Experimental vibrating table

A technology for vibrating tables and experiments, applied in the field of vibrating tables, can solve the problems of inconvenient disassembly and transfer of vibrating tables, difficulty in controlling the internal size of the vibrating machine, and unusable vibrating machines, etc., to achieve convenient disassembly and increased stability The effect of stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

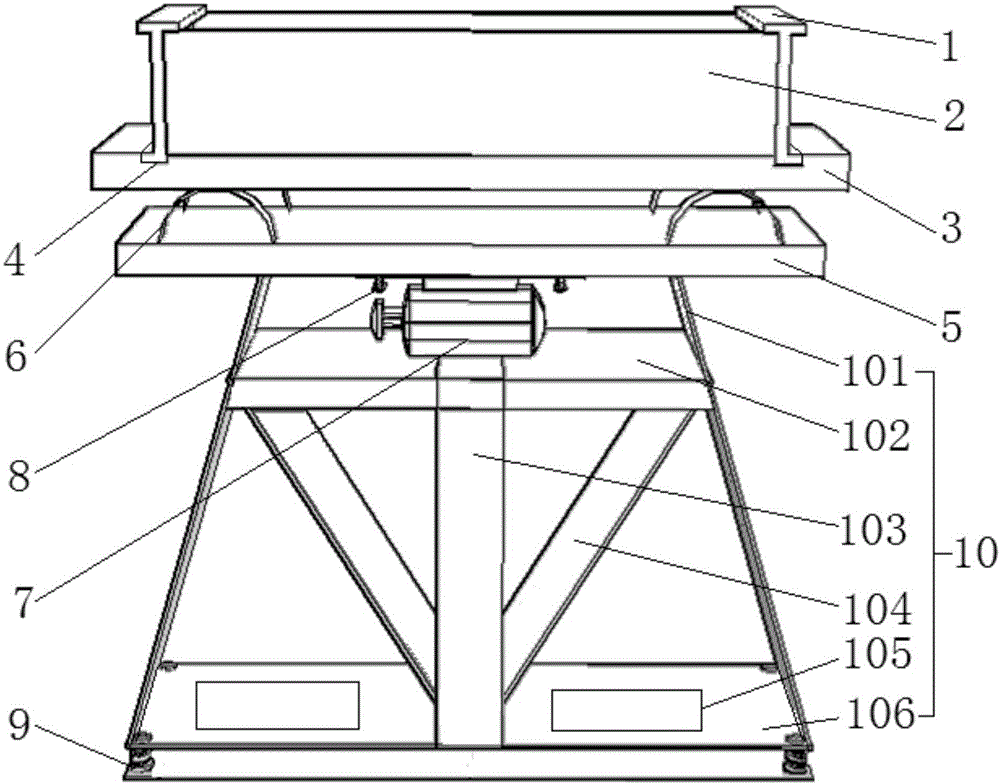

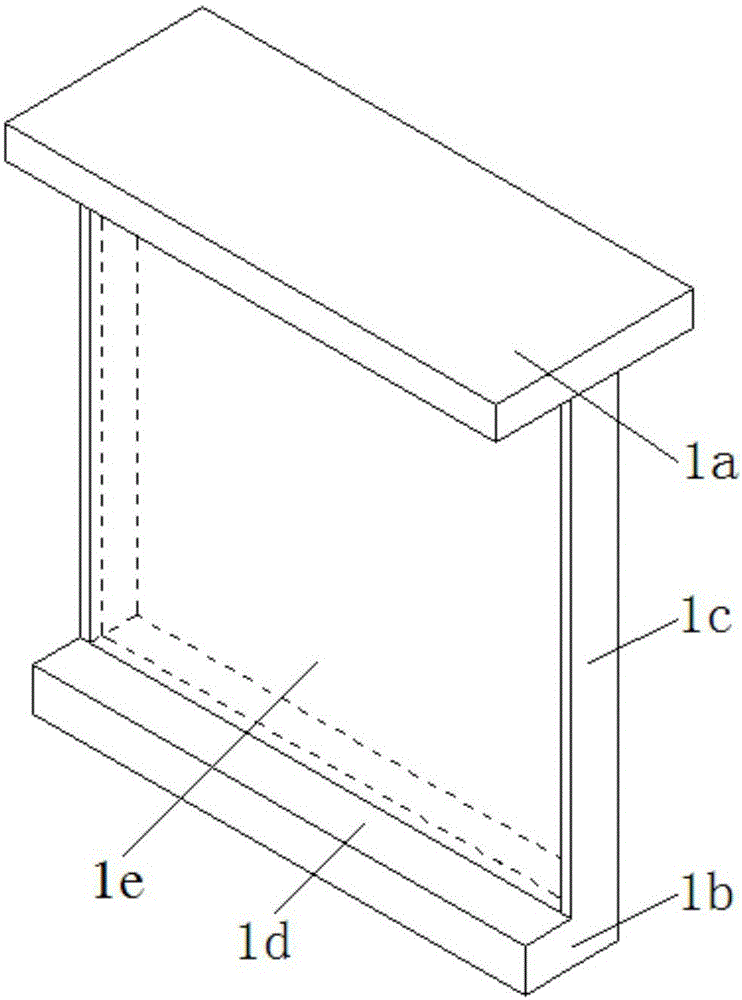

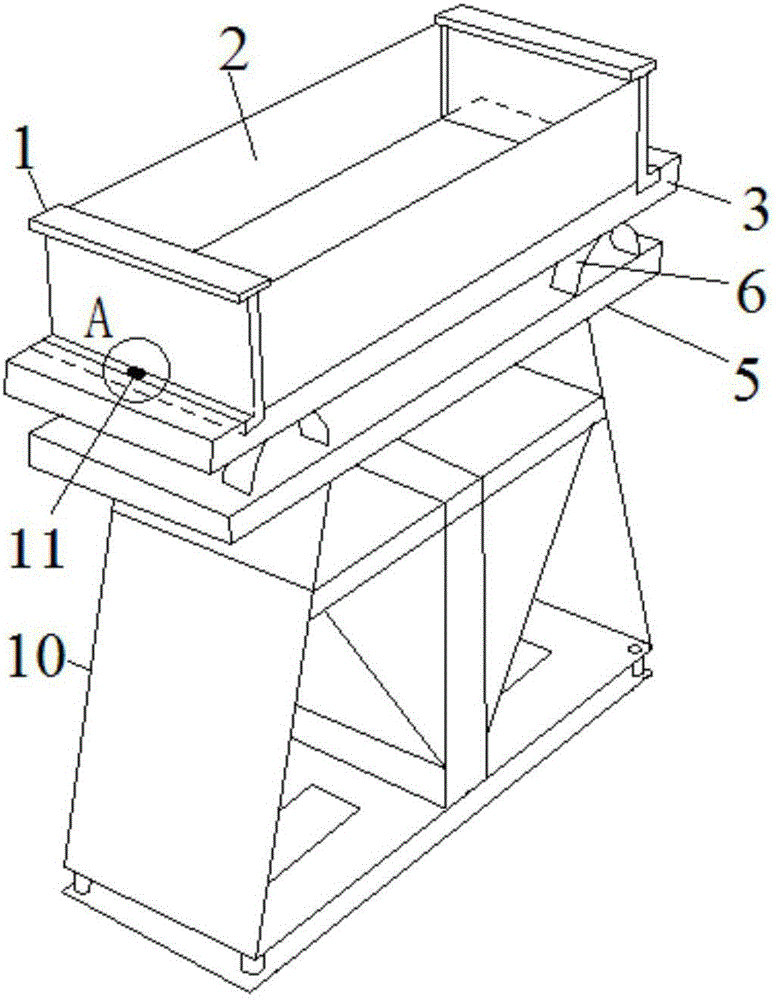

[0024] The experiment provided by the invention uses the vibrating platform, and its structure is as figure 1 and image 3 As shown, it includes a support table 10, a workbench 3, a base plate 5, a movable fixture 1, a test mold 2, a polarization motor 7 and 2 pairs of cushioning elements 6, and the polarization motor 7 and the workbench 3 pass through the base plate 5 and 2 pairs of cushioning elements. The shock element 6 realizes the transmission of the polarization force, the bottom plate 5 is supported by the support platform 10, the polarization motor 7 is located on the support platform and acts on the workbench, and is fixed on the lower surface of the bottom plate by the rivet 8, the polarization motor is a motor with multiple stages, supporting multiple Va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com