Patents

Literature

369results about How to "Hold firmly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

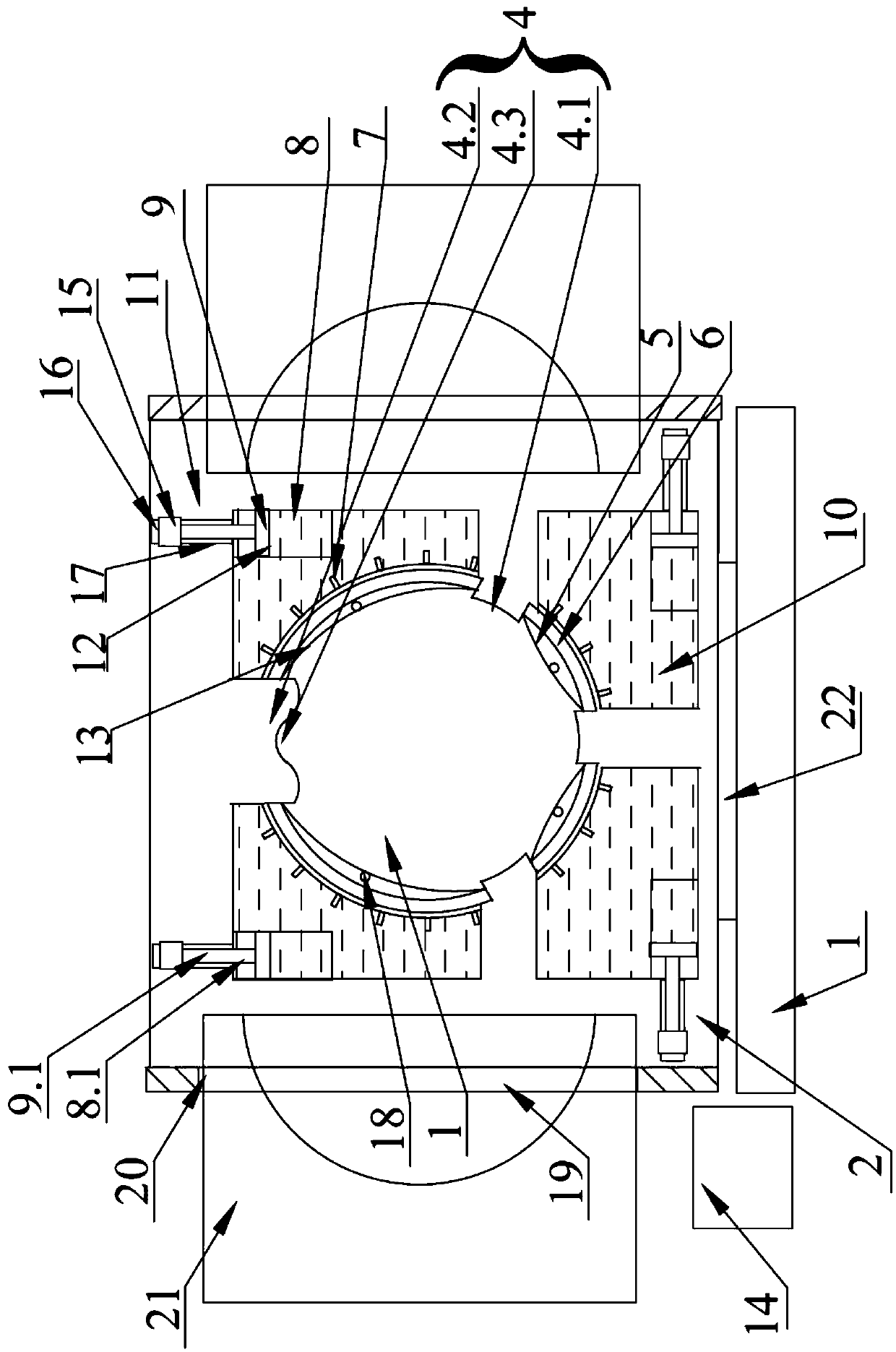

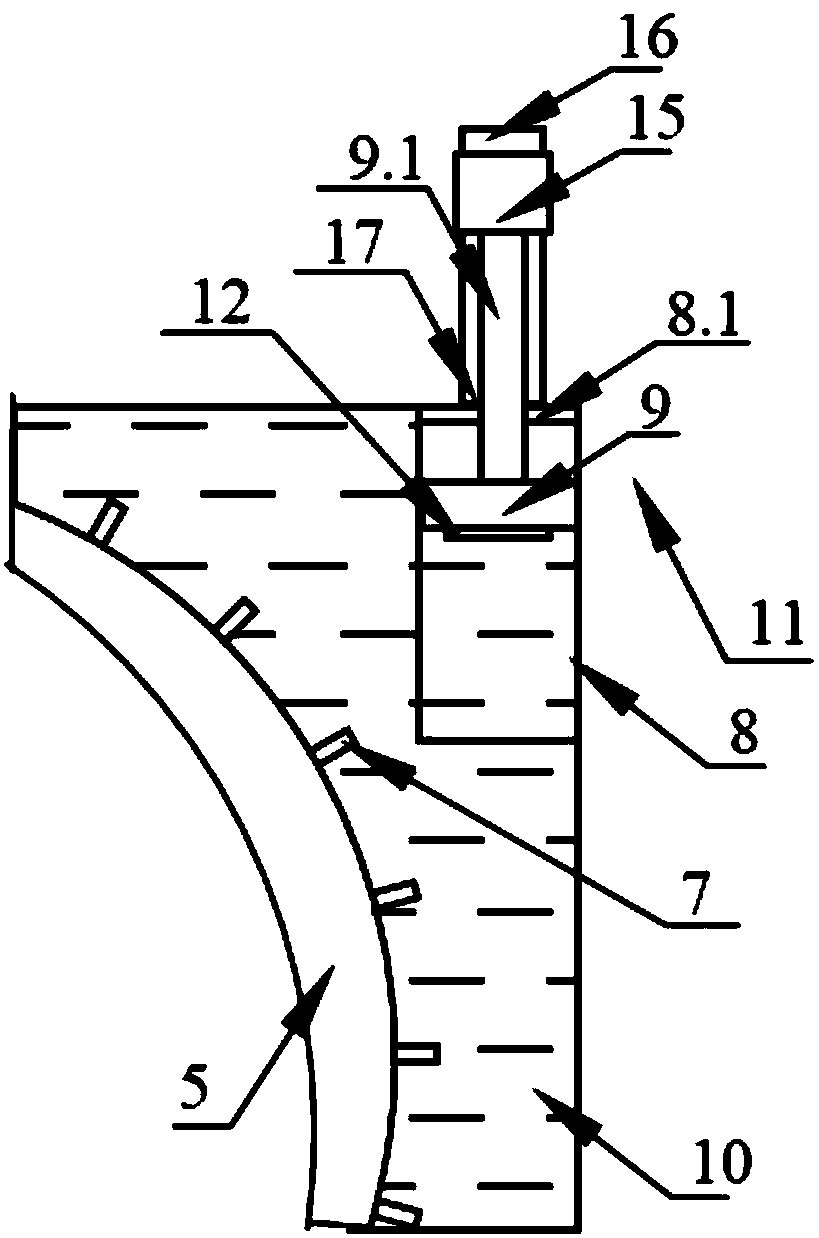

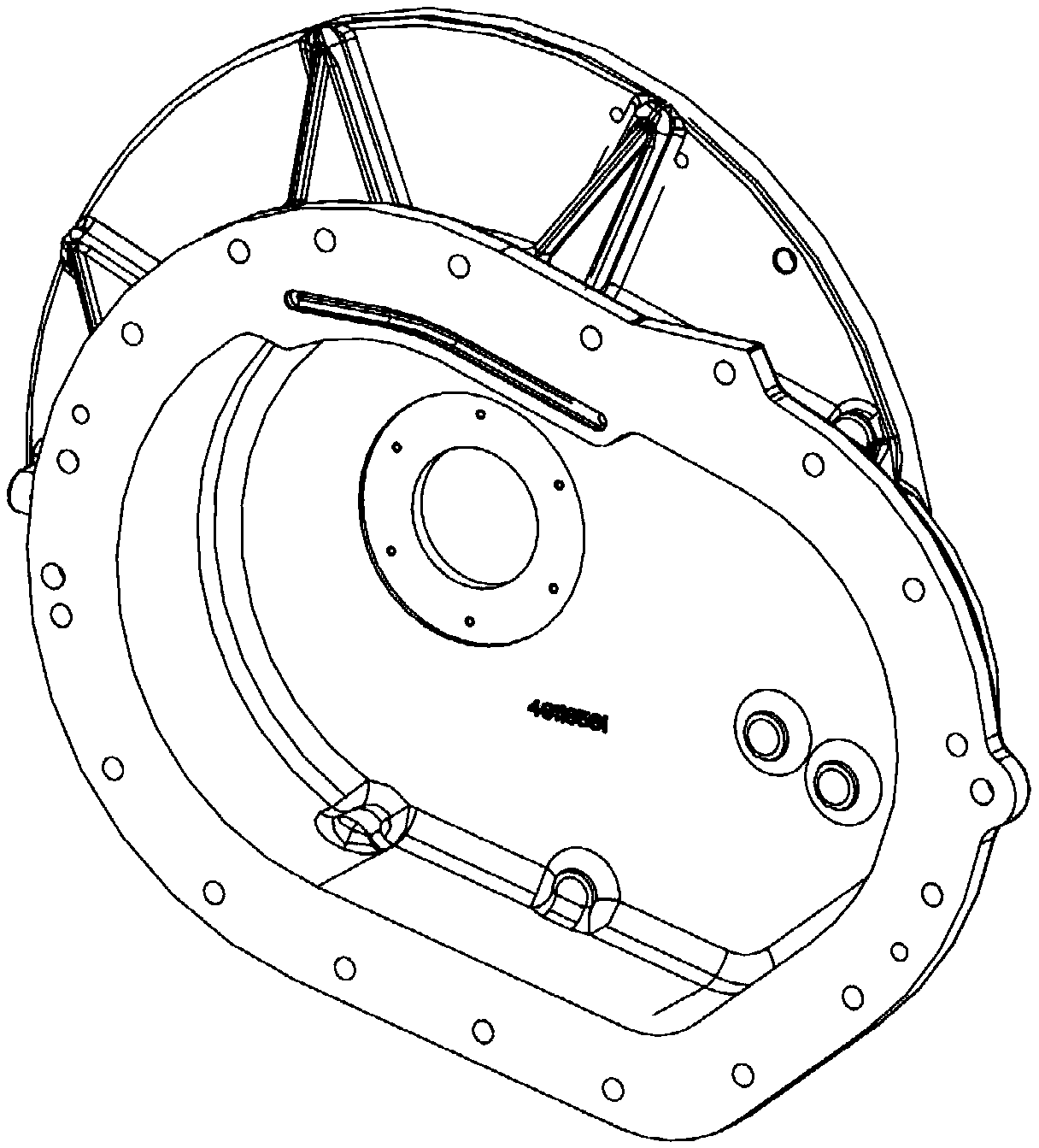

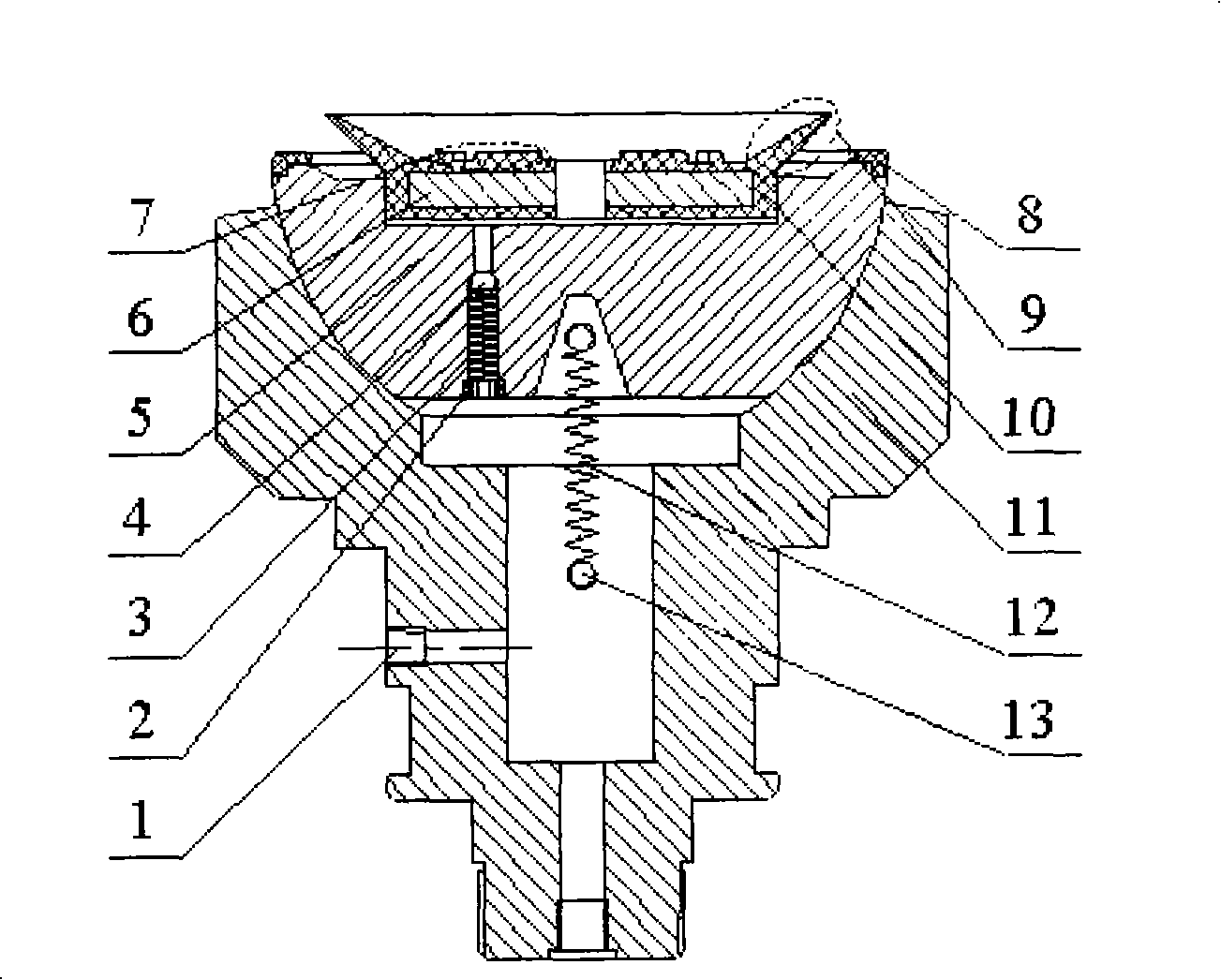

Electrorheological fluid clamping tool for light and low-noise gearbox

ActiveCN109623454AShorten the timeOverall small sizePositioning apparatusMetal-working holdersLow noiseEngineering

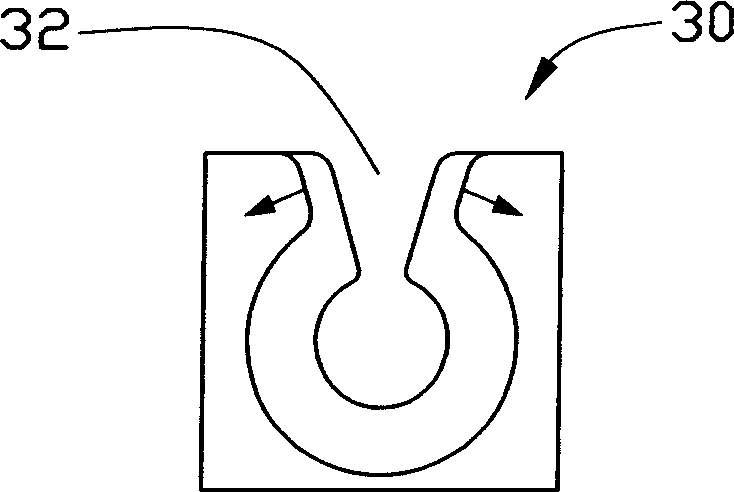

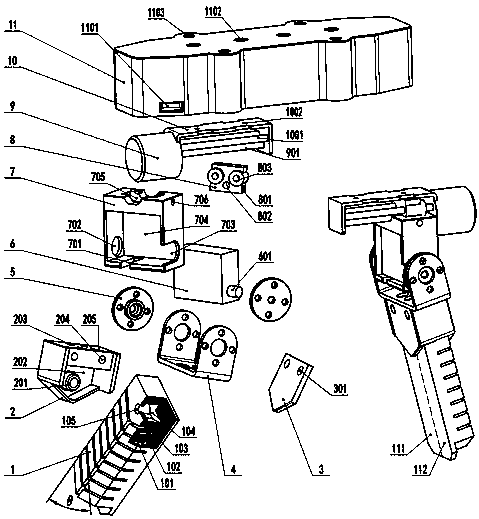

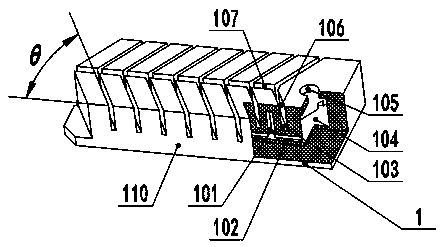

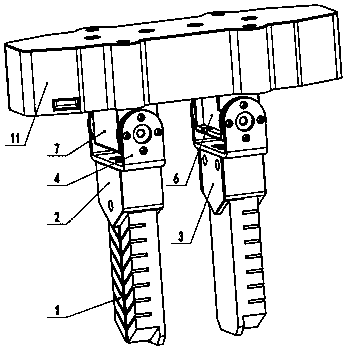

The invention discloses an electrorheological fluid clamping tool for a light and low-noise gearbox. The electrorheological fluid clamping tool is used for positioning and clamping the end face of thegearbox in the machining process, the tool comprises a base, the base is provided with a workpiece bearing plate perpendicular to the base, a through hole used for mounting and demounting the workpiece is formed in the middle of the workpiece bearing plate, protruding positioning blocks are arranged on the inner wall of the through hole, flexible fluid bag storing grooves are formed in the positions, between the positioning blocks, of the inner wall of the through hole, flexible fluid bags are arranged in the storing grooves and connected with a cylinder body through guiding pipes, the cylinder body is internally provided with a piston, the space, at one end of the piston, inside the cylinder body, the guiding pipes and the flexible fluid bags constitute an accommodating chamber for electrorheological fluid jointly, the other end of the piston is connected with a piston driving mechanism, positive electrodes and negative electrodes are arranged at one end of the piston and the inner walls of the flexible fluid bags correspondingly, and the positive electrodes and the negative electrodes are connected with a controller. The electrorheological fluid clamping tool is simple in structure, convenient to use and good in workpiece clamping effect, clamping force in all directions of the workpiece is uniform and firm, and the workpiece can be quickly mounted and demounted.

Owner:江阴市惠尔信精密装备股份有限公司

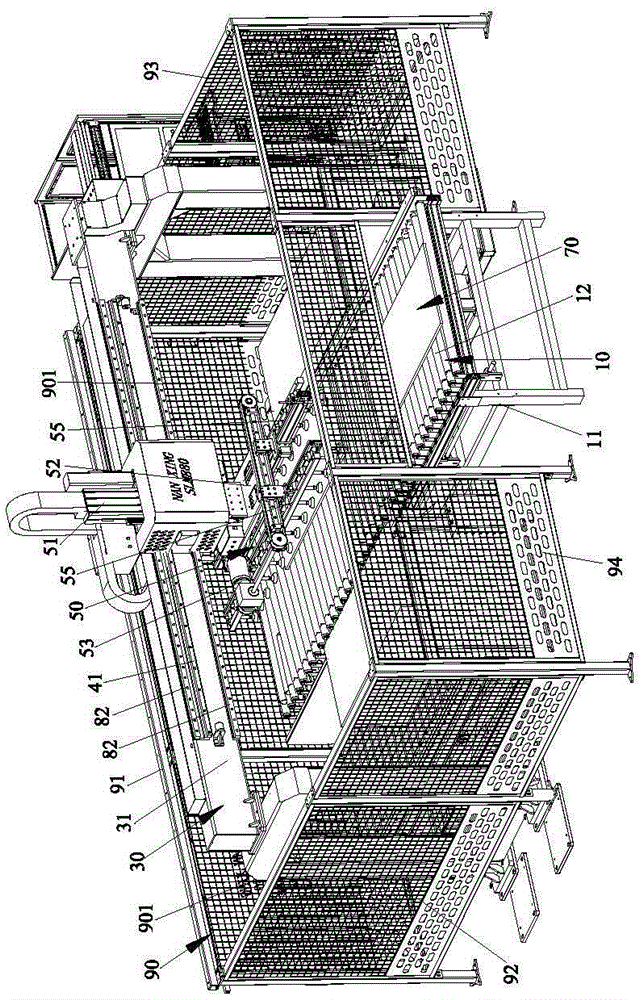

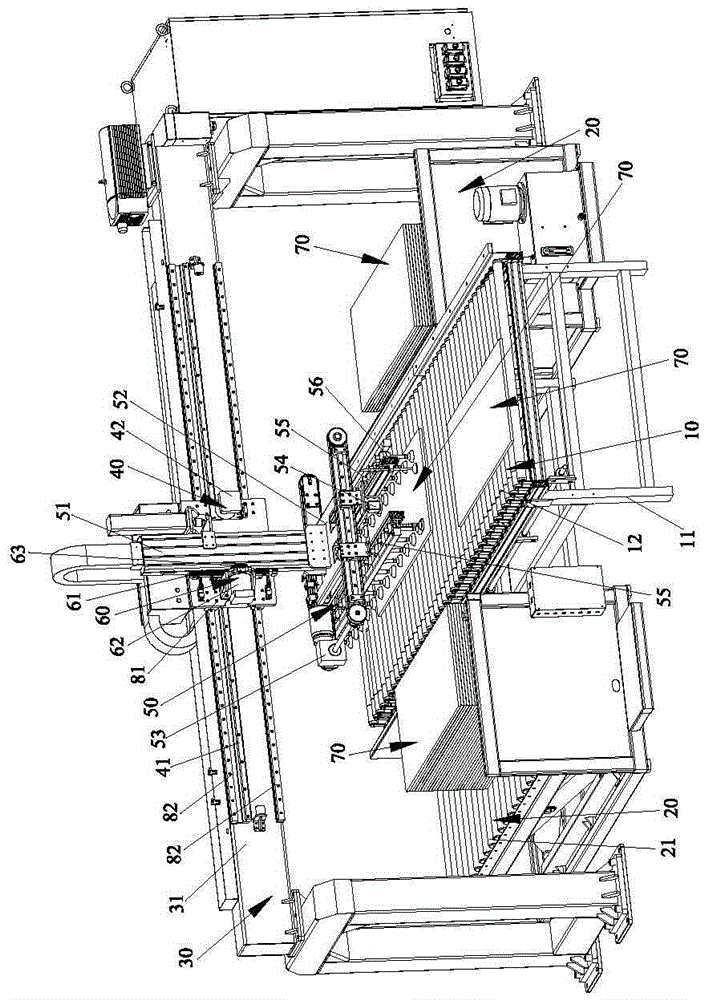

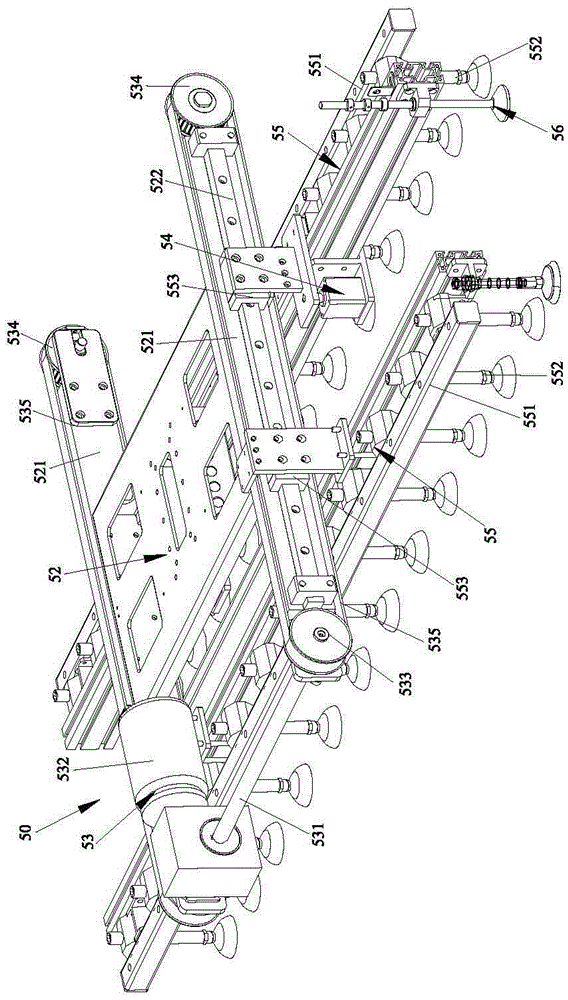

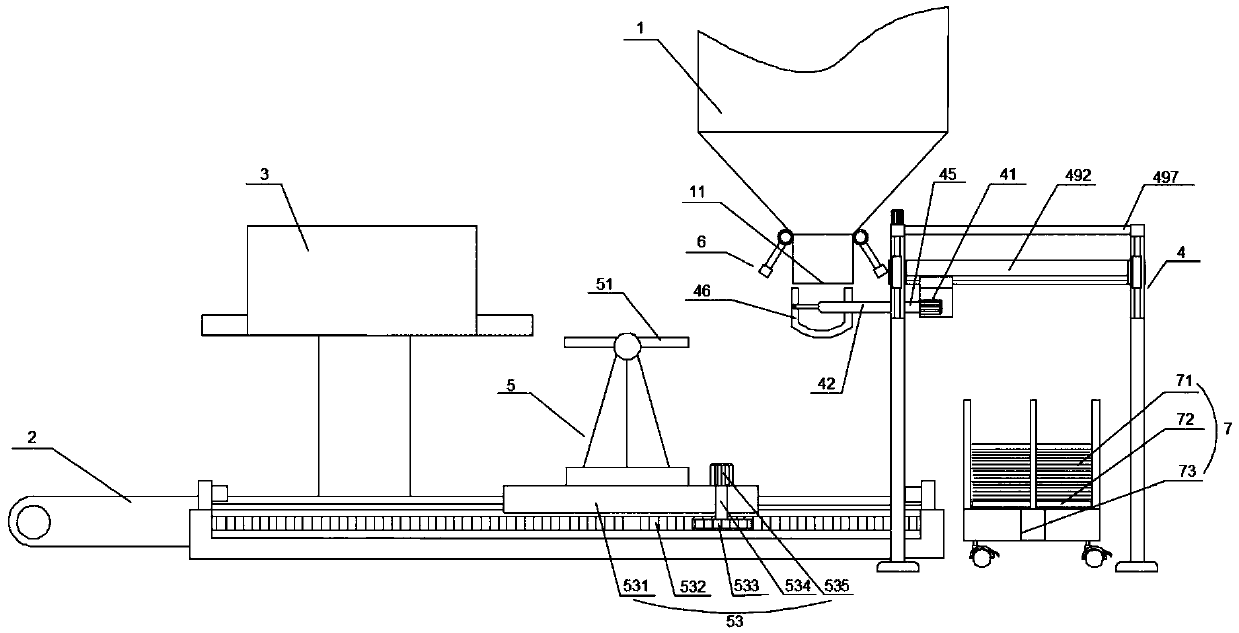

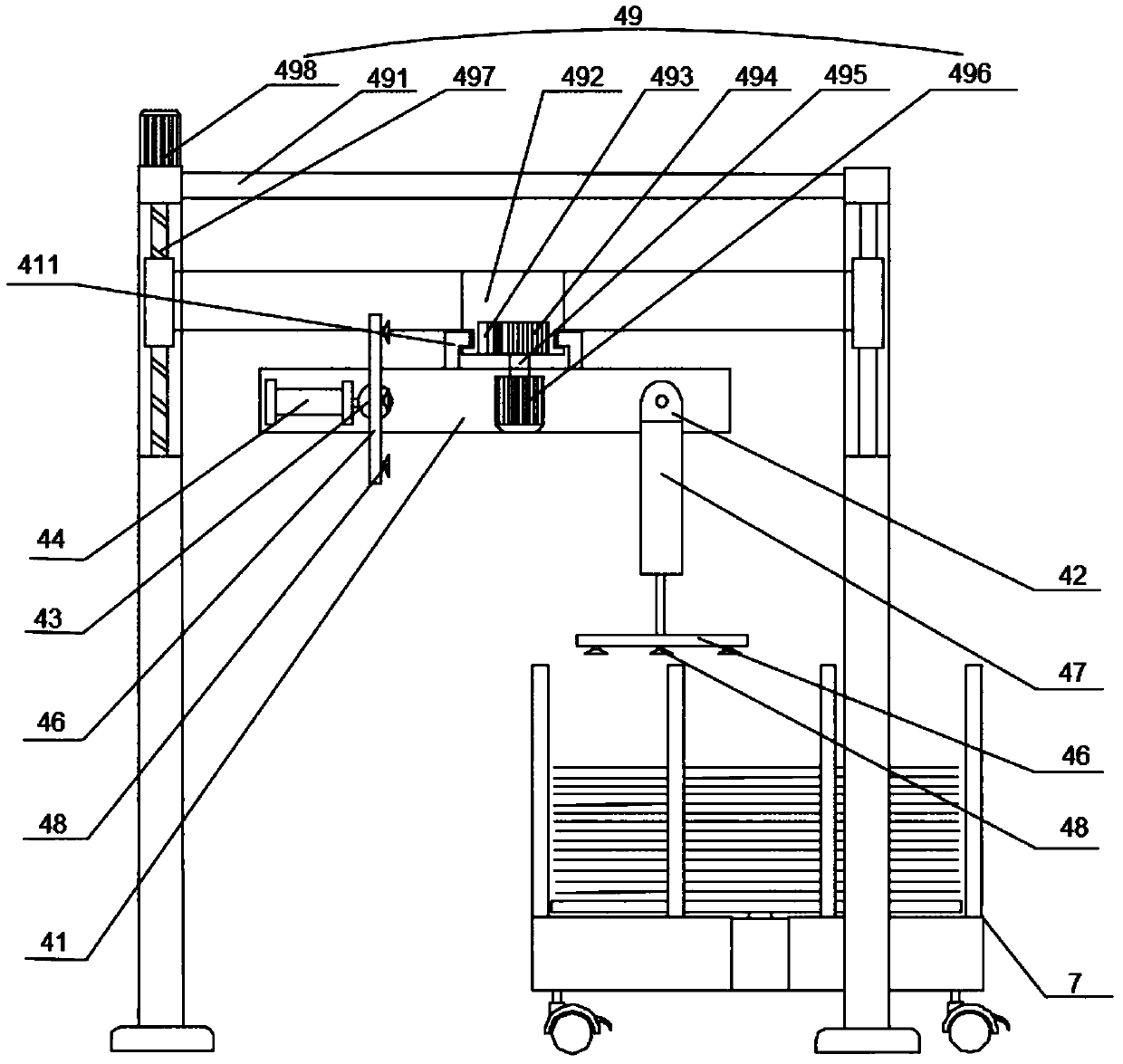

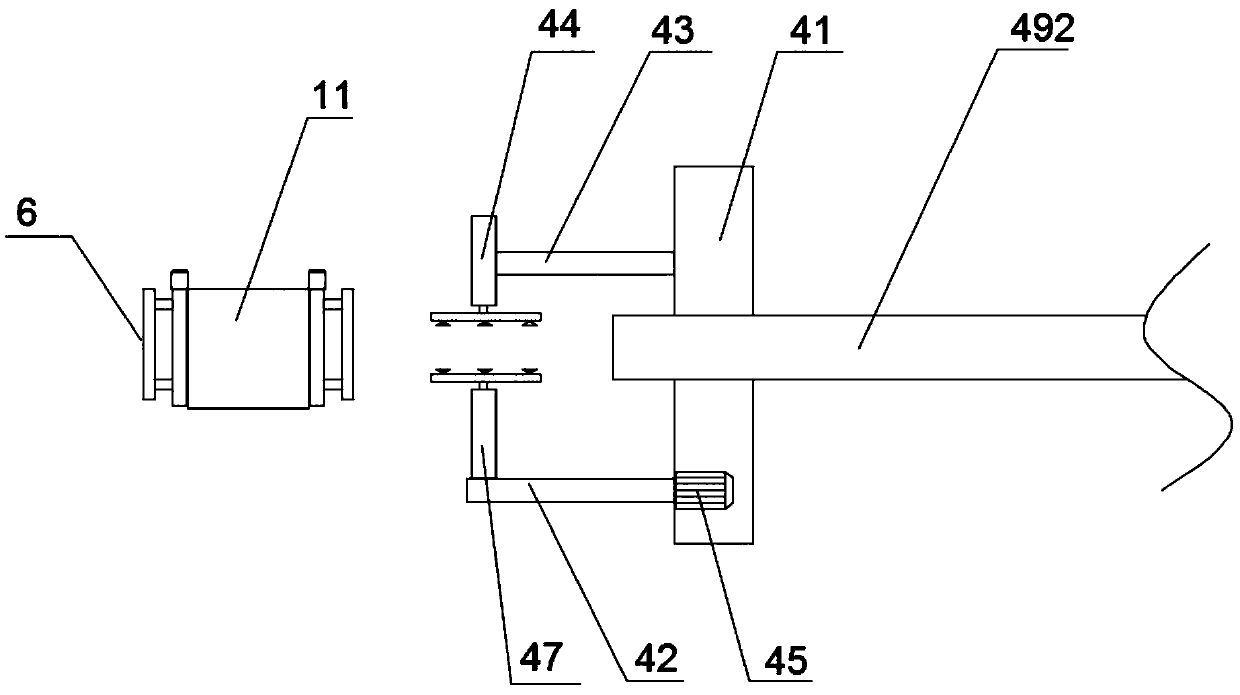

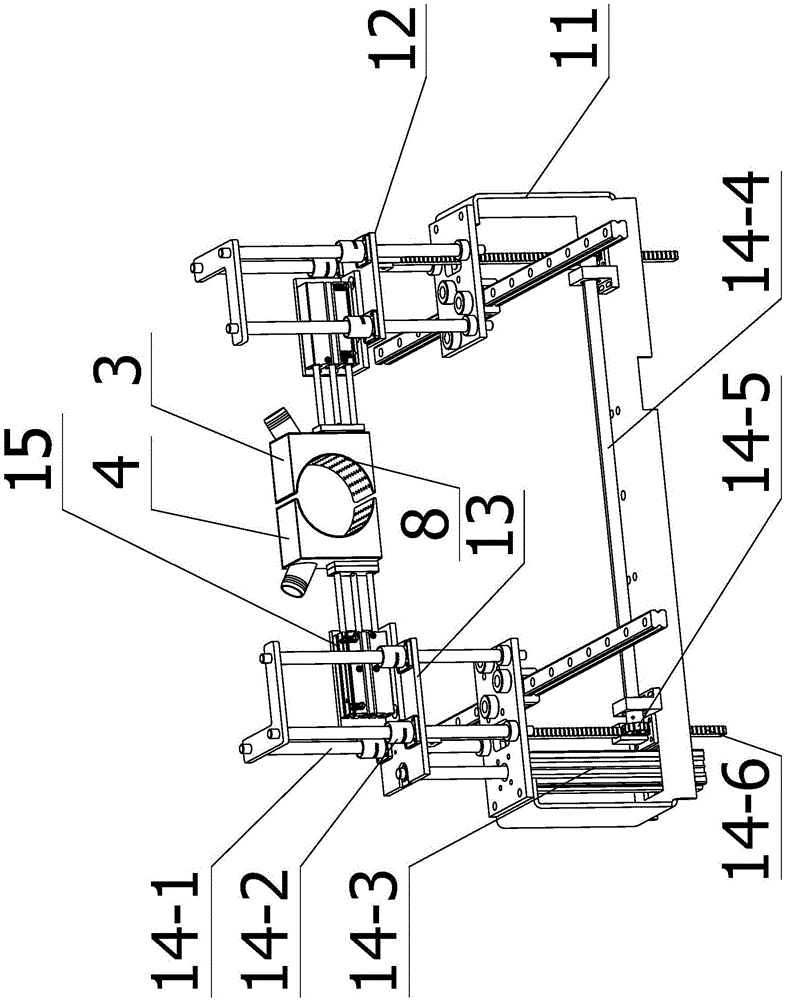

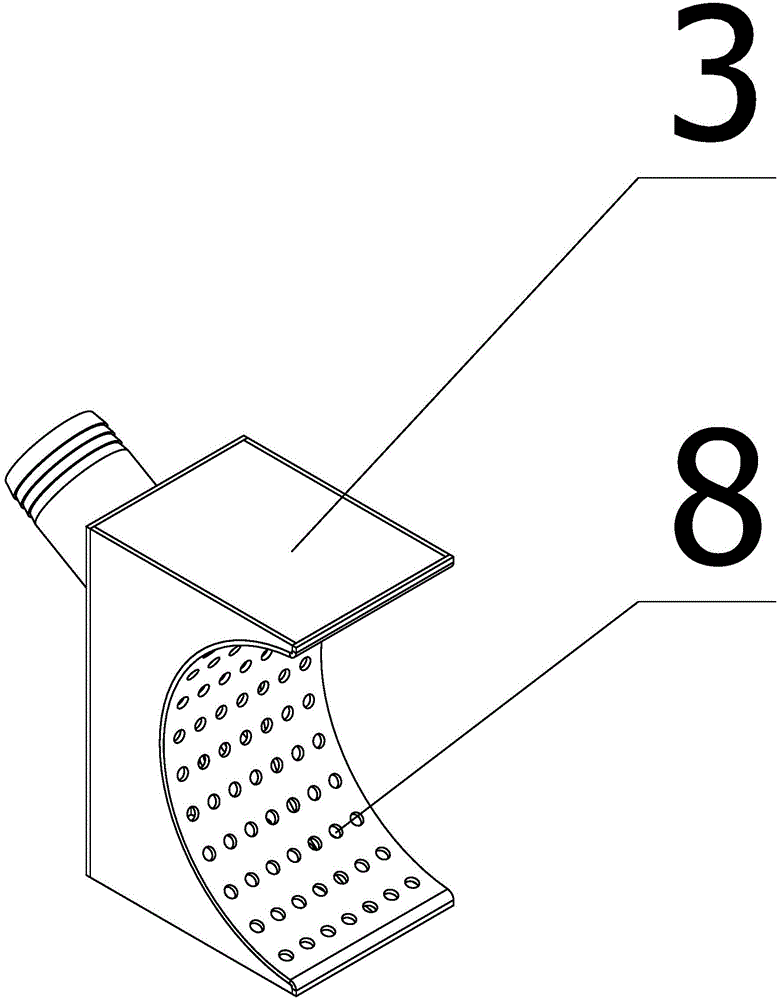

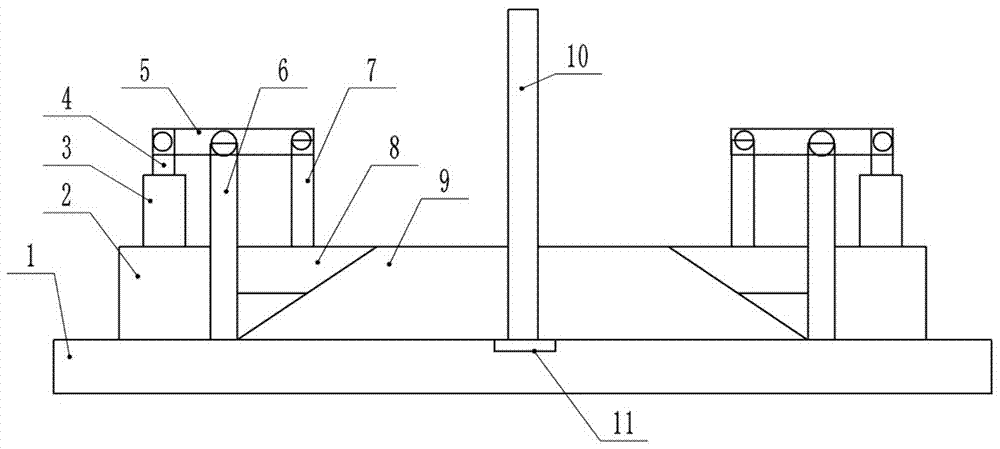

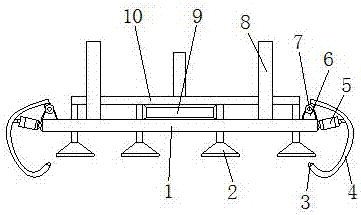

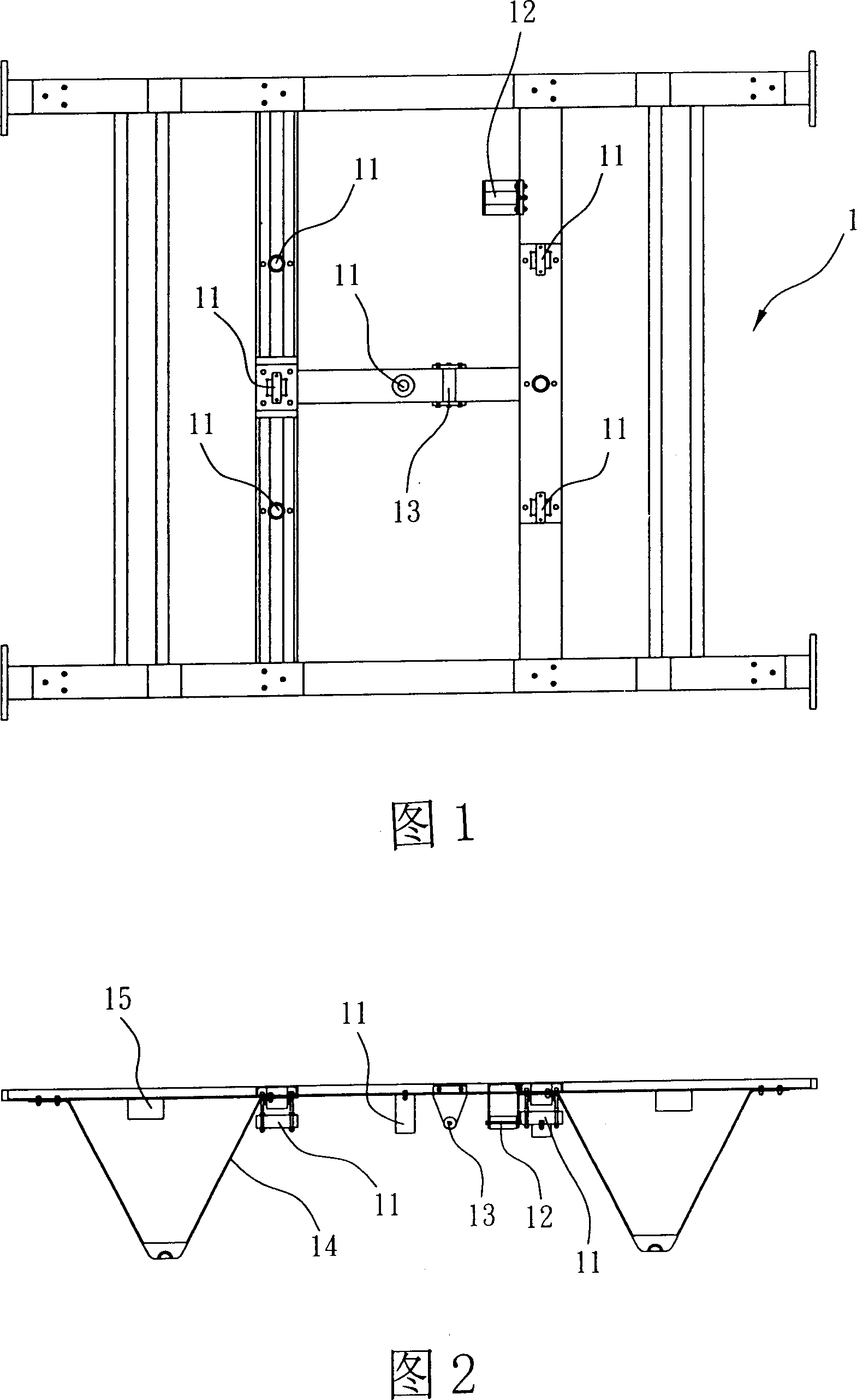

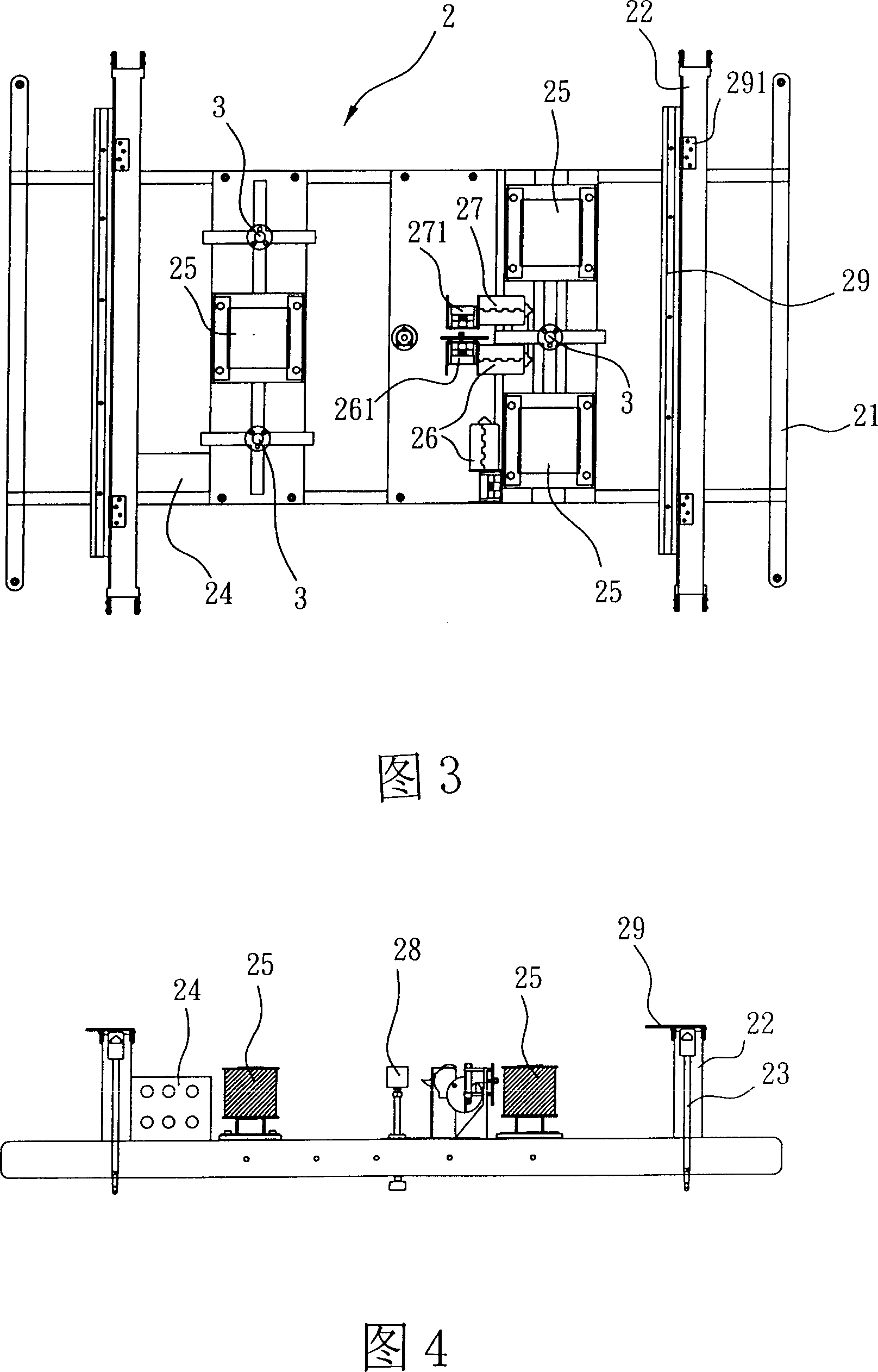

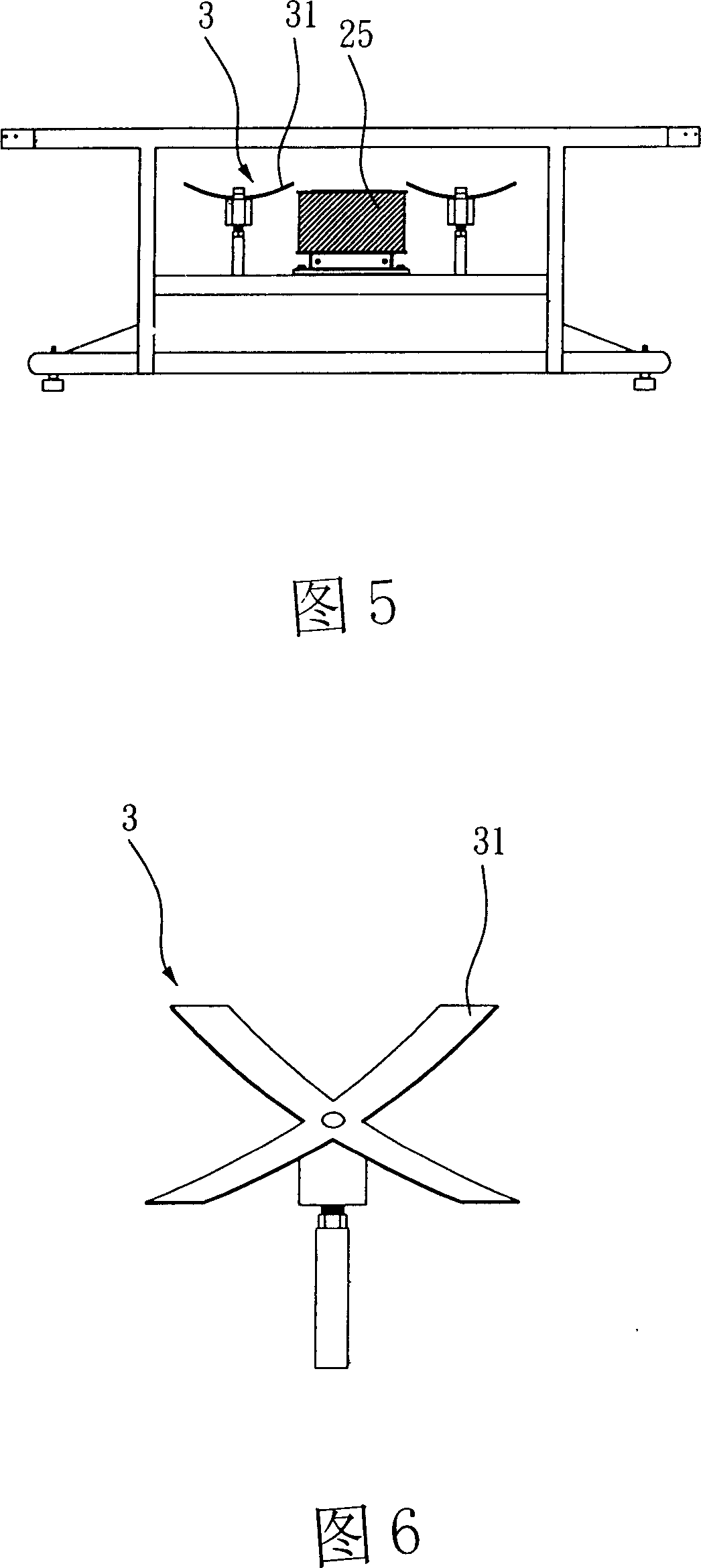

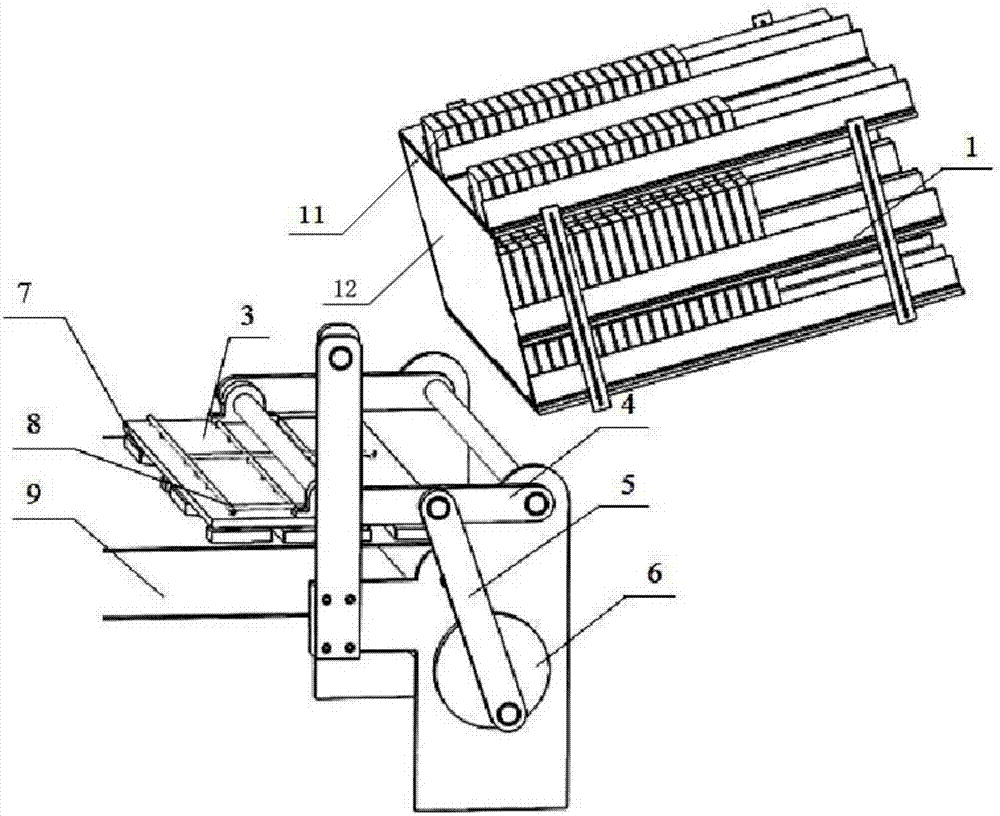

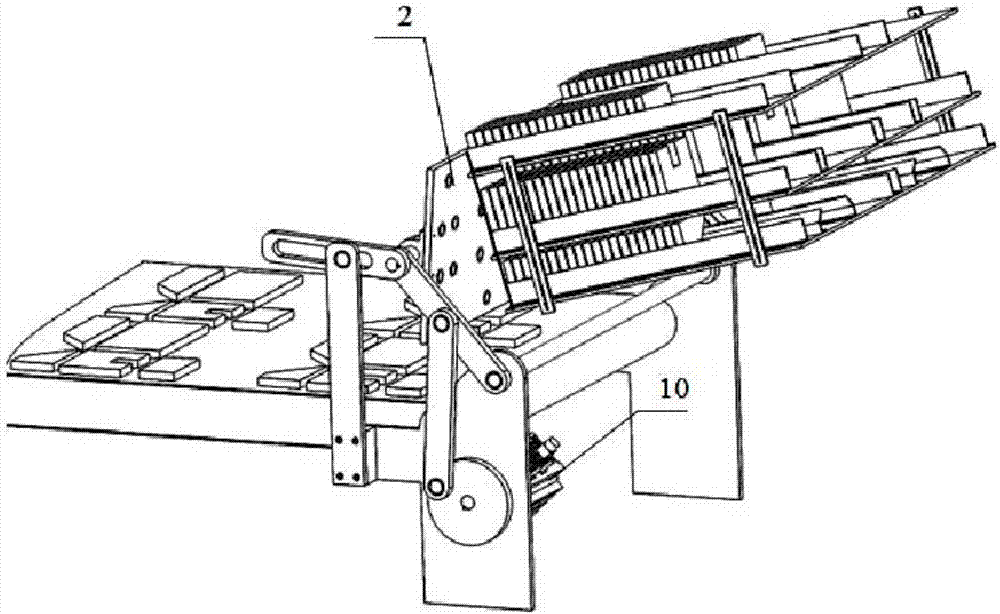

Gantry type sheet feeding and discharging manipulator for woodwork

ActiveCN105397872AShorten exercise distanceAvoid stickingGripping headsMulti-purpose machinesEngineeringStressed state

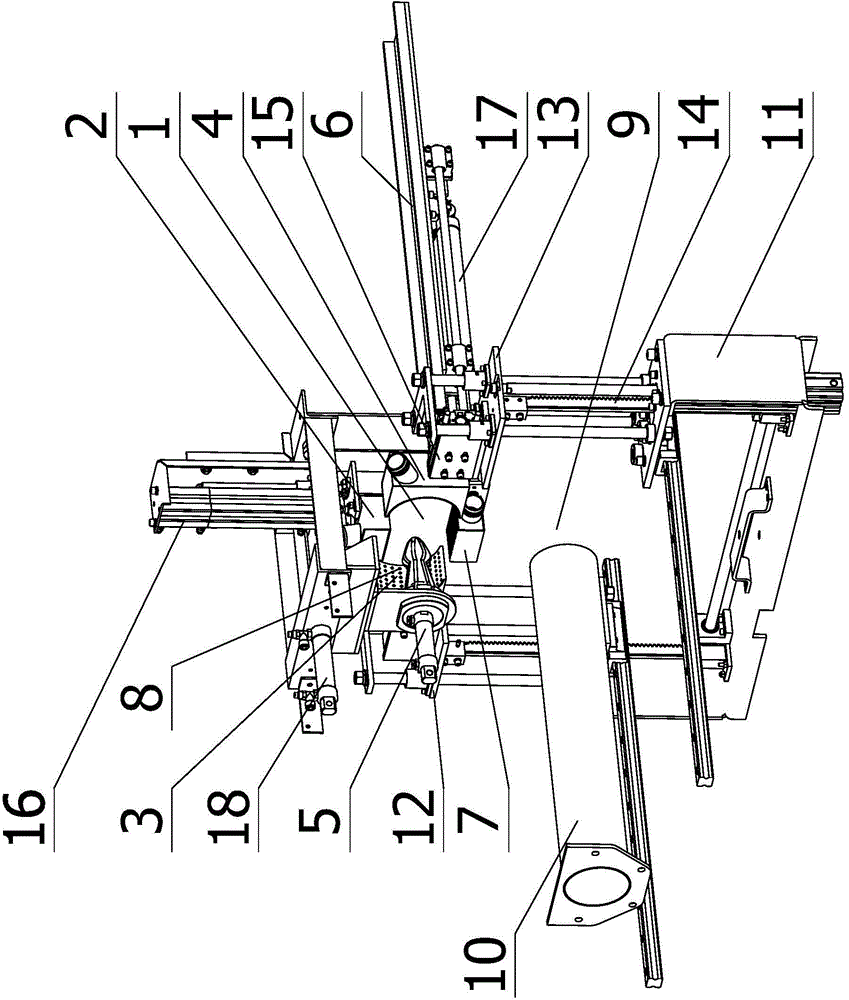

The invention discloses a gantry type sheet feeding and discharging manipulator for woodwork. The gantry type sheet feeding and discharging manipulator comprises a combined conveying table, a feeding device, a main support, a horizontal moving device, a grabbing device and a vertical moving device. The grabbing device comprises a stand column, a base, an opening and closing mechanism, an anti-adhesion shaking mechanism and at least two pressure maintaining type suction cup sets. Automatic feeding is achieved through the feeding device, the moving distance of the grabbing device in the vertical direction is reduced, and halt is not needed in the feeding process so that production efficiency can be effectively improved. The automatic opening and closing mechanism is adopted by the grabbing device, the distance between the pressure maintaining type suction cup sets can be automatically adjusted according to the sizes of sheets, and therefore abrasion of suction cups is reduced due to the fact that the suction cup sets are in a good stress state. The anti-adhesion shaking mechanism shakes after grabbing, so that adhesion of the sheets is effectively prevented; moreover, the grabbing device is made to firmly suck the sheets when a power supply is cut off, and the sheets are prevented from falling onto equipment; meanwhile, the situation that unnecessary harms are caused when operators enter a working zone after a power failure is prevented.

Owner:NANXING MACHINERY CO LTD

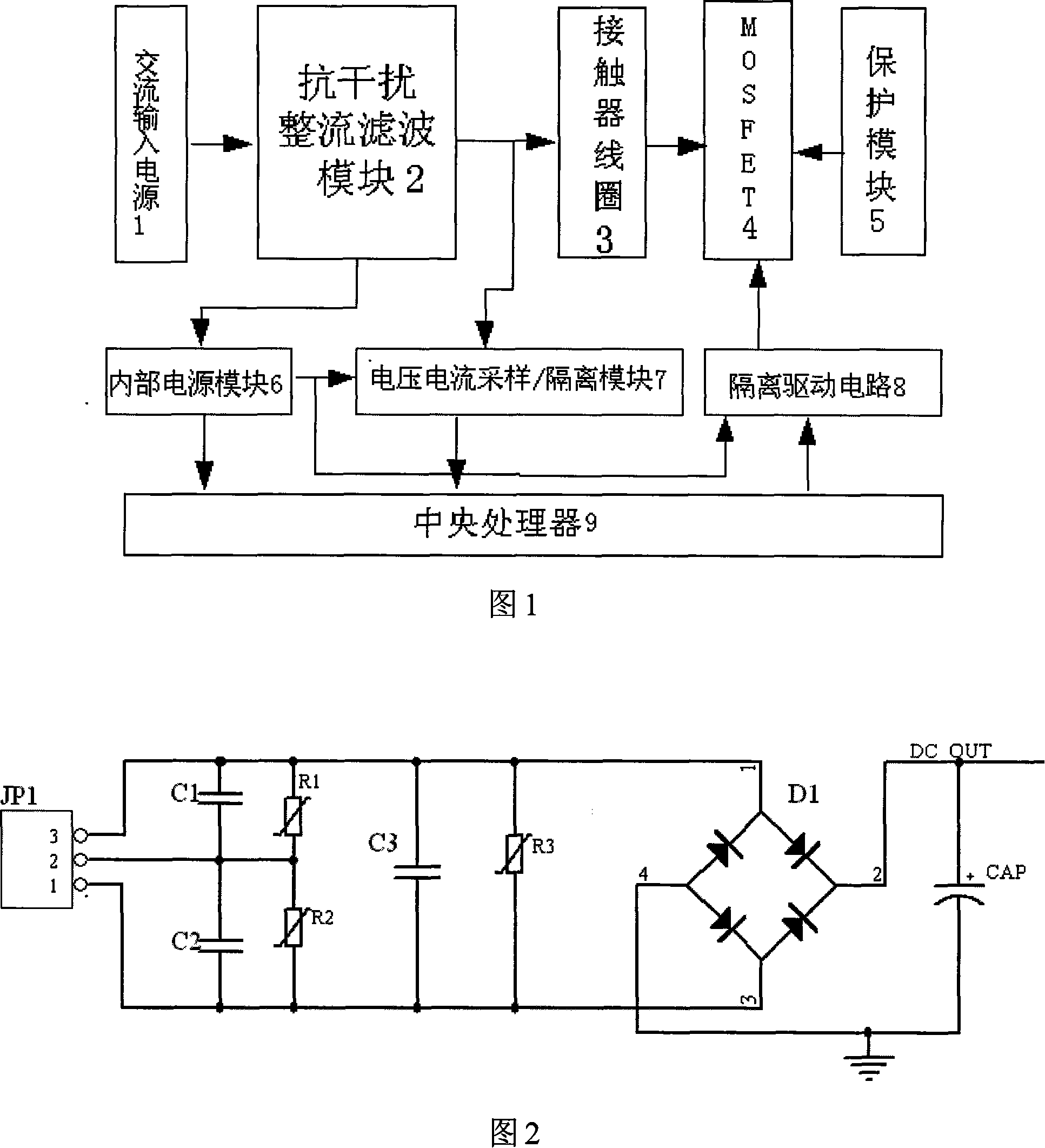

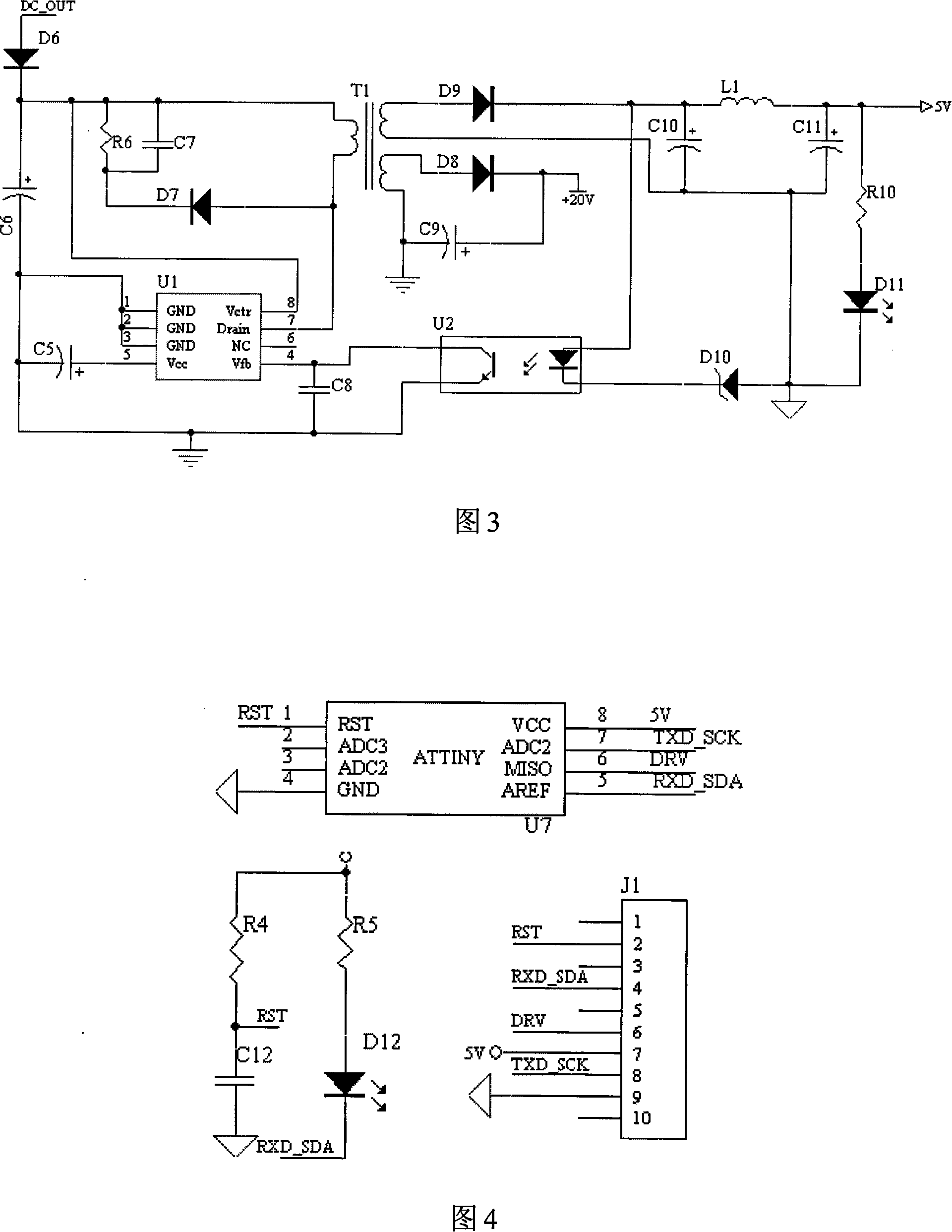

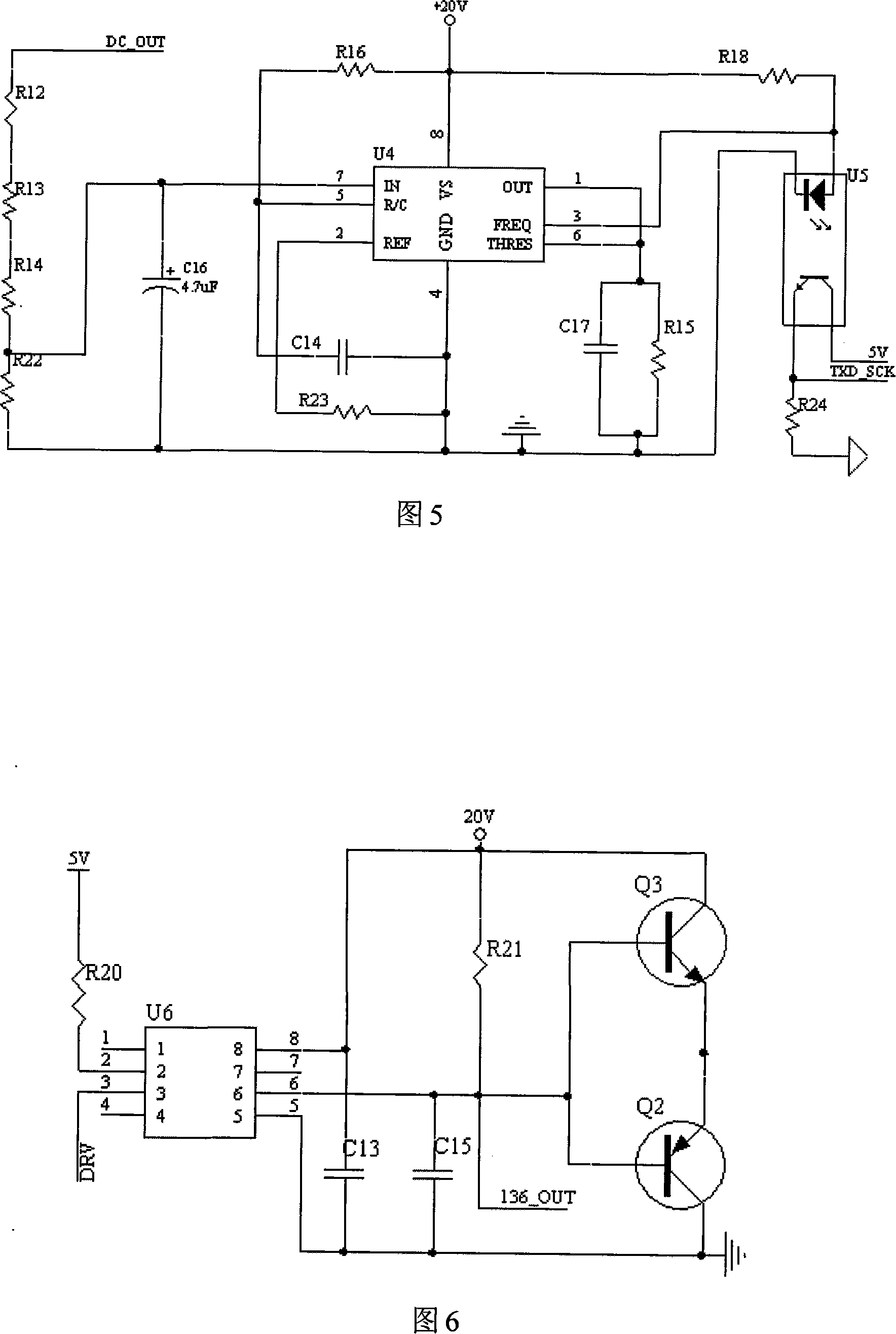

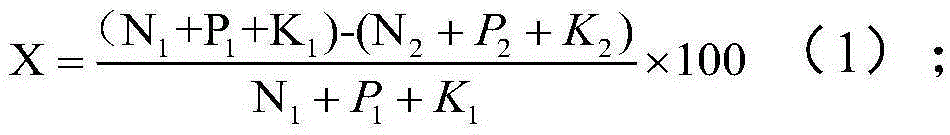

Intelligent AC contactor control unit based on current-variable control

The utility model relates to an intelligent AC contactor control unit based on variable current controlling, which comprising an anti-interference rectification filter module, a contactor coil and an MOSFET module, which are electrically connected in turn with the AC input power supply. Wherein, the output terminal of the anti-interference rectification filter module is connected with a central processing unit via a voltage current sample / isolation module; the central processing unit is connected with the input terminal of the MOSFET module via the isolation drive circuit; and an output terminal of the anti-interference rectification filter module is connected with the internal power module; the internal power module is electrically connected with the voltage current sample / isolation module, the isolation driving circuit and the central processing unit respectively. Due to real-time adjusting and holding the stage coil current and consumed power with the feedback samples collected via the voltage / current isolation module, the control unit can make the contactors keep the same action performance at different voltage class and realize stable operation with low power consumption in the holding period.

Owner:XI AN JIAOTONG UNIV +1

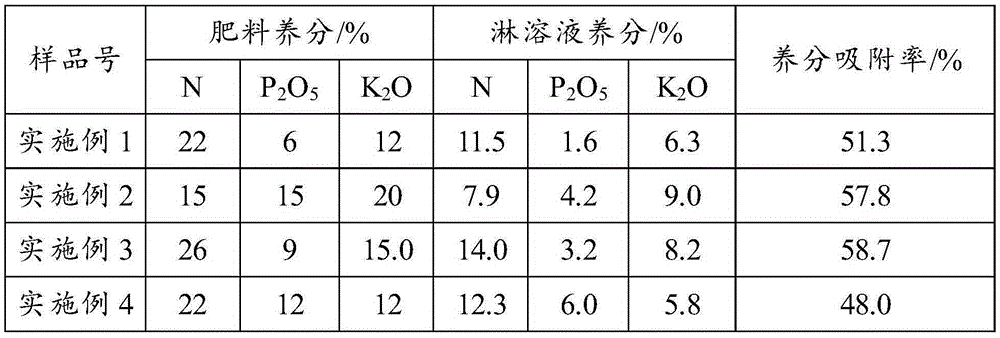

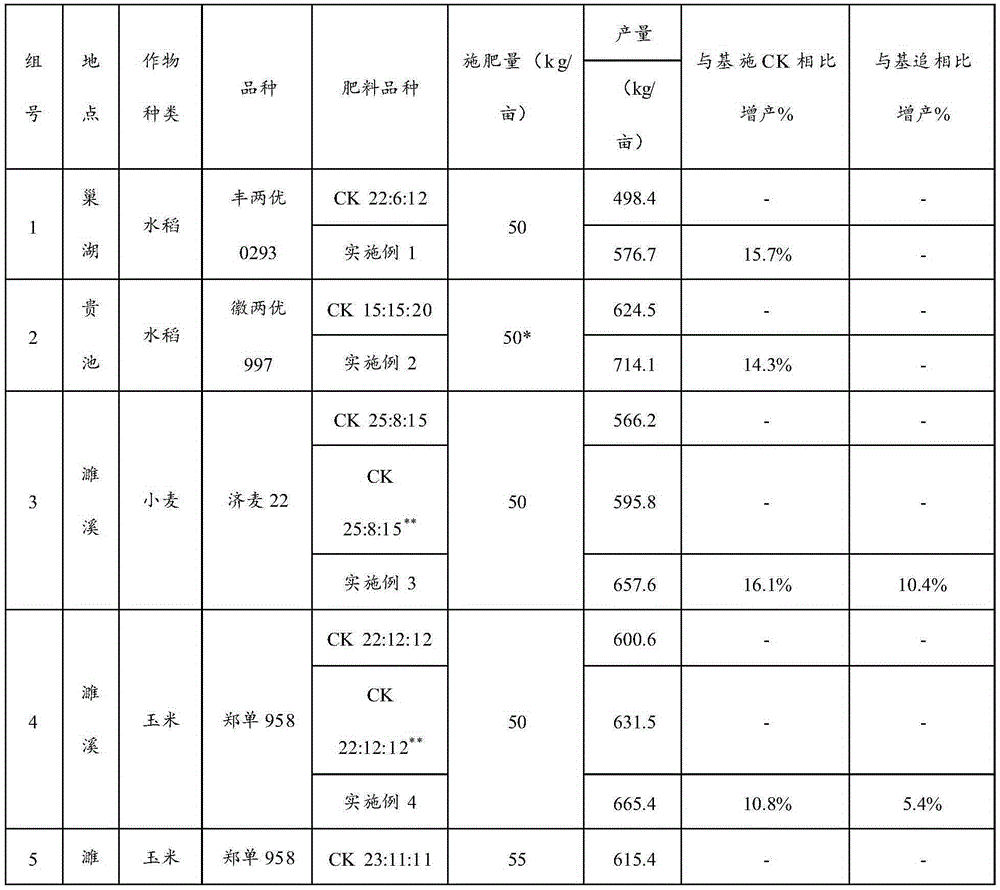

Efficient fertilizer containing biomass charcoal

InactiveCN105272684AStrong adsorption performanceReduce absorptionFertilizer mixturesFertilizerBiomass

The invention provides an efficient fertilizer containing biomass charcoal. The efficient fertilizer comprises manure and a manure additive, wherein the manure additive comprises biomass charcoal, active crop growth factors and a polymer material. The invention provides the low-cost, efficient and environment-friendly novel fertilizer which can be used for improving the soil structure, increasing the organic matters in soil and regulating the microenvironment of soil while increasing the utilization ratio, and furthermore, the risk that harmful substances such as heavy metals enter edible parts of crops is reduced, and the quality of the crops is improved.

Owner:安徽帝元生物科技有限公司

Material taking device

The invention relates to a material taking device which comprises a connecting plate and a driving device used for driving the connecting plate to move up and down, wherein the connecting plate is provided with a suction cup connecting rod; the lower end of the suction cup connecting rod is provided with a suction cup; the suction cup connecting rod is internally provided with a gas circuit; one end of the gas circuit is communicated with an adsorption surface of the suction cup; the other end of the gas circuit is connected with a vacuum pump by a pipeline; the pipeline is provided with an electromagnetic valve; the connecting plate is also provided with an approach switch; and the approach switch is connected with the electromagnetic valve in a communication way. The material taking device is applicable to taking materials for a pole plate of a storage battery. When the material taking device is used for taking the materials, the rejection rate of the pole plate of the storage battery can be reduced; furthermore, when being lifted, the pole plate of the storage battery is not inclined and does not easily fall off.

Owner:ZHANGJIAGANG SHUNCHEN MACHINERY CO LTD

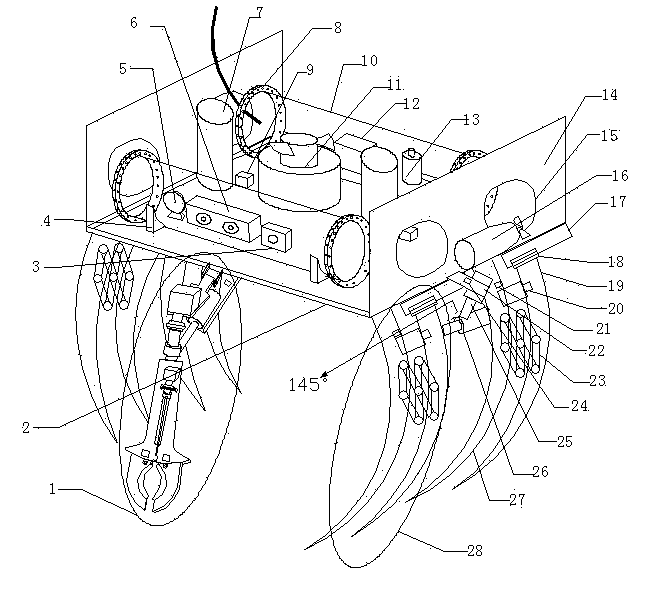

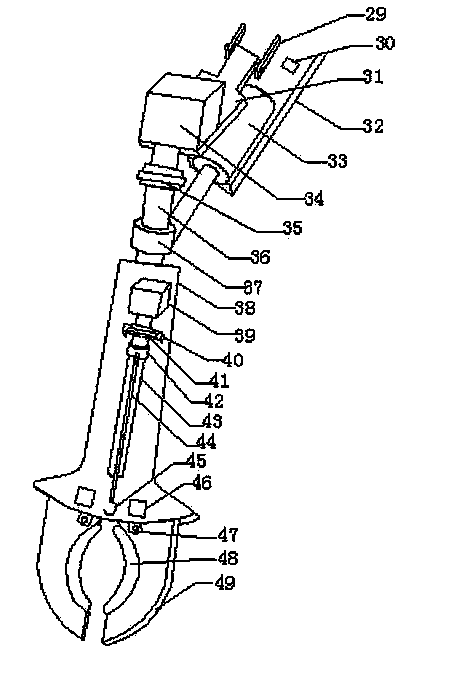

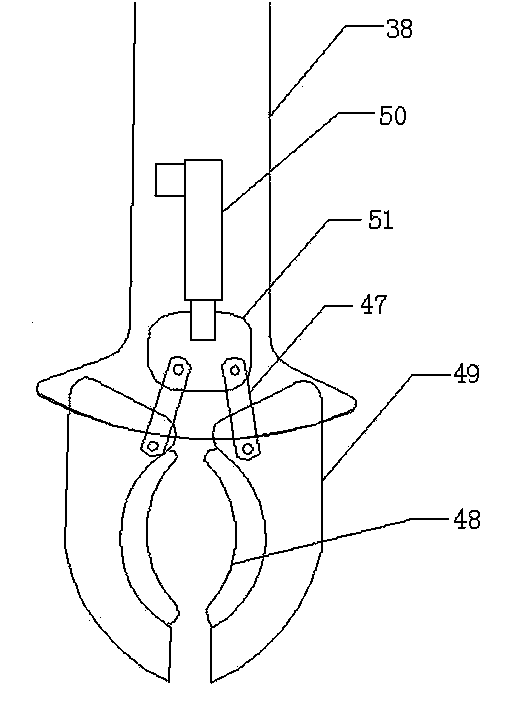

Underwater fishing robot

The invention discloses an underwater fishing robot, belonging to the technical field of robots. The underwater fishing robot comprises a manipulator, a bottom plate, a high-definition camera, support frames, an LED lamp, a binocular camera, a first airbag, a flange plate, a first air pump, an acrylic cylinder, a main propeller, a singlechip controller, a storage battery, a baffle, a notch, a side propeller, a sliding rail, a slide block, a second claw, a first cylinder, a first solenoid valve, a first supporting plate, a scissors arm, a second solenoid valve, a second cylinder, an expansion stick, a first claw, a mechanical claw, a bracket, a third solenoid valve, a first motor seat, a second supporting plate, a third cylinder, a first motor, a first coupling, a connecting shaft, a shaft sleeve, a mechanical arm, a second motor, a bearing rack, a second coupling, a nut, a lead screw, a long handle, a hook, a second air pump, a connecting rod, a second airbag, a finger clamp, an electric push rod and a connecting block, wherein four support frames are arranged on the bottom plate. The underwater fishing robot disclosed by the invention has the advantages of simple operation, wide motion range and high adaptability.

Owner:ZHEJIANG OCEAN UNIV

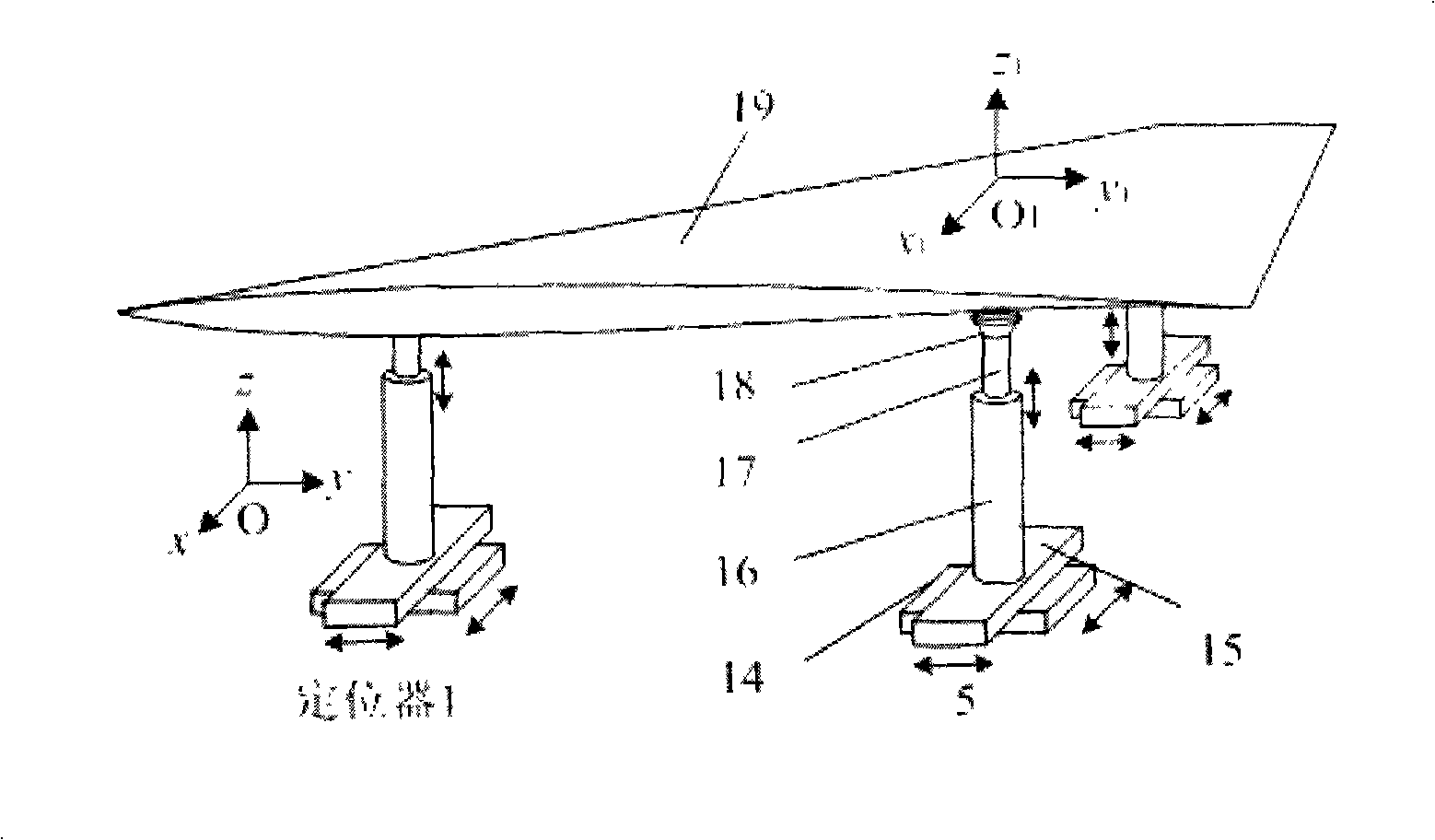

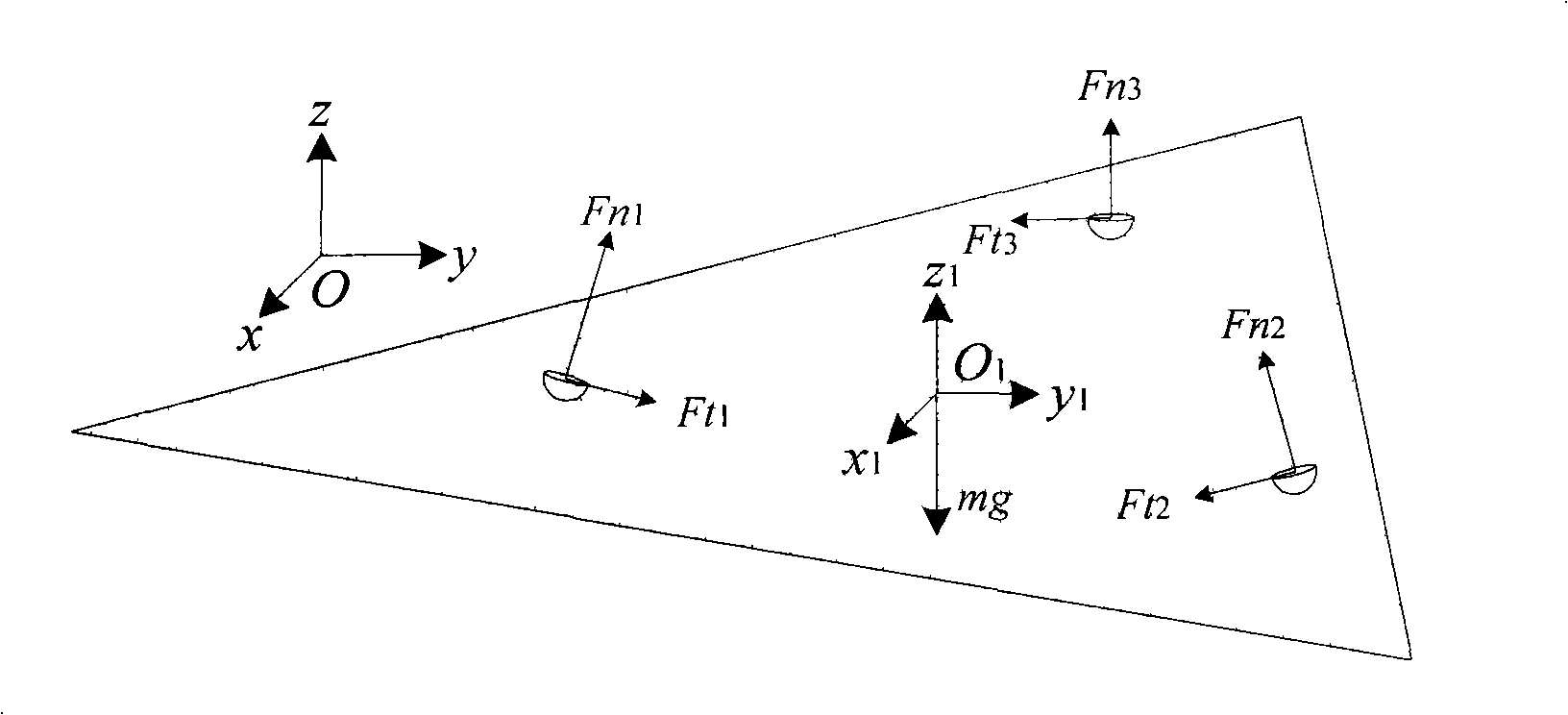

Three 3-axis localizer-based method for safely (stably) adjusting pose of airfoil member

The invention discloses a three 3-axis localizer-based method for safely (stably) adjusting the pose of airfoil member. The mode for flexibly adjusting the pose of the airfoil member, which is based on 3-axis vac-sorb localizers, is adopted; by analyzing the dynamical property of an actuator on the vac-sorb terminal of each localizer and establishing the pose adjusting dynamic model of the airfoil member, the evaluation index of the firm holding stability of the pose adjustment is defined; and according to the evaluation index, factors which influence the firm holding stability are analyzed, and the following measures are adopted to ensure the firm holding stability during pose adjustment: when the airfoil member needs to be laid on a supporting point, a much more horizontal position needs to be selected; the pose accuracy of positioning needs to be increased as much as possible during hoisting positioning, and the rotational angle of the spherical head of the terminal actuator is reduced; and under the premise that the efficiency of pose adjustment is ensured, the speed and the accelerated speed of the pose adjustment are reduced as as much as possible.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Packing box casing machine

The invention discloses a packing box casing machine which comprises a material taking mechanism, an overturn mechanism, a first product conveying belt and a second product conveying belt, wherein the first product conveying belt is sequentially connected with the second product conveying belt; the first product conveying belt is used for conveying vertical packing boxes; the second product conveying belt is used for conveying horizontal packing boxes; the overturn mechanism is positioned above one end, close to the first product conveying belt, of the second product conveying belt; and the material taking mechanism is related to an output end of the second product conveying belt. With the adoption of the packing box casing machine, the packing boxes can be changed from a vertical state to a horizontal state, and then are clamped and cased, so that the possibility of shaking of the packing boxes easily caused in a clamping process is reduced, the casing safety and an casing accuracy rate of the packing boxes are ensured, and the casing speed is increased.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Plank cutting device

The invention particularly relates to a plank cutting device. The plank cutting device can save time and labor, is high in cutting speed, can collect wood bits generated in the cutting process, and does not affect the surrounding environment. To achieve the above technical purposes, the plank cutting device comprises a placement board and the like; supporting legs are installed on the left side and the right side of the bottom of the placement board symmetrically; supporting rods are installed on the left side and the right side of the top of the placement board symmetrically; a top board is installed between the top ends of the supporting rods on the left side and the right side; a compressing device is arranged on the left side of the top board; a compressing component of the compressingdevice is located above the placement board; and a cutting device body is arranged on the right side of the bottom of the top board. Through a pushing device, the situation that a person makes contact with a plank and pushes the plank with hands is not needed, the person is not likely to be cut by a saw web, and a collection device can collect the wood bits generated in the cutting process, so that the effects of saving time and labor and being high in cutting speed are achieved.

Owner:钟清

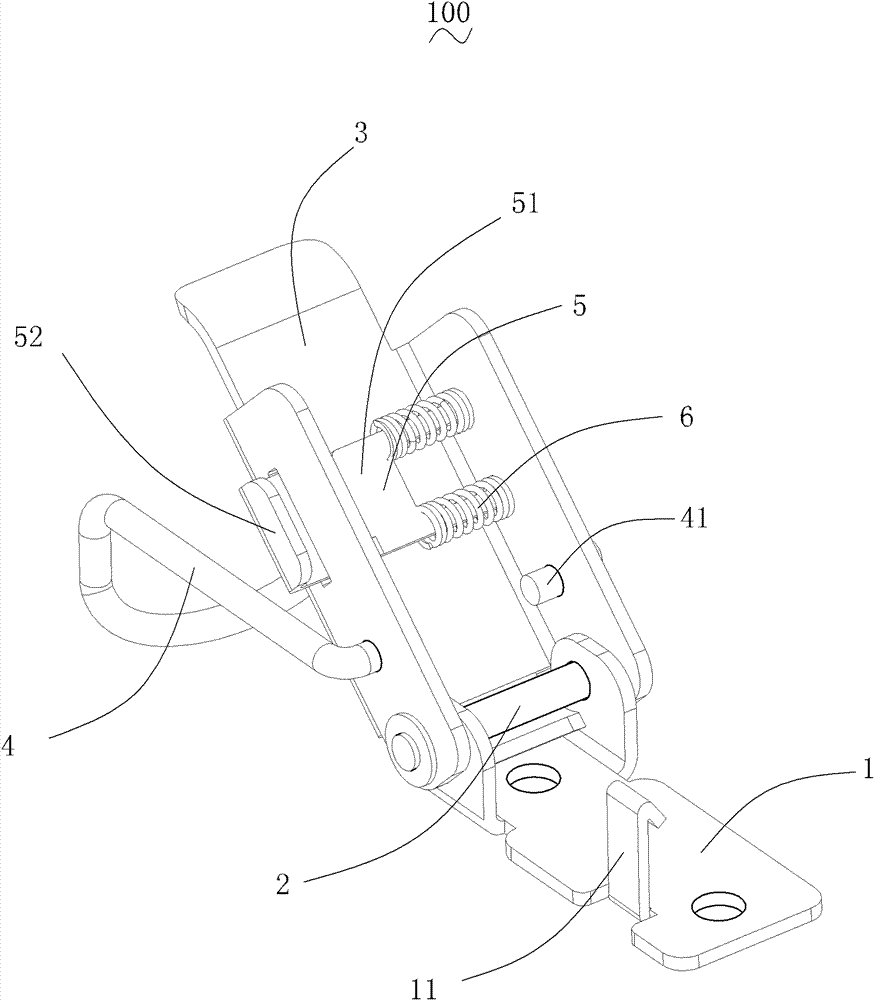

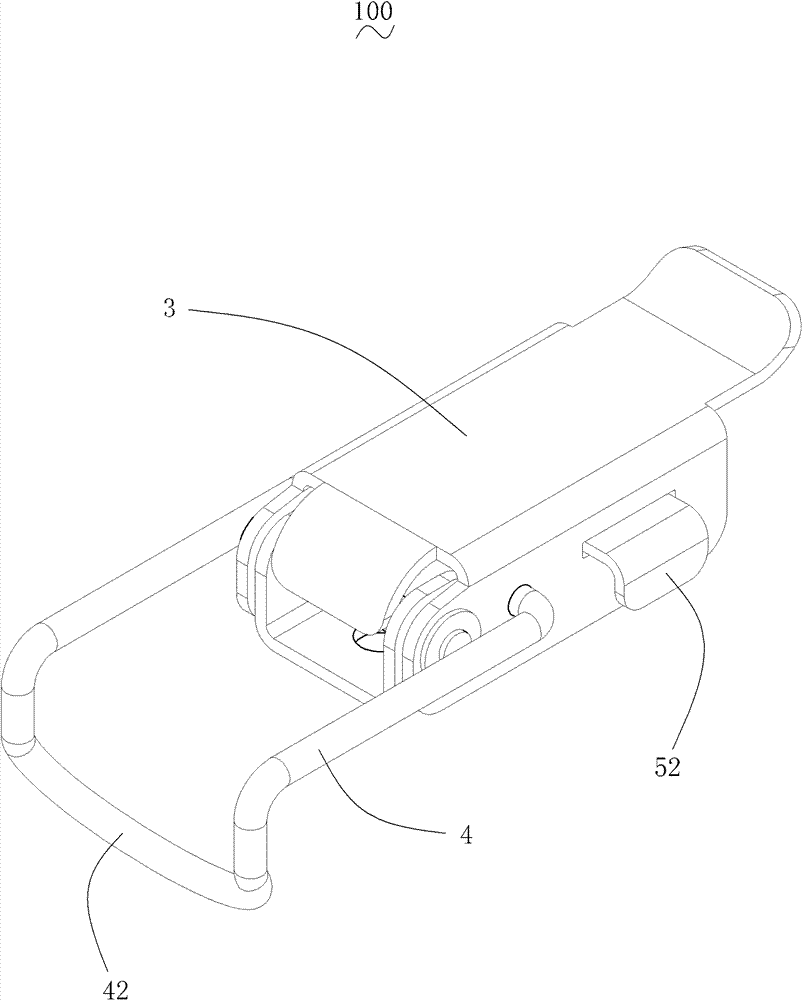

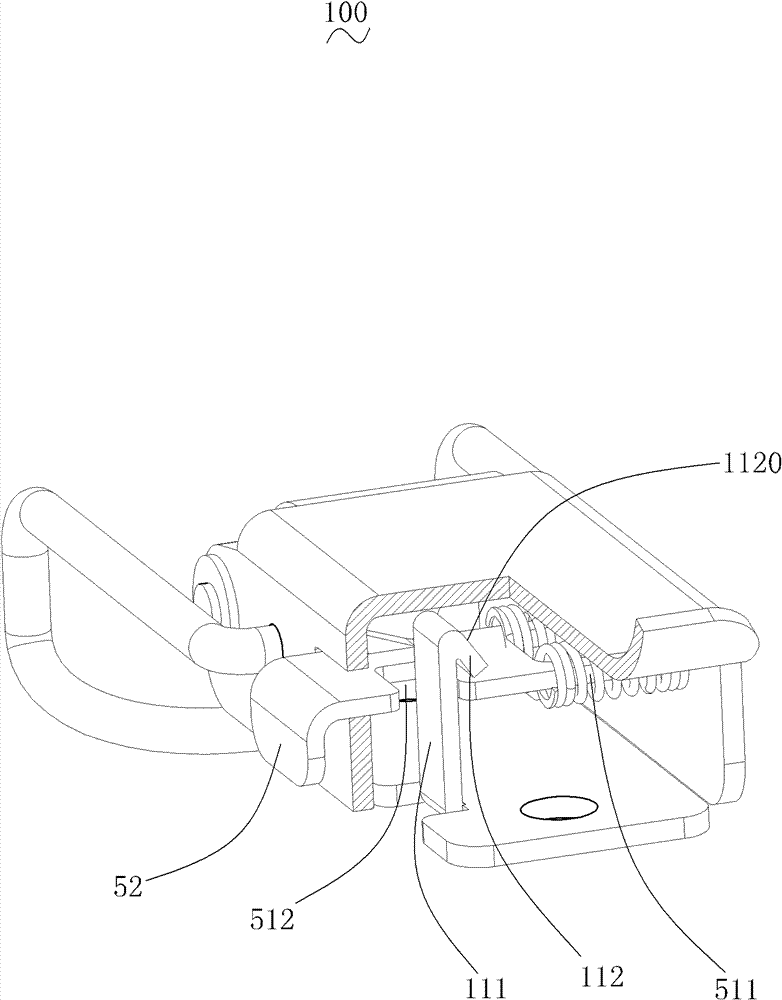

Hasp structure

The invention discloses a hasp structure, which is used for locking a lamp shell and comprises a basal body, a pin roll assembly which is arranged in the basal body in a penetrating way, a movable piece which is connected with the basal body through the pin roll assembly, and a hasp which is assembled on the movable piece. The hasp structure additionally comprises a locking piece, an elastic element which is connected with the locking piece and the movable piece, and a fastening part which extends from the basal body. The movable piece covers the basal body. The locking piece moves relative to the movable piece due to the elastic deformation of the elastic element. The fastening part automatically clamps the locking piece. Since the hasp structure comprises the fastening part which is arranged on the basal body and the locking piece which is elastically connected with the movable piece, when the movable piece covers the basal body, the fastening part automatically clamps the fastening piece to realize the stable fixation between the movable piece and the basal body, so as to enable the hasp structure to be in a stable closed state.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

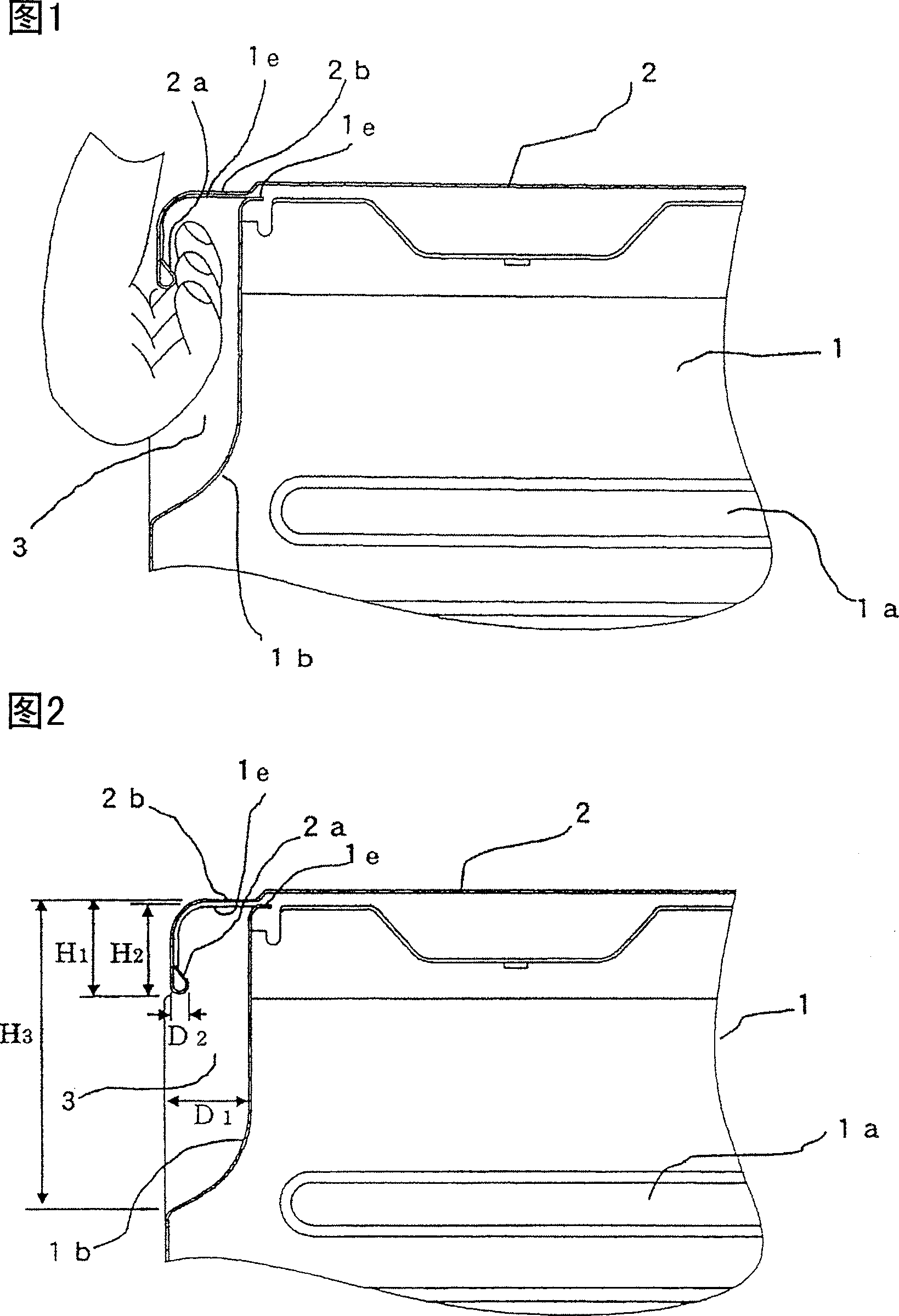

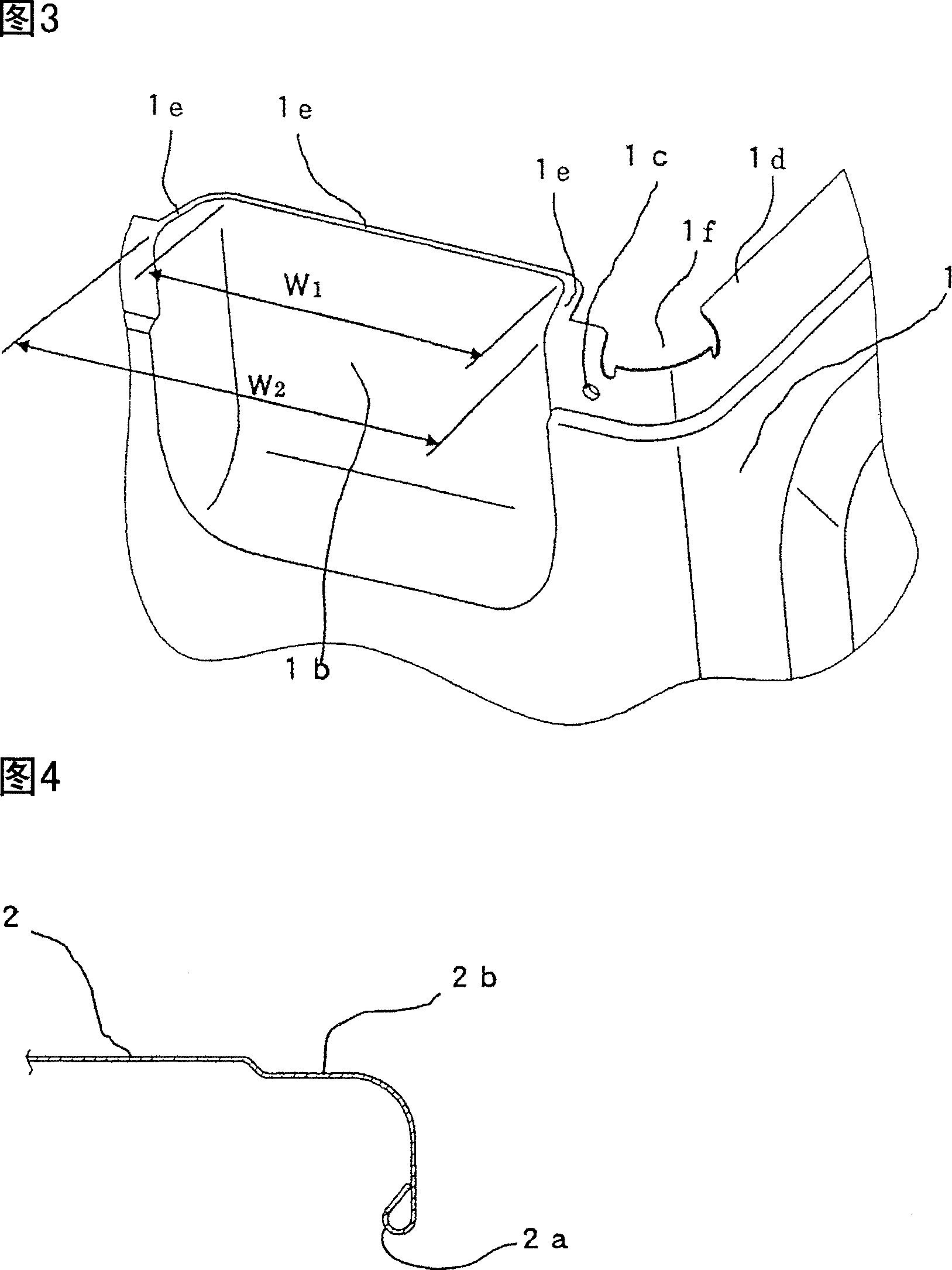

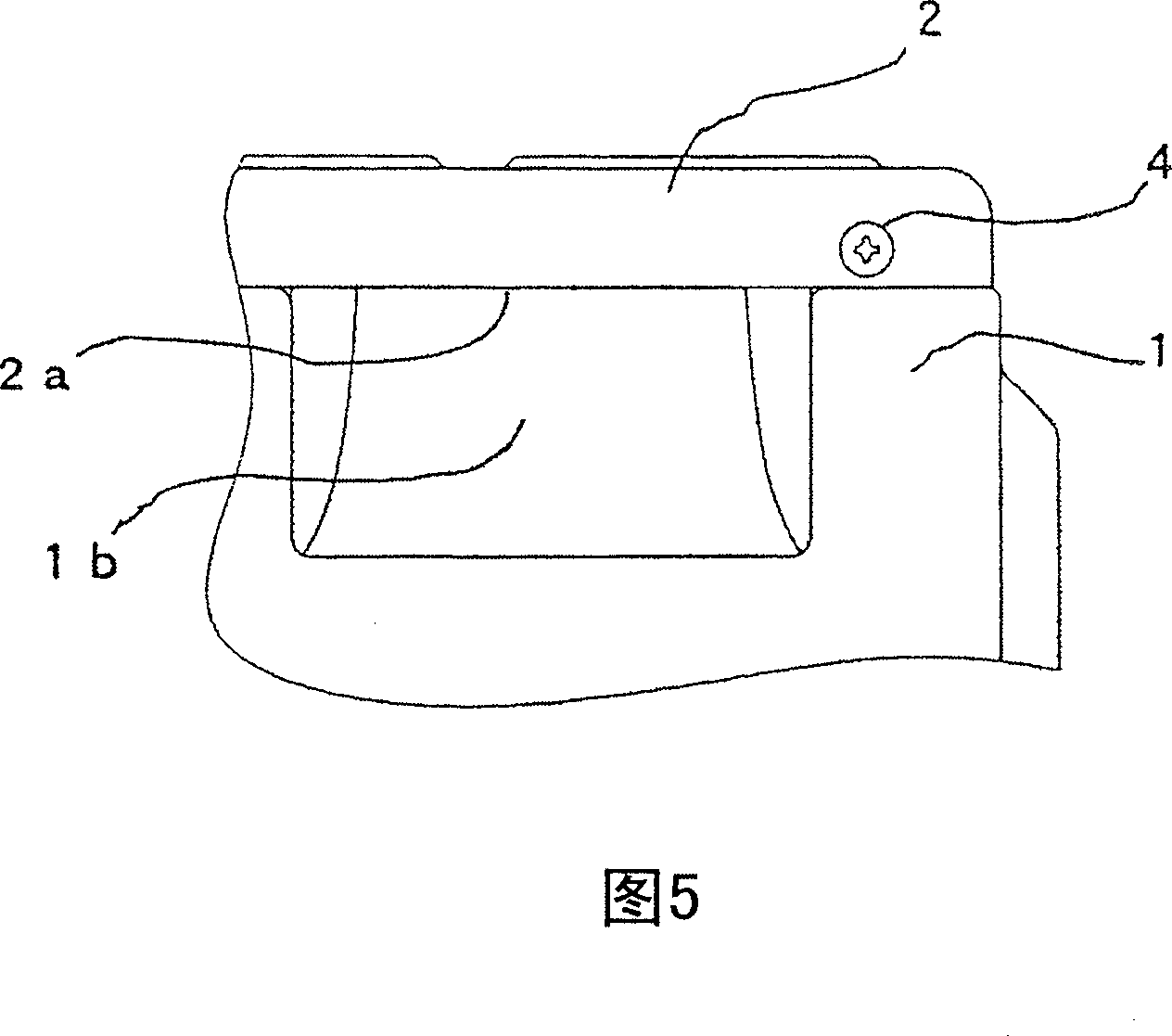

Outdoor machine of air conditioner

InactiveCN1952501AHigh strengthGuaranteed StrengthLighting and heating apparatusHeating and ventilation casings/coversMechanical engineering

The present invention provides an outdoor machine of an air conditioner capable of ensuring the housing strength without increasing the size of said outdoor machine, preventing handles for portage extruding out of left and right on the top panel of the housing, and being controlled easily without handles for portage extruding out of left and right on the top panel of the housing. The housing consists of the box body and upper parts uses for blocking the upper opening of said box body. Said upper parts comprise a handle part for portage formed integrally on end region of the short border side. A recessed part indenting into the box body is formed integrally on the side of said box body, where the formation position is corresponding to that of said handle part. A flat portion is adjacent to the recessed part. The top surface of said recessed part and the top surface of said flat portion adjacent to said recessed part are connected integrally and indent into inner side of said box body. The top surface of said recessed part is located in a place near of contacting the undersurface of said upper parts. A space for fingers insertion between the recessed part and said handle part forms a handle.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

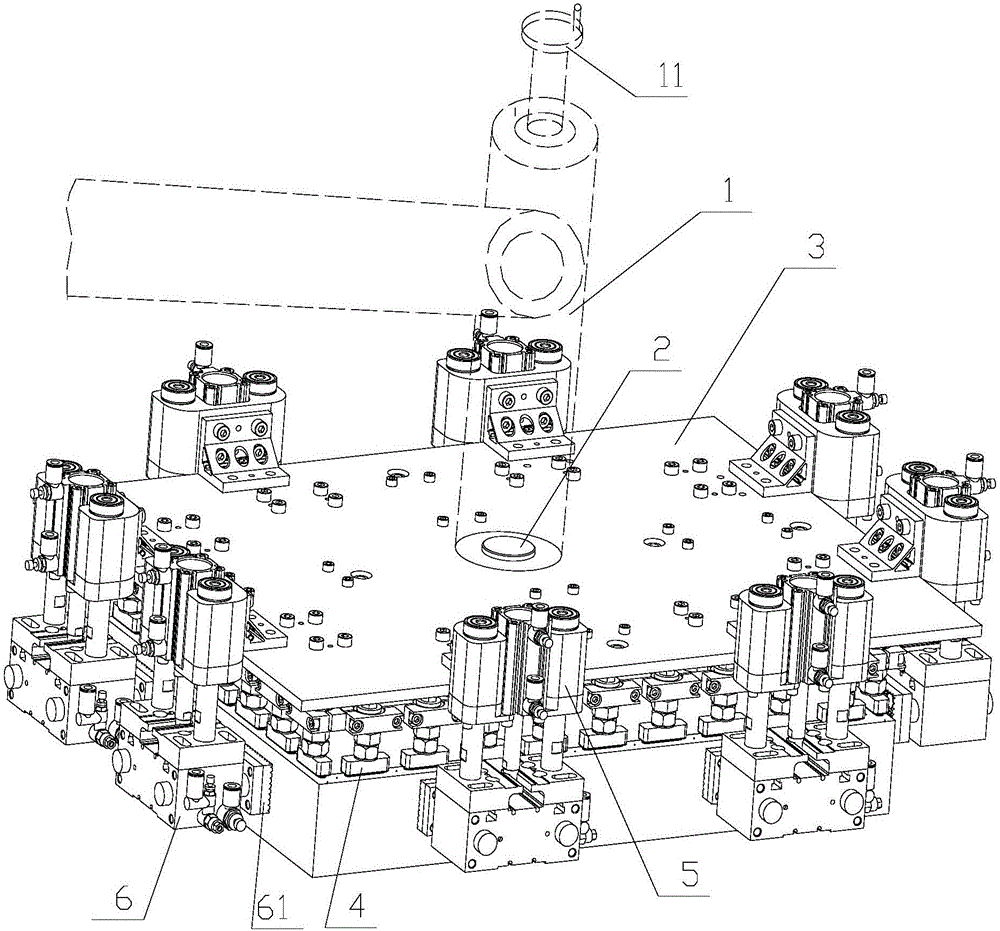

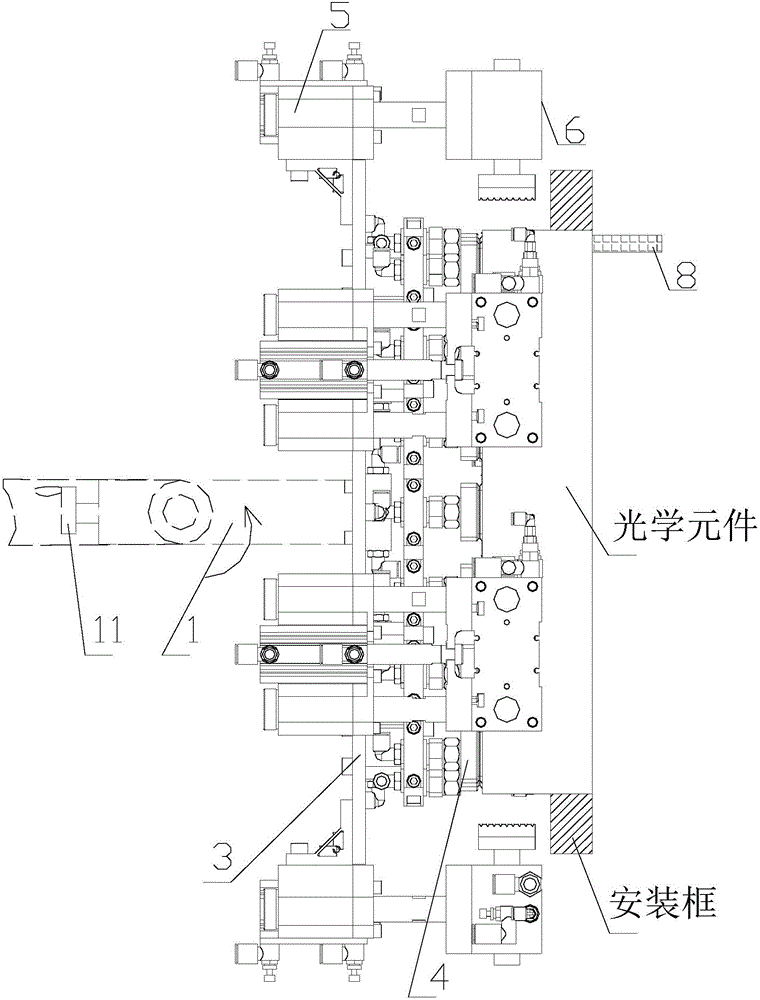

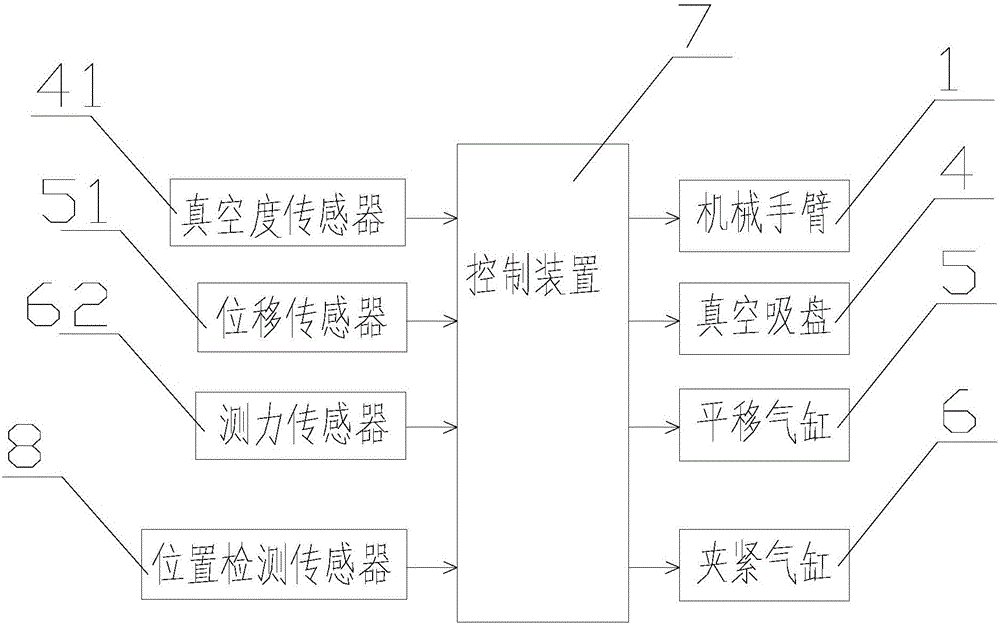

Vacuum absorbing and grabbing mechanism for optical elements and control method thereof

The invention discloses a vacuum absorbing and grabbing mechanism for optical elements and a control method thereof. The mechanism comprises a mechanical arm; the mechanical arm is connected to the upper surface of a fixed disc through a manipulator flange plate; multiple downward vacuum suckers are uniformly distributed on the lower surface of the fixed disc along the edge line for absorbing the optical elements to be grabbed; at least two translation cylinders are fixedly connected to the peripheral side wall of the fixed disc; the translation cylinders are longitudinally arranged; a piston rod of each translation cylinder is connected with a clamping cylinder; piston rods of the clamping cylinders are horizontally arranged towards the side surfaces of the optical elements; the translation cylinders drive the clamping cylinders to longitudinally move; the clamping cylinders laterally clamp the optical elements; and the mechanical arm, the vacuum suckers, the translation cylinders and the clamping cylinders are all connected to a control device. The mechanism can firmly grab the optical elements and gradually and stably mount the optical elements in an optical element mounting frame, is fast and convenient, and cannot damage the optical elements.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

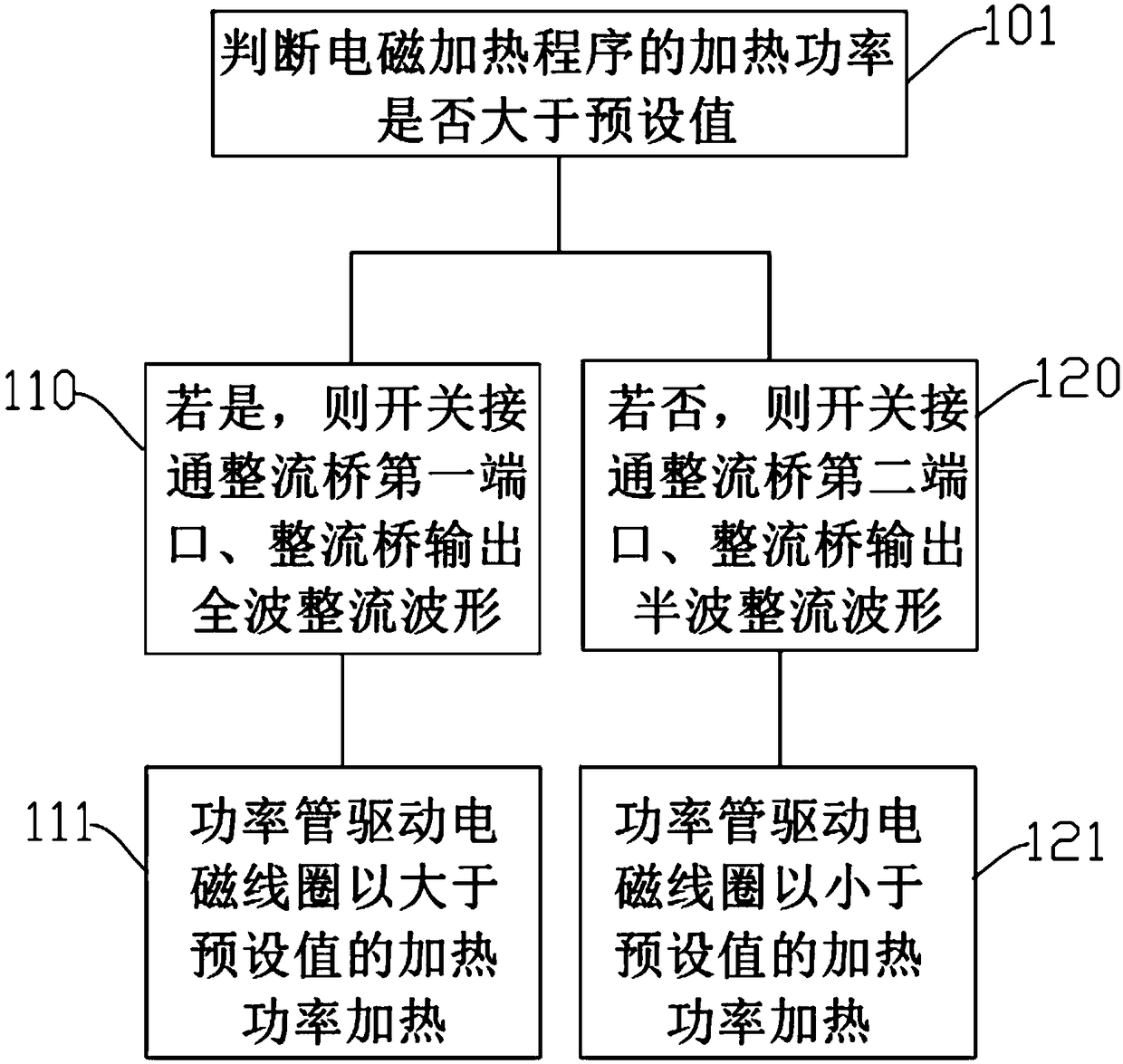

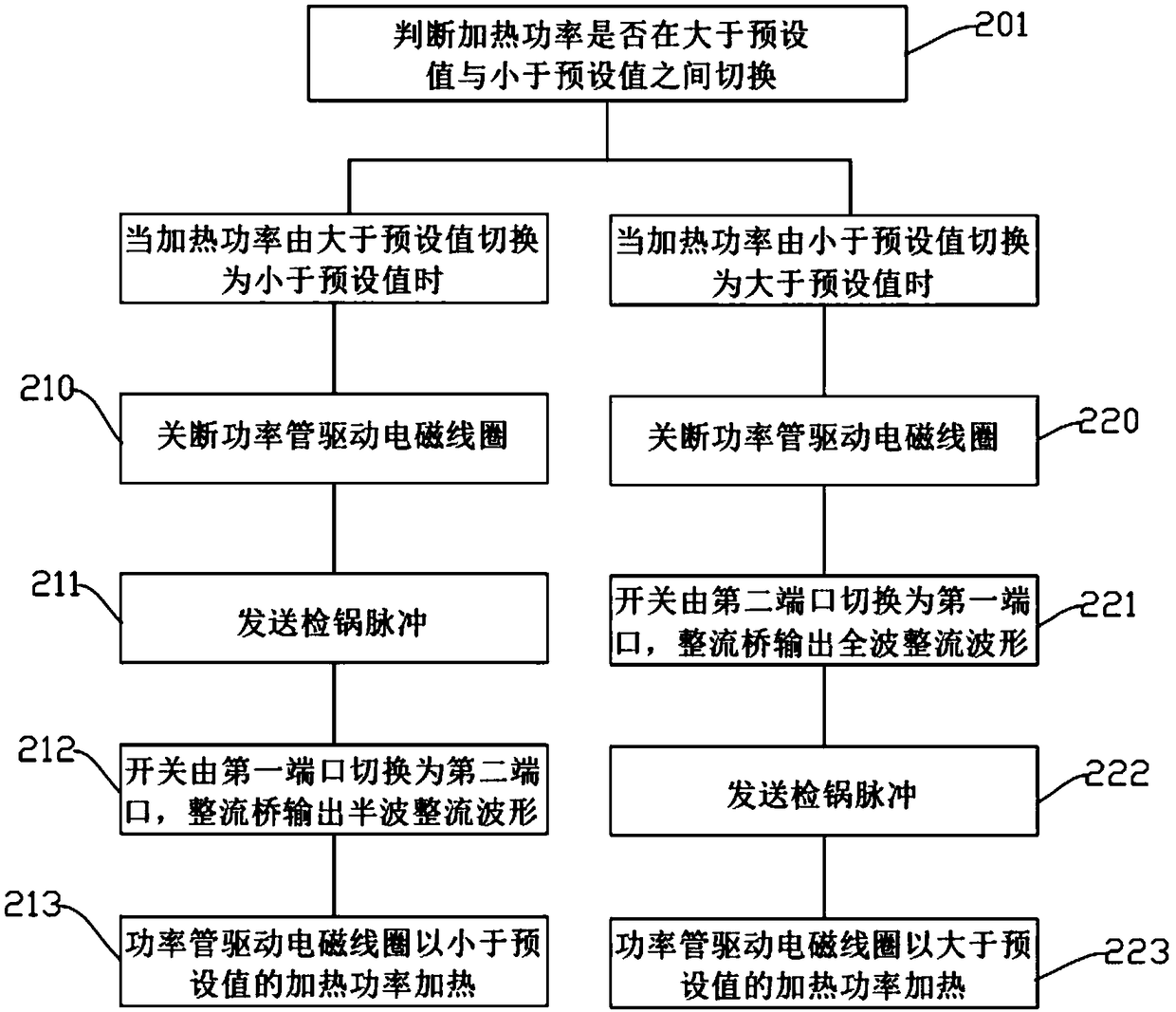

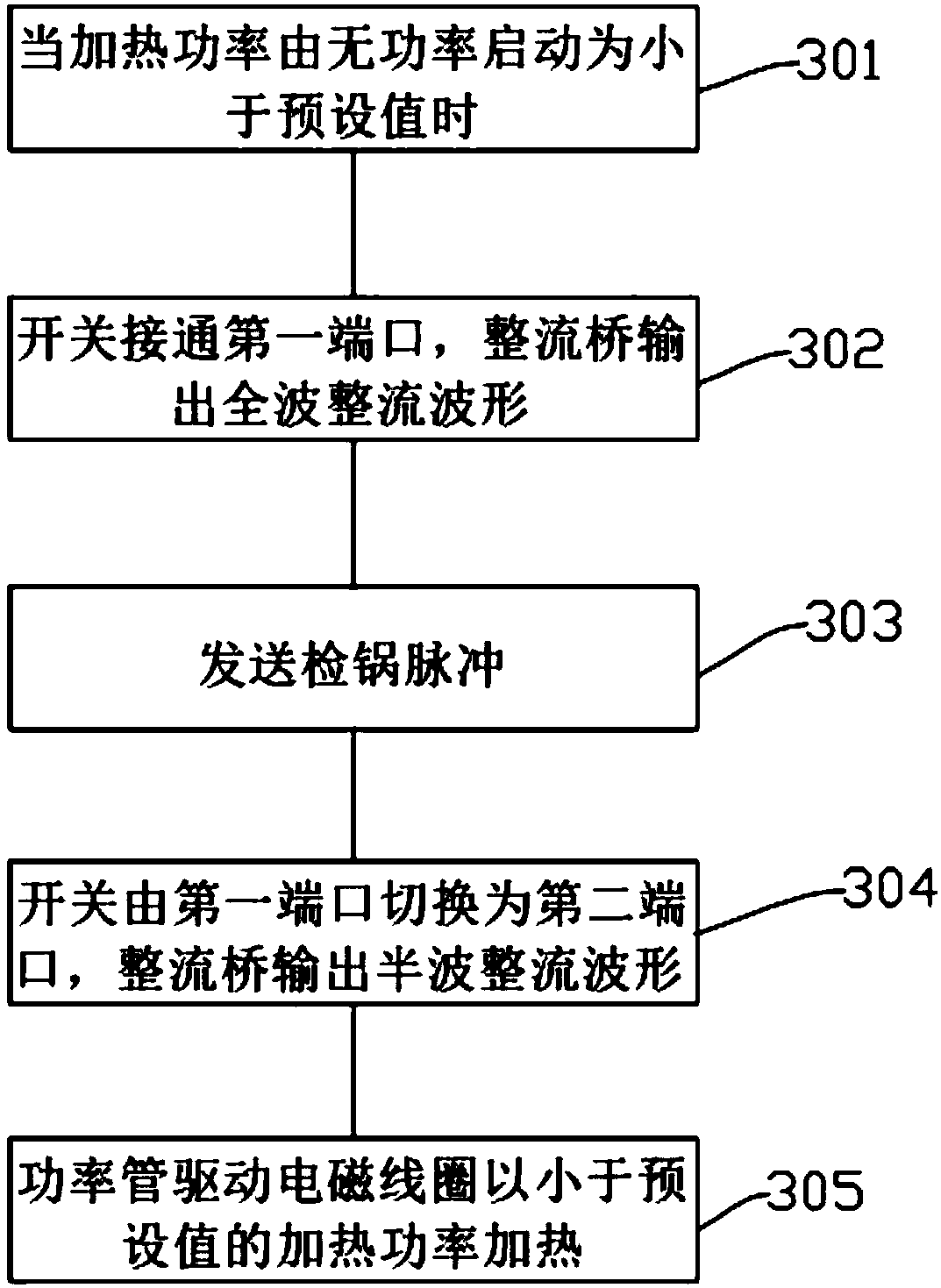

Power control circuit and method of electromagnetic heating device

InactiveCN108966397AThe circuit is simple and reliableGood stabilityInduction heating controlPower controlHardware circuits

The invention provides a power control circuit of an electromagnetic heating device. The power control circuit comprises a rectifier module, a control module, a power tube and a resonance module. Therectifier module comprises a rectifier bridge. The rectifier bridge has a first port and a second port. The power control circuit further includes a switch connected to the rectifier bridge. The switch switches between the first port and the second port under the control of the control module so that the rectifier bridge outputs a full-wave rectification waveform or a half-wave rectification waveform. The control module drives the power tube to control the resonance module to operate under the full-wave rectification waveform or the half-wave rectification waveform so as to output different heating powers. By means of the switch, the waveform output by the rectifier bridge can be a full-wave rectification waveform or a half-wave rectification waveform, thereby realizing switching between high-power heating and low-power heating. The power control circuit is realized by a hardware circuit, and is simple, reliable, and stable. The invention also provides a power control method of the electromagnetic heating device.

Owner:JOYOUNG CO LTD

Fingerprint recognition device and terminal with fingerprint recognition device

ActiveCN105426873AImprove structural stabilityImprove structural strengthPrint image acquisitionPattern recognitionLight guide

The invention provides a fingerprint recognition device and a terminal with the fingerprint recognition device, wherein the fingerprint recognition device comprises a support, a fingerprint recognition chip assembled under the support, at least one light source fixed on the periphery of the support and a cushion plate supported on the surface of the support, the cushion plate is located on the periphery of the light source, and the cushion plate is used to isolate external stray light along a side edge direction of the fingerprint recognition device from the light source; and the cushion plate is disposed to isolate the external stray light along the side edge direction of the fingerprint recognition device from the light source and hinder adverse influences brought by the external stray light to the fingerprint recognition device, and the light source is embraced in the cushion plate to reduce losses of light rays emitted by the light source and potentially increase luminous flux emitted by the light source into a light guide plate so as to better realize a fingerprint recognition function. In addition, setting of the cushion plate makes for immobilization and stabilization among a conduit plate, a cover plate and the support and enhances structural stability and overall strength of the whole fingerprint recognition device.

Owner:KUNSHAN JIAHUA ELECTRONICS

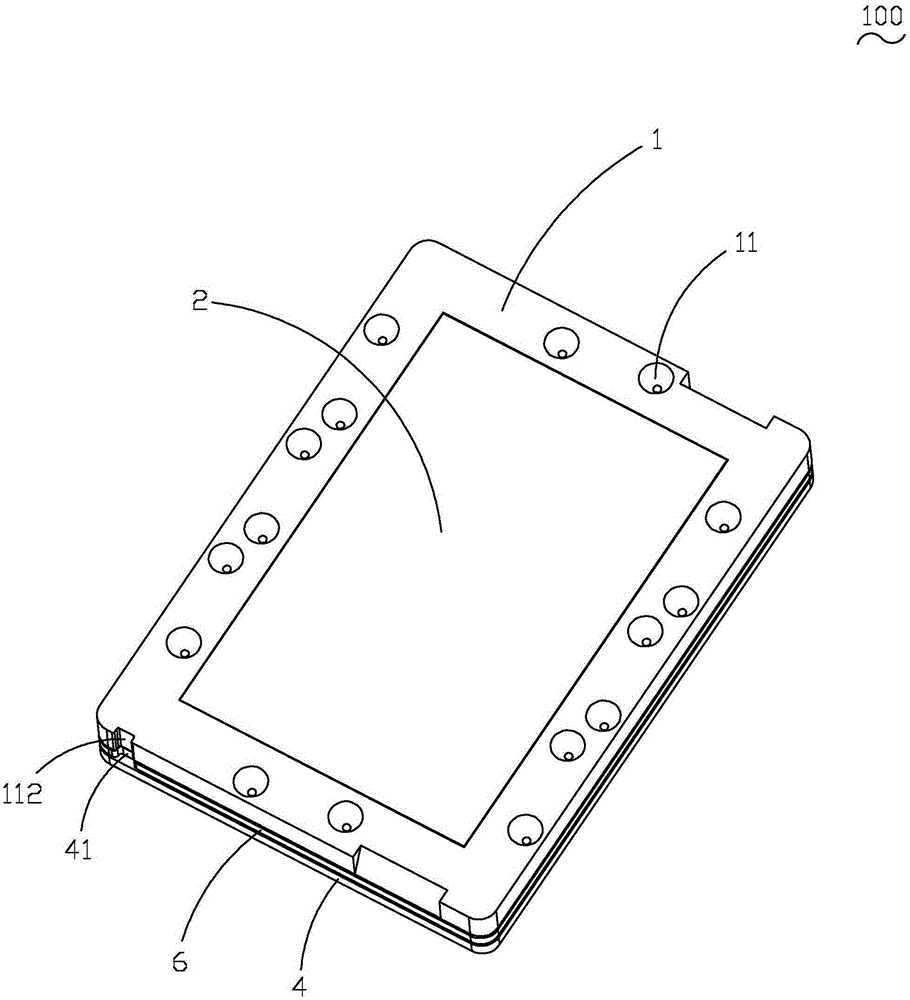

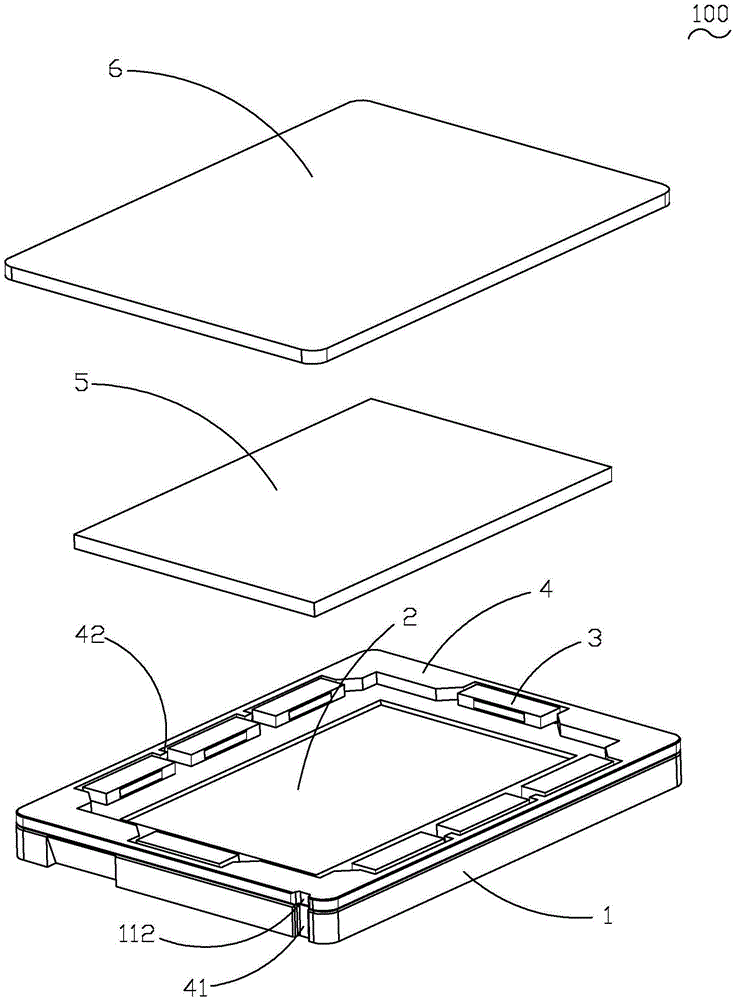

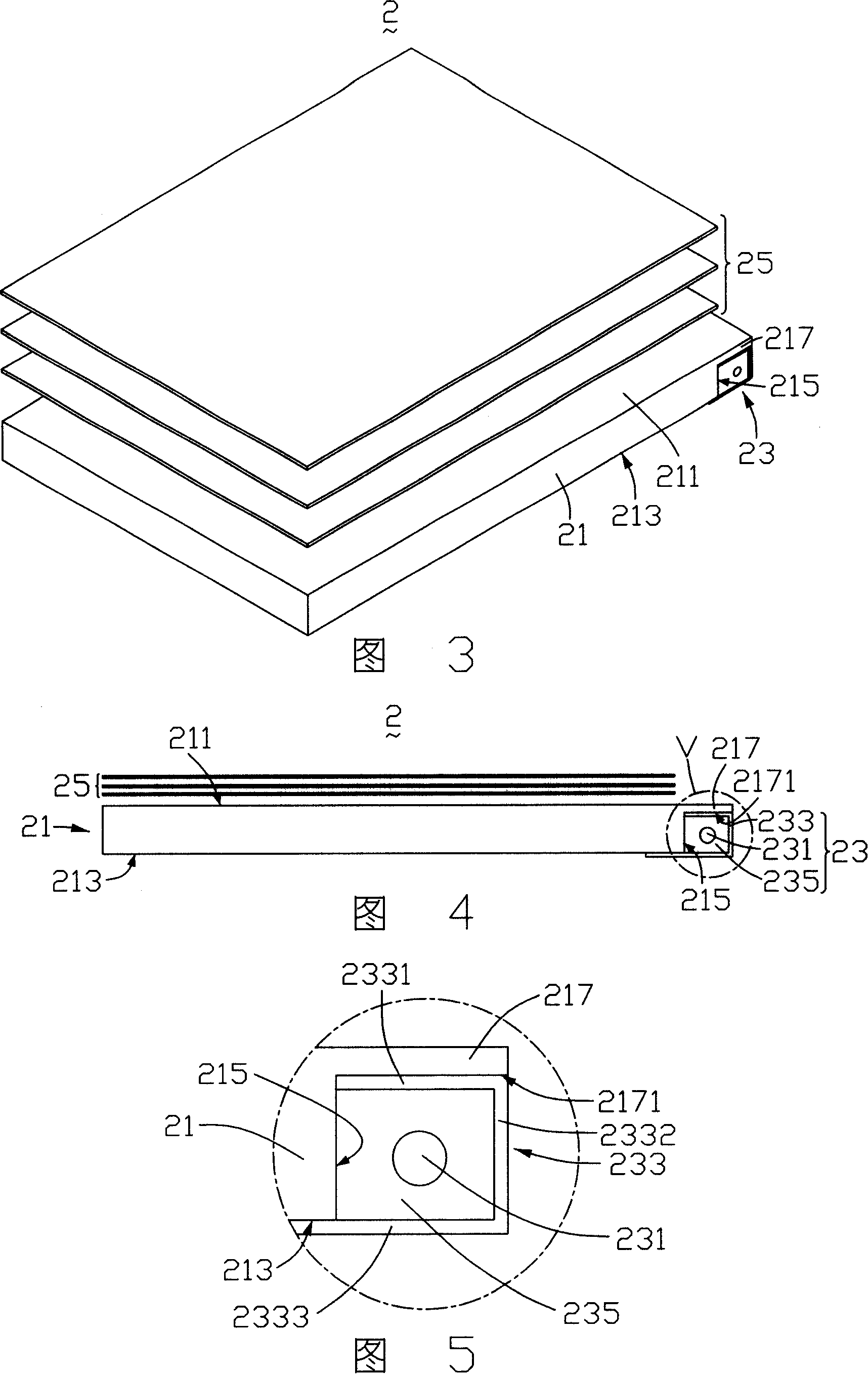

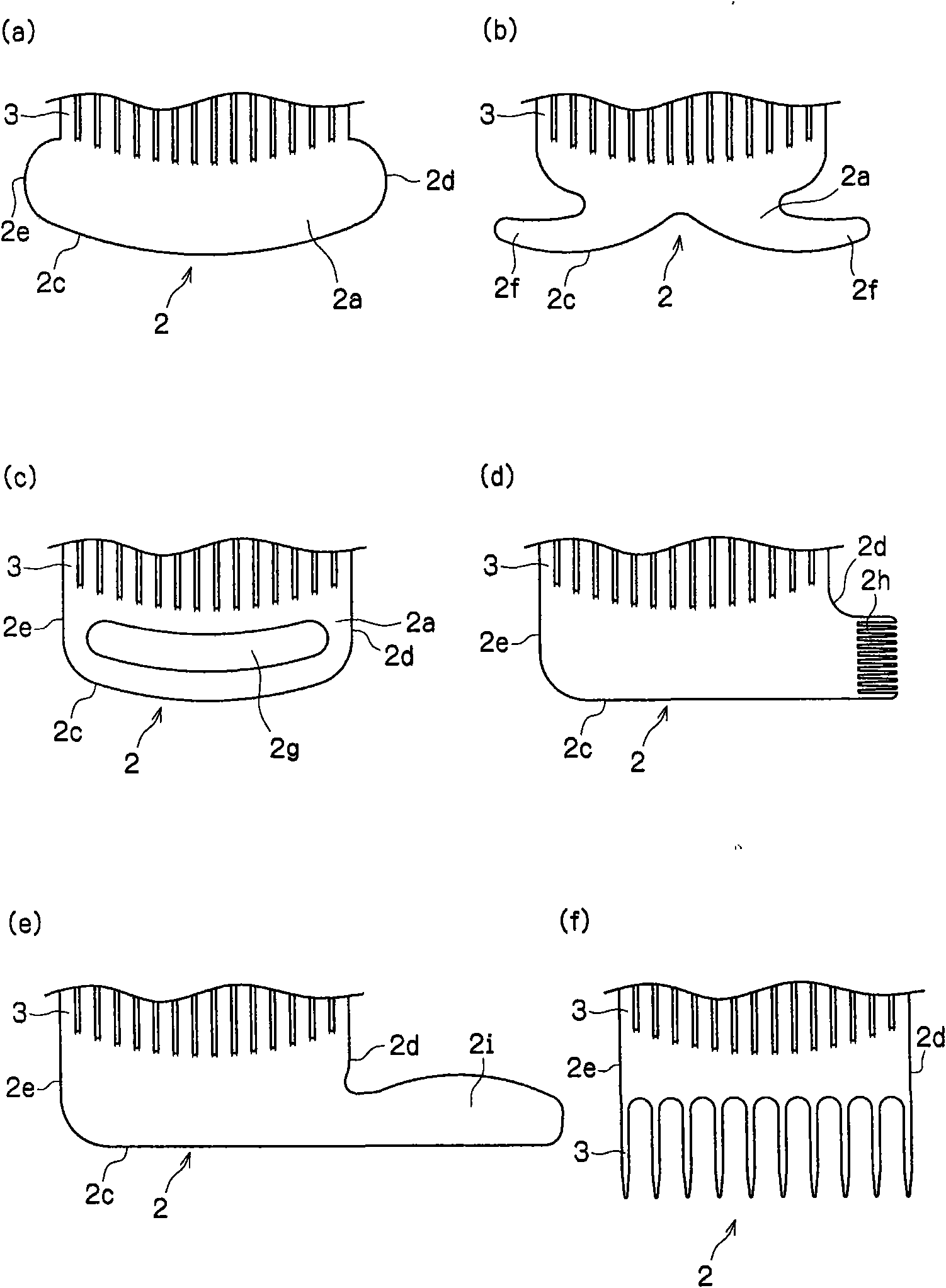

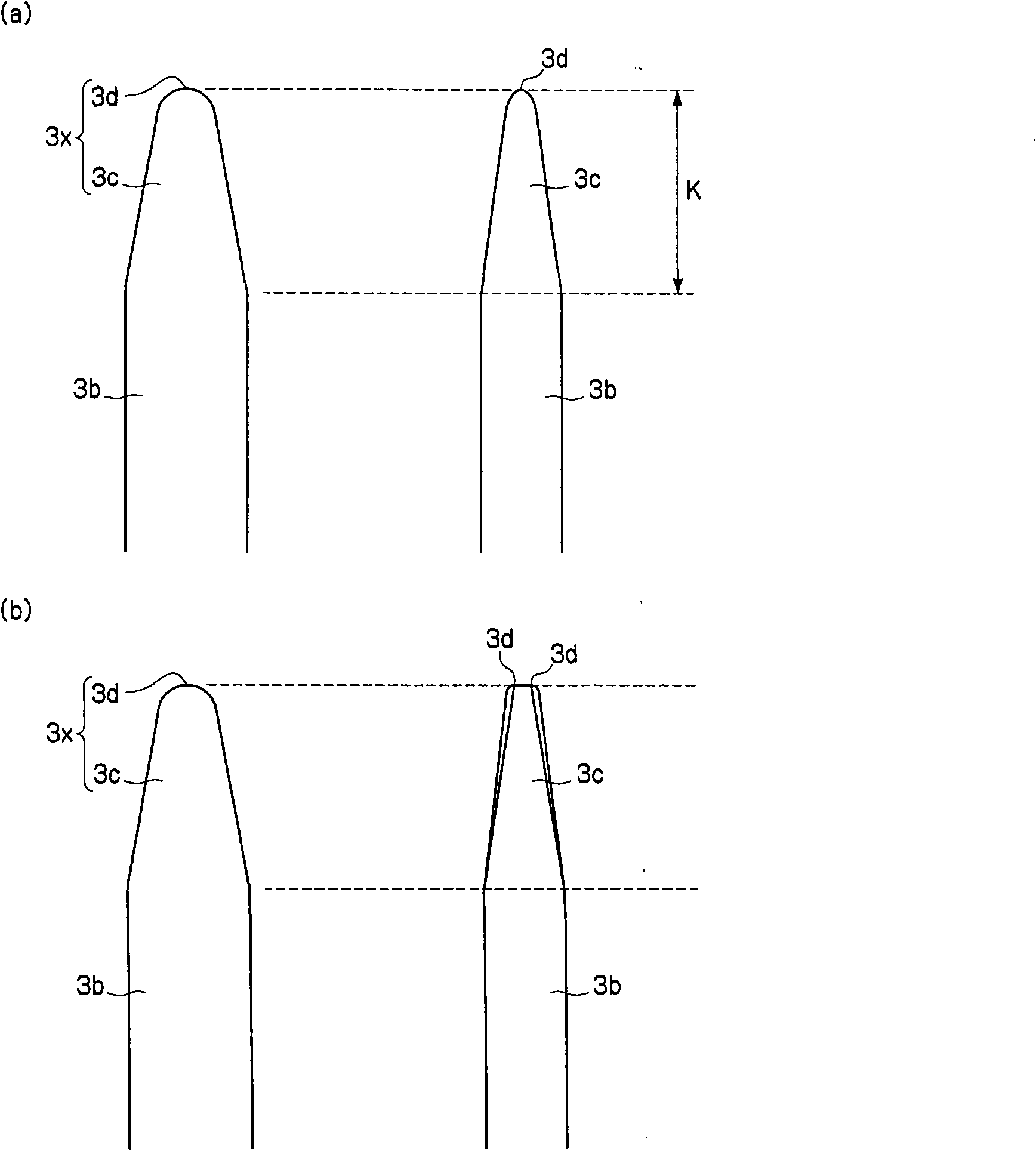

Backlight module and LCD apparatus

This invention relates to an aphototropism mode set and LCD apparatus, wherein, the aphototropism mode set comprises a base body and at least one pair of holding body located on the base body with at least one ditch. The ditch is a trough with various spaces along the axis direction with at least one linear light source located and elastically fixed in. The aphototropism mode set and LCD apparatus is of high property and can be quickly assembled with low cost.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

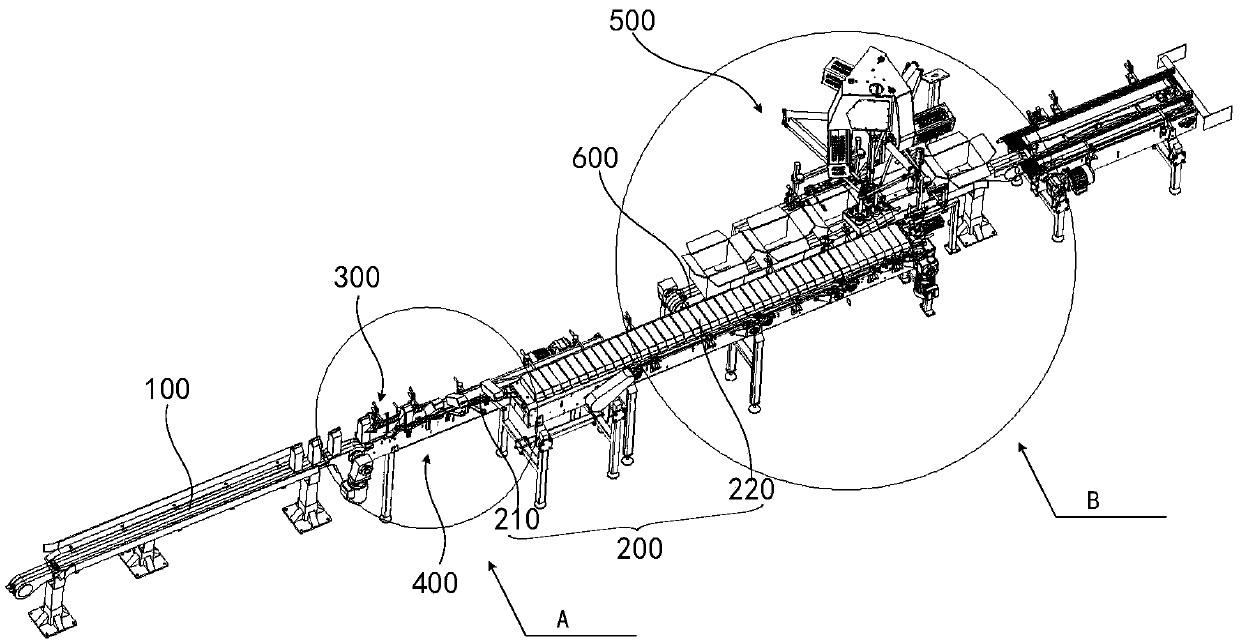

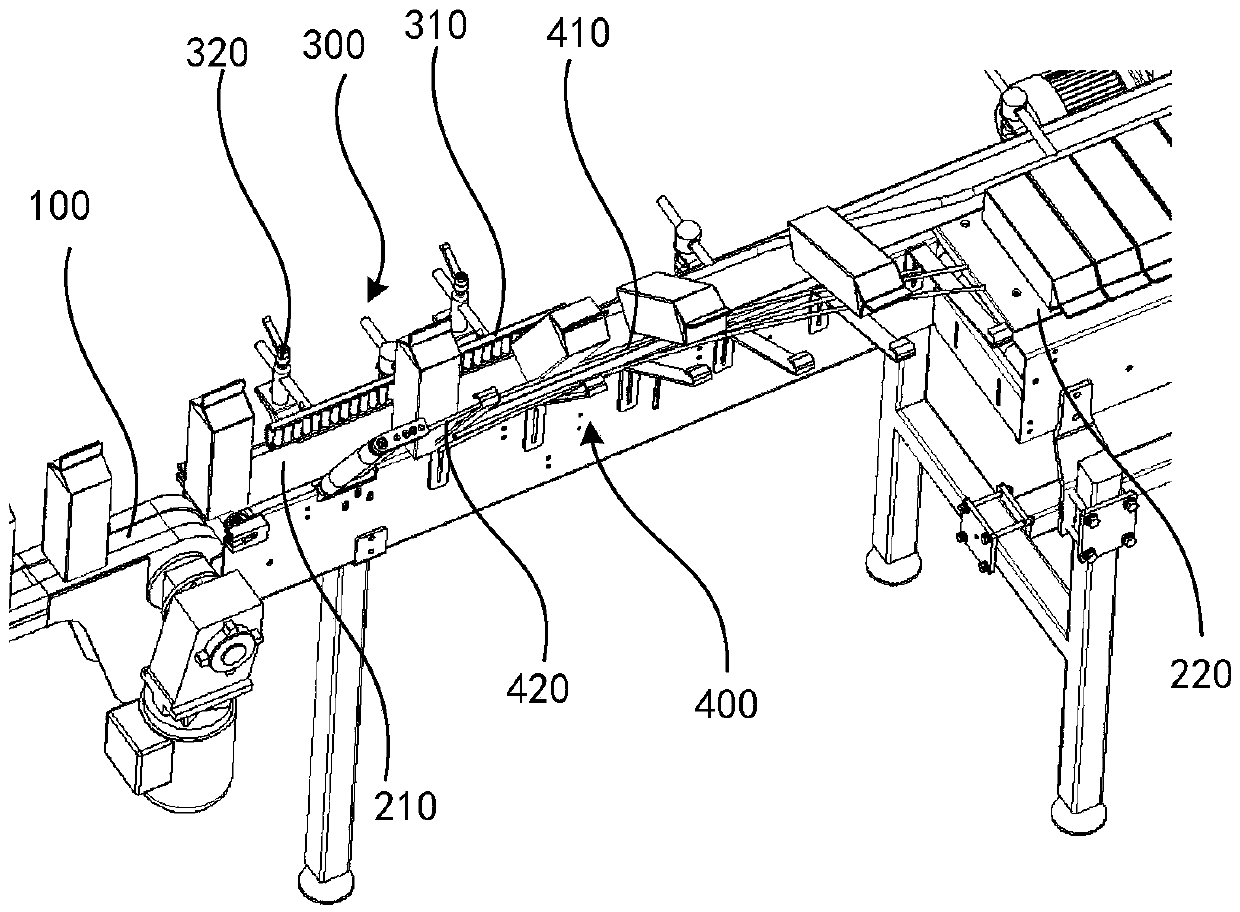

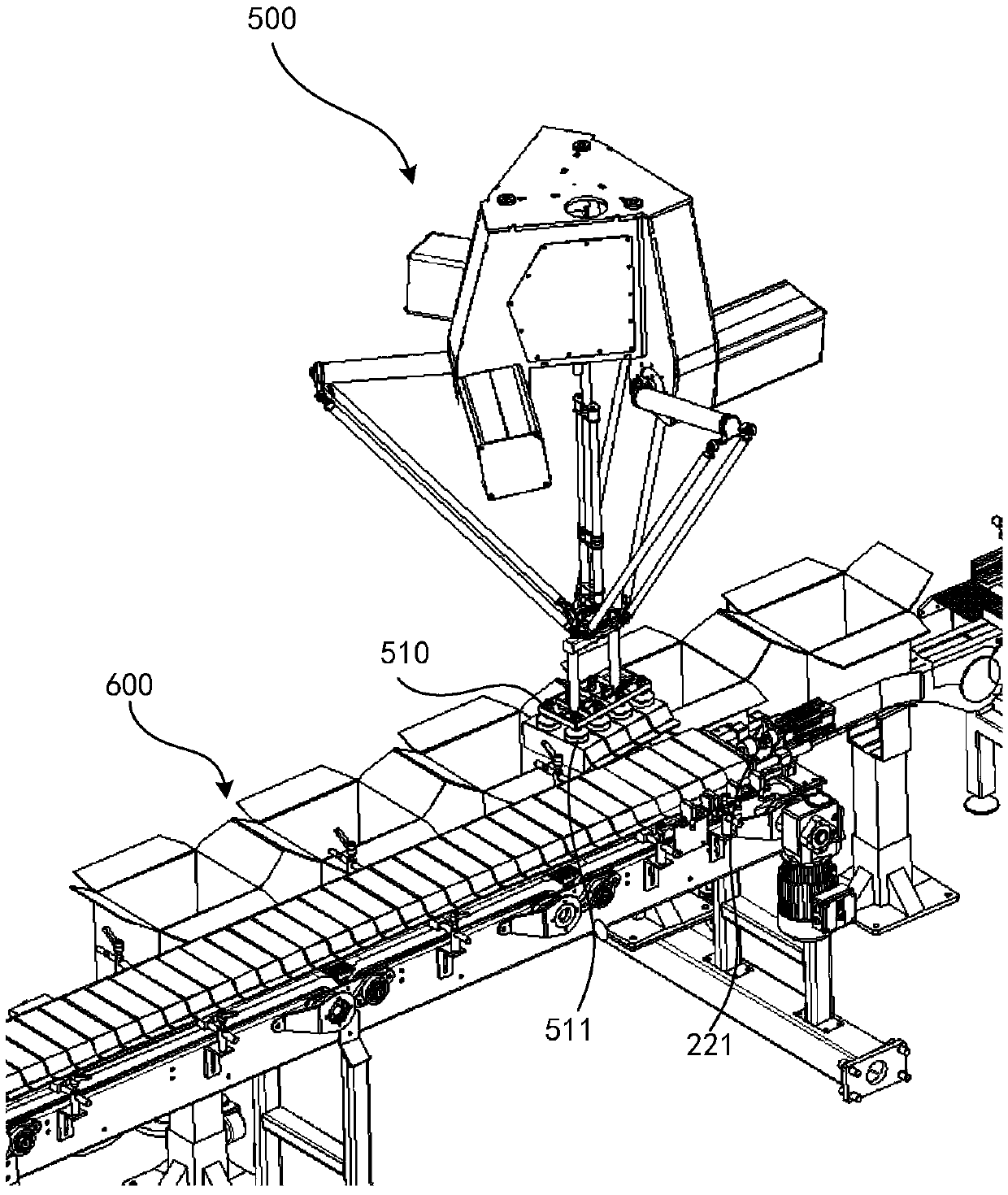

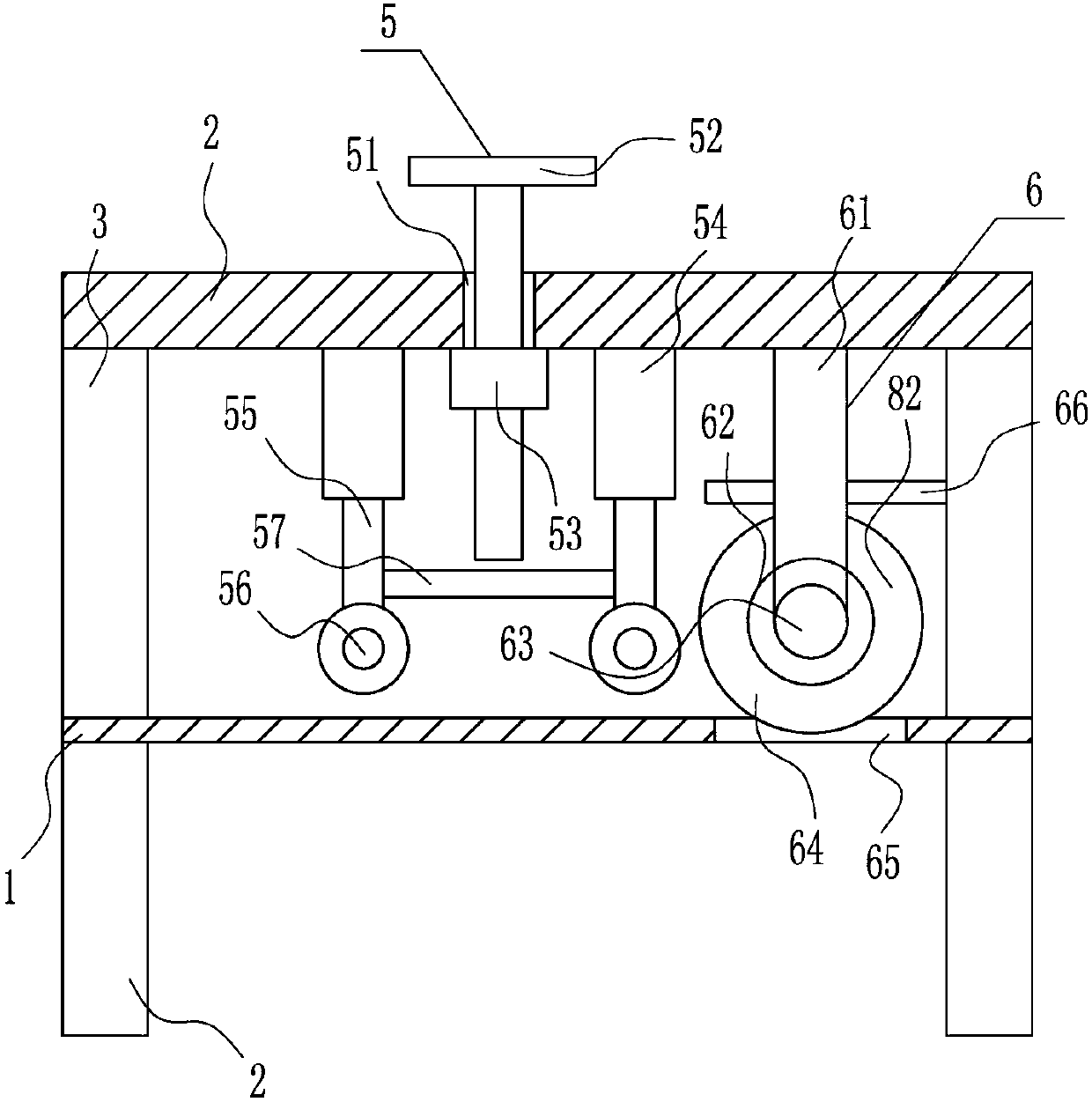

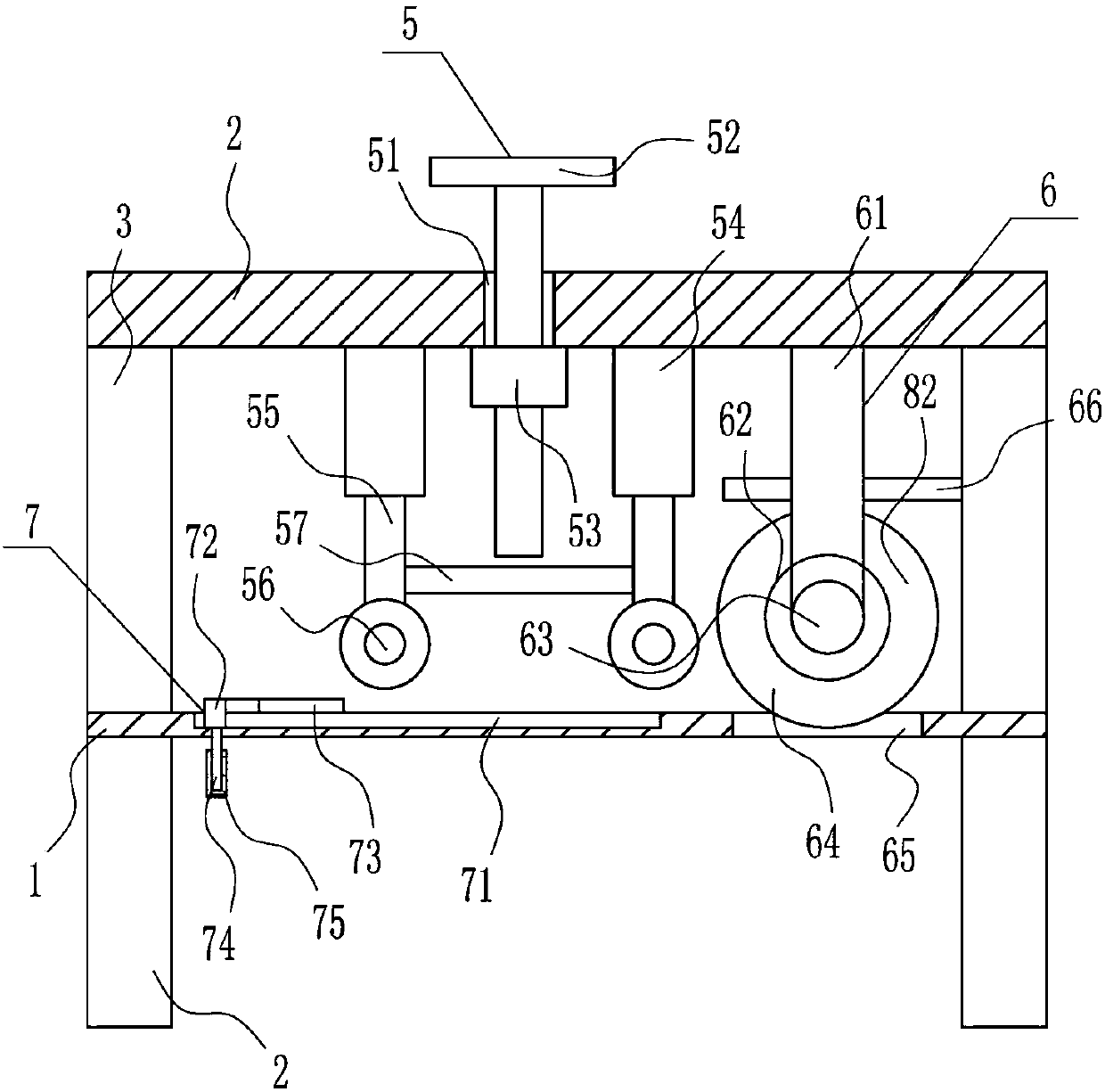

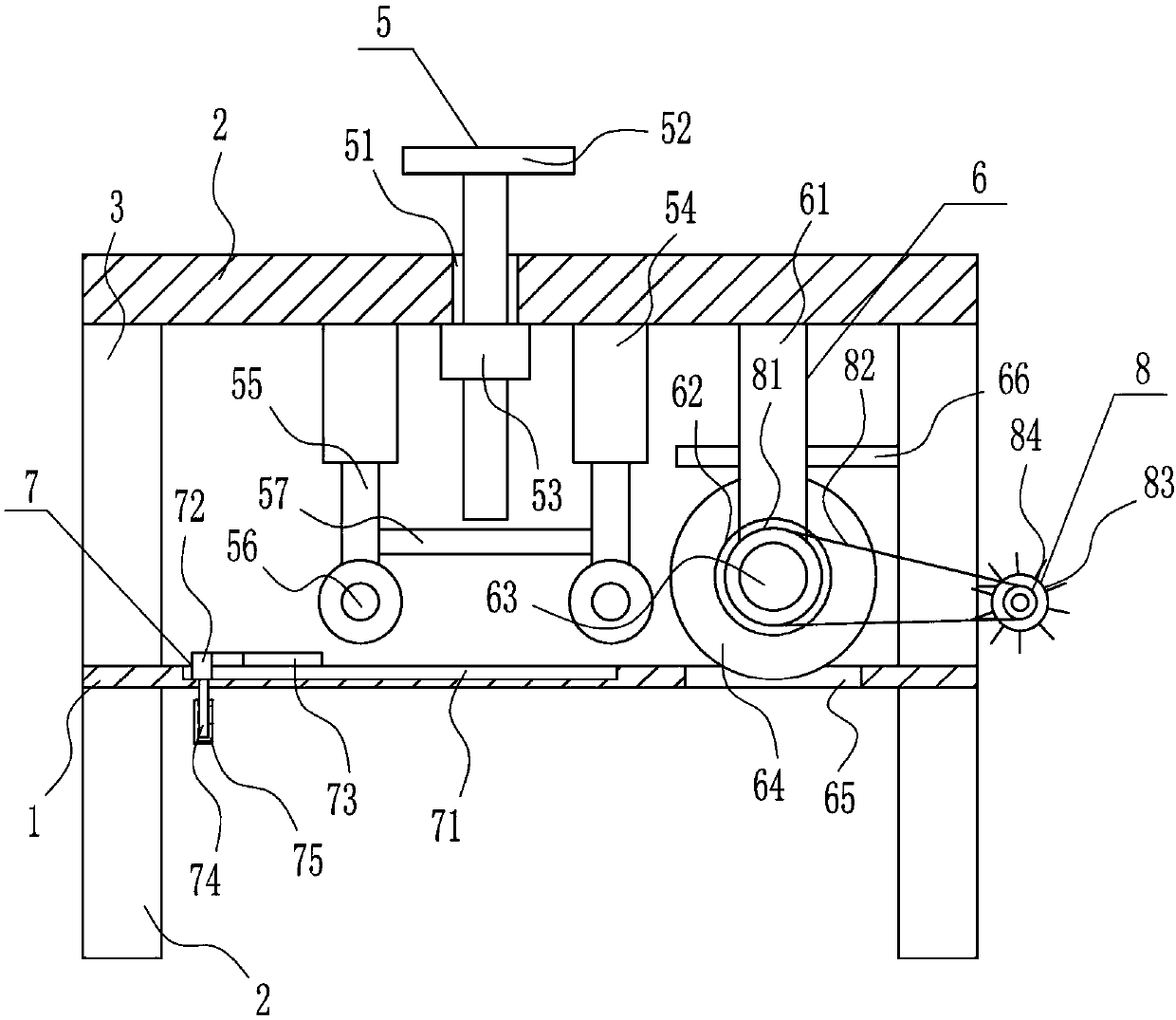

Putty powder production packaging system

PendingCN109515856ASave human effortHigh degree of automationWrapper twisting/gatheringEngineeringAssembly line

The invention discloses a putty powder production packaging system, and relates to the technical field of putty powder production. The problems that the putty powder packaging efficiency is low and potential safety hazards of manual operation are larger are solved. The putty powder production packaging system comprises an assembly line arranged under a discharging port of a finished product tank and a sewing machine arranged on one side of the assembly line, and further comprises a bagging mechanism arranged on one side of the discharging port and a clamping mechanism moving parallel with theassembly line. The bagging mechanism comprises a moving transverse frame, a main supporting arm and an auxiliary supporting arm are arranged on the moving transverse frame, and the main supporting armand the auxiliary supporting arm are horizontally parallel with each other and provided with main pawls and auxiliary pawls for grabbing packaging bags and opening the grabbing packaging bags; the moving transverse frame is provided with a first driving mechanism for driving the moving transverse frame to move horizontally and vertically; and an opening and closing mechanism is arranged at the discharging port. The putty powder production packaging system automatically grabs the packaging bags and opens the packaging bags, the opening and closing mechanism cooperates with the bagging mechanism to perform bagging and positioning on the packaging bags, the clamping mechanism sends finished products to the sewing mechanism to be sewn, bag opening, bagging and sewing are completed automatically, the manual operation is substituted, manual labor is effectively saved, and the automation level is improved.

Owner:河南赛利特建筑材料有限公司

Posture-controllable bending and twisting coupling flexible clamping jaw

The invention discloses a posture-controllable bending and twisting coupling flexible clamping jaw, and belongs to the technical field of mechanical clamps. The flexible clamping jaw comprises an adapter seat and is characterized in that two flexible clamping jaw assemblies are symmetrically arranged at the lower part of the adapter seat, each flexible clamping jaw assembly comprises a flexible finger assembly and a posture adjusting assembly, and each flexible finger assembly comprises a bending and twisting coupling flexible finger and further comprises a first rigid seat and a second rigidseat which are matched and fixedly connected with the bending and twisting coupling flexible finger. According to the flexible clamping jaw, through labyrinth type air chambers which are symmetricallyand obliquely arranged left and right, the planes on the inner sides of clamping jaw bodies form bent and changed V-shaped included angles through different air inflow, stable grabbing of objects, especially grabbing of objects with complex curved surfaces, is facilitated, and the bending and twisting coupling flexible clamping jaw can also effectively prevent target objects from being damaged; and through the arrangement of an angle posture adjusting mechanism in the vertical direction and a position regulation and control mechanism in the horizontal direction, target objects with differentsizes and different curved surface shapes can be better matched and grabbed.

Owner:杭州义顺科技有限公司 +1

Sucker type bag holding and sleeving device

The invention relates to a sucker type bag holding and sleeving device. The sucker type bag holding and sleeving device comprises a machine frame, an upper bag sucking device arranged above a bag opening and holding work position, a left bag sucking and holding device, a right bag sucking and holding device, a bag retaining and opening device, a bag placement platform and a lower bag sucking and moving device, wherein the left bag sucking and holding device and the right bag sucking and holding device are symmetrically arranged on the left side and the right side of the bag opening and holding work position, the bag retaining and opening device is arranged on the front side of the bag opening and holding work position, the bag placement platform is arranged on the rear side of the bag opening and holding work position, the lower bag sucking and moving device is arranged below the bag opening and holding work position, the left bag sucking and holding device and the right bag sucking and holding device are provided with bag holding surfaces matched with a packaging bag, and the bag holding surfaces, the lower surface of the upper bag sucking device and the upper surface of the lower bag sucking and moving device are provided with vacuum sucking holes. The sucker type bag holding and sleeving device continuously and automatically moves packaging bags to the bag opening and holding work position of the machine frame and opens the packaging bags so that the bag openings keep opened and the package bags can be automatically arranged on a discharging barrel in a sleeving mode later, automation of bag sleeving and filling of edible mushroom culturing is realized, the work efficiency is largely improved and the labor cost is reduced.

Owner:临沂高新物业管理有限公司

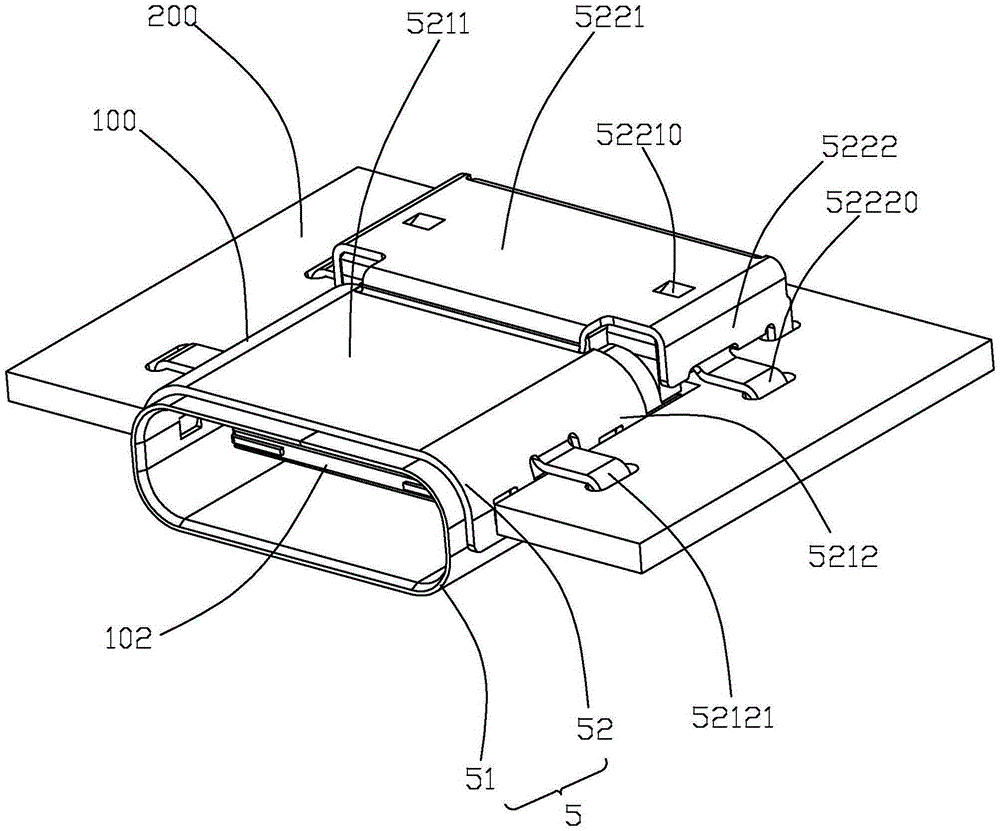

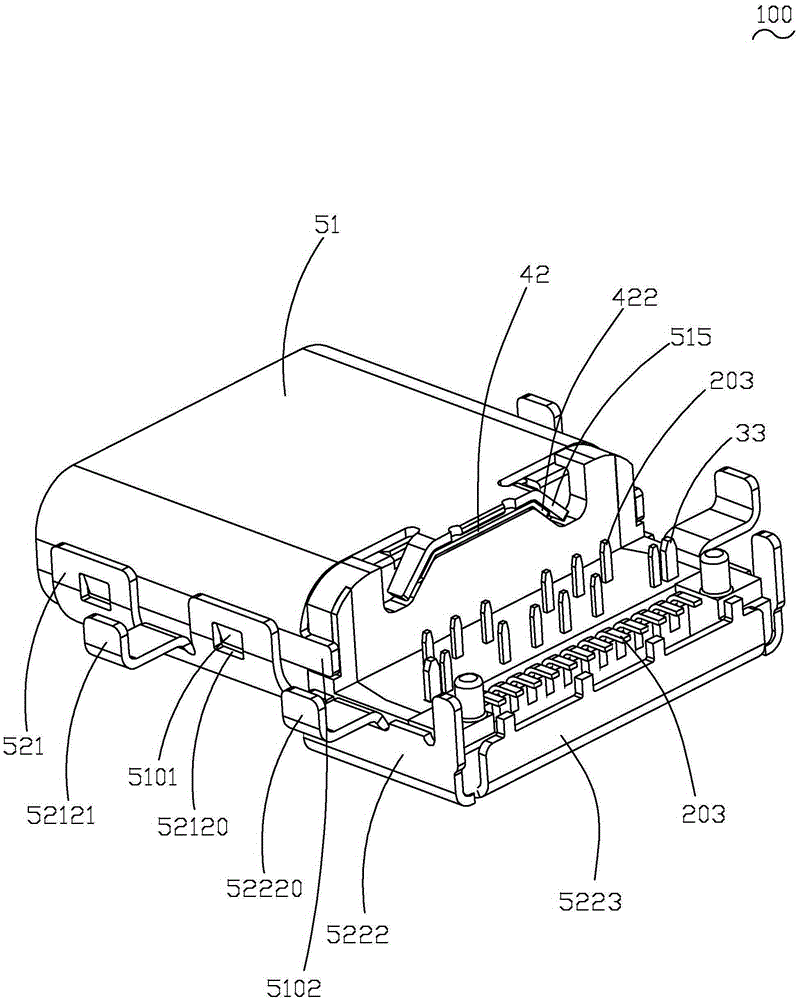

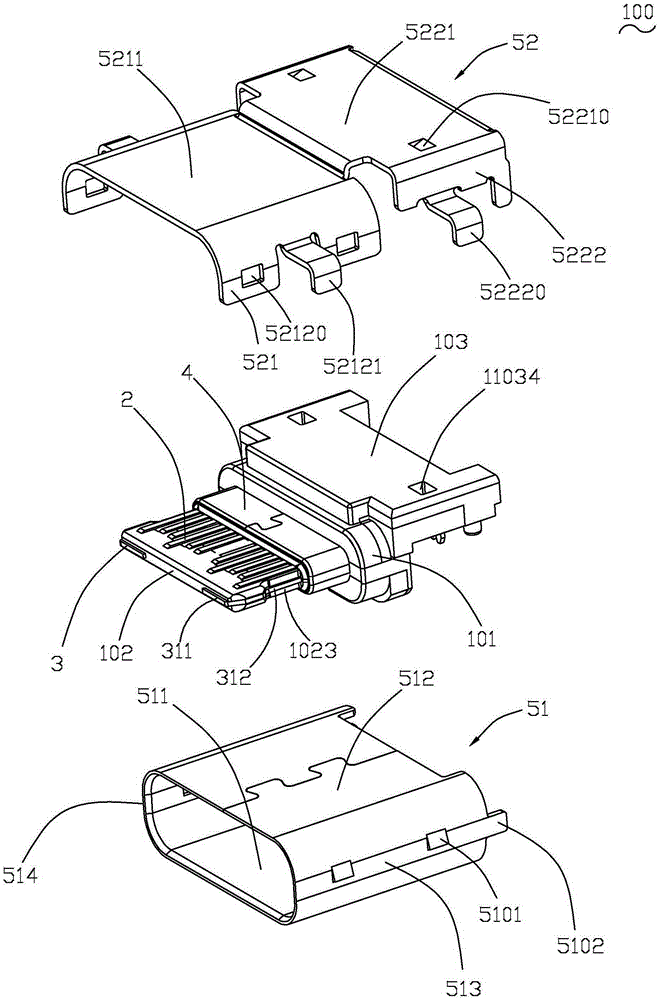

Electrical connector and manufacturing method thereof

InactiveCN106684668AHigh strengthImprove yieldContact member manufacturingContact member assembly/disassemblyElectrical connectionElectrical connector

The invention provides an electrical connector which comprises a first terminal module, a second terminal module, an inner metal part, a third insulator and a metal shell. The first terminal module, the terminal module and the inner metal part are fixed in one body by assembling. The third insulator is arranged at the periphery of the first terminal module, the second terminal module and the inner metal part by integrated molding. The first terminal module comprises a first insulator and a first terminal group including a plurality of first terminals formed in one body through injection molding. The second terminal module comprises a second insulator and a second terminal group including a plurality of second terminals formed in one body through injection molding. At least a part of the front end edge of each of the first terminals is exposed out of the first insulator and at least a part of the front end edge of each of the second terminals is exposed out of the second insulator so as to facilitate the positioning in injection molding. Through three times of injection molding, each terminal and an insulation body are fixed and stable, and the overall strength of the electric connector is good.

Owner:苏州优瑞信电子科技有限公司

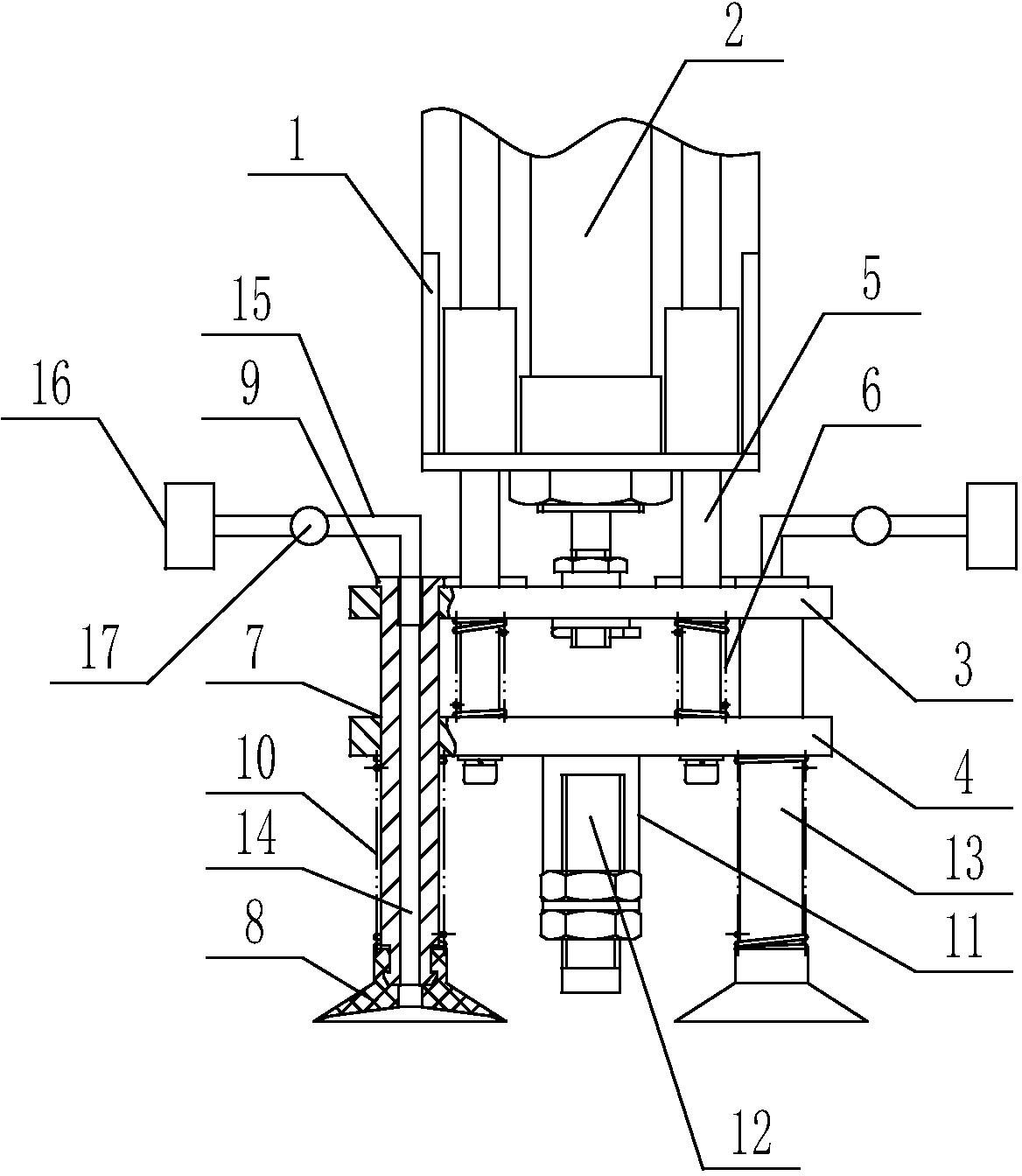

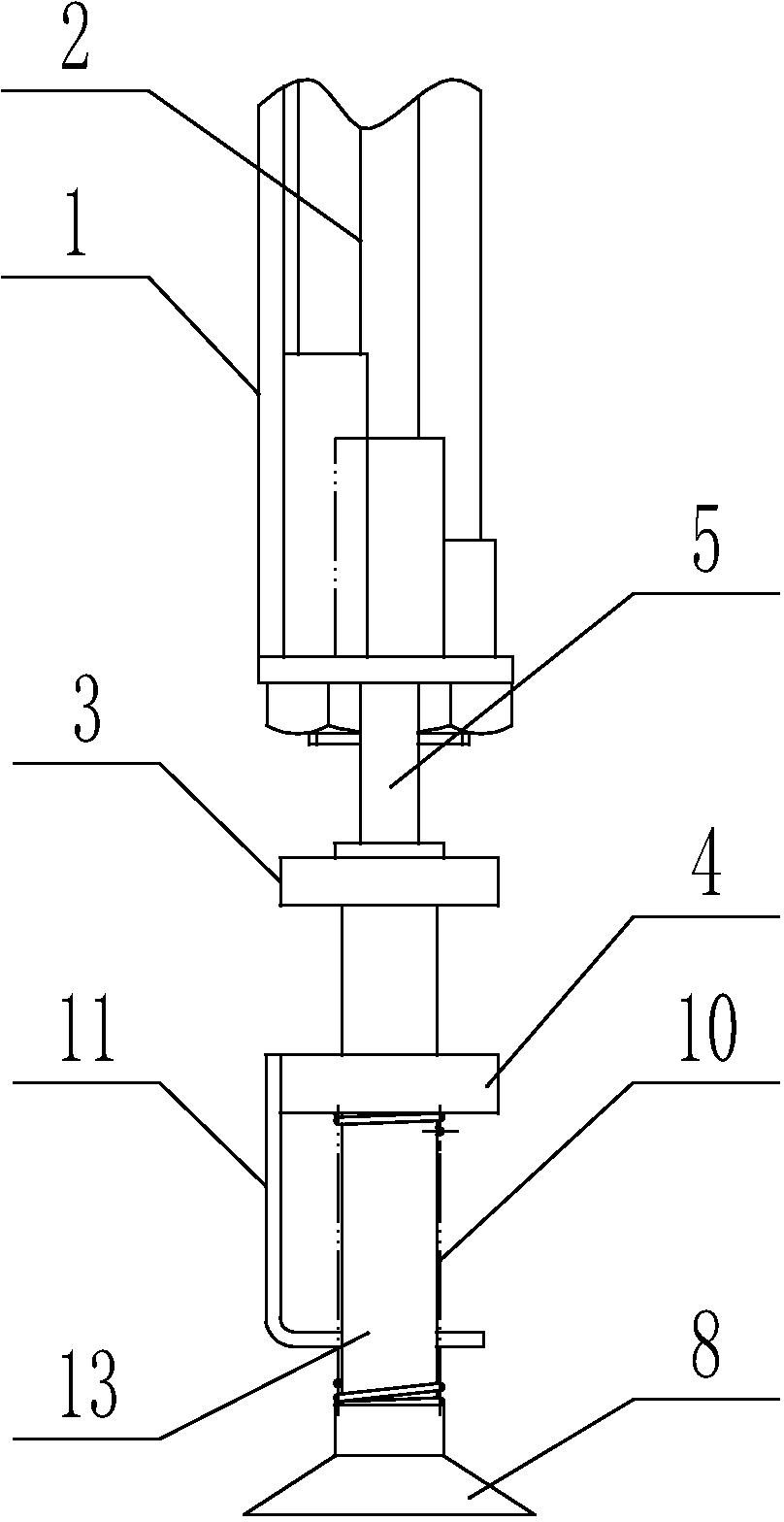

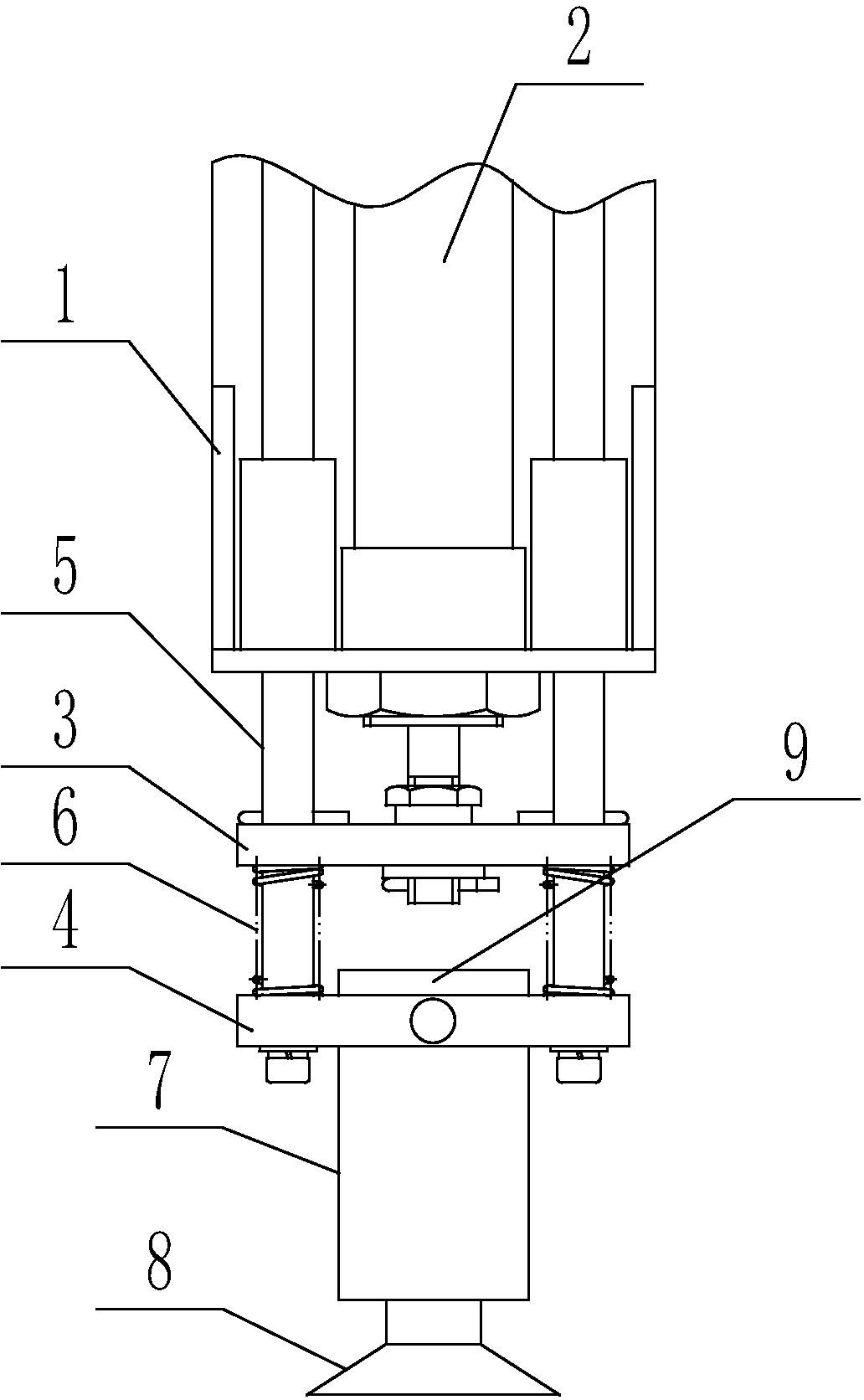

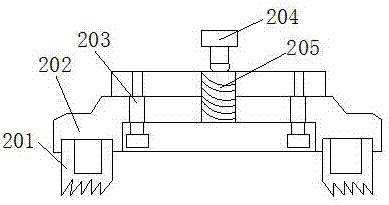

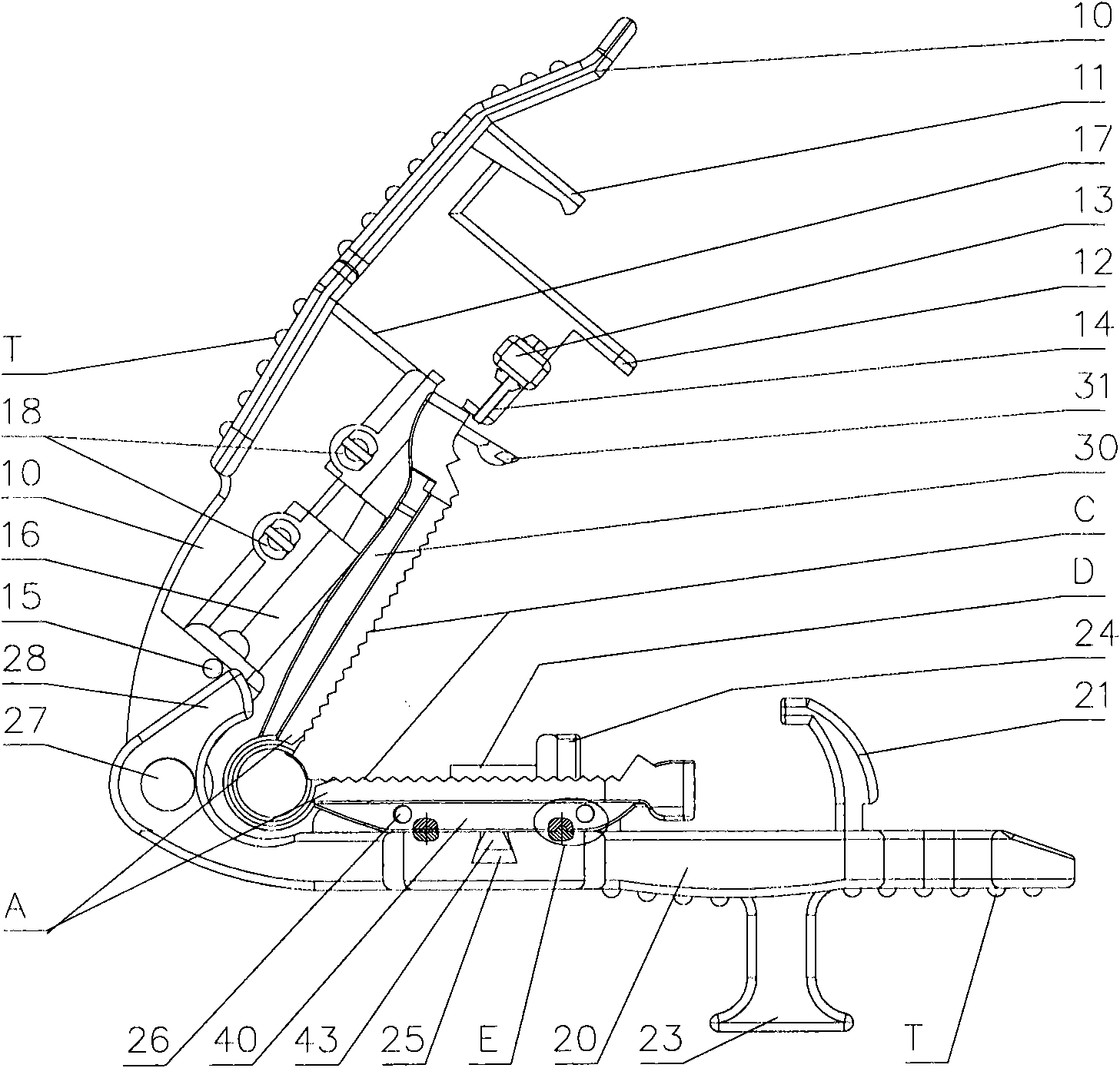

Hydraulic cylinder clamp

InactiveCN107486744AClamping, fastening, fasteningHold firmlyPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention belongs to the field of hydraulic equipment, and particularly relates to a hydraulic cylinder clamp. The hydraulic cylinder clamp comprises a base; a groove used for containing a workpiece is formed in the center line of the base; fixing columns are fixed to the two sides of the base; a sliding groove located between the fixing columns is formed in the base and is in sliding connection with two clamp bodies symmetrical with respect to the center line of the base; the side, facing the corresponding fixing column, of each clamp body is a slope forming an 45-degree included angle with the horizontal direction; a hydraulic cylinder is arranged on the top of each fixing column; a support rod is arranged at the output end of each hydraulic cylinder; a stand rod fixed to the base is arranged on the side, close to the center line of the base, of each fixing column; a transmission rod is hinged to the top of each stand rod; one end of each transmission rod is hinged to the corresponding support rod; a pressure rod is hinged to the other end of each transmission rod; a pressure block of a wedge-shaped structure is fixedly connected with the bottom of each pressure rod; the side, away from the corresponding fixing column, of each pressure block is parallel with the slope of the corresponding clamp body; and the slopes of the clamp bodies are frosted surfaces. The hydraulic cylinder clamp can be prevented from shifting due to inconsistent stress, so that the machining quality is ensured.

Owner:CHONGQING WEIQING HYDRAULIC MACHINERY CO LTD

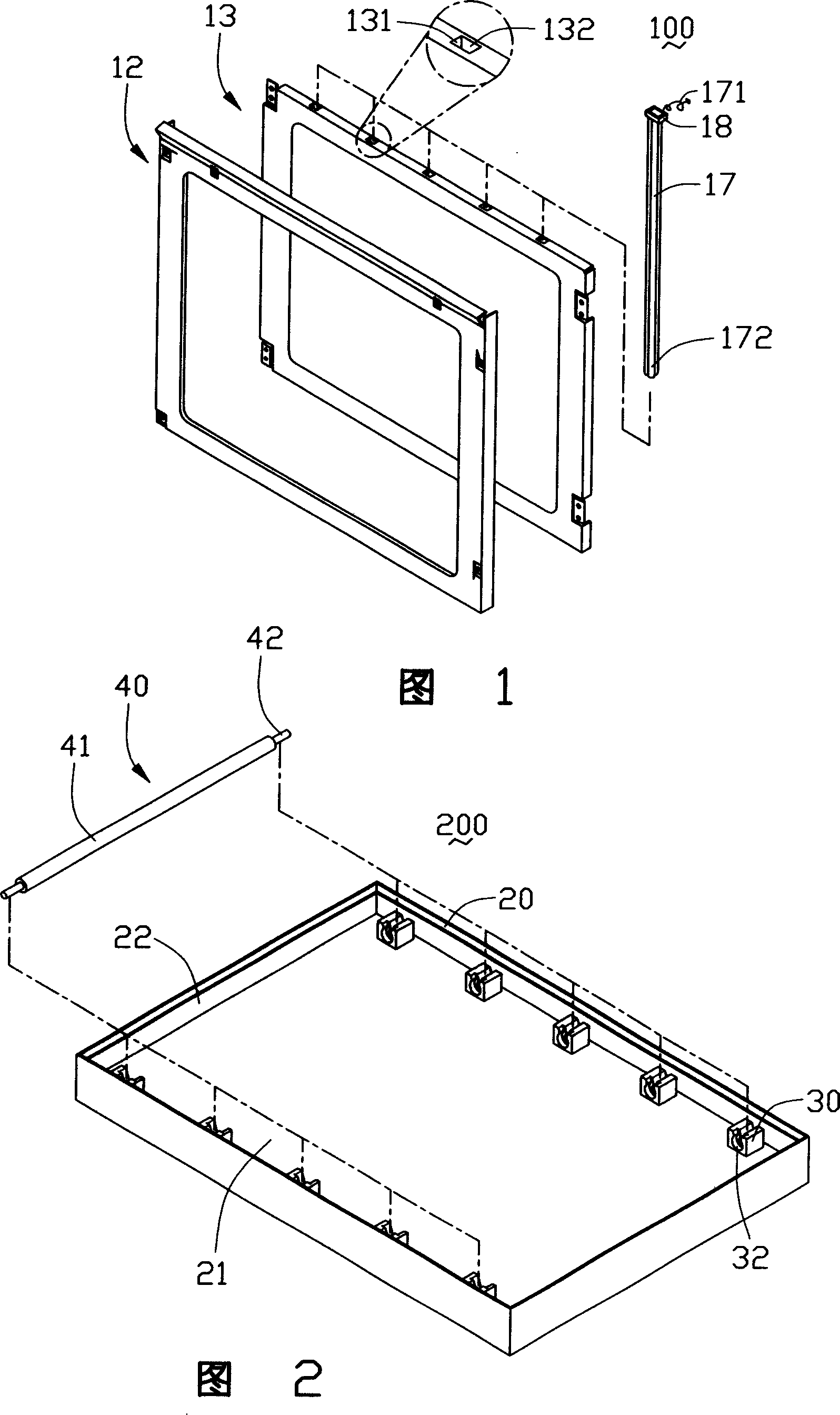

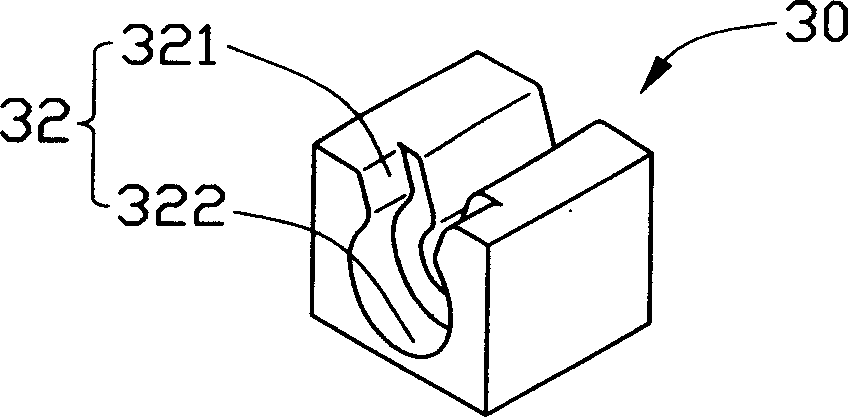

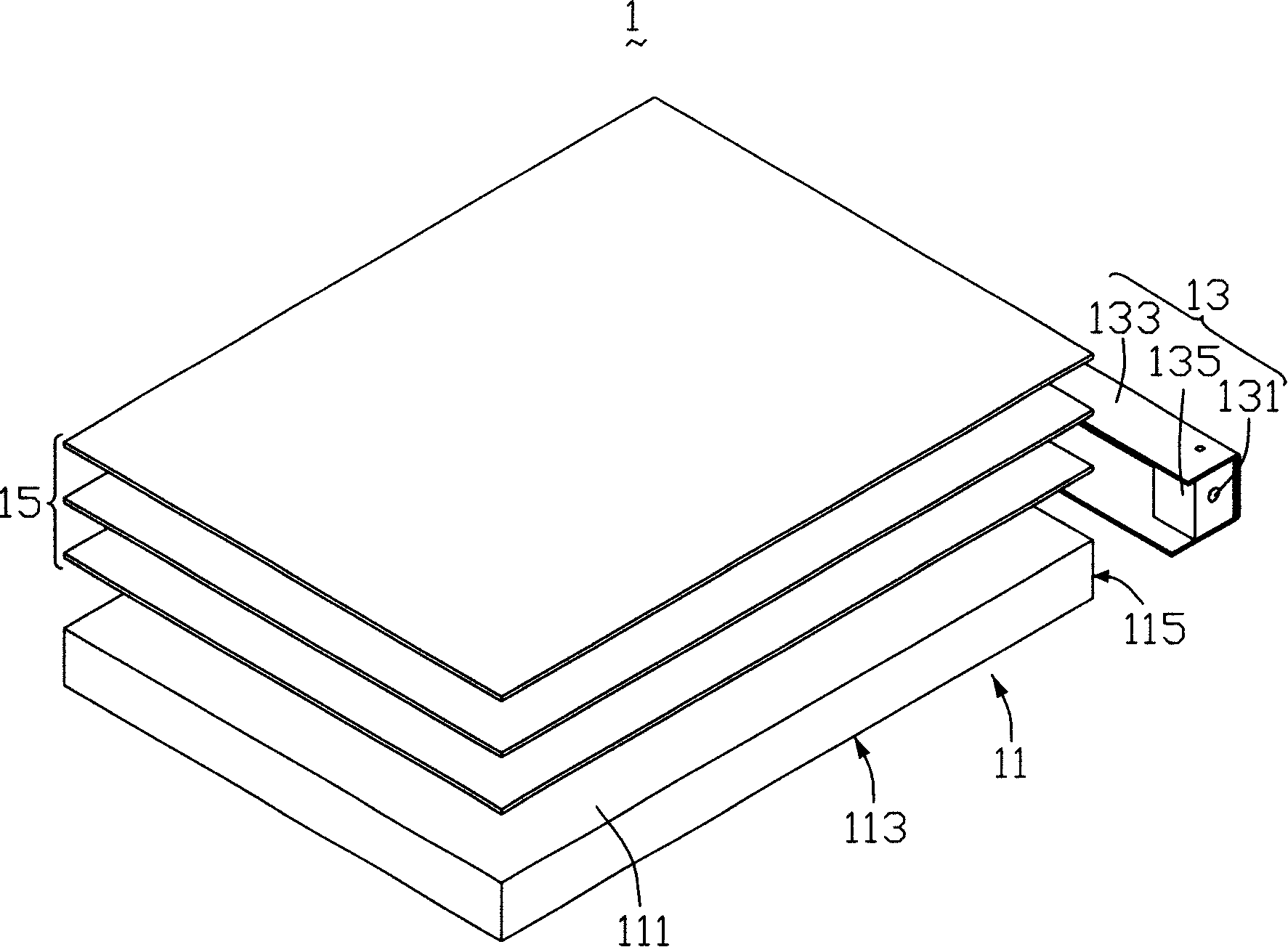

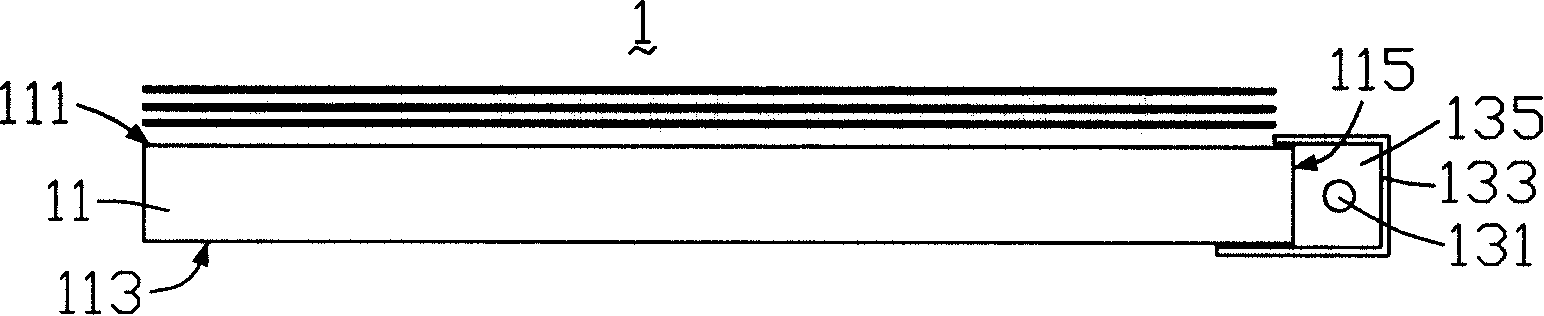

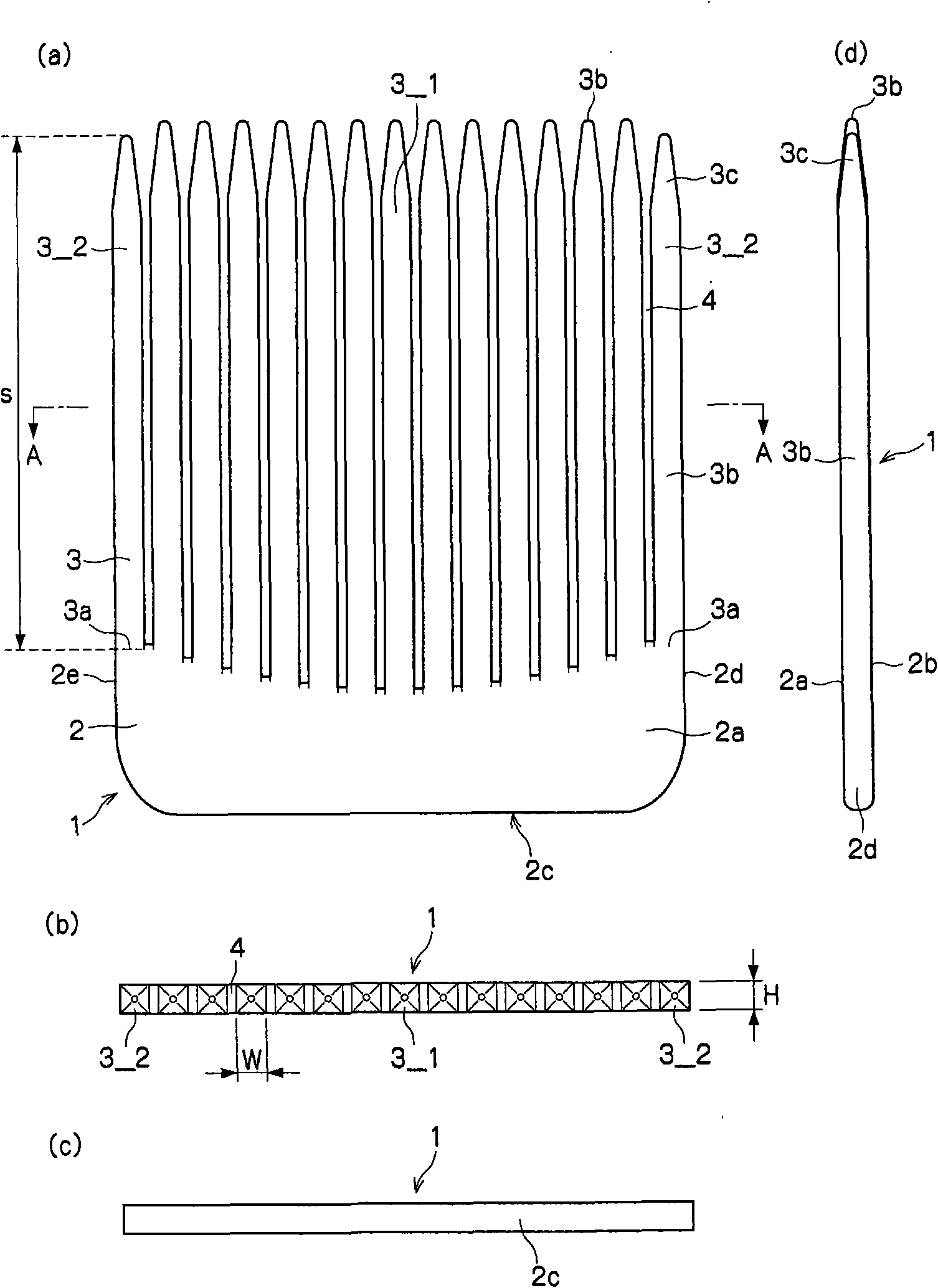

Backlight module group and liquid crystal display

InactiveCN101165563AReduce light leakageReduce warping and bendingStatic indicating devicesNon-linear opticsLiquid-crystal displayLight guide

The backlight module comprises a light guiding plate and at least one light source. Said light guiding plate comprises a light emergence face, and bottom face opposite to the light emergence face, and an light incidence face adjacent the light emergence face; said light source comprises a lamp tube and a reflection bowl; the light emergence face of the light guiding plate forms a bulge at the extension of the one side of the light incidence face; said bulge and the incidence face forms a holding space of holding the light source. The invention also provides a LCD display using said backlight module.

Owner:INNOCOM TECH SHENZHEN +1

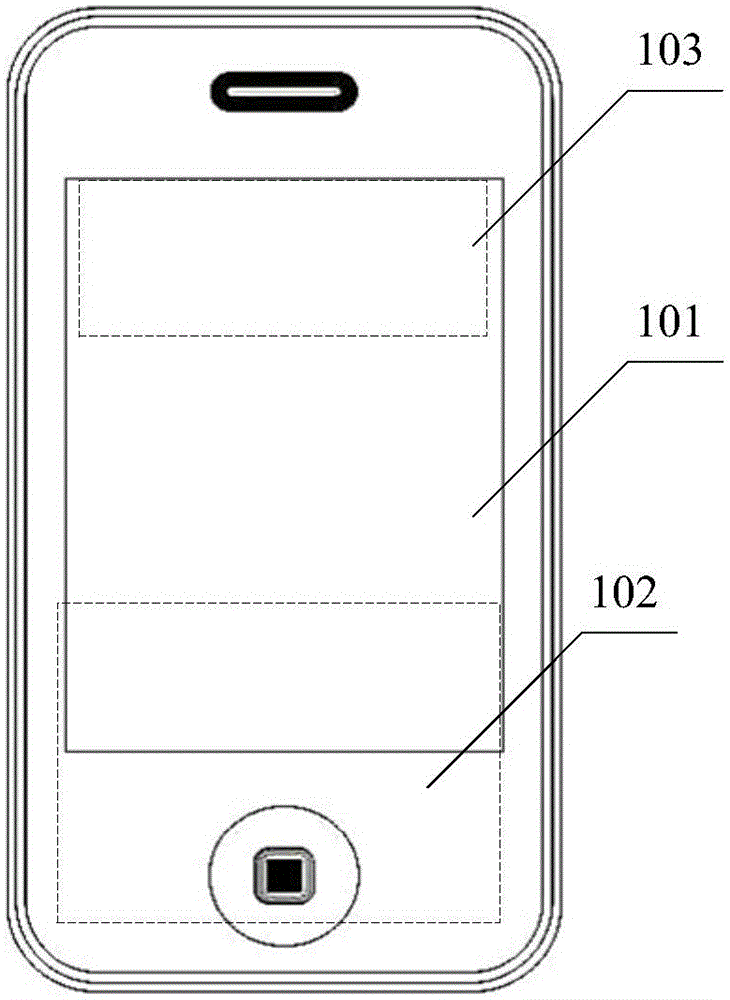

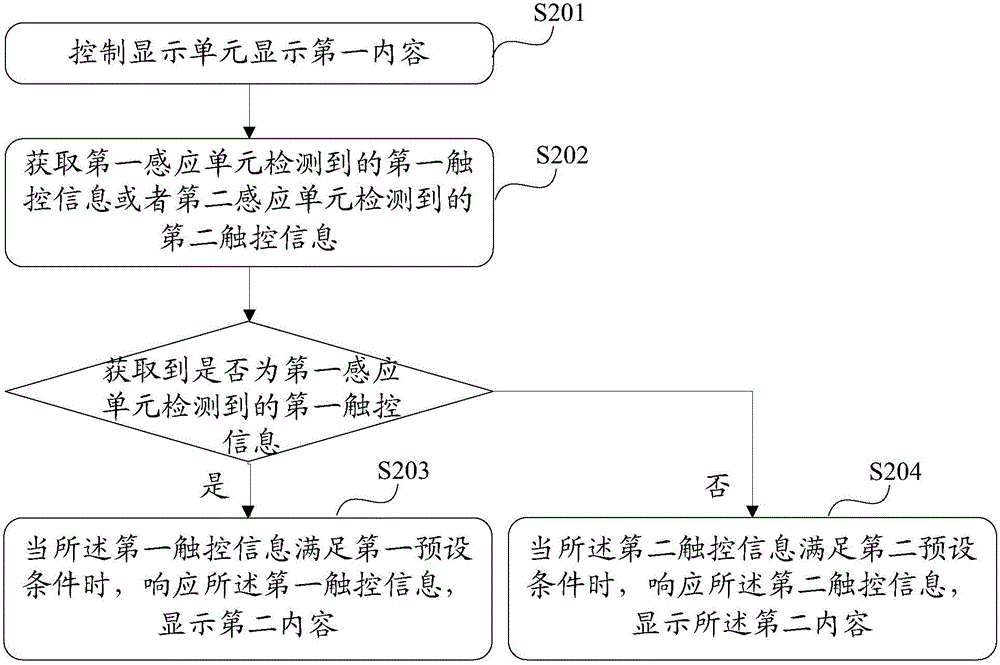

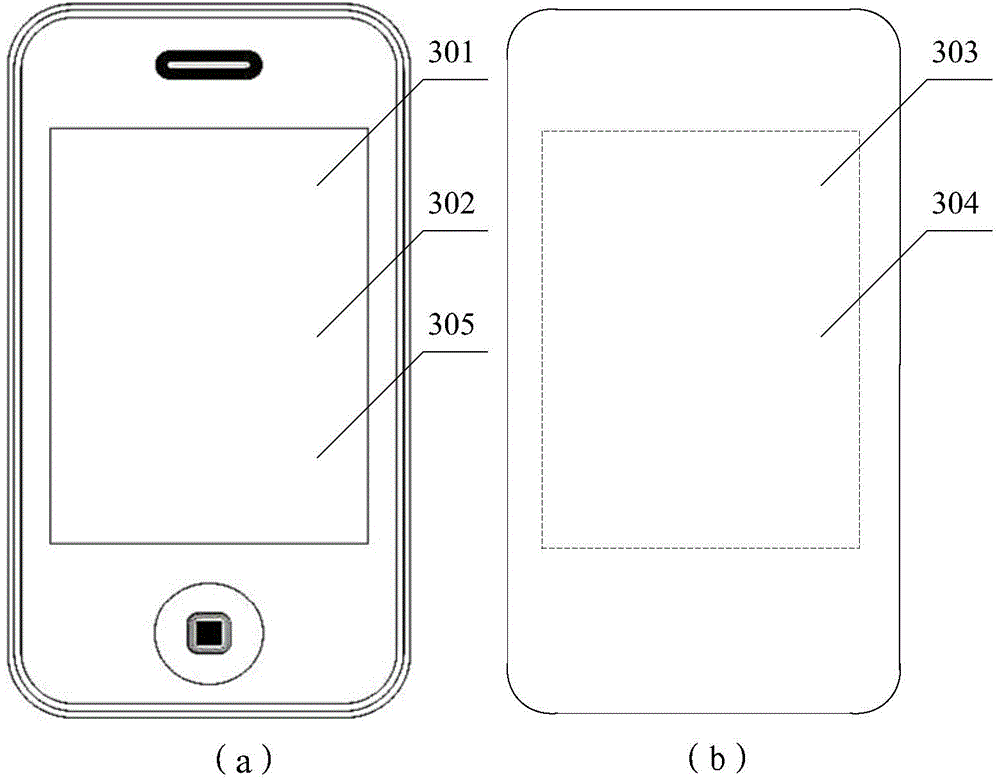

Displaying method and electronic equipment

InactiveCN104363345AStability and securitySecure hold steadySubstation equipmentElectric equipmentComputer science

The invention provides a displaying method. First touch information is obtained from a first outer surface, or second touch information is obtained from a second outer surface. When the first touch information meets a first preset condition, first touch information response is carried out, and second content is displayed. When the second touch information meets a second preset condition, second touch information response is carried out, and second content is displayed. At least parts of the first preset condition and the second preset condition are the same, so that the same results are obtained when similar operations are carried out on different surfaces of electronic equipment, and the purpose that when a user carries out matched or identical touch operations on two touch screens of the electronic equipment, the same operation results can be generated is achieved. When the user holds the electronic equipment by hand, the back face of the electronic equipment is used as the second outer surface, the user can use the index finger or the middle finger of one hand for carrying out the touch operation on the back face of the electronic equipment, and the operation results of the same operations carried out on the first outer surface on the front face of the electronic equipment are obtained.

Owner:LENOVO (BEIJING) LTD

Rapid board adsorption device

InactiveCN107150903AAvoid leaningPrevent rotationConveyorsConveyor partsHydraulic cylinderSelf locking

The invention discloses a fast absorbing device for plates, the structure of which comprises a fixed seat, a suction cup, a rubber pad, a curved rod, a hydraulic cylinder, a curved rod support seat, rollers, a lifting rod, a weight detection device, and an air suction pipe. The suction cup is composed of a sealing body, a disc body, a safety valve, a spring and a piston rod. The beneficial effect of the present invention is that a suction cup is provided, self-locking is carried out by vacuumizing the sealing body, no need for screw positioning, and the adsorption capacity is stronger, and it is easy to adjust the angle and the forward and backward sliding position, and then press the spring fastening device to avoid the lower part of the adsorber being subjected to lateral damage. When an external force or an external force rotating around the longitudinal axis causes the adsorber to be unstable, causing tilt or rotation problems. Ensure that the posture of the adsorber is stable, the adsorbed objects can be firmly sucked, and the construction safety is improved.

Owner:江苏蓝羊羊木业有限公司

Preparing method for sports apparatus grip leather capable of adjusting wet skid resistance along with temperature change

InactiveCN105803815AHold firmlyWon't slipPolyurea/polyurethane coatingsTextiles and paperWater basedMicrobubbles

The invention relates to a preparing method for sports apparatus grip leather capable of adjusting wet skid resistance along with temperature change.The method includes the following steps that 1, water-based dry method grip leather Bes slurry is prepared, wherein a dispersing agent, a crosslinking agent, tap water, filling powder, a foaming agent, foam stabilizer, water-based color paste and thickener are sequentially added into water-based polyurethane resin and stirred to obtain the water-based dry method grip leather Bes slurry; 2, printing slurry is prepared, wherein tap water, a defoaming agent, a flatting agent and thickener are sequentially added into resin and stirred to obtain the printing slurry; 3, the water-based dry method grip leather Bes slurry is introduced into a foaming machine to be foamed physically, and then water-based dry method grip leather Bes foamed slurry with air microbubbles is obtained; 4, elastic knitted fabric is uniformly coated with the water-based dry method grip leather Bes foamed slurry and dried to obtain water-based dry method grip Bes; 5, the printing slurry is printed on the water-based dry method grip Bes and dried to obtain the sports apparatus grip leather.The preparing method is simple in process and easy to implement.

Owner:LANZHOU KETIAN NEW MATERIAL CO LTD

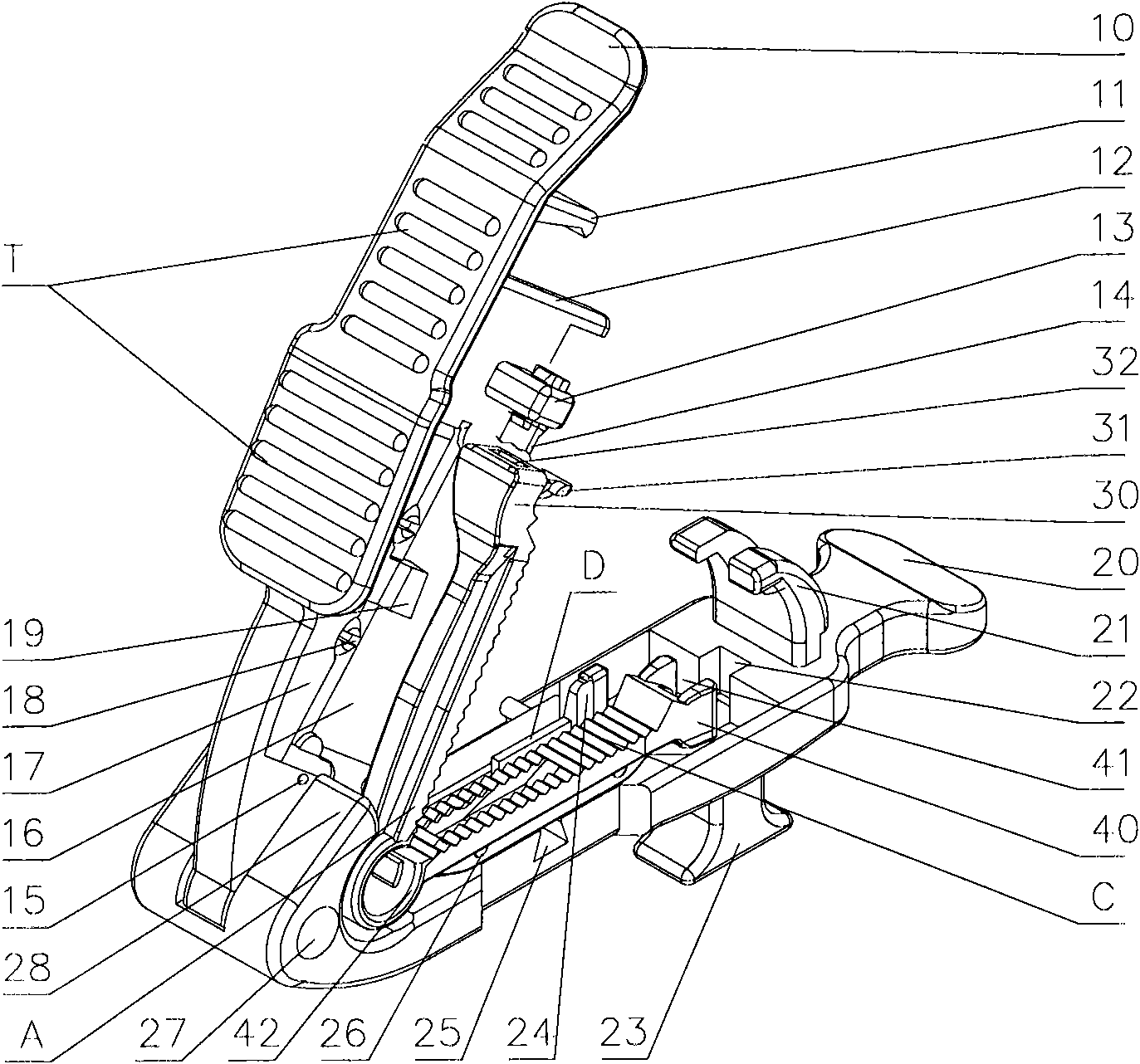

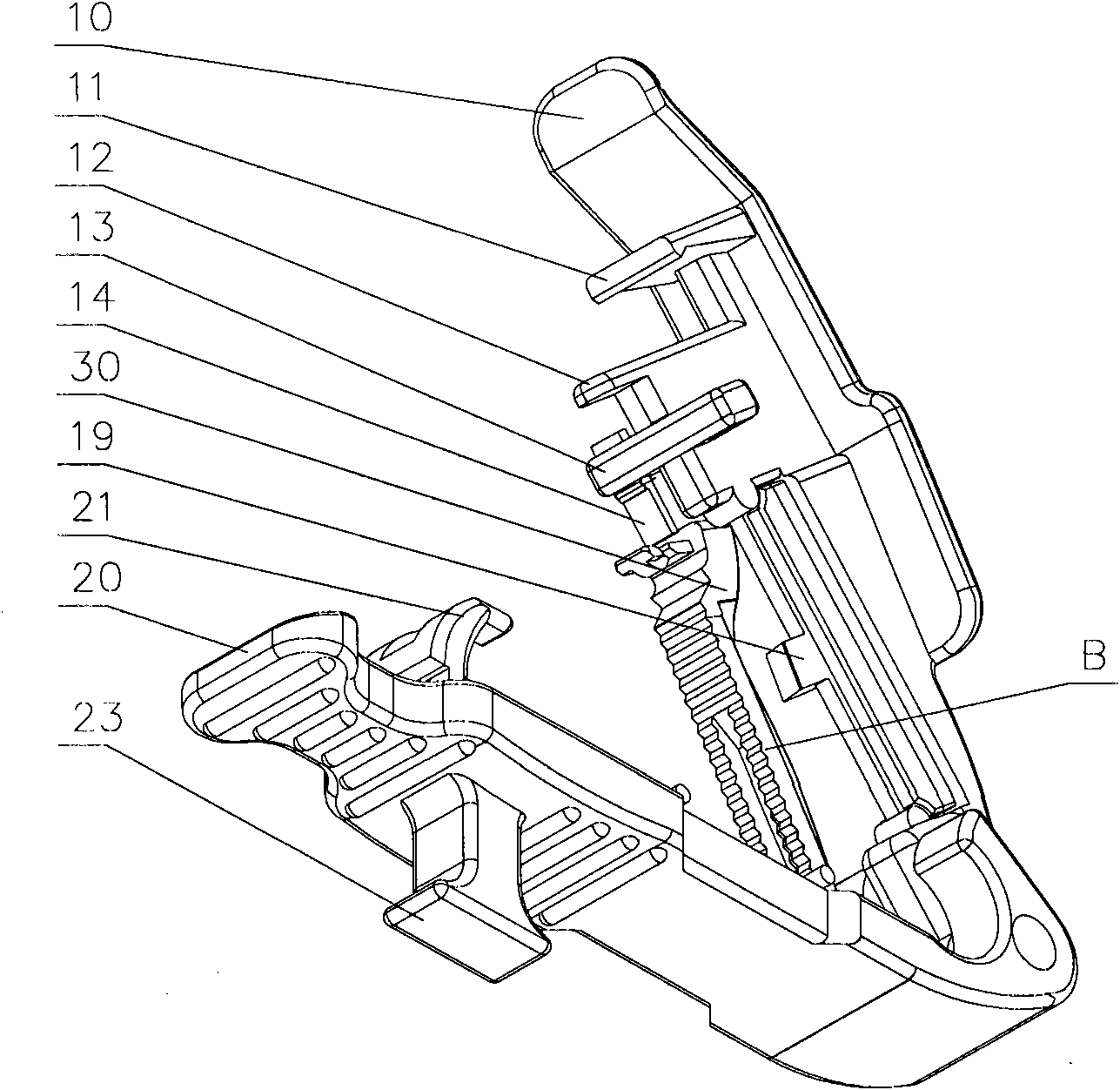

One-time bidirectional umbilical cord cutter

ActiveCN101856253AInconvenient to useBlock slide outObstetrical instrumentsEngineeringMechanical engineering

The invention provides an improvement on a conventional one-time bidirectional umbilical cord cutter. The one-time bidirectional umbilical cord cutter comprises that: an upper shell is provided with a side semi-convex sphere for preventing upper and lower shells from being closed upon a slight external force; one end of a stop body is provided with a stop lever for preventing the umbilical cord from sliding out of an open end of an umbilical clamp; the inner side of a convex pin of the lower shell is provided with an upright semi-convex sphere which is occluded with a spherical groove on the bottom surface of a lower clamping arm and used for preventing the umbilical clamp from transversely slipping; the bottom of the lower shell is provided with a handle for firmly gripping the umbilical cord cutter; the head of an upper clamping arm is provided with a longitudinal flat hole into which hold-down sheets at the two ends of a cross bar of the upper shell are inserted, so that the upper clamping arm and the hold-down sheets are more firmly positioned and occluded; a clamping hook of the upper clamping arm is firmly occluded with a concave platform in the clamping arm groove of the lower clamping arm, so that the upper clamping arm and the lower clamping arm are more firmly closed; a blade is movably arranged on a blade fixing frame through two conjoined elastic split convex pins and is convenient to separate; and when the blade is disassembled, the umbilical cord cutter is completely made of plastic, so the cutter can be recycled as waste plastic.

Owner:江西易通医疗器械有限公司

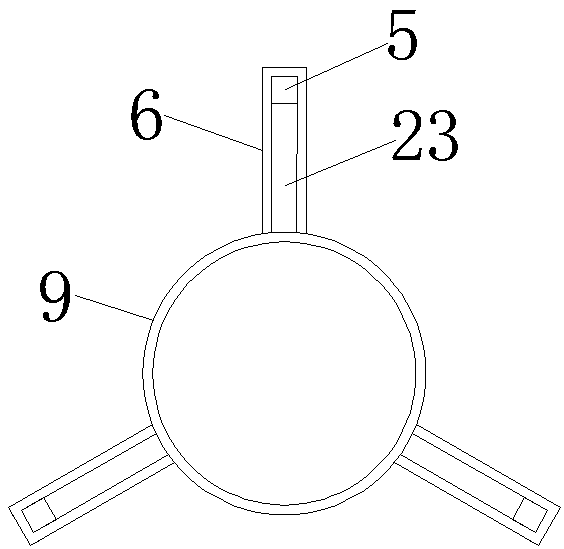

Magnetic levitation health-preserving bed

The invention discloses a magnetic levitation health preserving bed, which consists of bed chassis and bed rack, wherein the bed chassis contains power controlling box, electromagnetic array, first and second slow motors with cam, upper and lower parts and remote control signal receiver; the power controlling box and remote control signal receiver receive signal, which makes electromagnetic array, first and second slow motor move or stop; the permanent magnetic array, first and second cam mating mechanisms are set under the bed rack; the electromagnetic array overlaps permanent magnetic array, which generates repulsion and suction after powering to make bed rack away from bed chassis to suspend; the magnetic guide rail is set on the bed chassis; the ferric metal board or beam is set under bed rack with three safe protections, which corresponds oriental board to improve reliability.

Owner:郑绍司

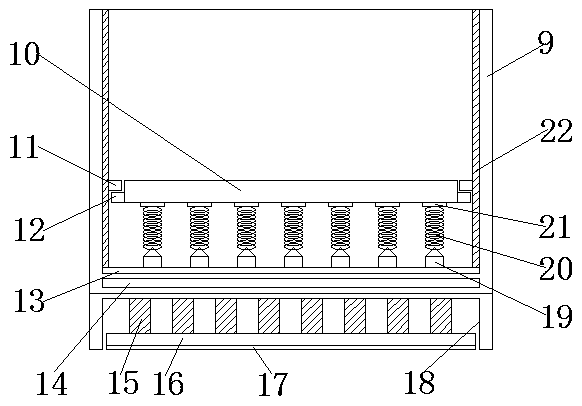

Buffering cushion supplying mechanism

InactiveCN107089488AAbsorb firmlyNo sideways sliding phenomenon occursPackagingConveyor partsSilica gelCushion

The invention discloses a buffer pad feeding mechanism, which comprises a feeding bracket on which a buffer pad is placed, the feeding bracket forms an included angle of 30° with the horizontal plane, and one side of the feeding bracket is provided with a There is a swing rod, the swing rod is provided with an adsorption device, the swing rod is connected with the crank rocker mechanism, and a buffer pad transmission device is arranged under the swing rod; One side of the device is adsorbed with a silica gel plate. The invention is convenient for manual supply of supplementary raw materials to meet the high-efficiency operation of production equipment; it ensures that the supply support is firmly adsorbed by the adsorption device, and no lateral sliding occurs during the discharge process; it has simple structure, convenient manufacture, stable operation, and is easy to use. debugging.

Owner:JURONG DINGSHENG CARTON PACKING

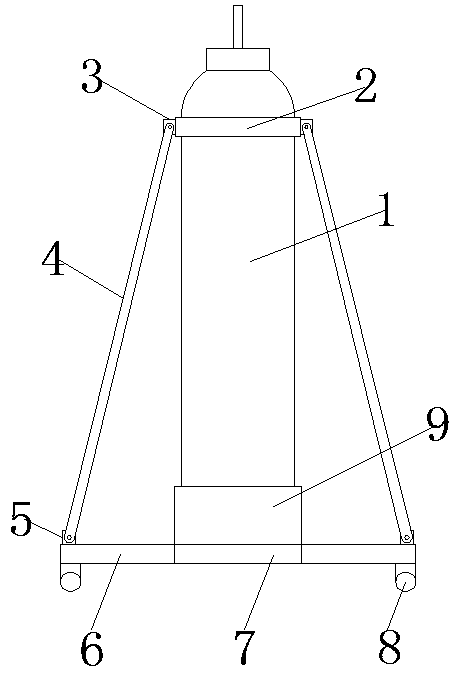

Oxygen bottle for medical treatment

InactiveCN108253291ANot easy to dumpEasy to moveVessel mounting detailsNon-rotating vibration suppressionMedical equipmentEngineering

The invention provides an oxygen bottle for medical treatment and relates to the field of medical equipment. The oxygen bottle for medical treatment comprises an oxygen bottle body, an oxygen bottle base is arranged at the bottom of the oxygen bottle body, and a rubber cushion is fixedly connected to the inner side of the inner wall of the oxygen bottle base. A damping cushion is fixedly connectedto the bottom of the inner wall of the oxygen bottle base, a supporting column is fixedly connected to the top of the damping cushion, and a damping spring is arranged at the top of the supporting column. A mounting cushion is fixedly connected to the top of the damping spring, a top plate is fixedly connected to the top of the mounting cushion, and a weight increasing block is arranged at the bottom of the damping cushion. According to the oxygen bottle for medical treatment, through a clamping ring, an anti-toppling transverse rod and an anti-toppling connecting rod, the oxygen bottle can be not liable to topple , the dangerous accident is avoided, equipment safety is improved, the oxygen bottle can be damped through the damping spring and the top plate, the oxygen bottle is effectivelydamped in moving, the accident caused by vibration is prevented, and the safety is effectively improved.

Owner:谢博

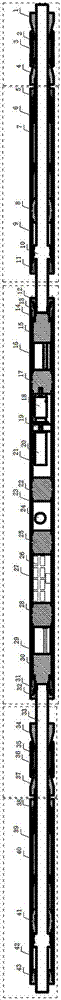

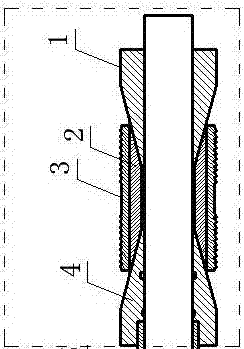

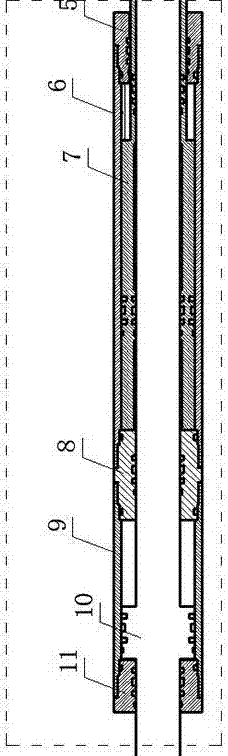

Coiled tubing traction robot

ActiveCN107366523AGuaranteed to pass throughCompact structureTubing catchersCoiled tubingAgricultural engineering

The invention discloses a coiled tubing traction robot, comprising a first segment, a second segment, a third segment, a fourth segment and a fifth segment arranged sequentially from right to left; both the front segment and the rear segment sleeve a front center shaft, both the fourth segment and the fifth segment sleeve a rear center shaft, and the left and right ends of the third segment sleeve the ends of the rear and front center shafts respectively. The coiled tubing traction robot has the advantages of high integrity level, high safety, high tractive capacity, and high success rate.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com