Sample clamping device of polishing machine

A sample holder and polishing machine technology, applied in the field of machinery, can solve the problems of reducing work efficiency, time-consuming and laborious, etc., and achieve the effects of improving work efficiency, reducing labor loss, and improving the quality of sample polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

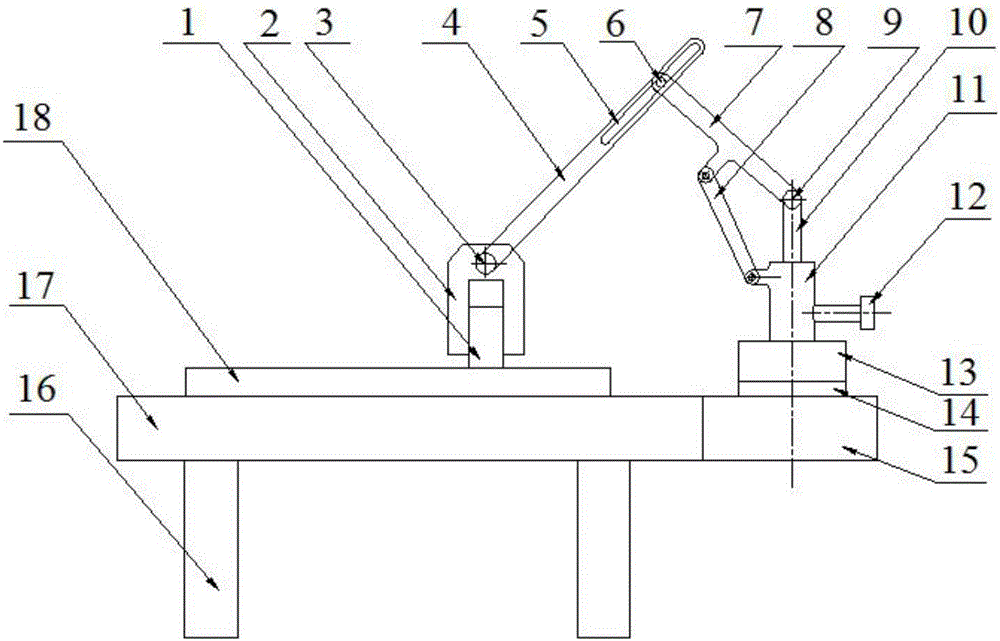

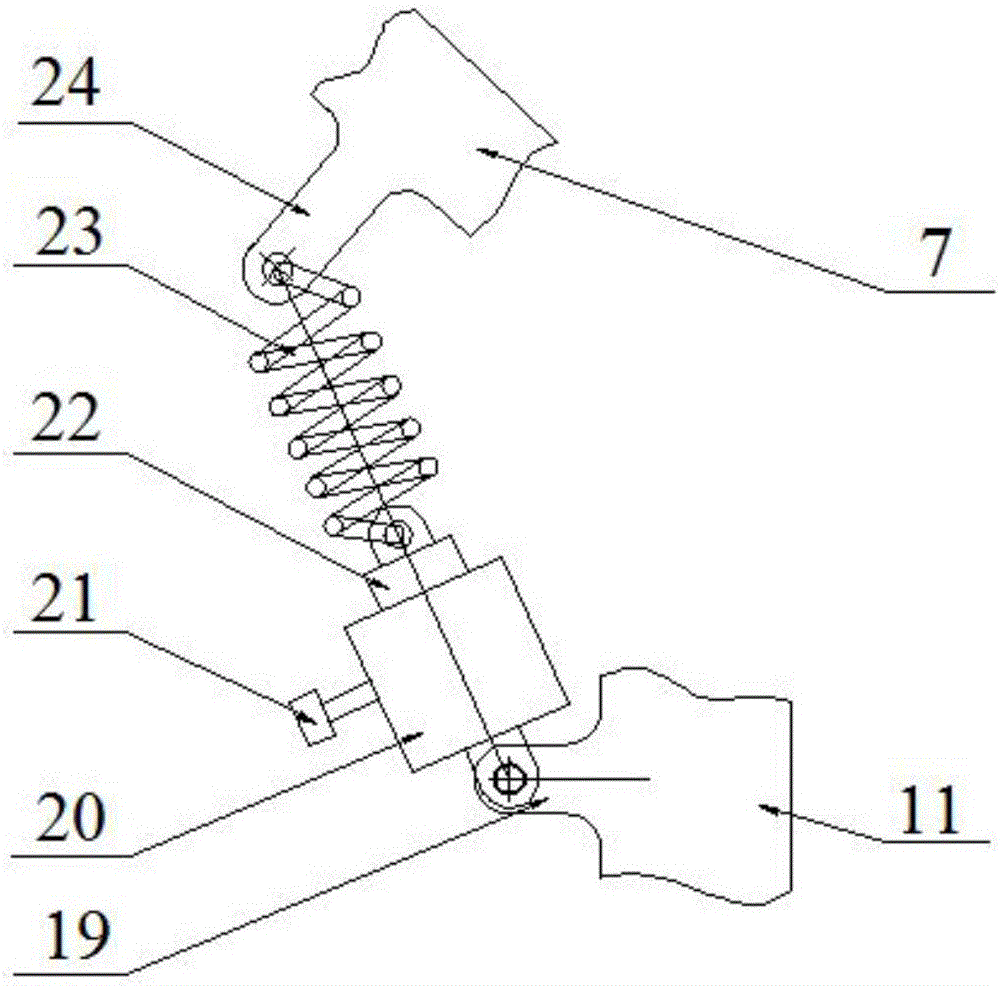

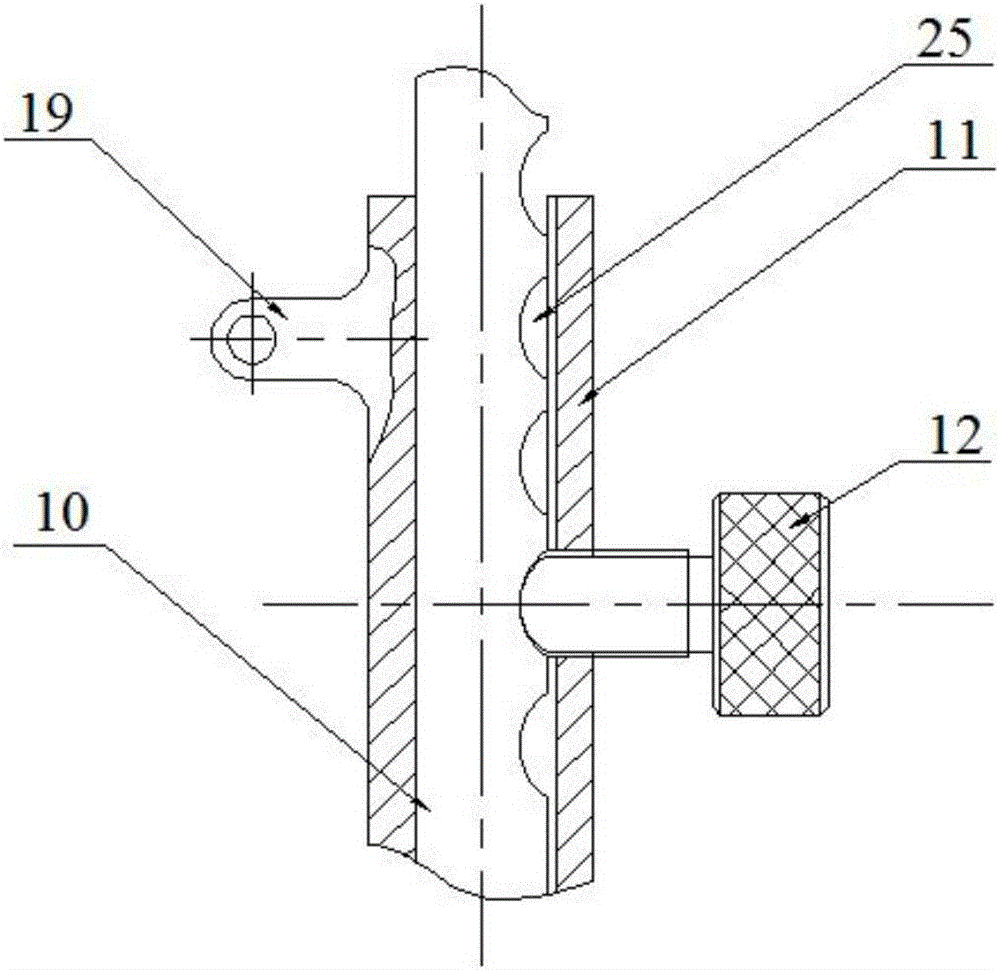

[0016] A sample clamping device for a polishing machine, which is composed of a sample 1, a clamping pliers 2, a locking bolt 3, a front clamping arm 4, a chute 5, a sliding adjustable bolt 6, a middle clamping arm 7, and a spring telescopic Device 8, adjustable bolt 9, final clamping arm 10, clamping table thin sleeve 11, clamping table top screw 12, clamping table thick sleeve 13, clamping table gasket 14, clamping table base 15. Bracket 16, worktable 17, polishing table 18, lug 19, telescopic sleeve 20, locking screw 21, telescopic rod 22, adjustment spring 23, mid-section clamping arm lug 24, end-section clamping arm groove 25. The telescopic rod groove 26, the jaw spring 27, the jaw gasket 28, the bolt screw hole 29, the clamp arm 30, and the jaw locking bolt 31 are characterized in that: the polishing table 18 is installed on the workbench In the upper part of 17, the workbench 17 is supported on the ground by the bracket 16. The clamping platform base 15 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com