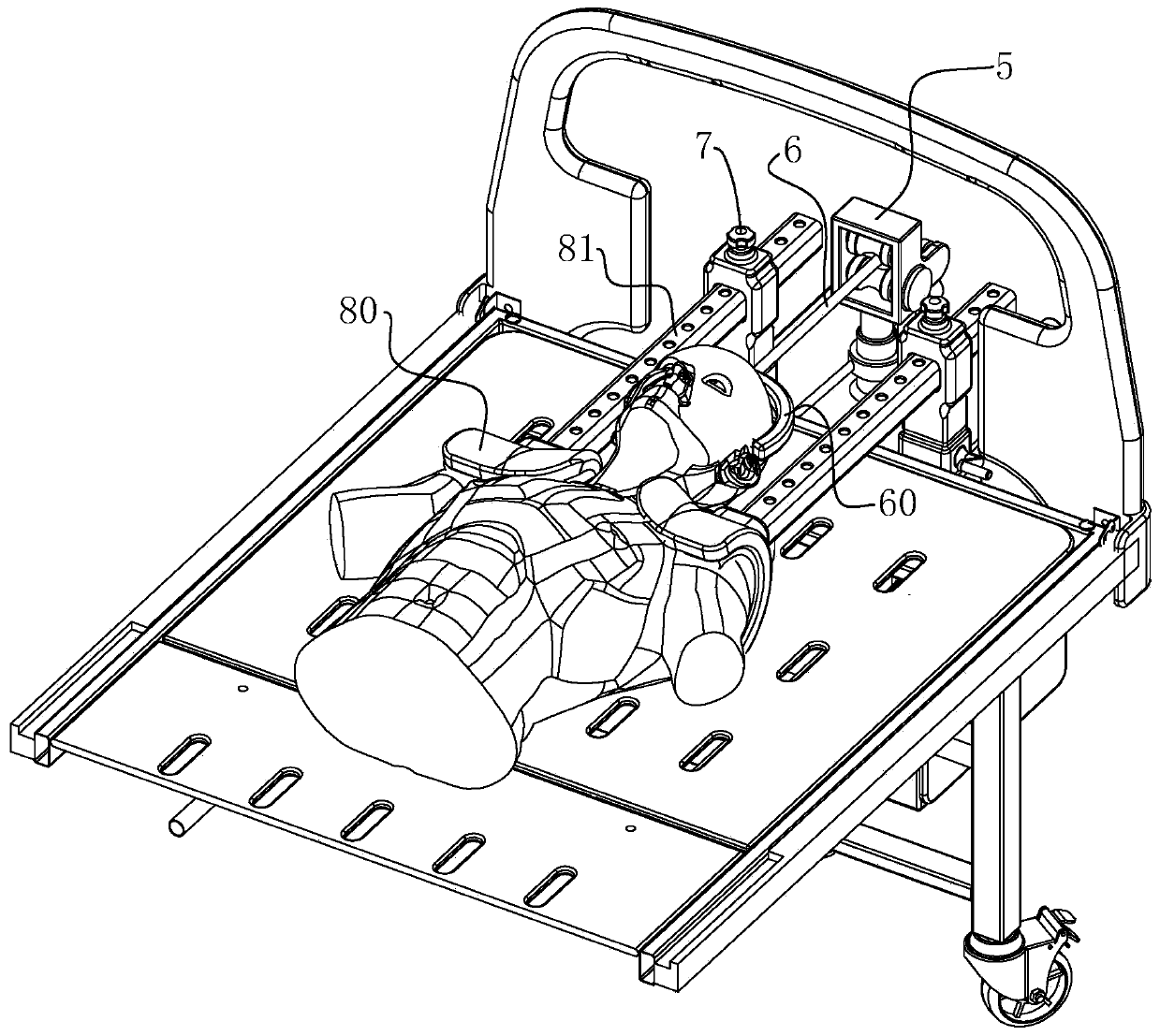

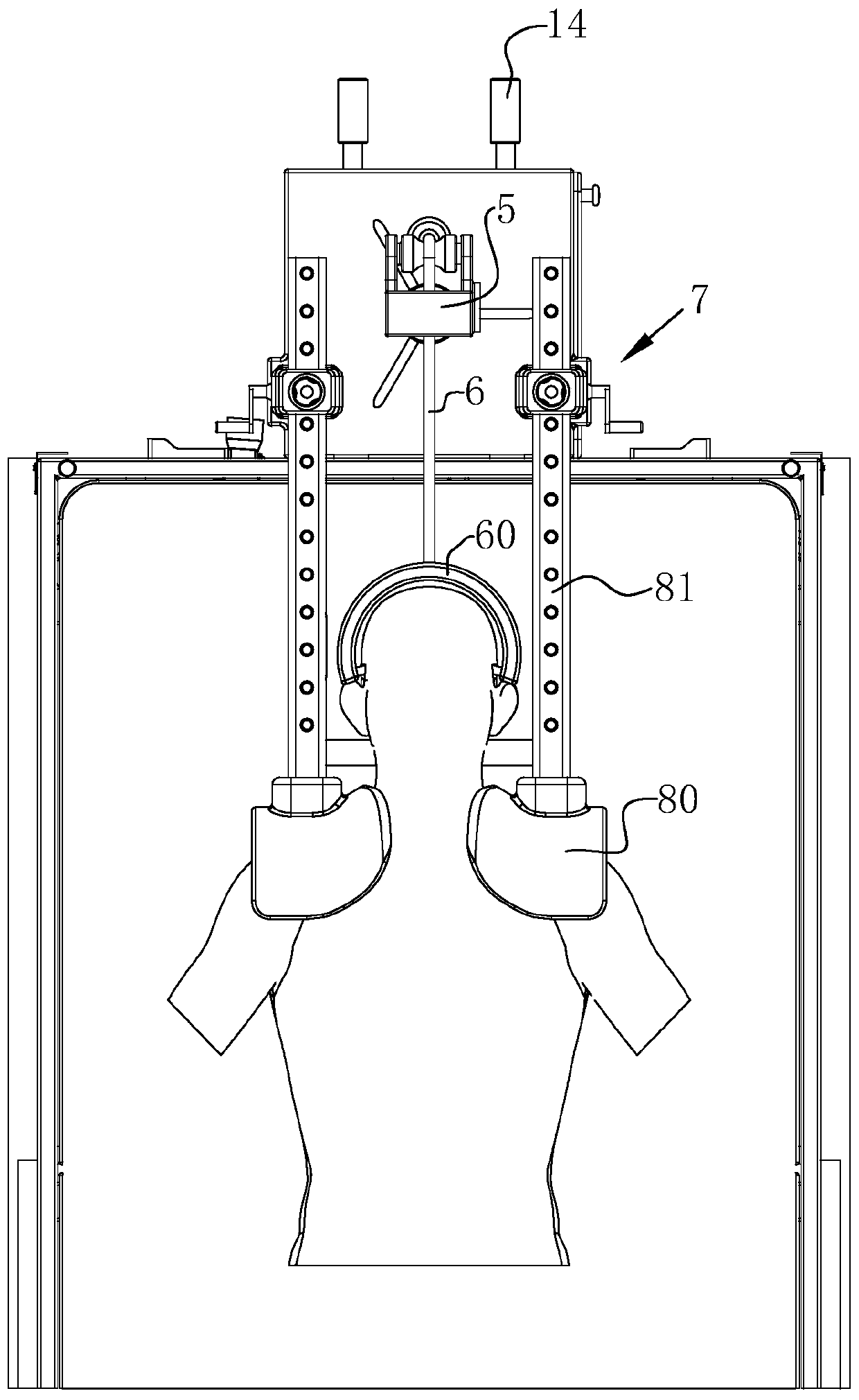

Skull traction device used for cervical vertebra dislocation

InactiveCN111407489AEasy to relaxImprove creepFractureMuscle relaxationPhysical medicine and rehabilitation

The invention discloses a skull traction device used for cervical vertebra dislocation. The skull traction device comprises a cabinet body, wherein one side of the top end of the cabinet body is rotatably provided with connecting components; the connecting components are used for detachably connecting the cabinet body to a hospital bed; the top end of the cabinet body is vertically provided with atelescopic element; the top end of the telescopic element is provided with a guide component used for guiding a traction rope; a traction element is arranged in the cabinet body; the top end of the cabinet body is provided with a through hole; and in addition, the bottom end of the traction rope penetrates through the through hole and is wound to the output end of the traction element. The skulltraction device disclosed by the invention can be flexibly suitable for the height of the hospital bed and is convenient to transport a patient along with the hospital bed, linear transition is increased for traction force, weight can be continuously increased so as to be favorable for muscle relaxation and cervical vertebra creepage and also favorable for restoration, and manpower loss is reduced.

Owner:HANGZHOU FIRST PEOPLES HOSPITAL

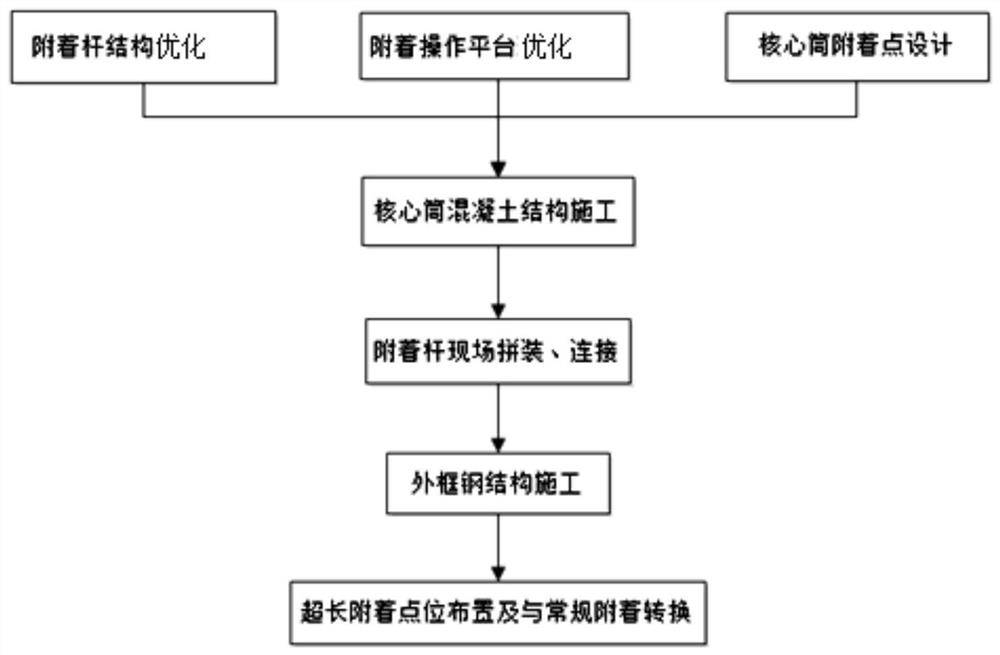

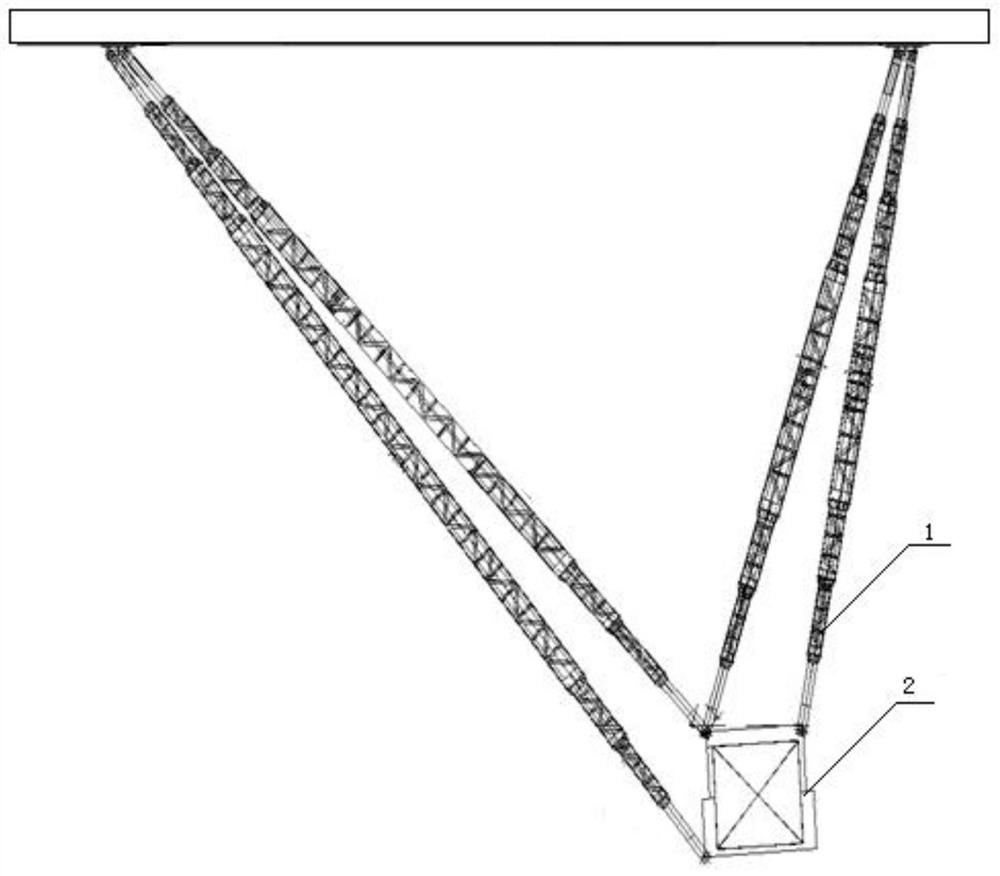

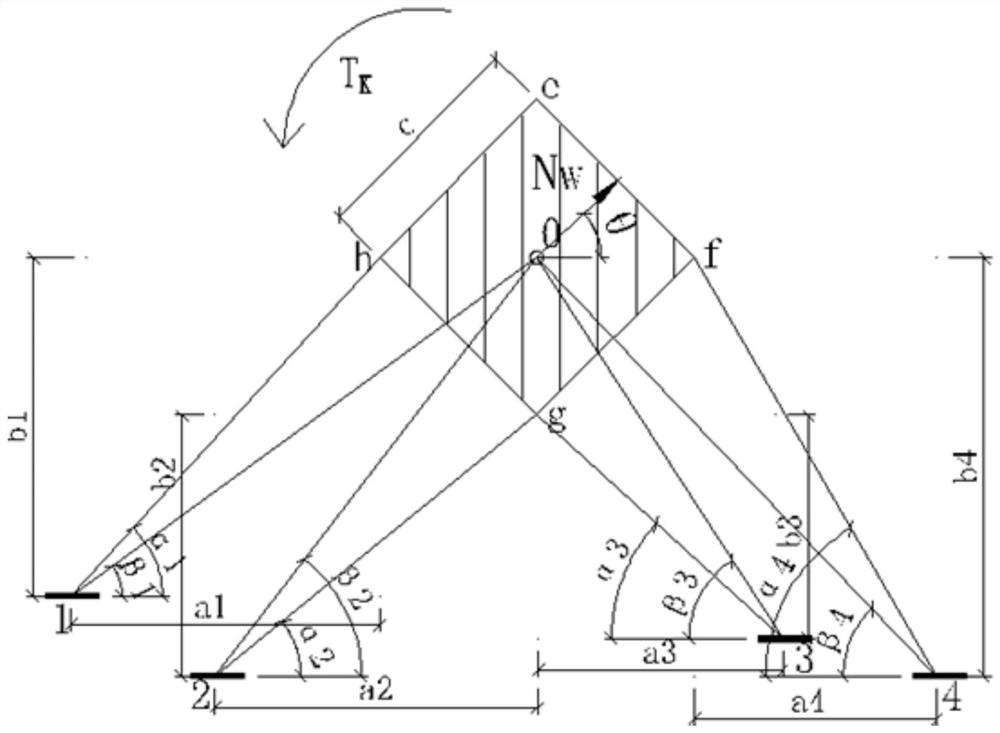

Super-long attachment construction method of tower crane

PendingCN111824983AReduce manufacturing costReduce manpower lossCranesArchitectural engineeringTower crane

The invention discloses a super-long attachment construction method of a tower crane, and relates to the technical field of super high-rise construction. According to the super-long attachment construction method of the tower crane, for the tower crane, basic parameters, related parameters and connection location parameters of an attachment bar and the tower crane during attachment positioning areobtained, the parameters of the attachment bar are optimized, an attachment point of a core tube during construction are determined by utilizing a wind load and attachment basic parameters, meanwhile, attachment operation platforms are separately arranged at the tower crane and an attachment surface operation point, assembly and disassembly and a structure of the operation platforms are optimized, construction of a concrete structure on the core tube is carried out, field splicing and connection of the attachment bar are carried out, construction of an outer frame steel structure is carried out, and arrangement and attachment conversion of a position of a core tube attachment point are performed simultaneously.

Owner:CHINA CONSTR EIGHTH ENG DIV

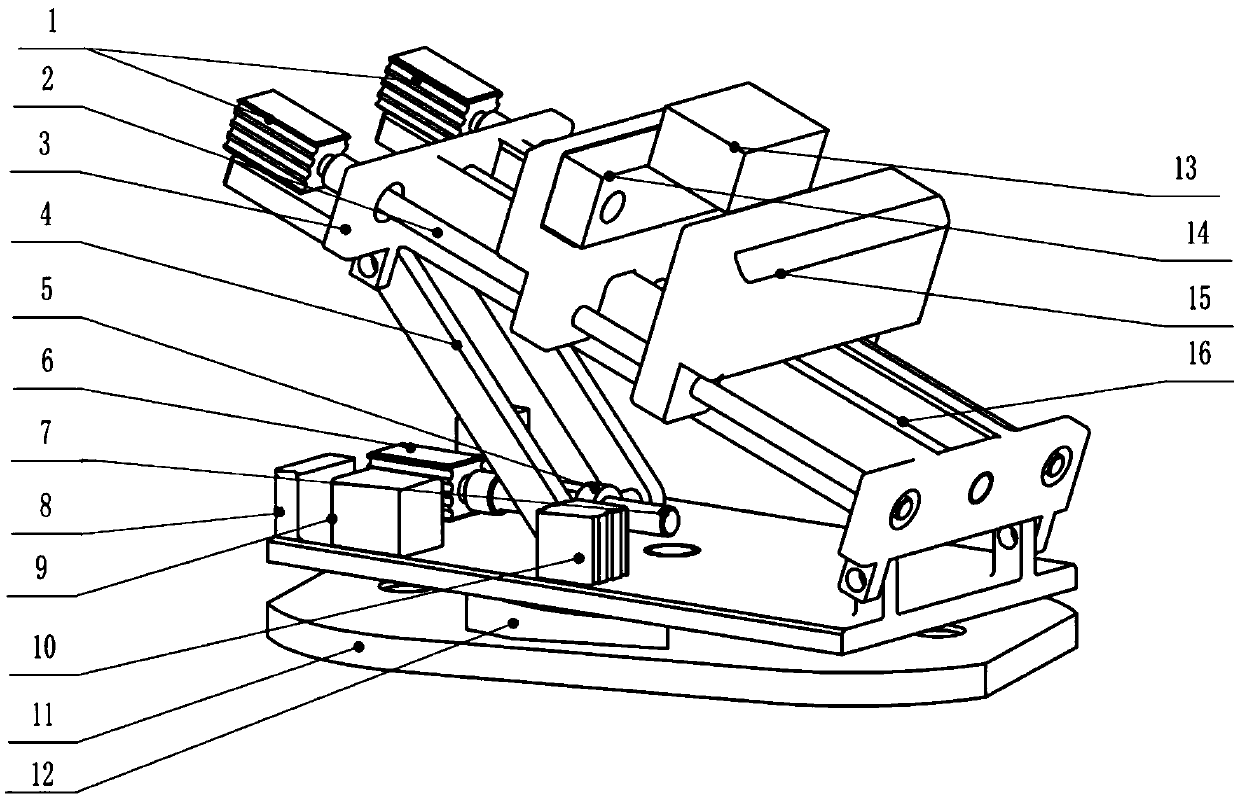

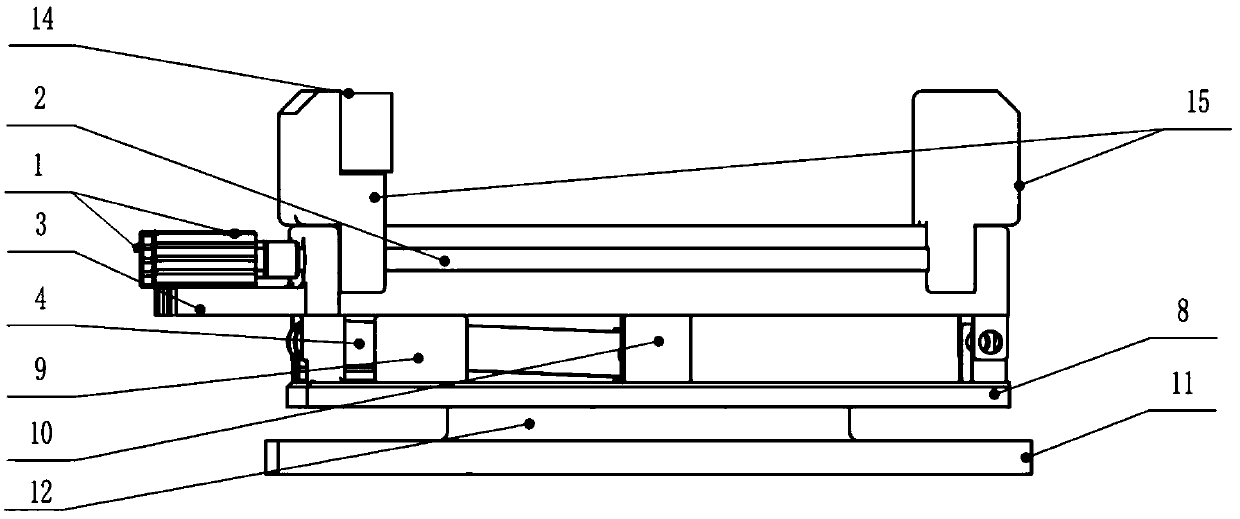

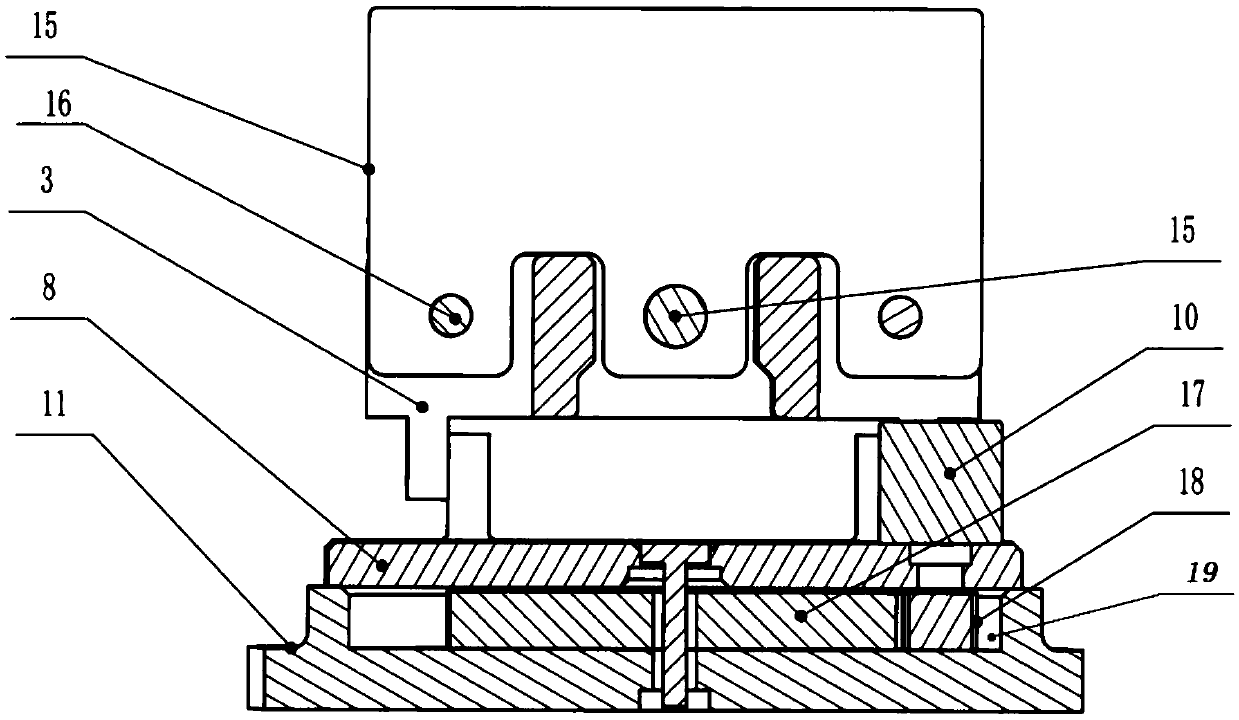

Electric machine vise with dual movable jaws

The invention relates to an electric machine vise with dual movable jaws. The electric machine vise comprises a rotary base, a clamping mechanism, an angle adjusting structure and a control box, wherein the clamping mechanism is arranged at one end of the rotary base through a hinge, the angle adjusting structure is arranged at the other end of the rotary base and used for adjusting the angle of the clamping mechanism, and the control box is used for controlling the clamping mechanism and the angle adjusting structure. The clamping mechanism comprises a vise seat and two movable vise bodies, and the two movable vise bodies are slidably arranged on the vise seat symmetrically. Driving lead screws arranged along the long edge of the vise seat are arranged on two sides of the vise seat respectively, threads on two sides of each driving lead screw are opposite in turning direction, a driving motor is connected to one end of each driving lead screw, and the driving lead screws are in threaded connection with two sides of the two movable vise bodies. The electric machine vise with the dual movable jaws has the advantages that a workpiece machining operation range becomes wider through the rotary base and the angle adjusting mechanism, time waste during workpiece clamping is reduced through the dual movable vise bodies, and clamping efficiency and reliability are both improved throughmotor driving.

Owner:SUZHOU VOCATIONAL UNIV

Automatic weighing and gathering sorting machine and goods gathering and straightening method

The invention discloses an automatic weighing and gathering sorting machine. The automatic weighing and gathering sorting machine comprises a rack, wherein the rack is connected with a first station, a second station and a third station in a matched manner in sequence. The first station comprises a first conveying device and a weighing device for weighing goods on the first conveying device. The second station comprises a second conveying device, wherein the second conveying device is used for conveying the goods conveyed by the first conveying device to the third station in an accelerated manner. The third station comprises a third conveying device and a limiting block located at the input end of the third conveying device, and each piece of the goods is conveyed to a transfer platform at the same state after being limited to the third conveying device by the limiting block at the placement angle. The automatic weighing and gathering sorting machine and a goods gathering and straightening method mainly have the beneficial effects that when the goods are gathered on the transfer platform, it can be guaranteed that the placement states of the goods are the same; and furthermore, through the design of a limiting groove, the goods can be in the straightened state on the transfer platform, and the subsequent sorting work is performed greatly conveniently.

Owner:SUZHOU GP LOGISTICS SYST

Resin raw material premixing device

ActiveCN111037773AEffective squeezeTo achieve the purpose of initial mixingGrain treatmentsBLENDER/MIXERAir pump

The invention discloses a resin raw material premixing device, and relates to the technical field of resin processing. The resin raw material premixing device includes a protective shell, a squeeze barrel, a crushing hopper and a mixing barrel. A feeding inlet and a barometer are arranged at the top end of the squeeze barrel, an air pump and a blower pump are arranged on two sides of the squeeze barrel, and a squeeze mechanism is arranged in the squeeze barrel; and a grinding roller is arranged on the communicating part of the crushing hopper and the mixing barrel, a stirring mechanism is arranged at the inner bottom end of the mixing barrel, and a material pump which separately communicates with the squeeze barrel, crushing hopper and the mixing barrel is arranged outside the protective shell. According to the resin raw material premixing device, deficiencies of the prior art are overcome, design is reasonable, use is convenient, a single device is used for realizing multiple mixing methods, the mixing efficiency of resin is effectively improved, the addition of auxiliary materials is facilitated, the control in the mixing process is facilitated, and the manpower loss is reduced.

Owner:天长市诚信塑业有限公司

Cutting and adhesive spraying integrated machine

InactiveCN107253236AReduce generationNot easy to cutGripping devicesClamping devicesAdhesiveEngineering

The invention relates to a cutting and adhesive spraying integrated machine which comprises a base; a board cutting device is arranged on the base, and an adhesive spraying device is connected to the rear portion of the board cutting device; the board cutting device comprises a first synchronous belt conveying mechanism, a transverse moving mechanism located above the first synchronous belt conveying mechanism and clamping devices symmetrically distributed on the two sides of the first synchronous belt conveying mechanism; and the adhesive spraying device comprises a second synchronous belt conveying mechanism, an adhesive spraying mechanism located at the upper end of the second synchronous belt conveying mechanism and an evenly-smearing mechanism connected with the adhesive spraying mechanism. According to the cutting and adhesive spraying integrated machine, the machine is adopted to replace manual work, labor consumption is reduced, the cost is reduced, and the efficiency is improved; the board cutting device is adopted, board cutting can be conducted in a large-scale mode, and particularly, the condition that a thickened board is not prone to being cut can be well solved by the cutting and adhesive spraying integrated machine; the adopted board cutting device and adhesive spraying device are in sliding-fit with the base correspondingly, adhesive smearing can be evenly conducted, and production of defective products is greatly reduced.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

Dust removal device for textile processing

ActiveCN110525923AEasy to remove dust from the surfaceReduce manpower lossMechanical cleaningPressure cleaningEngineeringThreaded rod

The invention discloses a dust removal device for textile processing. The device comprises a first box body, springs and a fixing frame, a bolt is arranged at the edge of the outer side of the first box body, and one side of the first box body is connected with a second box body through the bolt, wherein through holes are formed at the two sides of the first box body and the two sides of the second box body. The springs are connected with the threaded columns, the fixing frame penetrates through the interior of the first box body and the interior of the second box body through a connecting base, and the bearing bases are arranged at the two ends of the inner side of the first box body. The threaded rods are connected into the bearing bases, and the threaded sleeves are connected to the outer sides of the threaded rods. The dust removal device for textile processing is provided with the threaded rods, and the threaded rods are driven to rotate in the bearing bases by rotating a rotary disc, so that the threaded sleeves on the threaded rods move left and right, and the moving threaded sleeves move in the sliding groove holes through the cylindrical rods to drive a wind direction plate to rotate in a wind suction hopper around a rotary shaft, and accordingly the angle of the wind direction plate is conveniently adjusted.

Owner:沅江瑞鸿服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com