Foam glass insulation and photovoltaic decoration integrated panel and preparation method thereof

A foam glass and thermal insulation board technology is applied in chemical instruments and methods, photovoltaic power generation, glass/slag layered products, etc. The effect of strong resistance, high tensile strength and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

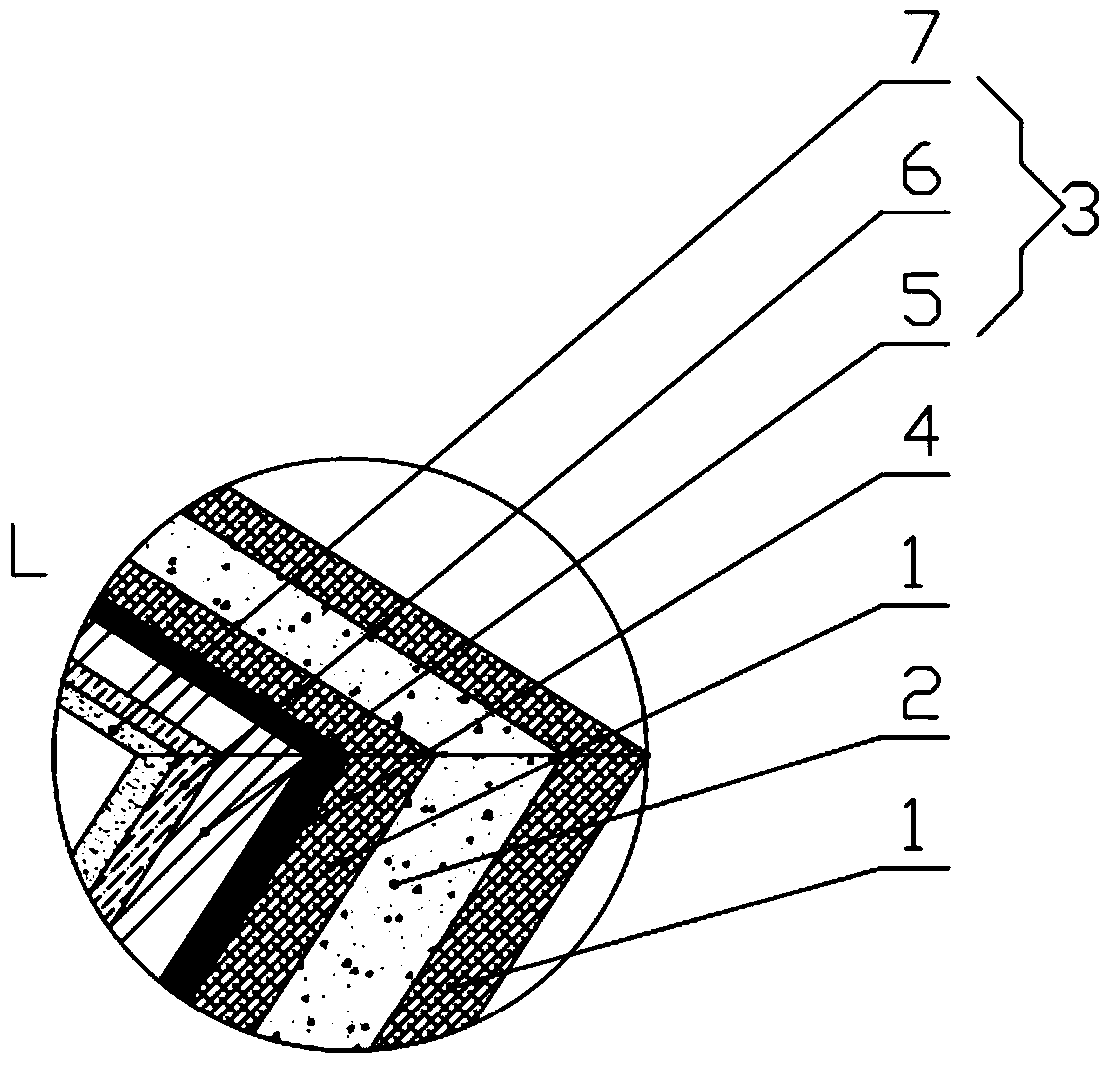

[0027] The integrated plate of the present invention is as figure 1 with figure 2 As shown, it includes a thermal insulation layer 2 and a photovoltaic decorative layer 3. The thermal insulation layer 2 is a foam glass thermal insulation board with a thickness of 30mm and is sealed and wrapped by a waterproof coiled material 1. The waterproof coiled material 1 is composed of tire base and polymer cement mortar Composite, with a thickness of 2 mm, the tire base is a composite felt of polyester-cotton non-woven fabric and glass fiber grid cloth. The photovoltaic decoration layer 3 includes a flexible thin film battery component 5, a film layer 6 and a paint layer 7 from the inside to the outside; the flexible thin film battery component 5 is an amorphous silicon flexible solar thin film battery; the film layer 6 is a fluorine-containing TPT polyester film or ethylene-tetrafluoroethylene copolymer (ETFE) film with a thickness of 250um; the coating layer 7 is coated with a self-...

Embodiment 2

[0030] The insulation layer 2 of the integrated board of the present invention has a foam glass insulation board thickness of 60mm, the thickness of the waterproof coiled material 1 is 2.5mm, the flexible thin film battery assembly 5 is a copper indium potassium selenium thin film solar cell, and the coating Layer 7 has a thickness of 50um, and the others are the same as in Embodiment 1.

Embodiment 3

[0032] The insulation layer 2 of the integrated board of the present invention has a foam glass insulation board thickness of 50mm, the thickness of the waterproof coiled material 1 is 1.5mm, the flexible thin film battery assembly 5 is a dye-sensitized battery, and the thickness of the coating layer 7 is Be 70um, other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com