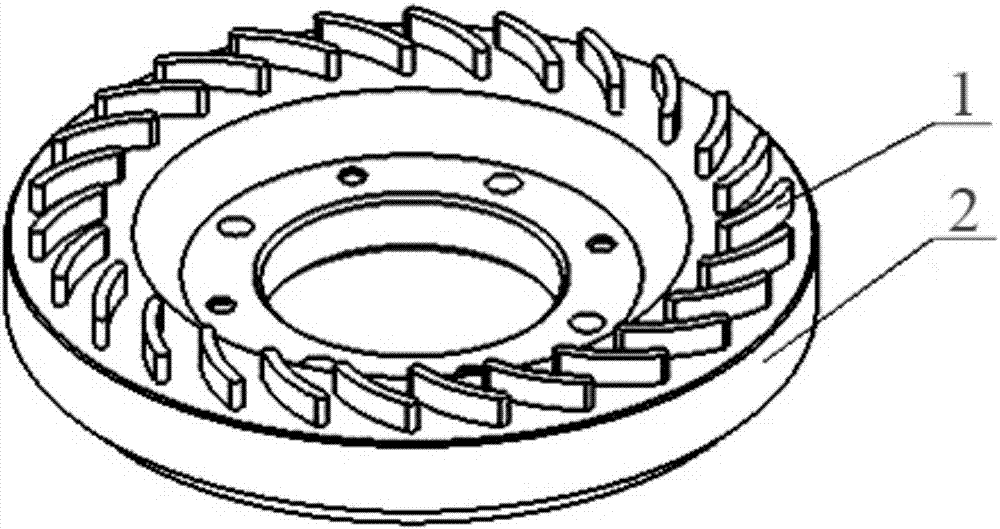

Metallic bond, diamond grinding wheel prepared through bond and preparation method of diamond grinding wheel

A metal bond, diamond grinding wheel technology, applied in the field of diamond grinding wheels, can solve the problems of low grinding efficiency, insufficient diamond holding force, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

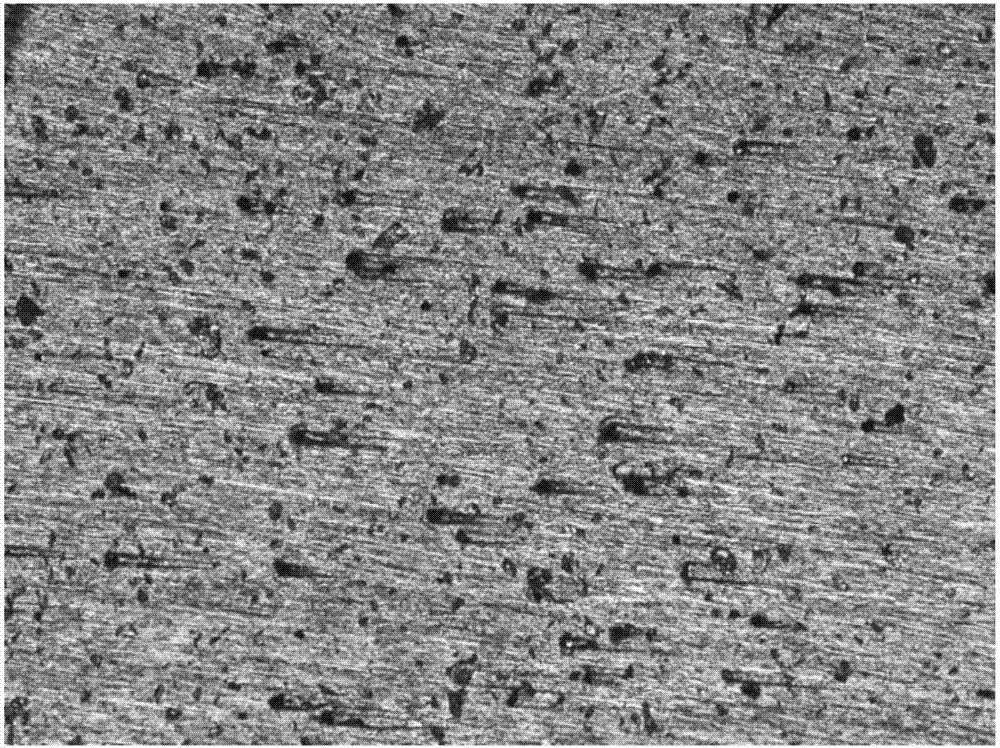

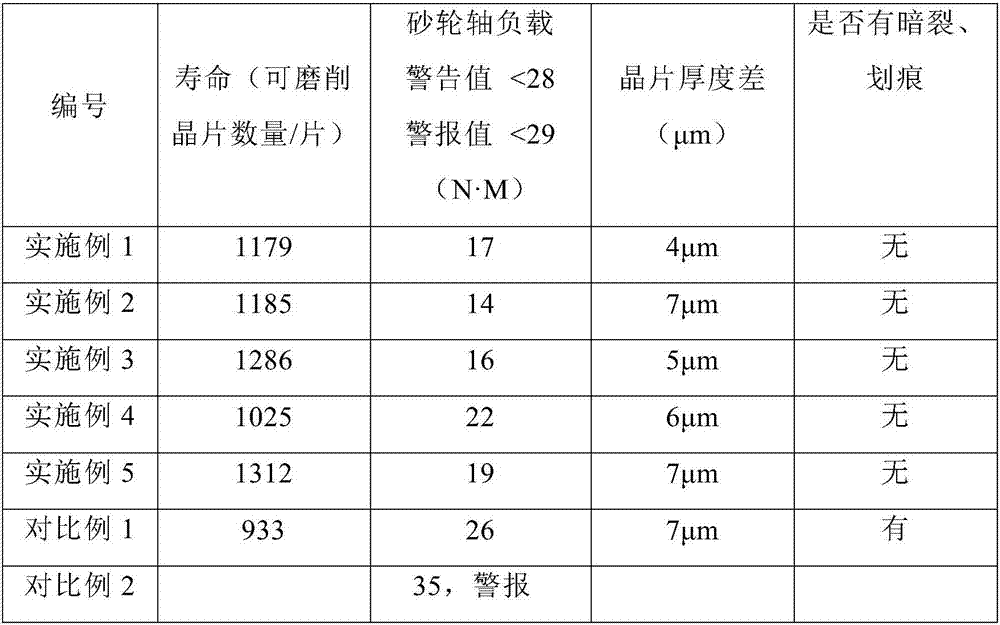

Examples

Embodiment 1

[0049] The components and proportions of the metal binder used in this embodiment are as follows: 96.5wt% of copper-tin pre-alloyed powder (CuSn40, wherein the weight percentage of Sn is 40wt%, and the rest is Cu) with a particle size of 20-50 μm, the particle size Graphite powder 3wt% with a diameter of 20-70μm, nano α-Al 2 o 3 0.5 wt%.

[0050] (1) Batching and mixing: according to the above weight percentage, get 96.5% of the copper-tin pre-alloyed powder (CuSn40, wherein the weight percentage of Sn is 40% of Sn, and the rest is Cu) with a particle size of 20-50 μm, and 3% of the particle size is 20 - 70μm graphite powder, and 0.5% nano α-Al 2 o 3 Mix together, pass through 80 mesh sieve, take the undersieve, add Zhan CuSn40, graphite powder and nano α-Al 2 o 3 The total mass of 2% glycerol alcohol solution (glycerin, alcohol ratio is 1:4), and put it into a three-dimensional mixer for mixing for 1 hour. Then add diamond with a concentration of 50% (made at 400% conc...

Embodiment 2

[0057] The components and proportioning of the metal binder used in the present embodiment are as follows: the copper-tin pre-alloyed powder (CuSn45, wherein the weight percentage of Sn is 45%, and the rest is Cu) 98wt% with a particle diameter of 20-50 μm. 20-70μm graphite powder 1wt%, nano α-Al 2 o 3 1 wt%.

[0058] (1) Batching and mixing: according to the above percentage by weight, 98% of the particle size is 20-50 μm copper-tin pre-alloyed powder (CuSn45, wherein the weight percentage of Sn is 45%, and the rest is Cu), 1% of the particle size is 20 - 70μm graphite powder, and 1% nano α-Al 2 o 3 Mix together, pass through 80 mesh sieve, take the undersieve, add Zhan CuSn40, graphite powder and nano α-Al 2 o 3 The total mass of 2% glycerol alcohol solution (glycerin, alcohol ratio is 1:4), and put it into a three-dimensional mixer for mixing for 1 hour. Then add diamond with a concentration of 45% (made according to 400% concentration) and a particle size of 20-30 μ...

Embodiment 3

[0065] The components and proportions of the metal binder used in this embodiment are as follows: 97.5wt% of copper-tin pre-alloyed powder (CuSn50, wherein the weight percentage of Sn is 50%, and the rest is Cu) with a particle size of 20-50 μm. 0.5wt% of graphite powder with a diameter of 20-70μm, and 2wt% of nanometer α-Al2O3.

[0066] (1) Batching and mixing: according to the above weight percentage, get 97.5% of the copper-tin pre-alloyed powder (CuSn50, wherein the weight percentage of Sn is 50% of Sn, and the rest are Cu) with a particle size of 20-50 μm, and 0.5% of the particle size is 20 - 70μm graphite powder, and 2% nano α-Al 2 o 3 Mix together, pass through 80 mesh sieve, take the undersieve, add Zhan CuSn40, graphite powder and nano α-Al 2 o 3 The total mass of 2% glycerol alcohol solution (glycerin, alcohol ratio is 1:4), and put it into a three-dimensional mixer for mixing for 1 hour. Then add diamond with a concentration of 40% (made according to 400% conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com