Plank cutting device

A technology for cutting devices and boards, which is applied in the direction of feeding devices, clamping devices, sawing components, etc., and can solve the problems of slow cutting speed, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

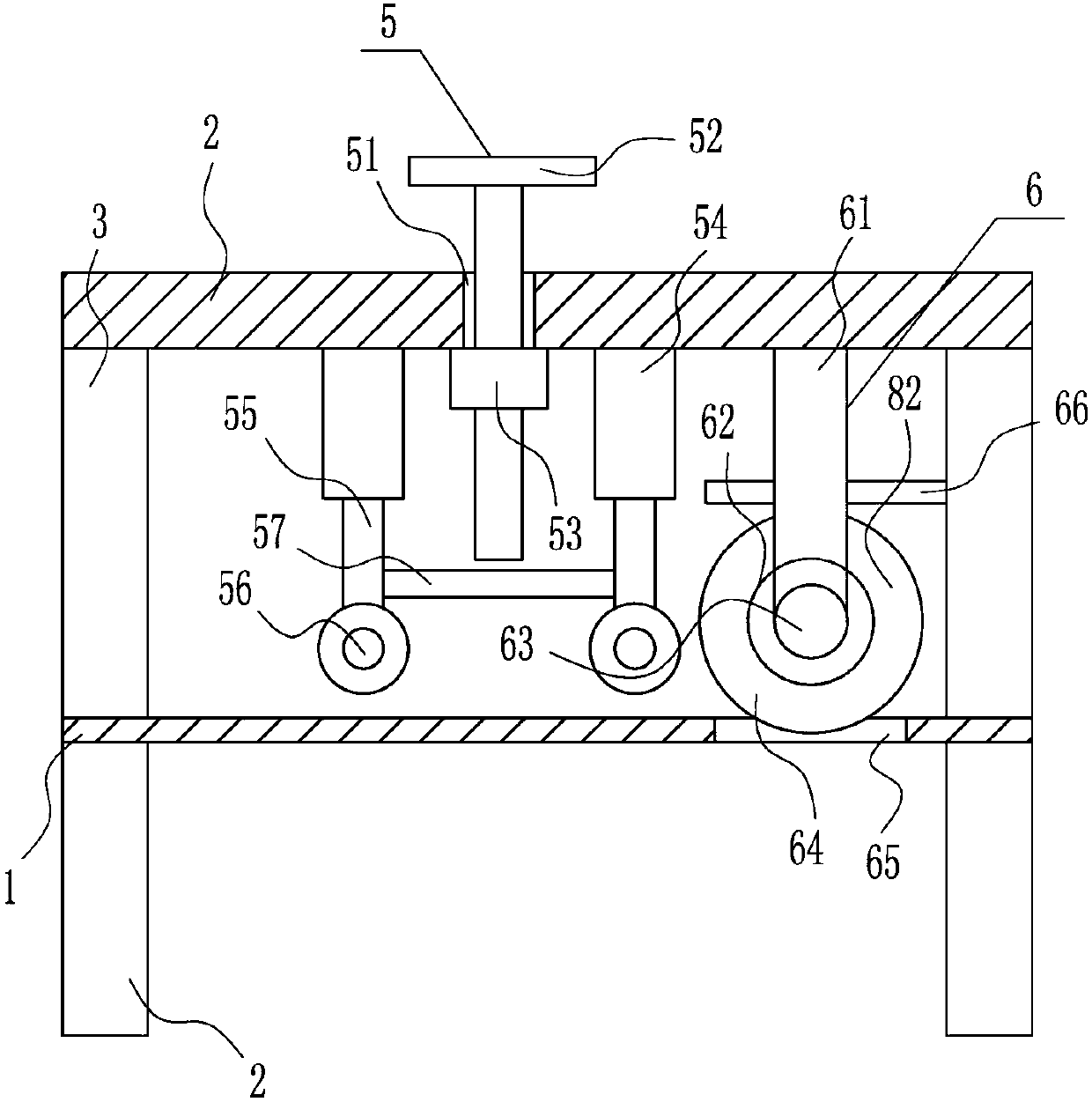

[0035] A wood cutting device such as Figure 1-5 As shown, it includes a placement board 1, legs 2, poles 3, a top board 4, a pressing device 5 and a cutting device 6, and the left and right sides of the bottom of the placement board 1 are symmetrically equipped with outriggers 2, and the top of the placement board 1 is left and right. Both sides are symmetrically equipped with struts 3, and a top plate 4 is installed between the tops of the struts 3 on the left and right sides. The left side of the top plate 4 is provided with a pressing device 5, and the pressing part of the pressing device 5 is located above the placement plate 1. A cutting device 6 is provided on the right side of the bottom of the top plate 4 .

Embodiment 2

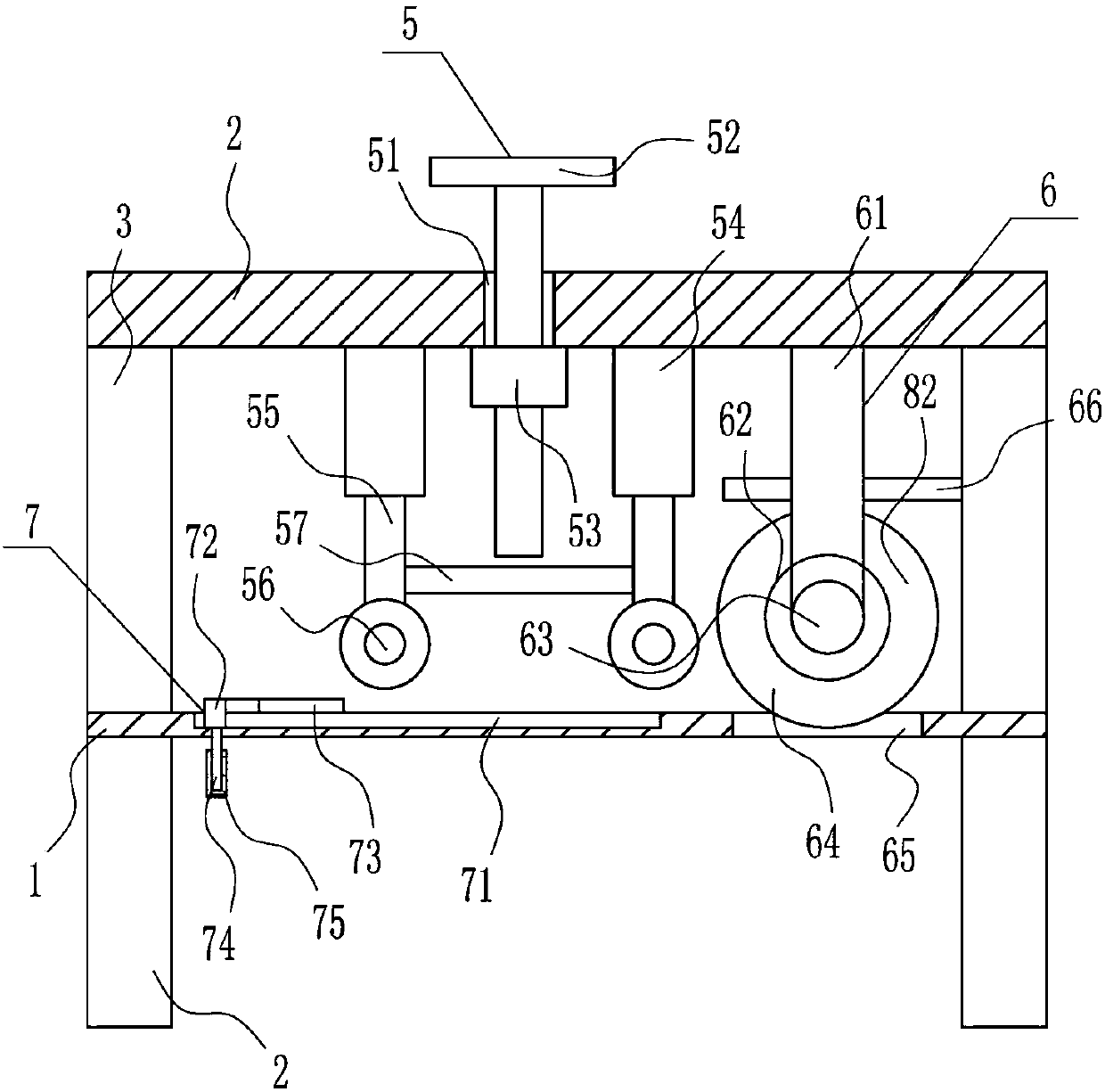

[0037] A wood cutting device such as Figure 1-5 As shown, it includes a placement board 1, legs 2, poles 3, a top board 4, a pressing device 5 and a cutting device 6, and the left and right sides of the bottom of the placement board 1 are symmetrically equipped with outriggers 2, and the top of the placement board 1 is left and right. Both sides are symmetrically equipped with struts 3, and a top plate 4 is installed between the tops of the struts 3 on the left and right sides. The left side of the top plate 4 is provided with a pressing device 5, and the pressing part of the pressing device 5 is located above the placement plate 1. A cutting device 6 is provided on the right side of the bottom of the top plate 4 .

[0038] Pressing device 5 comprises screw rod 52, nut 53, sleeve 54, movable bar 55, roller 56 and connecting plate 57, and top plate 4 left side has threaded hole 51, is provided with screw rod 52 in threaded hole 51, is provided with on the bolt. Nut 53, the to...

Embodiment 3

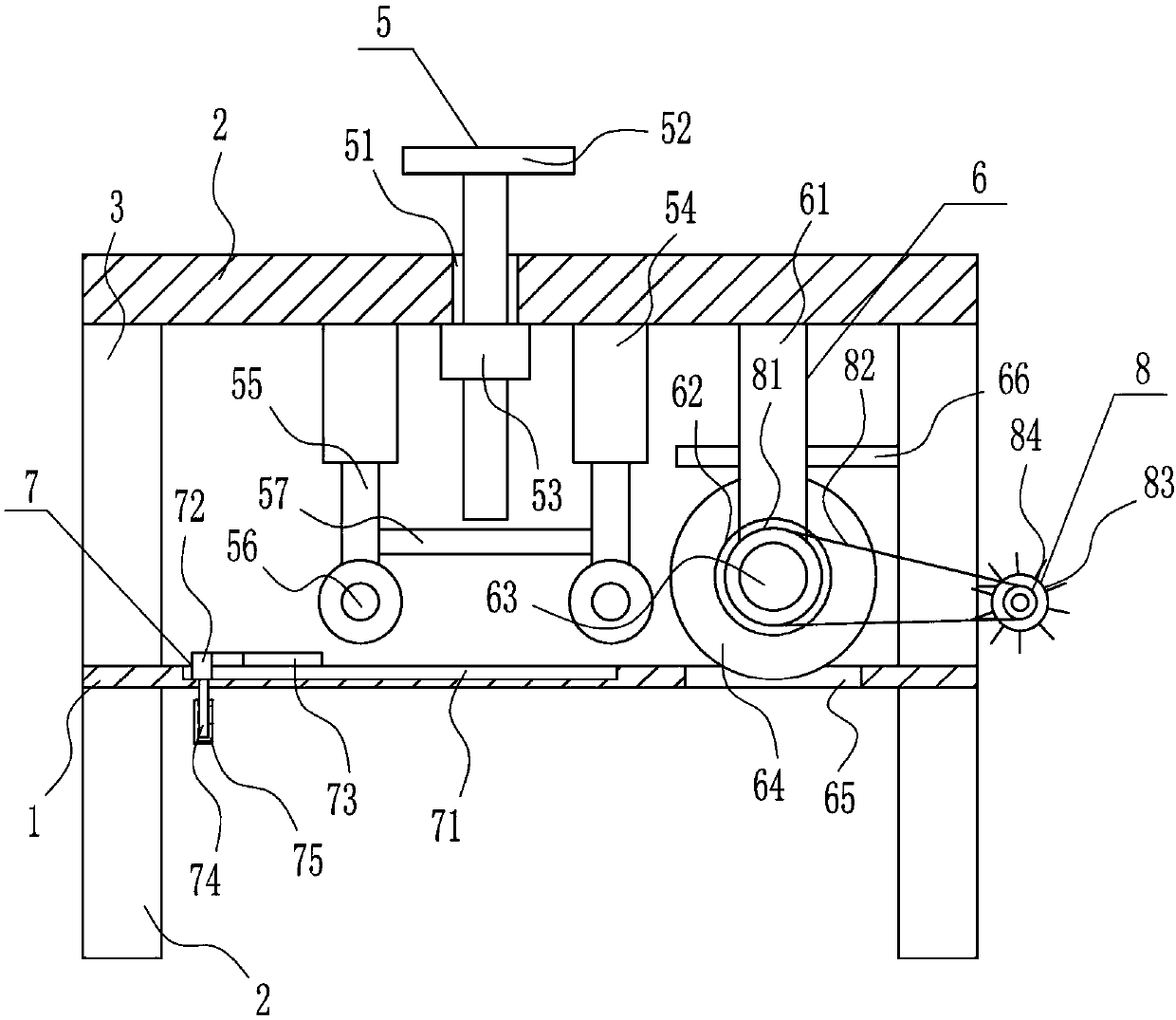

[0040] A wood cutting device such as Figure 1-5 As shown, it includes a placement board 1, legs 2, poles 3, a top board 4, a pressing device 5 and a cutting device 6, and the left and right sides of the bottom of the placement board 1 are symmetrically equipped with outriggers 2, and the top of the placement board 1 is left and right. Both sides are symmetrically equipped with struts 3, and a top plate 4 is installed between the tops of the struts 3 on the left and right sides. The left side of the top plate 4 is provided with a pressing device 5, and the pressing part of the pressing device 5 is located above the placement plate 1. A cutting device 6 is provided on the right side of the bottom of the top plate 4 .

[0041] Pressing device 5 comprises screw rod 52, nut 53, sleeve 54, movable bar 55, roller 56 and connecting plate 57, and top plate 4 left side has threaded hole 51, is provided with screw rod 52 in threaded hole 51, is provided with on the bolt. Nut 53, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com