Fuel gas vortex combustion device with oxygen supplied for front end

A combustion device and gas technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of low combustion temperature, inconvenient oxygen supply and gas distribution, and easy blockage of small holes in ceramic plates, and achieve sufficient combustion. , prolong the residence time, improve the effect of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

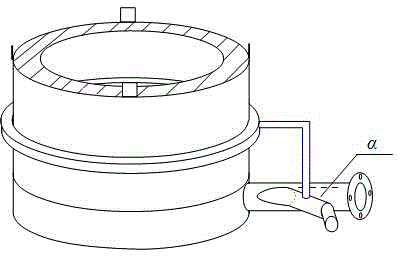

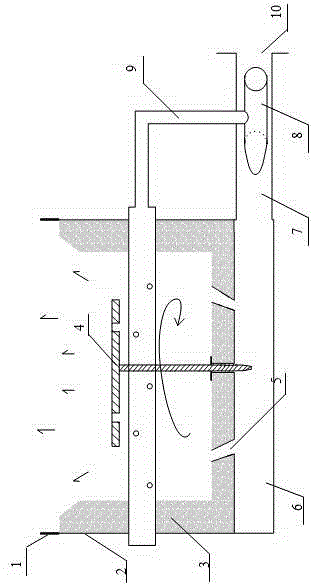

[0021] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 And attached figure 2 , the front-end oxygen distribution gas vortex combustion device described in this embodiment includes a pan frame 1, a stove body shell 2, a refractory layer 3, a fire pressure plate 4, an air intake pipe 5, a gas mixing chamber 6, a gas mixture pipe 7, and an air intake pipe 8. Secondary air intake pipe 9, gas pipe 10, wherein, the pot support 1 is installed on the top of the stove body shell 2, and the stove body shell 2 is provided with a refractory layer 3; the bottom of the stove body shell 2 is provided with a gas mixing chamber 6, and the gas mixing The side wall of the chamber 6 is connected to one end of the mixed gas pipe 7, and the other end of the mixed gas pipe 7 is connected to the air inlet pipe 8 and the gas pipe 10 respectively; after the gas is mixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com