Dangerous waste staff whirl wind gasified melting system

A technology of hazardous waste, gasification and melting, applied in the field of incineration of hazardous waste, can solve the problem of high economic cost, and achieve the effects of improving separation efficiency, preventing slagging and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

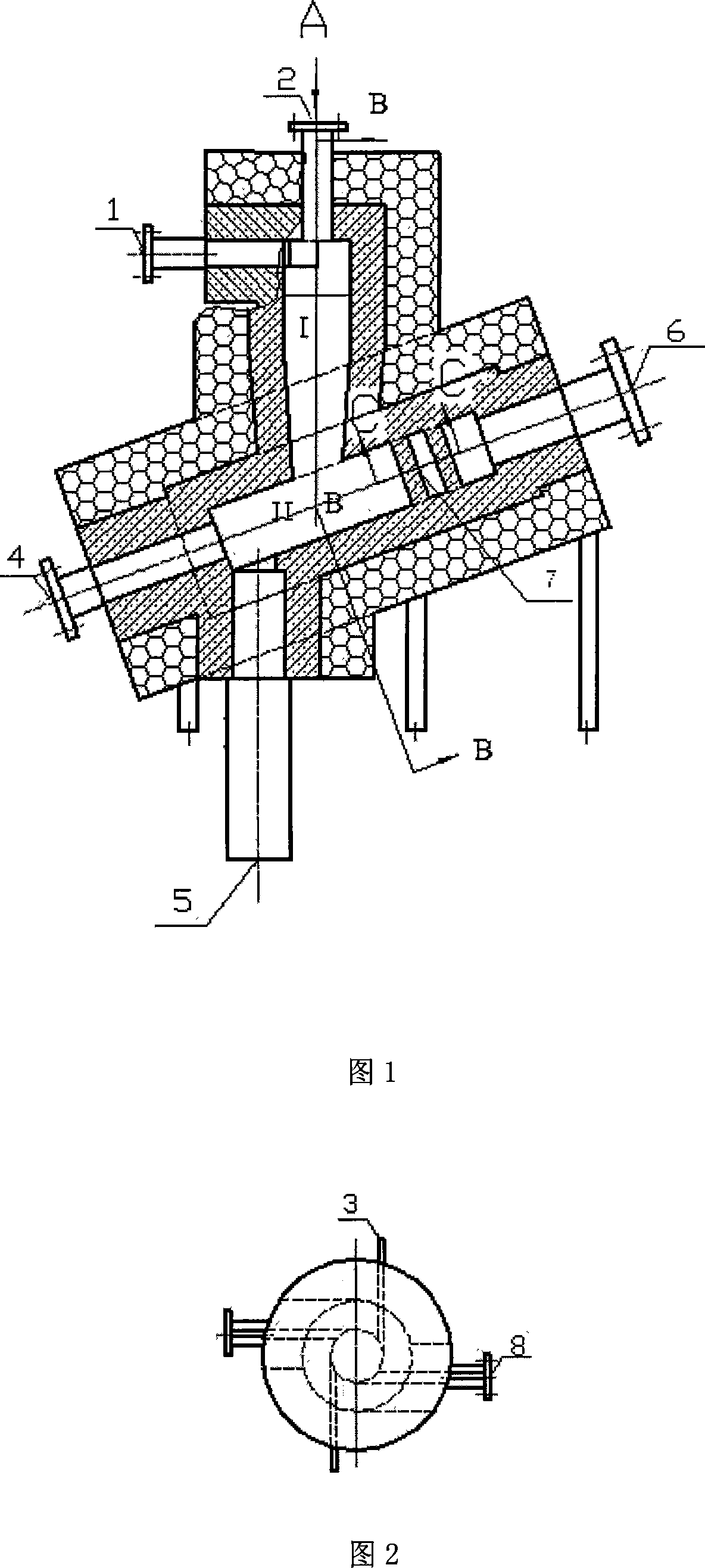

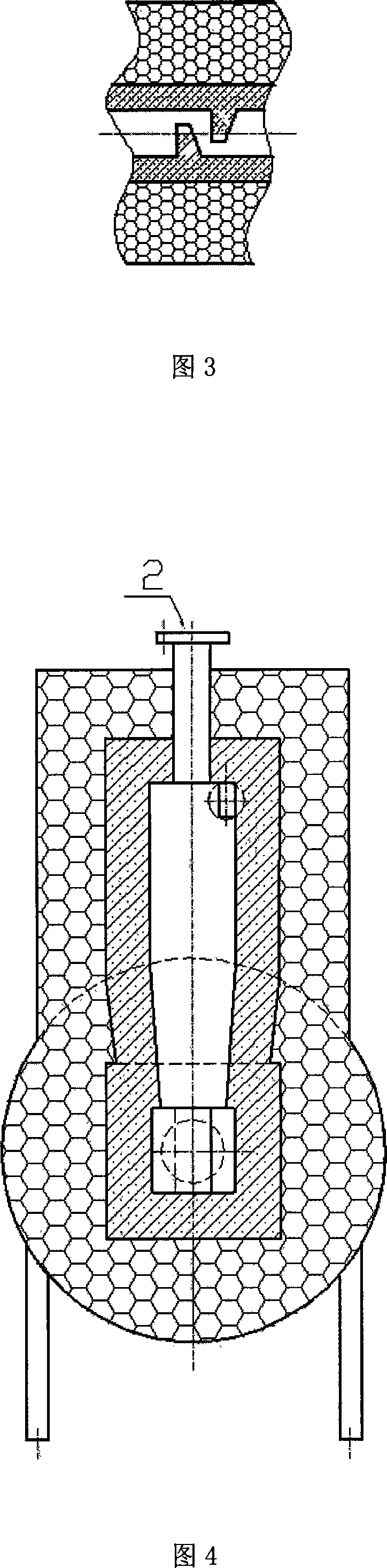

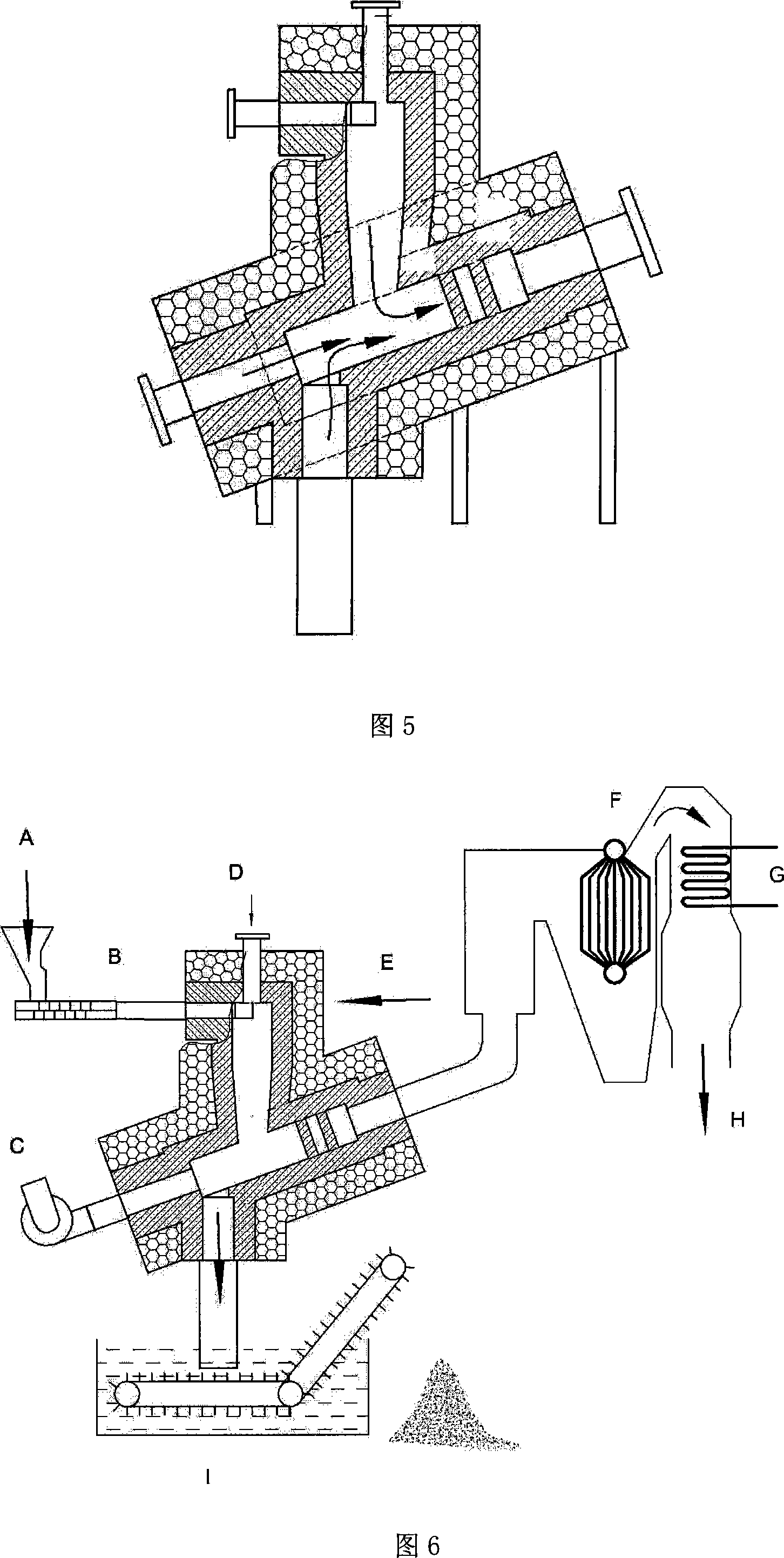

[0027] This embodiment is provided with the main combustion chamber I and the secondary combustion chamber II which communicate, and the main combustion chamber I is provided with a hazardous waste feed inlet 1, an additive / fly ash / combustion-supporting fuel inlet 2, a combustion-supporting air inlet 3, and the secondary combustion chamber II is equipped with secondary air inlet 4, slag discharge pipe 5, flue gas outlet 6, gas auxiliary fuel inlet 8, auxiliary burner is provided at secondary air inlet 4 in secondary combustion chamber II, and flue gas outlet 6 The front is equipped with 7 inertial separators.

[0028] The diameter of the additive / fly ash / combustion-supporting fuel inlet 2 is 83mm; the lower part of the main combustion chamber I is a conical section with a taper of 8°; the combustion-supporting air inlet 3 is two symmetrically arranged as shown in Figure 2; inertial separation The device 7 is a folding plate type, and the distance between the folding plates is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com