High-strength reinforcing steel bar with spiral fins and processing method of high-strength reinforcing steel bar

A processing method and technology of ribbed steel bars, which are applied in the field of high-strength spiral rib steel bars and their processing, can solve the problems of poor ductility of spiral rib steel wires, inability to connect spiral rib steel wires with threads, and a narrow range of use, and achieve high anchoring strength and rigidity. Anchorage performance, good for anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

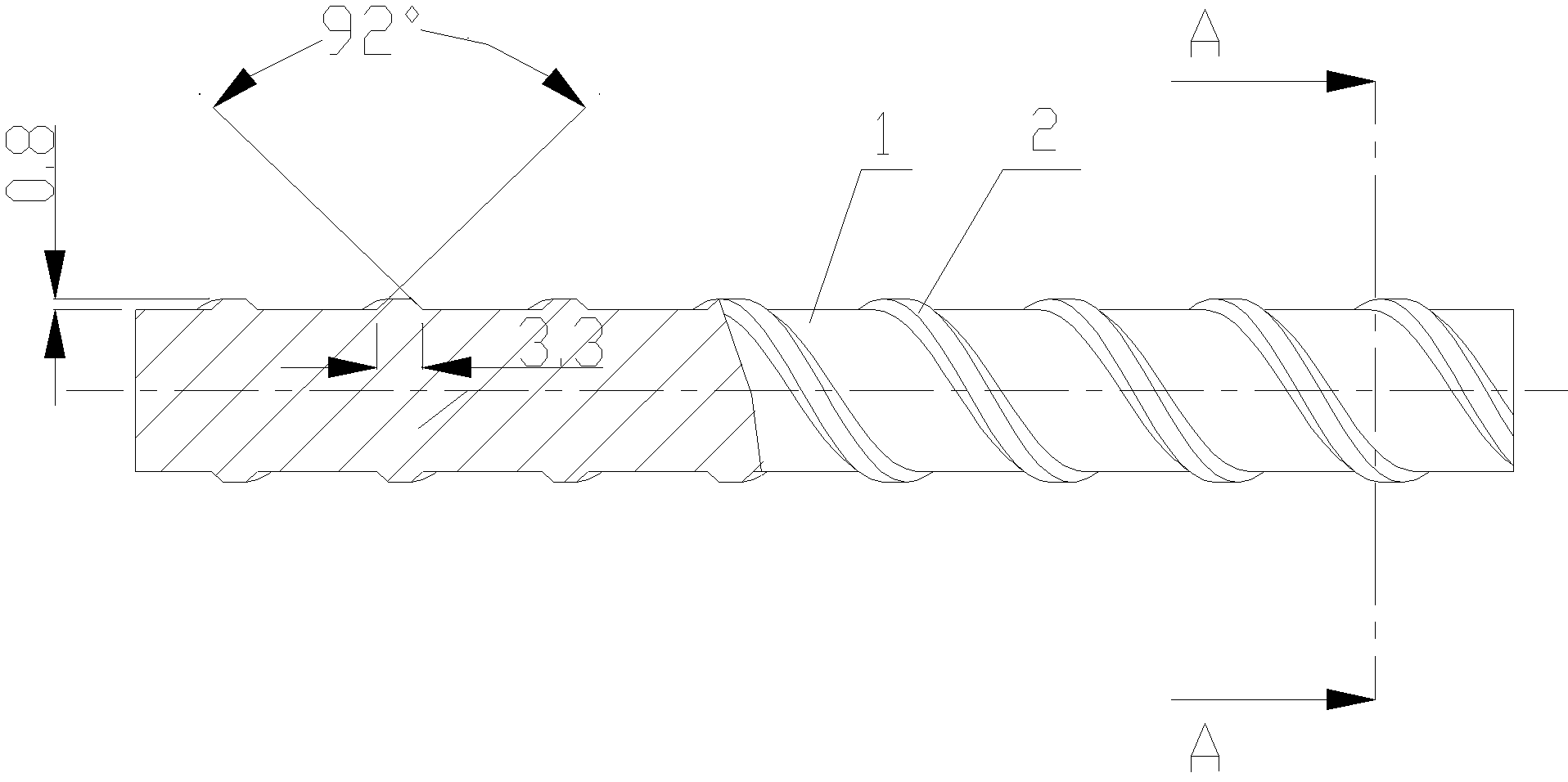

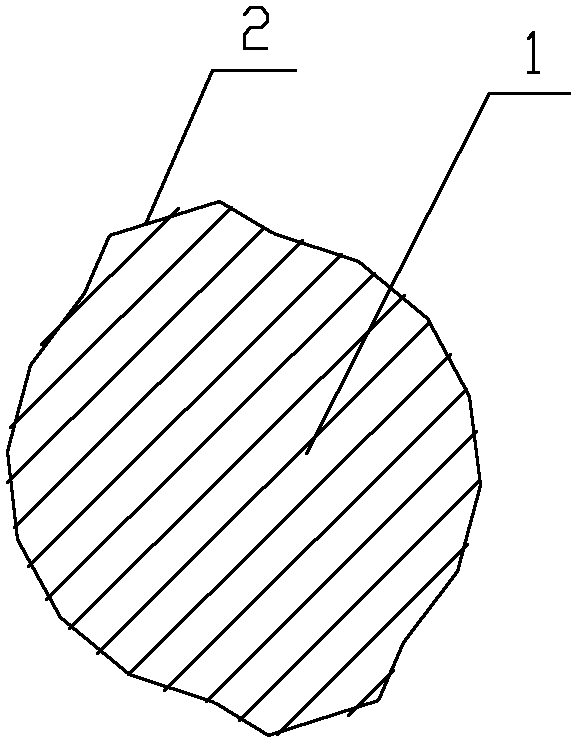

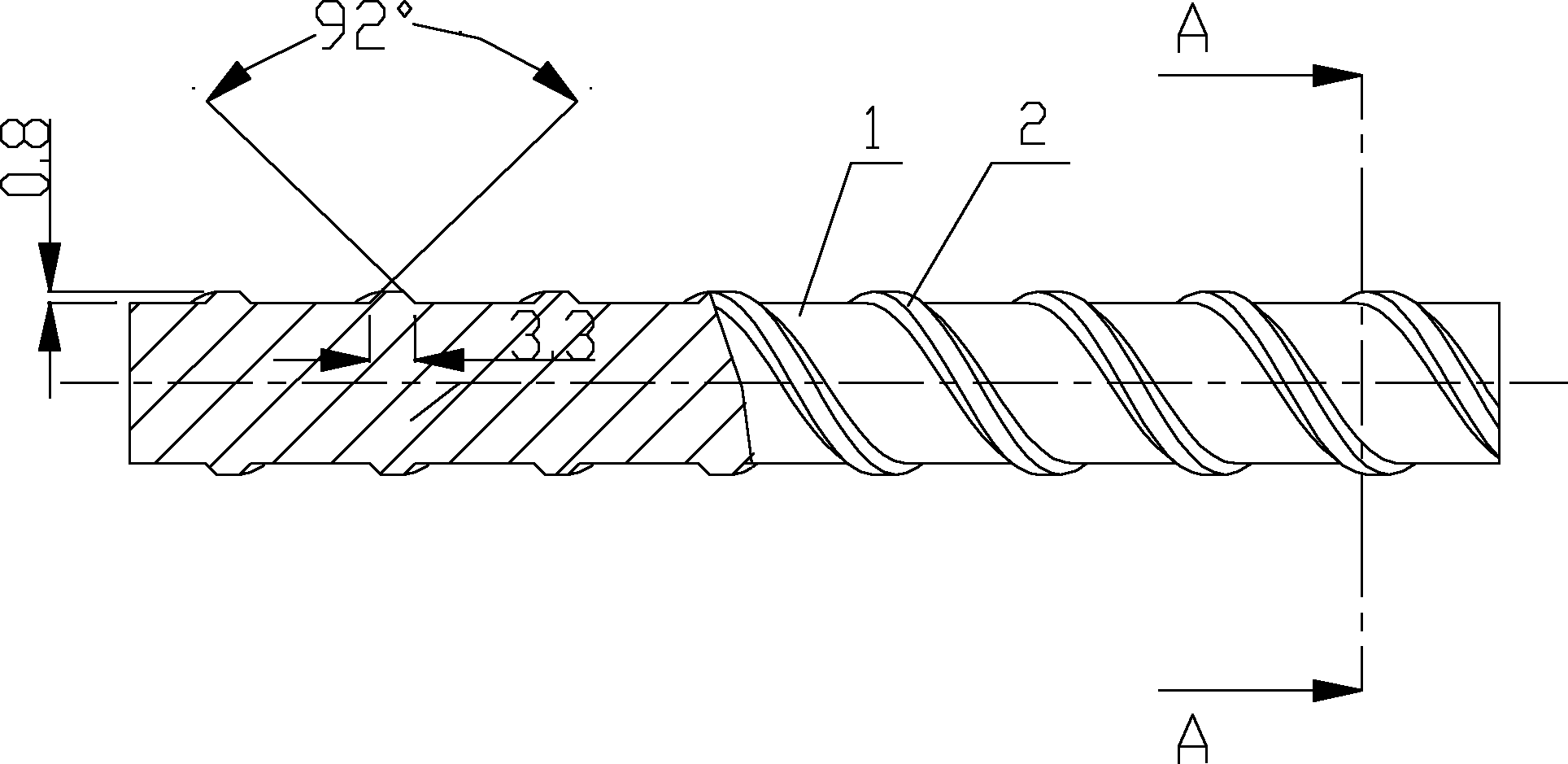

[0030] This embodiment proposes a high-strength spiral rib steel bar, the structure shown in 1, including a steel bar body 1 and two spiral ribs 2 on the surface of the steel bar body, the spiral ribs 2 are continuously distributed on the surface of the steel bar body, and each continuous spiral rib 2 The angle between the two tangent lines between the two sides and the surface of the steel bar is 90°, and the width of each continuous spiral rib is 3mm and the height is 0.5mm.

[0031] The high-strength spiral rib steel bar of this embodiment contains the following components by weight percentage: C: 0.25%, Si: 0.1%, Mn: 0.3%, Nb: 0.04%, Cr: 0.08%, V: 0.01%, B: 0.002 %, Mo: 0.001%, Al: 0.015%, S: 0.002%, Ti: 0.008%, Ni: 0.004%, compound rare earth: 3%, and the balance is Fe. In the composite rare earth, the following components are contained by weight percentage: La: 25%, Ce: 20%, Y: 8%, Sc: 12%, Gd: 5%, Sm: 5%, Dy: 5%, Pr: 20 %.

[0032] The processing method of high-streng...

Embodiment 2

[0037] This embodiment proposes a high-strength spiral rib steel bar, the structure shown in 1, including a steel bar body 1 and two spiral ribs 2 on the surface of the steel bar body, the spiral ribs 2 are continuously distributed on the surface of the steel bar body, and each continuous spiral rib 2 The angle formed by the two tangent lines between the two sides and the reinforcement surface is 92°, and the width of each continuous spiral rib is 3.3mm and the height is 0.7mm.

[0038] The high-strength spiral rib steel bar of this embodiment contains the following components by weight percentage: C: 0.3%, Si: 0.15%, Mn: 0.4%, Nb: 0.045%, Cr: 0.085%, V: 0.03%, B: 0.0025 %, Mo: 0.002%, Al: 0.025%, S: 0.0025%, Ti: 0.0085%, Ni: 0.0045%, compound rare earth: 4%, and the balance is Fe. In the composite rare earth, the following components are contained by weight percentage: La: 33%, Ce: 17%, Y: 5%, Sc: 10%, Gd: 5%, Sm: 7%, Dy: 3%, Pr: 20 %.

[0039] The processing method of high...

Embodiment 3

[0044] This embodiment proposes a high-strength spiral rib steel bar, the structure shown in 1, including a steel bar body 1 and two spiral ribs 2 on the surface of the steel bar body, the spiral ribs 2 are continuously distributed on the surface of the steel bar body, and each continuous spiral rib 2 The angle between the two tangent lines between the two sides and the steel bar surface is 95°, and the width of each continuous spiral rib is 3.5mm and the height is 0.9mm.

[0045] The high-strength spiral rib steel bar of this embodiment contains the following components by weight percentage: C: 0.4%, Si: 0.2%, Mn: 0.45%, Nb: 0.05%, Cr: 0.09%, V: 0.04%, B: 0.003 %, Mo: 0.003%, Al: 0.03%, S: 0.003%, Ti: 0.009%, Ni: 0.005%, compound rare earth: 5%, and the balance is Fe. In the composite rare earth, the following components are contained by weight percentage: La: 35%, Ce: 15%, Y: 7%, Sc: 11%, Gd: 4%, Sm: 6%, Dy: 4%, Pr: 18 %.

[0046] The processing method of high-strength spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com