Three 3-axis localizer-based method for safely (stably) adjusting pose of airfoil member

A three-coordinate locator and locator technology, applied in aircraft parts, aircraft assembly, ground installations, etc., can solve the problems of low production efficiency, low degree of automation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

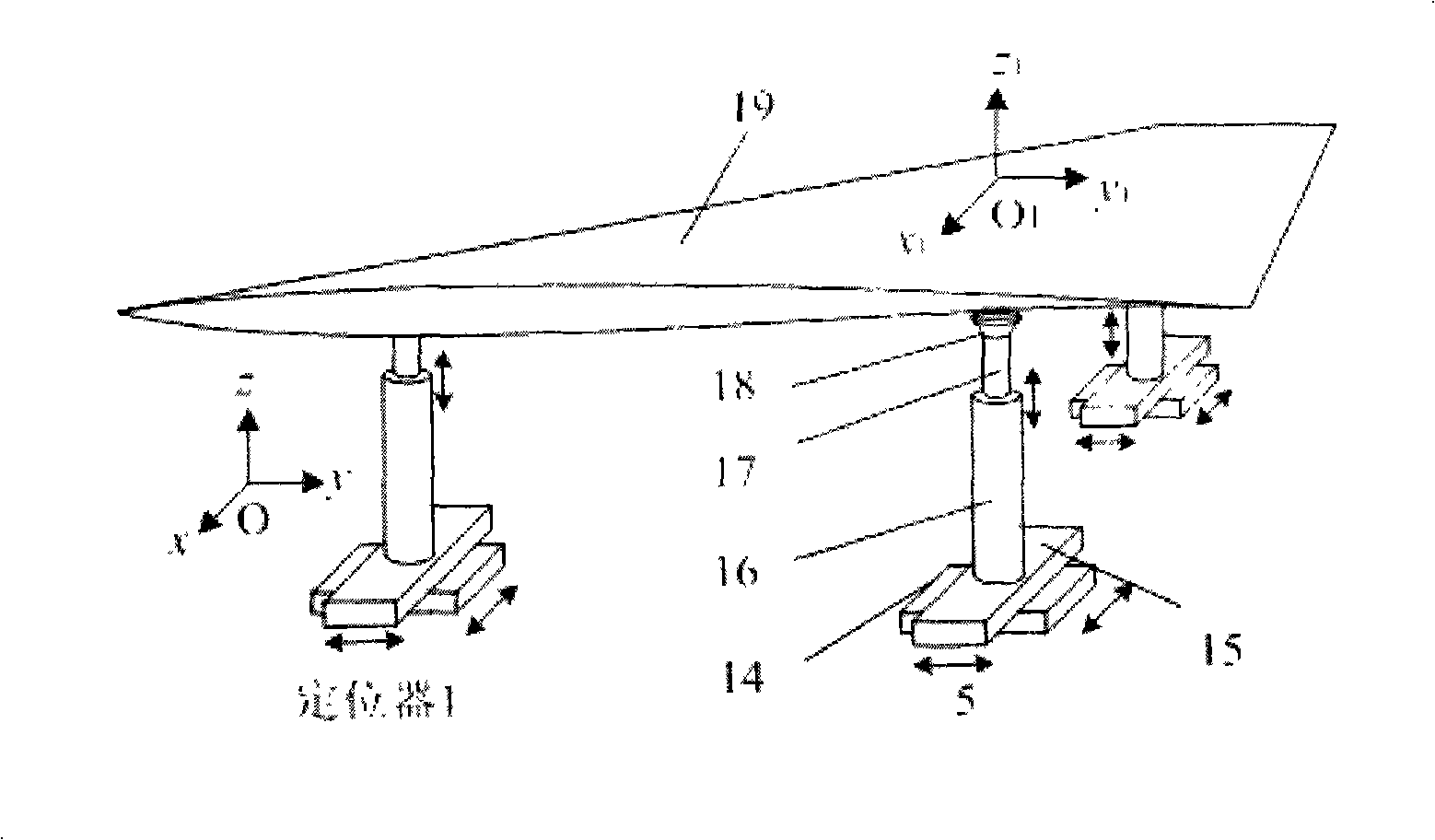

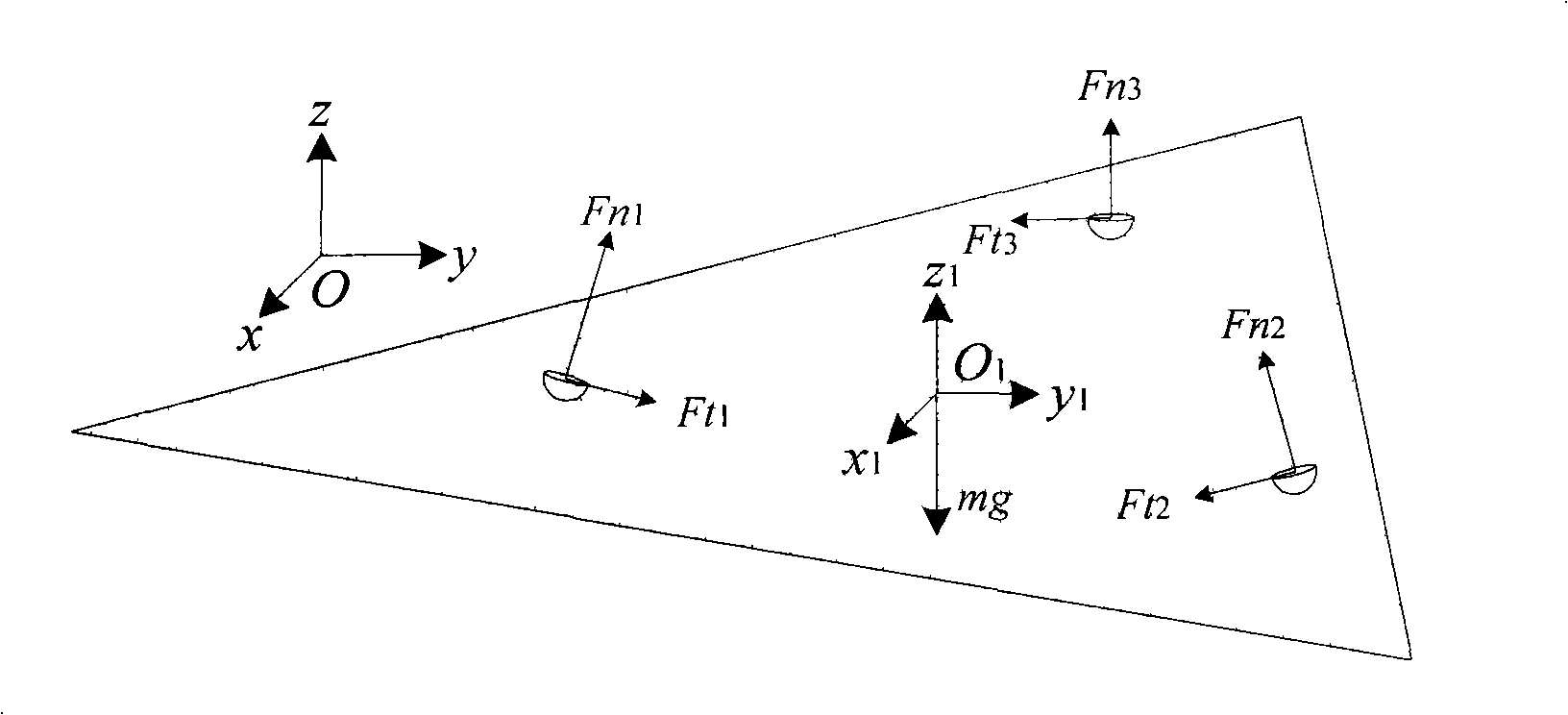

[0056] like figure 1 As shown, the cylinder 16 is fixed on the y-direction slider 15 , and the z-direction moving cylinder 17 can move up and down in the cylinder 16 in the axial direction. The end effector 18 is a spherical hinge structure, which is connected with the wing components by vacuum adsorption. During attitude adjustment, the x- and y-direction moving sliders and the z-direction moving cylinder are driven by servo motors, and the position and posture of wing components required for attitude adjustment can be measured by a laser tracking measurement system.

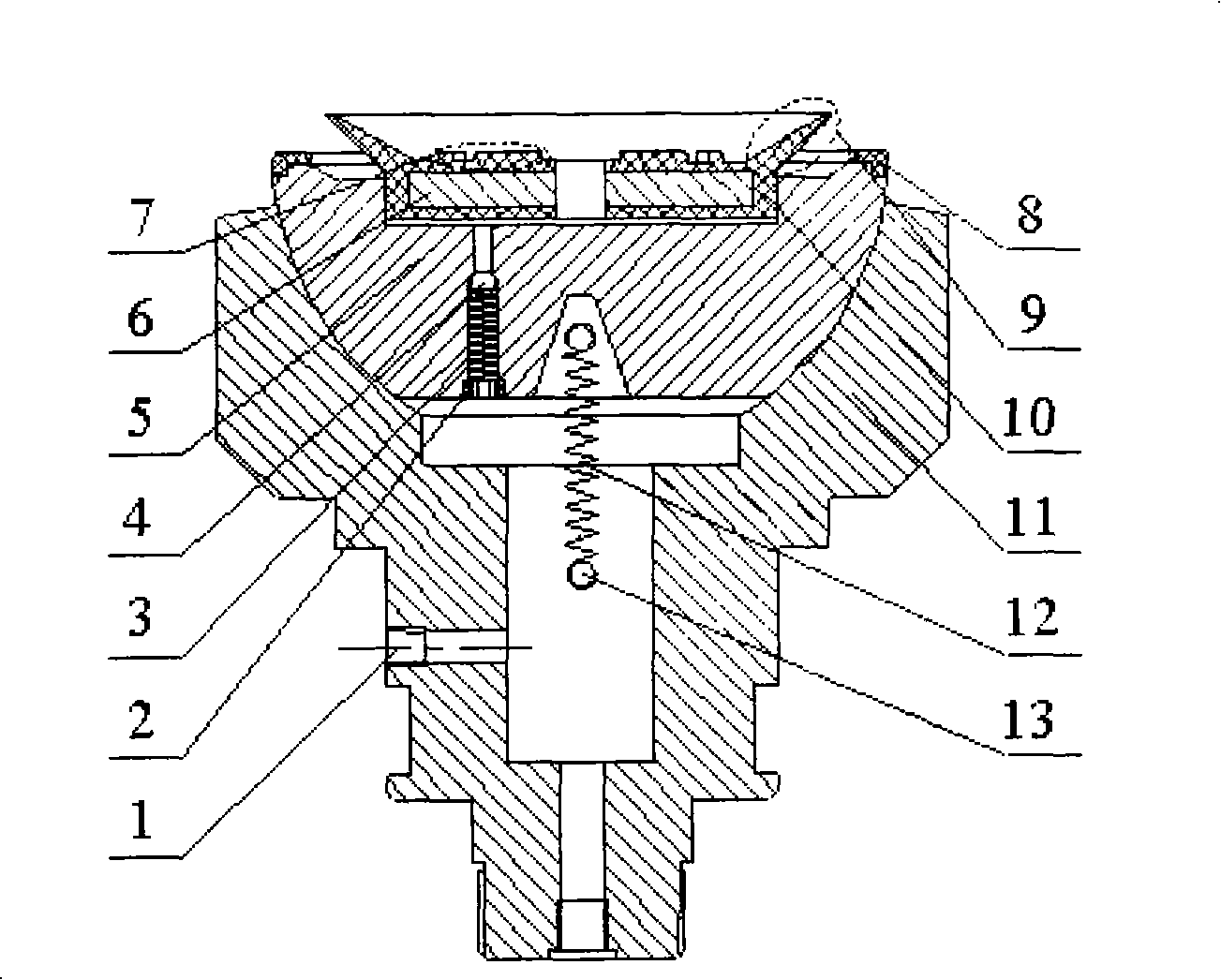

[0057] like figure 2 As shown, the ball seat is fixed on the top of the z-direction moving cylinder through a threaded connection, and the ball head is fastened by a tension spring 12 and a pin 13 . The ball head 5 can rotate around the center of the ball in the ball seat 11, on which a vacuum suction cup and a nylon washer are installed. When adjusting the attitude, the vacuum generator draws a vacuum from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com