Comb and method for hairdressing and beauty

A comb and hairdressing technology, applied in the field of hairdressing combs, can solve problems such as inability to work efficiently, achieve the effect of shortening time and improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

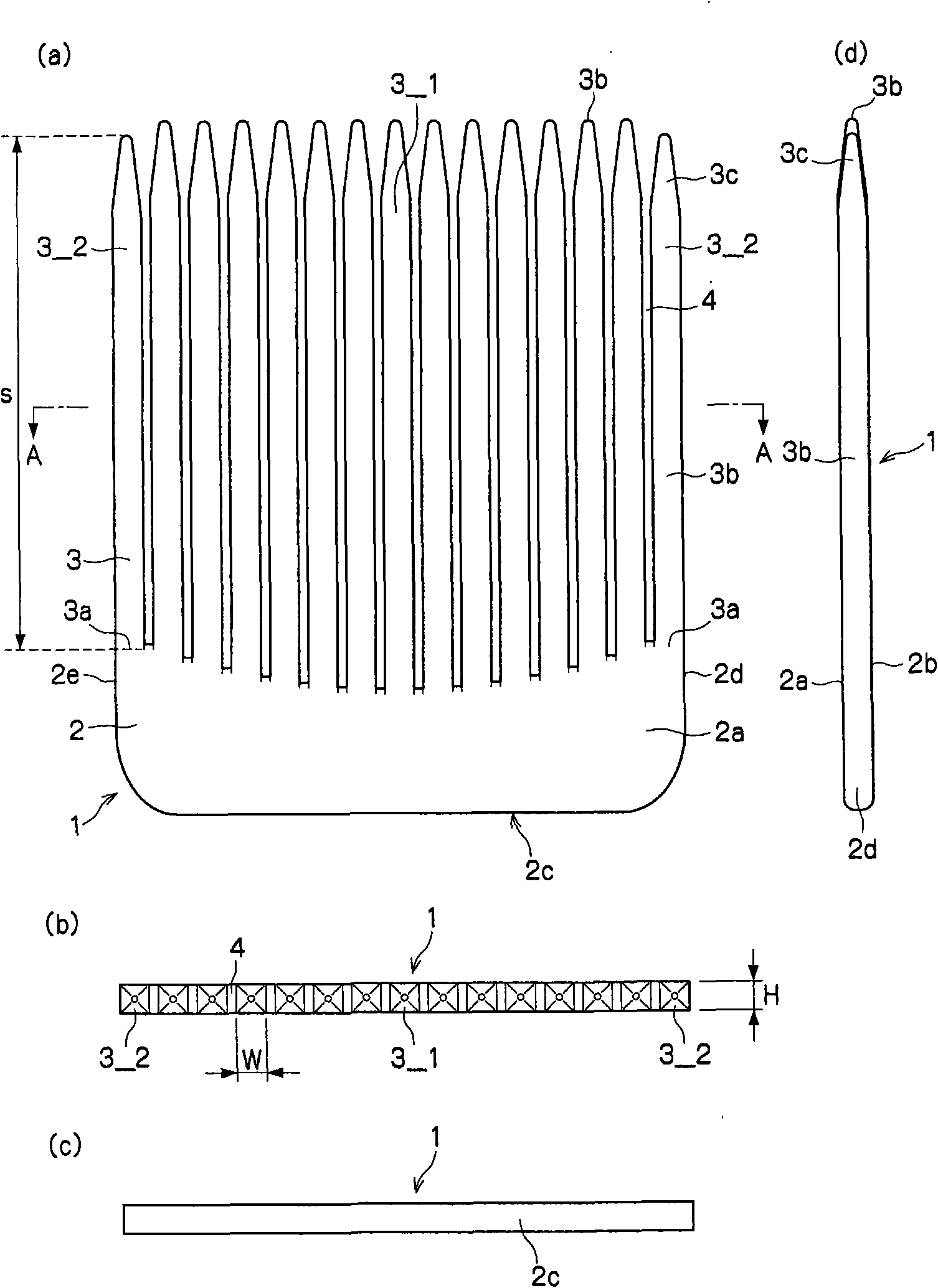

Embodiment 1

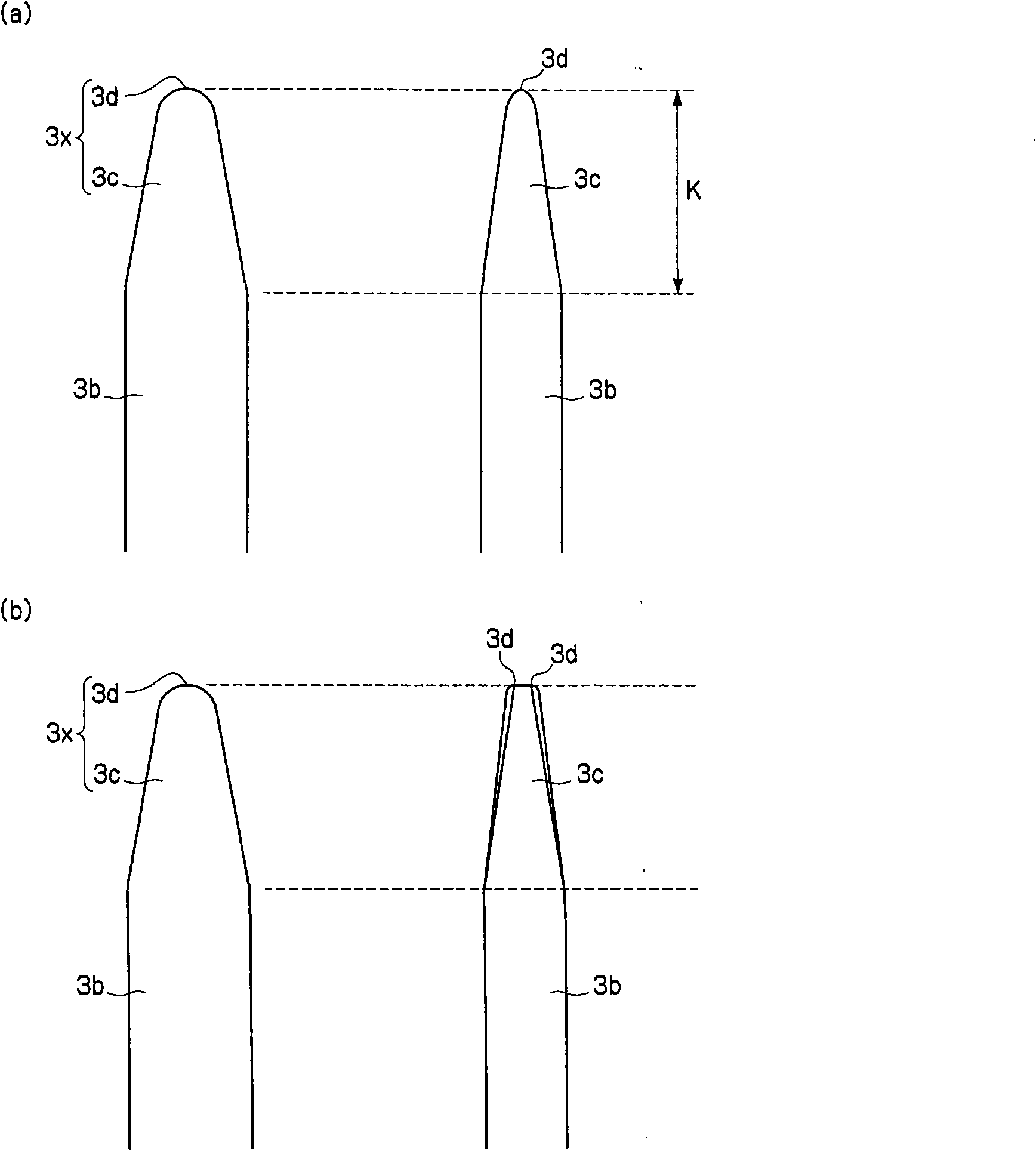

[0089] When the width W of the comb teeth 3 and the length k of the front end portion 3x are constant, if the radius of curvature of the front end 3d becomes smaller, the angle of the narrow portion 3c with respect to the central axis in the extending direction of the comb teeth 3 becomes larger. Therefore, the distance between the tips 3d of adjacent comb teeth 3 becomes larger than the interval L between the comb teeth 3. Therefore, the operator can dispense more hair 6. However, since the contact surface of the front end 3d and the head 5 is small, when the front end 3d abuts on the operator, the operator feels discomfort. Conversely, if the radius of curvature of the tip 3d becomes larger, the angle of the narrow portion 3c with respect to the central axis in the extending direction of the comb teeth 3 becomes smaller. Therefore, the distance between the tips 3d of adjacent comb teeth 3 is close to the interval L of the comb teeth 3. Therefore, relatively, the operator ca...

Embodiment 2

[0101] When the predetermined maximum vertical height h needs to be obtained, when conditions other than the length s of the comb teeth 3 are constant, the longer the length s of the comb teeth 3, the more the operator can flex the comb teeth 3 significantly with lighter force . However, if the length s of the comb teeth 3 is too long, the comb teeth 3 may unnecessarily contact the head 5 of the operator.

[0102] Therefore, the inventors conducted the following experiment 2 in order to clarify the appropriate range of the length s of the comb teeth 3.

[0103] In Experiment 2, 20 types of combs 1 for hairdressing whose length s of the comb teeth 3_1 were varied from 5.0 to 24.0 cm were prepared. Furthermore, the load (g weight) required to obtain the maximum vertical height h=1.5 (cm) was measured, and at the same time, it was clarified that the operator performing the hair cutting operation when using the hairdressing comb 1 to perform the hair cutting operation has an effect on...

Embodiment 3

[0116] When conditions other than the bending elastic modulus of the components of the comb teeth 3 remain constant, the smaller the bending elastic modulus, the greater the maximum vertical height h of the comb teeth 3. As a result, the operator can greatly flex the comb teeth 3 with a relatively light force. However, it takes longer for the comb teeth 3 to return to their original state by elastic deformation. Conversely, the larger the bending elastic modulus, the smaller the maximum vertical height h of the comb teeth 3. Therefore, the operator 3 needs a large force to bend the comb teeth 3. However, the time for the comb teeth 3 to return to their original state by elastic deformation is shortened.

[0117] Therefore, the inventors conducted the following experiment 3 in order to clarify the appropriate range of the maximum vertical height h of the comb teeth 3.

[0118] In Experiment 3, six types of combs 1 for hairdressing with the maximum height h of the comb teeth 3 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com