Electrorheological fluid clamping tool for light and low-noise gearbox

An electrorheological fluid, clamping tooling technology, applied in clamping, positioning devices, manufacturing tools, etc., can solve the problems of low production efficiency, prolonging the finishing time of the gearbox, and the gearbox being dropped and damaged. The force is uniform and firm, the workpiece clamping effect is good, and the effect of fast loading and unloading of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

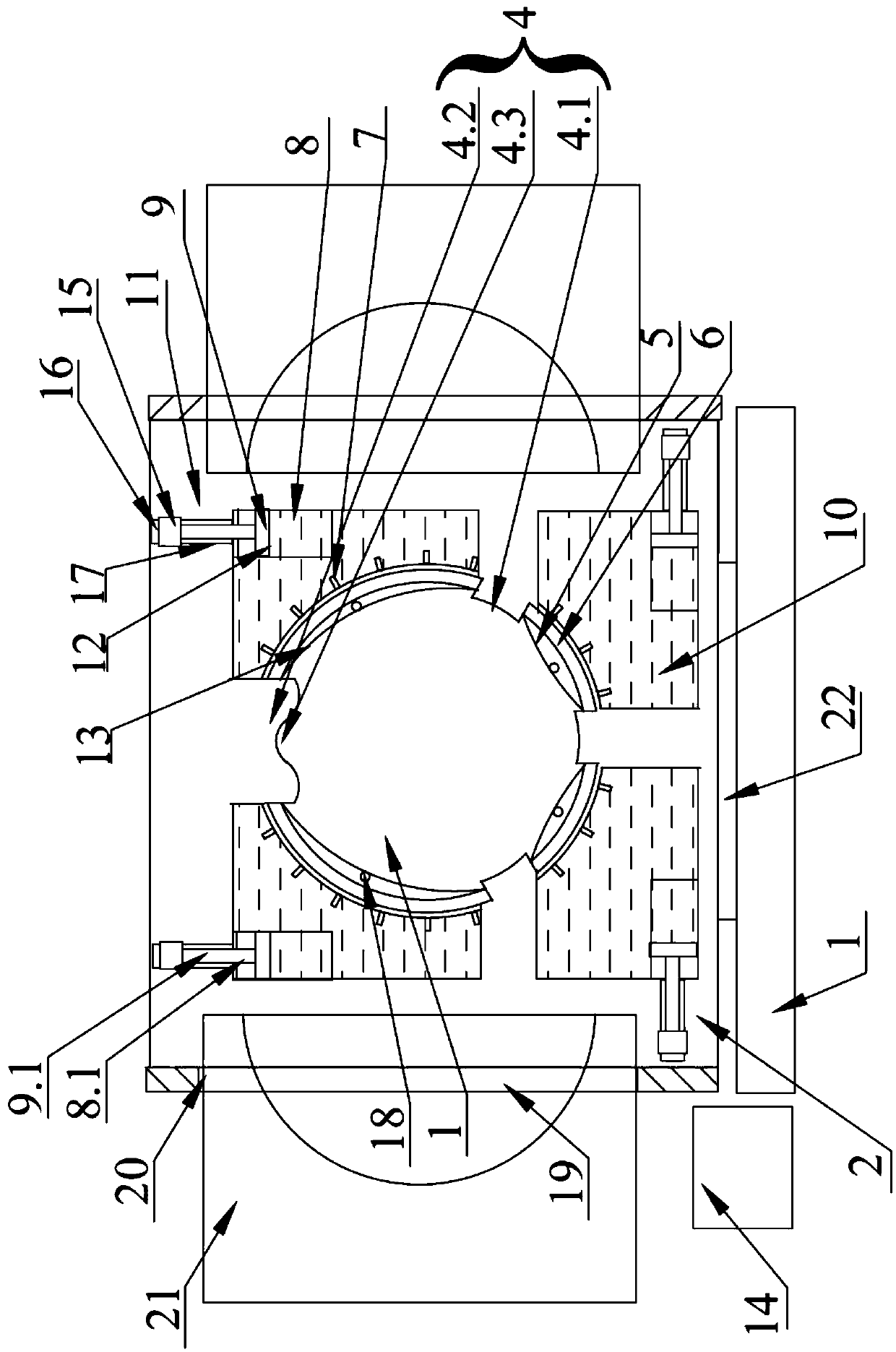

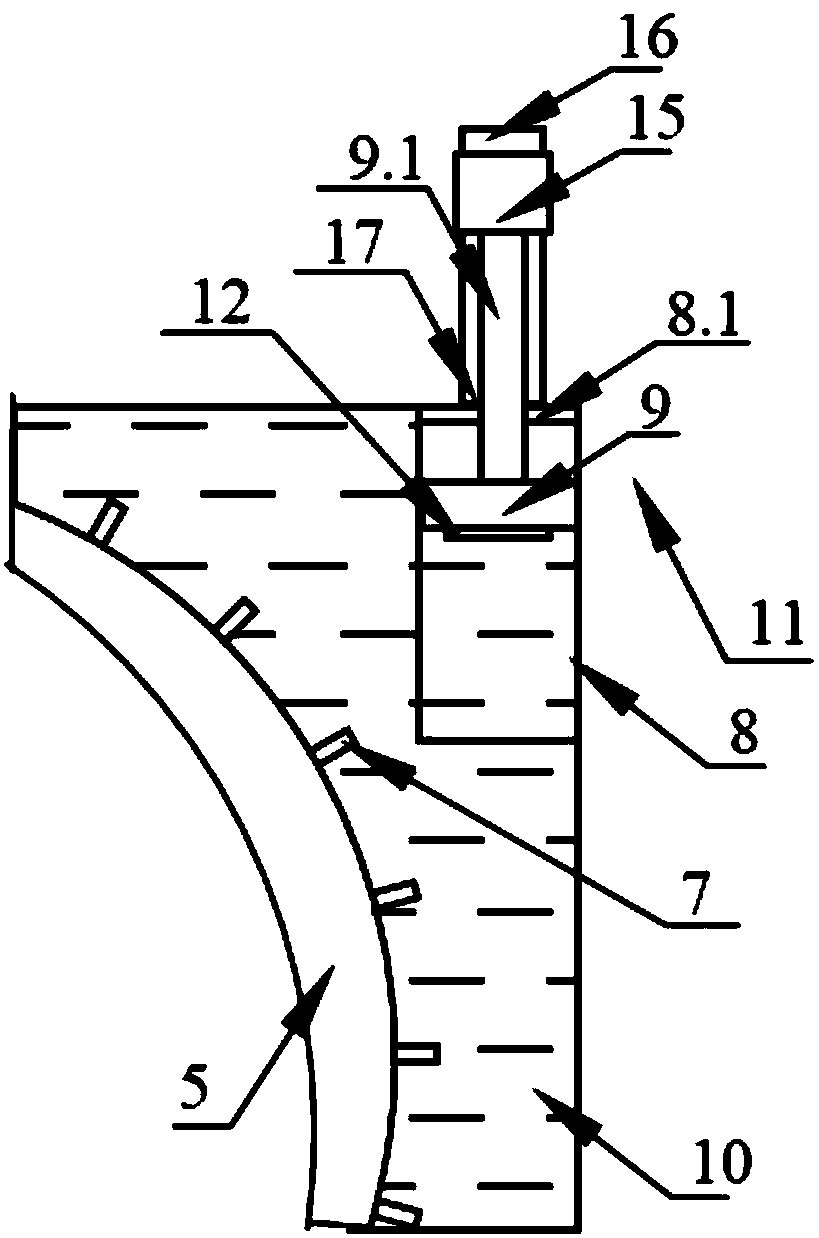

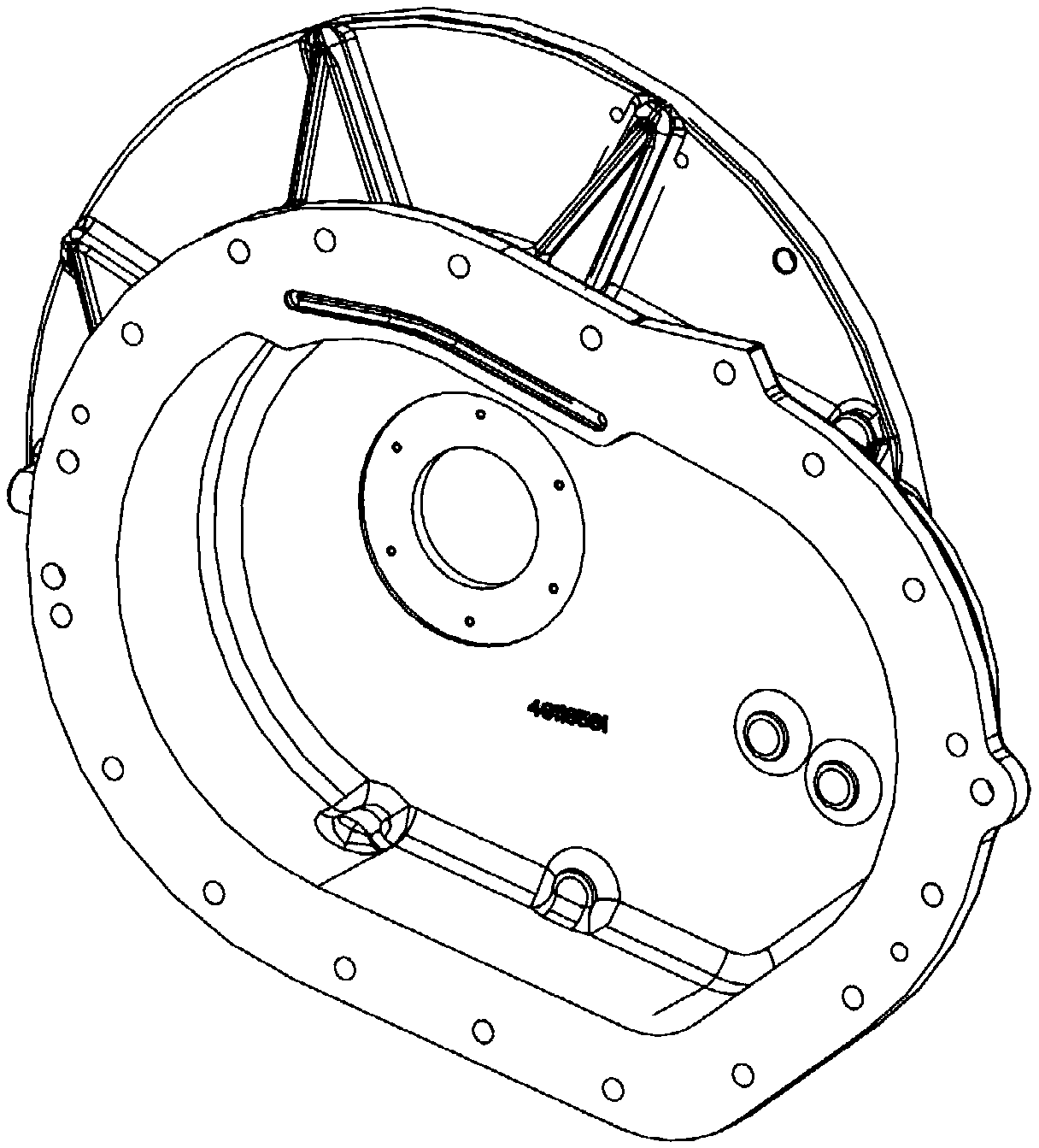

[0022] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] Such as Figure 1~2 As shown, the present invention is an electrorheological fluid clamping tool for a light-duty low-noise gearbox, which is used for positioning and clamping the end face of the gearbox during processing. The tool includes a base 1 on which a There is a workpiece carrying plate 2 perpendicular to the base 1, the middle part of the workpiece carrying plate 2 is provided with a through hole 3 for loading and unloading the workpiece, the inner wall of the through hole 3 is provided with a protruding positioning block 4, and the passage between the positioning blocks 4 The inner wall of the hole 3 is provided with a flexible liquid bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com