Backlight module group and liquid crystal display

A backlight module and light source technology, which is applied to static indicators, instruments, optics, etc., can solve the problems of easy deformation of the optical diaphragm group, easy breakage of the lamp tube, and poor fit between the light source and the light guide plate, so as to reduce light leakage and The effect of bending and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

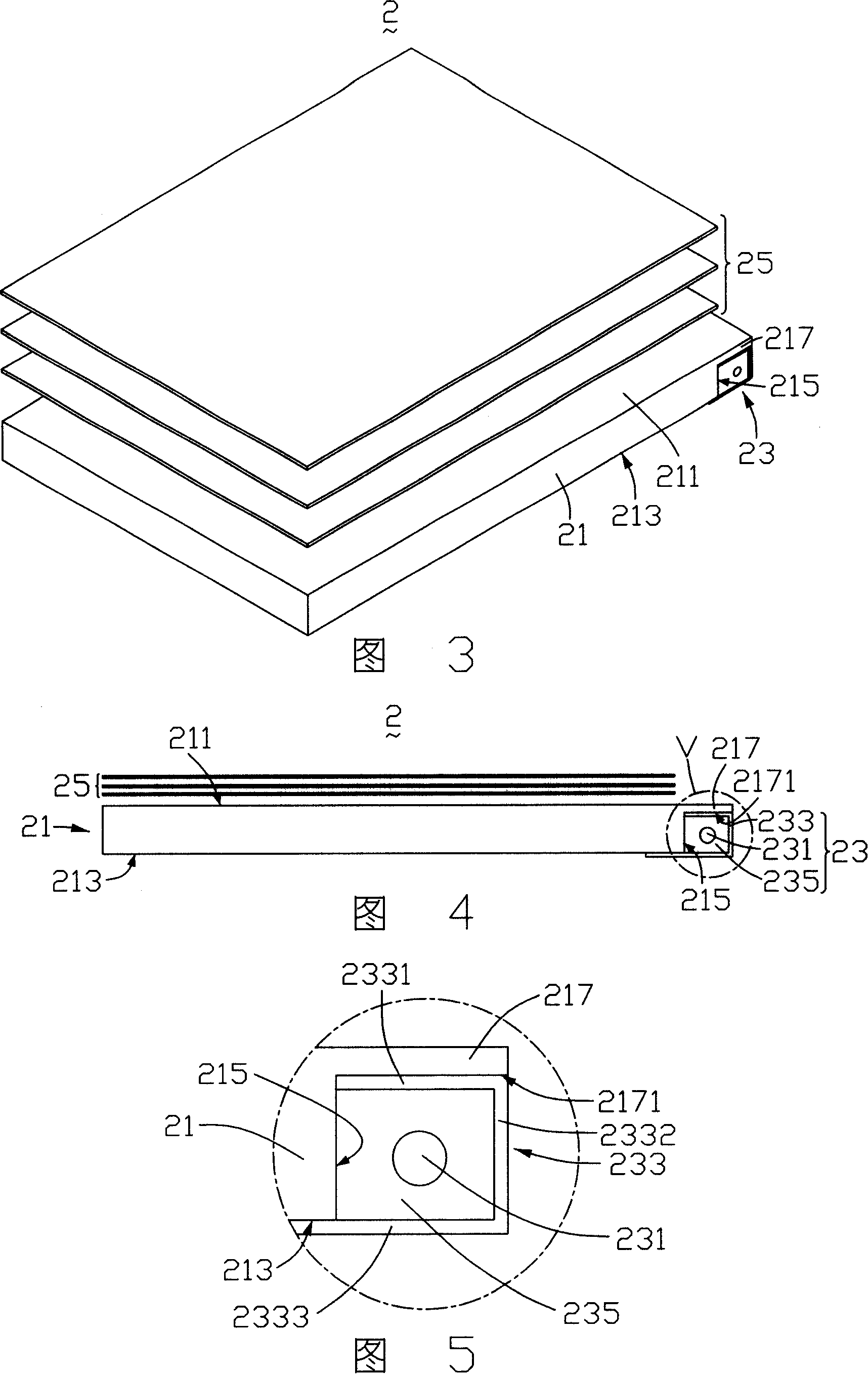

[0021] Please refer to FIG. 3 , which is a schematic perspective view of the first embodiment of the backlight module of the present invention. The backlight module 2 includes a light guide plate 21 , a light source 23 and an optical film set 25 placed on the light guide plate 21 .

[0022] Please also refer to FIG. 4 , which is a schematic structural diagram of the backlight module 2 shown in FIG. 3 . The light guide plate 21 includes a light emitting surface 211 , a bottom surface 213 opposite to the light emitting surface 211 , and a light incident surface 215 adjacent to the light emitting surface 211 . A protrusion 217 extends from the light emitting surface 211 of the light guide plate 21 on the light incident surface 215 side. The bump 217 can be manufactured by plastic molding or milling. The protrusion 217 includes a lower surface 2171 , the lower surface 2171 intersects the light incident surface 215 of the light guide plate 21 to form a receiving space (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com