Intelligent AC contactor control unit based on current-variable control

An AC contactor, current control technology, applied in relays, electrical components, circuits, etc., can solve the problems of energy waste, large amount of contactor, huge energy consumption, etc., to reduce energy consumption, reduce ablation, and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

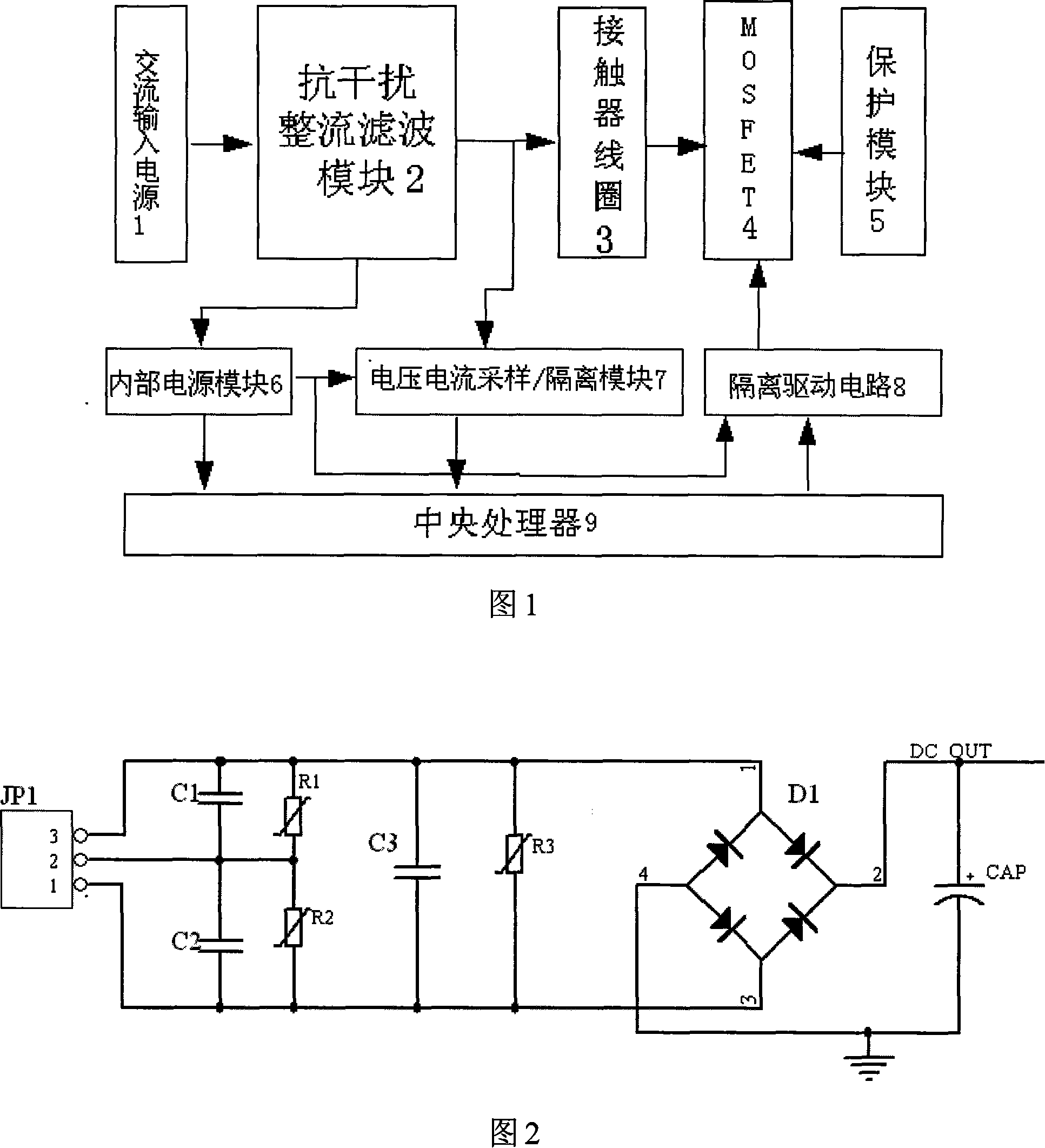

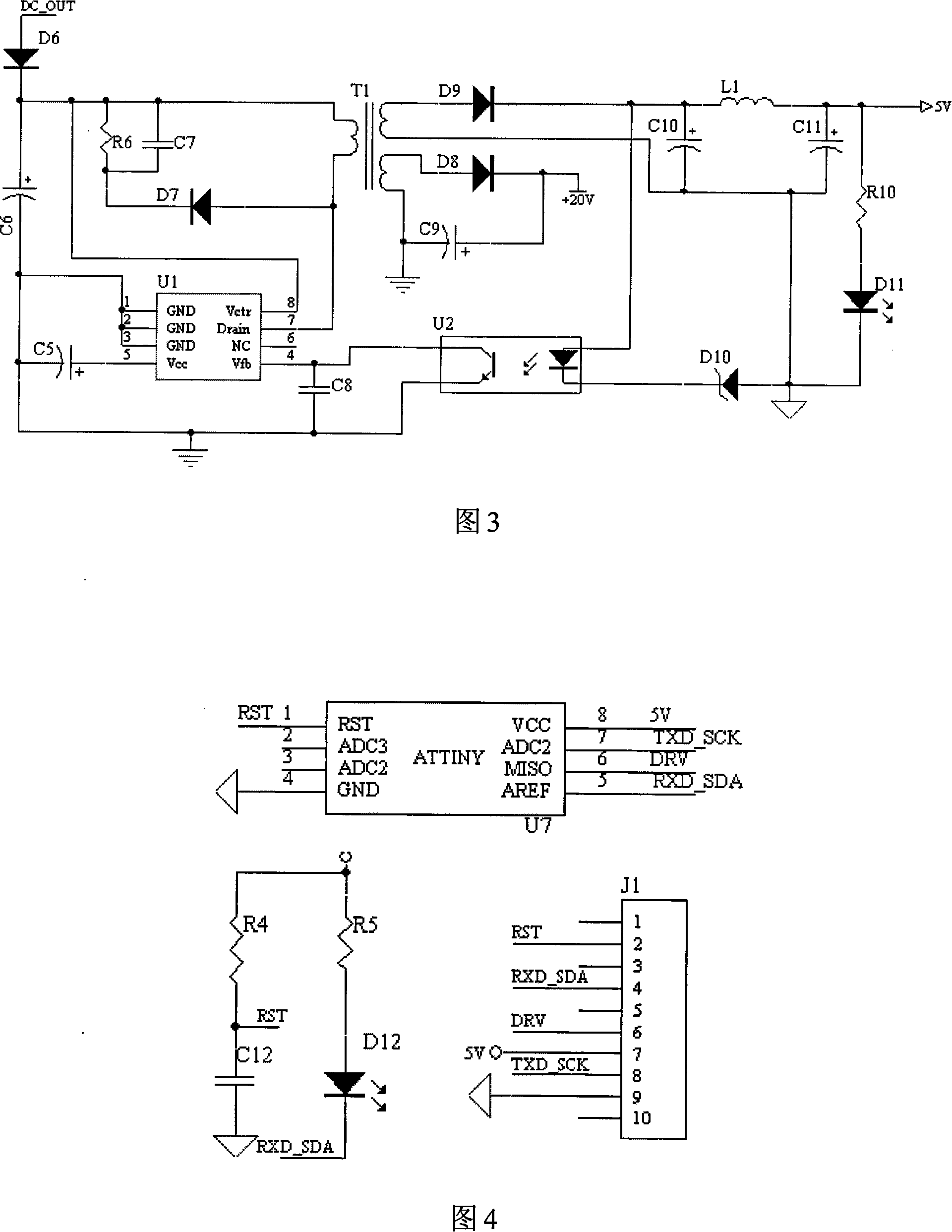

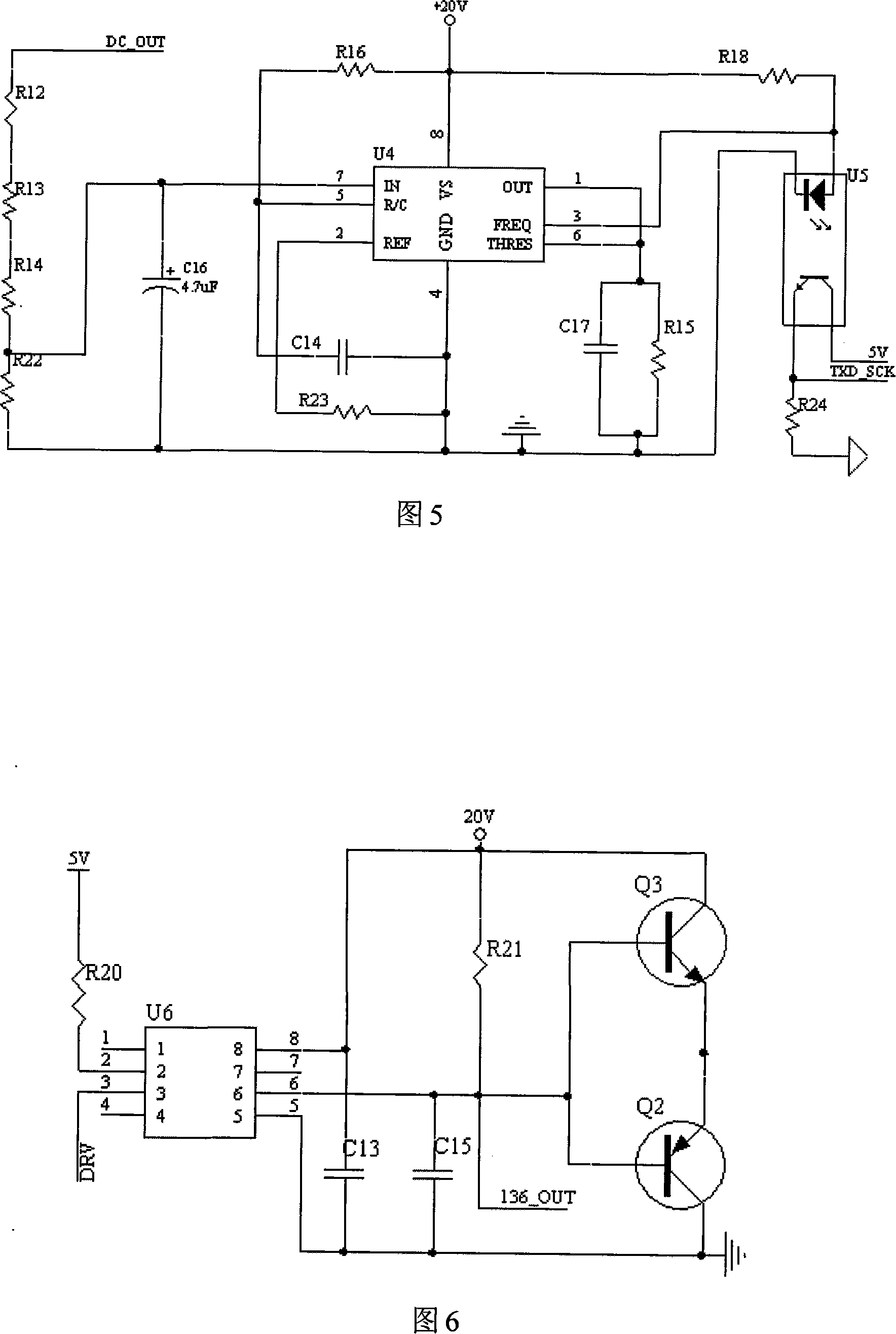

[0022] Referring to Fig. 1, the present invention includes an anti-jamming module 2 directly connected to an AC input power supply 1. The anti-jamming module 2 is used to prevent surge impact and fast burst interference. After the AC input power supply 1 is rectified by a rectifying and filtering module 3, After becoming a pulsating DC voltage with a frequency of 100Hz, it is filtered by a high-voltage electrolytic capacitor to become a DC voltage with smaller ripples. The DC voltage is divided into two circuits, one of which is adjusted by the internal power supply module 7 to become two output voltages of +5V and +20V. The driving circuit 8 provides an operating voltage. The voltage and current sampling / isolation module 9 utilizes the principle of A / D conversion to collect voltage signals through single-channel sampling and current signals through two-chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com