Putty powder production packaging system

A packaging system and putty powder technology, which is applied in the field of putty powder, can solve the problems of low packaging efficiency of putty powder and large safety hazards of manual operation, and achieve the effects of saving manpower, low failure rate and high motion precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

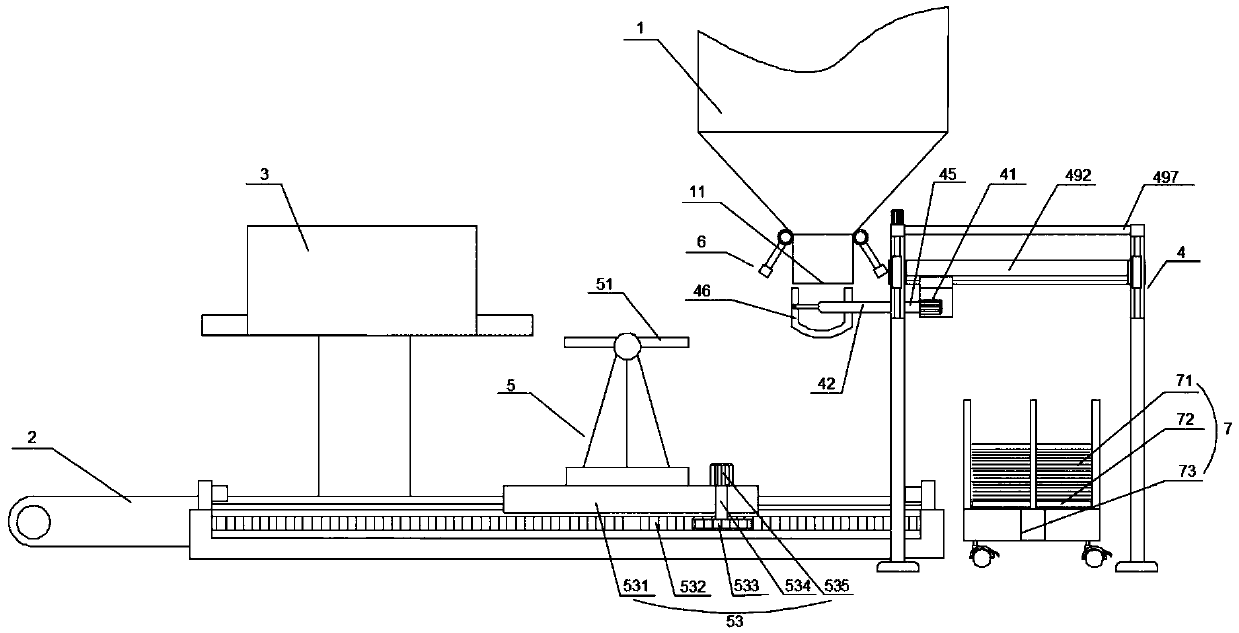

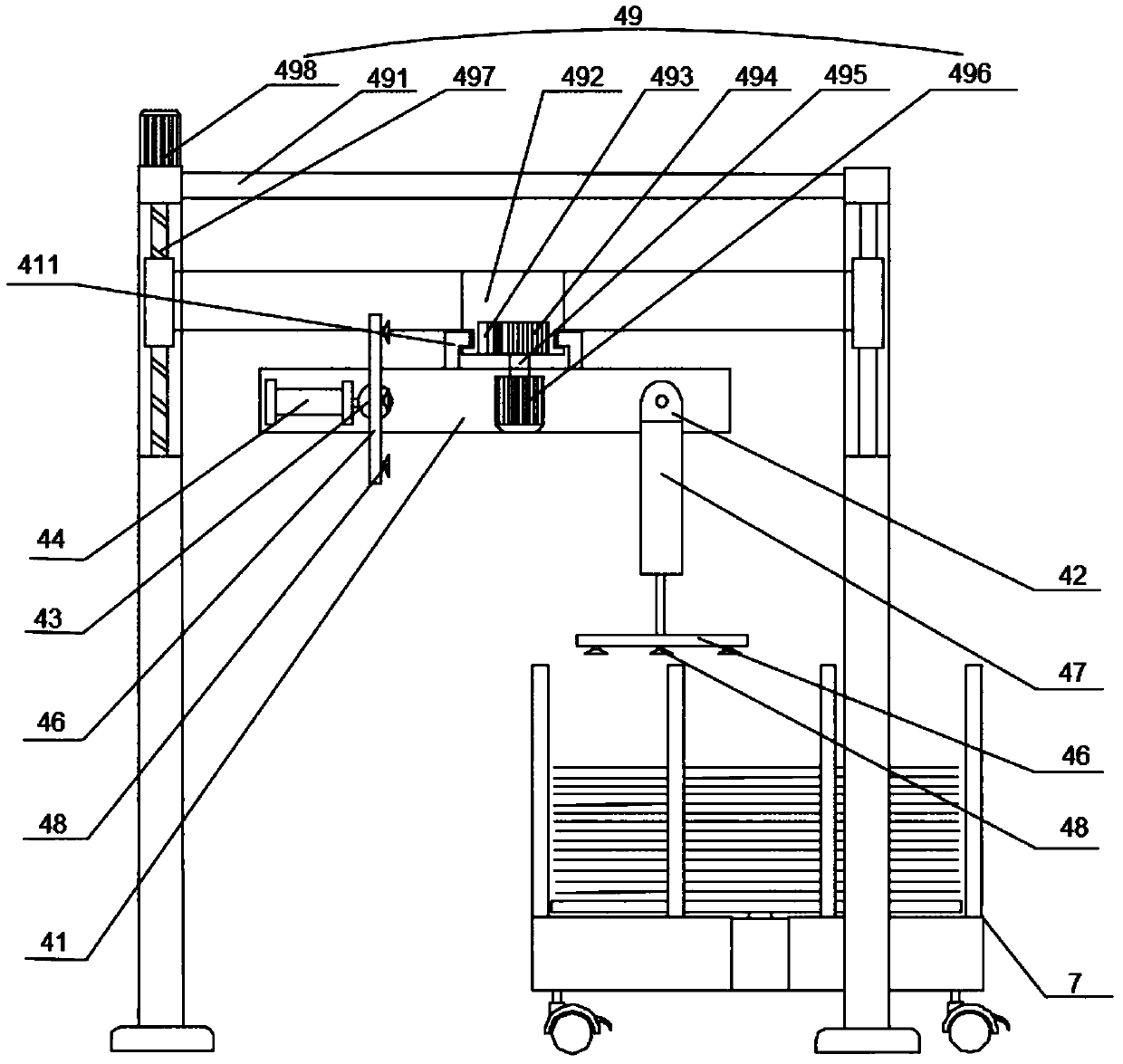

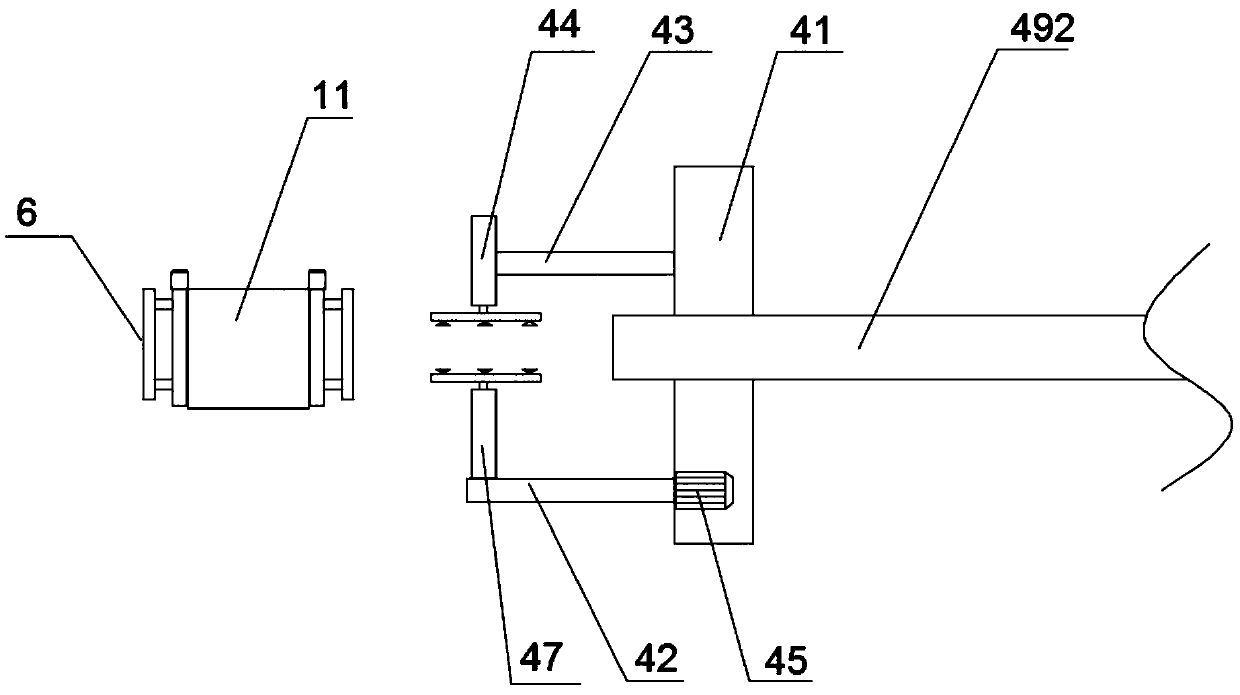

[0033] Such as Figure 1 to Figure 5 As shown, this embodiment provides a putty powder production and packaging system, which includes an assembly line 2 arranged below the discharge port 11 of the finished product tank 1 and a sewing machine 3 on one side of the assembly line. The assembly line 2 is arranged horizontally, and also includes the assembly line arranged in the finished product tank. 1 The bagging mechanism 4 on the right side for covering the packaging bag at the discharge opening 11 and the clamping mechanism 5 for clamping the packaging bag running parallel to the assembly line 2; the bagging mechanism 4 includes a movable horizontal frame 41, the The movable cross frame 41 is connected with a first driving mechanism 49 that drives the movable cross frame 41 to move in the horizontal and vertical directions. The discharging port 11 is provided with an opening and closing mechanism 6 that cooperates with the bag taking assembly; the movable cross frame 41 is provi...

Embodiment 2

[0038] Such as figure 1 with Figure 4 As shown, this embodiment is further optimized on the basis of Embodiment 1, specifically:

[0039] The clamping mechanism 5 includes clamping jaws 51 symmetrically arranged on both sides of the pipeline 2, a second driving mechanism 52 that drives the two clamping jaws 51 to move in opposite directions, and a third driving mechanism that drives the two clamping jaws 51 to move parallel to the pipeline 2 53. The second driving mechanism 52 includes a bidirectional screw 521 and a fifth motor 522 that drives the bidirectional screw 521 to rotate. Two clamping jaws 51 are respectively connected with two screw nuts 523 of the bidirectional screw 521. The three-drive mechanism 53 includes a sliding plate 531, a second rack 532 parallel to the pipeline 2, and a second gear 533 meshing with the second rack 532. The second gear 533 is connected with a connecting shaft 534, and the connecting shaft 534 is far away from the second gear 533 One end of...

Embodiment 3

[0041] Such as figure 1 with figure 2 As shown, this embodiment is further optimized on the basis of Embodiments 1 and 2, specifically:

[0042] A packaging bag feeder 7 is provided. The packaging bag feeder 7 includes a limit frame 71 adapted to the size of the packaging bag. The bottom of the limit frame 71 is provided with a movable bottom plate 72, and the movable bottom plate 72 is connected with a driving activity The fourth driving mechanism 73 of the bottom plate 72 moves up and down. The fourth driving mechanism 73 preferably uses an electric cylinder of the prior art. In this way, dozens of packaging bags can be placed horizontally in the limit frame 71 to play a role in positioning the packaging bags. As the main claw takes away the packaging bag, the bottom plate 72 is gradually raised under the drive of the electric cylinder, so that the main claw can remove the packaging bag every time the main claw drops to the same position, avoiding the failure of the main claw t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com