Semiconductor material equipment based on industrialization

A semiconductor and equipment technology, applied in the field of semiconductor material equipment based on industrialization, can solve the problems of non-rotatable, manual rotation of the console, and the impact of semiconductor material processing and production, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

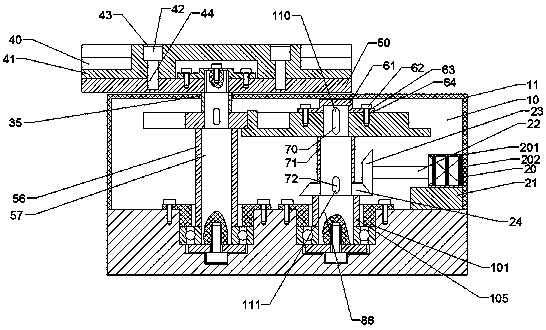

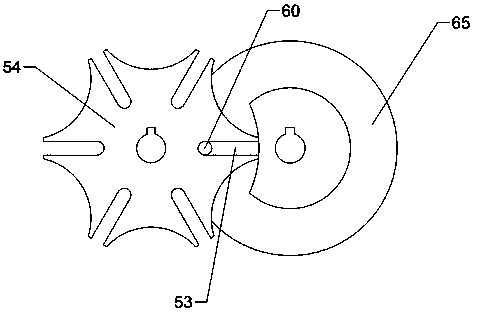

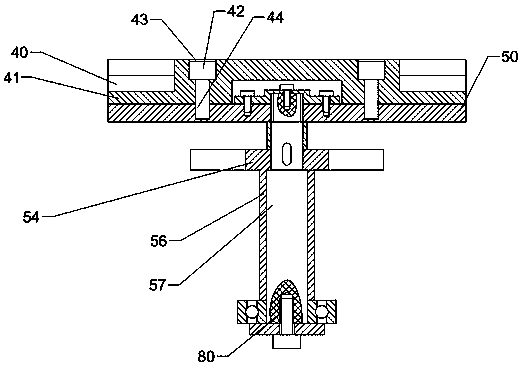

[0016] Combine below Figure 1-5 The present invention will be described in detail.

[0017] refer to Figure 1-5 According to an embodiment of the present invention, an industrialized semiconductor material equipment includes a first fixed plate 12 and an assembly box 11 fixedly installed on the first fixed plate 12, and the first fixed plate 12 has an inherent The first placement groove 103 and the second placement groove 101, the assembly box 11 has a steering chamber 10, the first fixing plate 12 is fixedly installed with an assembly block 21, and the motor 20 is fixed on the assembly block 21, The outer side of the motor 20 is provided with a bearing device, the bearing device includes a vibration-removing thick plate 201 and a heat-reducing aluminum sheet 202, the motor 20 is fixed with a steering shaft 22, and the first tapered edge is fixedly installed on the steering shaft 22 wheel 23, the first bevel wheel 23 is connected with the second bevel wheel 24, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com