Filling body and surrounding rock composite rock mass routine test sample manufacturing mould and manufacturing method

A technology for routine testing and filling, which is applied in the preparation, sampling, and measuring devices of samples for testing. Loss and waste of time, avoid damage, reduce the effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

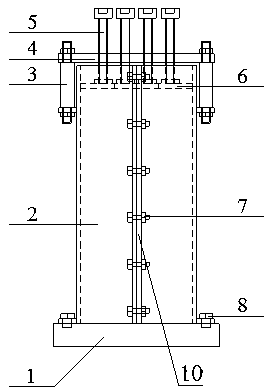

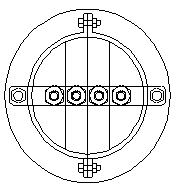

Embodiment 1

[0059] Such as Figure 8-1 to 8-5 As shown, when the cementing surface is 0 to 60°, the surrounding rock is processed according to the size of the surrounding rock part of the composite rock mass sample; the bottom plate 1 and the two semicircular structure are formed by connecting screws 7 and bottom plate connecting screws 8 2 Combine together, and put the processed surrounding rock into the circular cavity formed by the template 2; connect the mold plate 2 and the reaction frame 4 through the fixing bolt 3; because the maximum height of the surrounding rock is not formed in the circle The upper plane structure in the cavity, therefore, there is no need to apply the upper pressure plate 6. According to the proportion and concentration requirements of the composite rock body filling part, the filler slurry is made and poured into the circular cavity composed of the template 2; The upper pressing plate 6 is composed of a separate structure, and the upper pressing plate 6 seals t...

Embodiment 2

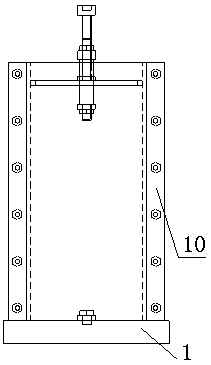

[0061] Such as Figure 8-6 to 8-7 As shown, when the cementation surface is 75° to 90° (or less than 75° but greater than 60°, as long as the upper plane can appear according to the ratio of the bottom surface to the height), according to the size of the surrounding rock part of the composite rock sample Process the surrounding rock; combine the bottom plate 1 with the template 2 composed of two semicircular structures through the connection screw 7 and the bottom plate connection screw 8, and put the processed surrounding rock into the circular cavity composed of the template 2 ; Connect the mold plate 2 and the reaction frame 4 through the fixing bolt 3; Because the maximum height of the surrounding rock has formed an upper plane structure in the circular cavity;

[0062] When the bonding surface is 75°, therefore, the upper pressure plate 6 needs to be applied, and the rightmost part of the upper pressure plate 6 needs to be applied, that is, the fourth split structure 604, (r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com