Thermal overload relay

一种继电器、过载电流的技术,应用在热动型过载继电器领域,能够解决热动型过载继电器动作特性不稳定等问题,达到动作特性稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

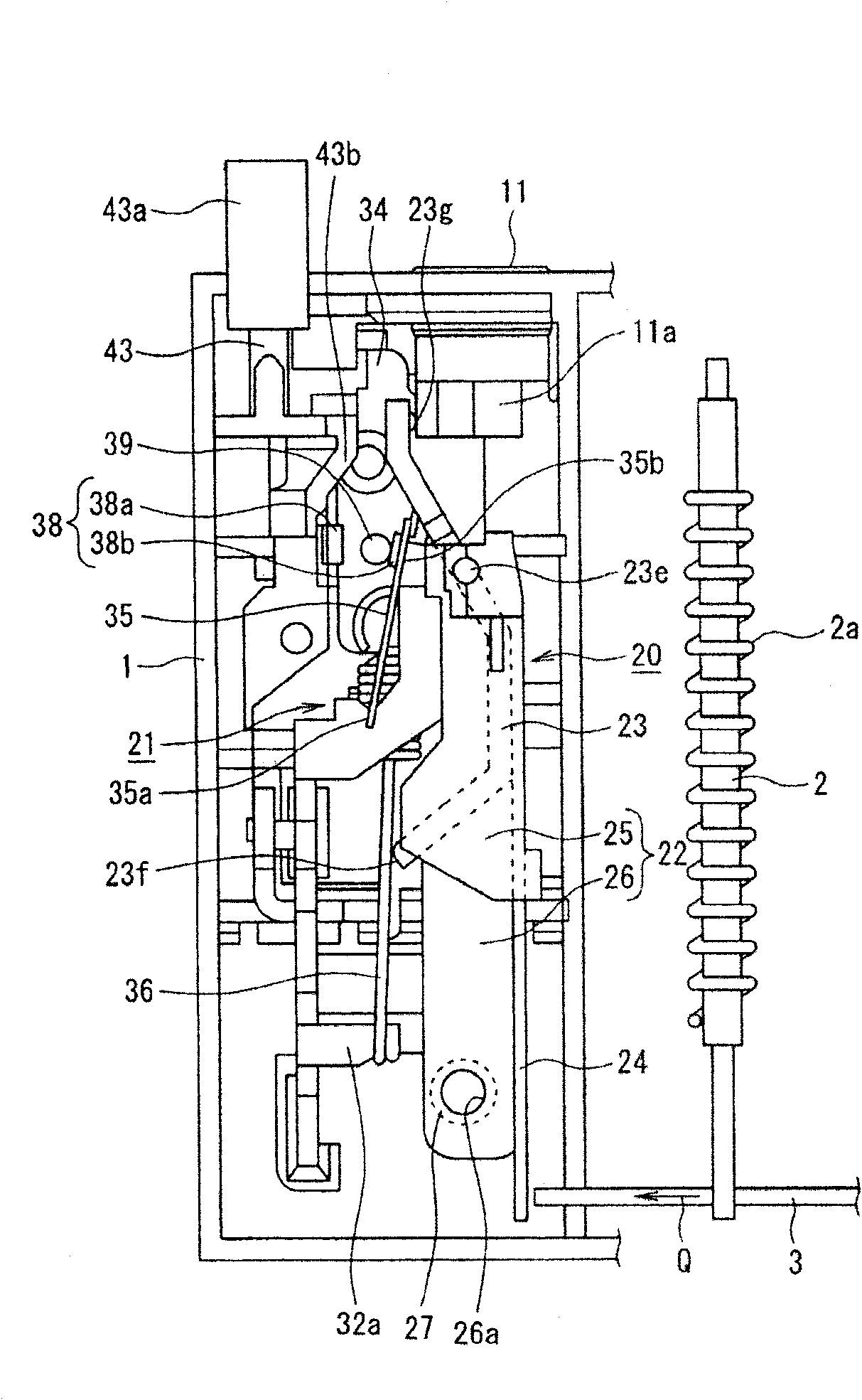

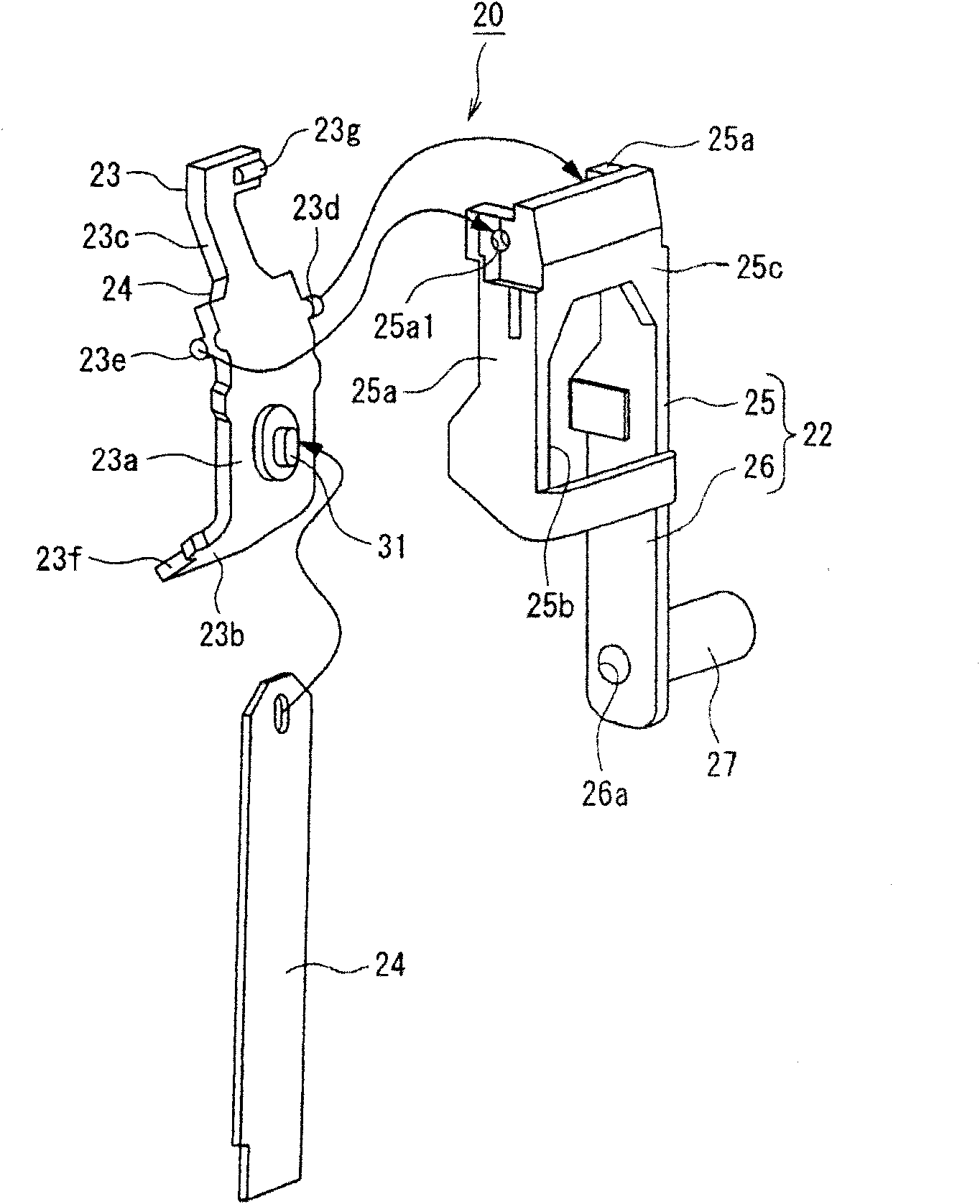

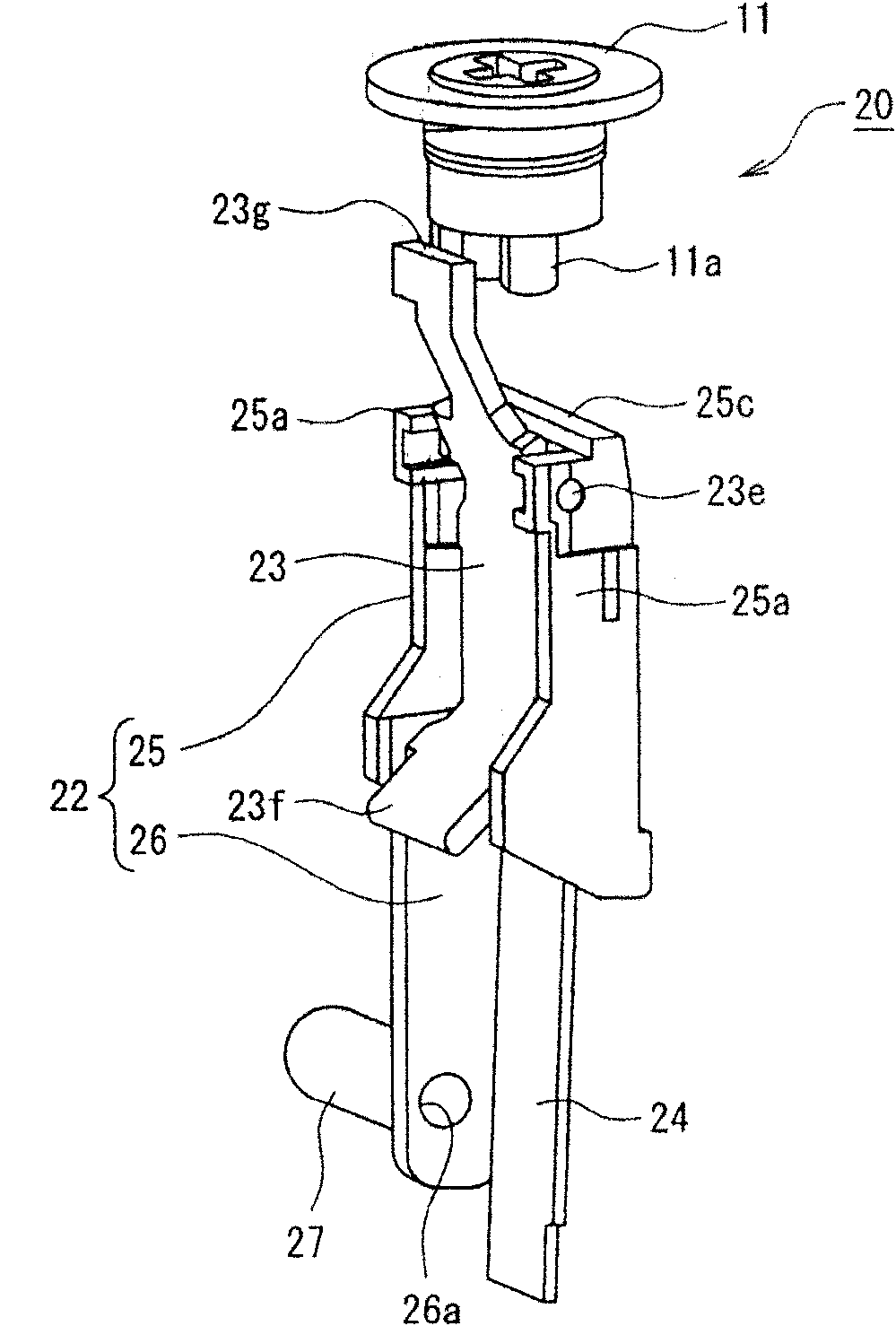

[0086] Hereinafter, the best mode for carrying out the present invention (hereinafter referred to as embodiment) will be described in detail with reference to the drawings. Also, for Figure 8 and Figure 9 Structural components that represent the same structure are marked with the same symbols, and their descriptions are omitted.

[0087] Figure 1 to Figure 7 Showing one embodiment of the thermal overload relay of the present invention, figure 1 It is a diagram showing the normal state of the main parts of the thermal overload relay, figure 2 It is an exploded diagram of the adjustment mechanism of the thermal overload relay, image 3 is a diagram showing the adjustment mechanism in contact with the adjustment dial, Figure 4 It is a diagram showing the contact inversion mechanism of the thermal overload relay, and Fig. 5(a) is a diagram showing the contact inversion mechanism and the normally open contact (a contact) in the normal state or reset state, and Fig. 5(b) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com