Coiled tubing traction robot

A technology of robots and oil pipes, which is applied in oil traps, wellbore/well components, earthwork drilling and production, etc., can solve the problems of traction robot research and no products put into the market, and achieve improved recovery efficiency and safety, compact structure, The effect of improving traction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

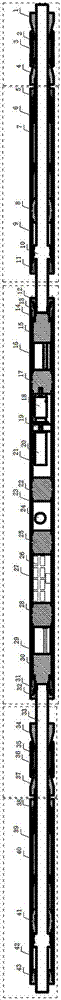

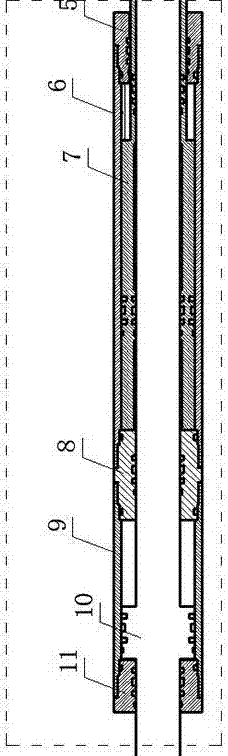

[0038] A coiled tubing traction robot, comprising a first segment body, a second segment body, a third segment body, a fourth segment body and a fifth segment body arranged in sequence from right to left, the first segment body and the second segment body are both Set on the front central shaft 10, the fourth segment body and the fifth segment body are both sleeved on the rear central shaft 33, and the left ends of the third segment body are respectively sleeved on the rear central shaft 33 and the end of the front central shaft 10 .

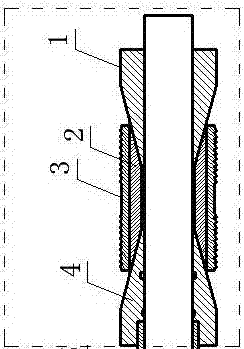

[0039]Specifically, the first section includes a front right slanting block 1, a front left slanting block 4, a front support block 2 and a front friction block 3, and the left and right ends of the front support block 2 are respectively sleeved on the front left slant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com