Patents

Literature

318results about How to "Not easy to cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

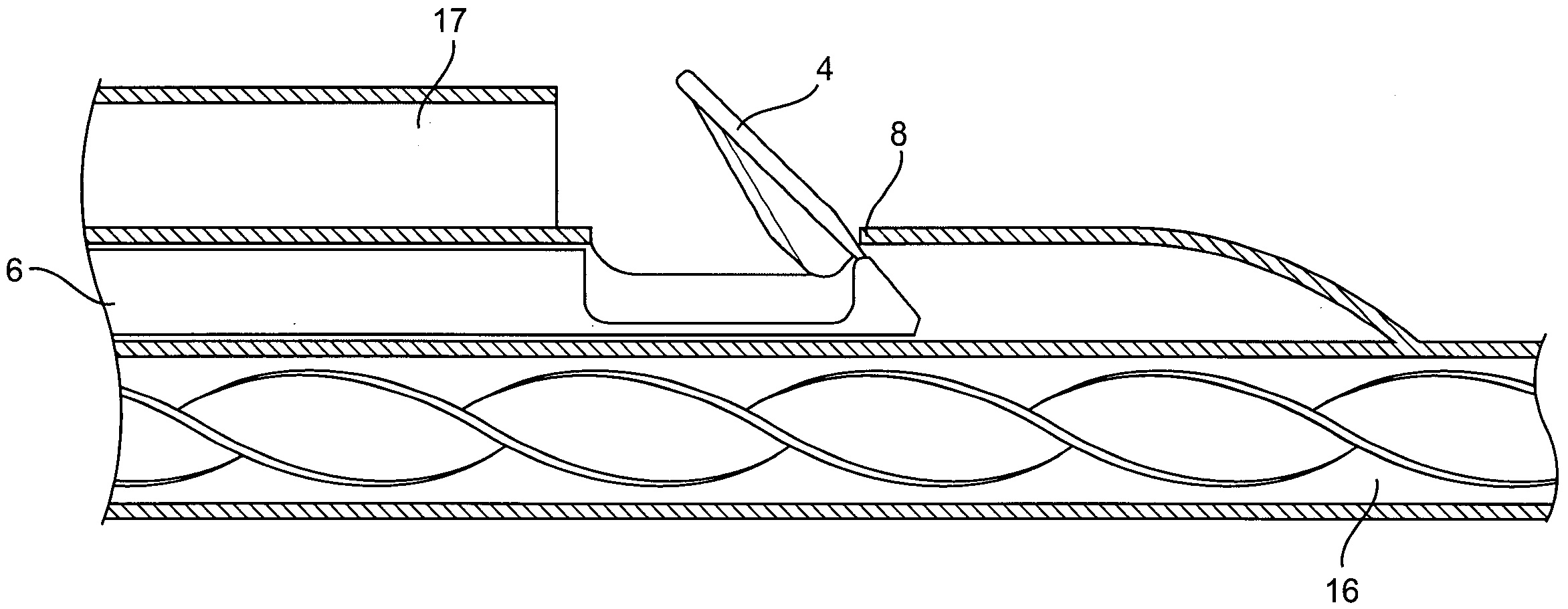

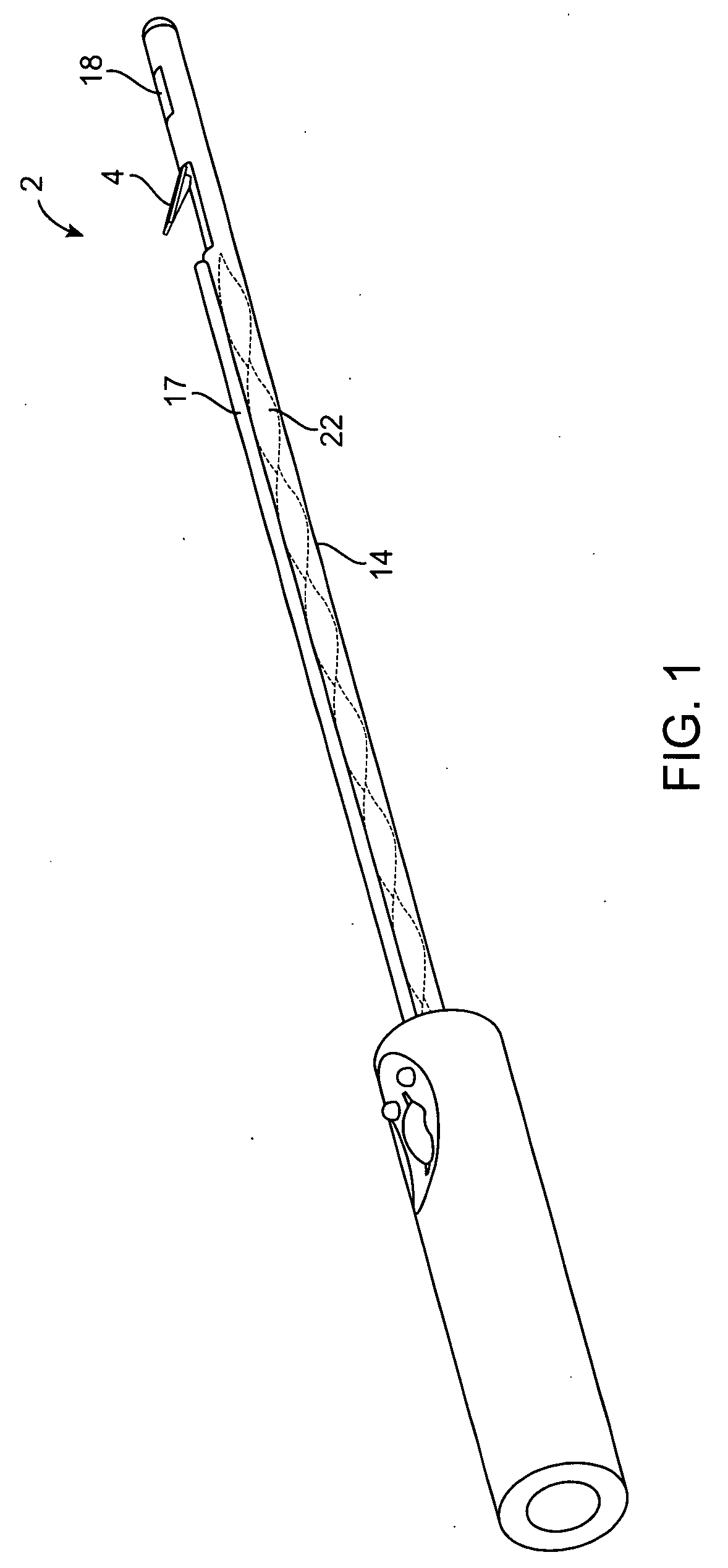

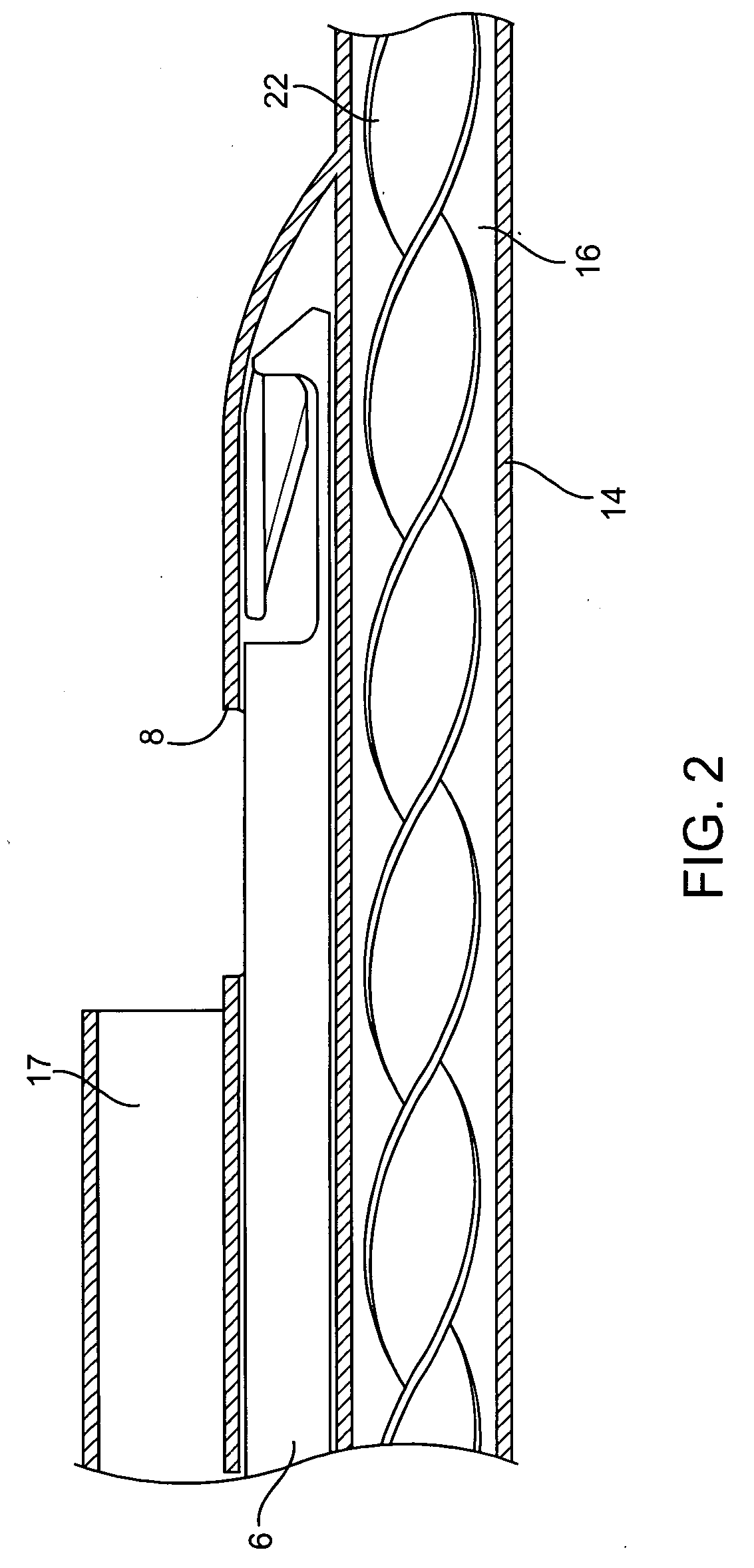

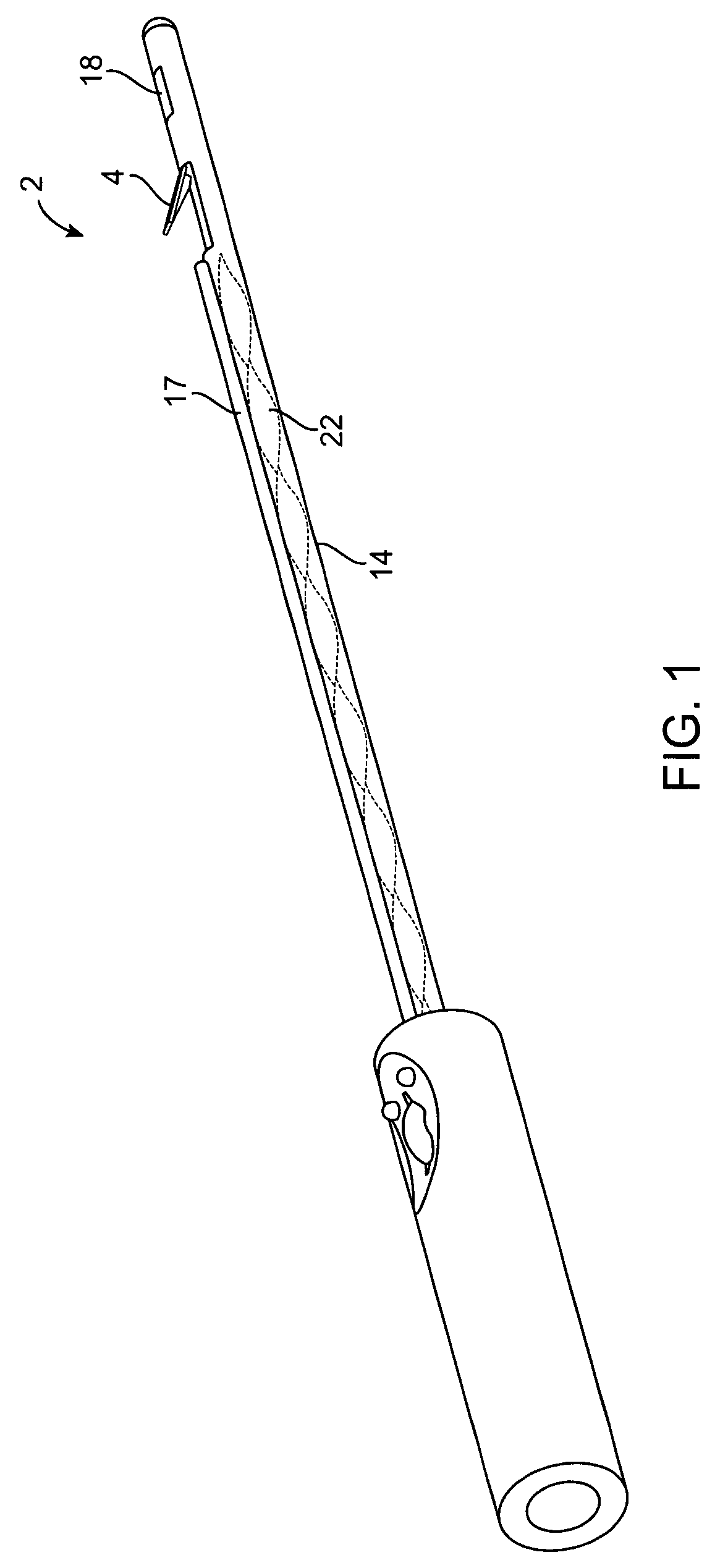

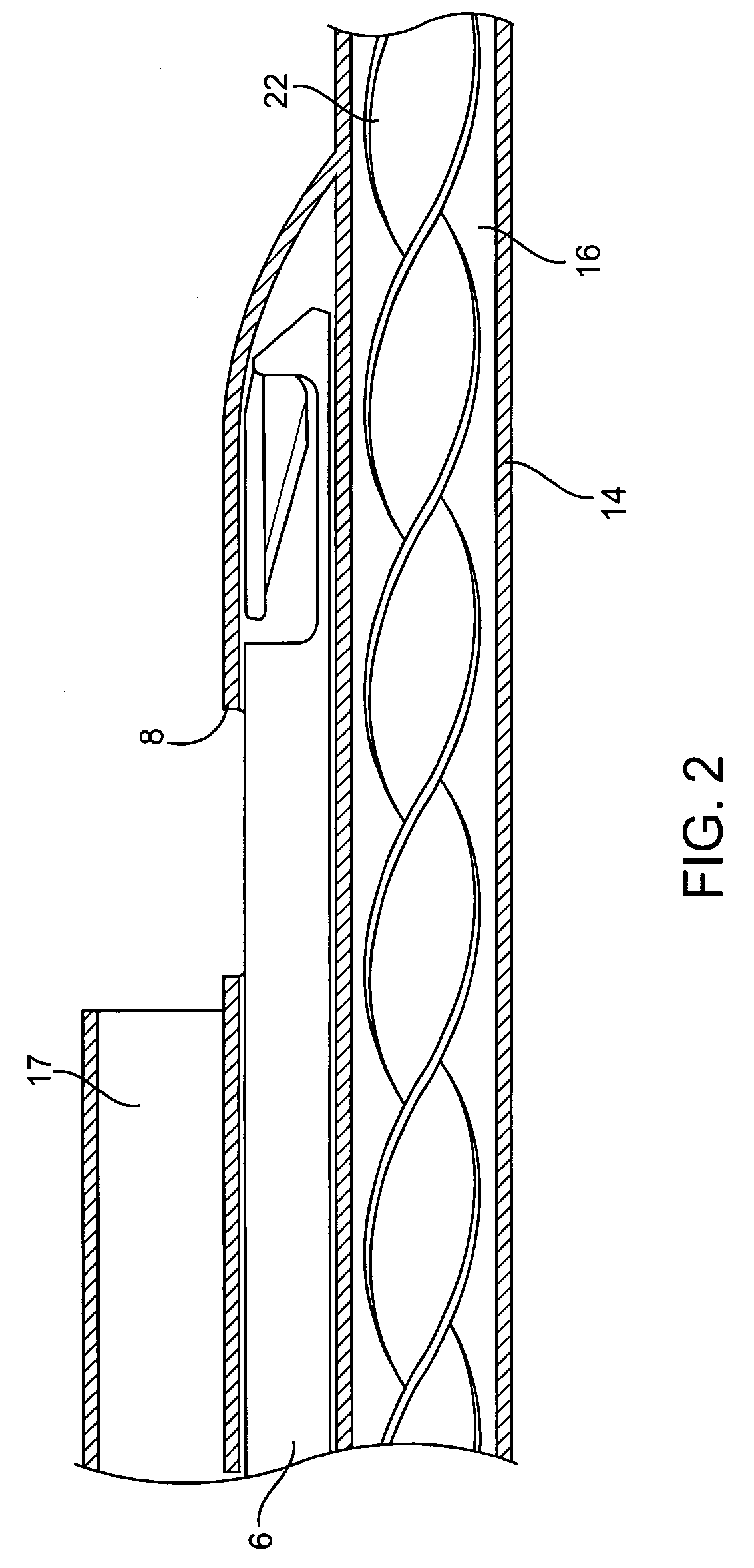

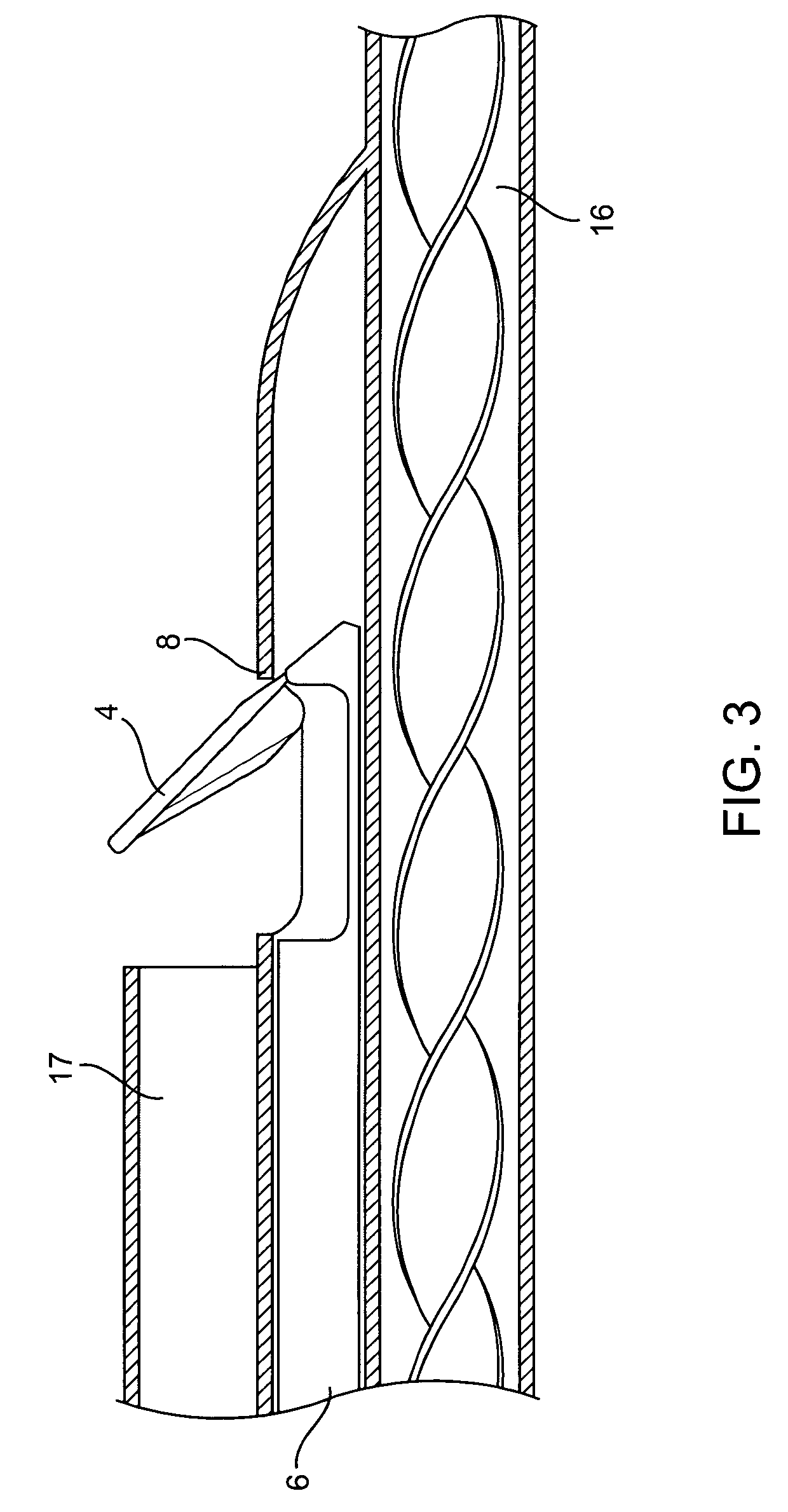

Methods and devices for improving the appearance of tissue

ActiveUS20100057056A1Easy to navigateNot easy to cutChiropractic devicesEye exercisersRadiologyCellulite

Cellulite is treated by severing septae, which interconnects the skin with the underlying muscle. The septae may be severed in connection with a liposuction procedure or independent of a liposuction procedure.

Owner:TAUTONA GRP IP HLDG CO L L C

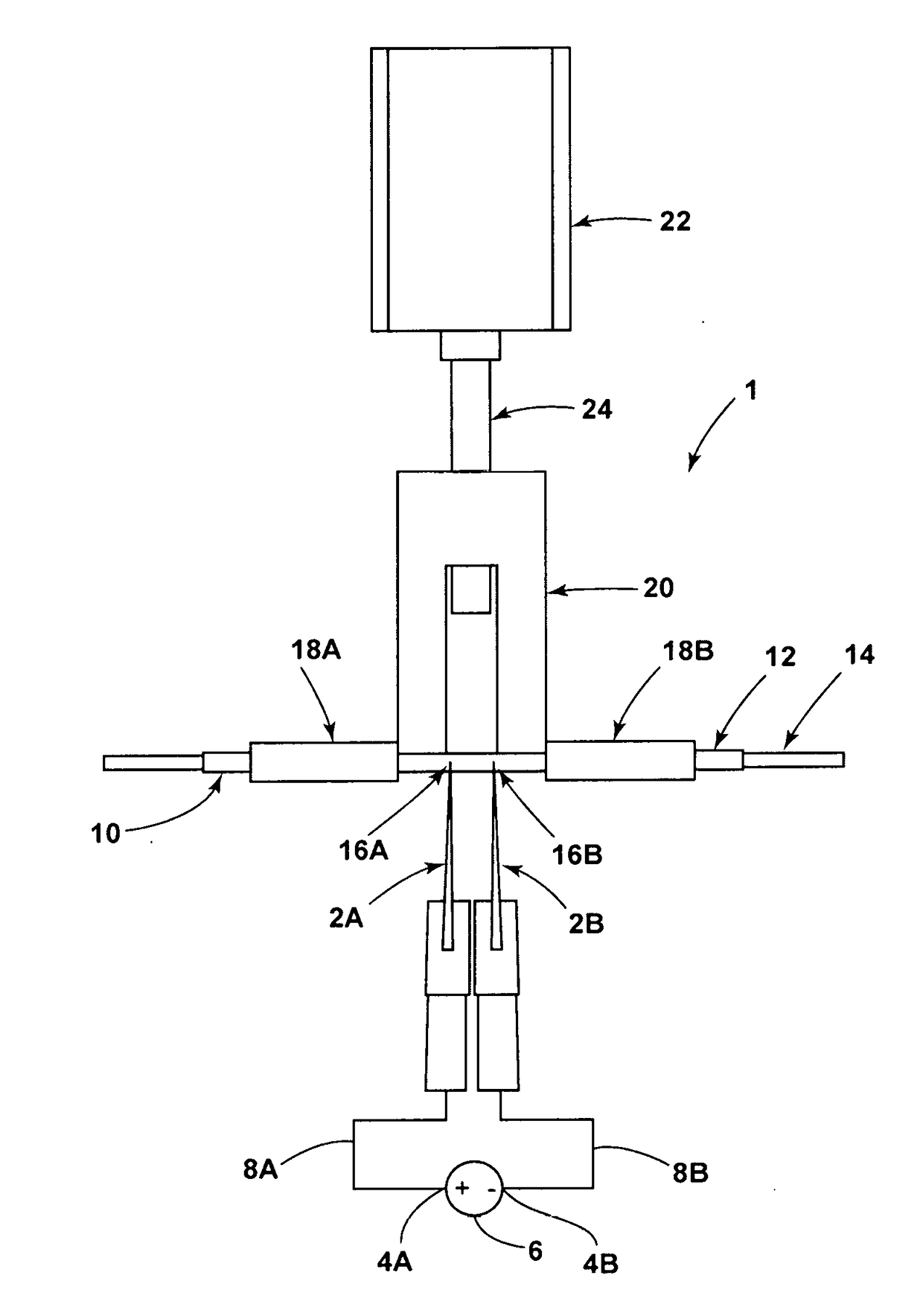

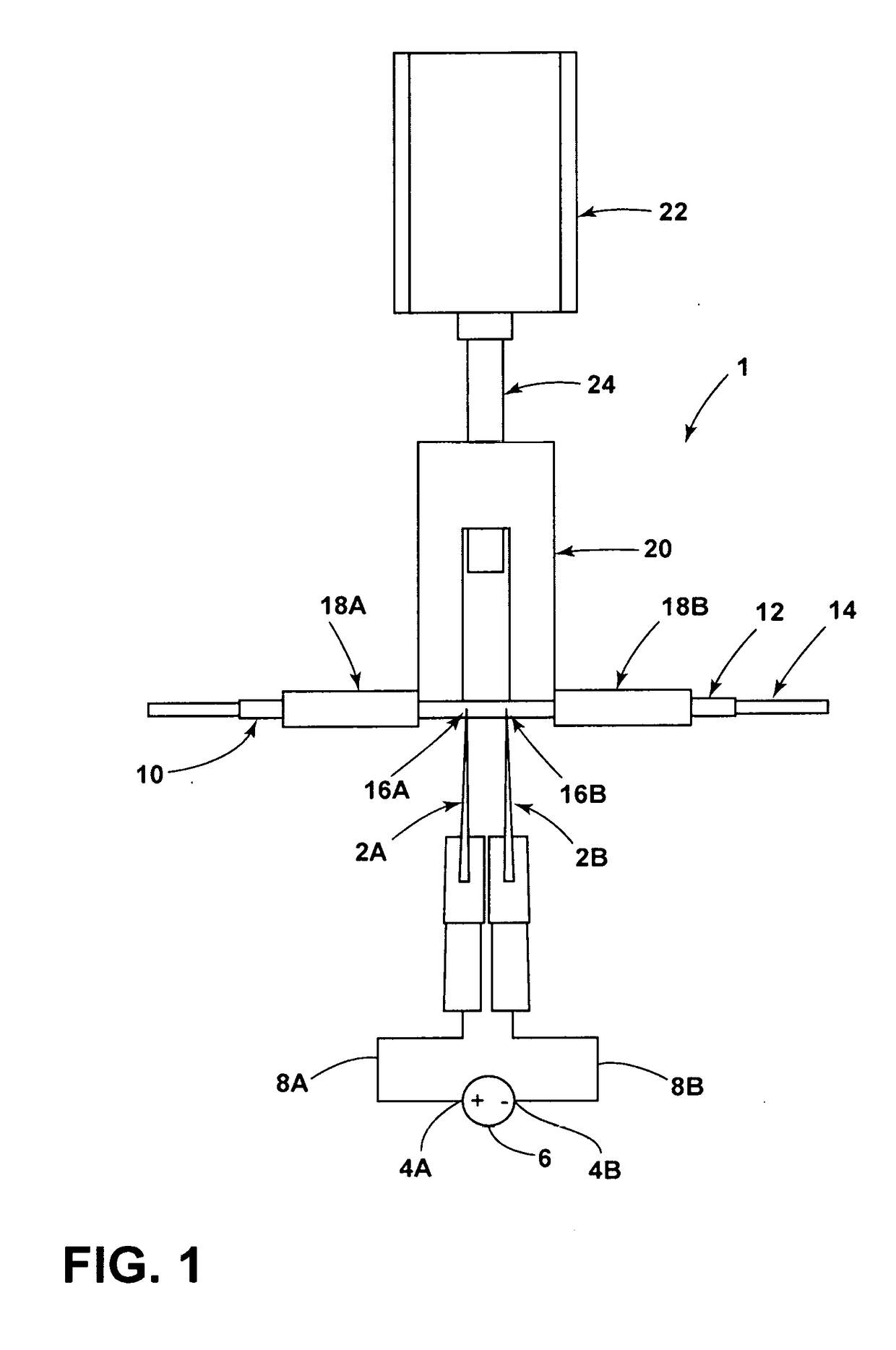

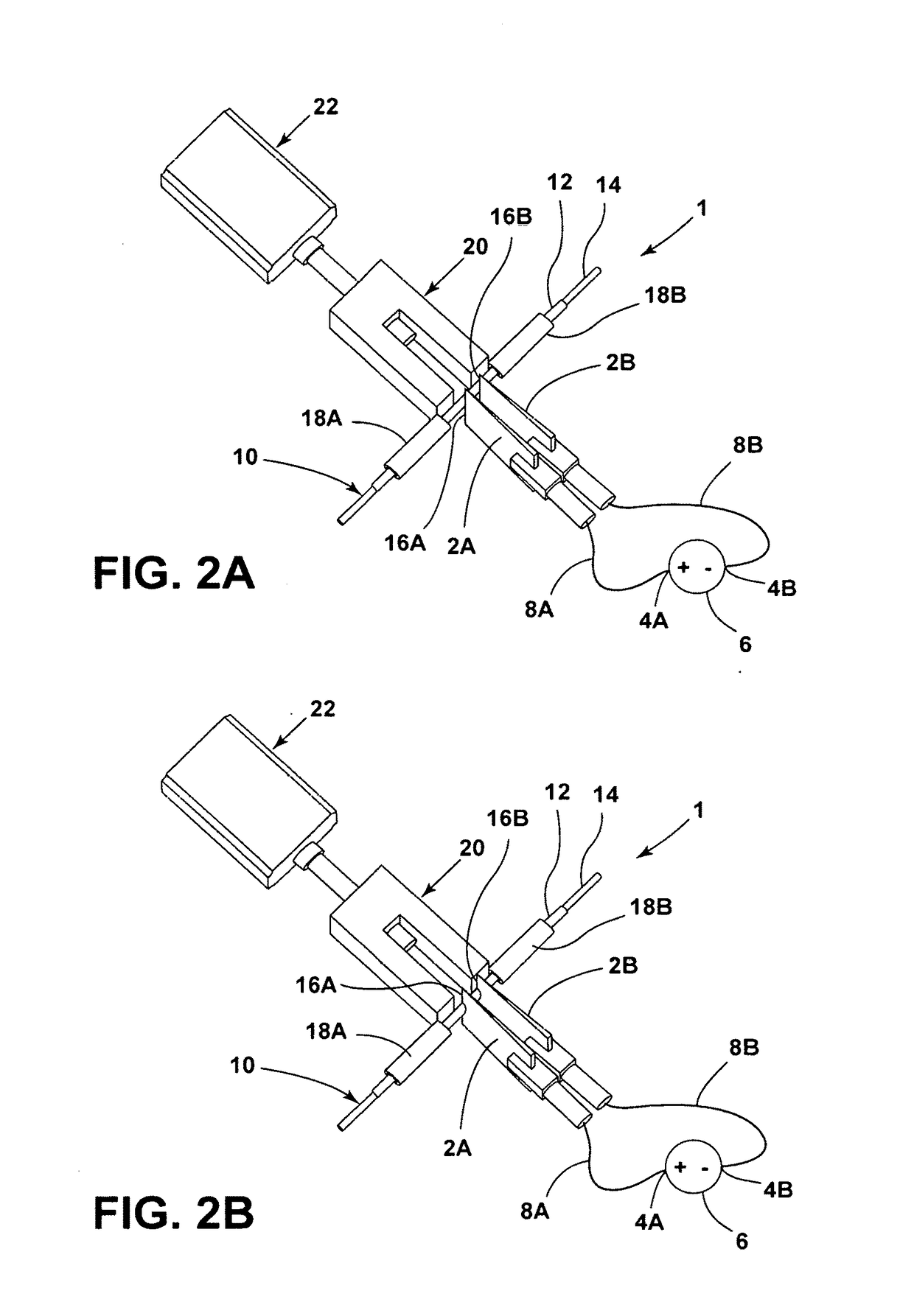

Cutting mechanism for carbon nanotube yarns, tapes, sheets and polymer composites thereof

ActiveUS20170129182A1Easy to cutRobust cutting method3D object support structuresManufacturing data aquisition/processingPower flowCarbon nanotube yarn

A cutting mechanism includes electrodes that are utilized to cut or score a non-conductive outer material of a filament or sheet. The electrodes contact a conductive reinforcing material of the filament or sheet to complete an electric circuit. Electric current flows through and heats the conductive material to oxidize or otherwise separate / cut the conductive material and any remaining non-conductive material.

Owner:NAT INST AEROSPACE ASSOC +1

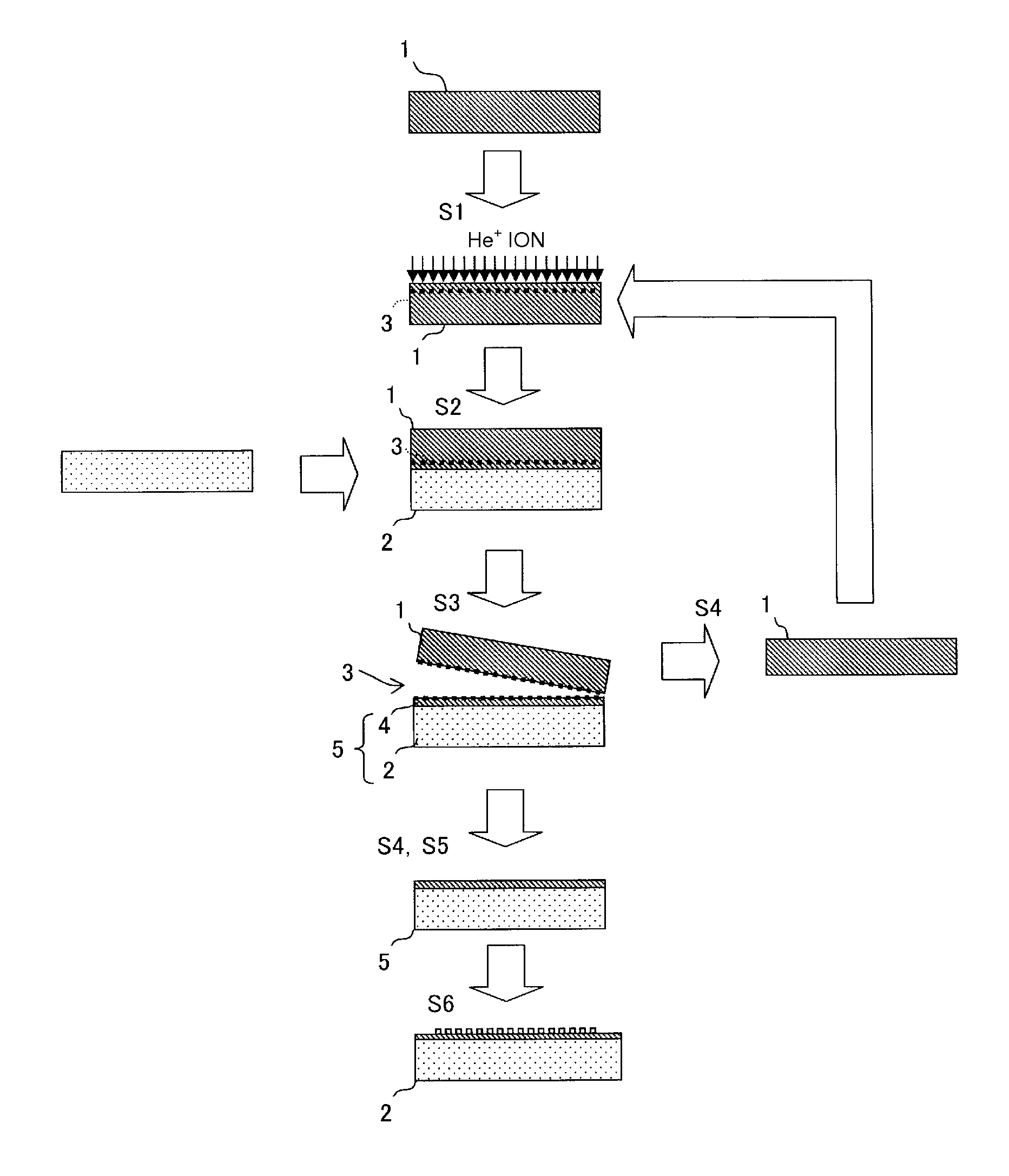

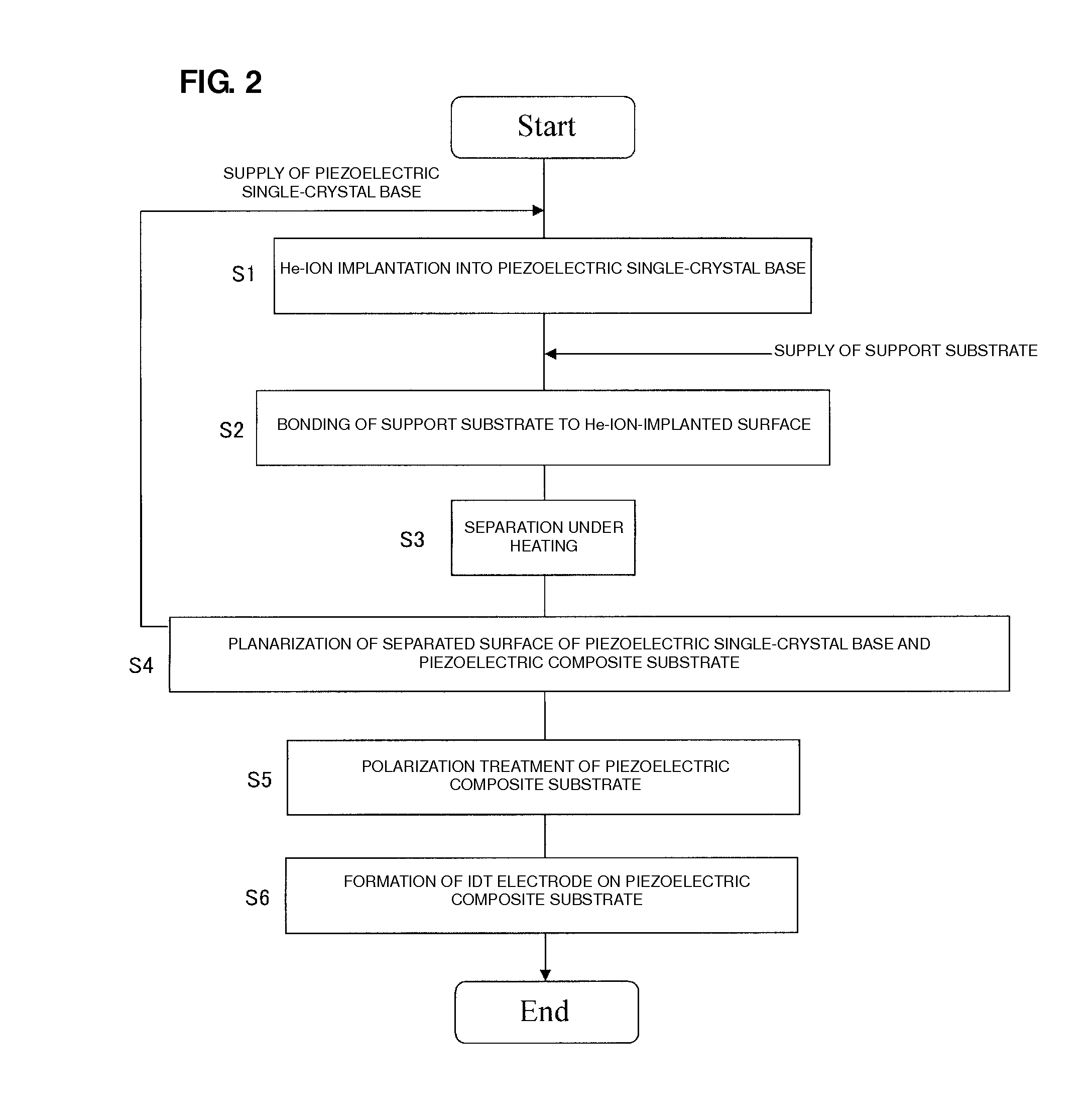

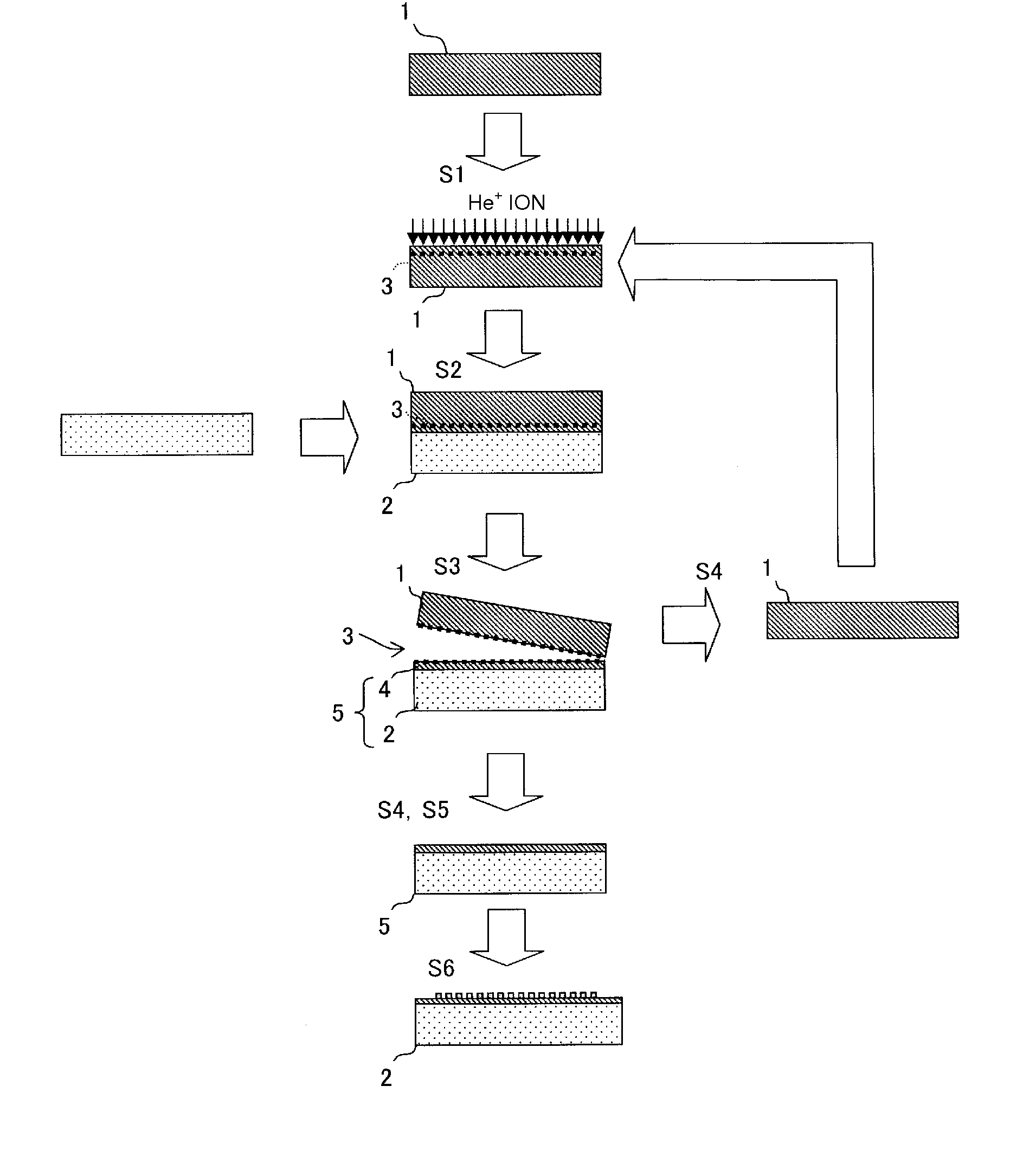

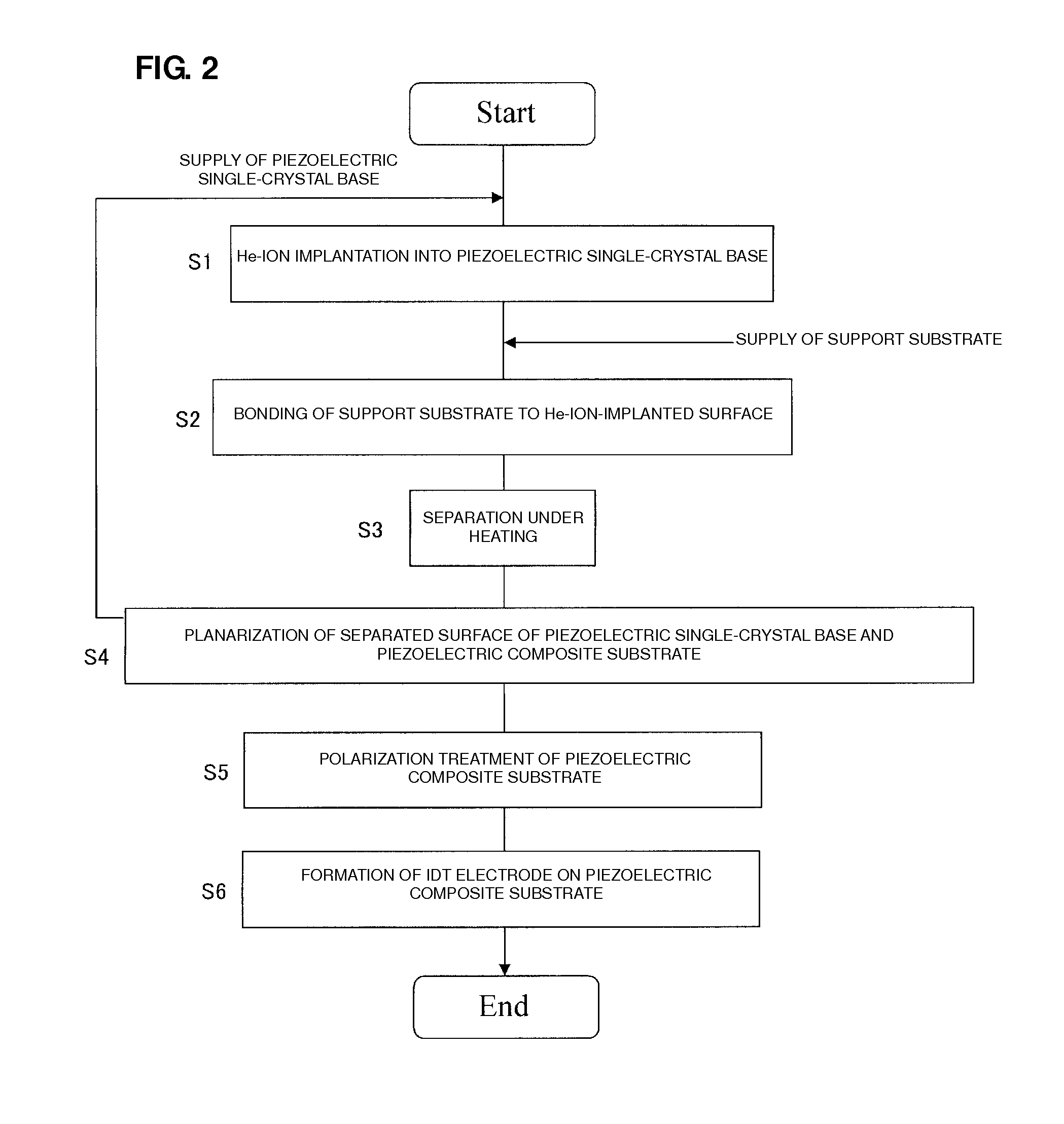

Method for producing piezoelectric composite substrate

ActiveUS8932686B2Improve utilization efficiencyUniform thicknessAfter-treatment detailsImpedence networksSingle crystalPiezoelectric composite

A method for producing a piezoelectric composite substrate having a single-crystal thin film of a piezoelectric material includes an ion-implantation step and a separation step. In the ion-implantation step, He+ ions are implanted into the single-crystal base made of the piezoelectric material to form localized microcavities in a separation layer located inside the single-crystal base and apart from a surface of the single-crystal base. In the separation step, the microcavities formed in the ion-implantation step are subjected to thermal stress to divide the separation layer of the piezoelectric single-crystal base, thereby detaching the single-crystal thin film.

Owner:MURATA MFG CO LTD

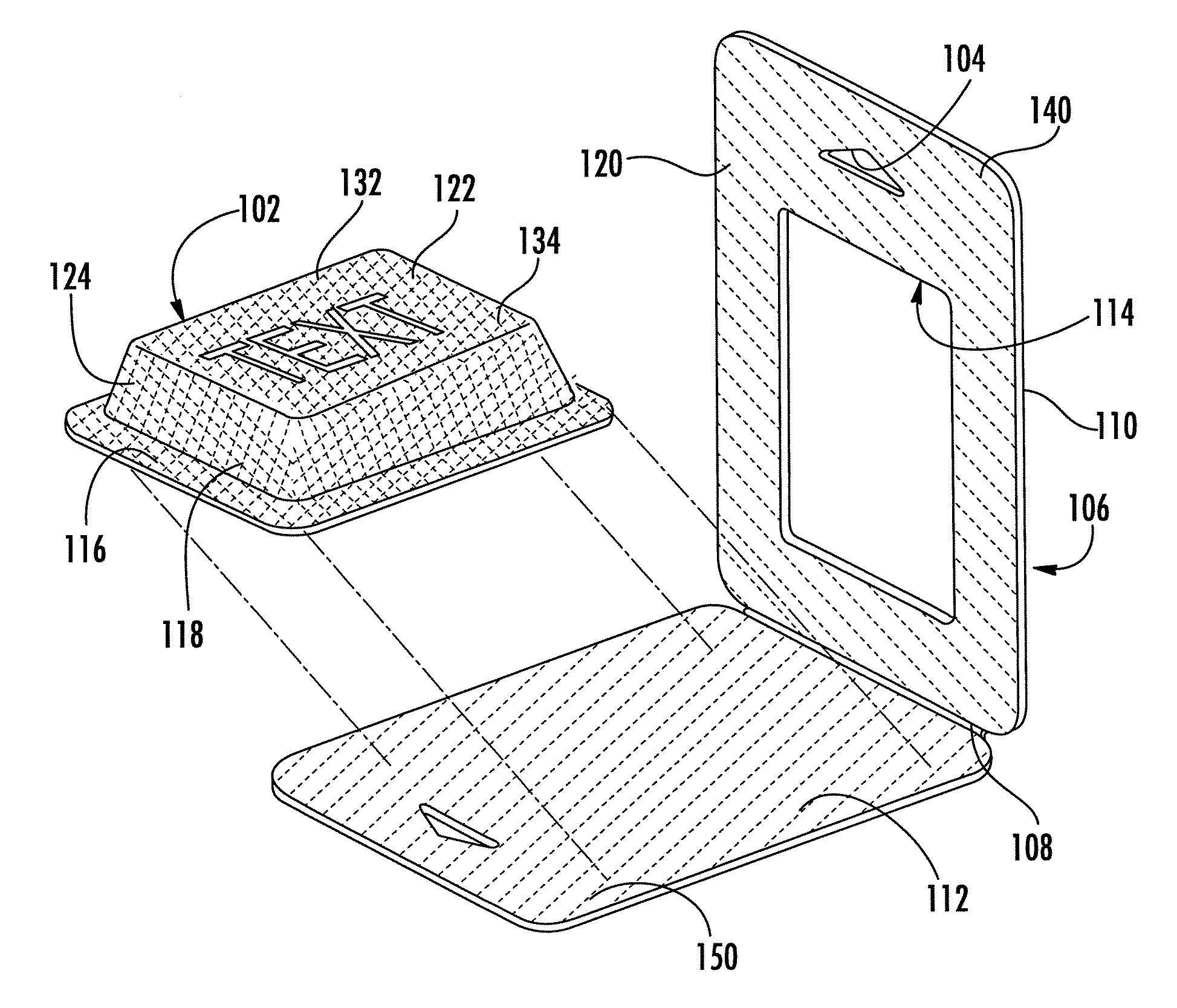

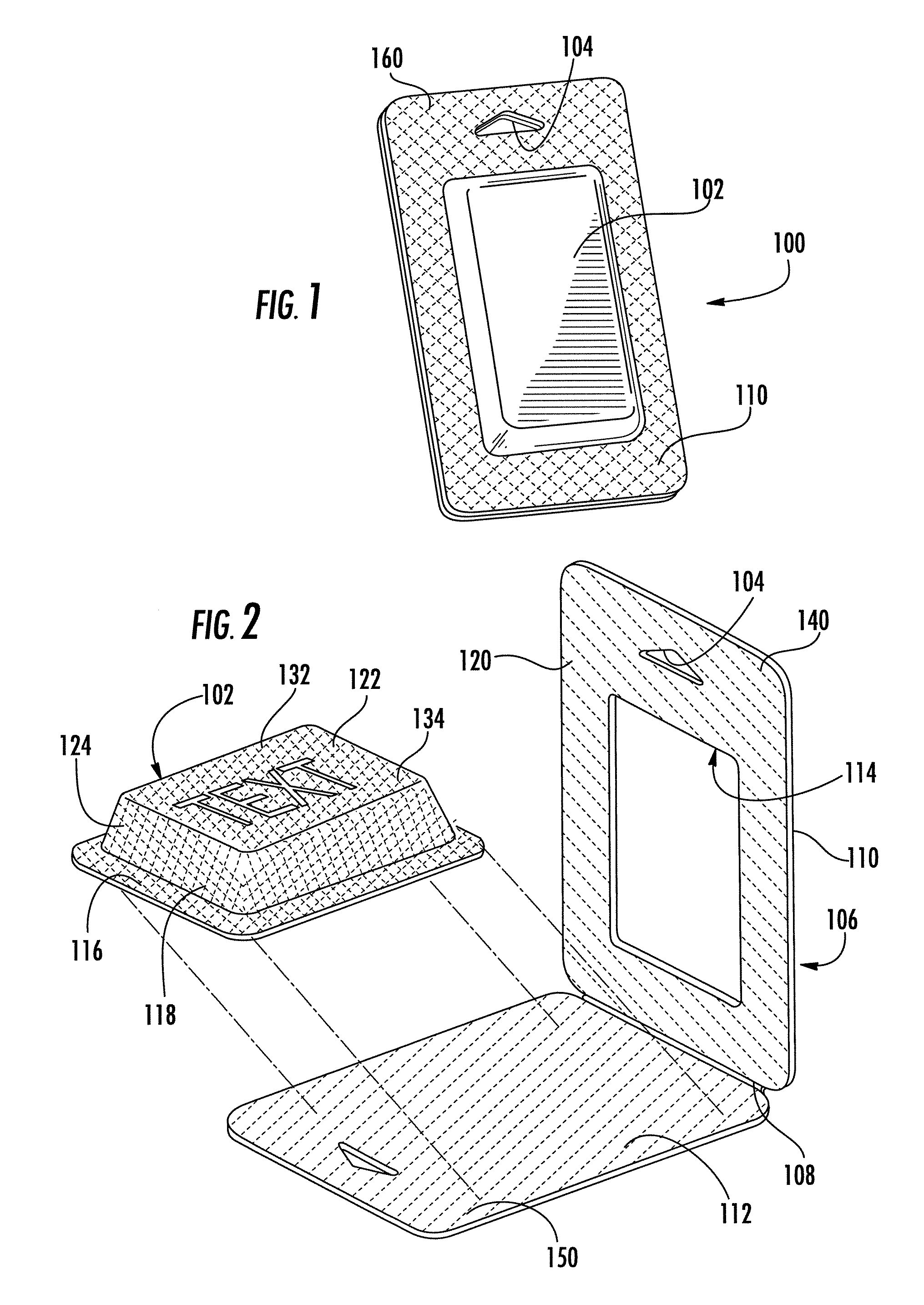

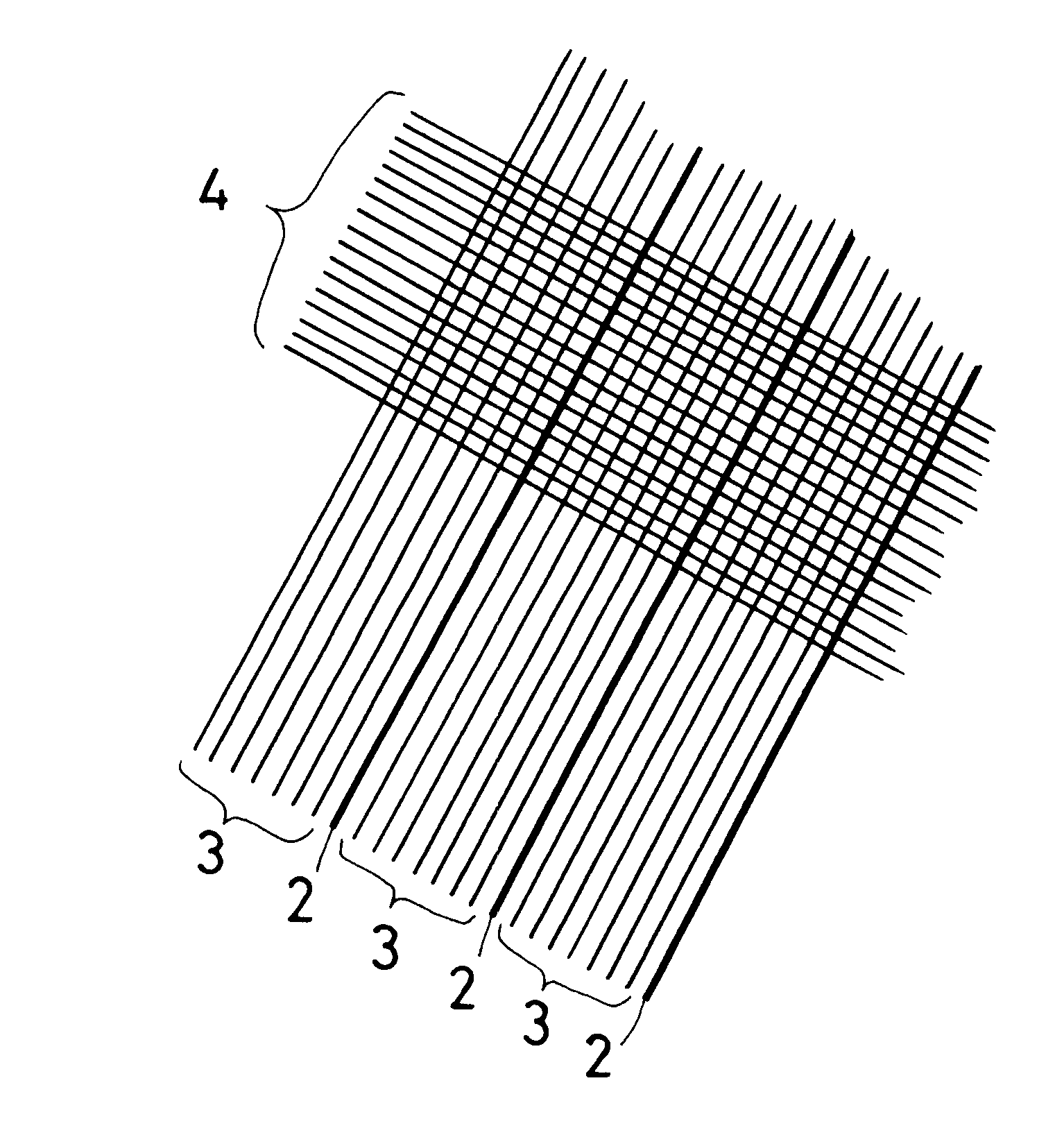

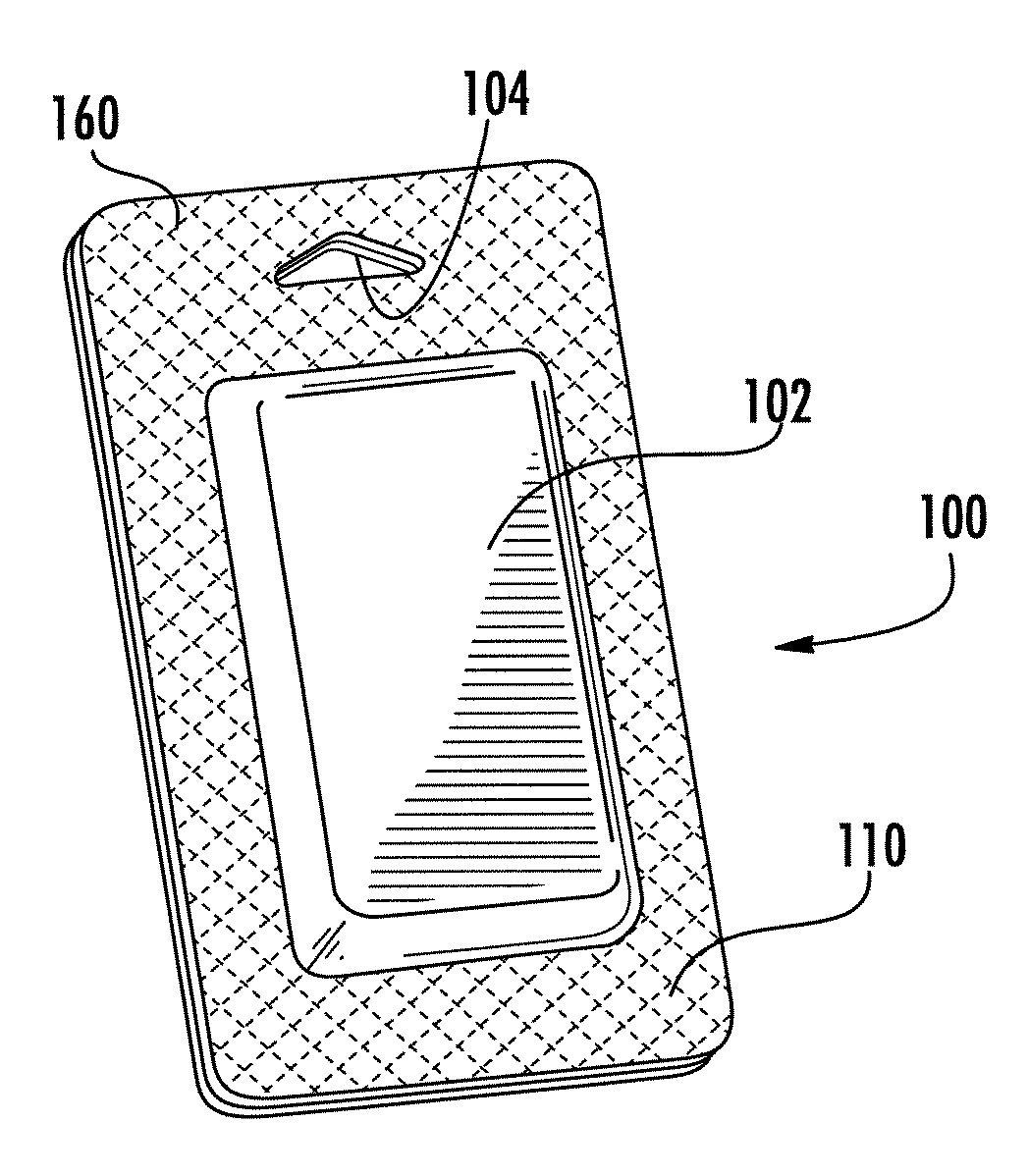

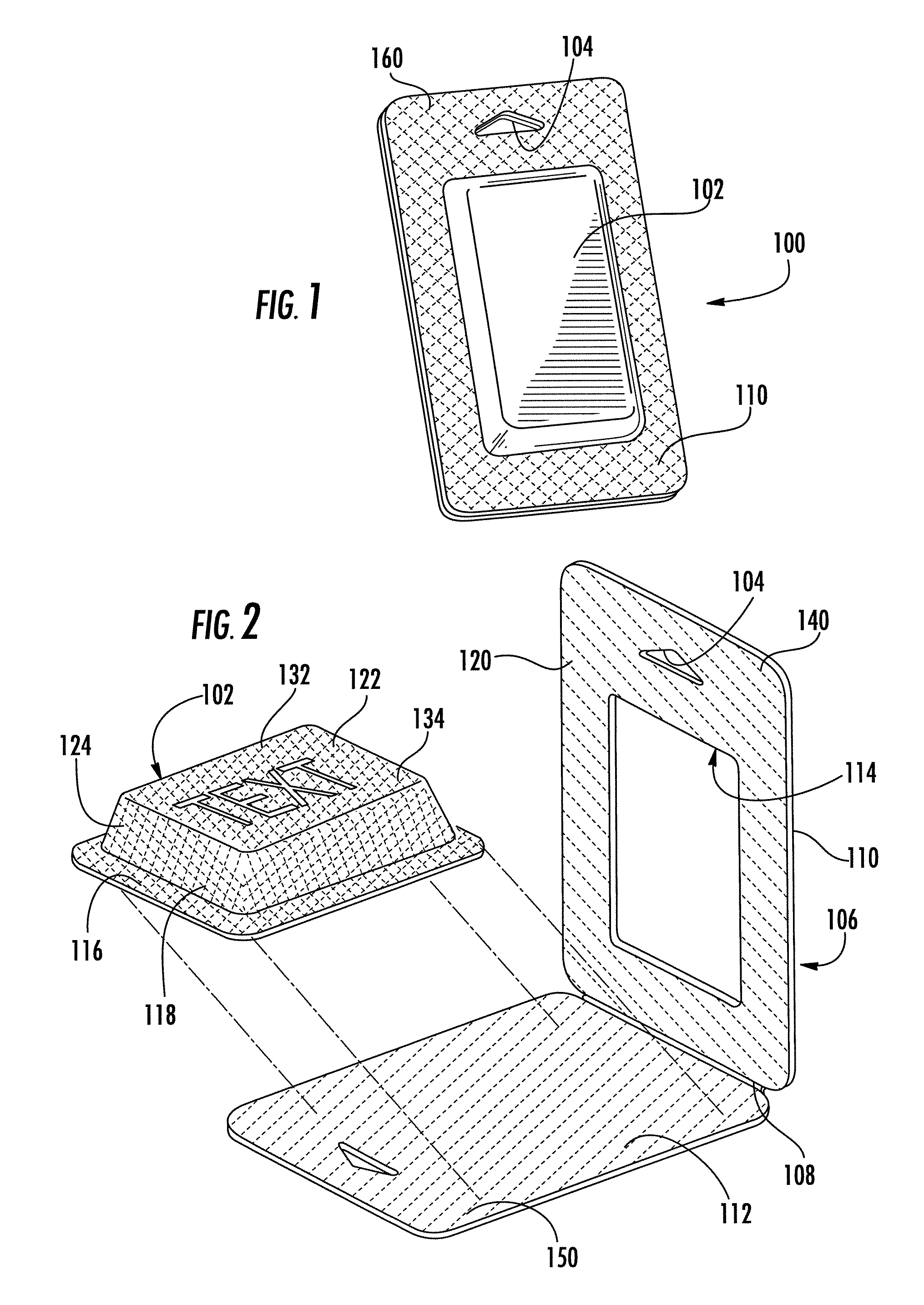

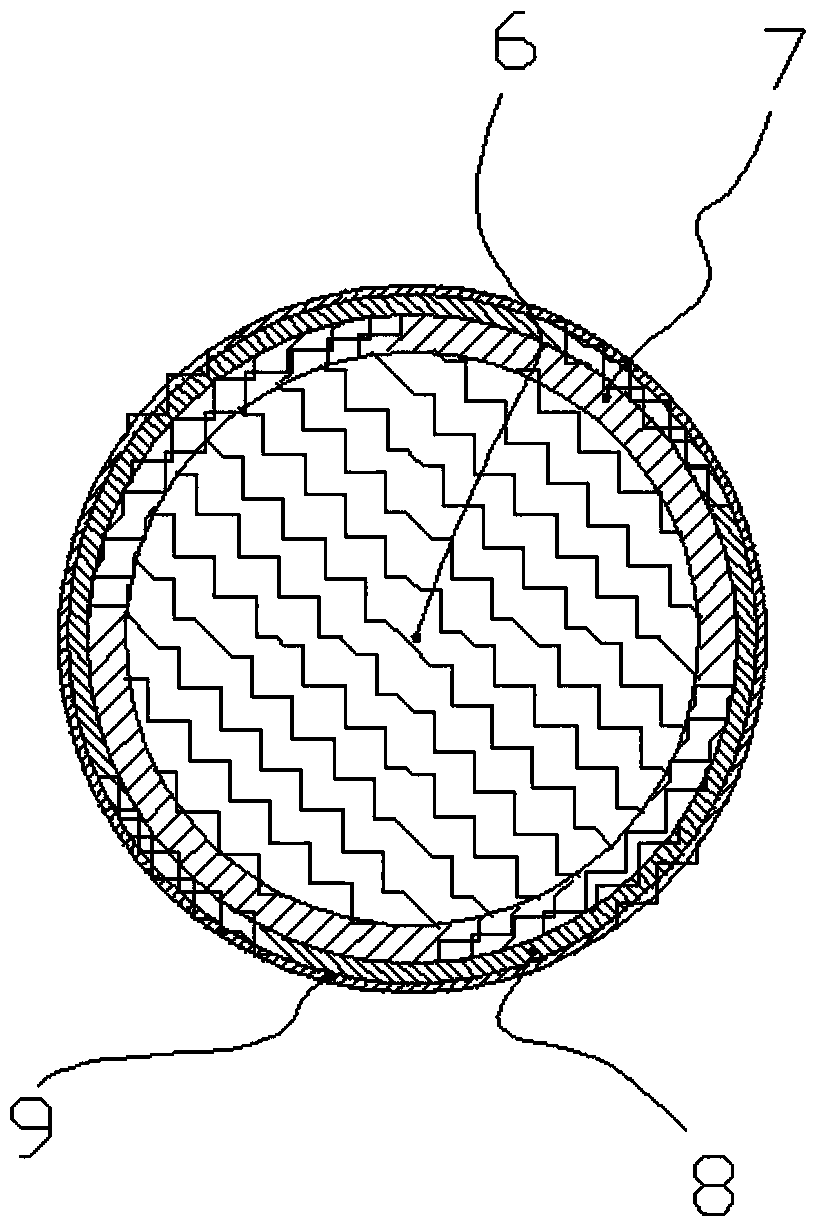

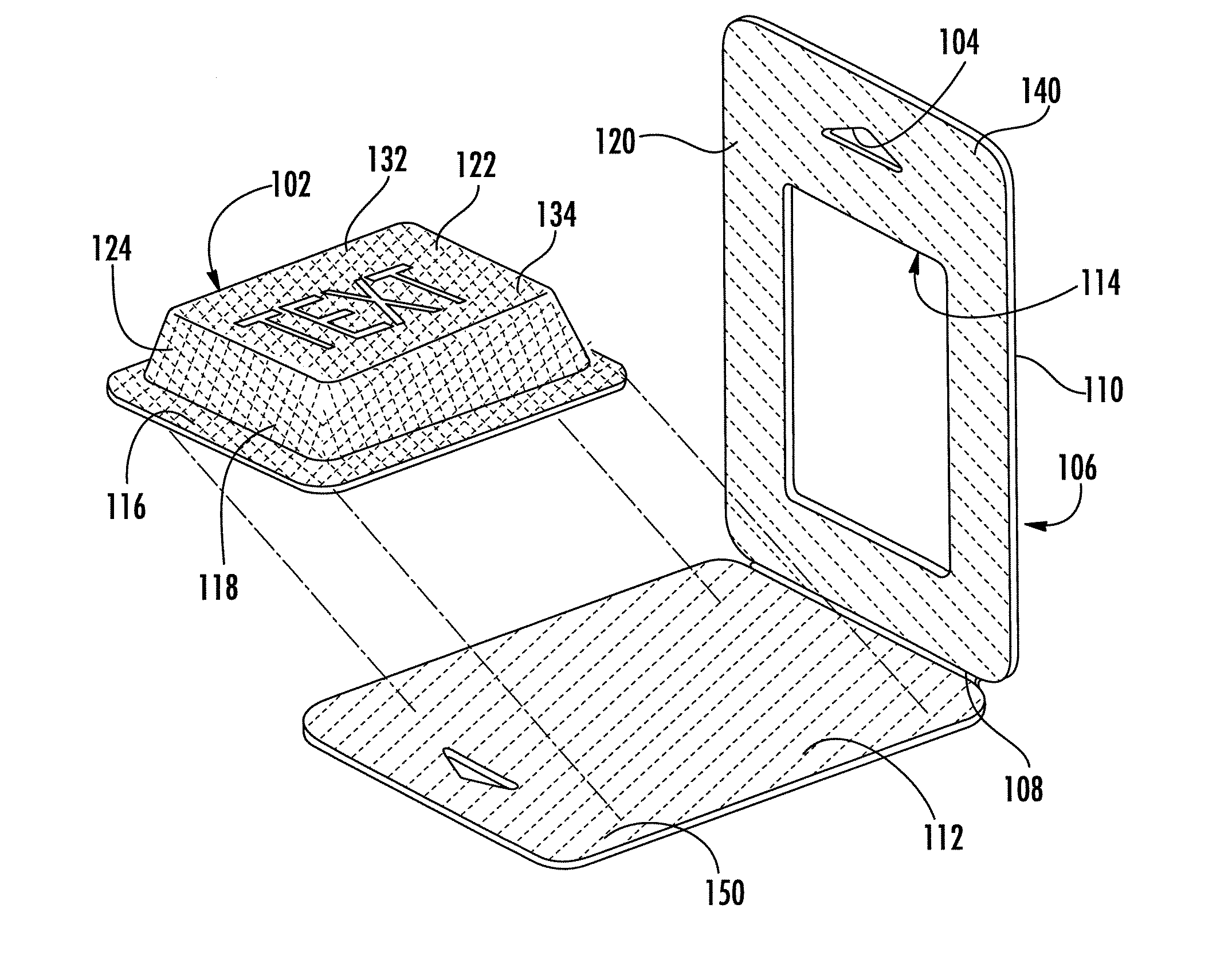

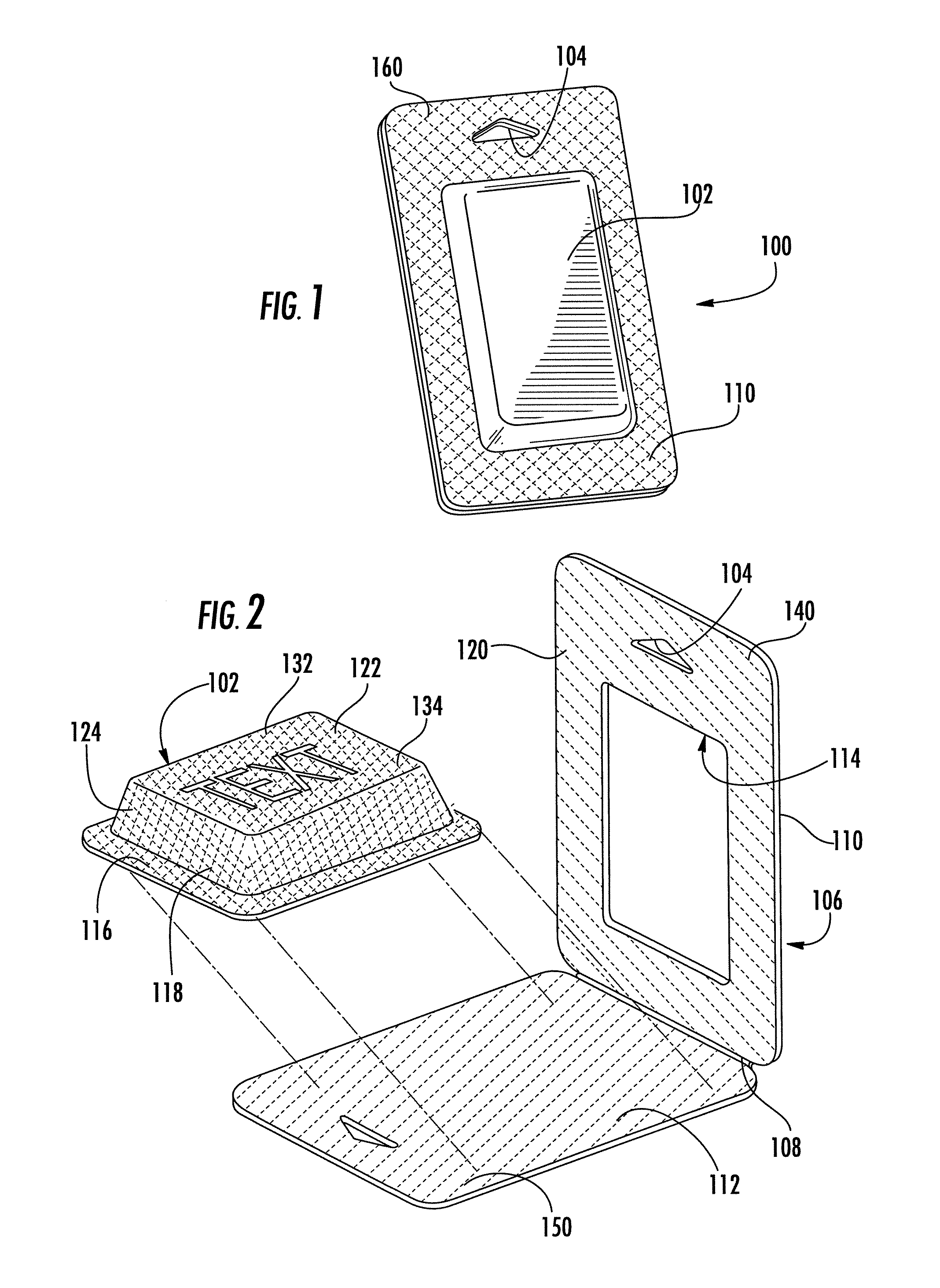

Packaging container having product holding chambers and method for making the same

InactiveUS20070187273A1Improve rigidityNot easy to cutSmall article dispensingPharmaceutical containersEngineeringPaper sheet

A packaging container for displaying and housing products that is aesthetically pleasing, effective and safe to open. The packaging container may include a substantially tear-resistant housing that encloses a tray that is preferably made from a paper material. The tray is substantially opaque to display graphics and / or to prevent viewing of the contents. The tray is preferably seamless such that it may not be opened without scissors, a knife or the like and, when opened, such opening is readily apparent. A second tray may also be used to create a dual-sided tray for housing the products, wherein the second tray may be substantially opaque or substantially transparent. An insert card may be used within the housing to reinforce the container and may be contained by fold-over edges of the housing.

Owner:COLBERT PACKAGING CORP

Methods and devices for improving the appearance of tissue

ActiveUS8652123B2Easy to navigateNot easy to cutChiropractic devicesEye exercisersRadiologyLiposuction procedure

Cellulite is treated by severing septae, which interconnects the skin with the underlying muscle. The septae may be severed in connection with a liposuction procedure or independent of a liposuction procedure.

Owner:TAUTONA GRP IP HLDG CO L L C

Food wrapping cloth

A food wrapping cloth comprises a fabric serving as a material and formed of a warp and a weft; the warp being composed of a cellulosic fiber yarn and a twist yarn formed by twisting an antibacterial yarn with a cellulosic fiber yarn, the antibacterial yarn being formed by depositing an antibacterial metal on a synthetic resin film and cutting the antibacterial metal deposited on the synthetic resin film to be a fine and long yarn; and the weft being composed of a cellulosic fiber yarn.

Owner:TOYOSHIMA & CO LTD 50 +2

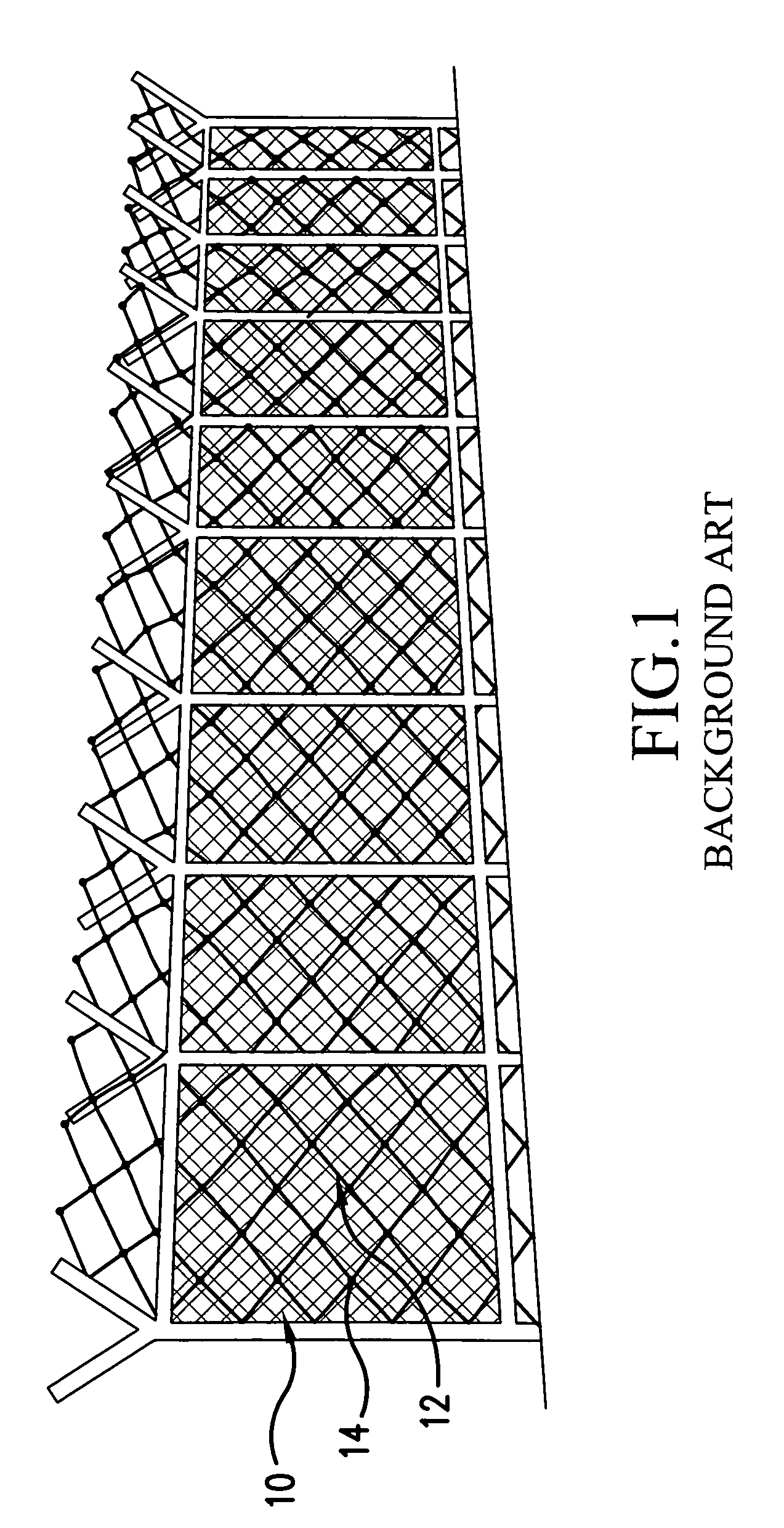

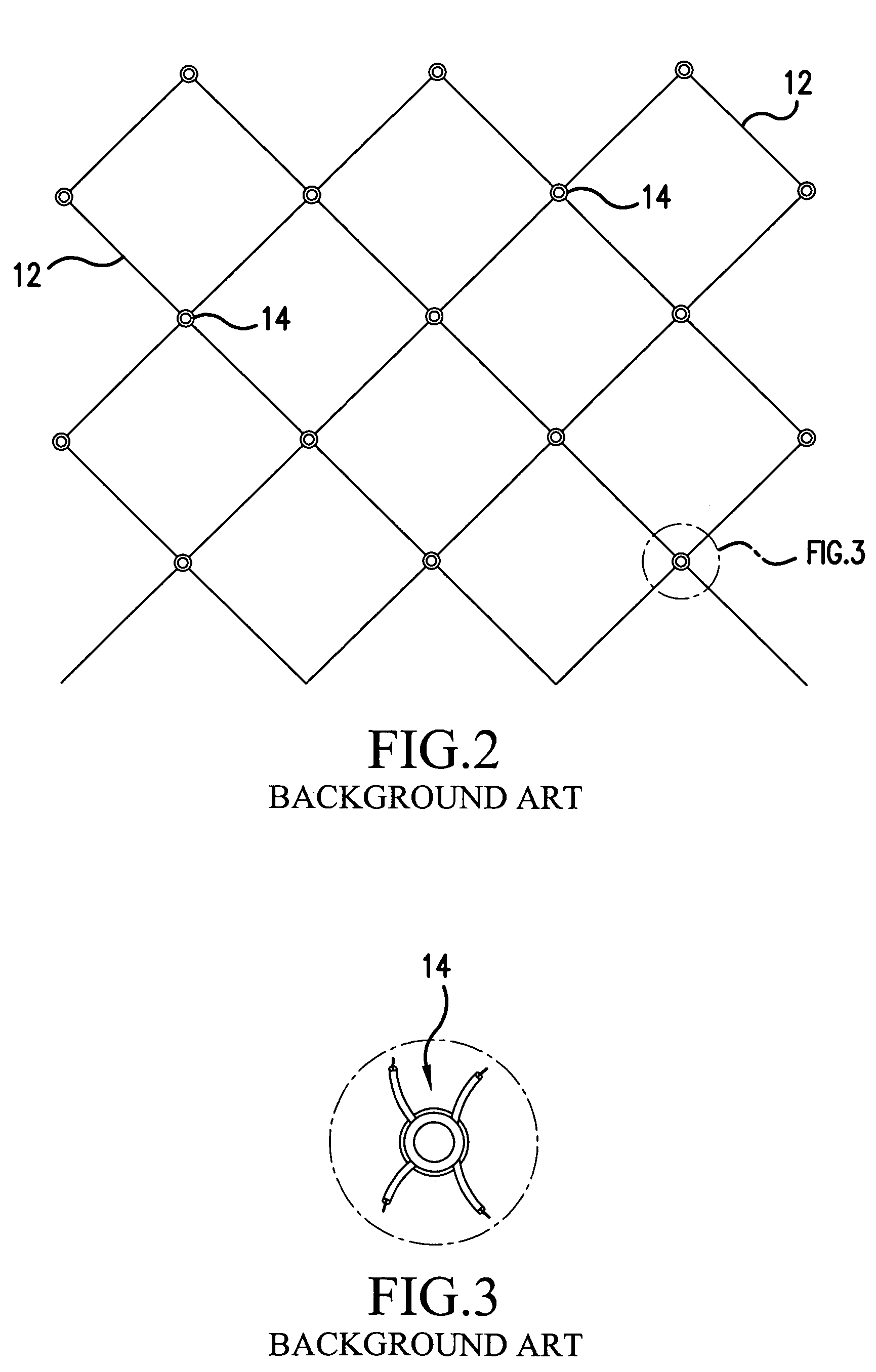

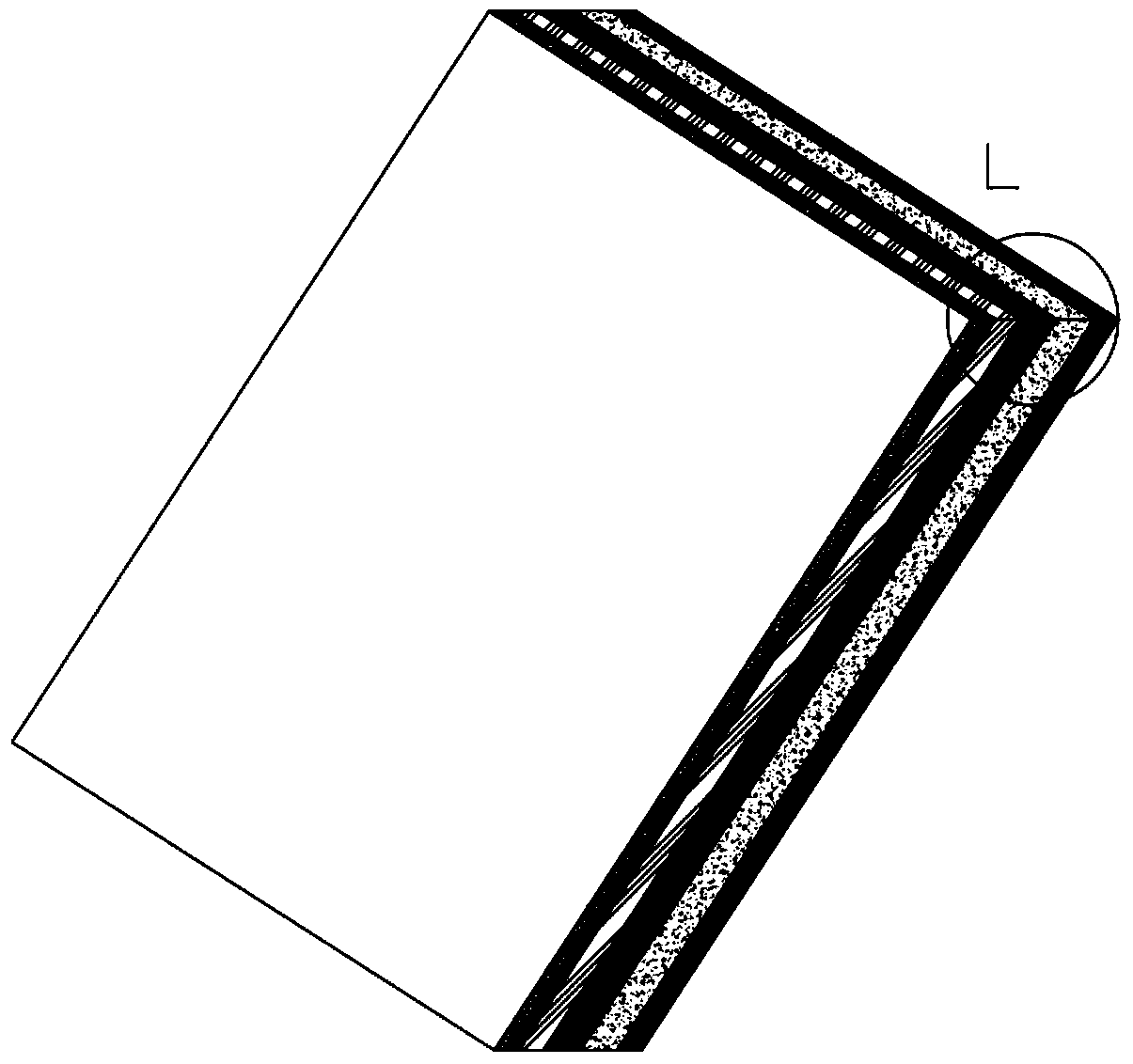

Clips for holding fiber optic cables of a security fence

InactiveUS7177518B2Avoid breakingNot easy to cutOptical fibre/cable installationCoupling light guidesFiberEngineering

A clip for holding a first section of fiber optic cable to a second section of fiber optic cable is useful in forming a weave pattern in a fiber optic security fence. The fiber optic security fence is constructed by forming a zigzag pattern in a fiber optic cable and attaching this pattern to an existing barrier fence, e.g. a galvanized chain-link fence. Clips are provided to hold portions of the fiber optic cable together in the zigzag pattern. The clips are formed such that, once installed, they are very difficult to remove without cutting, stressing or bending the fiber optic cable sections passing therethrough. Therefore, the clips will prevent intruders from disconnecting the pattern of the fiber optic cable, in order to cut through the barrier fence and gain entry into a secure area.

Owner:HUNEED TECH

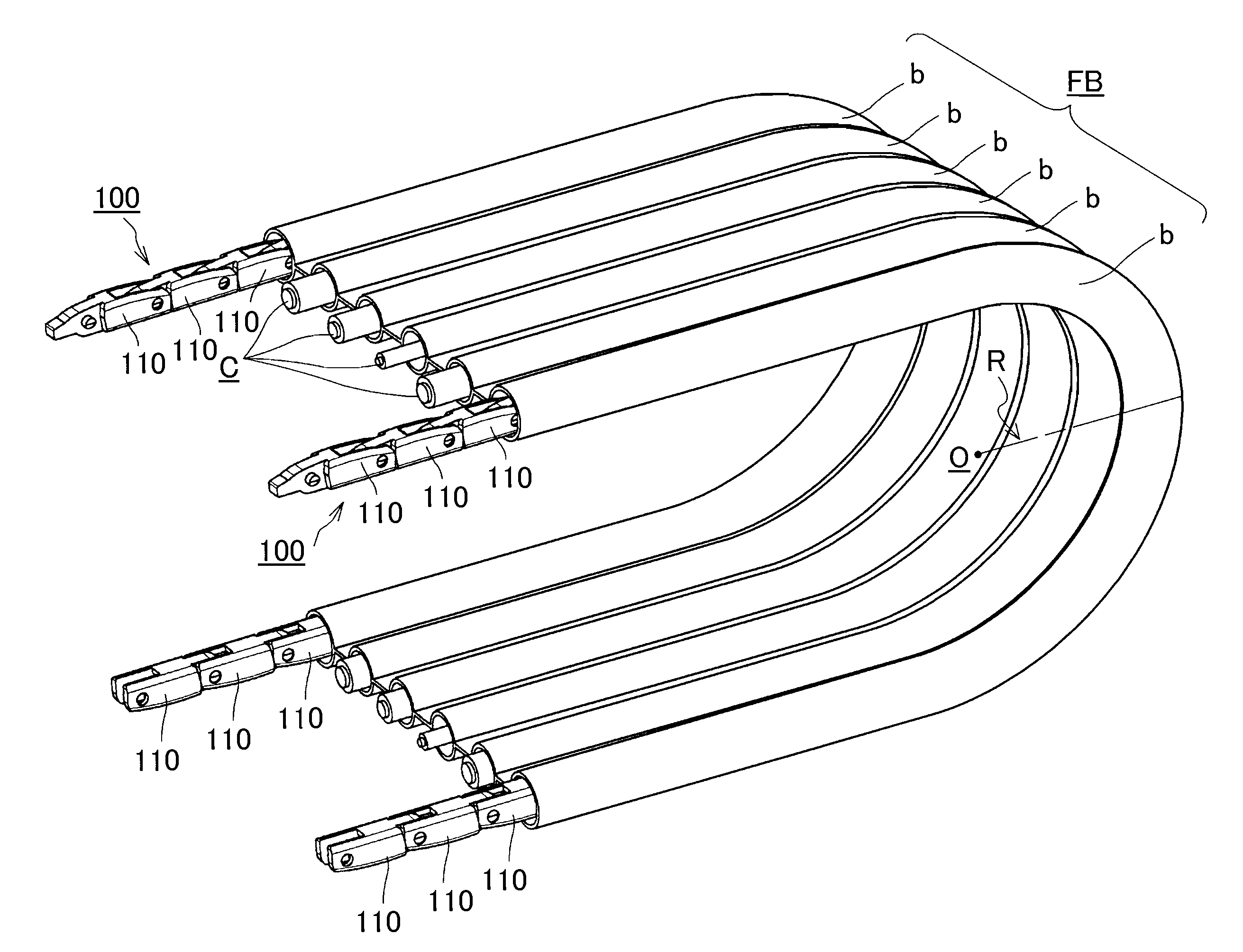

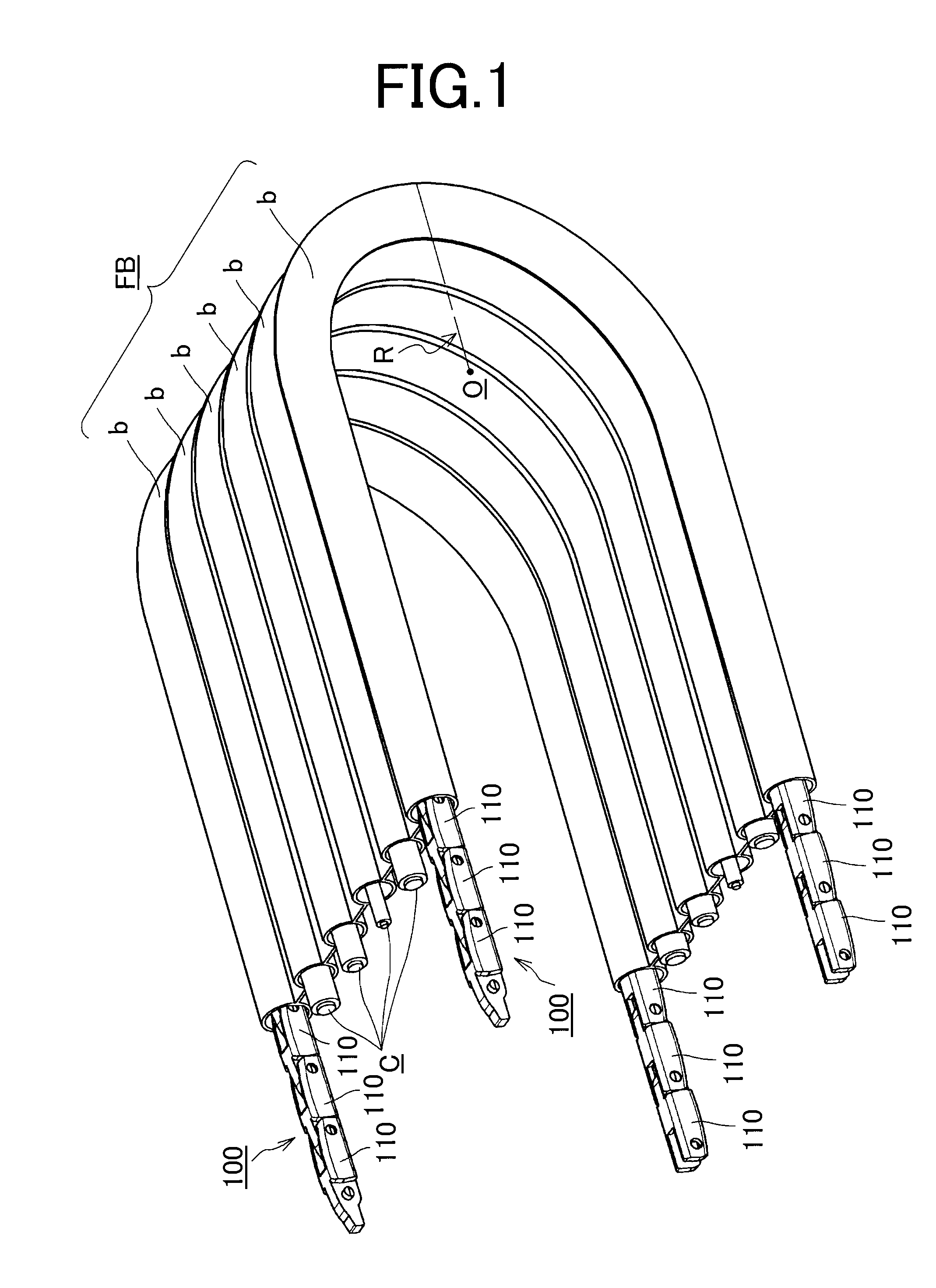

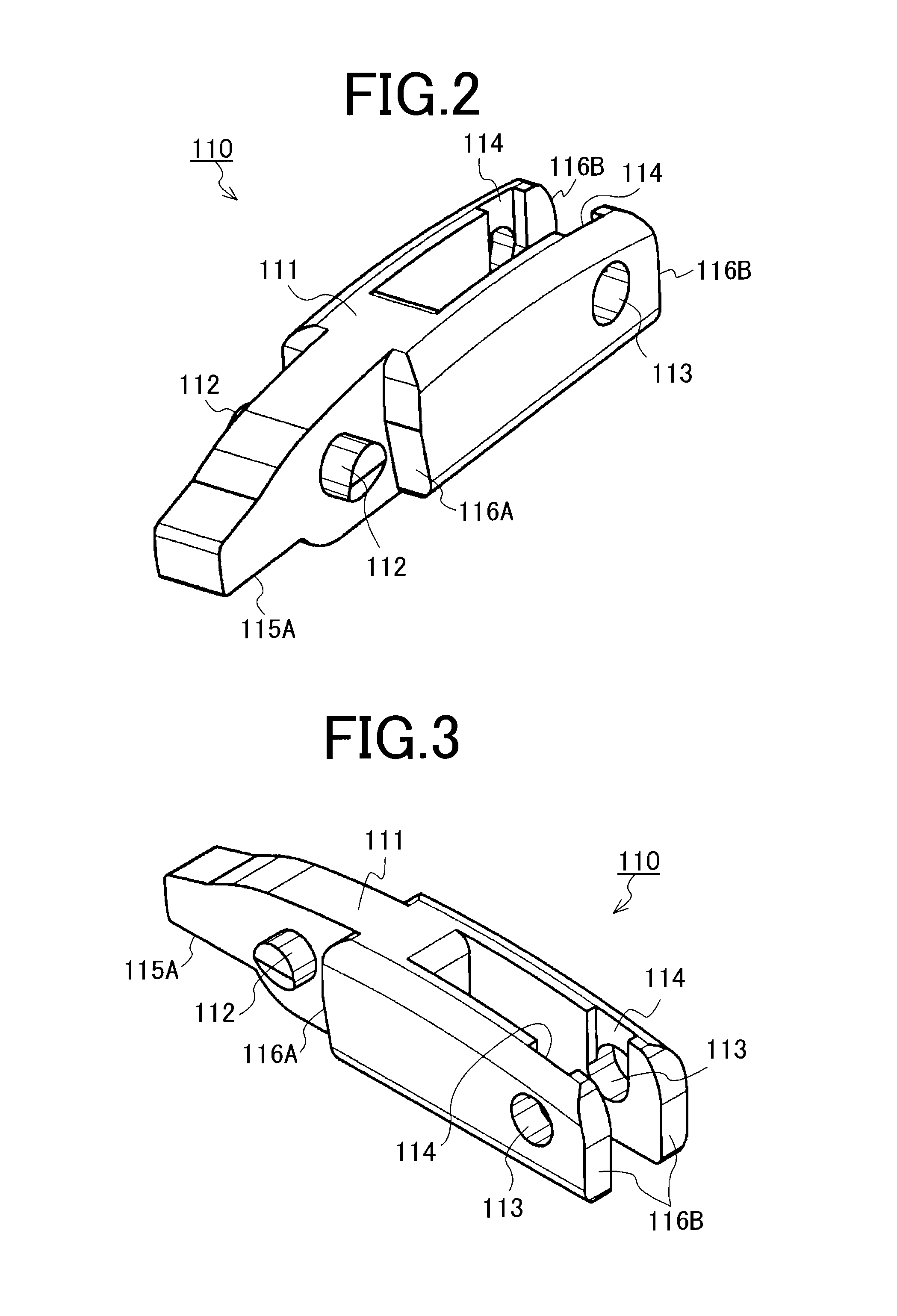

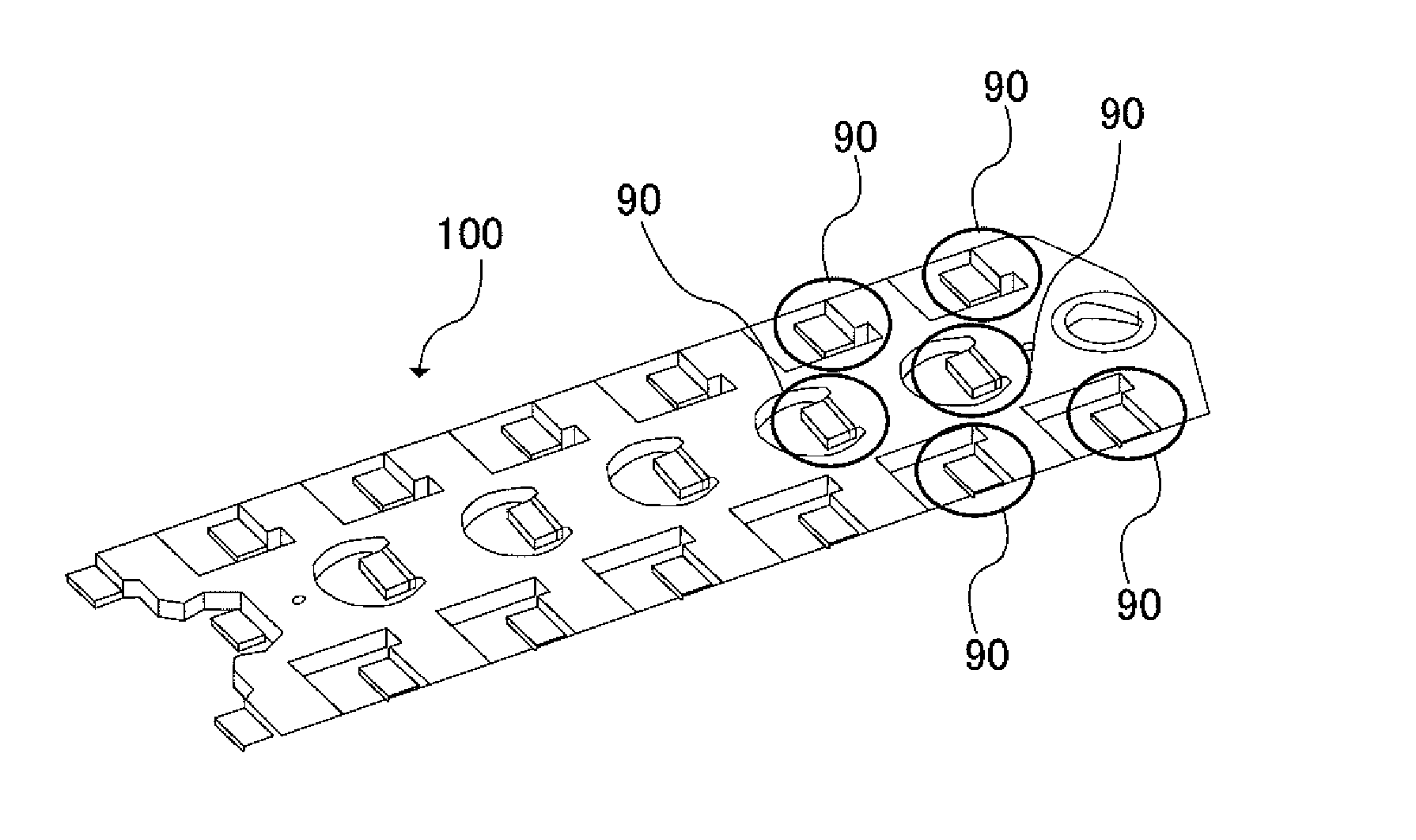

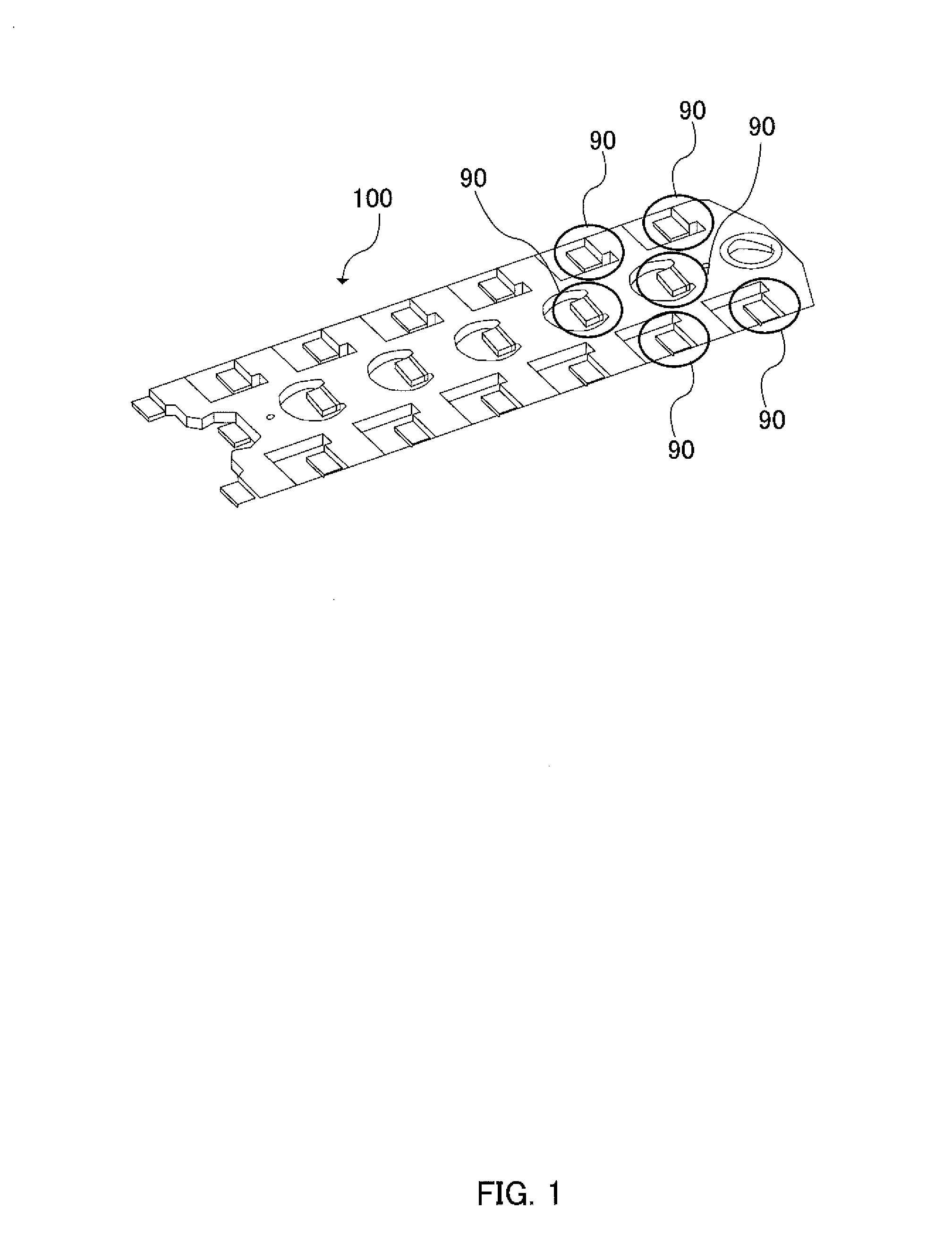

Multi-joint cable protection and guide device

ActiveUS20110240805A1Easy to disconnectFlexible connectionPipe supportsStands/trestlesFlexed postureEngineering

There is provided a multi-joint cable protection and guide device that fits well with a flexible belt member in a flexed posture, that steadily protects and smoothly guides cables that assume the flexed posture, that requires fewer parts and that may be readily connected and disconnected corresponding as desired according to usage. The multi-joint supporting member has the flexible belt member in which cable inserting tubular portions are unitarily molded in parallel and a train comprising a plurality of block bodies flexibly connected with each other by concave-convex snap-fittings. The train of block bodies is inserted through the cable inserting tubular portions to control and support straight and flexed postures of the flexible belt member and each block body has a flexion outer peripheral-side curved surface whose curvature is equal to a radius of a flexed circular arc in the flexed posture.

Owner:TSUBAKIMOTO CHAIN CO

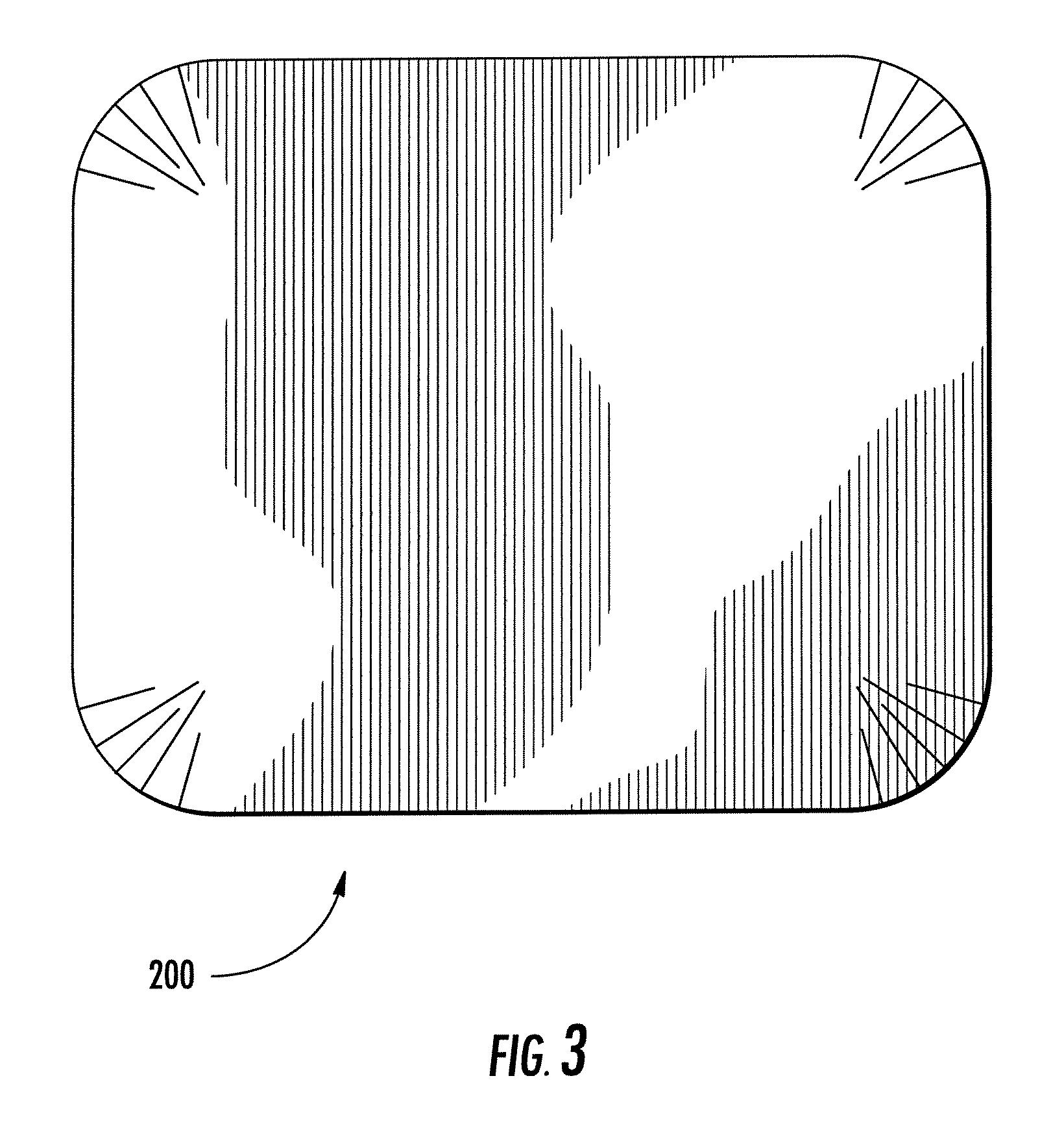

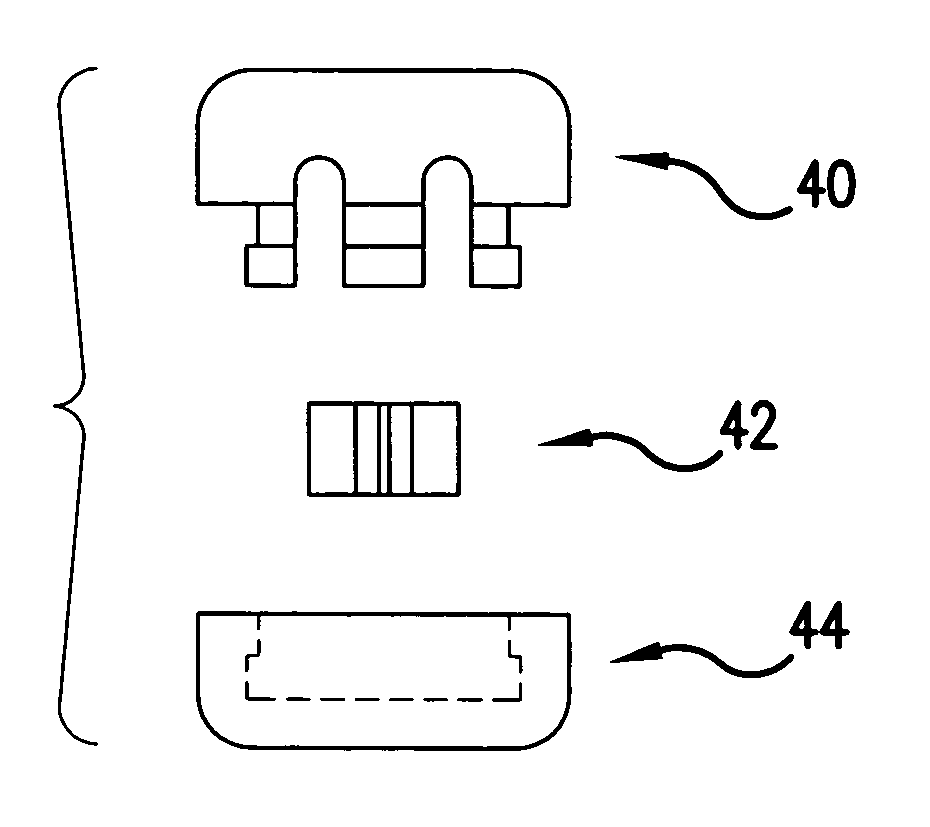

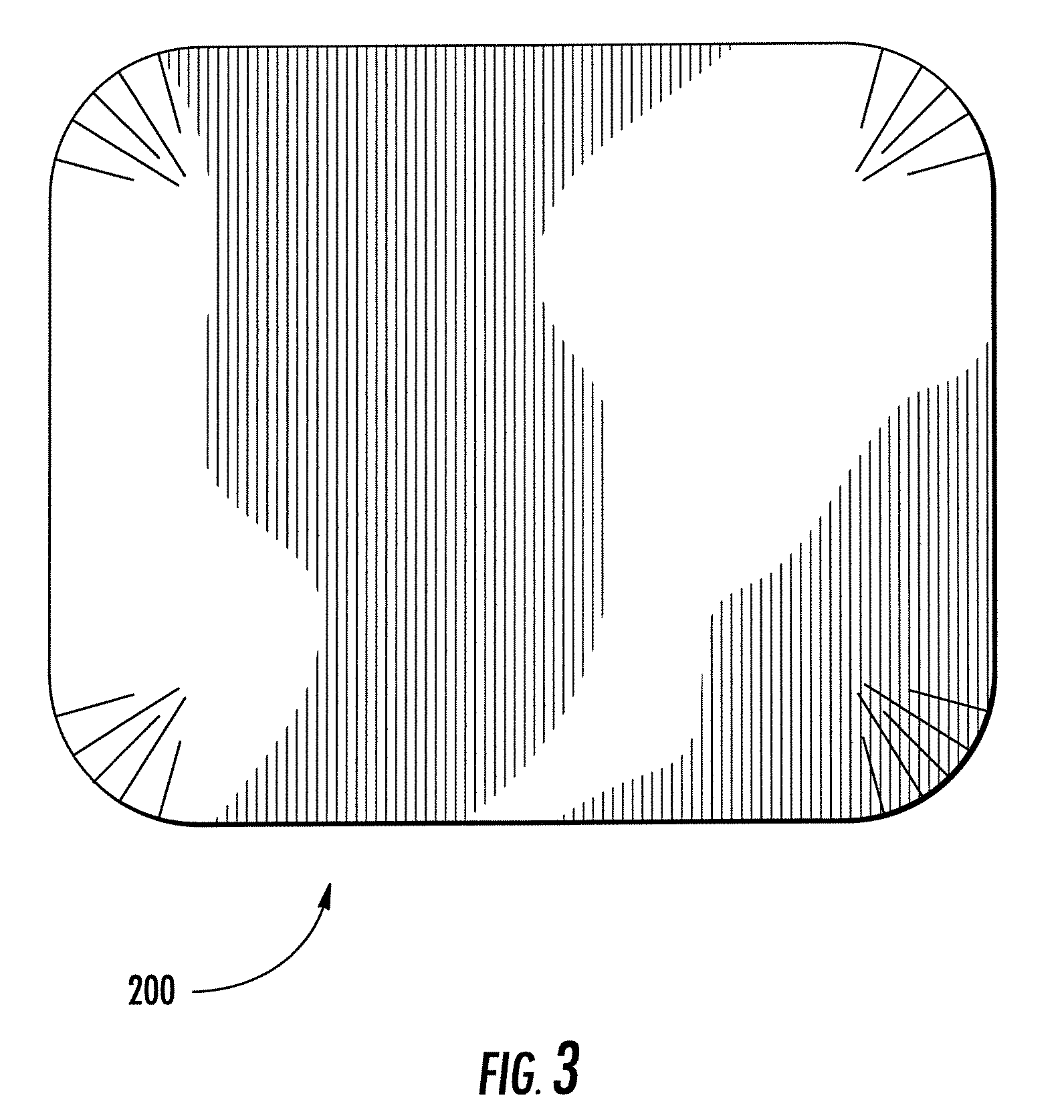

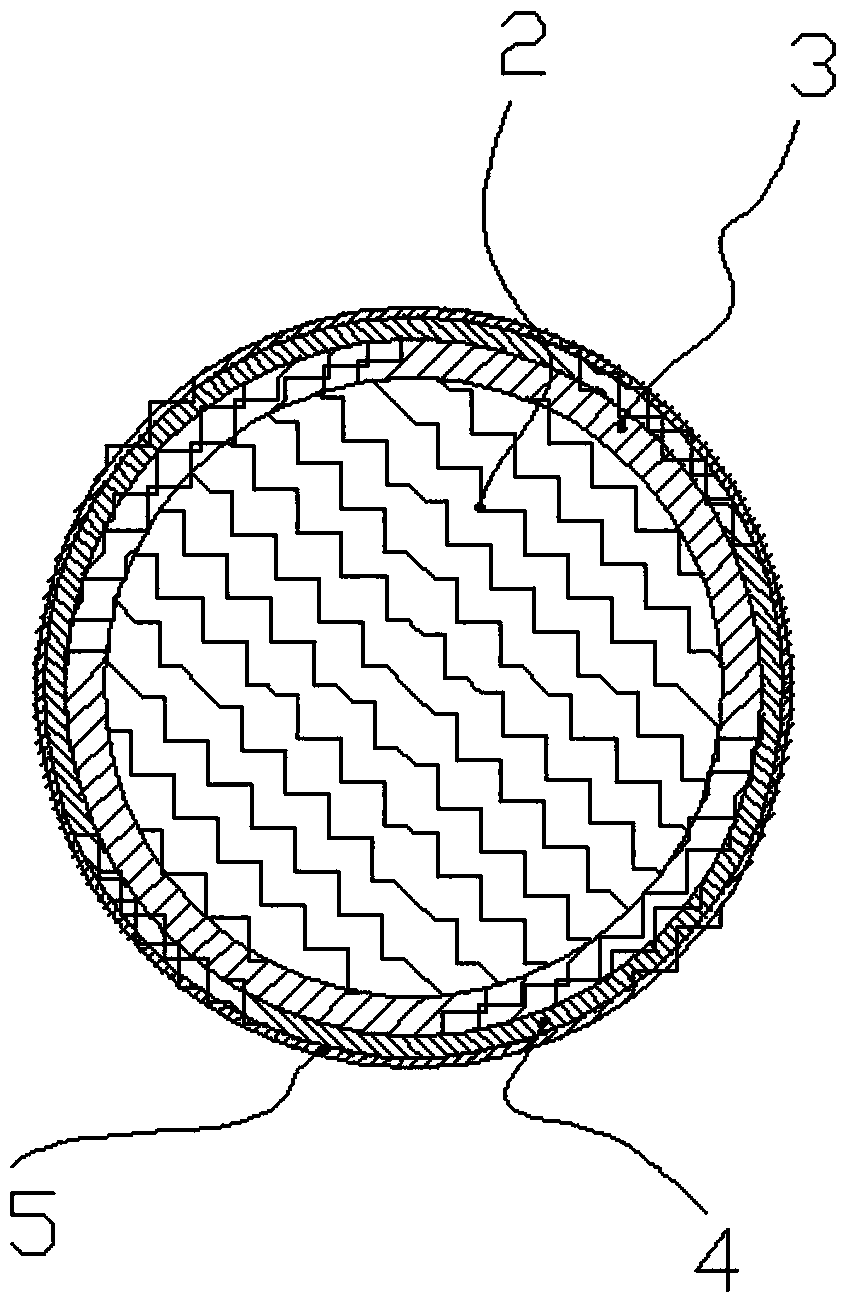

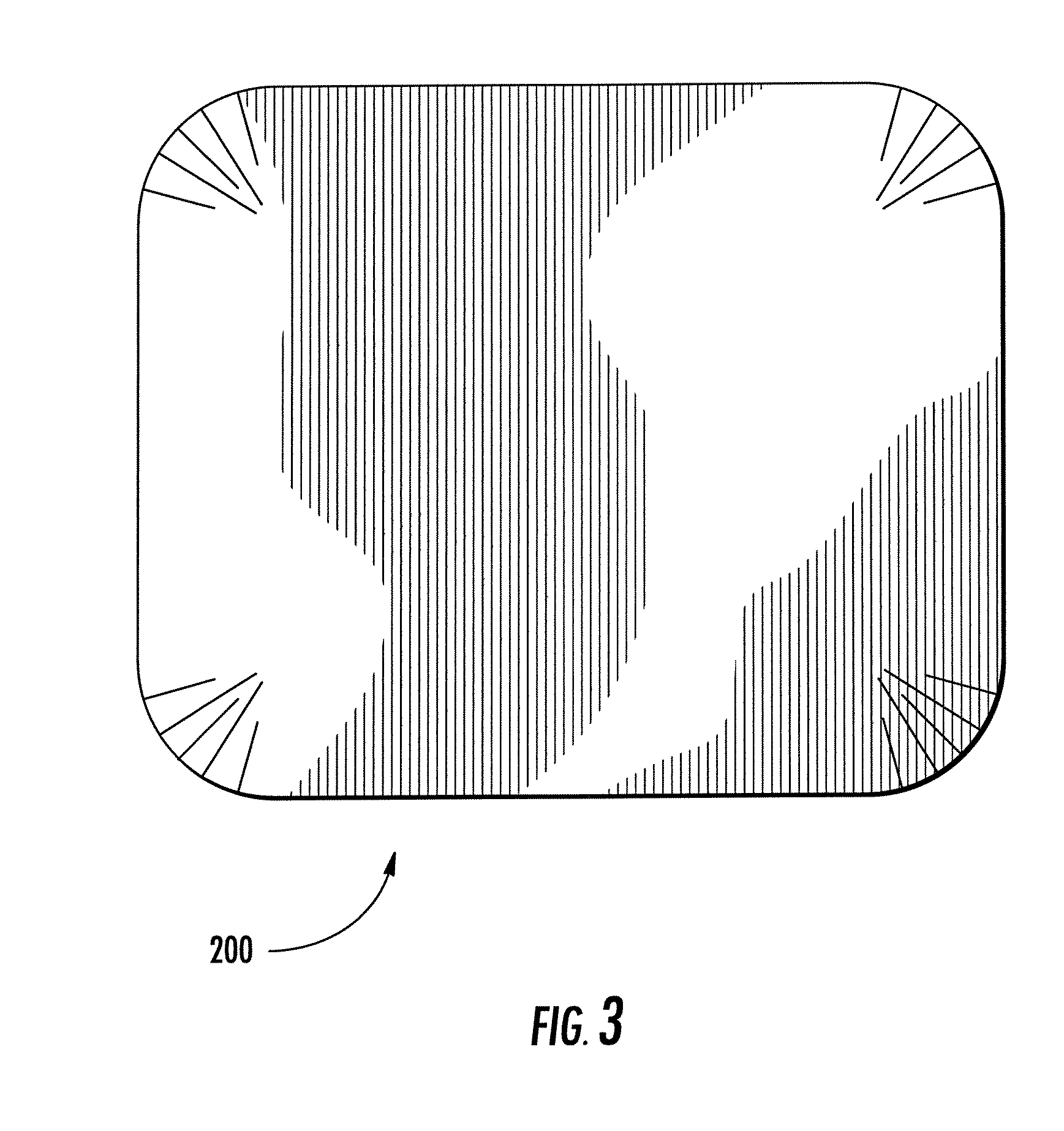

Packaging container with criss-cross grain pattern having product holding chambers and method for making the same

InactiveUS7681733B2Improve rigidityNot easy to cutSmall article dispensingPharmaceutical containersHOLDING CHAMBEREngineering

A packaging container for displaying and housing products that is aesthetically pleasing, effective and safe to open. The packaging container may include a substantially tear-resistant housing that encloses a tray that is preferably made from a paper material. The tray is substantially opaque to display graphics and / or to prevent viewing of the contents. The tray is preferably seamless such that it may not be opened without scissors, a knife or the like and, when opened, such opening is readily apparent. A second tray may also be used to create a dual-sided tray for housing the products, wherein the second tray may be substantially opaque or substantially transparent. An insert card may be used within the housing to reinforce the container and may be contained by fold-over edges of the housing.

Owner:COLBERT PACKAGING CORP

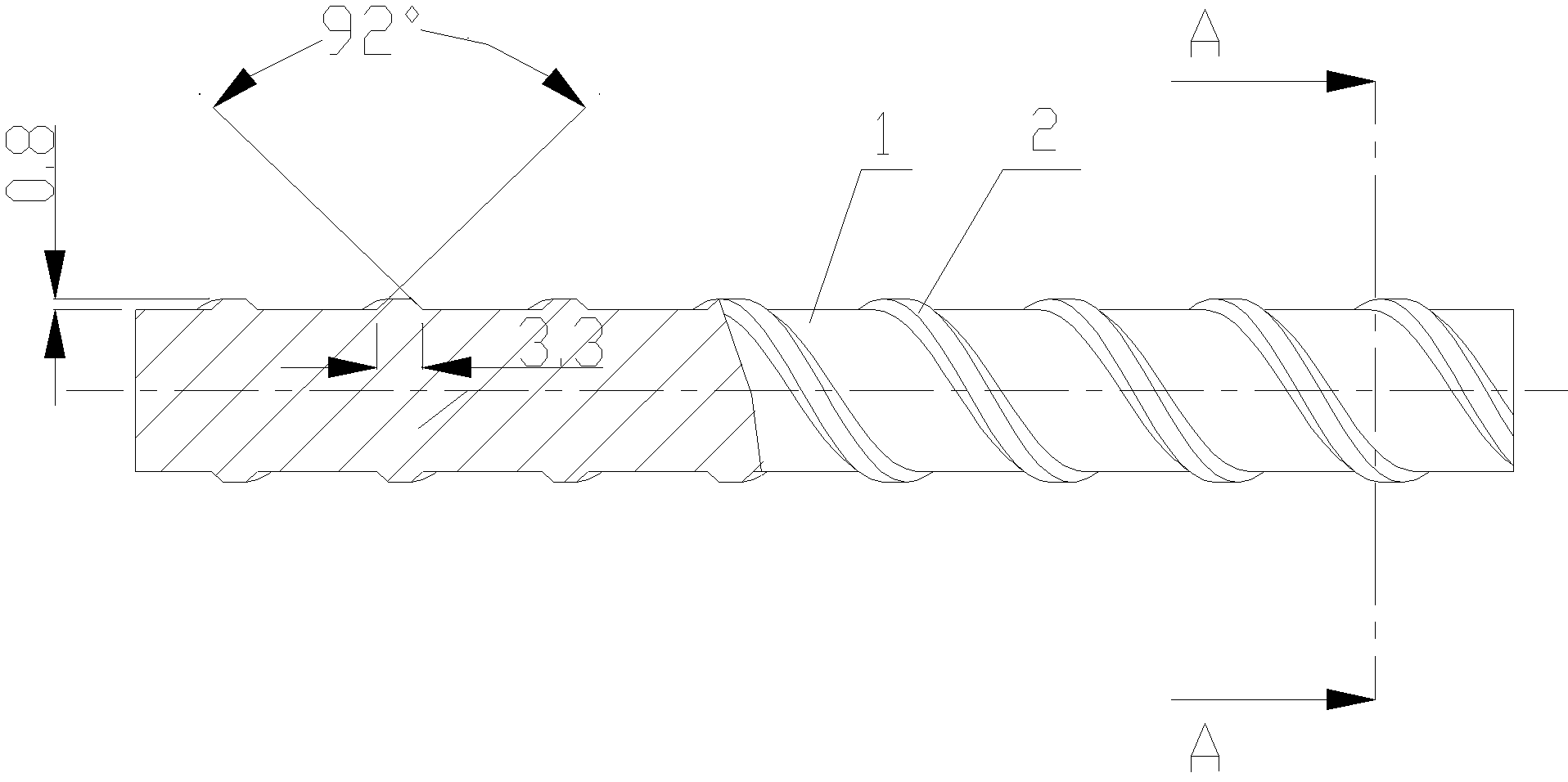

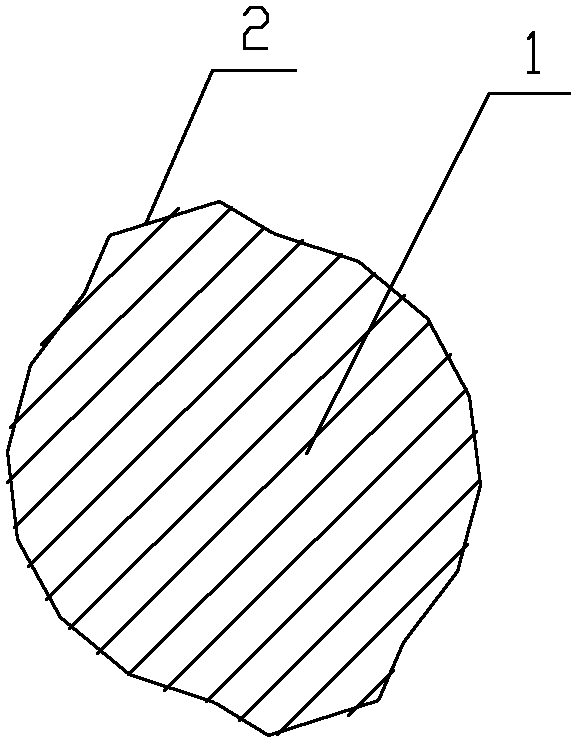

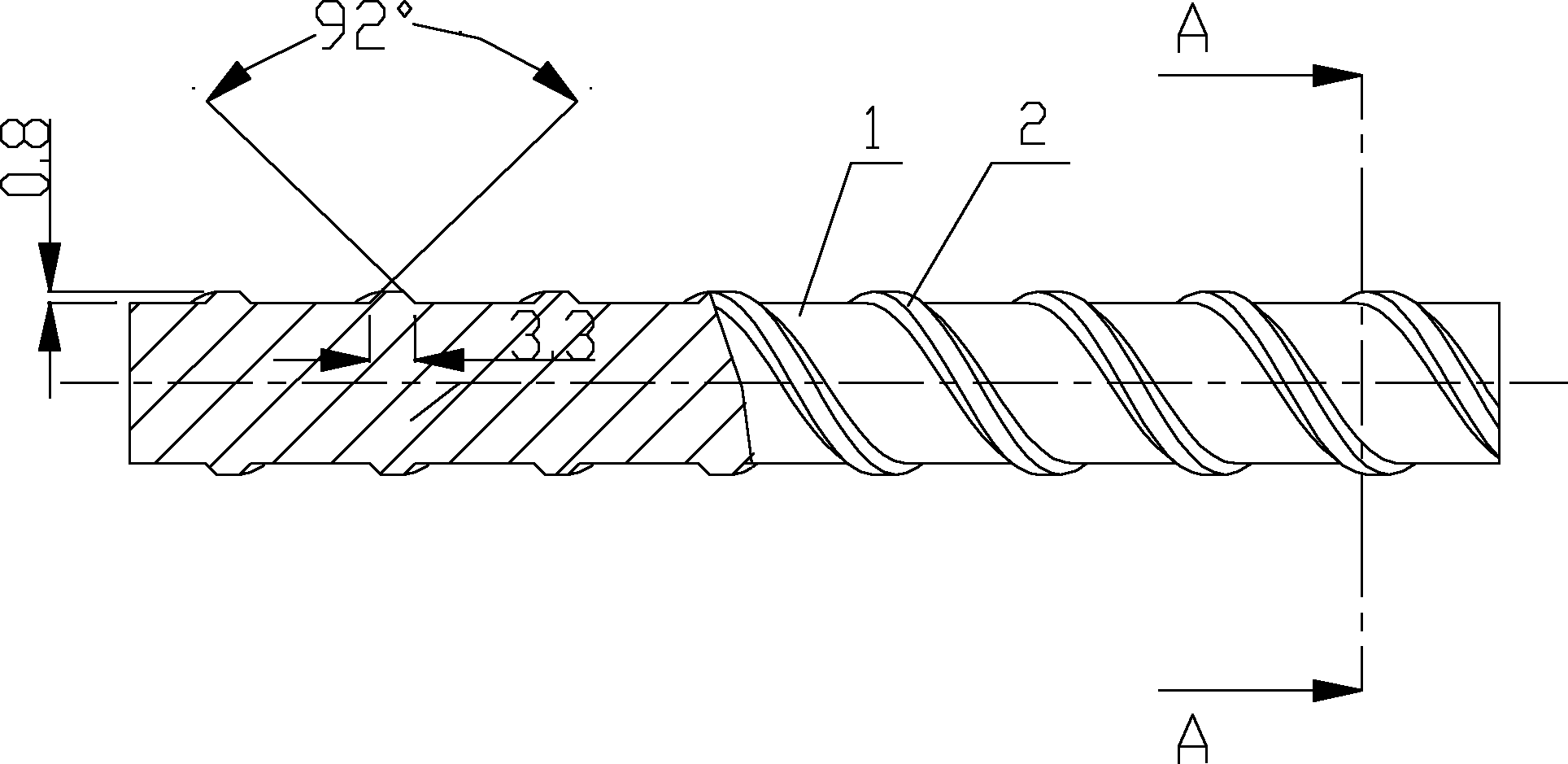

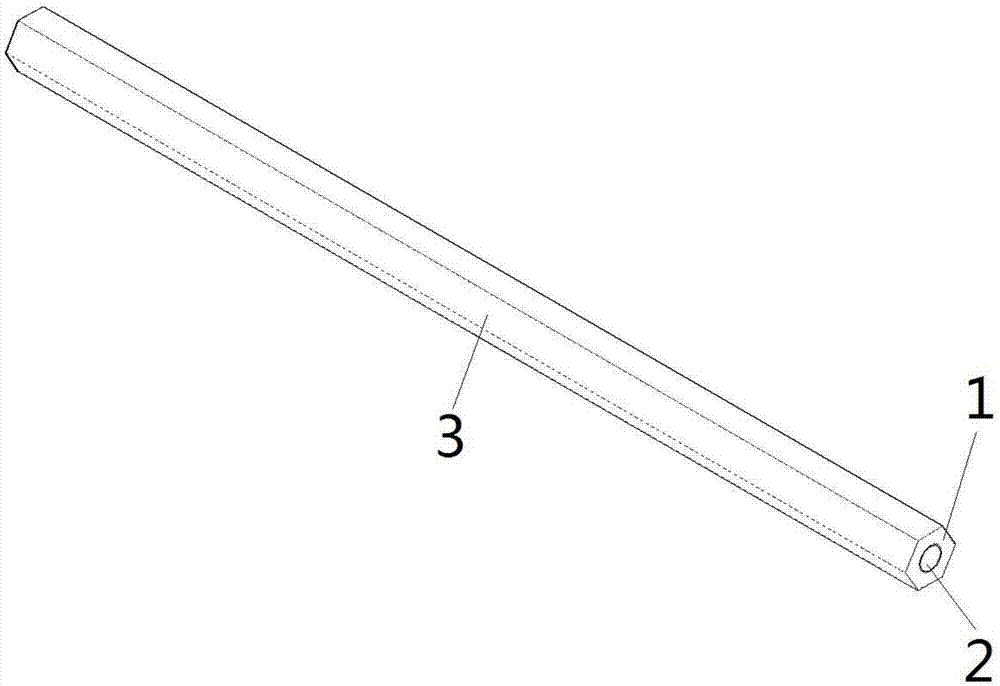

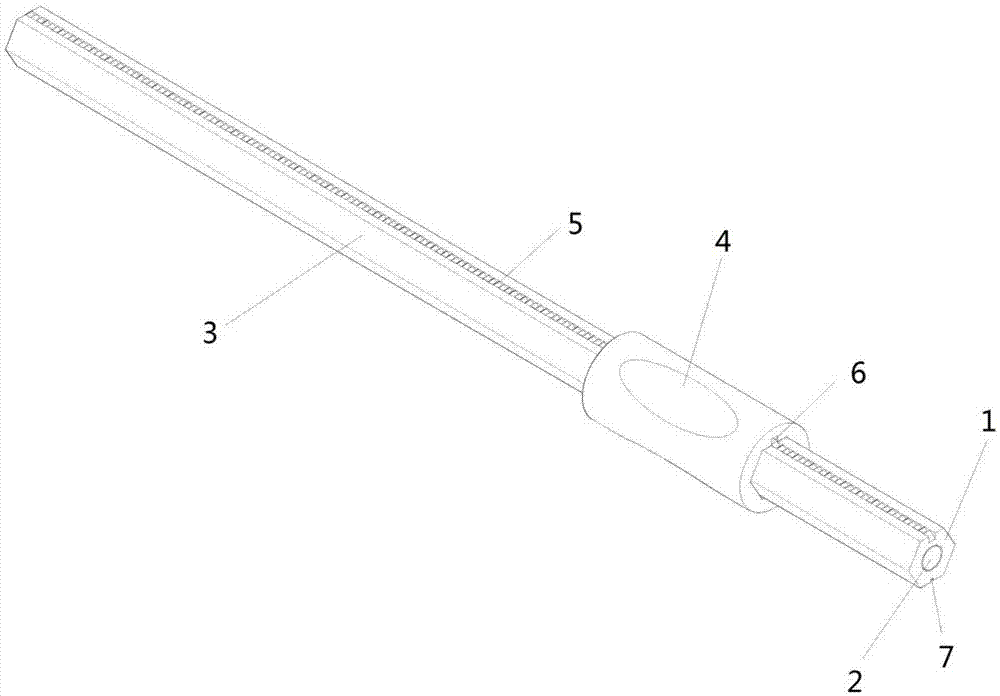

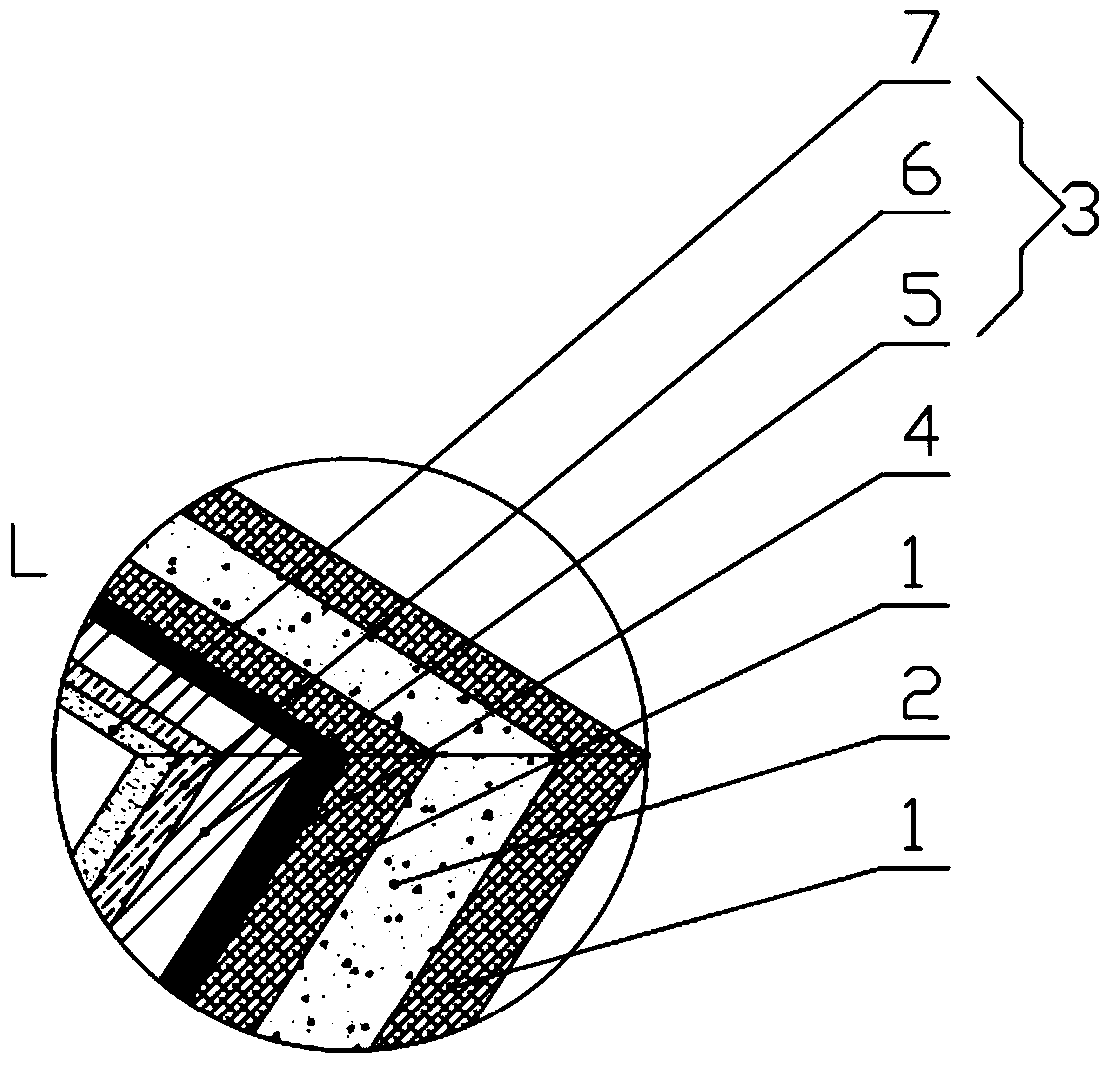

Wire electrode for WEDM-LS electrical discharge machining and preparation method of wire electrode

ActiveCN103537768ADoes not affect machining accuracyFast processingElectrical-based machining electrodesZincOxide

The invention discloses a wire electrode for WEDM-LS electrical discharge machining and a preparation method of the wire electrode. The wire electrode comprises a core portion, a transition layer, a covering layer and an oxide layer. The core portion is made of brass alloy or red copper. The transition layer covers the outer layer of the core portion and comprises a continuous portion and an interruption portion formed by beta-phase pinchbeck alloy protruding from the continuous portion. The covering layer is formed by the interruption portion formed by the beta-phase pinchbeck alloy, cracked gamma-phase pinchbeck alloy inlaid on the interruption and gaps. The inevitable oxide layer is formed on the surface of the covering layer. The zinc content at the joint between the core portion and the transition layer and the zinc content at the joint between the transition layer and the covering layer are distributed in a linear increase mode. According to the wire electrode with the special tissue structure, the gasification capacity of zinc can be adjusted in the cutting process, cutting efficiency and cutting accuracy are promoted, cost is saved to the largest degree and machining quality is improved.

Owner:NINGBO BODE HIGHTECH CO LTD

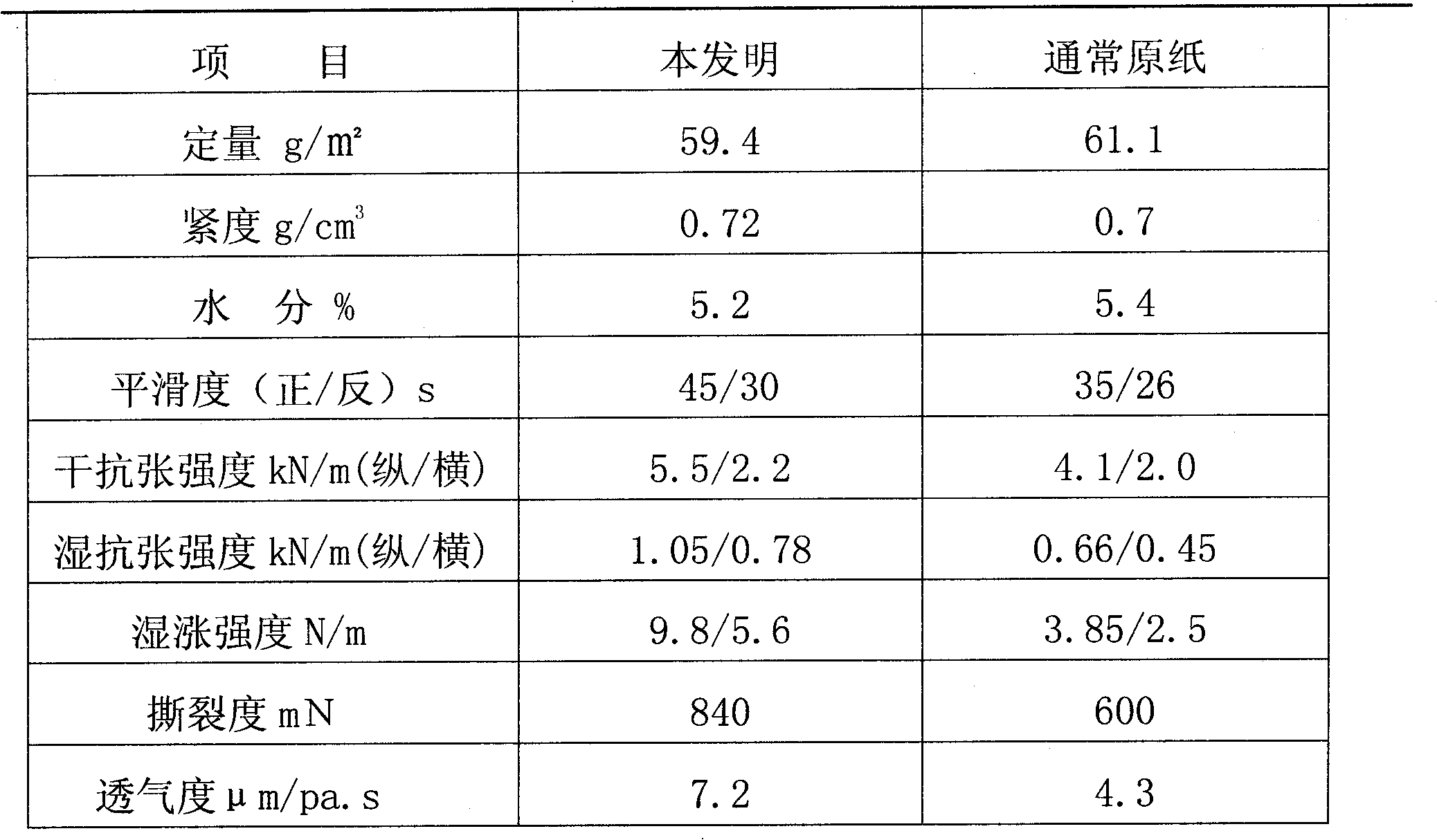

Production method for bactericidal packing paper

ActiveCN102154944AImprove breathabilityHigh strengthPaper coatingReinforcing agents additionBursting strengthCarboxymethyl cellulose

The invention discloses a production method for bactericidal packing paper, which comprises the following steps of: (1) preparation working procedure of applying glue solution to pulp; (2) preparation working procedure of applying glue solution to a surface; (3) working procedure of sizing agent repulping, selecting Southern pipes produced in America to make pulp, adding sodium carbonate and carboxymethyl cellulose into a repulping liquid; (4) working procedure of pulp matching, adding a wet strength agent; (5) working procedure of webbing and forming; (6) working procedure of applying glue solution to the surface, using modified tapicoa starch and polyvinyl alcohol for applying the glue solution to the surface; and (7) completion working procedure. The bactericidal packing paper has good air permeability, high surface strength, tearing resistance after disinfection and high bursting strength and can block bacterium invasion.

Owner:安徽华邦古楼新材料有限公司

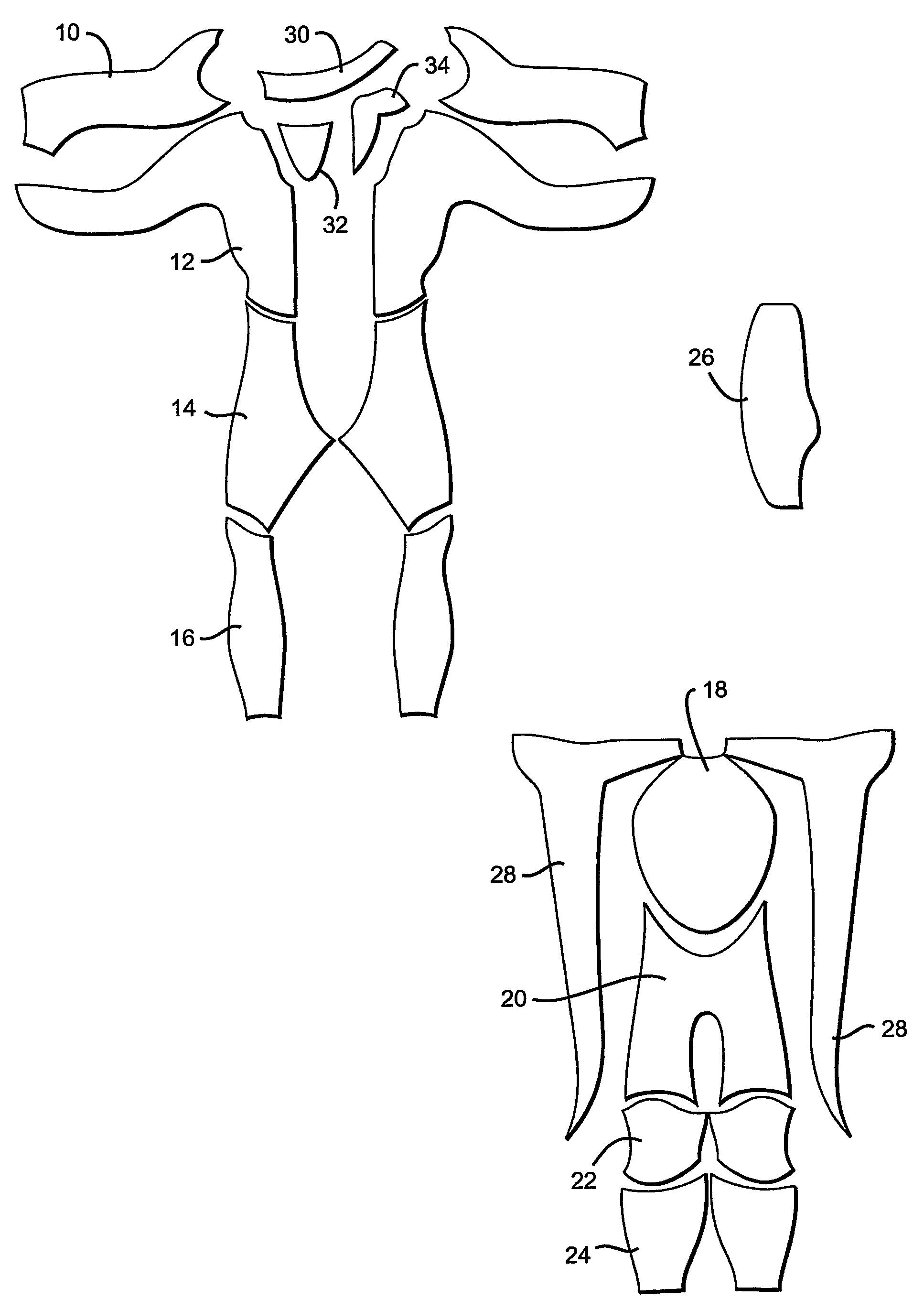

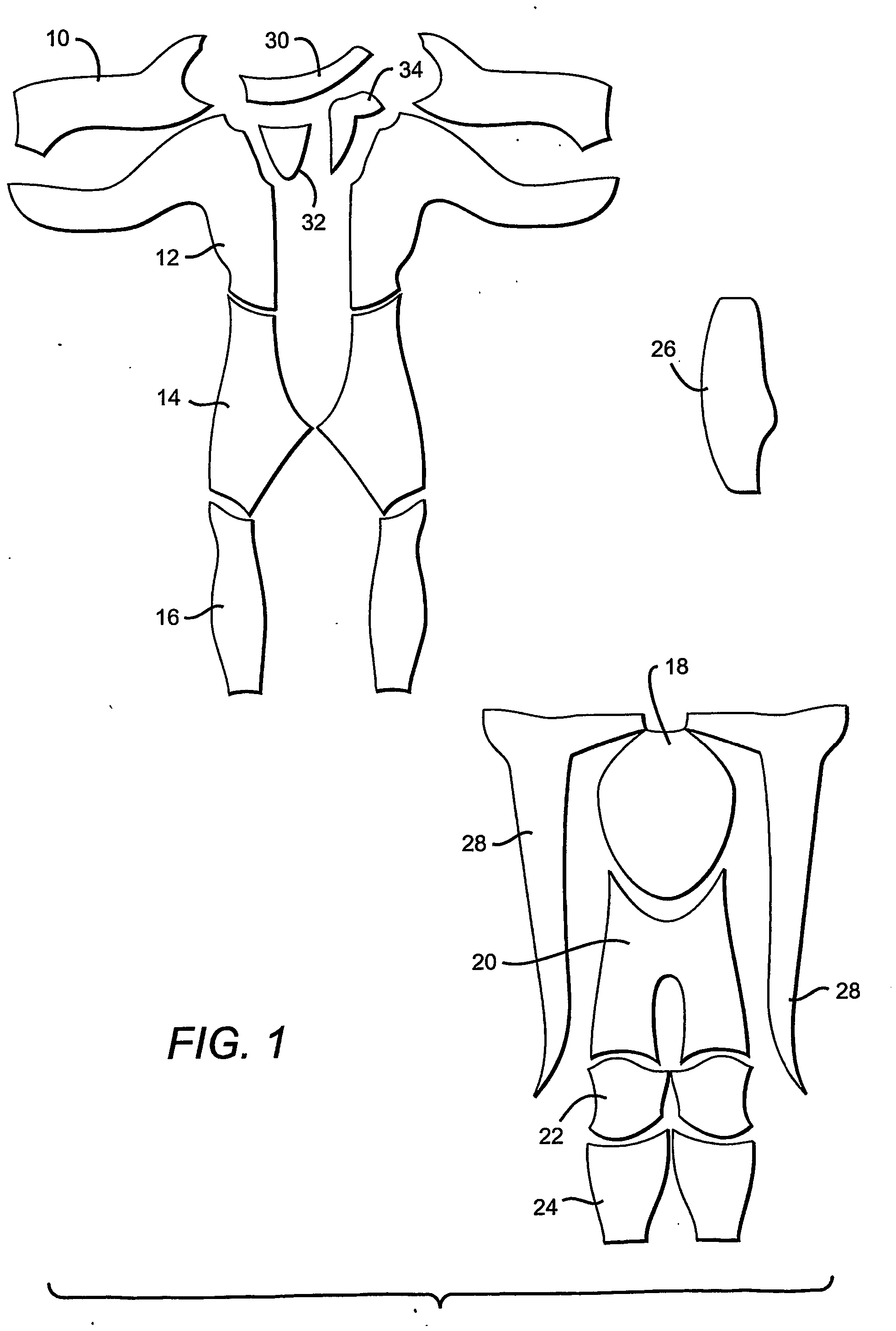

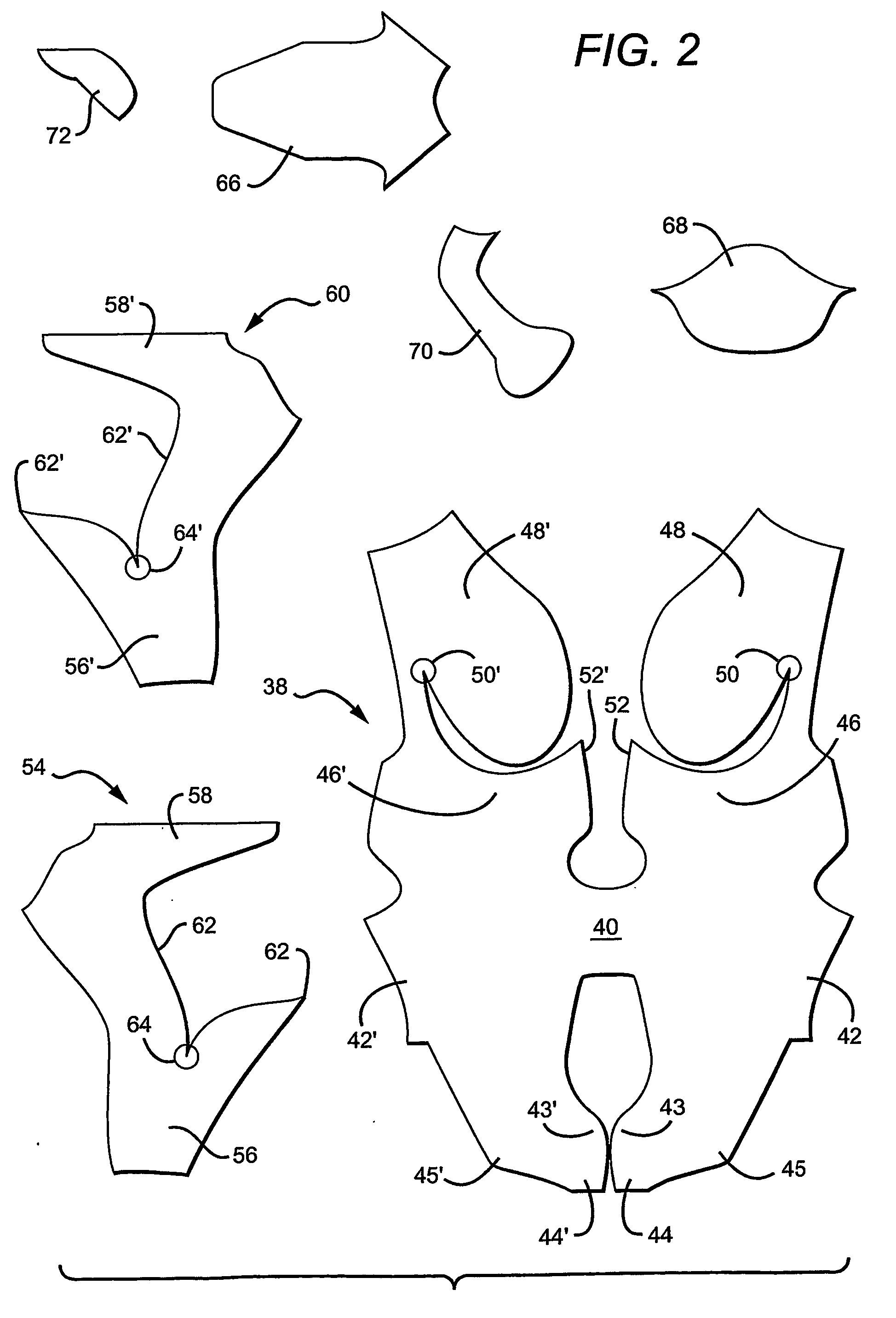

Minimal seemed fitted garment

InactiveUS20050241044A1Simplify garment productionImproved garmentProtective garmentShirtsEngineeringMechanical engineering

Garments that utilize complex panel shapes to minimize the to number of panels used, the number of seams, and total seam length. Increasing the complexity of panel shapes tends to make the cutting of panels more difficult and often results in more wastage of material, but the reduction of the number of panels and reduction in the number of seams and total seam length will actually simplify garment production and result in improved garments. Simplifying garment production will in turn generally result in an increase in the rate of production. Reducing seam length and the number of seams also reduces the chances of seams wearing out or splitting.

Owner:BOARDRIDERS IP HLDG LLC +1

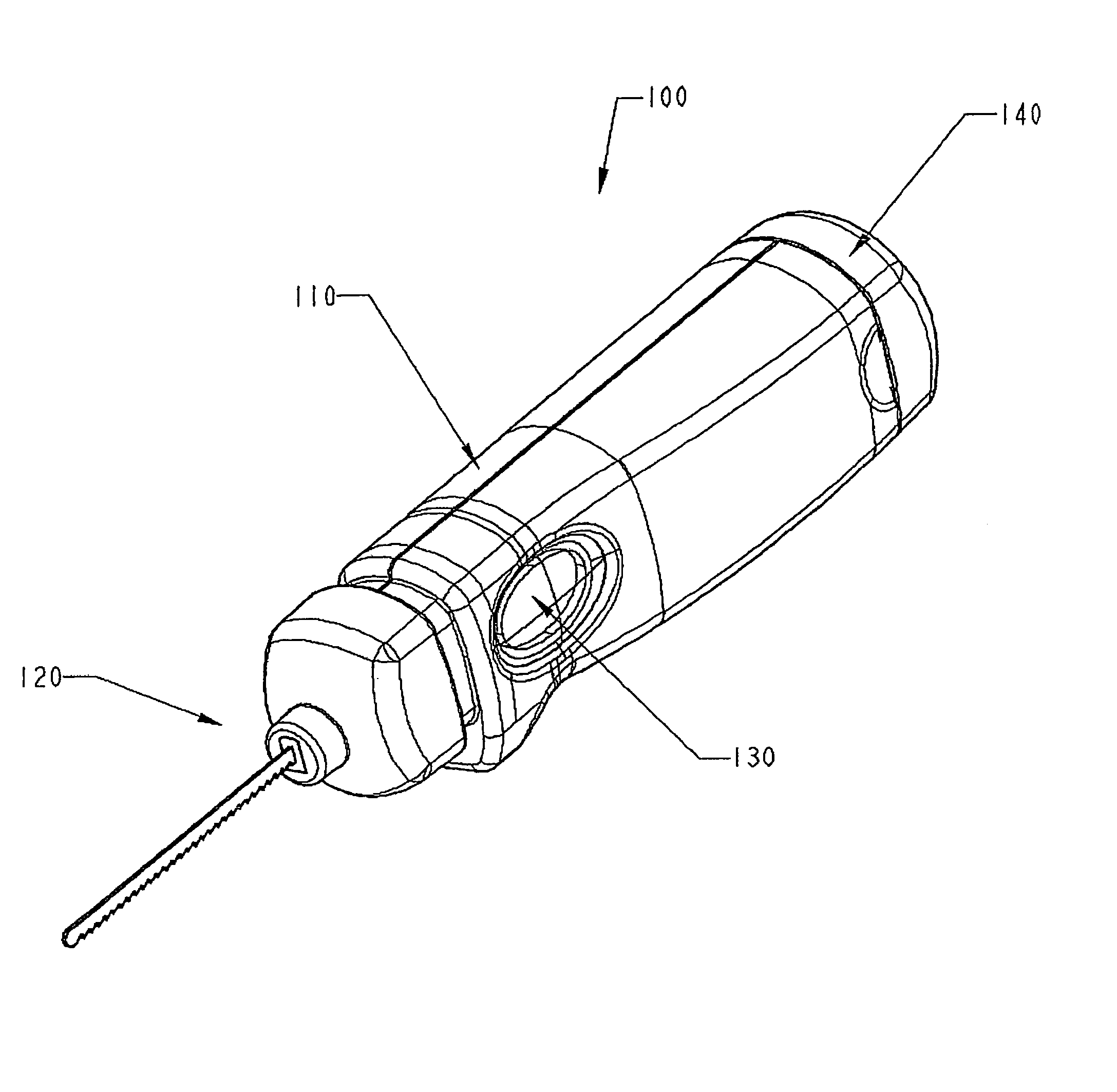

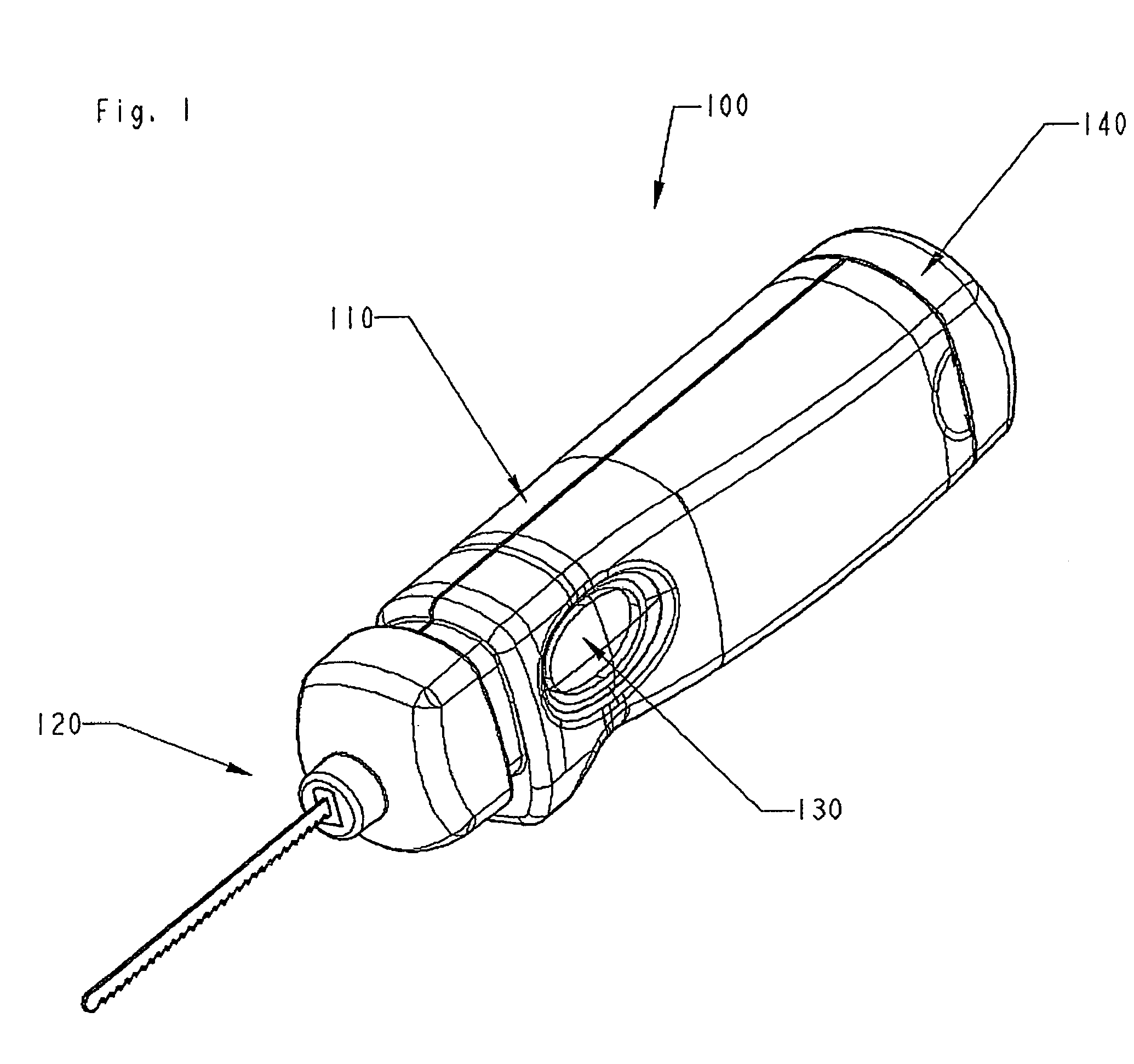

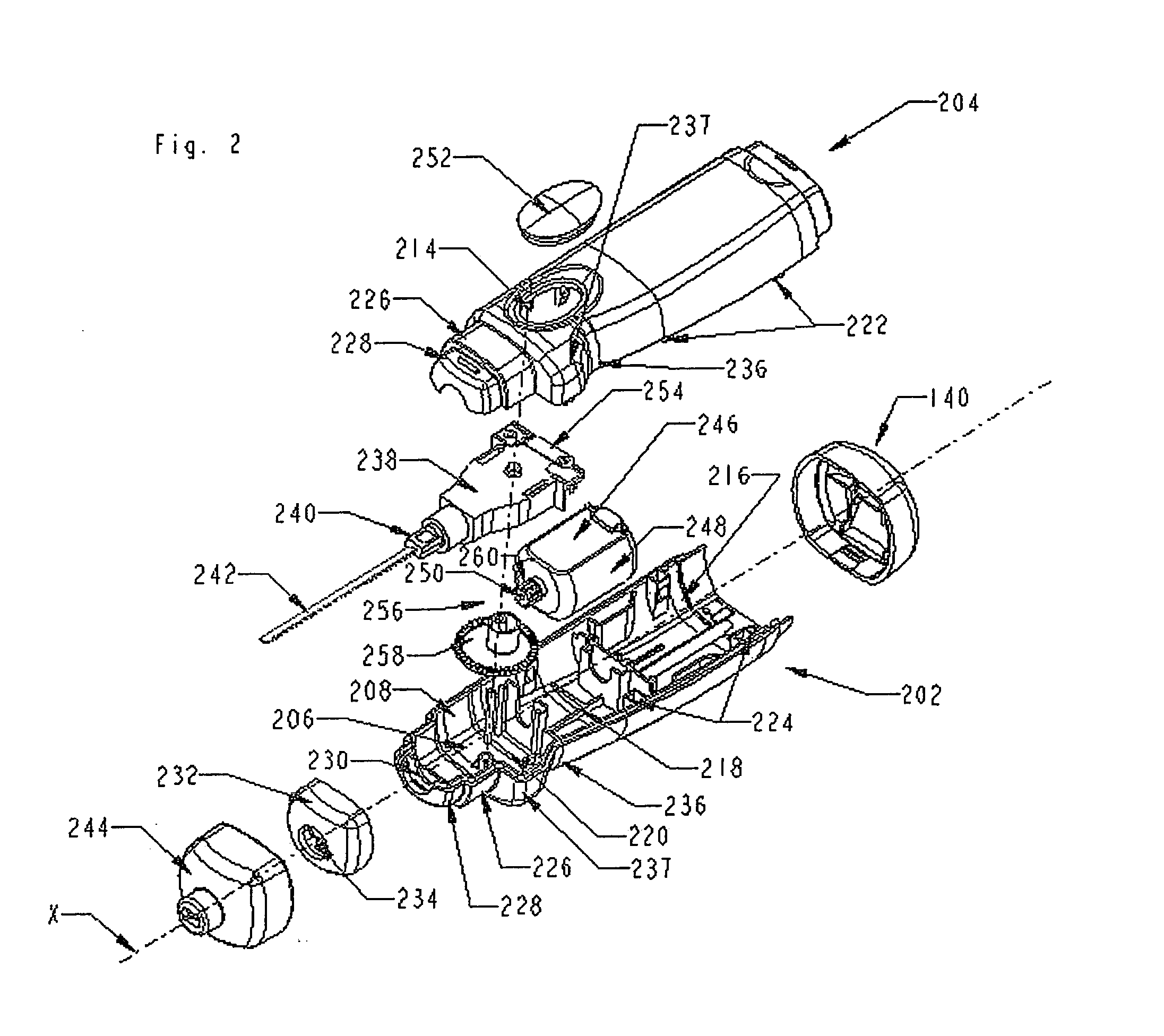

Electric knife adapted for safely craving pumpkins and other fruits and vegetables

ActiveUS20060005402A1Not easy to cutAccurately efficiently carveMetal sawing devicesToysVegetable matterHusk

According to one embodiment of the present invention, an electric knife is provided that includes a blade that is adapted to cut the pulp and shell of pumpkins and other fruits and vegetables but not readily cut the skin and flesh of humans. According to a preferred embodiment of the present invention, the electric knife also includes a shield that that is adapted to prevent fruit or vegetable matter from entering the housing of the electric knife.

Owner:CIT BANK A DIVISION OF FIRST-CITIZENS BANK & TRUST CO

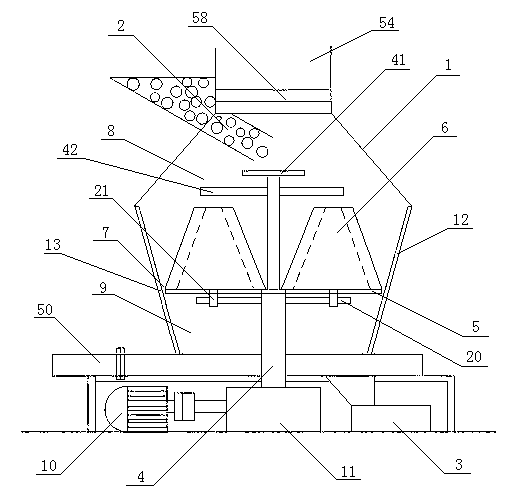

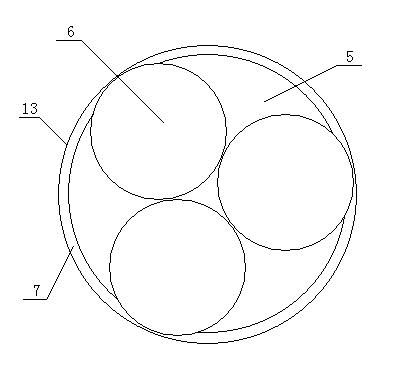

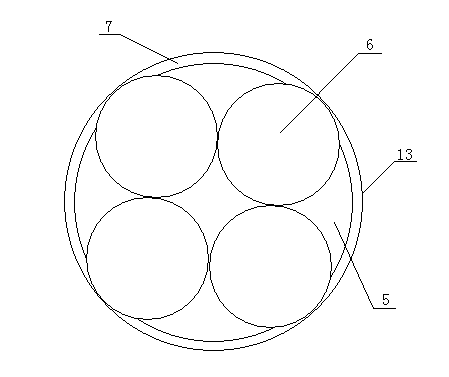

Drying and sorting integrated crusher and process

InactiveCN102698835ASimple production processLess investmentDrying gas arrangementsGrain treatmentsEngineeringHardness

The invention discloses a drying and sorting integrated crusher and a process thereof. The crusher comprises a crushing device, an air blast device, a sorting device and a drying preheating device. Ores are preheated by the drying preheating device and are crushed by the crushing device, and dust formed after the ores are crushed by the crushing device is raised by air which is blown by the air blast device into the sorting device; and a finished product is obtained by the settlement of the dust in the sorting device. According to the drying and sorting integrated crusher, the crushing device comprises a spindle, a crushing disc and 3 to 8 grinding rollers; the spindle is vertical; the crushing disc is horizontal; the grinding rollers are erected on the crushing disc and are meshed with the inner wall of a crushing cavity; and the adjacent grinding rollers are meshed with each other. When the crushing device runs, the grinding rollers revolve on the own axis while rotating around the spindle. The crushing device has a high-efficiency crushing effect on low-hardness ores, and is particularly suitable for crushing asbestos ores. When the drying and sorting integrated crusher is applied to the asbestos ores, the process can be simplified, investment of equipment and capital construction can be reduced, energy consumption and cost can be reduced, and the production efficiency can be improved greatly.

Owner:NANJING EFFUL

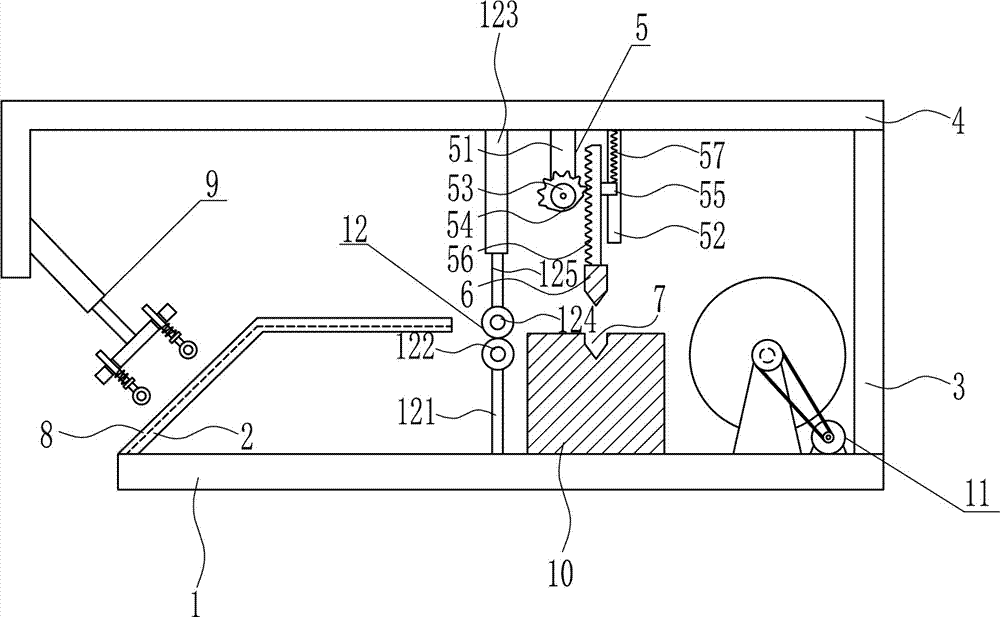

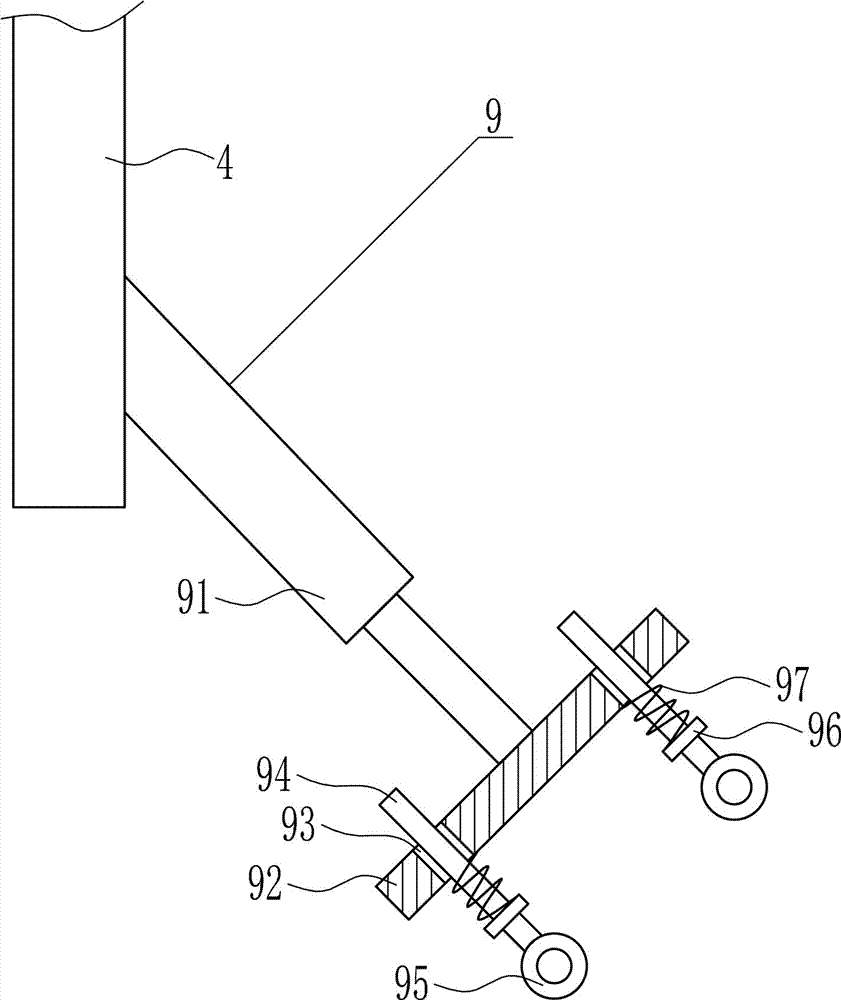

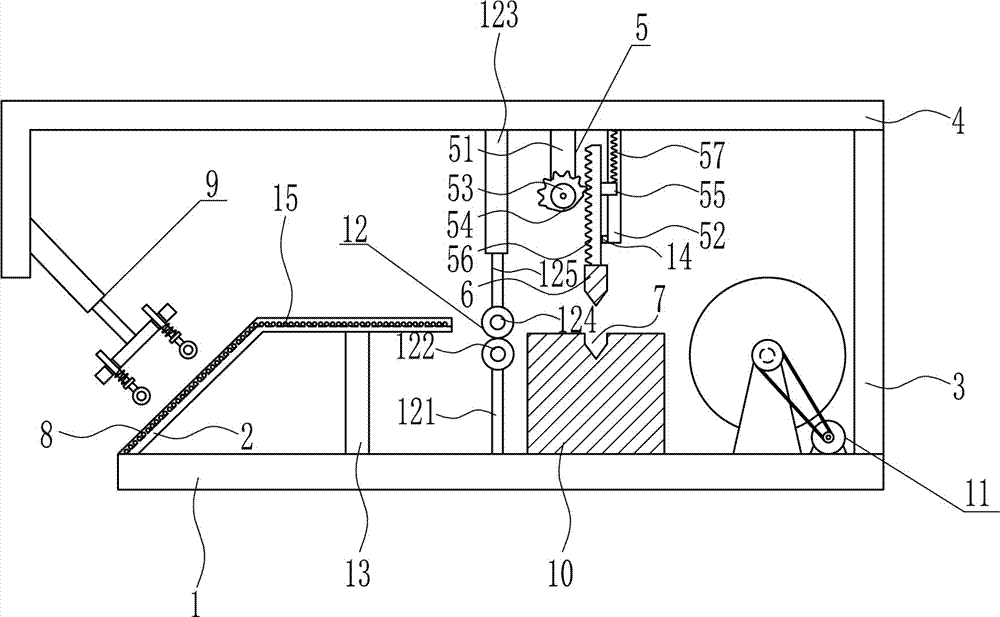

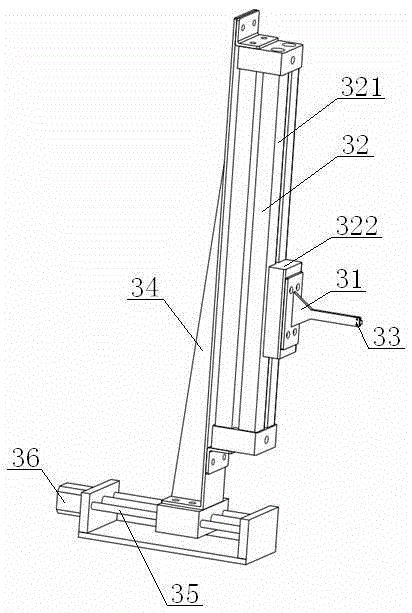

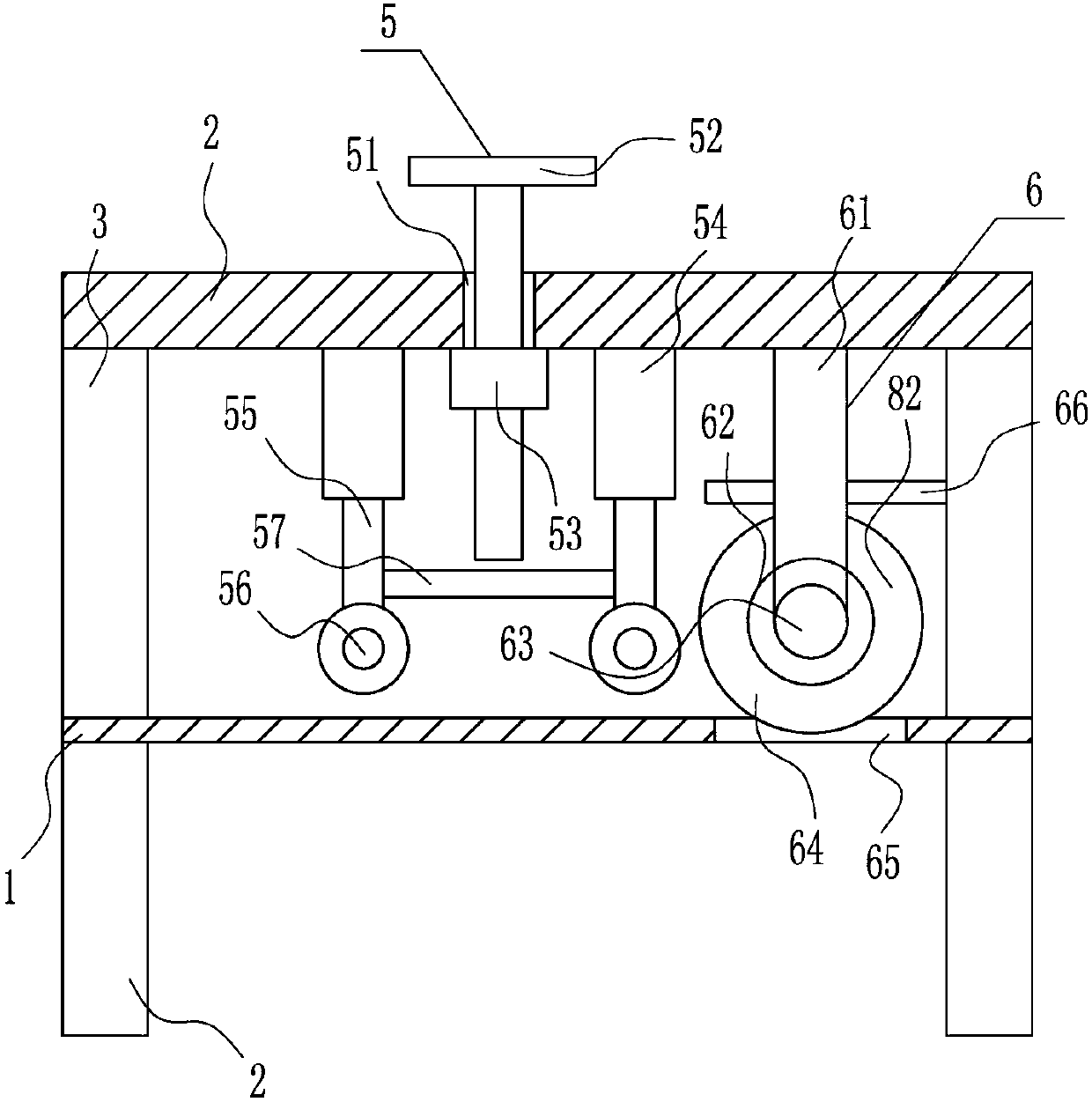

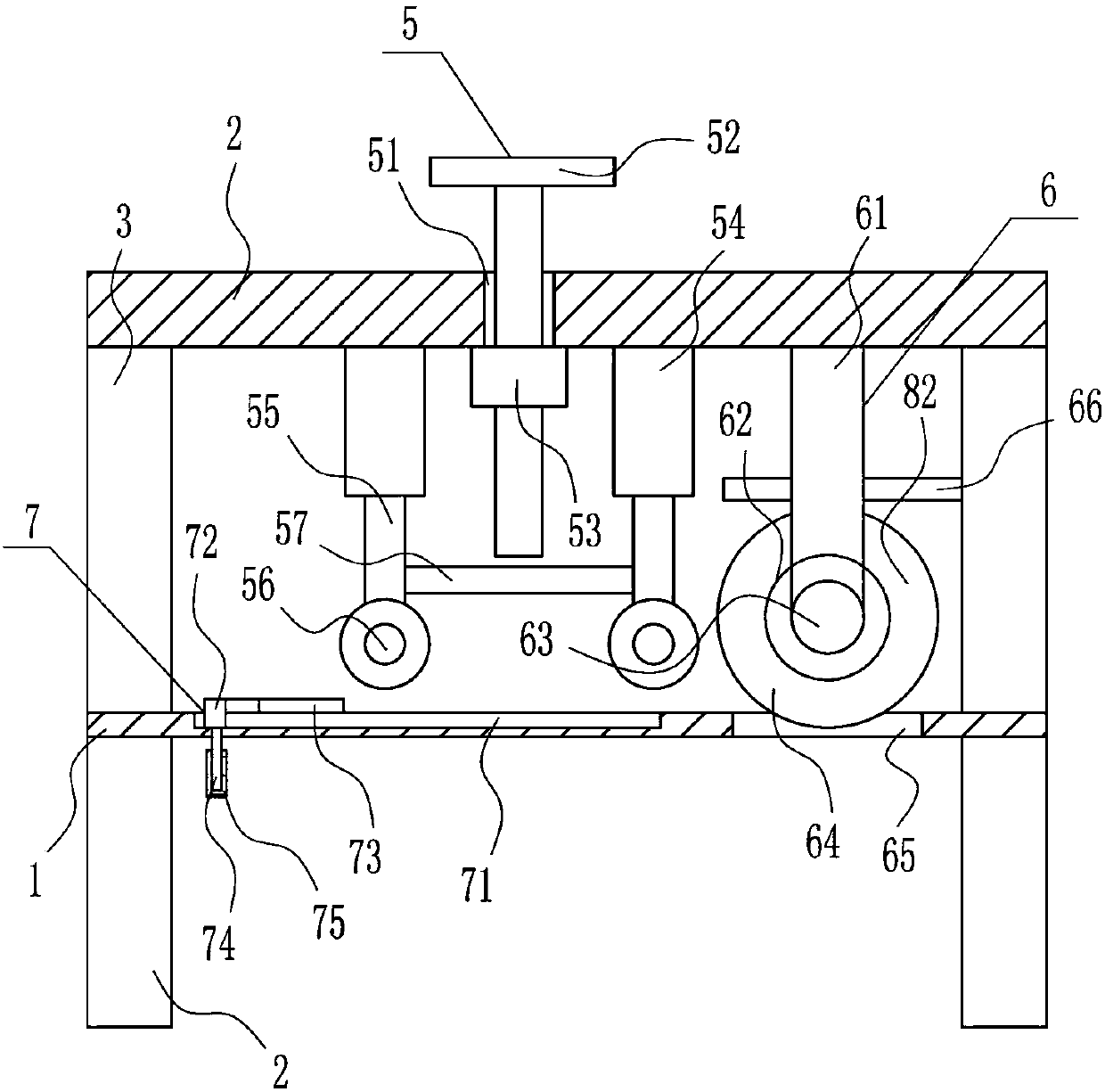

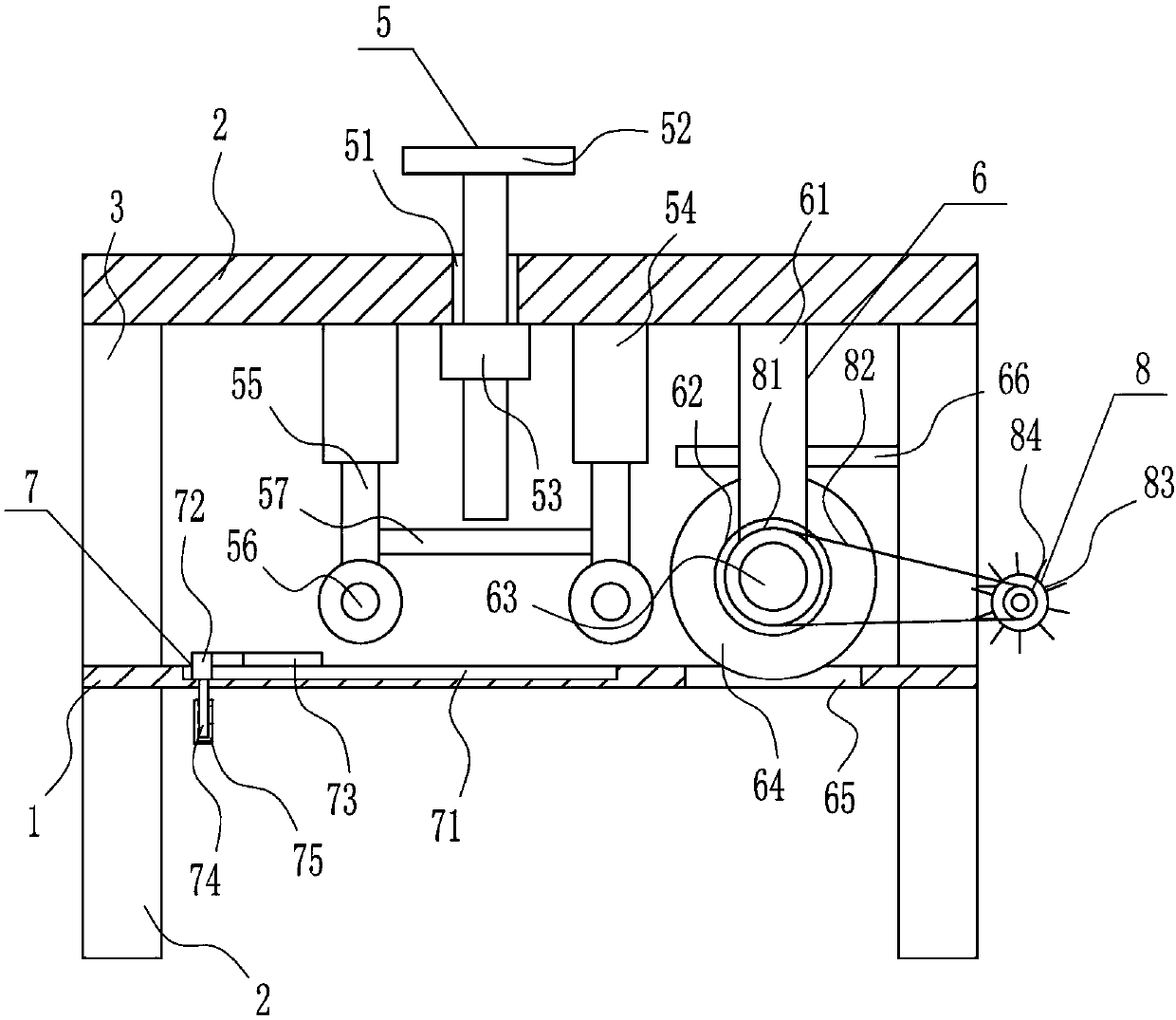

Wire harness cutting equipment for electronic product maintenance

InactiveCN107030229ANot easy to cutThe working environment is not messyWorking environmentConductor Coil

The invention relates to a wire harness cutting device, in particular to a wire harness cutting device for electronic product maintenance. The technical problem to be solved by the present invention is to provide a wire harness cutting device for maintenance of electronic products that saves time and effort, has high safety, and is not easy to cut hands. In order to solve the above-mentioned technical problems, the present invention provides such a wire harness cutting equipment for maintenance of electronic products, which includes a bottom plate, a connecting plate, a bracket, an L-shaped top plate, a lifting mechanism, a cutter, a positioning guide and a fixing seat, and the top of the bottom plate is from From left to right, connecting plates are connected by bolt connection; the top of the bracket is connected horizontally by bolt connection to an L-shaped top plate, and a lifting mechanism is installed on the right side of the inner top of the L-shaped top plate. The lifting part of the lifting mechanism is connected with a cutting Knife. The invention automatically transports the wire harness to be cut to the fixed seat through the electric roller, and winds up the wire harness through the winding device, so that the working environment is not messy.

Owner:吴俊俊

Method for producing piezoelectric composite substrate

ActiveUS20100108248A1Improve utilization efficiencyUniform thicknessAfter-treatment detailsLamination ancillary operationsSingle crystalPiezoelectric composite

A method for producing a piezoelectric composite substrate having a single-crystal thin film of a piezoelectric material includes an ion-implantation step and a separation step. In the ion-implantation step, He+ ions are implanted into the single-crystal base made of the piezoelectric material to form localized microcavities in a separation layer located inside the single-crystal base and apart from a surface of the single-crystal base. In the separation step, the microcavities formed in the ion-implantation step are subjected to thermal stress to divide the separation layer of the piezoelectric single-crystal base, thereby detaching the single-crystal thin film.

Owner:MURATA MFG CO LTD

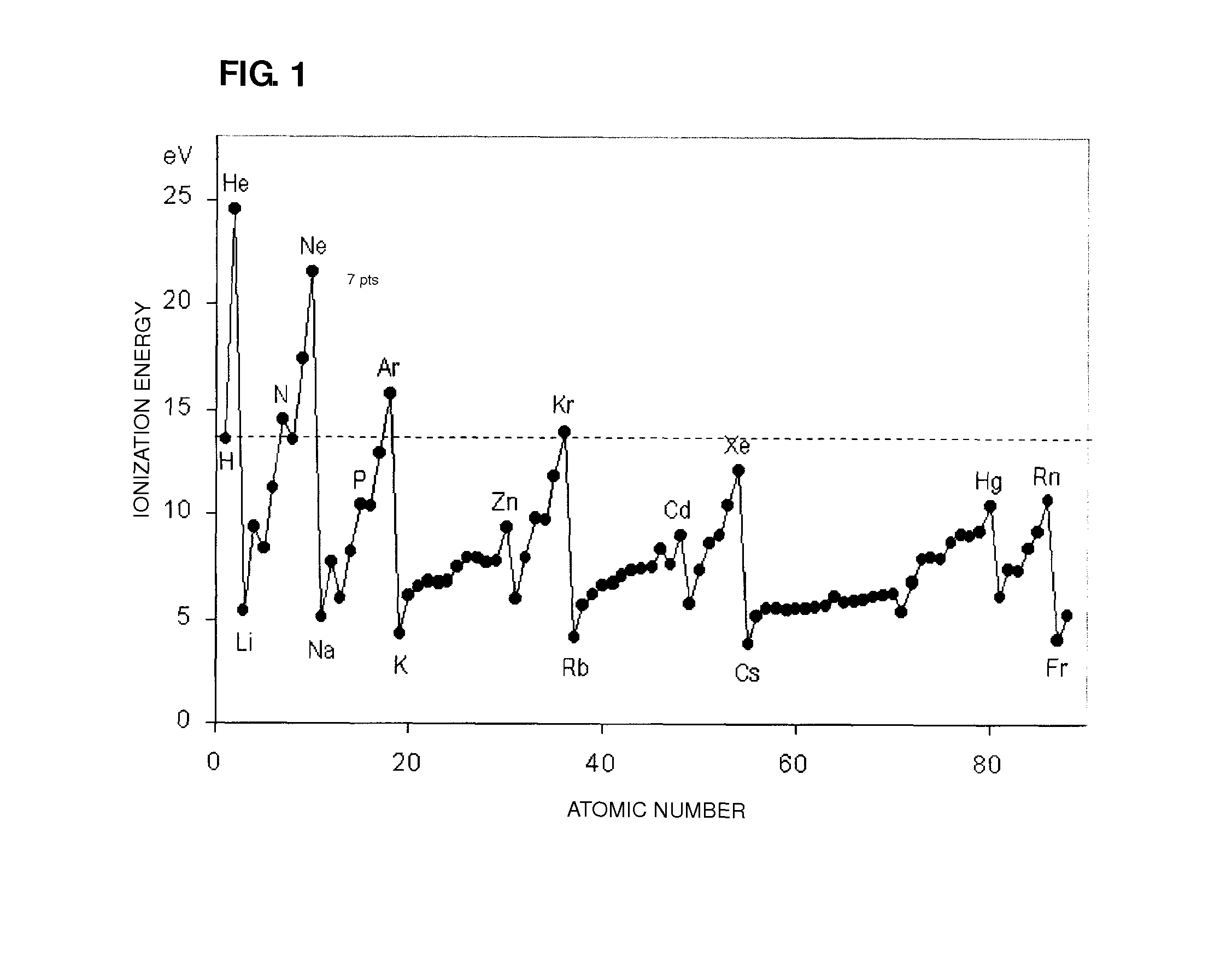

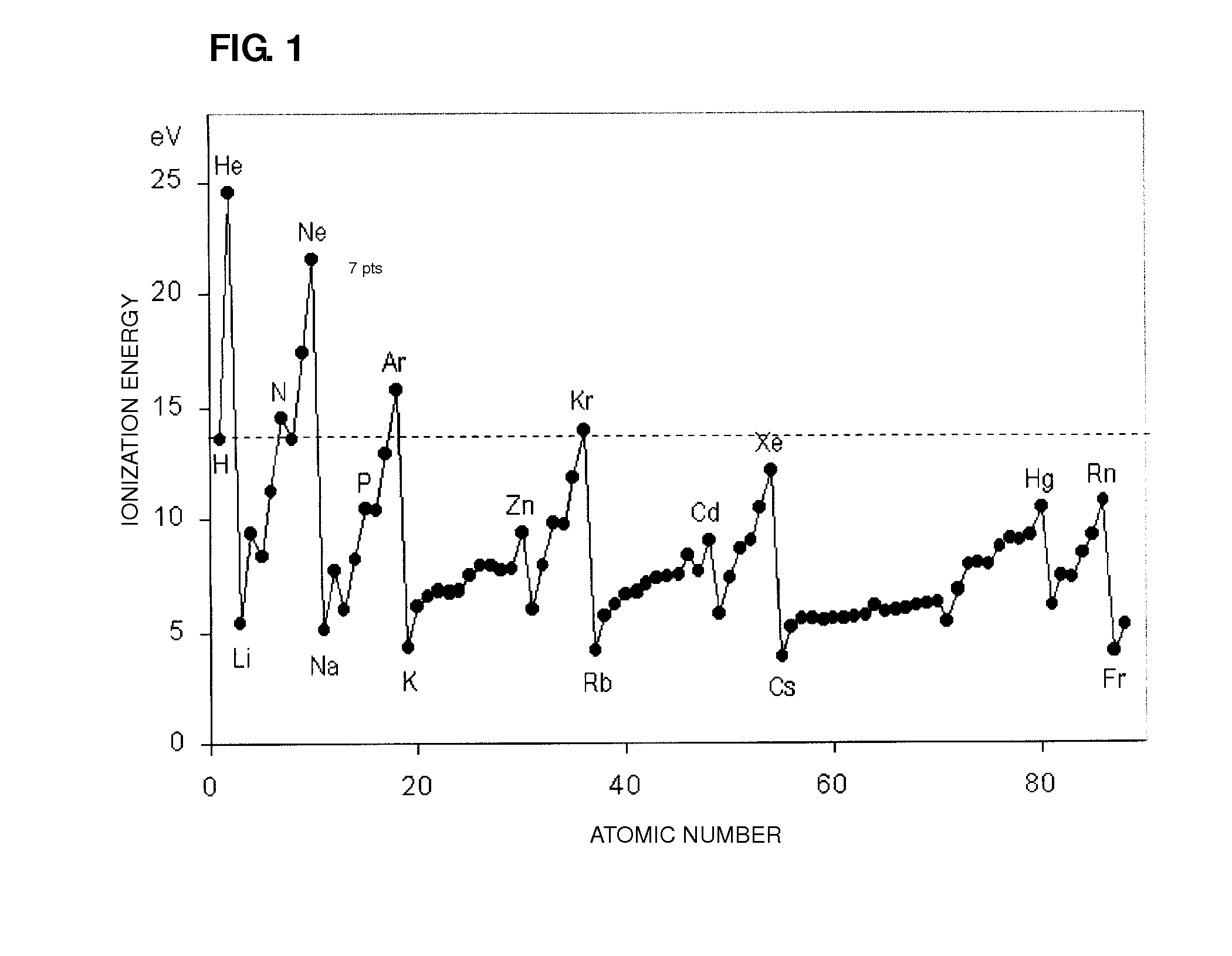

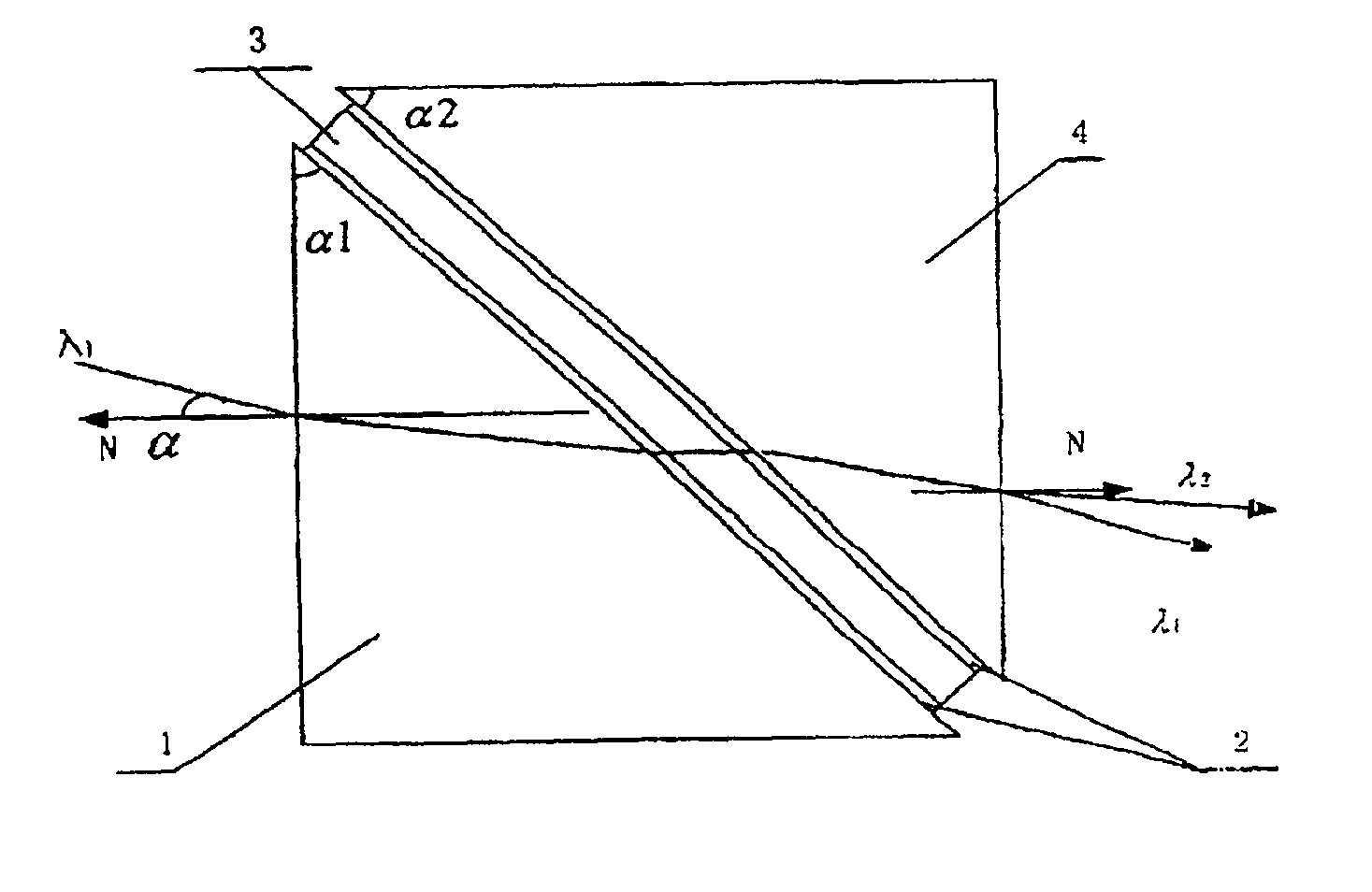

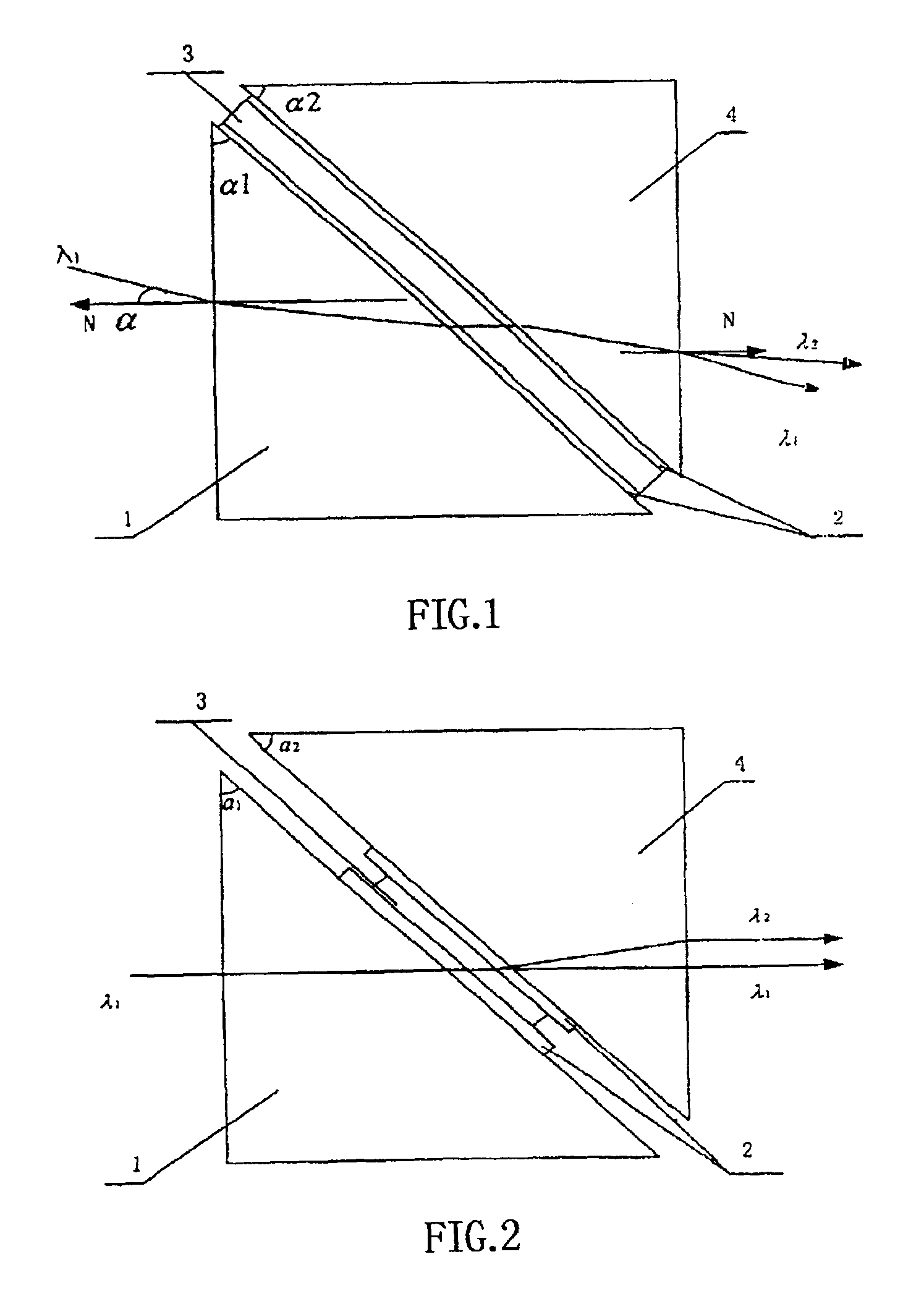

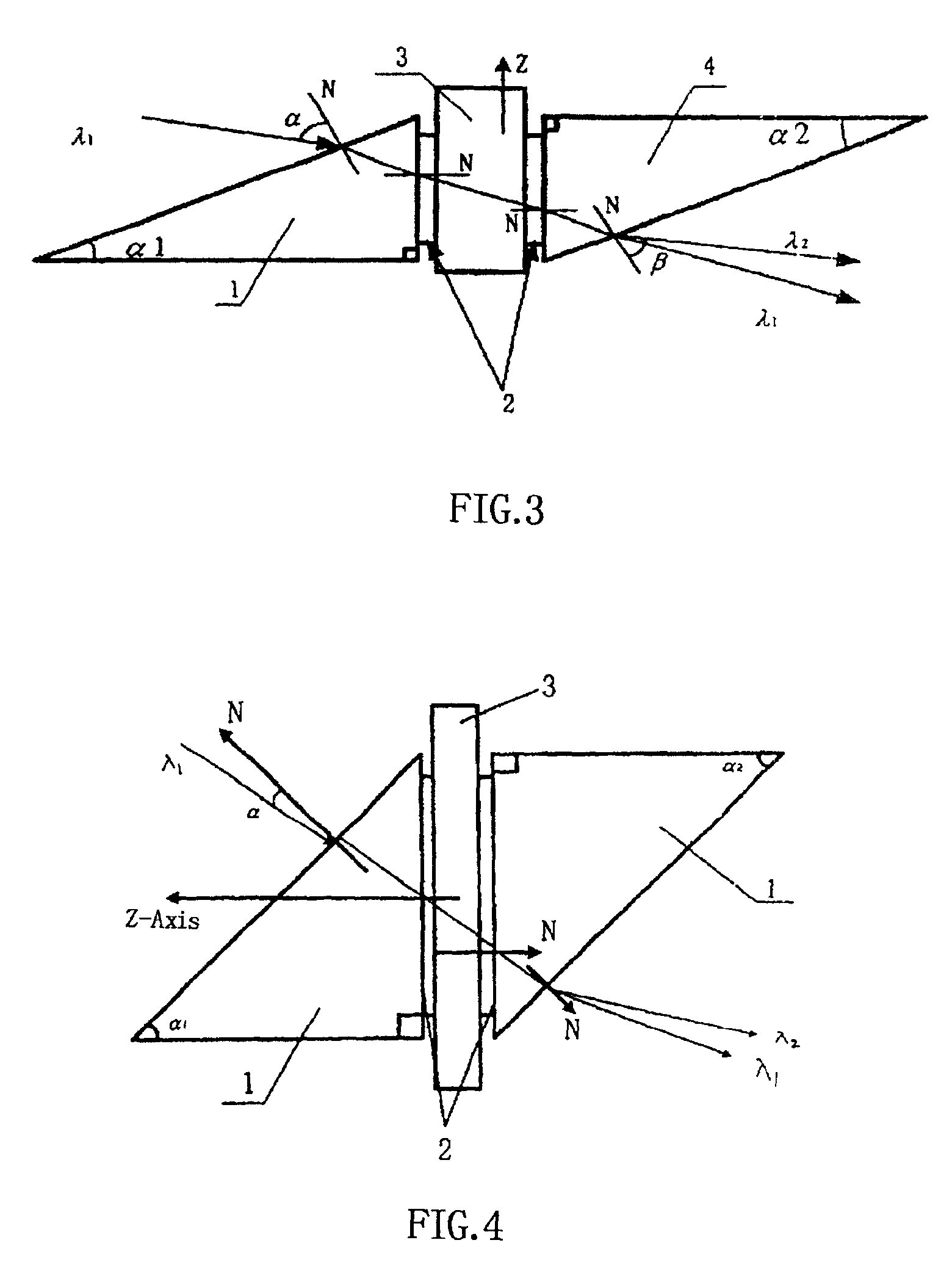

Prism-nonlinear optical crystal coupler for laser frequency conversion

InactiveUS6859305B2Not easy to cutCan not be cutPrismsLight demodulationNonlinear optical crystalRight triangle

The present invention relates to prism-nonlinear optical crystal couplers for frequency conversion, including M pieces of nonlinear optical crystal and one coupling prism stuck to the incident surface or / and exit surface of the crystal by optical stick or a matching liquid. The coupling prisms are the same triangle prisms of right triangle prism, equilateral triangle prism, or inequlateral triangle prism, or are different triangle prisms. It is hopeful to obtain frequency 6th harmonic output.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

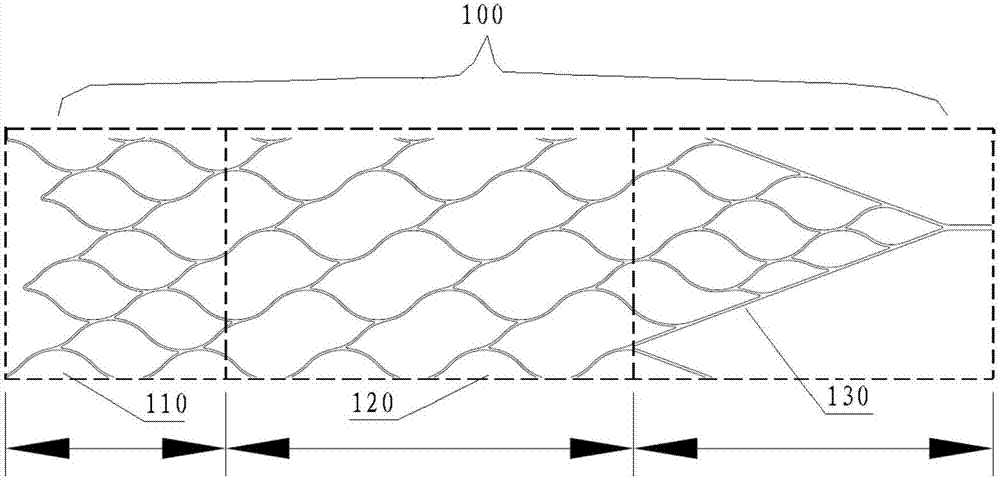

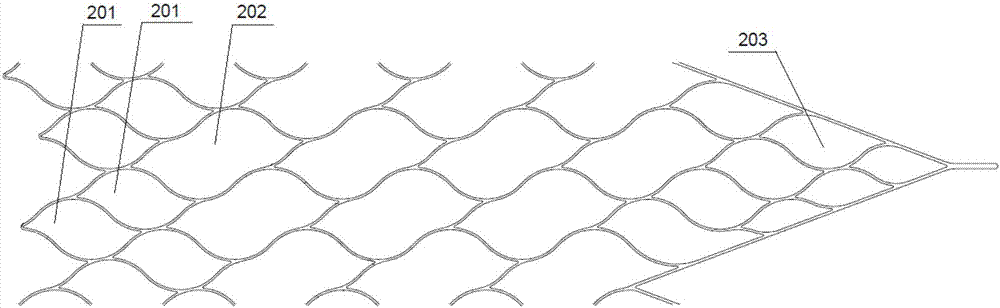

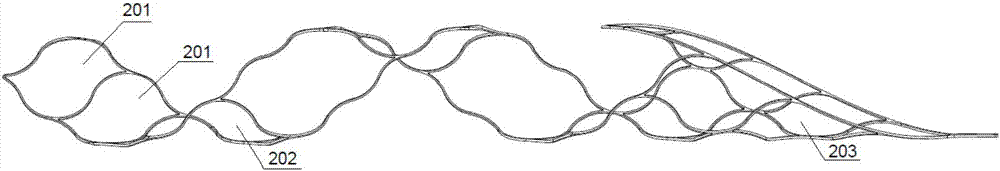

Thrombus extraction stent and thrombus extraction device

The invention relates to the technical field of medical apparatuses for internal medicine, and in particular to a thrombus extraction stent and a thrombus extraction device. The thrombus extraction stent comprises a stent main body which achieves self-expanding in a circumferential direction of a longitudinal axis, wherein the stent main body comprises a distal portion, a middle portion and a proximal portion connected to a push rod, and the distal portion, the middle portion and the proximal portion are sequentially connected; the distal portion comprises first closed-loop net units; the plurality of first closed-loop net units are mutually connected, so that a sleeve structure is defined; the middle portion comprises a plurality of second closed-loop net units; the plurality of second closed-loop net units are mutually connected, so that a sleeve structure is defined; the proximal portion comprises a plurality of third closed-loop net units; the plurality of third closed-loop net units are mutually connected, so that a taper-tube structure is defined; and both the first closed-loop net units and the third closed-loop net units are less than the second closed-loop net units in meshes. The invention also provides the thrombus extraction device. Due to small-mesh design of the distal portion and the proximal portion, thrombus displacement and falling-off are prevented from easily occurring in a withdrawal process. With large-mesh design of the middle portion, a thrombus can be conveniently taken out as a whole body.

Owner:XINKAINUO MEDICAL TECH SHANGHAI CO LTD

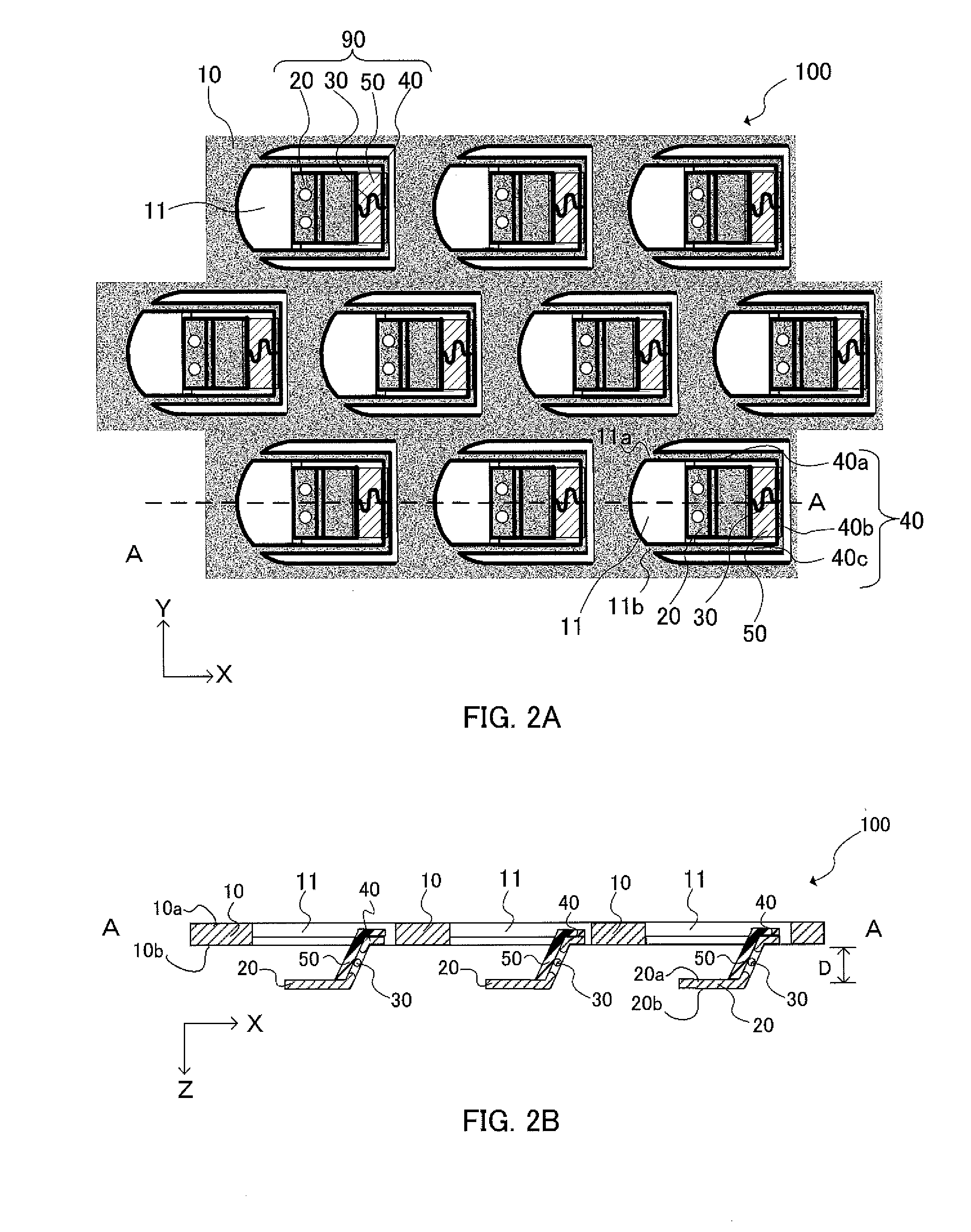

Fuse board and battery block equipped with same

ActiveUS20130202941A1Simply manufactureNot easily cutFuse device manufactureSmall-sized cells cases/jacketsEngineeringElectrical and Electronics engineering

A fuse board including a metal plate, a connection portion connected to a cell, a fuse portion connecting the metal plate to the connection portion, and an insulating resin film bonded to the fuse portion, wherein a wiring pattern of the fuse portion has a bent portion, and the insulating resin film has a rectangular sheet-like shape that covers one surface of the fuse portion.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

High-strength reinforcing steel bar with spiral fins and processing method of high-strength reinforcing steel bar

The invention relates to a reinforcing steel bar and a processing method thereof, in particular to a high-strength reinforcing steel bar with spiral fins and a processing method of the high-strength reinforcing steel bar. The high-strength reinforcing steel bar consists of following components including, in weight percentage, from 0.25 to 0.4% of C, from 0.1 to 0.2% of Si, from 0.3 to 0.45% of Mn, from 0.04 to 0.05% of Nb, from 0.08 to 0.09% of Cr, from 0.01 to 0.04% of V, from 0.002 to 0.003% of B, from 0.001 to 0.003% of Mo, from 0.015 to 0.03 of Al, from 0.002 to 0.003% of S, from 0.008 to0.009% of Ti, from 0.004 to 0.005% of Ni, from 3 to 5% of composite rear earth and the balance Fe. The processing method includes using a roll to roll a reinforcing steel bar into a reinforcing steelbar with the continuous spiral fins on the surface in a hot state; feeding the reinforcing steel bar with the continuous spiral fins on the surface after hot rolling into a heating furnace and heating the reinforcing steel bar to the temperature of 880-990 DEG C; then fast cooling the reinforcing steel bar to the temperature of 650-680 DEG C by an online cooling device via compressed air or vaporous quenching liquid; quenching in a quenching device by water or quenching liquid for 15-25 seconds; and tempering after heating the reinforcing steel bar to the temperature of 500-550 DEG C via a tempering heating furnace. The high-strength reinforcing steel bar with the spiral fins has a good anchoring property, fine ductility and a high yielding-to-tensile ratio.

Owner:TIANSHUN GROUP +2

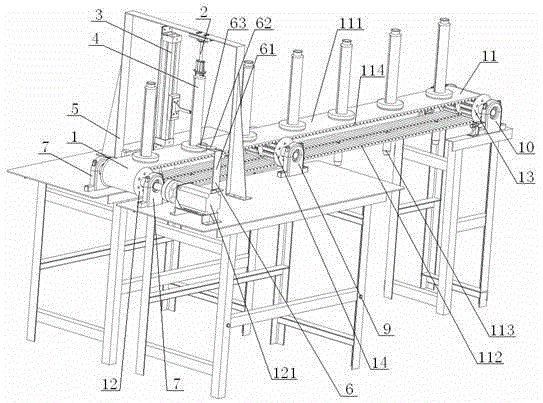

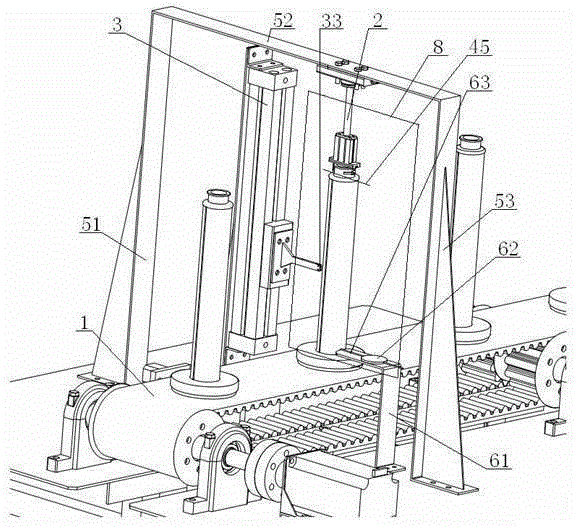

Glass fiber bobbin rest yarn removing device and control method thereof

A glass fiber bobbin rest yarn removing device includes a bobbin delivery part, a bobbin rotation positioning part, and a glass fiber cutting part; the bobbin delivery part includes a synchronous gear-shaped belt which is provided with bobbins with grooves, and the bobbin rotation positioning part is arranged above the bobbins; the bobbin rotation positioning part includes a rotary cylinder and a bobbin clamping rack, the glass fiber cutting part is arranged at one side of the bobbins, the glass fiber cutting part includes a cutting blade, a bobbin position detecting sensor with a detecting probe is arranged at the other side of the bobbins, and the detecting probe contacts the bobbins. When the glass fiber bobbin rest yarn removing device is controlled to remove rest yarns by a control method, the synchronous gear-shaped belt is firstly controlled to move until the bobbins move to the position under the bobbin clamping rack, then the rotary cylinder is controlled to allow the bobbins to axially rotate, and then the cutting blade is controlled to move up and down along the grooves at the other side of the bobbins to cut the rest yarns in the bobbins when the detecting probe extends into the grooves at one side of the bobbins. The glass fiber bobbin rest yarn removing device is good in yarn-cutting effect, is high in yarn-cutting efficiency, and cannot cut the bobbins.

Owner:WUHAN TEXTILE UNIV

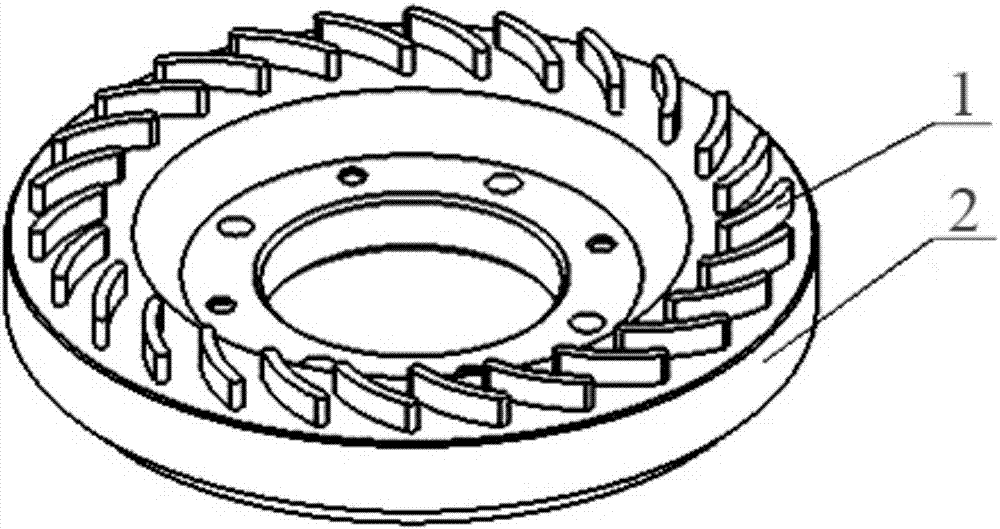

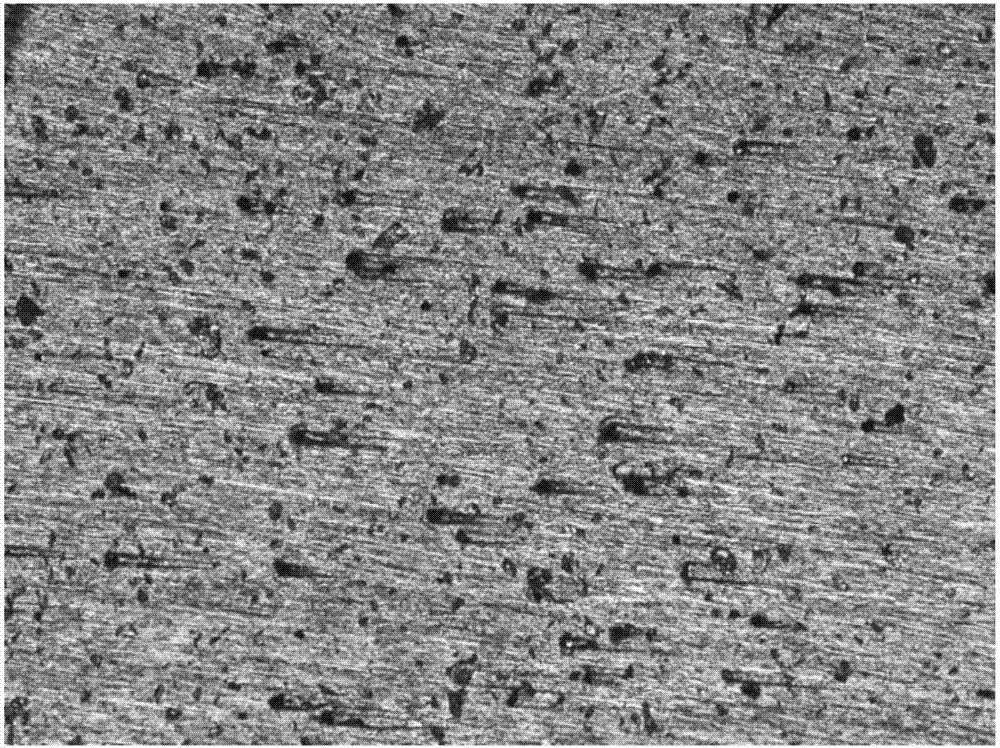

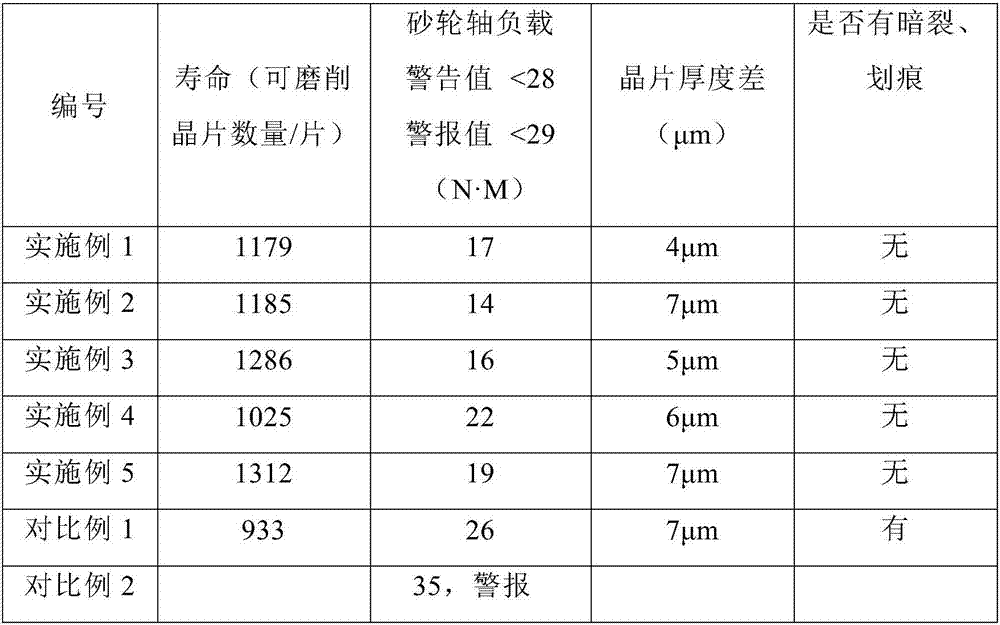

Metallic bond, diamond grinding wheel prepared through bond and preparation method of diamond grinding wheel

The invention relates to a metallic bond, a diamond grinding wheel prepared through the bond and a preparation method of the diamond grinding wheel. The metallic bond comprises, by weight percent, 95%-99% of copper-tin prealloyed powder, 0.5%-3% of graphite powder and 0.5%-2% of nanometer alpha-Al2O3. The copper-tin prealloyed powder, the graphite powder, the nanometer alpha-Al2O3 and diamond are taken according to a certain proportion, procedures of burdening and material mixing, pelletizing, compression, sintering and aftertreatment are carried out in sequence, and tool bits can be prepared. The multiple tool bits are arranged on a matrix at equal distance in the circumferential direction, the cambered surfaces of the tool bits are perpendicular to the matrix, and the diamond grinding wheel is prepared. The above tool bits are uniform in ingredient and good in density, diamond distribution is uniform, and the control effect of the metallic bond on the diamond is good. The grinding wheel has the beneficial effects of being good in ground workpiece surface quality, free of dark cracks and scratches, sharp in grinding and long in service life, facilitating large-scale production and the like and is especially suitable for producing sapphire wafers with the thinning thickness ranging from 100 micrometers to 700 micrometers.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Plank cutting device

The invention particularly relates to a plank cutting device. The plank cutting device can save time and labor, is high in cutting speed, can collect wood bits generated in the cutting process, and does not affect the surrounding environment. To achieve the above technical purposes, the plank cutting device comprises a placement board and the like; supporting legs are installed on the left side and the right side of the bottom of the placement board symmetrically; supporting rods are installed on the left side and the right side of the top of the placement board symmetrically; a top board is installed between the top ends of the supporting rods on the left side and the right side; a compressing device is arranged on the left side of the top board; a compressing component of the compressingdevice is located above the placement board; and a cutting device body is arranged on the right side of the bottom of the top board. Through a pushing device, the situation that a person makes contact with a plank and pushes the plank with hands is not needed, the person is not likely to be cut by a saw web, and a collection device can collect the wood bits generated in the cutting process, so that the effects of saving time and labor and being high in cutting speed are achieved.

Owner:钟清

Plastic pencil and preparation method thereof

The present invention relates to a plastic pencil, which comprises a pencil rod, a pencil core and a pencil skin, wherein the components of the pencil rod comprise 30-50 wt% of polystyrene (PS), 10-30 wt% of a synthetic rubber, 2-8 wt% of a nucleating agent, 30-50 wt% of talc powder, and 5-10 wt% of calcium stearate, and are added with polyethylene (PE), the components of the pencil core comprise 20-50 wt% of polystyrene (PS), 2-10 wt% of an organosilicon polymer, 30-60 wt% of graphite powder, 2-10 wt% of hydrogenated palm oil, 2-10 wt% of oleic acid amide, and 5-10 wt% of a synthetic rubber, and the components of the pencil skin comprise 70-90 wt% of polystyrene (PS), 5-20 wt% of color master batch, and 2-10 wt% of hydrogenated palm oil. According to the present invention, the pencil rod and the pencil core are not easily broken, the pencil core has characteristics of good striking degree, good brightness and dreg falling resistance, and the manufacturing cost is low.

Owner:JIANGXI JISHUI GEMSTAR STATIONERY CO LTD

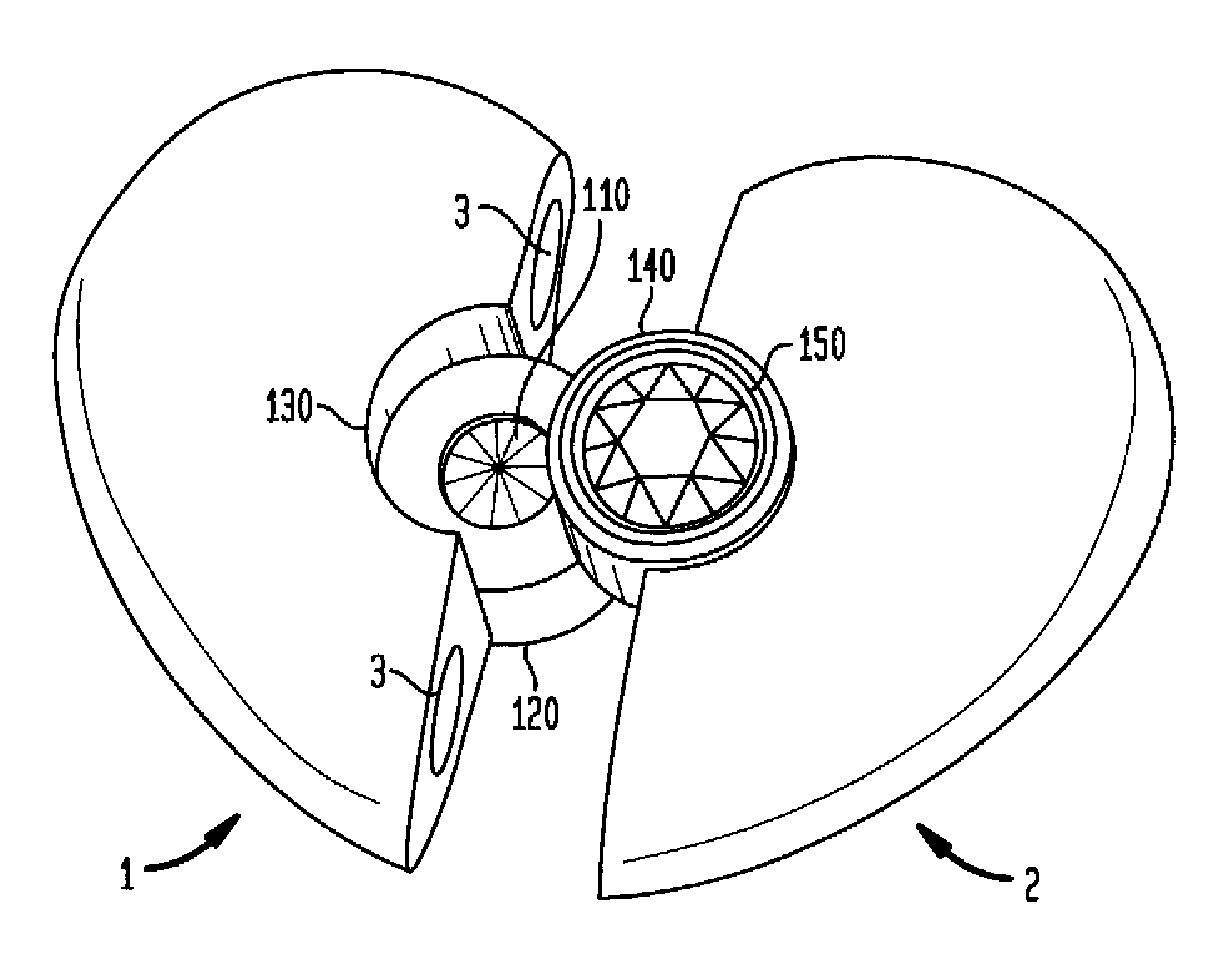

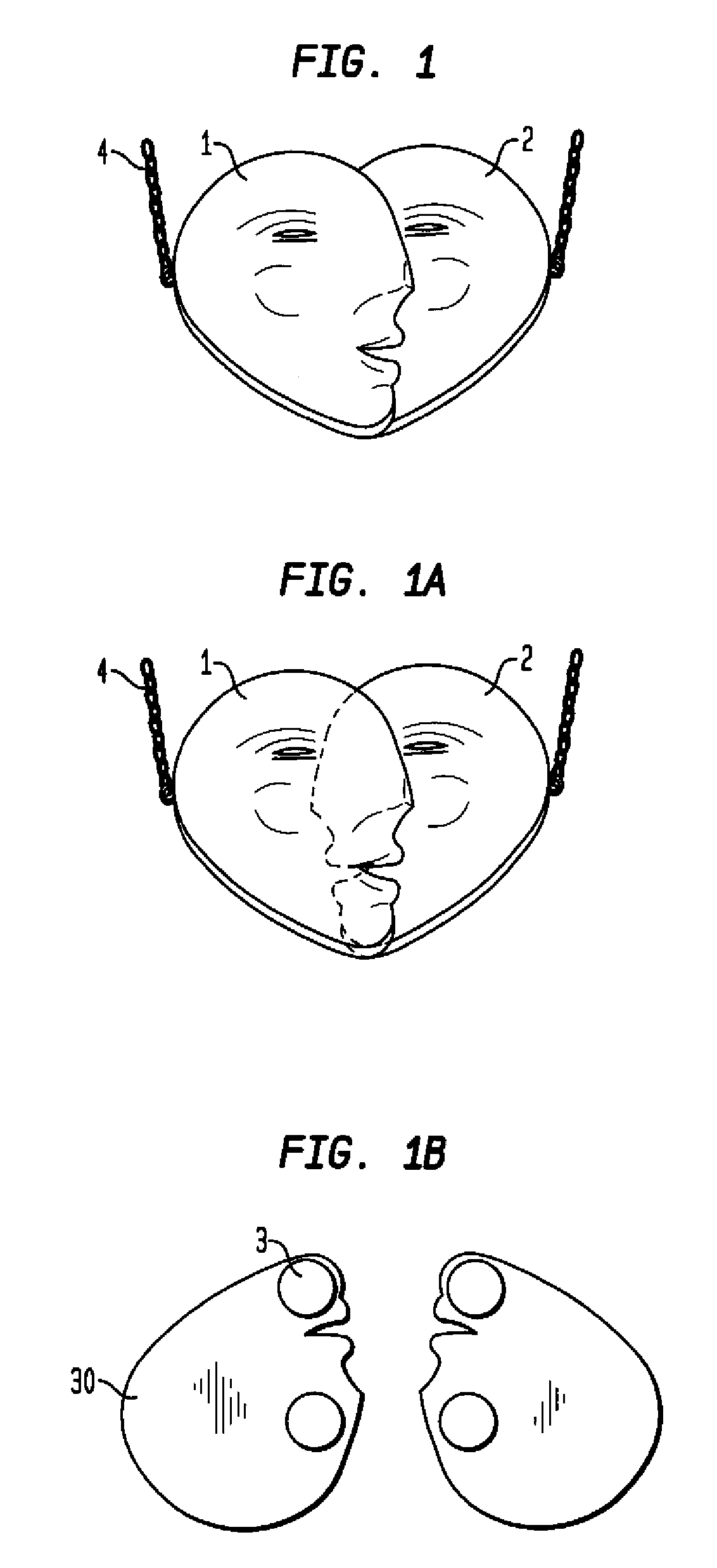

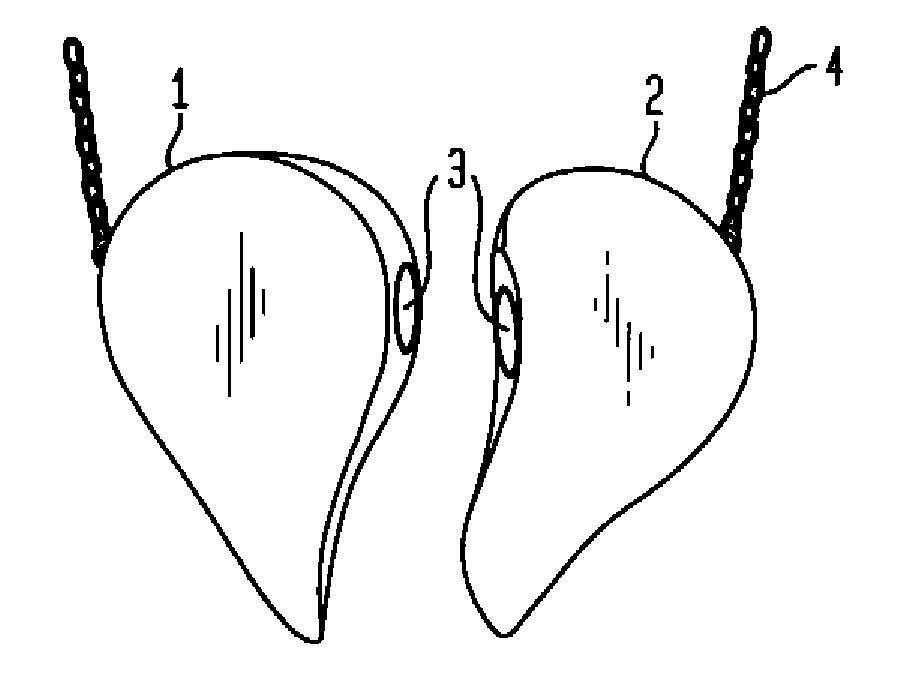

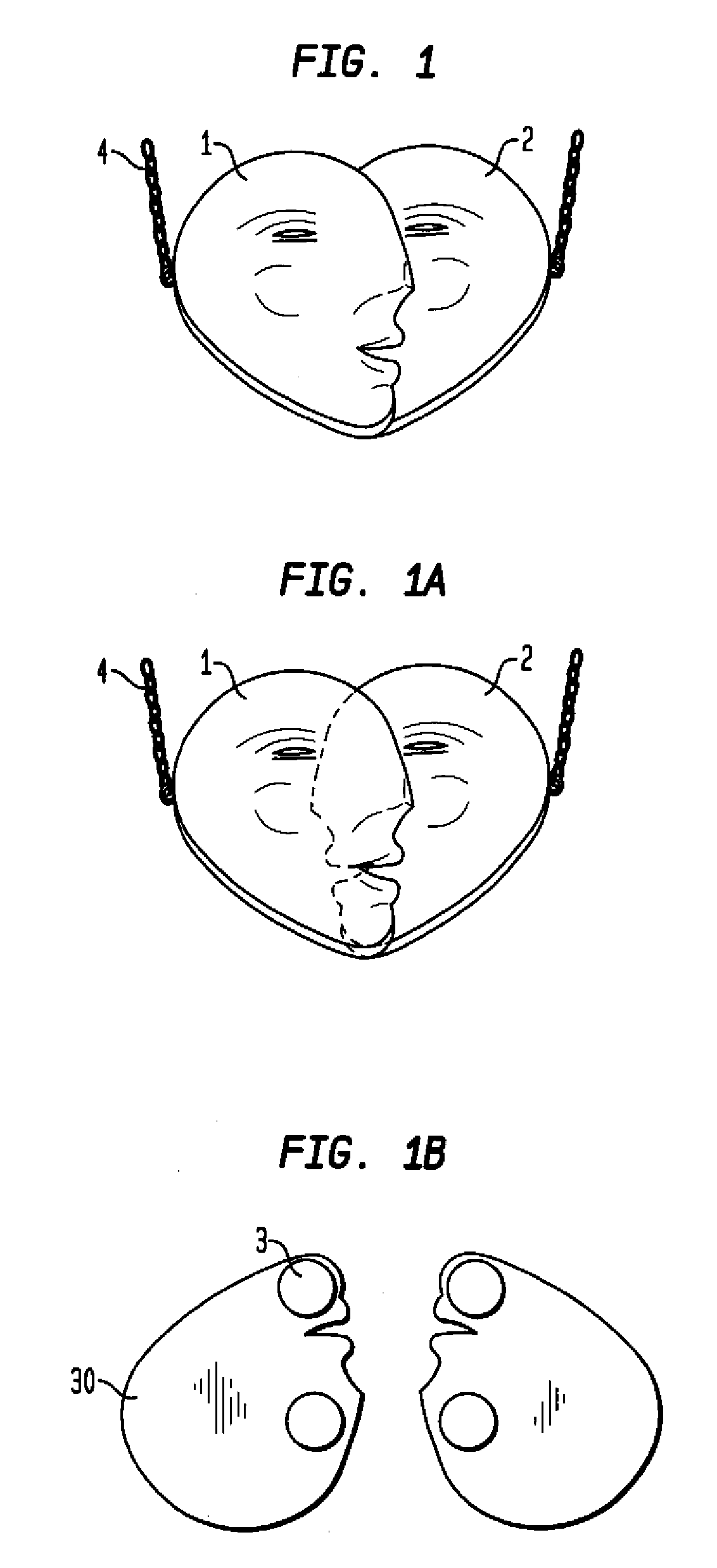

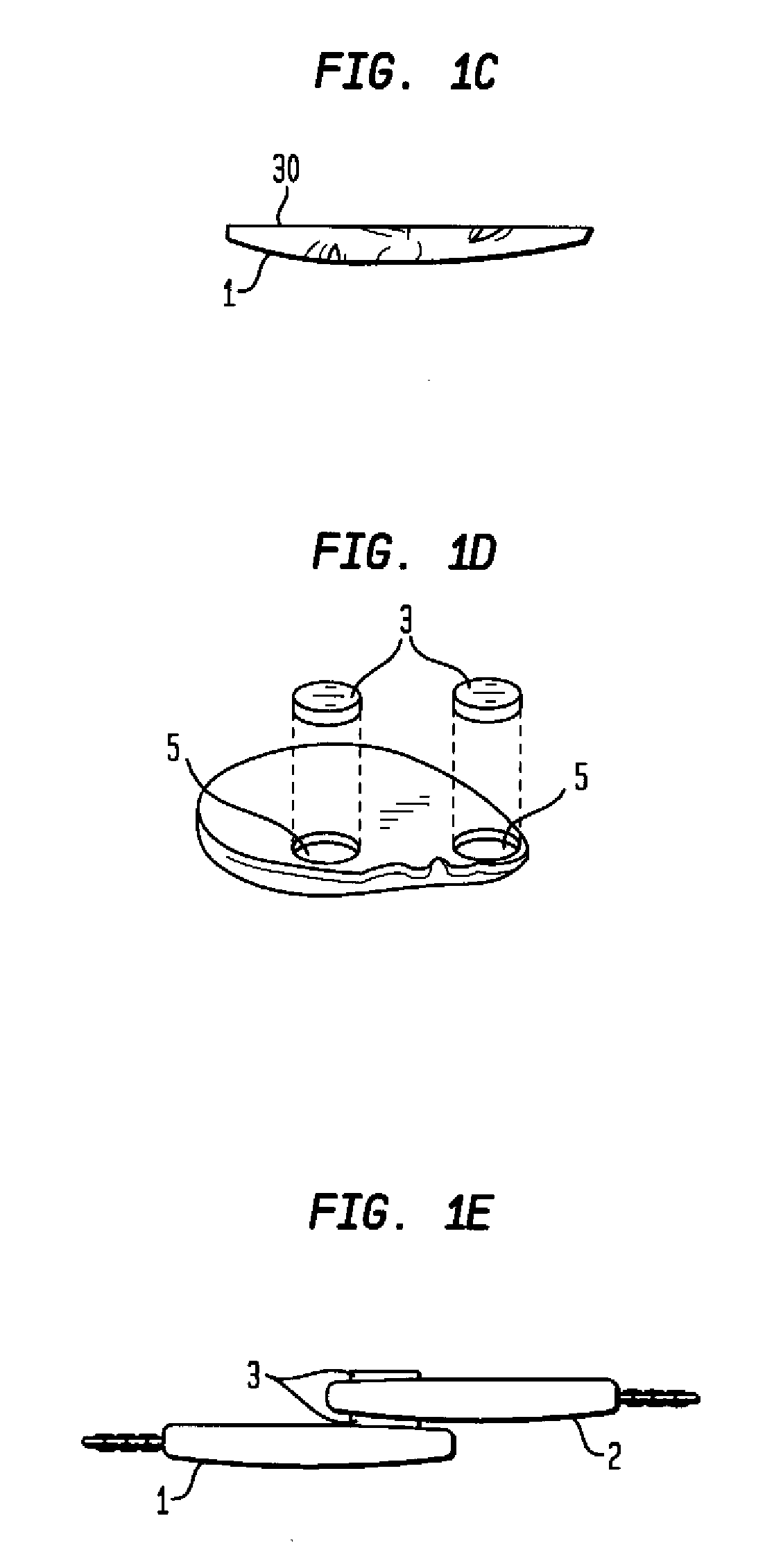

Split piece of jewelry

InactiveUS7654110B2Undesired movement is also preventedImprove connectivitySnap fastenersClothes buttonsMagnetEngineering

Owner:HB CONCEPTS

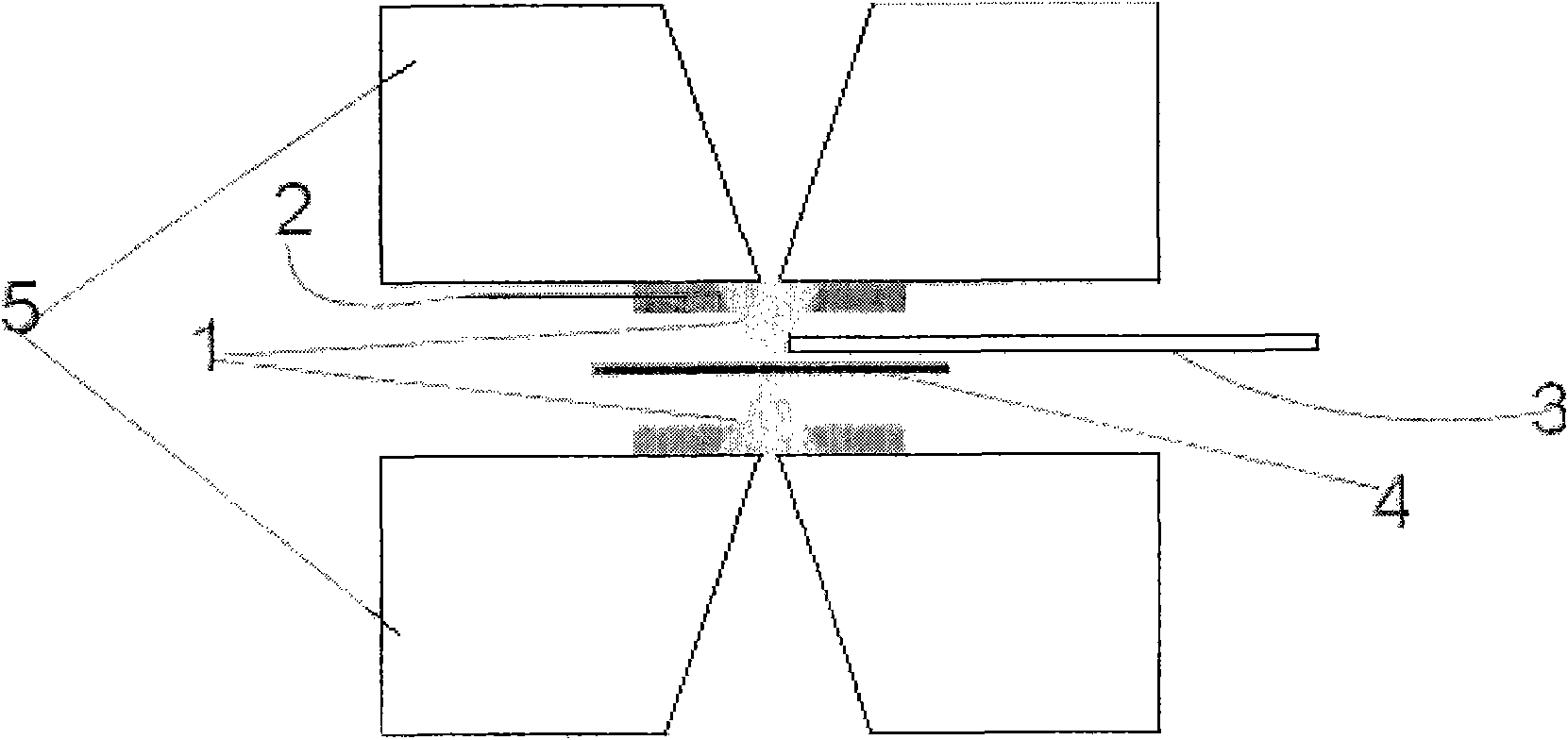

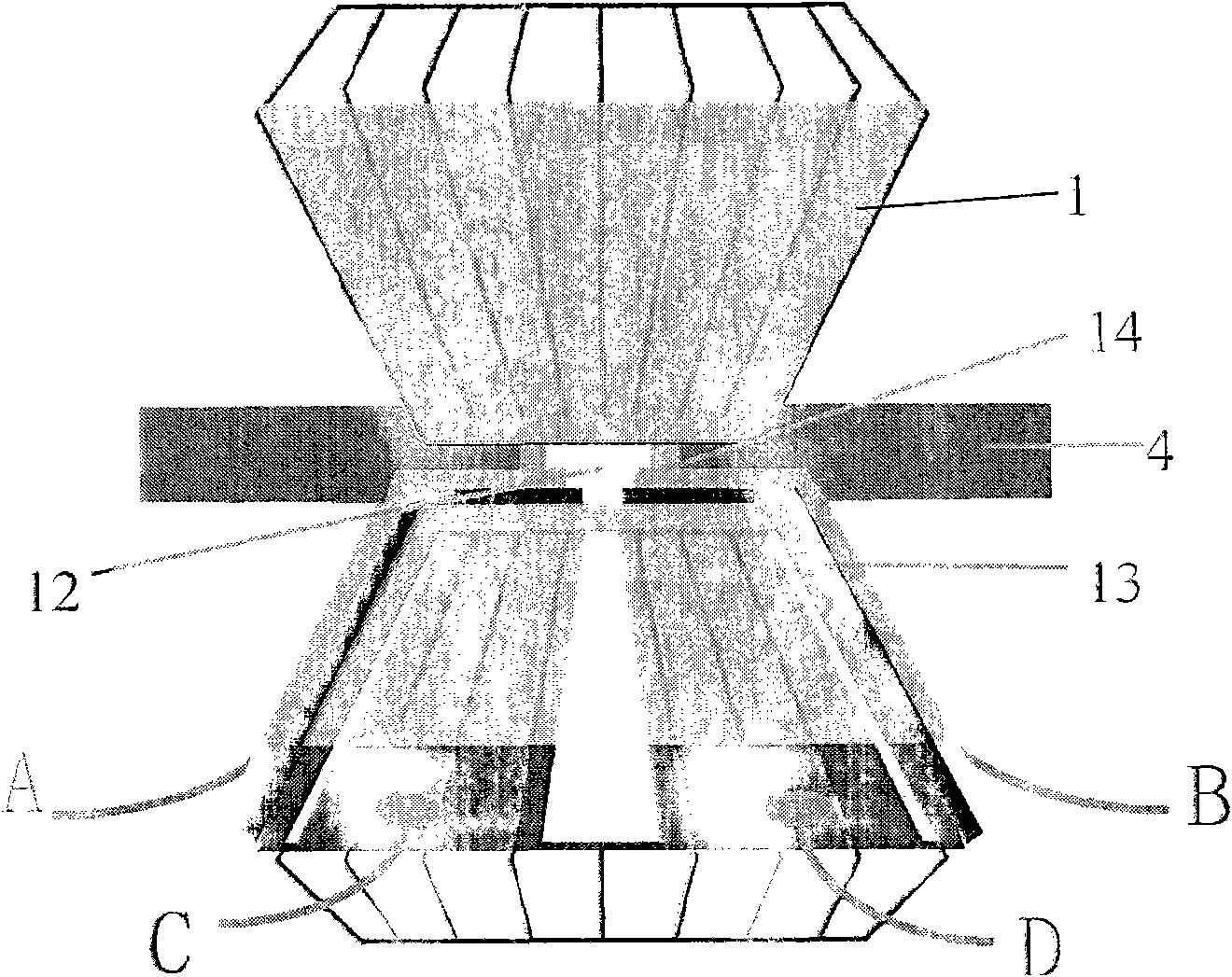

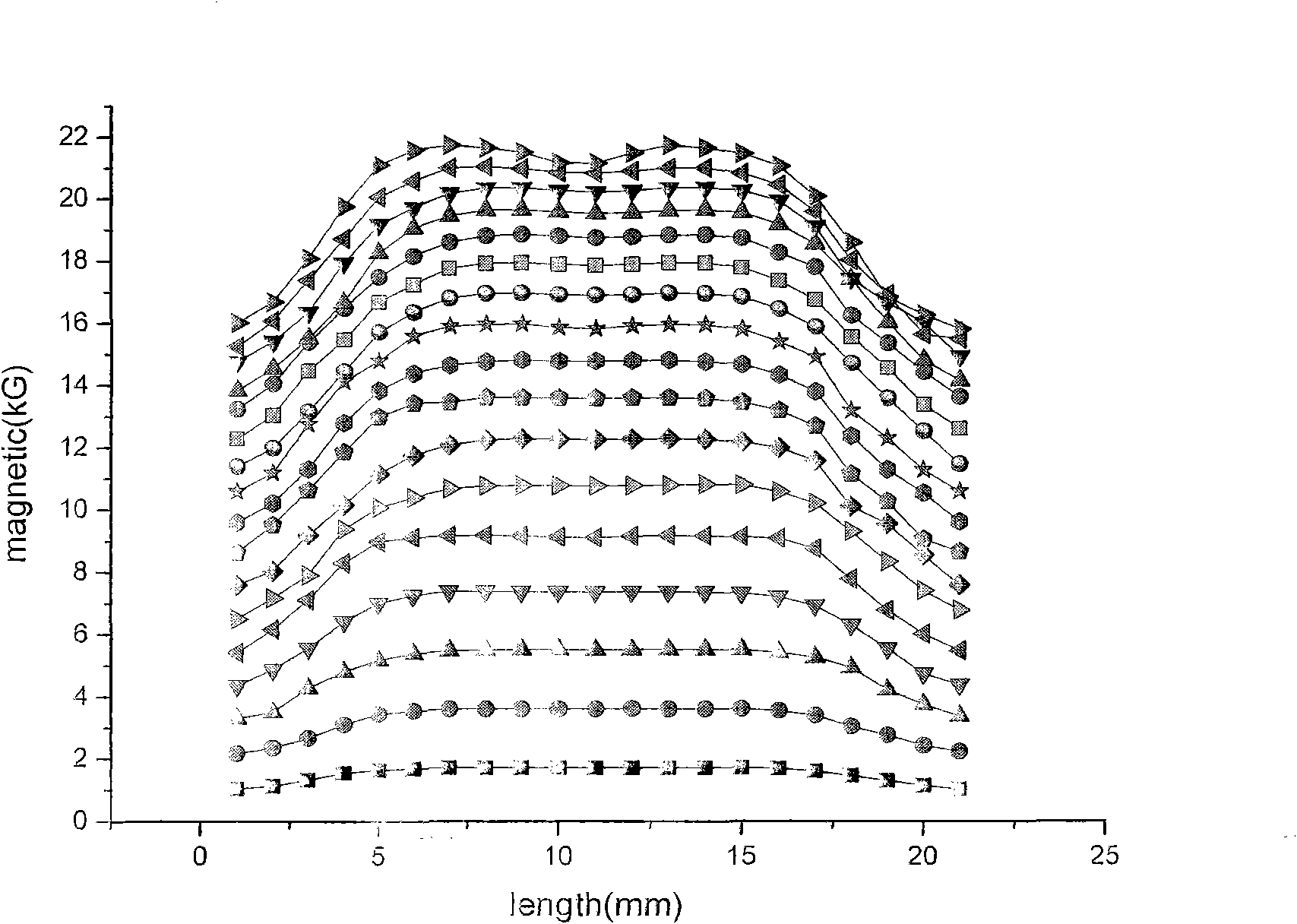

Measuring method of magnetic resistivity of substance under the condition of high voltage

InactiveCN101900762AEasy to cutAvoid deformationResistance/reactance/impedenceMetal electrodesContact resistance

The invention relates to a measuring method of the magnetic resistivity of a substance under the condition of high voltage, belonging to the technical field of measurement of physical quantities. The magnetic resistivity of the substance is measured on diamond anvil cells of a metal film electrode (13) on the basis of the van der pauw resistance measurement method according to the following test steps of: assembling equipment; regulating a magnetic field; carrying out the in-site measurement of magnetic field strength; measuring the magnetic resistivity; and the like. The metal film electrode (13) is deposited on one the used diamond anvil cells; a pressing machine (5) and a spacer (4) are both made of nonmagnetic materials; and only a shaking table (2) is made of steel materials. The invention mainly obtains the technical effect of accurately measuring the magnetoresistance effect of a sample under the condition of the high voltage, establishes a nonmagnetic measurement environment, provides a uniform magnetic field on space for the sample, eliminates the influences of lead resistance and contact resistance and carries out the in-site measurement on the magnetic field strength inside a cavity of the sample; and in addition, the used metal electrode (13) can bear high pressure without being cut easily.

Owner:JILIN UNIV

Split Piece of Jewelry

InactiveUS20080066267A1Eliminate needUndesired movement is also preventedSnap fastenersClothes buttonsEngineeringMagnet

Owner:HB CONCEPTS

Packaging container having product holding chambers and method for making the same

InactiveUS20100170821A1Improve rigidityNot easy to cutSmall article dispensingPharmaceutical containersGraphicsPaper sheet

A packaging container for displaying and housing products that is aesthetically pleasing, effective and safe to open. The packaging container may include a substantially tear-resistant housing that encloses a tray that is preferably made from a paper material. The tray is substantially opaque to display graphics and / or to prevent viewing of the contents and may be seamless. The tray also may include at least one raised area extending around the walls of the tray. A second tray may also be used to create a dual-sided tray for housing the products, wherein the second tray may be substantially opaque or substantially transparent. An insert card may be used within the housing to reinforce the container and may be contained by fold-over edges of the housing.

Owner:COLBERT PACKAGING CORP

Foam glass insulation and photovoltaic decoration integrated panel and preparation method thereof

ActiveCN103410289ALow thermal conductivityGood thermal performanceRoof covering using slabs/sheetsRoof covering using tiles/slatesThermal insulationGreen building

The invention discloses a foam glass insulation and photovoltaic decoration integrated panel and a preparation method thereof. The integrated panel comprises an insulation layer and a photovoltaic decoration layer, the insulation layer is a foam glass insulation board and is wrapped by a waterproof rolling material in a sealing way, and the photovoltaic decoration layer comprises a flexible film battery component, a film layer and a coating layer in sequence from inside to outside. The integrated panel has fire resistance, flame-retardant performance and good durability, thermal insulation and photovoltaic power generation can be realized, and the integrated panel complies with green building concepts such as energy conservation, emission reduction and zero power consumption.

Owner:湖北亚细亚陶瓷有限公司 +1

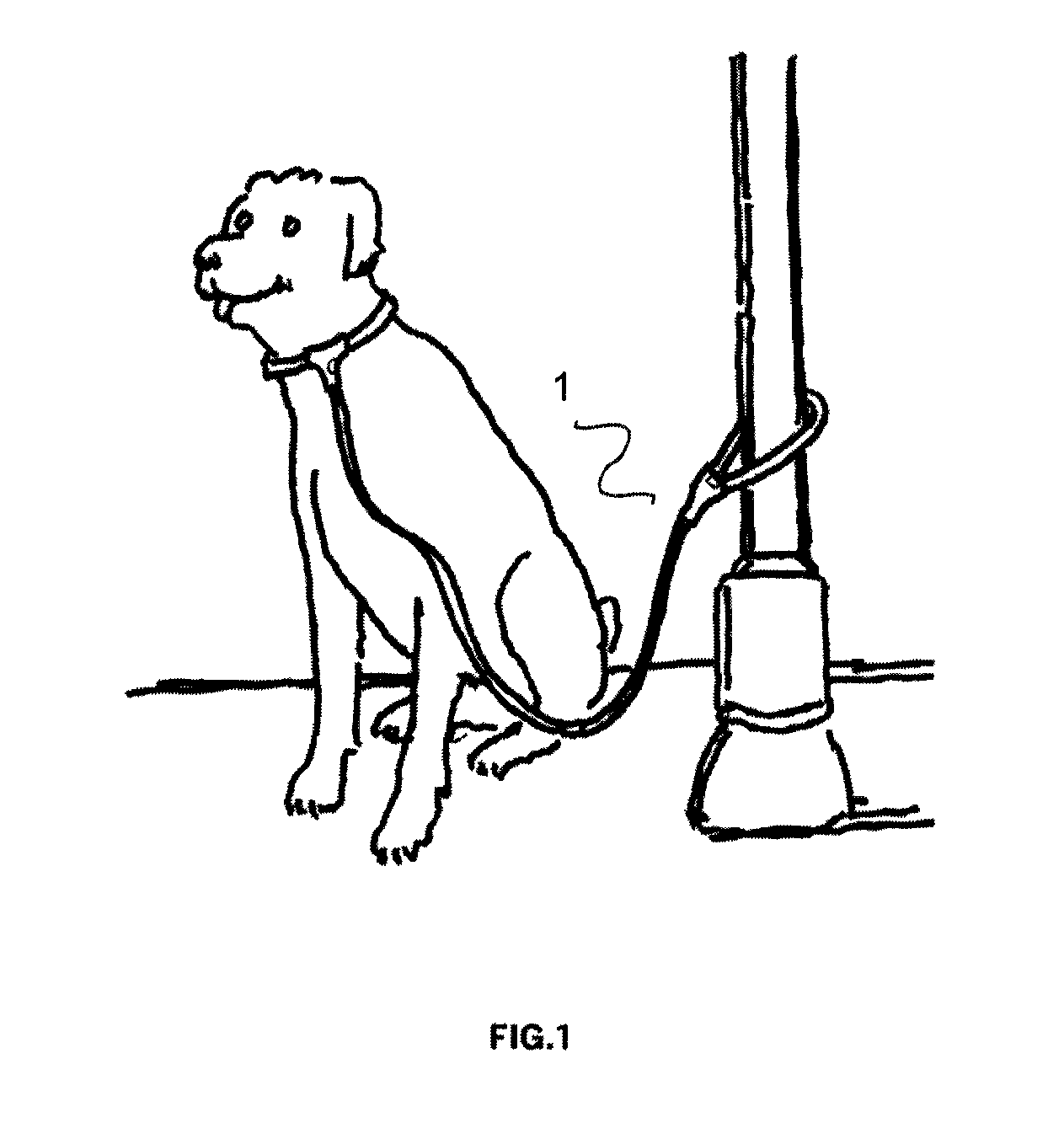

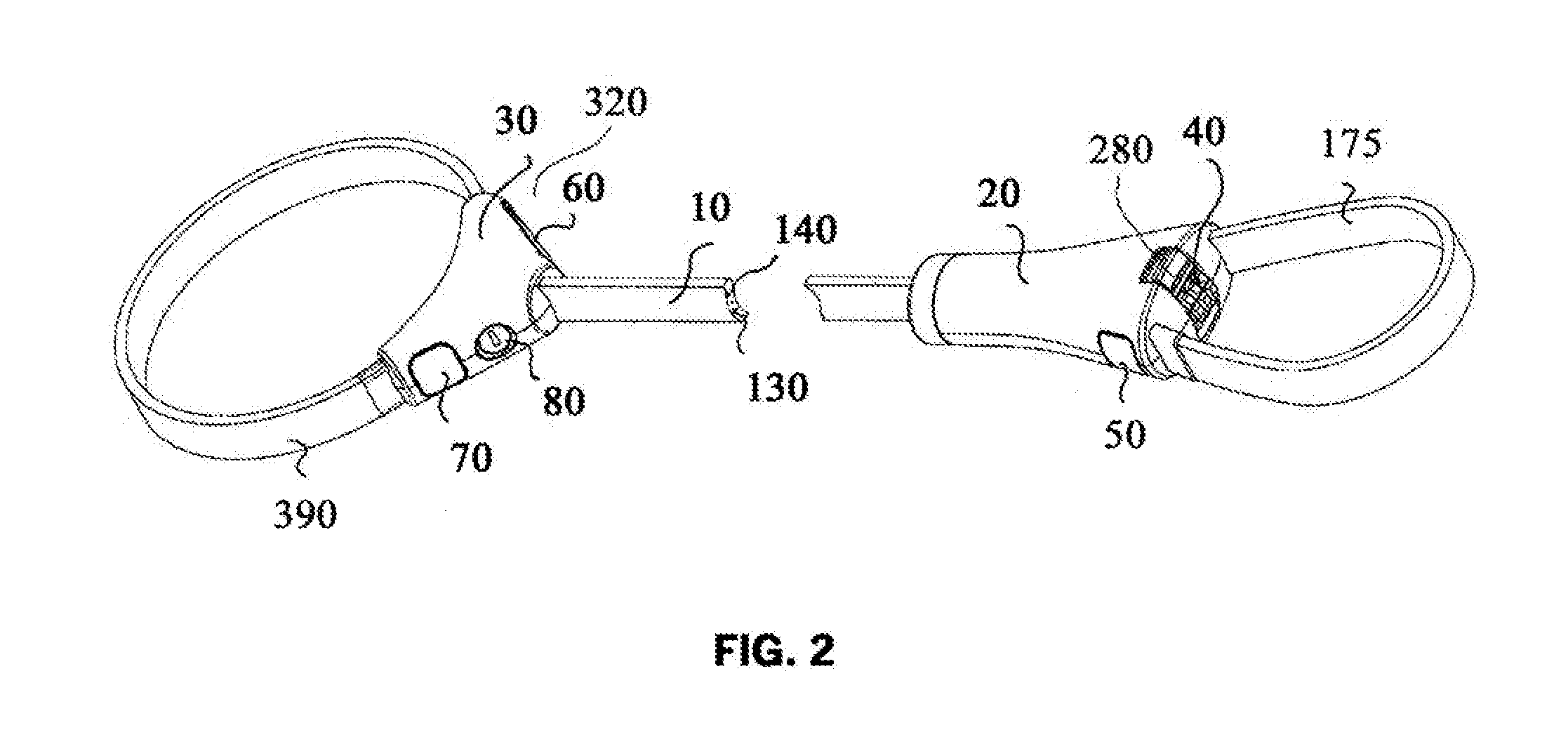

Locking pet lead system comprising a leash and collar to prevent the theft of pets

ActiveUS8683959B2Ease of usePrevent theftClothing locksLocks for portable objectsAnimal scienceMedicine

A lead system for domesticated animals has a lock capable of securing the collar and the handle ends to prevent theft of the animal. The lead system has a leash having a handle at one end and a collar at the opposing end. The lead system may have a first lock at the collar end and a second lock at the handle end which are separately activated for fastening the handle to the leash at one end of the leash and the collar to the leash at the other end for securing an animal to an immovable object. Alternatively, the lead system may have a lock capable of simultaneously securing the collar and handle ends. The lead system may also allow for adjustment of the circumference of the collar and the handle through the use of levers, with the lock(s) capable of also securing the levers.

Owner:SIRIUS PAWZ OPCO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com