Guide base

A guide seat and automatic manufacturing technology, which is applied in the direction of textiles and papermaking, cloth feeding mechanism, sewing equipment, etc., can solve the problems of unstable positioning, deviation of sewing stitches, and heavy operating burden of operators, so as to reduce the work burden Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

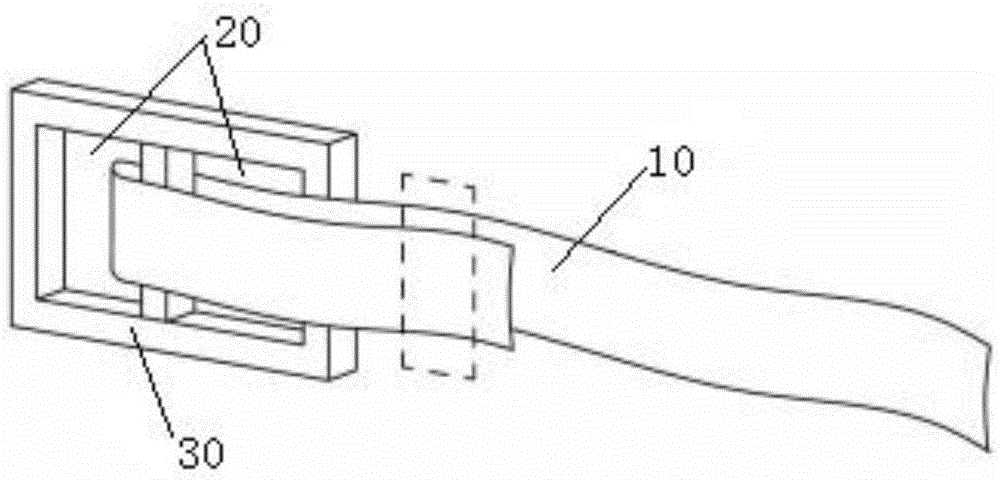

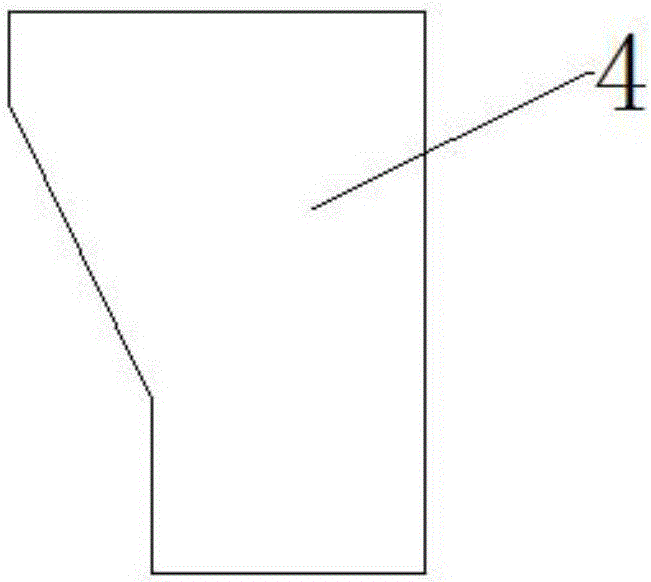

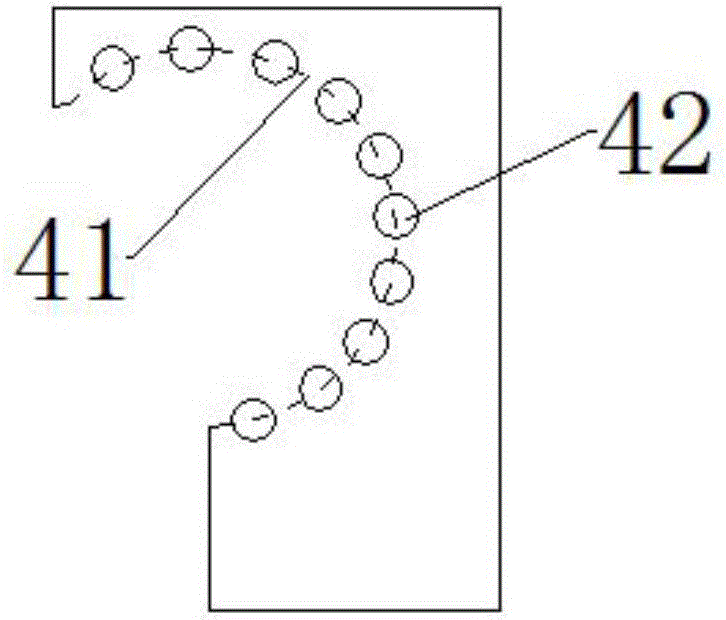

[0027] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended Figures 1 to 5 The guide seat provided by the present invention is described in detail.

[0028] refer to Figure 2a , is a side view of the appearance structure of an embodiment of a lead seat; combined Figure 2b , is a side view of the internal structure of an embodiment of a guide seat; and Figure 2c , is a bottom view of an embodiment of a guide seat; and Figure 3a and Figure 3b , is a top view and a side view diagram of an embodiment of a guide seat applied to an automatic belt-making machine, and in order to clearly show the structural features of the present invention, part of the structure in the figure is shown in perspective or half-section, and some commonly used structures is omitted, and, Figure 3a and Figure 3b The conveying direction of the belt conveyor 1 sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com