Backlight module and LCD apparatus

A liquid crystal display device and backlight module technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of poor mechanical performance, high cost, poor mechanical performance of backlight module, etc., and achieve high mechanical performance, low cost, Effect of reducing assembly time and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

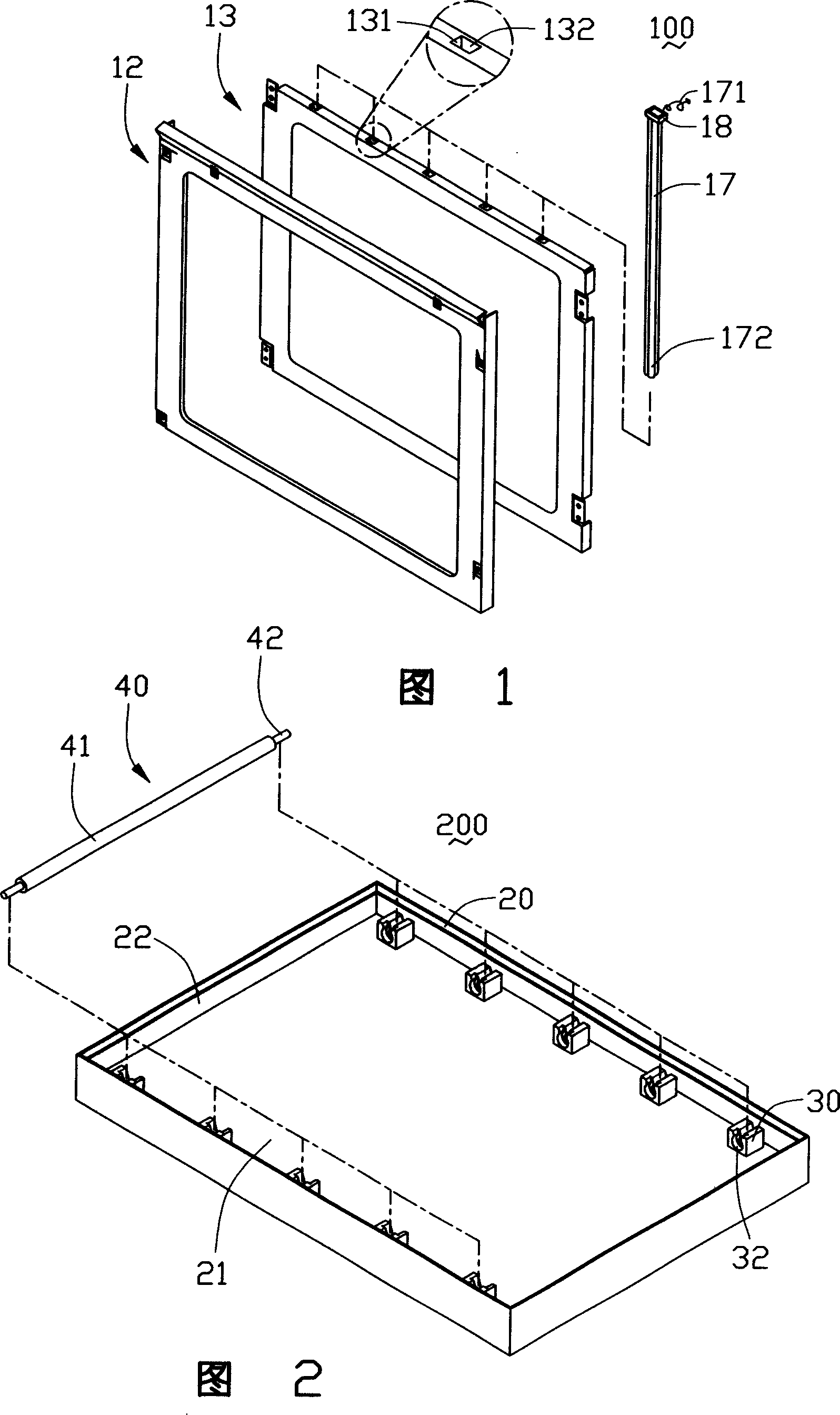

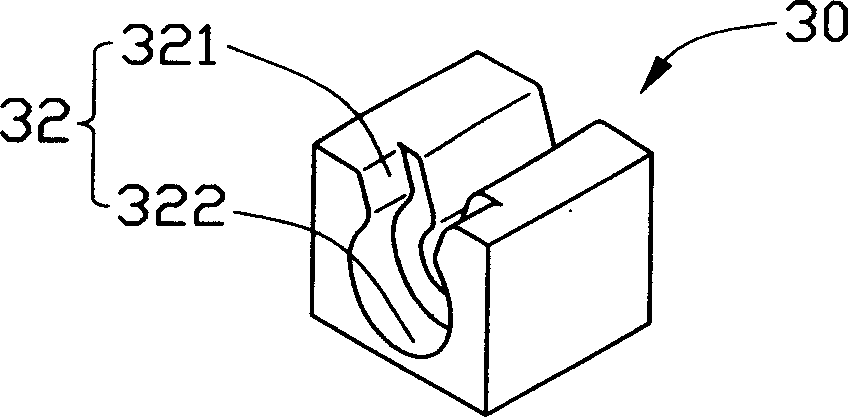

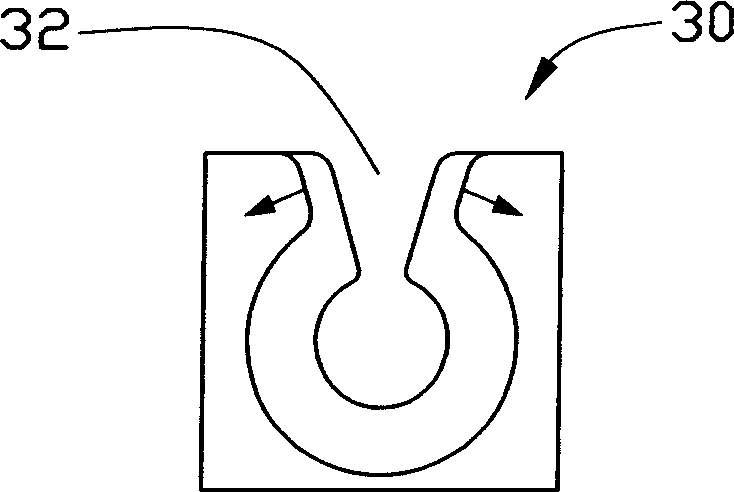

[0030] Please refer to FIG. 2 , which is an exploded perspective view of the first embodiment of the backlight module of the present invention. The backlight module 200 includes a base body 20 and one or more pairs of holders 30. The base body 20 is a box-like frame with a light-reflecting base plate 21 and walls 22 protruding from the base plate 21. The body 30 is fixed in the frame, and it has a groove body 32. The groove body 32 is a groove with different sizes in the axial space. A plurality of linear light sources 40 are accommodated in the plurality of groove bodies 32. The two ends of the groove body are The tank body 32 is held elastically. The linear light source 40 includes a light source body 41 and an electrode 42 protruding from the end of the light source body 41 . The diameter of the electrode 42 is smaller than that of the light source body 41 , and is electrically connected to a power source (not shown).

[0031] Please also refer to image 3 and Figure 4 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com