Variable-damping vibration damper for washing machine and washing machine

A vibration damping device and variable damping technology, applied in the field of washing machines, can solve problems such as abnormal vibration noise, loss of vibration damping effect, large vibration of washing machines, etc., and achieve the effect of improving vibration noise level, improving vibration damping performance, and good dehydration stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

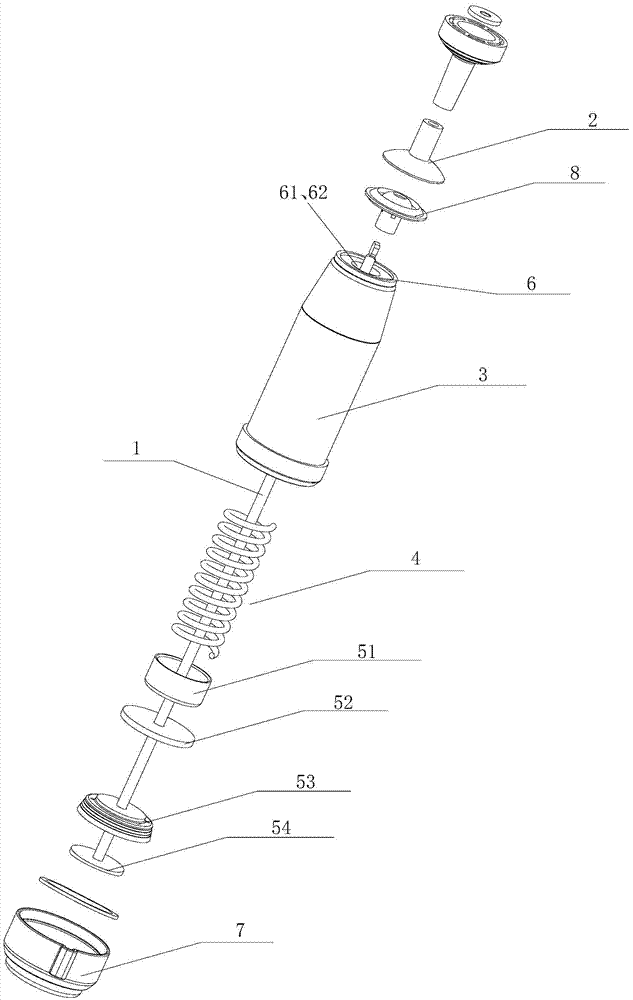

[0037] Such as Figure 4As shown, the upper surface of the tray 81 described in this embodiment is provided with an annular protrusion 84 along the outer periphery of the boom installation hole 83. The annular protrusion 84 is gradually lowered from the inside to the outside. The missing shape structure, the boom mounting hole 83 runs through the center, and the contact surface between the lower part of the upper support 2 and the upper surface of the tray 81 is a concave pressing surface matched with the ring-shaped protrusion 84 (refer to Figure 6 ), the annular protrusion 84 is the first variable damping structure 9 on the tray 81 .

[0038] Further, the first variable damping structure 9 is two concentric ring-shaped protrusions 84 on the inner and outer surfaces of the tray 81 .

Embodiment 2

[0040] Such as Figure 5 As shown, at least one compression bead 85 is provided on the peripheral wall of the support sleeve 82 described in this embodiment. The rib 85 is the second variable damping structure 10 on the support sleeve 82 . The upwardly extending end of the compression rib 85 is smoothly connected to the lower surface of the tray 81 .

[0041] Preferably, there are 4-6 compression ribs 85 uniformly distributed along the circumferential direction of the support sleeve 82 .

Embodiment 3

[0043] The difference between this embodiment and the second embodiment is that the outer diameter of the support sleeve gradually increases from bottom to top, and the upper end of the support sleeve and the lower surface of the tray smoothly transition (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com