Brick machine supporting plate

A pallet and brick machine technology, applied to rigid containers, containers, packaging, etc., can solve problems such as inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

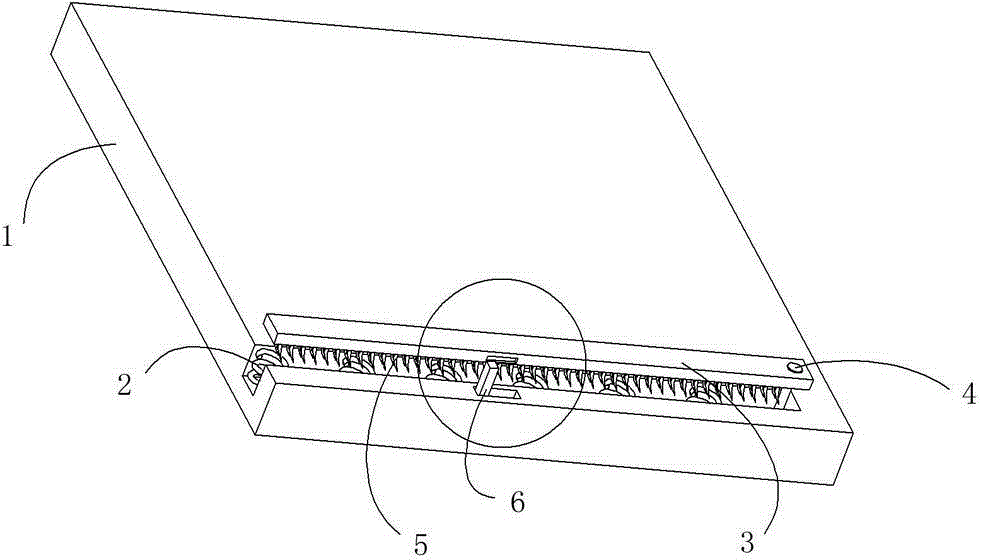

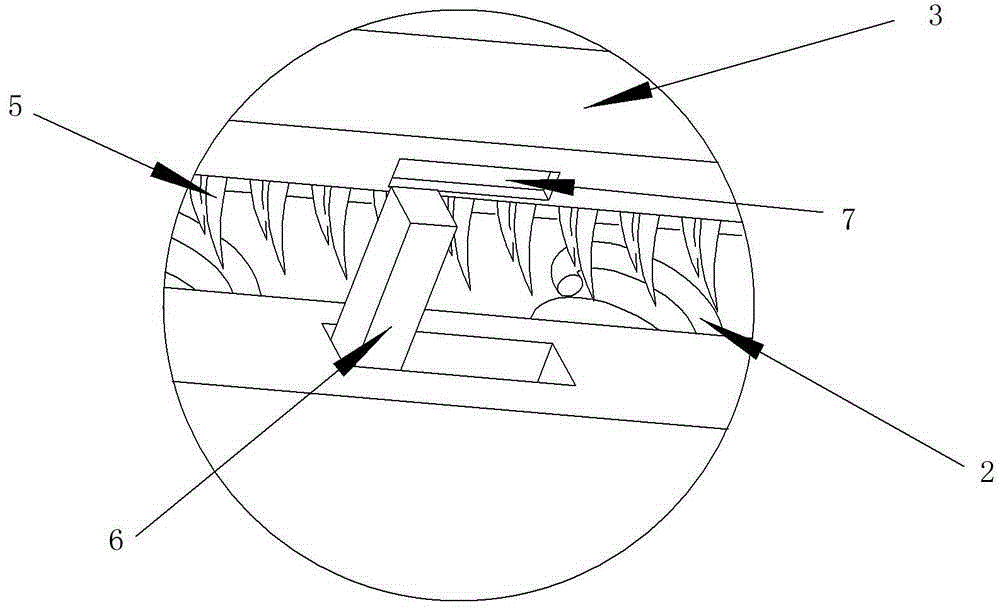

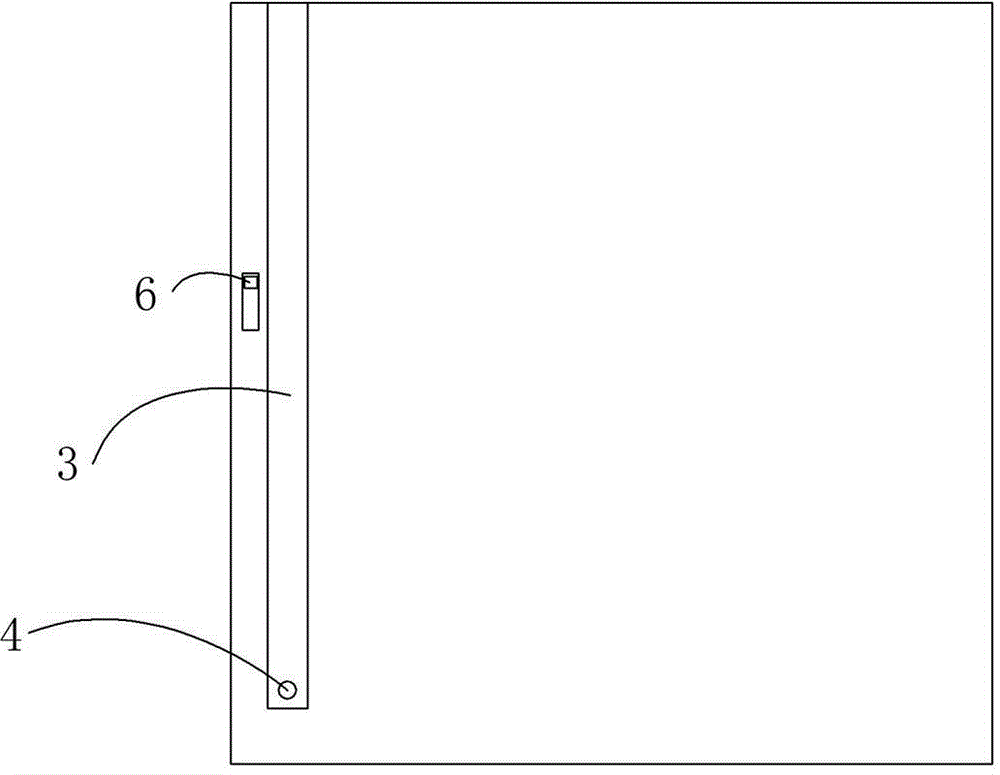

[0016] The reference signs in the description of the drawings are: pallet body 1, spring 2, cleaning rod 3, telescoping rod 4, brush 5, carbon steel block 6, magnet 7, limit block 8.

[0017] Such as figure 1 , image 3 As shown, this embodiment discloses a brick machine pallet, the upper bottom surface of the pallet body 1 is provided with a first groove, the first groove is provided with a spring 2, and one end of the cleaning rod 3 is hinged on the On the pallet body 1 , the cleaning rod 3 and the brush 5 form a cleaning device for cleaning the pallet body 1 . Such as figure 2 As shown, the cleaning rod 3 is provided with a second groove, the second groove is provided with a magnet 7, and the side of the cleaning rod 3 near the carbon steel block 6 is also provided with a third groove, and the third groove is also provided with a third groove. There is a carbon steel block 6 whose length is greater than the depth of the second groove. Such as Figure 4 As shown, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com