Gantry type sheet feeding and discharging manipulator for woodwork

A gantry-type, manipulator technology, applied in manipulators, multi-purpose machinery, wood processing appliances, etc., can solve the problems of increasing safety hazards, reducing production efficiency, and increasing suction cup wear, reducing wear, improving production efficiency, and preventing adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

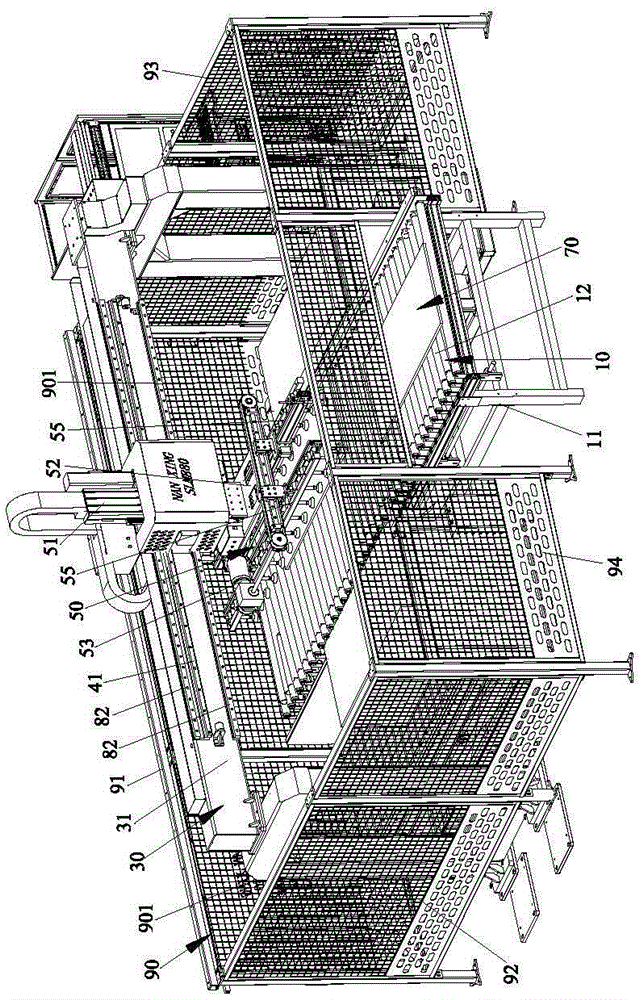

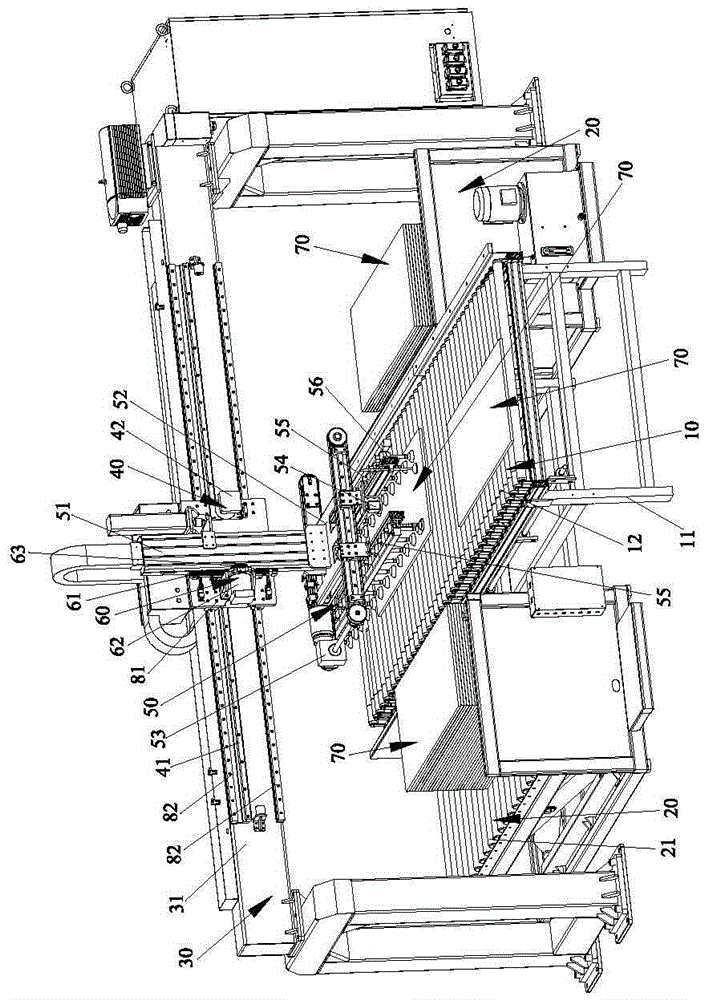

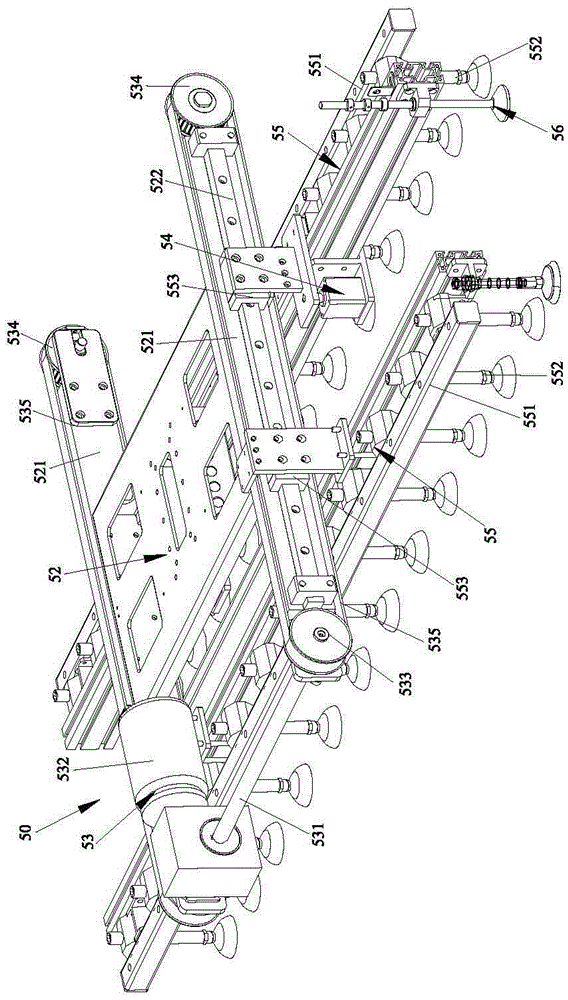

[0043] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a compound conveying platform 10, a feeding device 20, a main body support 30, a horizontal moving device 40, a grabbing device 50 and a vertical moving device 60.

[0044] The composite conveying platform 10 includes a supporting frame 11 and a plurality of conveying rollers 12, and the conveying rollers 12 are installed on the supporting frame 11 at a certain angle to each other. When conveying the plate 70, the plate 70 will automatically pull over and enter the processing equipment.

[0045] The feeding device 20 is arranged on the side of the compound conveying platform 10; The feeding device 20 has a lifting table 21, adopts a single-station cycle feeding control mode, no need to stop during the feeding process, and reduces unnecessary time consumption.

[0046] The main body support 30 straddles the feeding device 20 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com