Electrical connector and manufacturing method thereof

A technology of an electrical connector and a manufacturing method, which is applied in the directions of contact manufacturing, connection, and components of a connecting device, etc., can solve the problems of small size of the electrical connector, poor bending and deformation of terminals, and peeling off of the insulating body of the terminal head. Achieve the effect of good overall strength and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

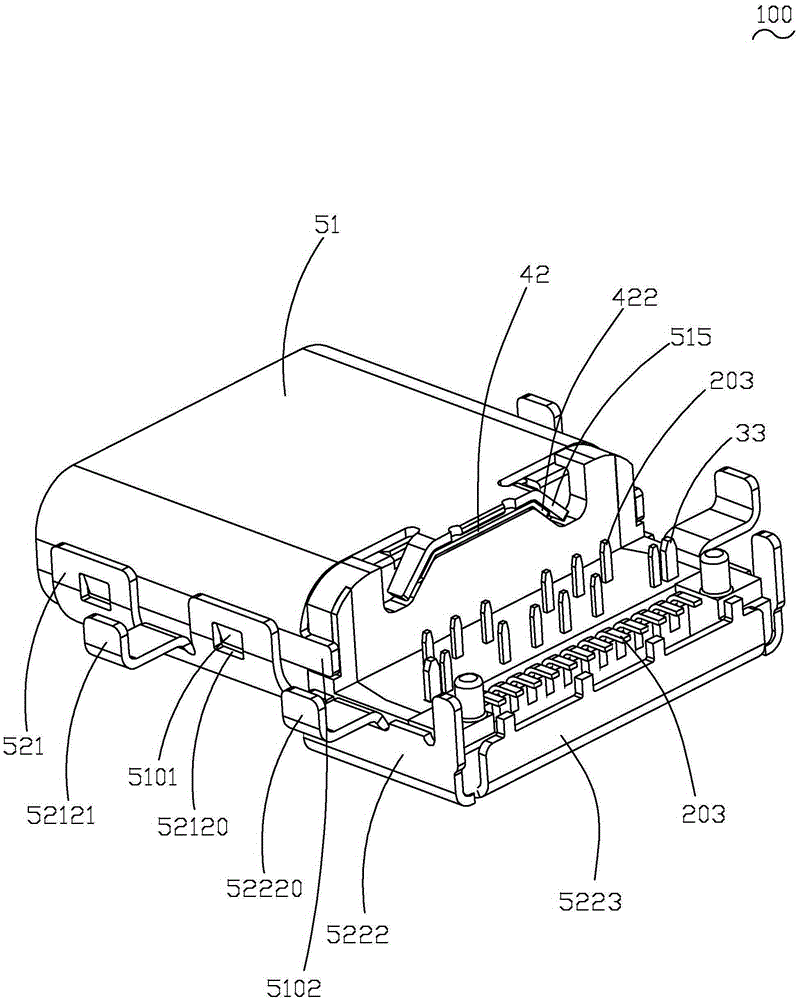

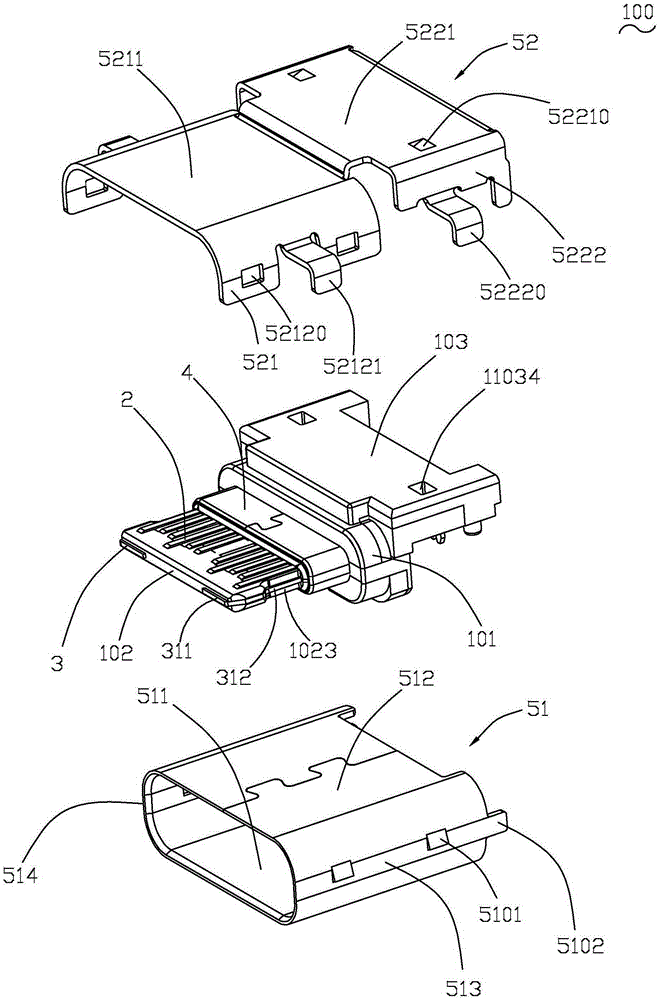

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings. For the convenience of expression, all the directions in this article involving the front and back, up and down, etc. are all in the form of figure 2 The direction is for reference, and the mating end of the electrical connector 100 is regarded as the front end, and the other end thereof is regarded as the rear end.

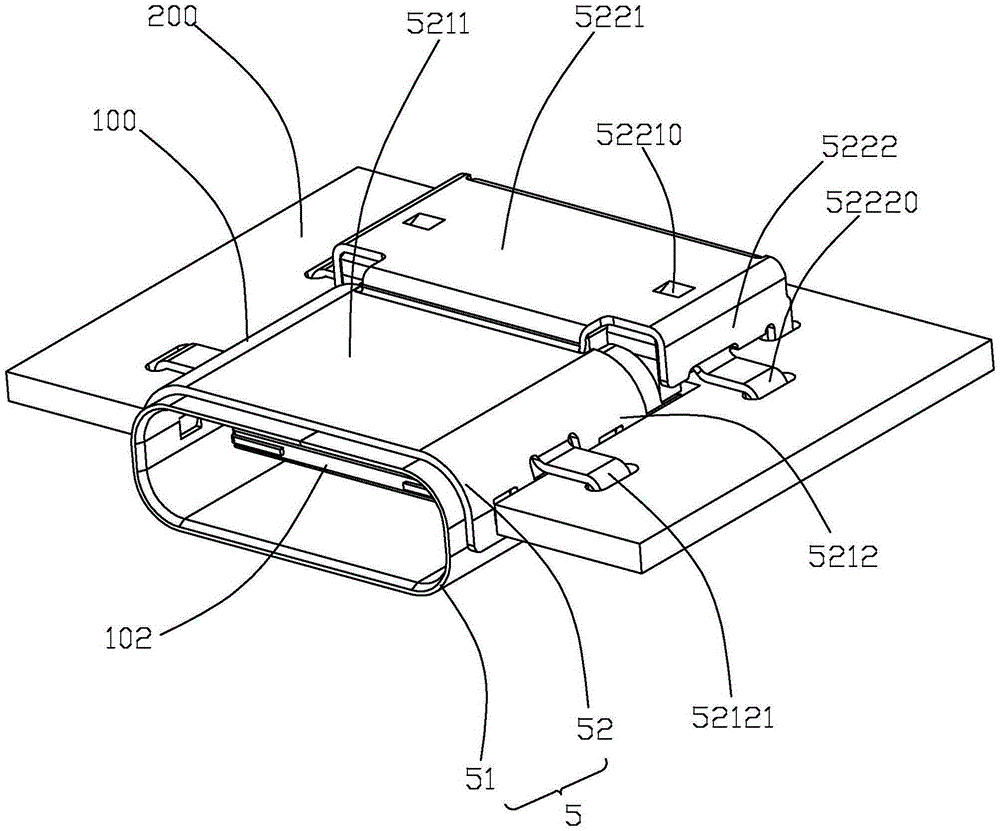

[0033] see Figure 1 to Figure 10 As shown, the present invention discloses an electrical connector 100, which includes an insulating body 1, a terminal 2 and an inner metal part 3 fixed in the insulating body 1, a shielding member 4 and a sleeve set on a part of the outer periphery of the insulating body 1. The metal shell 5 arranged on the periphery of the insulating body 1 . The shielding element 4 is electrically connected to the metal shell 5 . The electrical connector 100 is designed to be fixed on the docking circuit board 200 in a sunken plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com