Patents

Literature

69results about How to "Not easy to strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

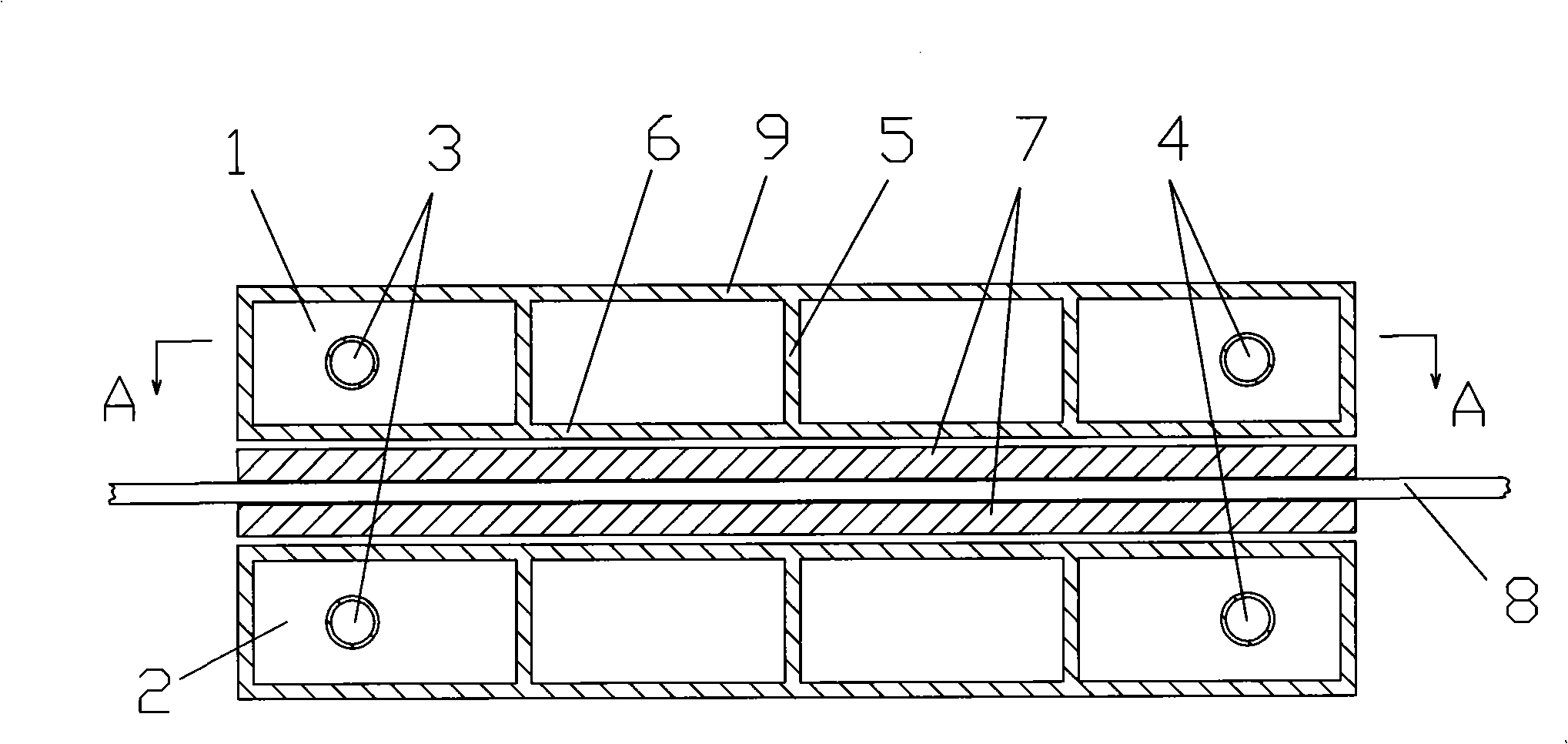

Non-hydraulic plate quenching device for steel belt continuous quenching and steel belt cooling method

InactiveCN101348858AClose contactImprove thermal conductivityFurnace typesHeat treatment furnacesSurface finishThermodynamics

The invention discloses a quenching device without a hydraulic plate with continuous quenching of a steel belt and a steel belt cooling method. The quenching device without the hydraulic plate comprises an upper water tank and a lower water tank, wherein a water inlet and a water outlet are arranged on each water tank; a plurality of water guide plates are arranged inside the water tanks; the steel belt passes through the two water tanks; one side of each water tank close to the steel belt is provided with a pressure plate; and a protective plate is arranged between the pressure plate and the steel belt. The quenching steel belt cooling method without the hydraulic plate transfers heat of the heated steel belt to flowing water by utilization of solid heat conduction and the temperature of the steel belt is quickly reduced to below the martensite transition temperature Ms without the necessity of direct cooling of liquid, thereby the steel belt texture is transformed from austenite to martensite. The quenching device without the hydraulic plate and the steel belt cooling method have the advantages of no necessity of any liquid quenching medium, no environmental pollution, simple equipment, high production efficiency, and good surface finish degree and flatness.

Owner:ZHEJIANG BAINAI STEEL STRIP

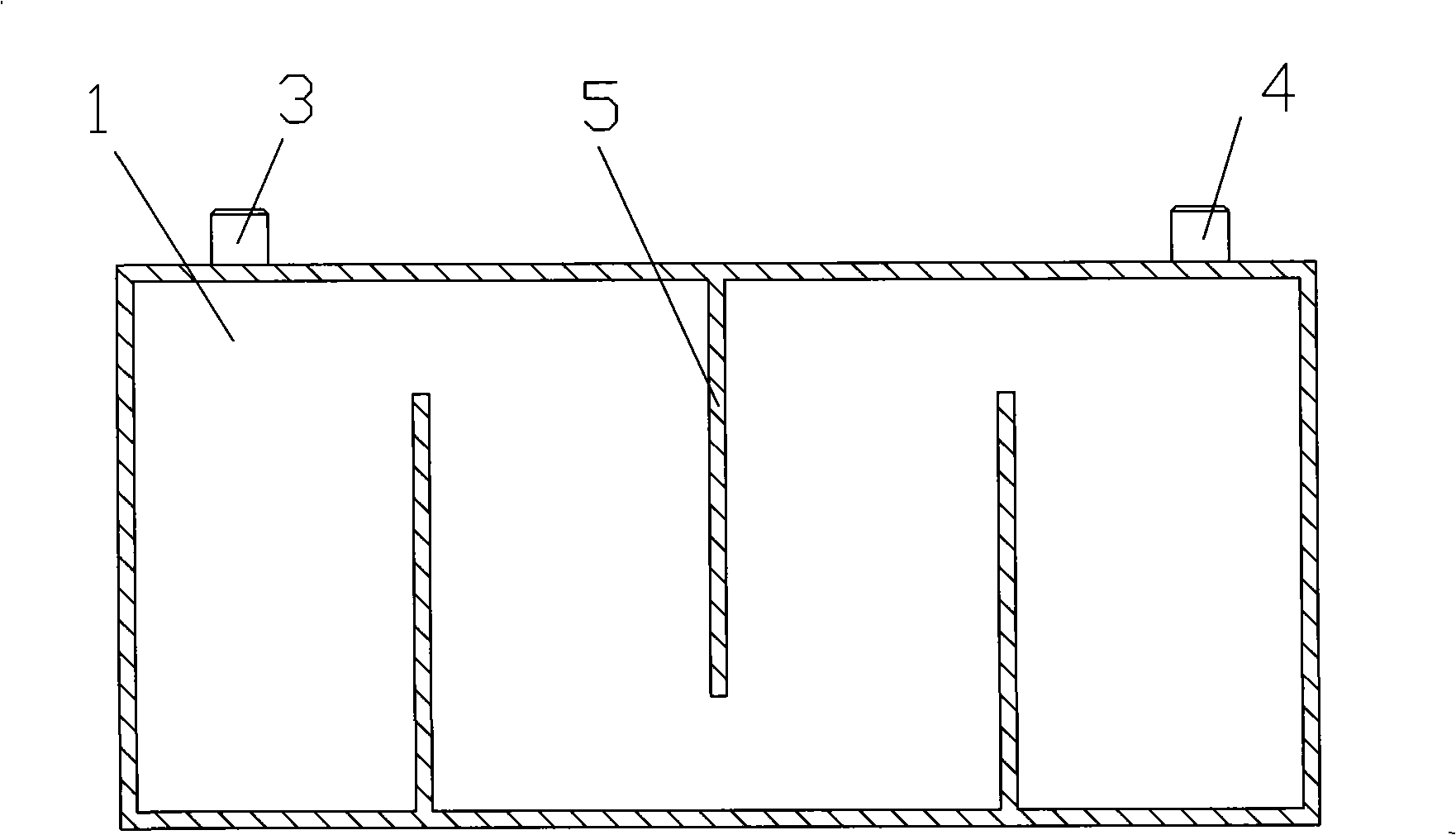

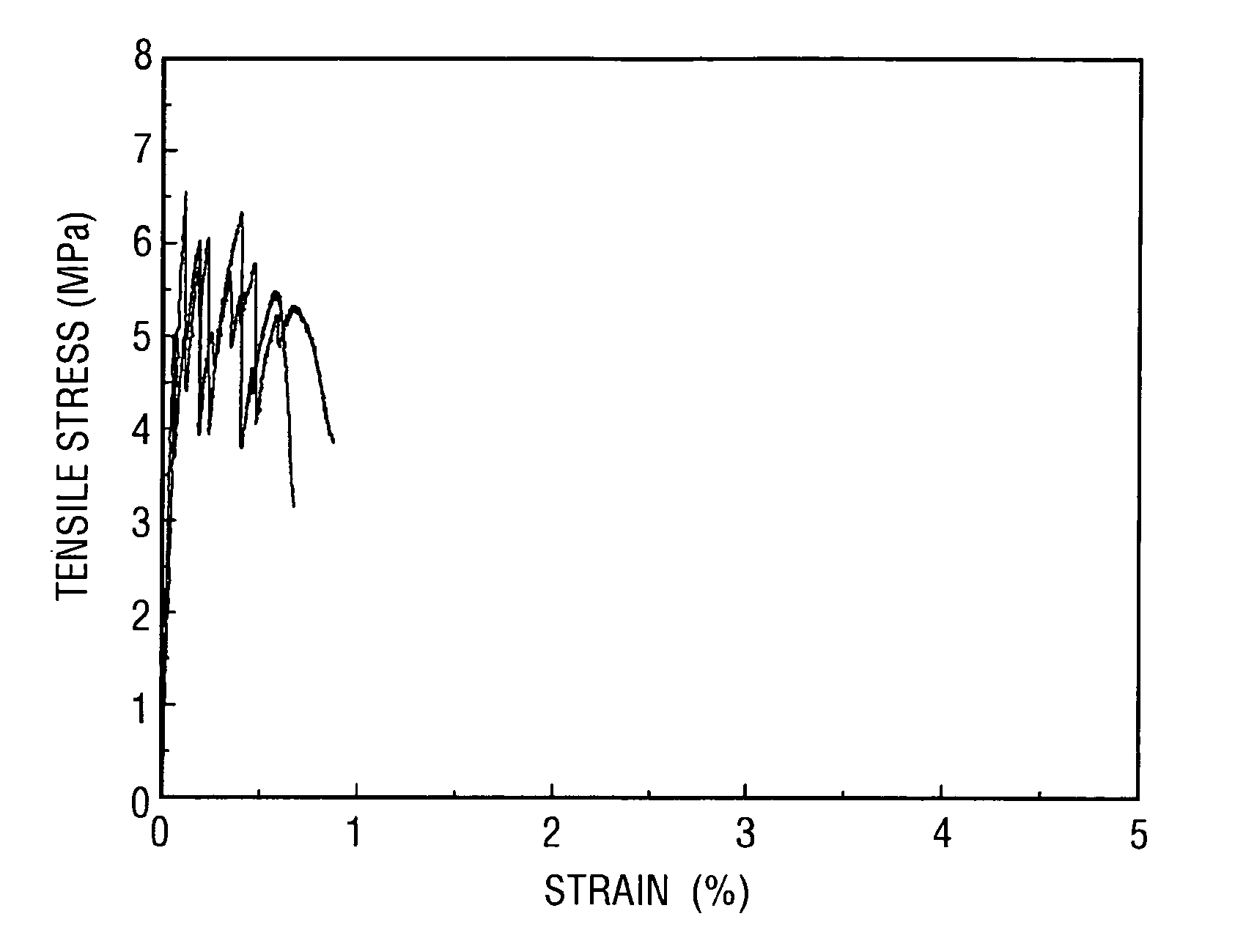

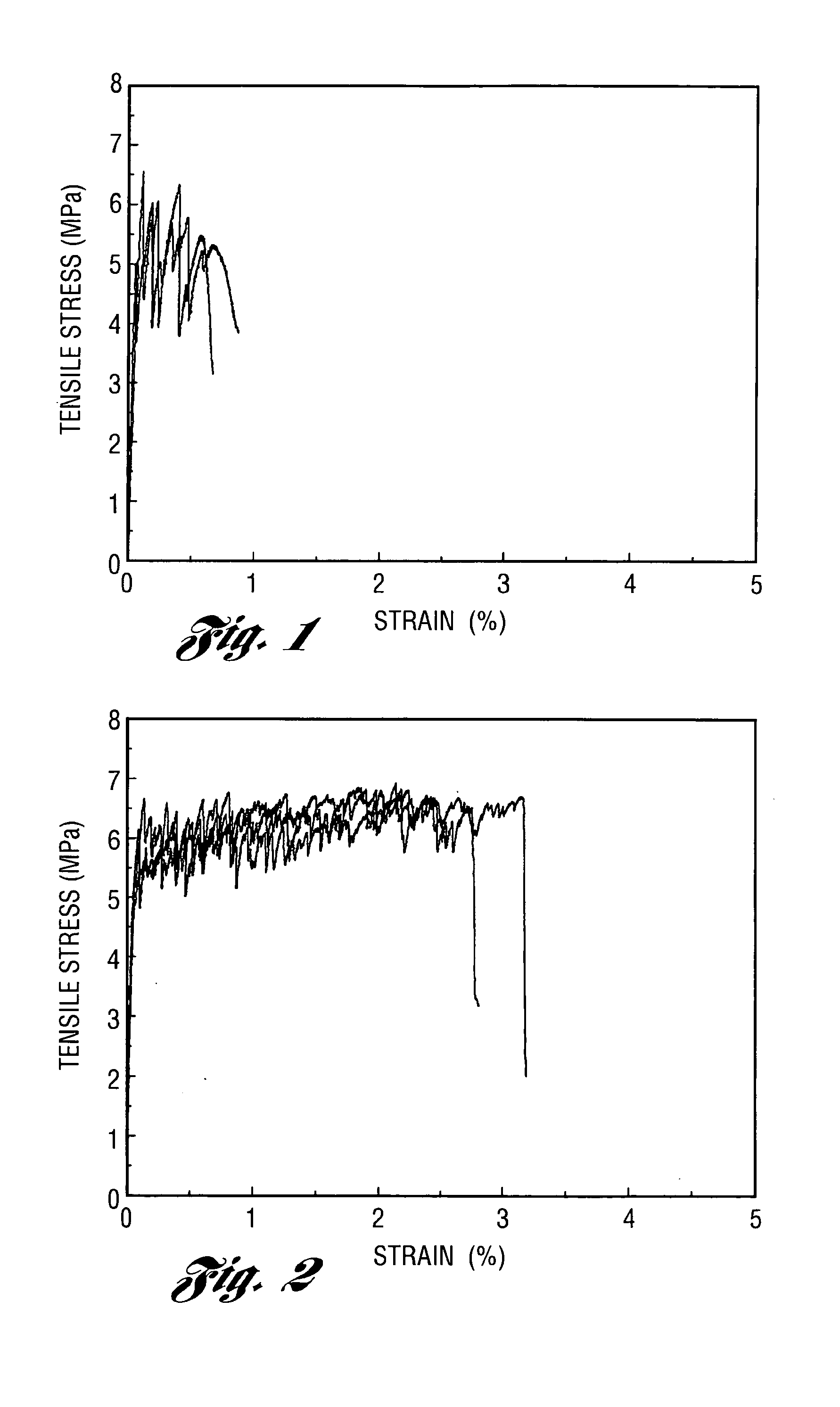

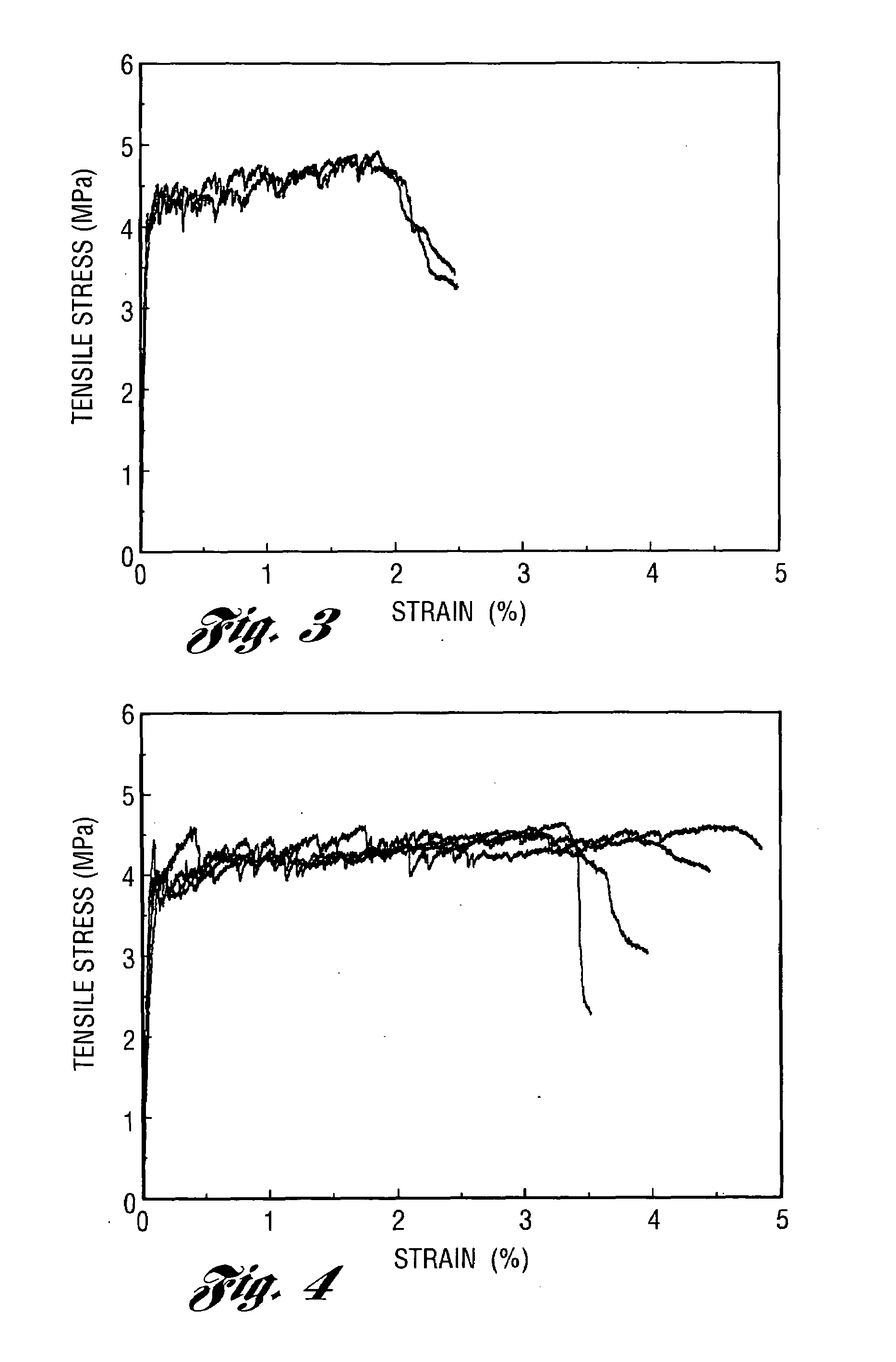

Process for increasing the ductility of high performance fiber-reinforced brittle matrix composites, and composites produced thereby

Purposeful addition of crack-initiating voids in the form of low tensile strength particulates, particulates having low matrix interaction, or gas bubbles formed by chemical reaction, in a size range of 0.5 mm to about 5 mm, and preferably of a size commensurate with or larger than naturally occurring crack-initiating gaseous voids, to fiber-reinforced strain hardening cementitious composites generates controlled and uniform cracking which increases strain hardening behavior in conventionally dense cementitious compositions.

Owner:RGT UNIV OF MICHIGAN

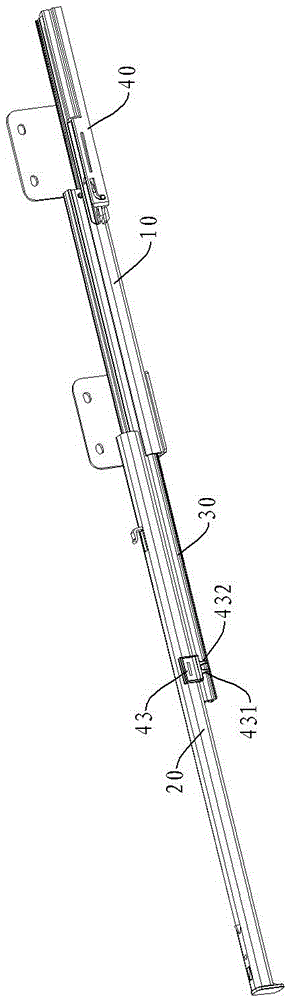

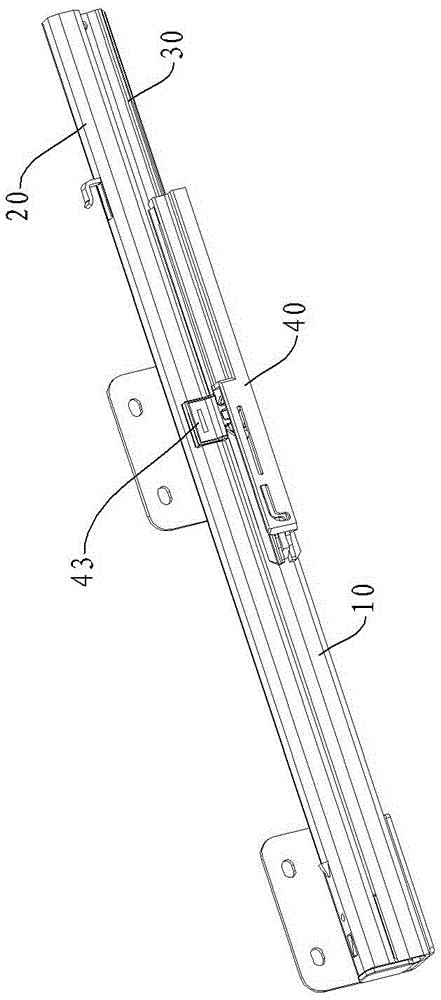

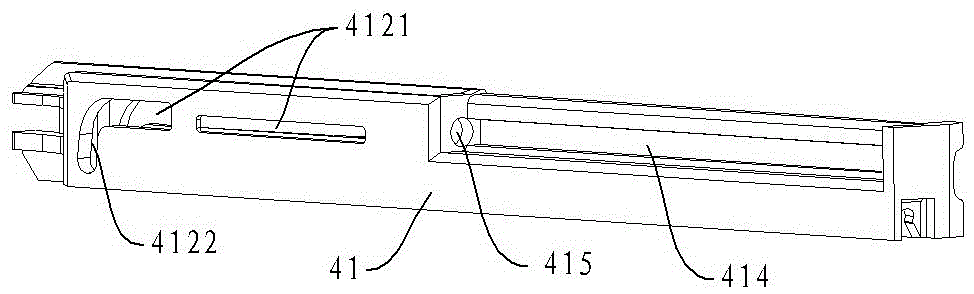

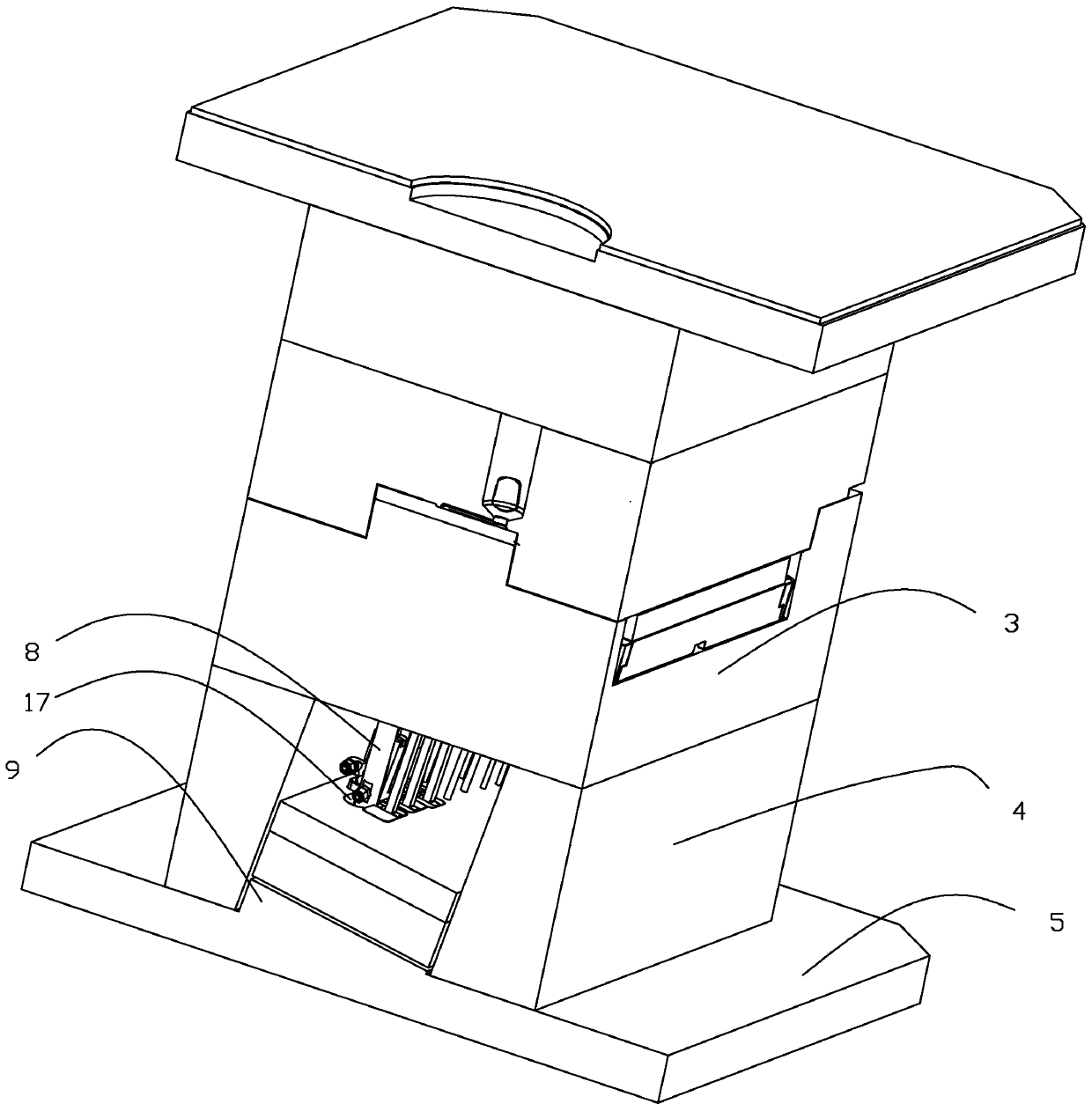

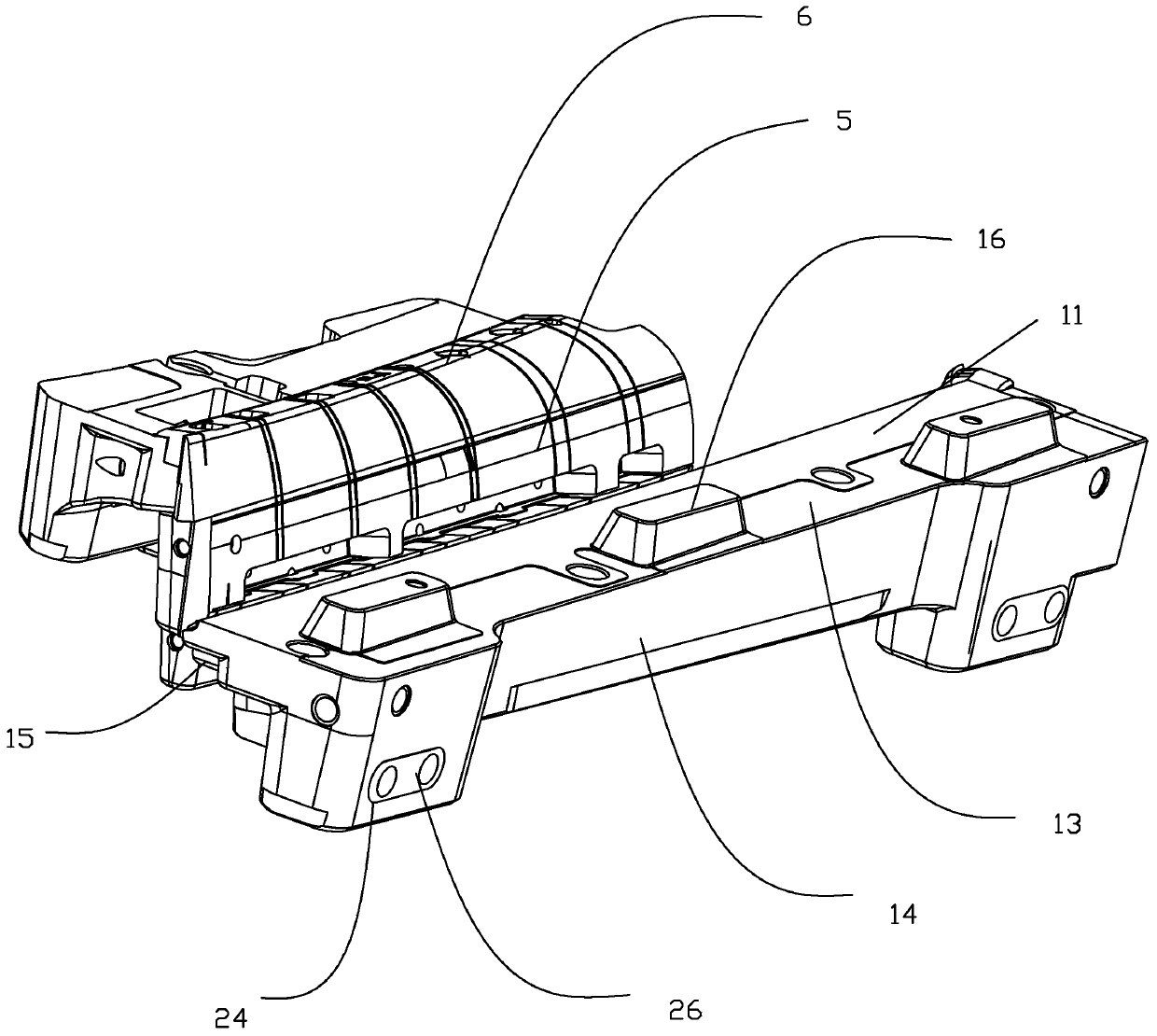

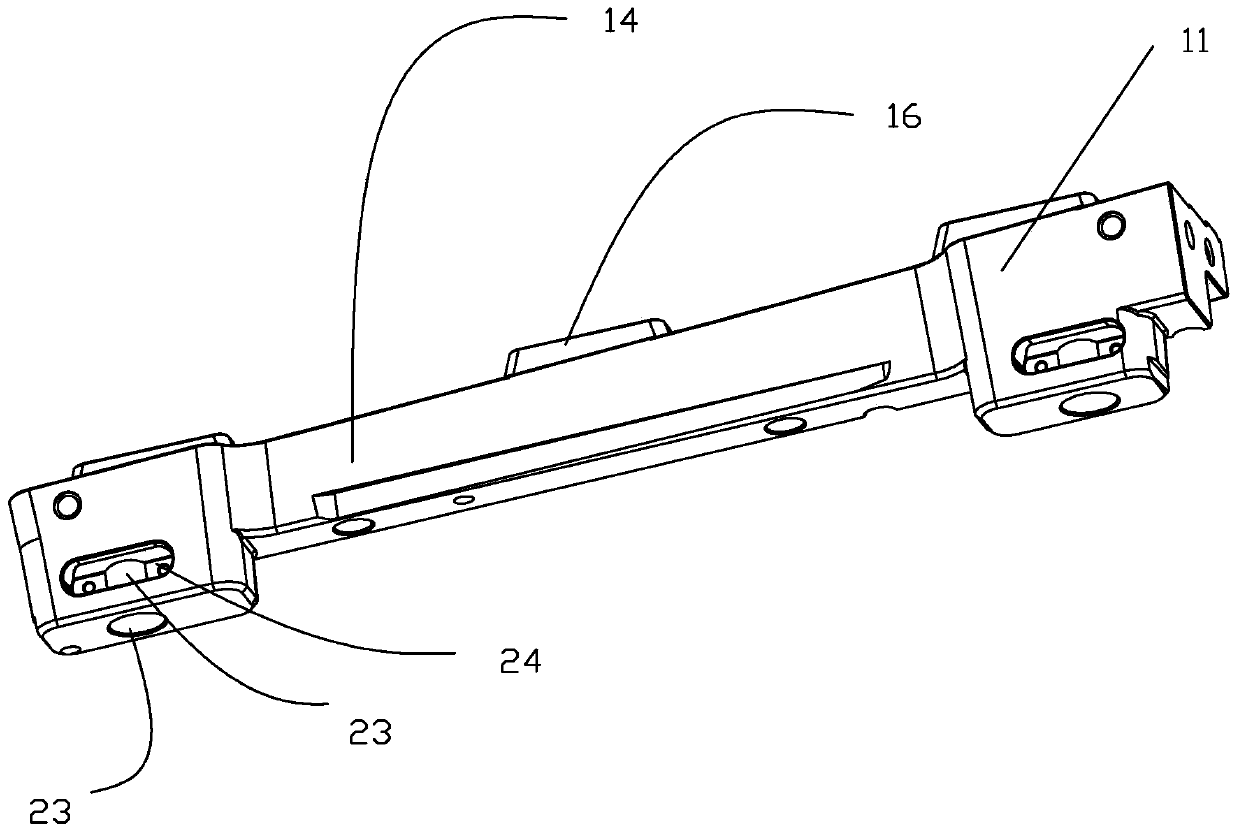

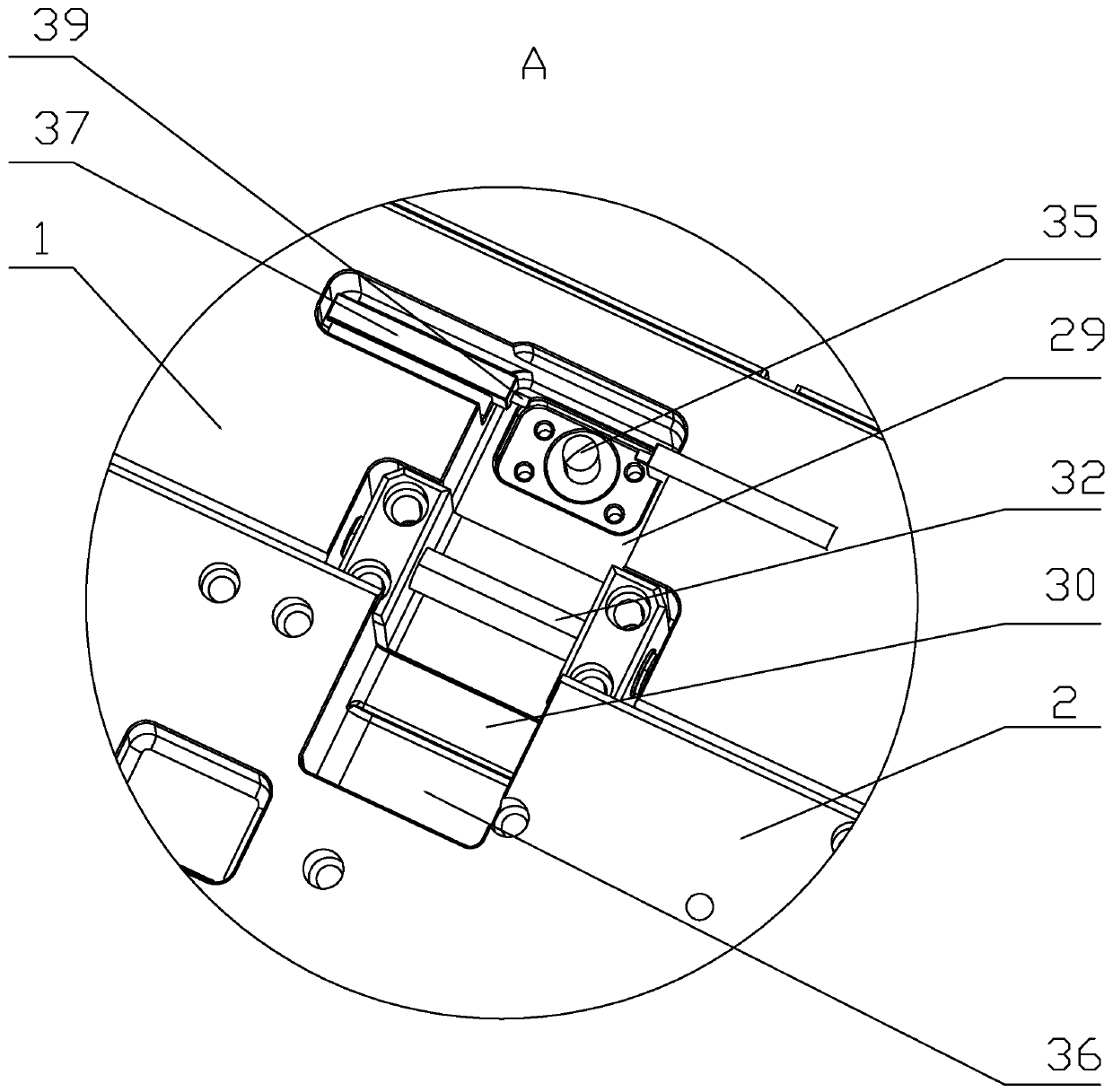

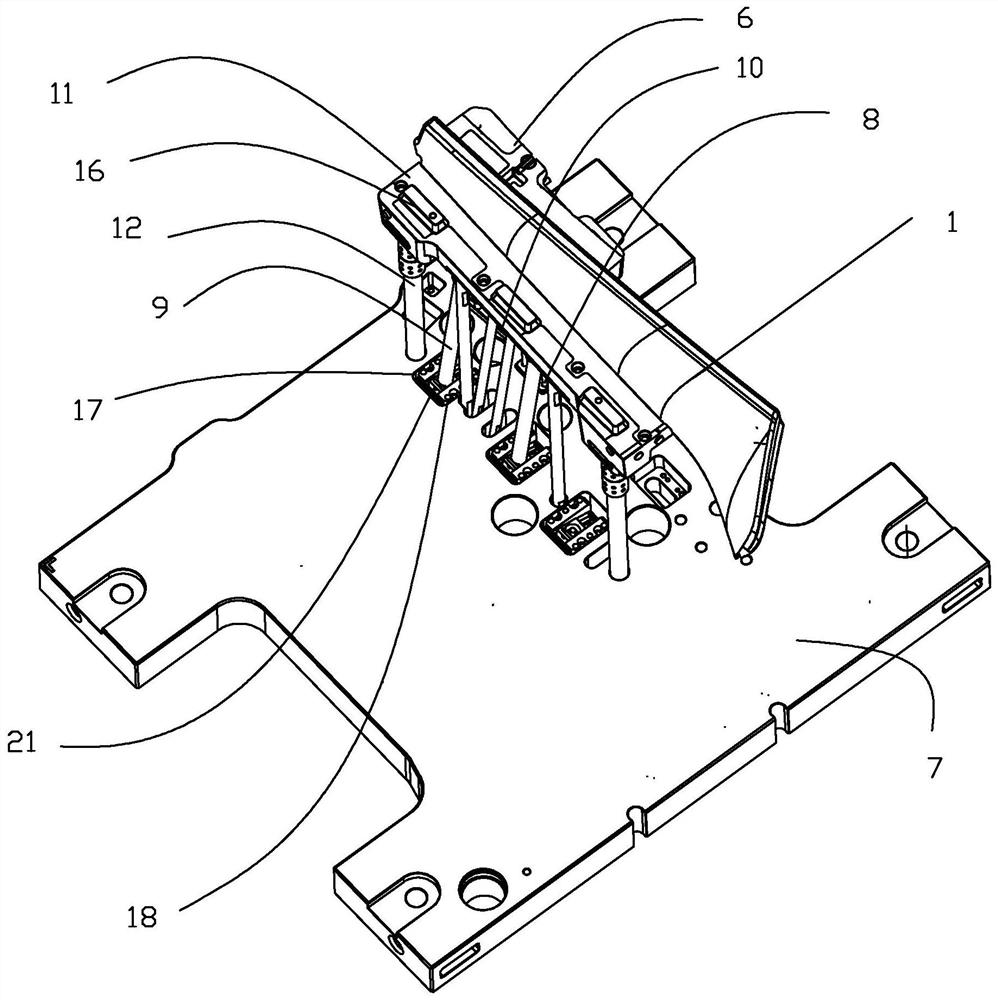

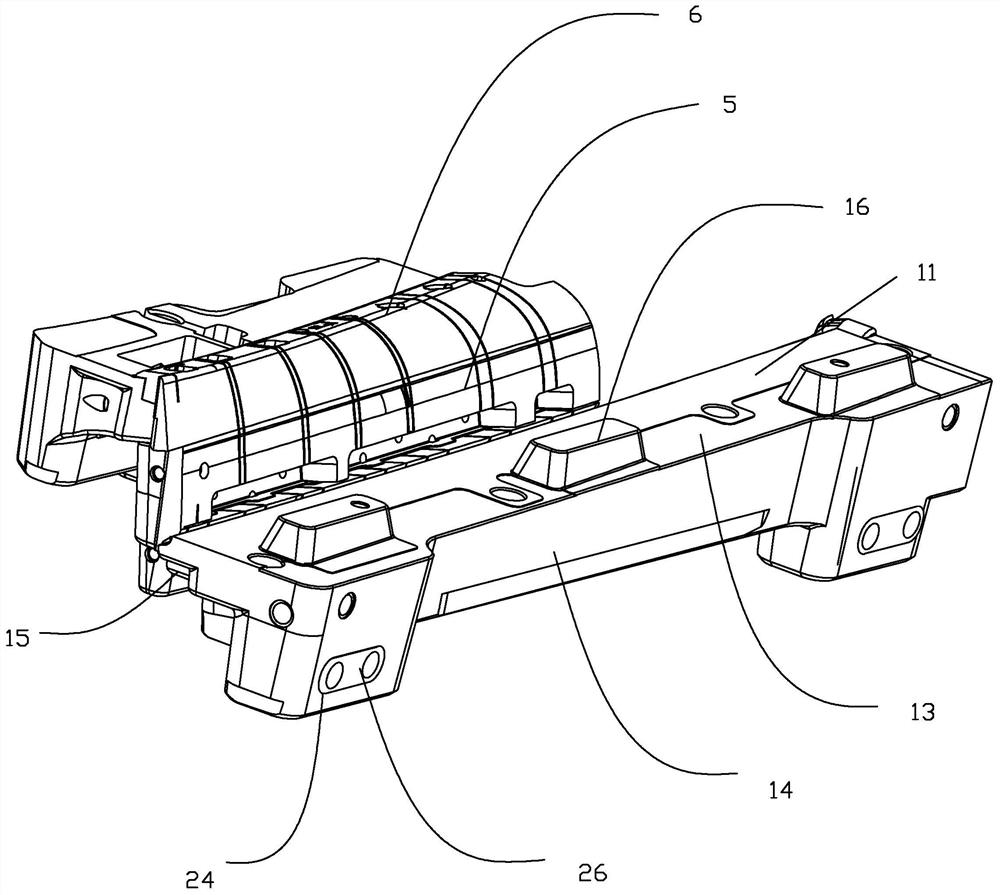

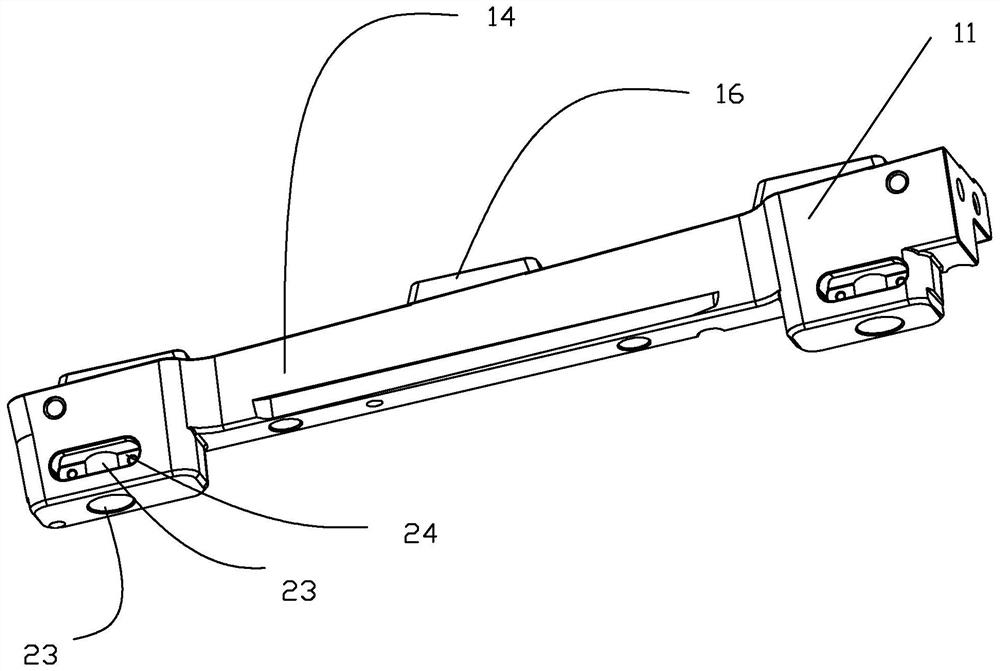

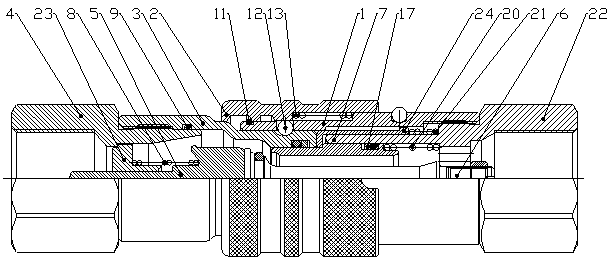

Self-closing device of sliding rail component

The invention provides a self-closing device of a sliding rail component. The self-closing device of the sliding rail component can be used for solving the problems that an existing device is big in assembling difficulty and low in efficiency and damage can be easily caused. A main body is fixedly arranged at one side edge of a fixed guide rail, a sliding guide rail is slidably assembled on the fixed guide rail, a sliding block is contained in the cavity extending along the moving direction of the sliding guide rail inside the main body, and symmetric guide grooves are formed in the two side walls of the cavity, so that the sliding block can move along the guide grooves; a pawl is downward fixedly arranged on the sliding guide rail and can be in fit with the sliding block, an integrated extending part is arranged at the rear end of the main body, a damping piece mounting slot extending in the same direction of the cavity is formed in the extending part, a damping piece is fixedly mounted in the damping piece mounting slot, a piston rod of the damping piece is fixedly connected with the rear end of the sliding block by virtue of a small hole which is formed in the front end surface of the damping piece mounting slot and runs through the cavity, and a spring slot is formed in the bottom of the extending part, runs through the cavity and is used for containing a spring with one end fixed with the rear end of the spring slot and the other end connected with the sliding block.

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

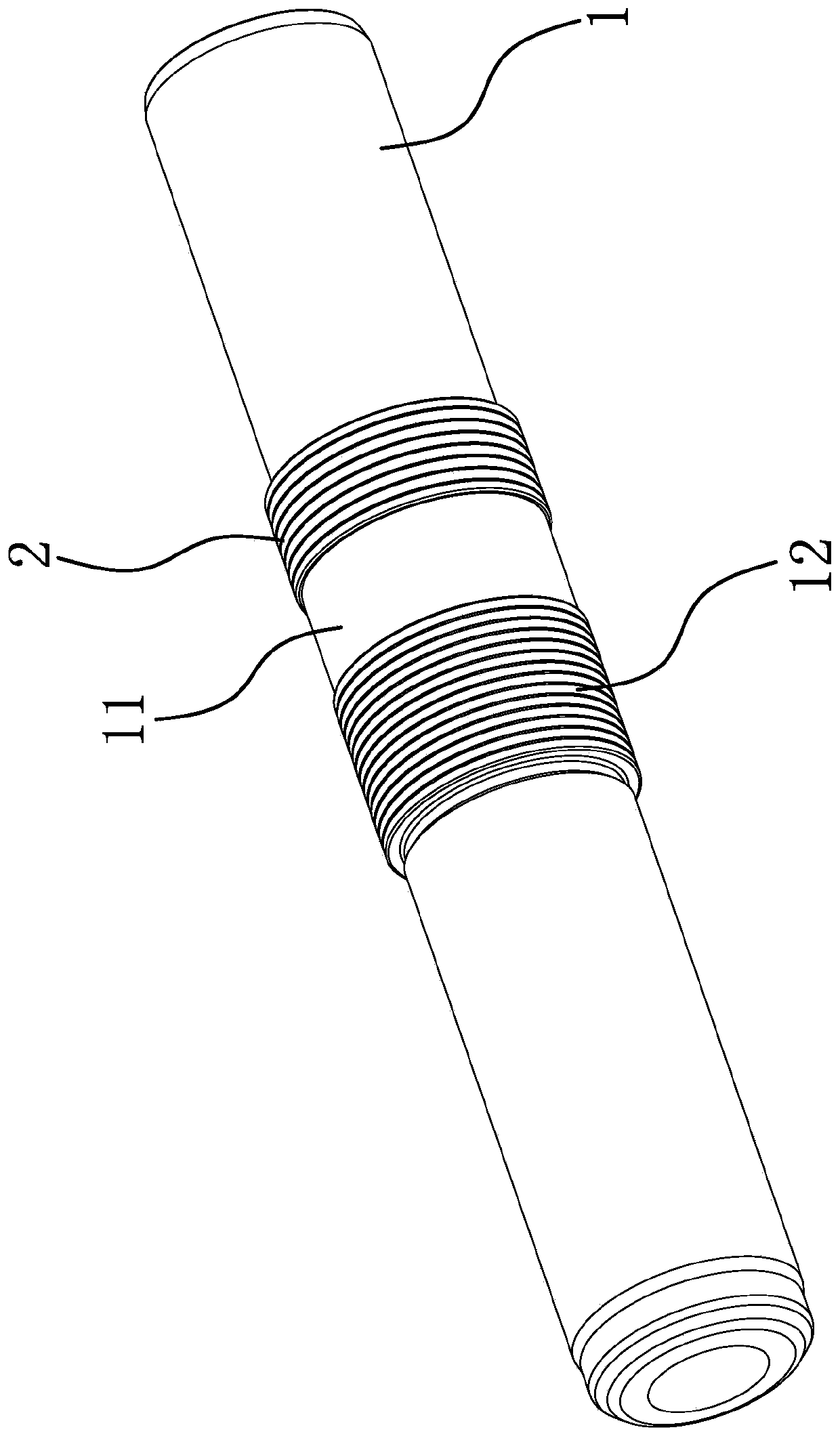

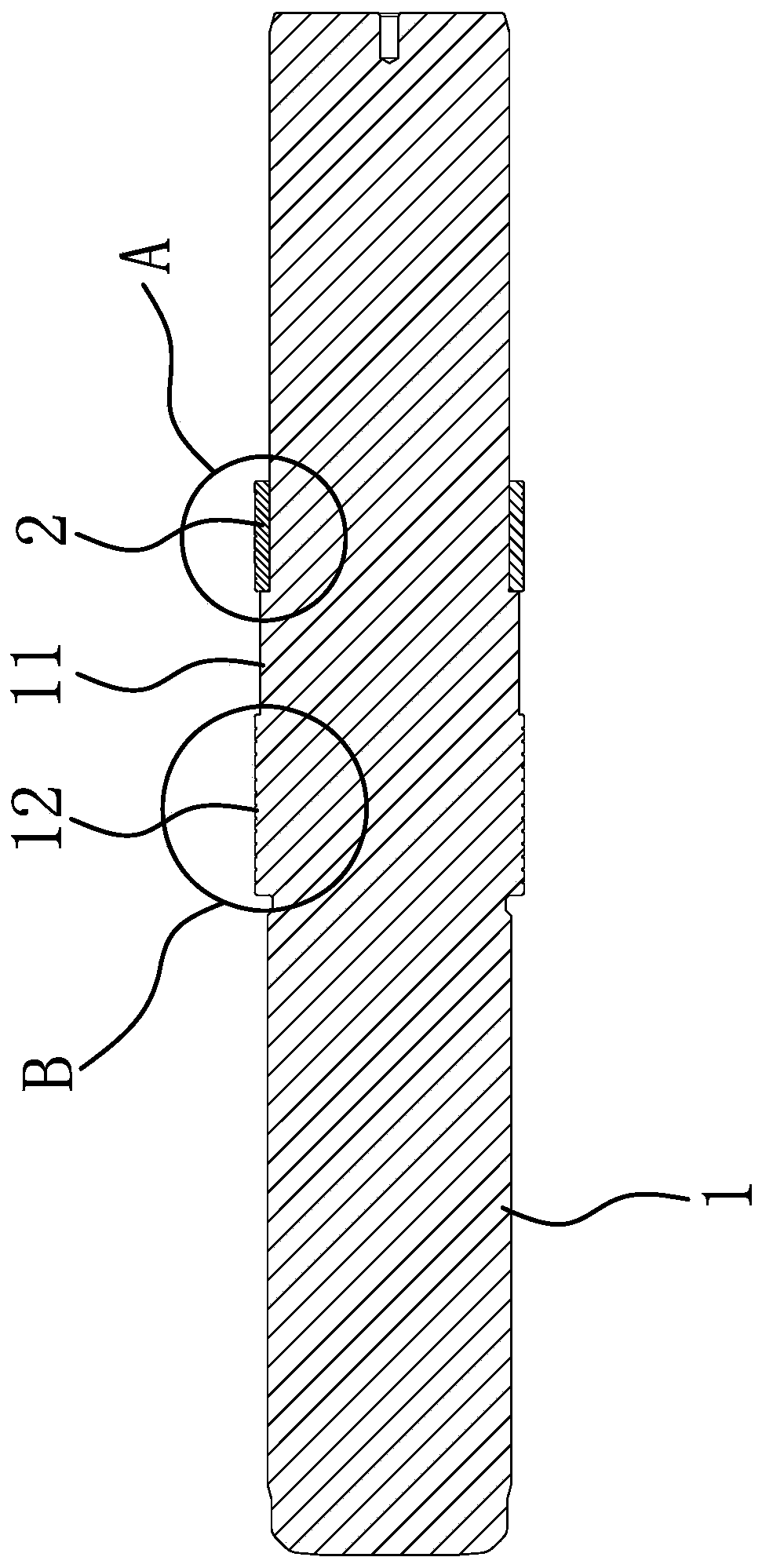

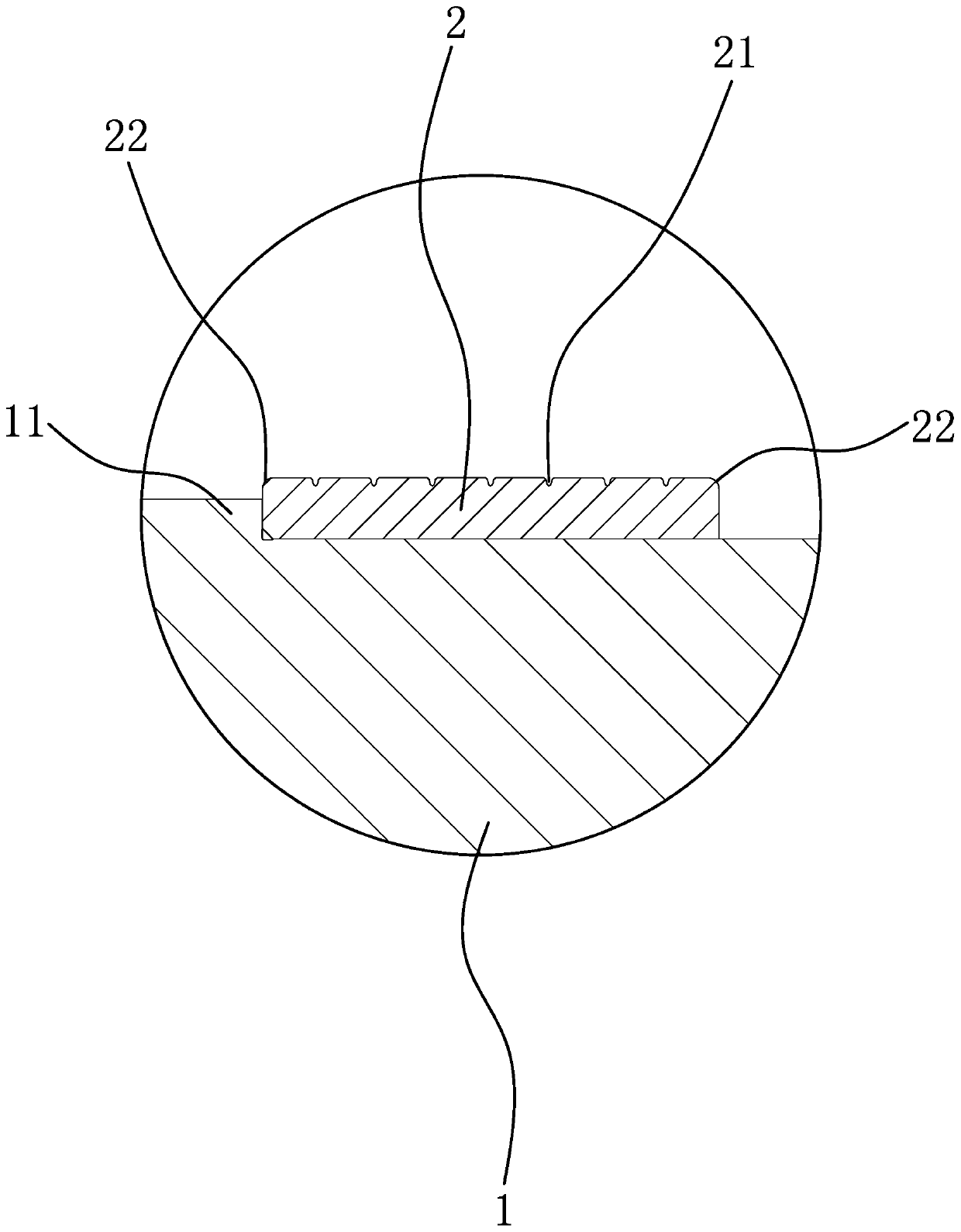

Piston for breaking hammer and manufacturing method thereof

ActiveCN111120651AReduce maintenance costsNot easy to wearPlungersMechanical machines/dredgersCylinder blockDrill

The invention provides a piston for a breaking hammer and a manufacturing method thereof, and belongs to the technical field of breaking hammers. The problem that an existing piston cannot simultaneously meet the hardness and the anti-friction performance is solved. According to the piston for the breaking hammer and the manufacturing method thereof, the piston comprises a piston main body, wherein the outer peripheral surface of the piston main body is provided with an annular positioning boss, wear-resistant sleeves are arranged at the positions, on the front side or / and the rear side of thepositioning boss, of the piston main body in a sleeving mode, the wear-resistant sleeves are positioned on the piston main body, the outer diameter of the wear-resistant sleeves is larger than the outer diameter of the positioning boss, and one end surface of each wear-resistant sleeve abuts against one end surface of the positioning boss. According to the structure, the anti-loosening performance of a nut is remarkably improved. When the outer peripheral surfaces of the wear-resistant sleeves in the structure rub with the inner wall of a cylinder body of the breaking hammer, the outer peripheral surfaces of the wear-resistant sleeves are not likely to wear, and then it is ensured that the piston cannot be broken in the process of striking a drill rod and the boss also has very good friction resistance, so that the piston is not likely to wear and tear, and the service life of the piston is prolonged.

Owner:TAIZHOU BEILITE MASCH CO LTD

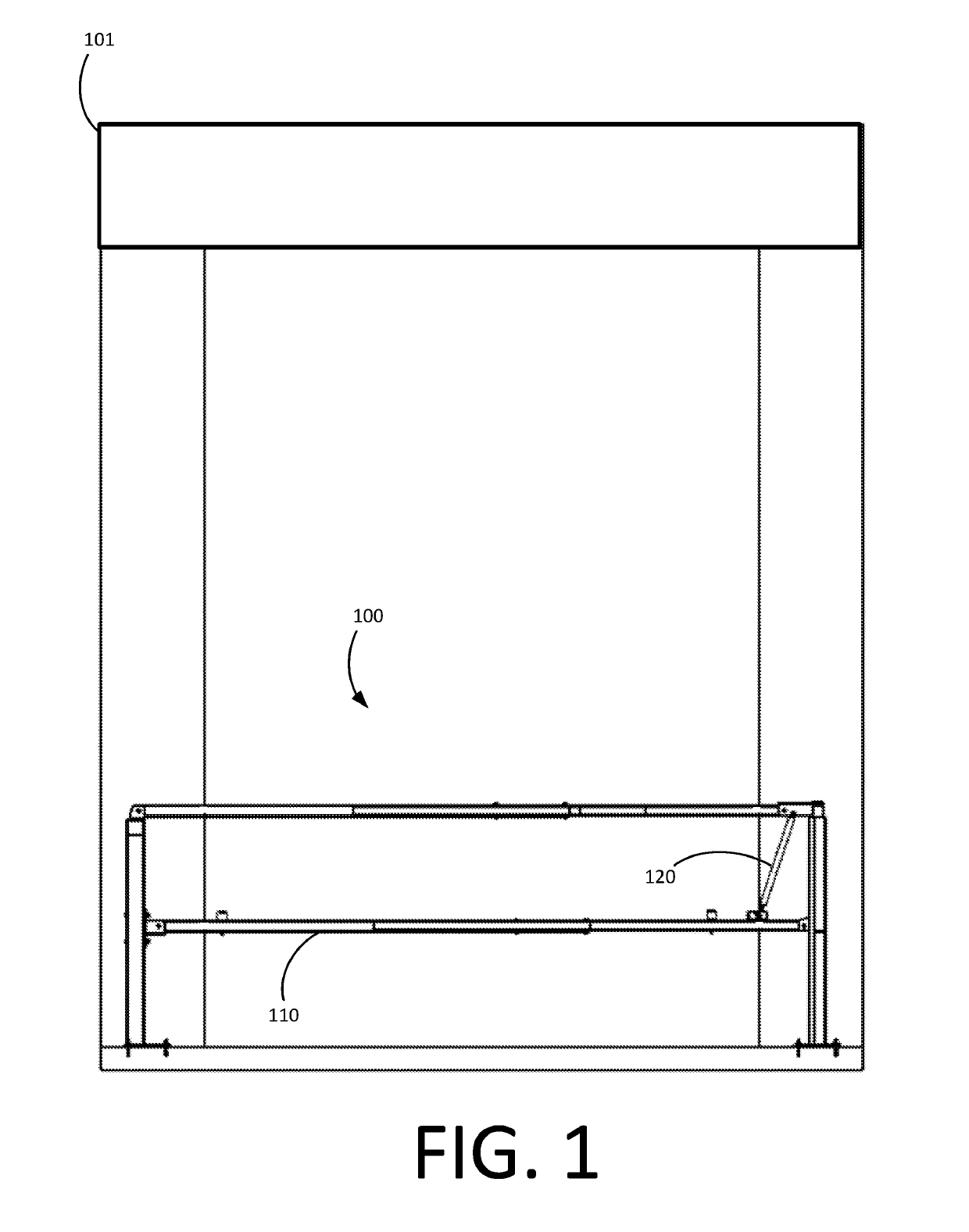

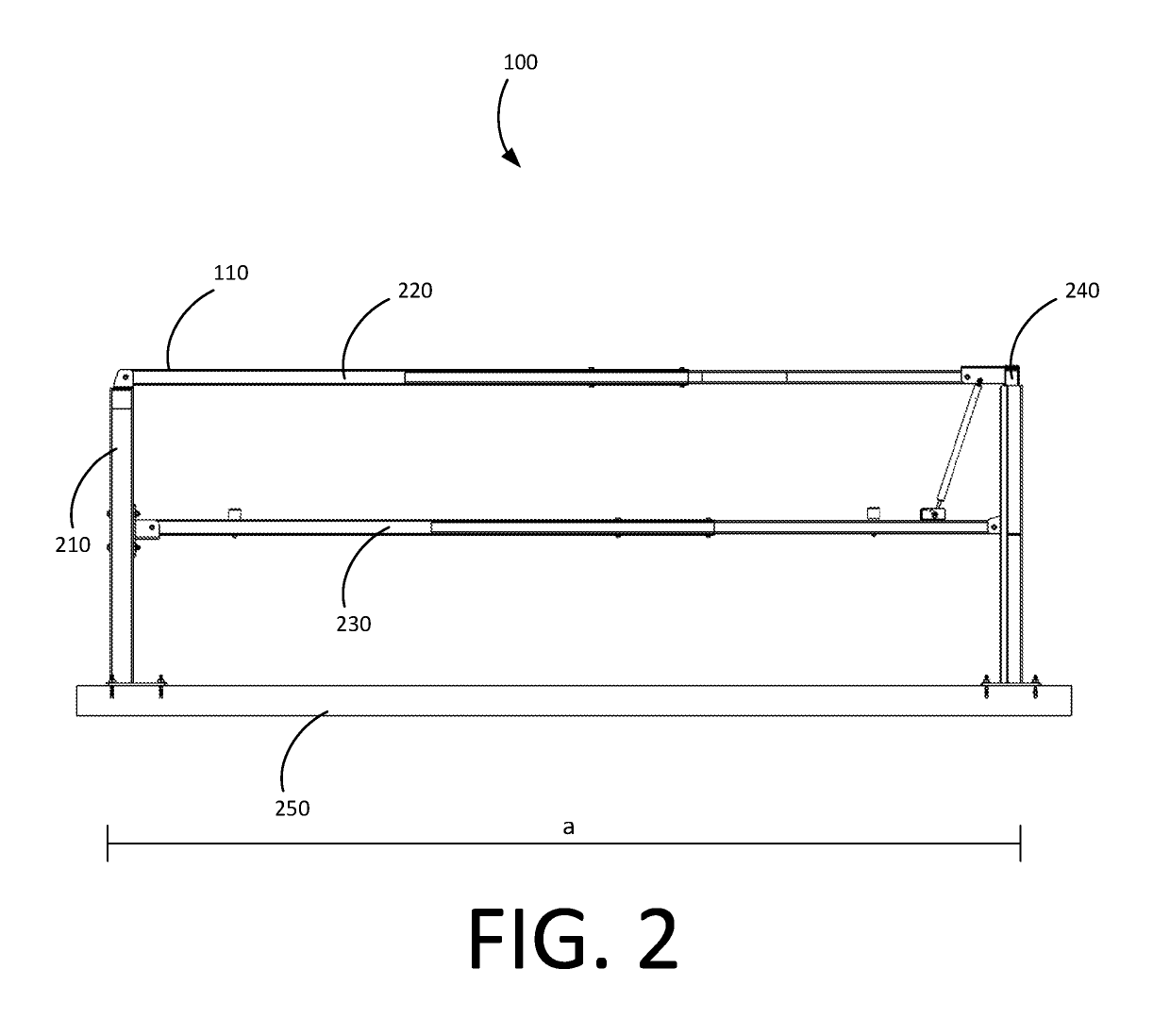

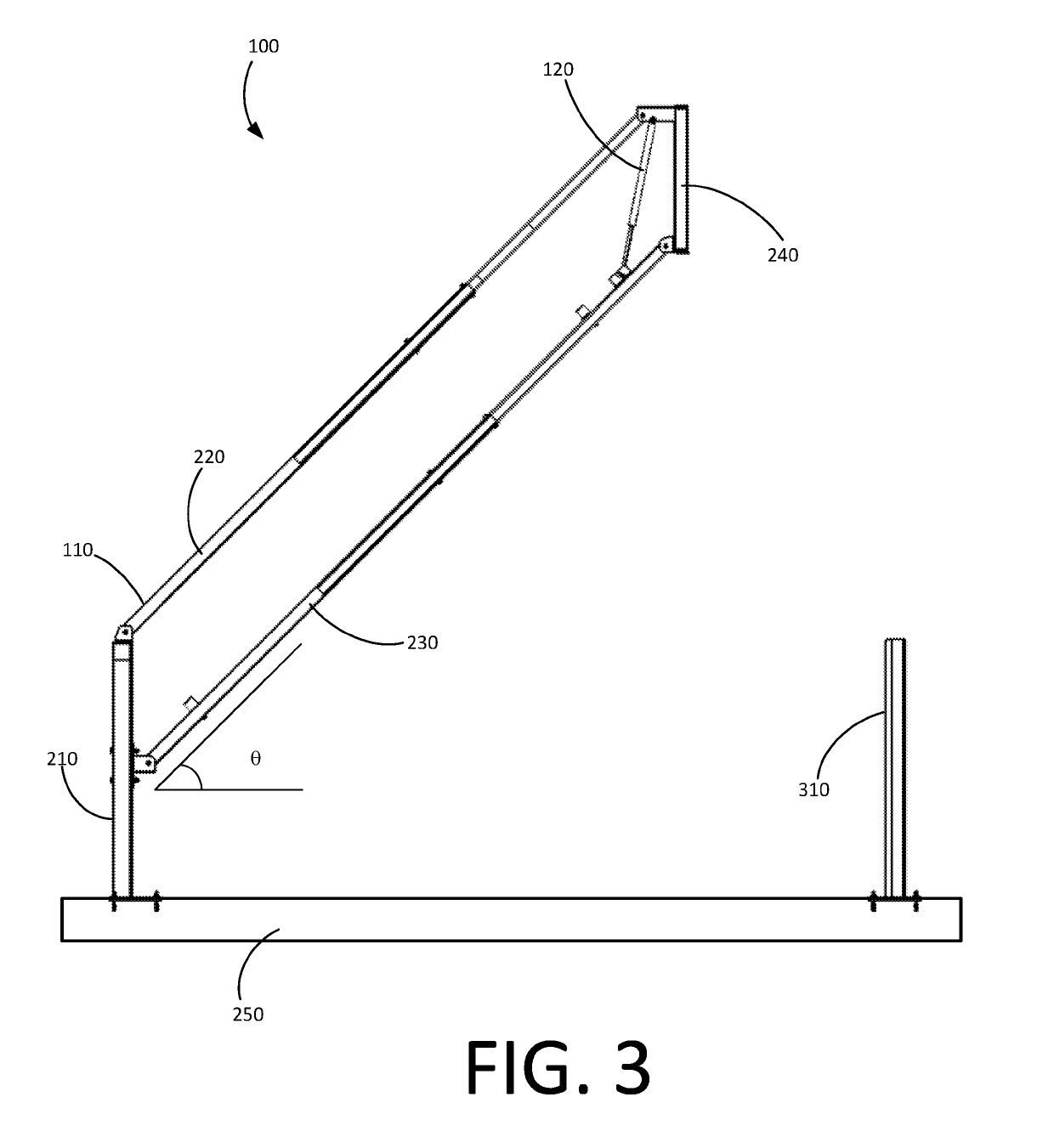

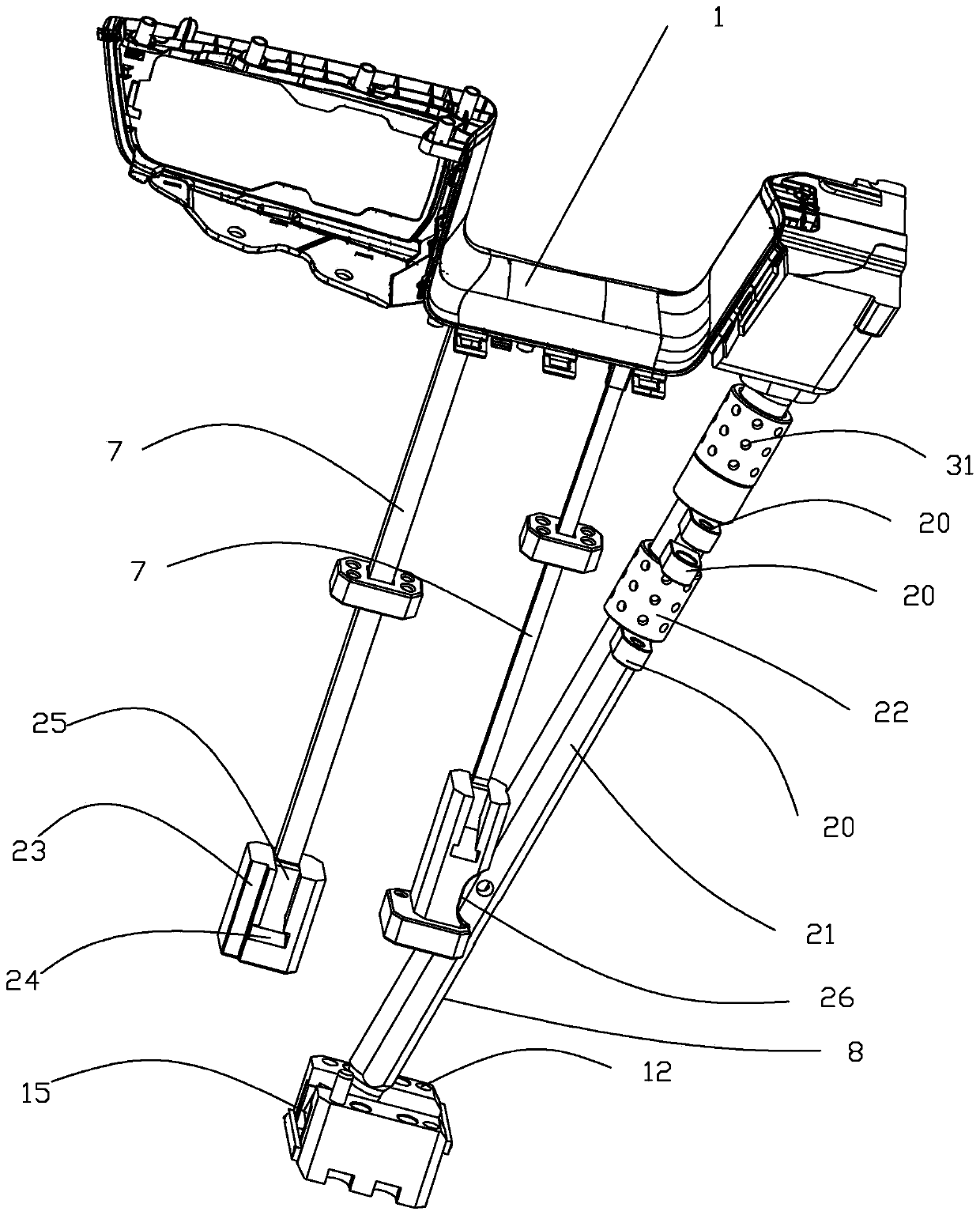

Safety gate

ActiveUS20190218730A1Minimal frictionEasy to operateShutters/ movable grillesWing openersEngineeringMechanical engineering

This disclosure provides apparatus and methods for assembling, installing, and operating a manually operated gate (e.g., a safety gate). The manually operated safety gate can include a gate frame and a spring assembly. The gate frame can include a proximal upright member, a distal upright member, an upper arm, and a lower arm. The proximal upright member can be anchored to a stationary surface. The upper arm and lower arm can be pivotably coupled to the proximal upright member and distal upright member to form a parallelogram. The manually operated gate can be configured to pivot between an open position and closed position at a constant angular velocity. The gate can freely pivot to the closed position from a self-close position. A kit can contain the required structural components and instructions and can be used to assemble the manually operated gate assembly.

Owner:PS IND INC

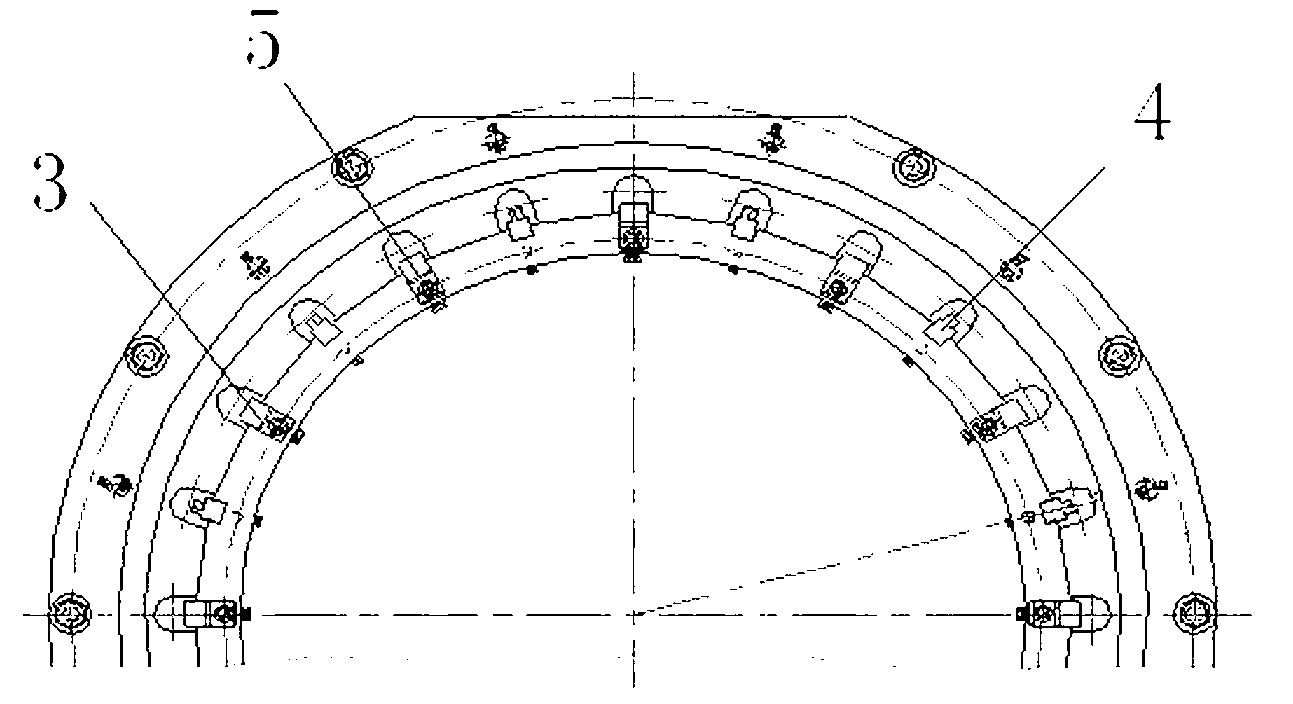

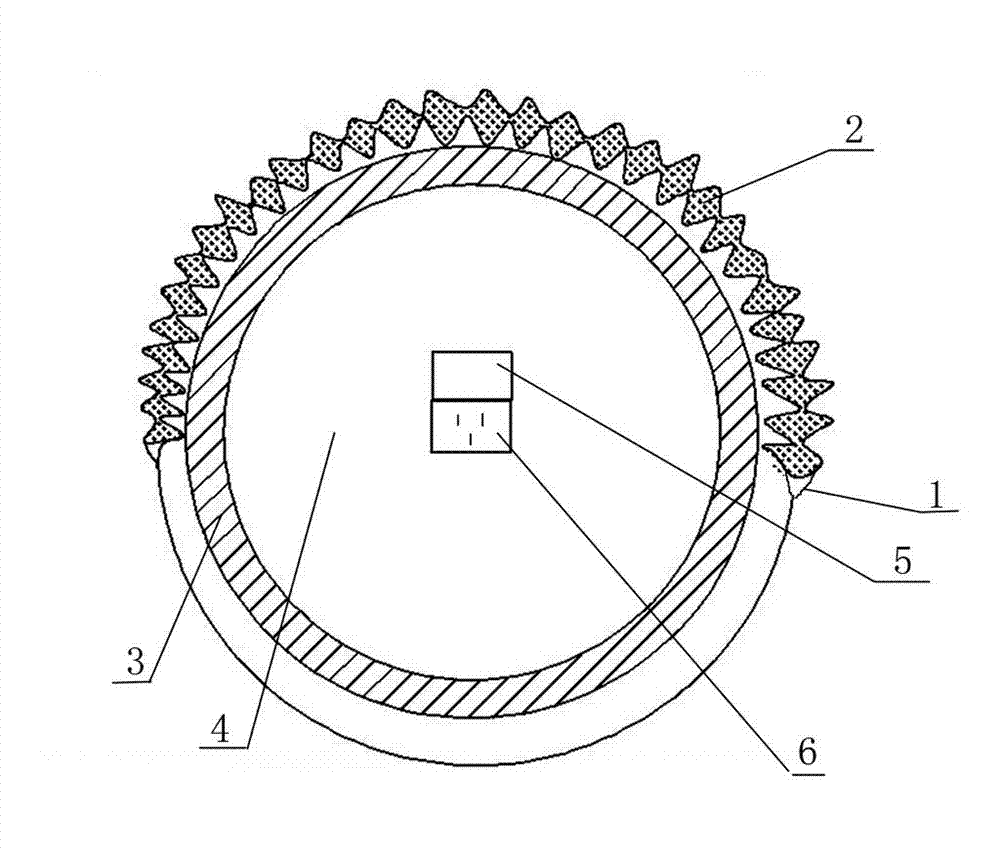

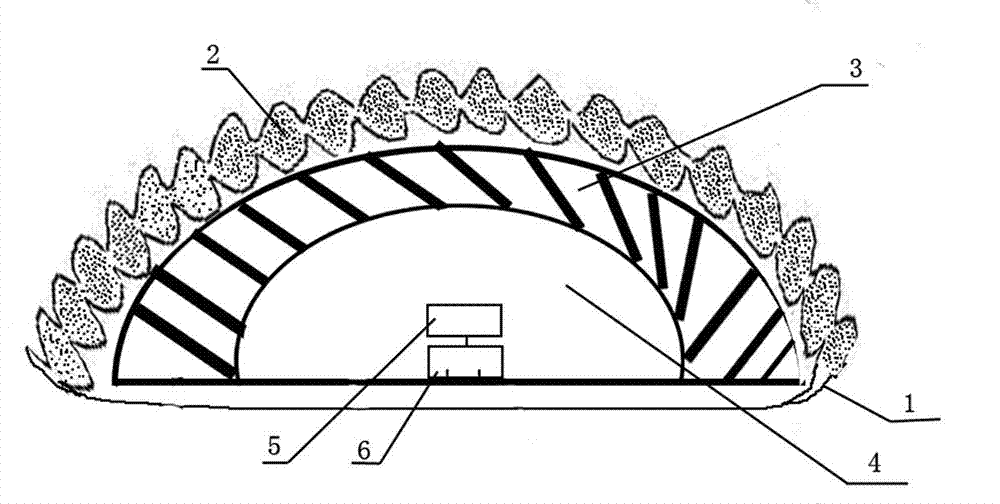

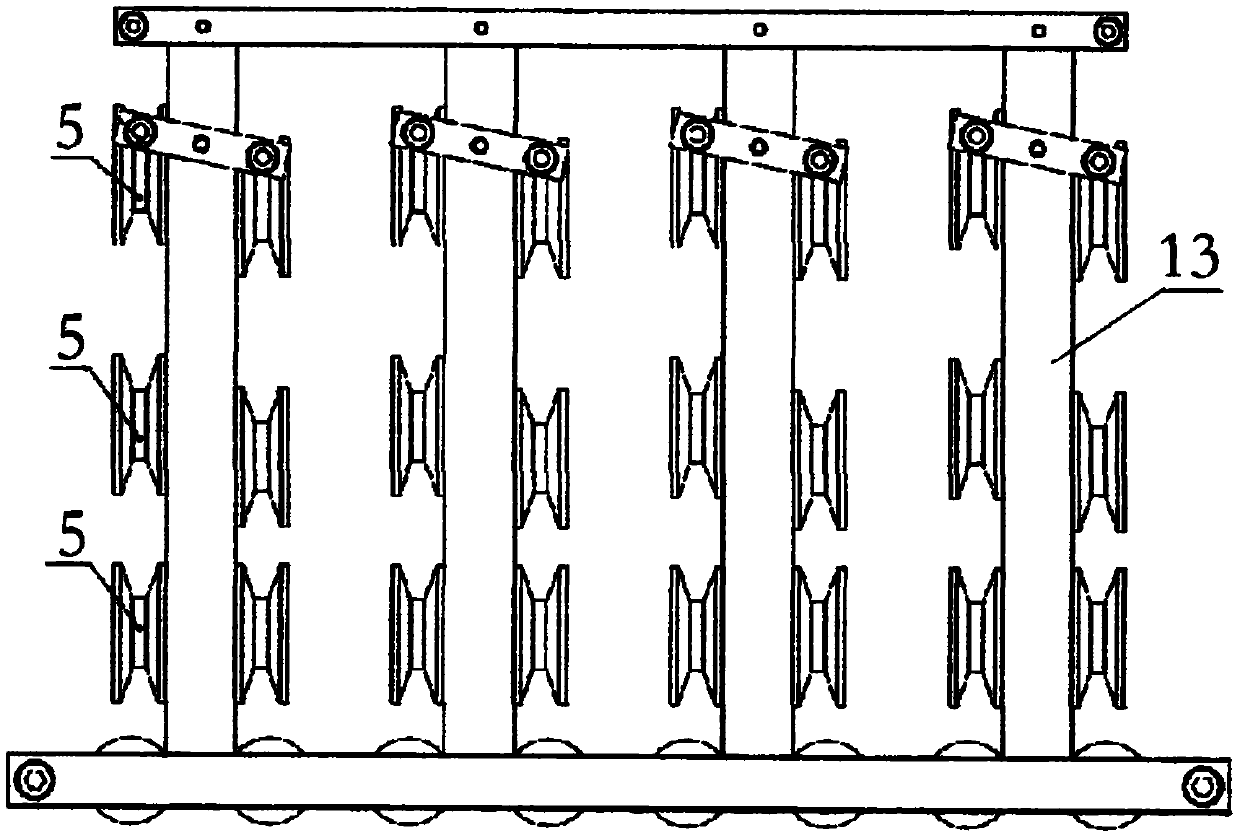

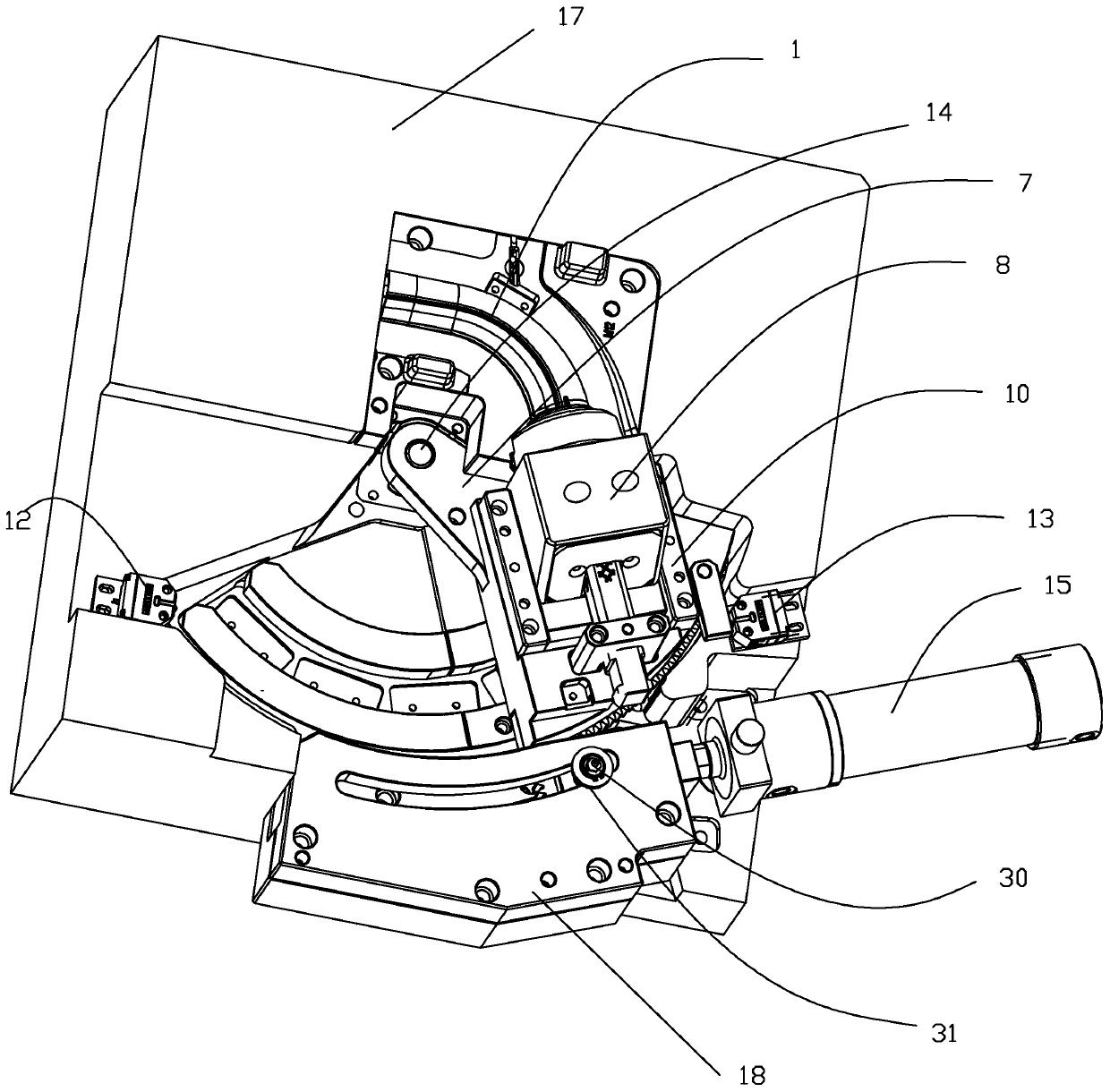

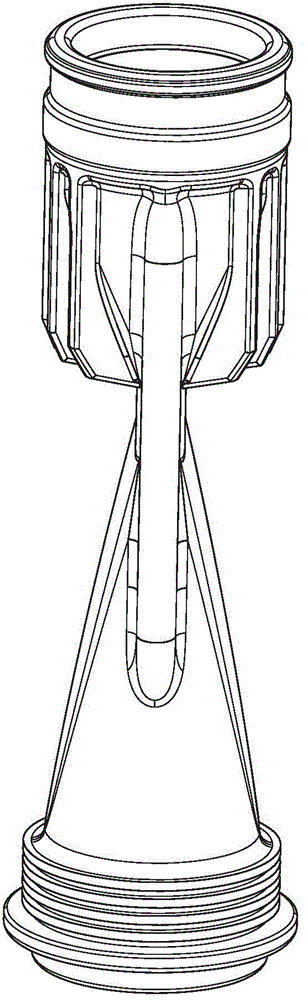

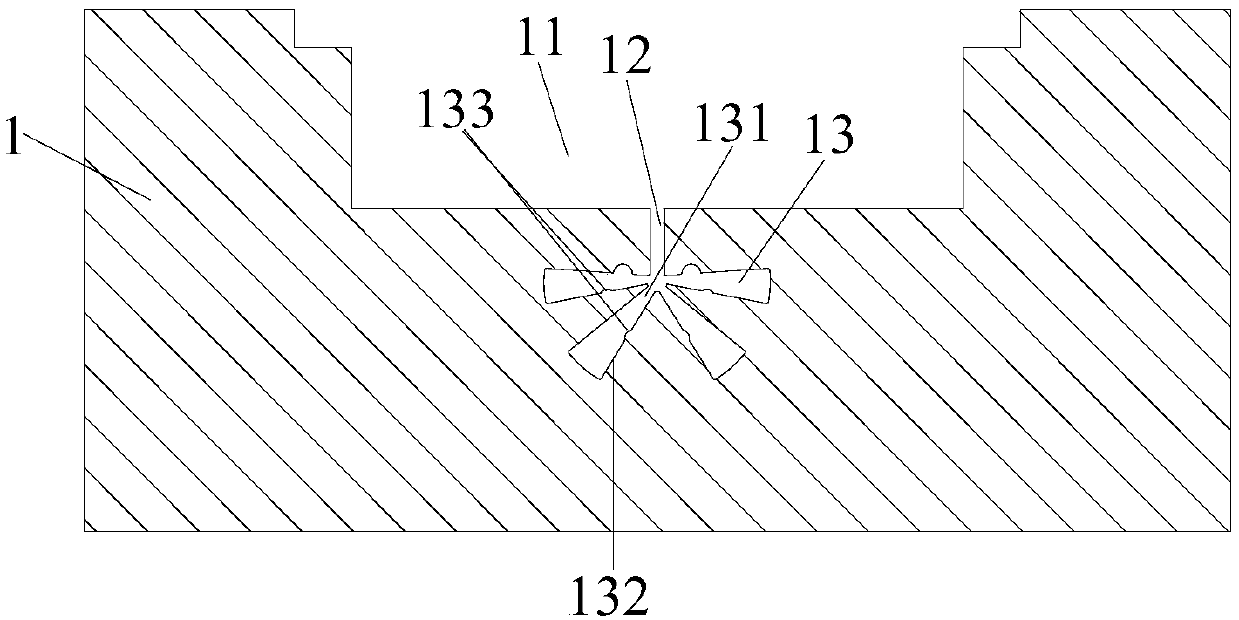

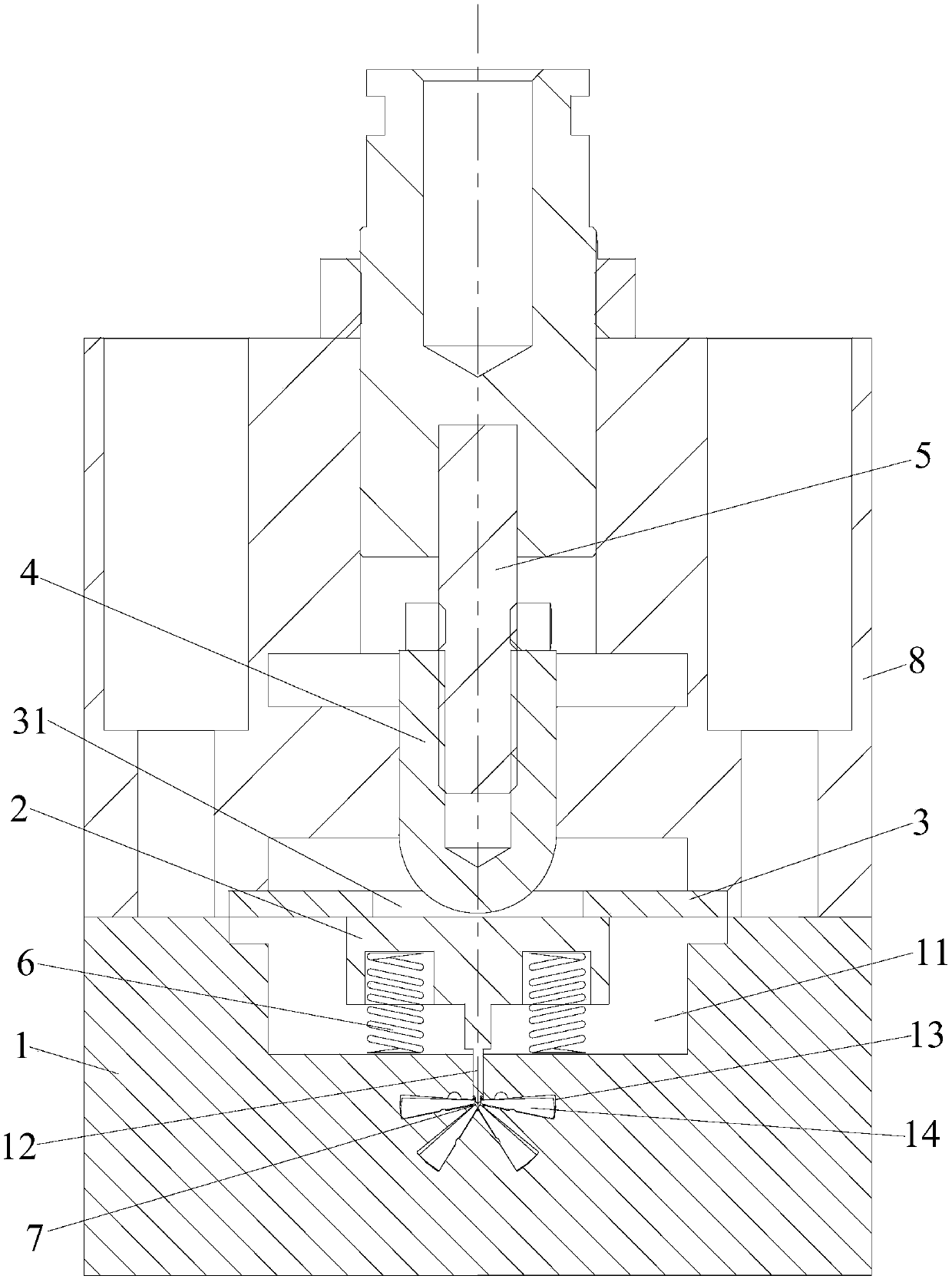

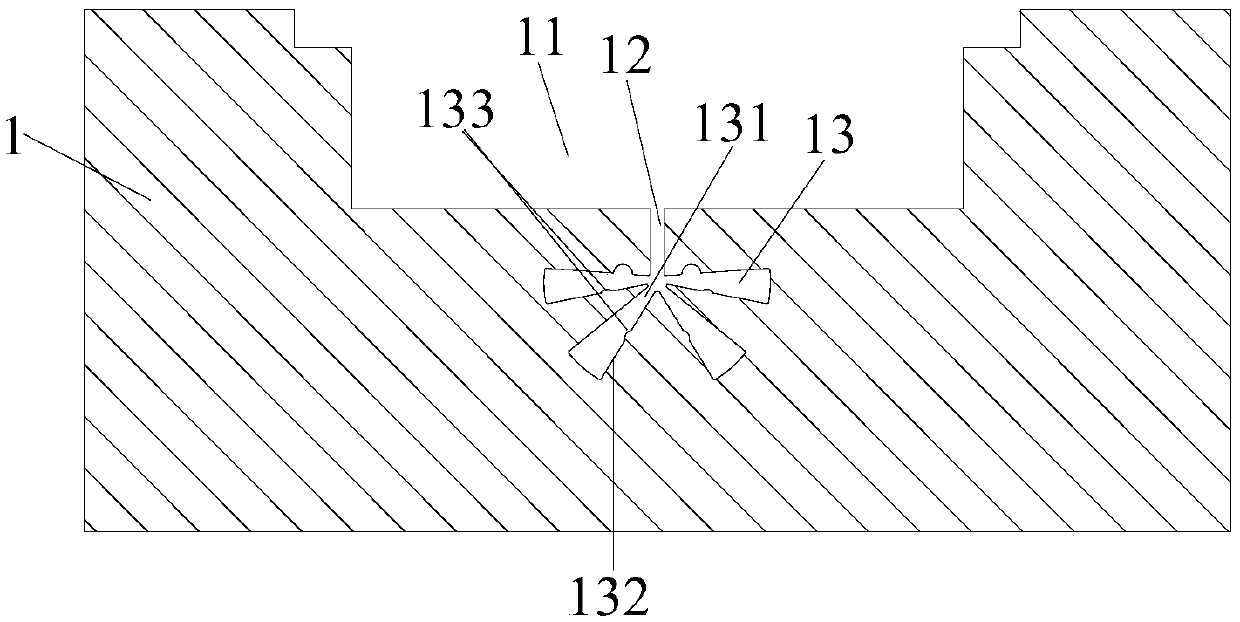

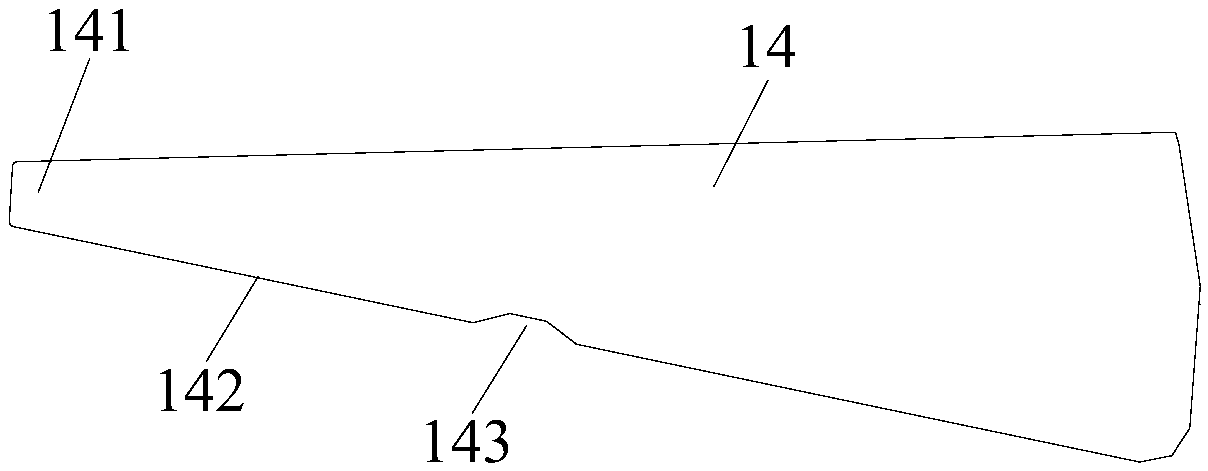

Skewed slot stator iron core non-pull overlying device

ActiveCN103259378ANot easy to strainReasonable and reliable structural designManufacturing stator/rotor bodiesJackscrewEngineering

The invention particularly discloses a skewed slot stator iron core non-pull overlying device. The skewed slot stator iron core non-pull overlying device resolves the problem that an existing stator iron core overlying device damages an iron core easily in a pulling mode during the process of making bodiless lacquerware, and quality is not easy to control. The skewed slot stator iron core non-pull overlying device comprises an overlying base, wherein a column-shaped core cylinder is arranged on the overlying base, a plurality of taper slots which are vertically arranged are radially formed in the outer circumferential face of the core cylinder in an evenly-distributing mode, skewed wedges and locating taper keys are arranged inside the taper slot at intervals, the skewed wedges and the locating taper keys are in clearance fit with the skewed wedges and the locating taper keys, the upper end faces of the skewed wedges are provided with jackscrews with the lower ends contacted with the upper end of the core cylinder in a screwing mode, the inner wall of the core cylinder is provided with a fastening bolt which is fixed with the skewed wedges in a screwing mode, and the outer sides of the locating screwed keys are of a spiral structure which is matched with a stator core skewed slot. By the combination of advantages of the stator iron core of a skewed slot structure, and through a novel structure, overlying of stator iron core of the skewed slot structure is achieved, the angle of an skewed slot can be effectively guaranteed, the quality is easy to control, the process of making bodiless lacquerware is easy to achieve, and the iron core is not pulled easily, and besides, the skewed slot stator iron core non-pull overlying device has the advantages of being simple in structure, convenient to operate, and low in cost.

Owner:CRRC YONGJI ELECTRIC CO LTD

Cervical and lumbar vertebra rehabilitating medicine pillow and preparation method thereof

InactiveCN102784435AImprove permeabilityPromote blood circulationPillowsMedical devicesDiseaseMonkshoods

The invention provides a cervical and lumbar vertebra rehabilitating medicine pillow and a preparation method of the cervical and lumbar vertebra rehabilitating medicine pillow. The cervical and lumbar vertebra rehabilitating medicine pillow is divided into a cervical pillow part and a lumbar pillow part based on the part used for treating, wherein the cervical pillow part and the lumbar pillow part comprise cotton cloth wrapping layers, traditional Chinese medicine compositions filled in the cotton cloth wrapping layers, hard housings, heating liners, temperature control elements and power plugs; the traditional Chinese medicine compositions filled in the cotton cloth wrapping layers comprise the ingredients as follows: 20g of lycopodium clavatum, 20g of garden balsam stem, 20g of beautiful sweetgum fruit, 20g of frankincense, 20g of myrrh, 20g of rhizoma drynariae, 20g of angelica sinensis, 20g of radix angelicae, 20g of monkshood, 20g of radix aconiti agrestis, 20g of carthamus tinctorius, 20g of achyranthes bidentata, 10g of buthus martensi kirsch, 10g of manis pentadactyla, 10g of silkworm larva, 6 centipedes, and 1g of musk. According to the cervical and lumbar vertebra rehabilitating medicine pillow provided by the invention, effective treatment on lumbar spondylosis, cervical spondylosis and back disease of people can achieved by the combination of a heating device and the traditional Chinese medicine composition.

Owner:王罡

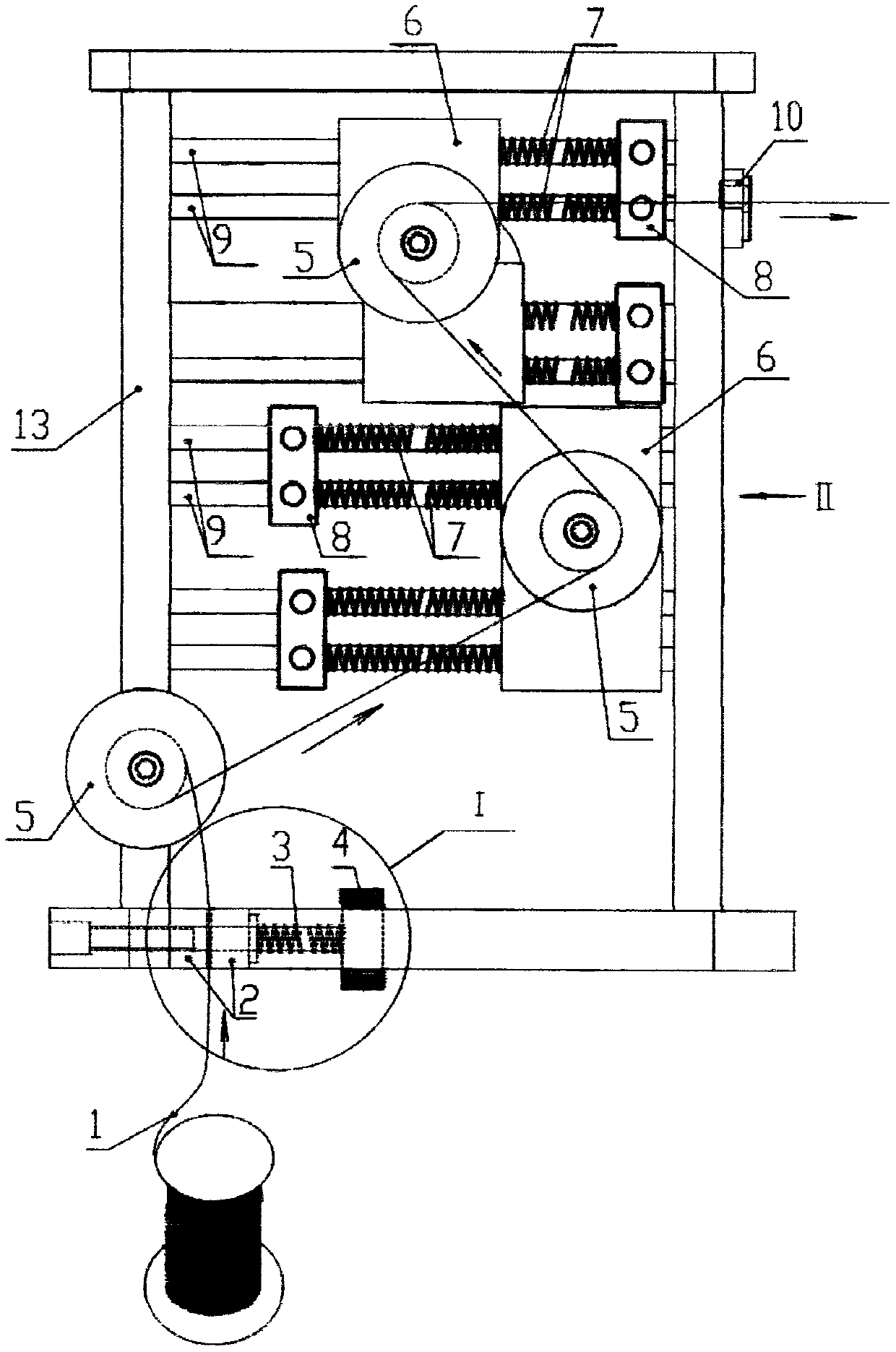

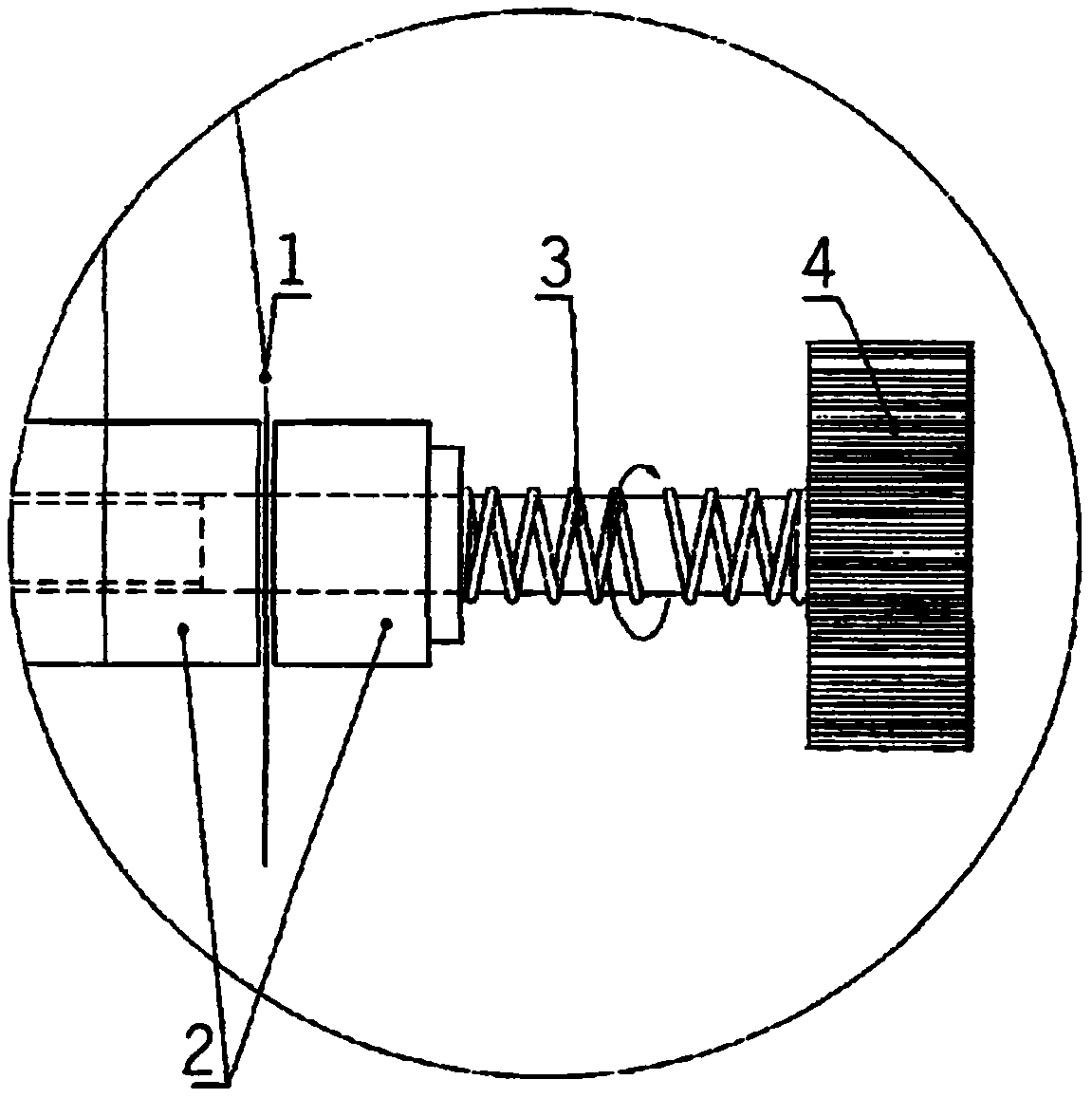

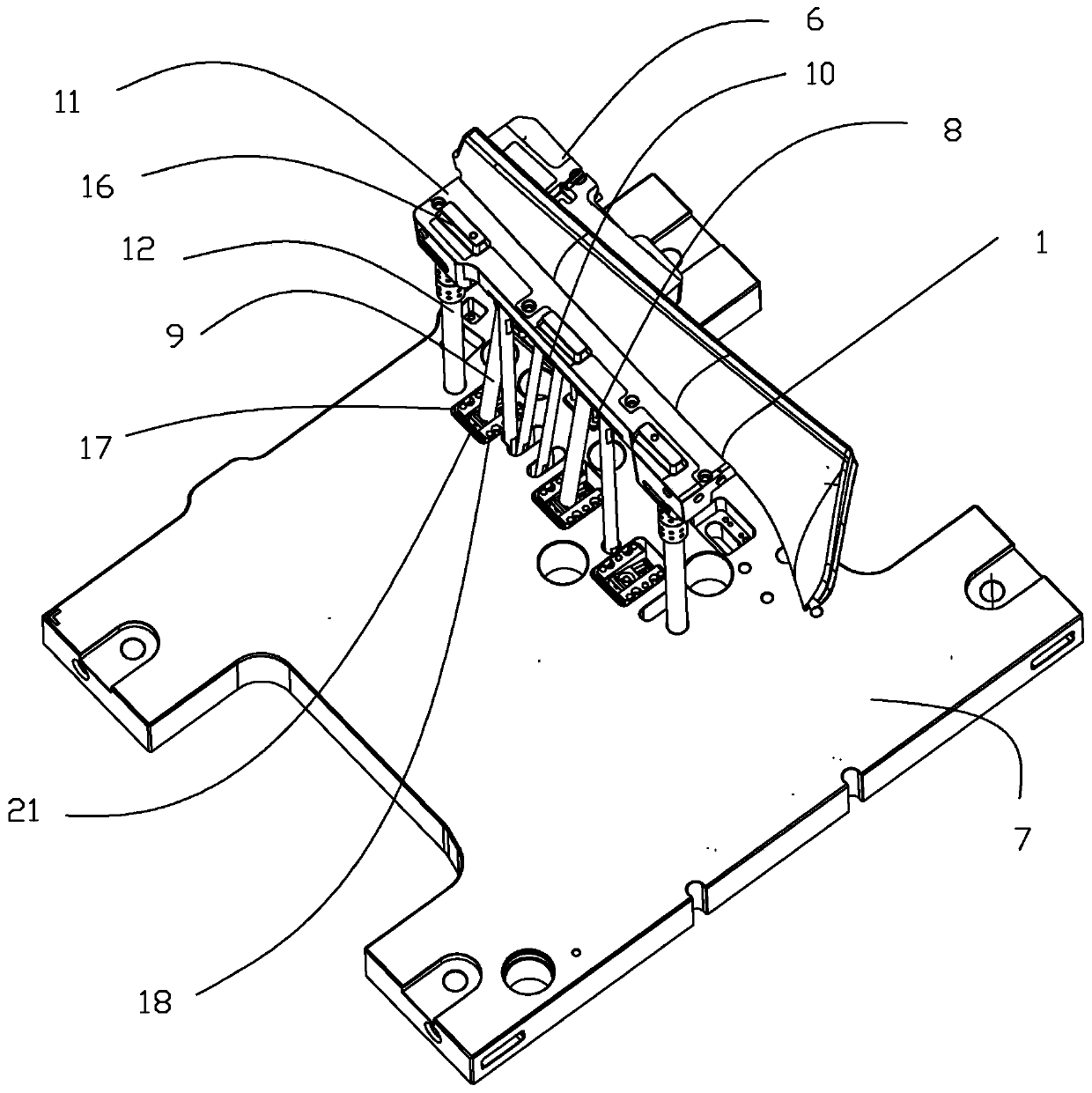

Wire leading structure capable of automatically inserting wire

The invention relates to a wire leading structure capable of automatically inserting wire. A wire feeding device is arranged on one side of the bottom of a main frame; three wire leading wheels are arranged, the wire leading wheel at the bottom is adjacent to the upper portion of the wire feeding device, the wire leading wheel in the middle and the wire guide wheel at the upper part are arranged on two guide sliding blocks at the upper part and in the middle respectively; two transversely-through shaft holes are formed in each guide sliding block; the middle part and the upper part of the mainframe each is provided with a pair of transversely-parallel shafts, the pair of shafts at the middle part and the pair of shafts at the upper part are inserted into the shaft hole of the guide sliding block at the middle part of the main frame and the shaft hole of the guide sliding block at the upper part of the main frame respectively, and the guide sliding blocks can stably slide and be fixedon the shafts; and porcelain eyes are arranged on the positions, opposite to the upper wire guide wheel, of the main frame. According to the wire leading structure, the three wire wheels are used forreducing sliding friction, so that enameled copper wire is steady and smooth in transition. Linear bearings in the guide sliding blocks increase guide contact points, so that linear guide sliding is smooth, the phenomenon that the enameled copper wire is not stable and easy to stuck and broken is solved, and the phenomenon that enameled copper wire paint coating is prone to scratch and breakage issolved. The wire leading structure is simple in structure and small in occupied space.

Owner:浙江朝朝机电制造有限公司

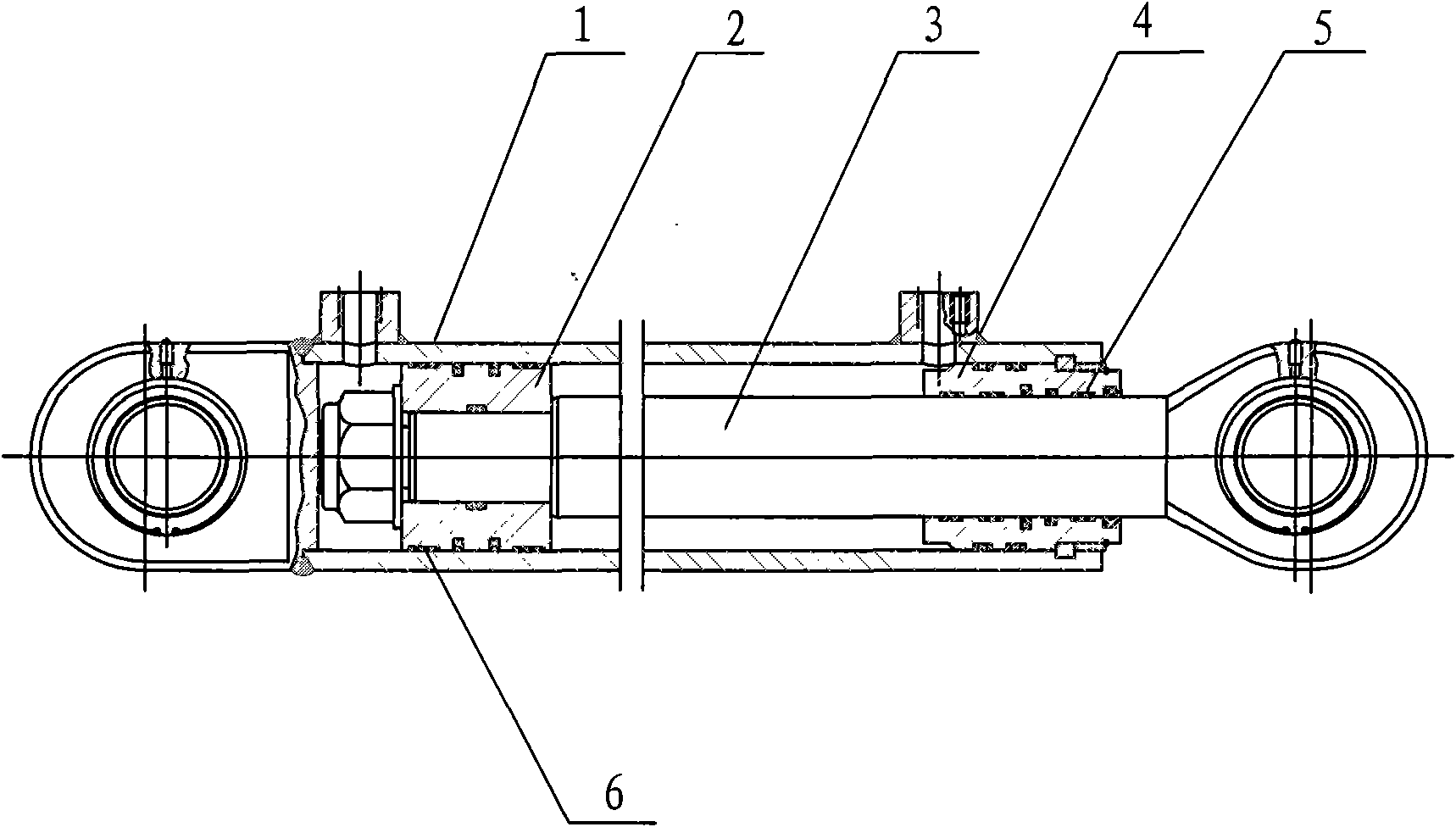

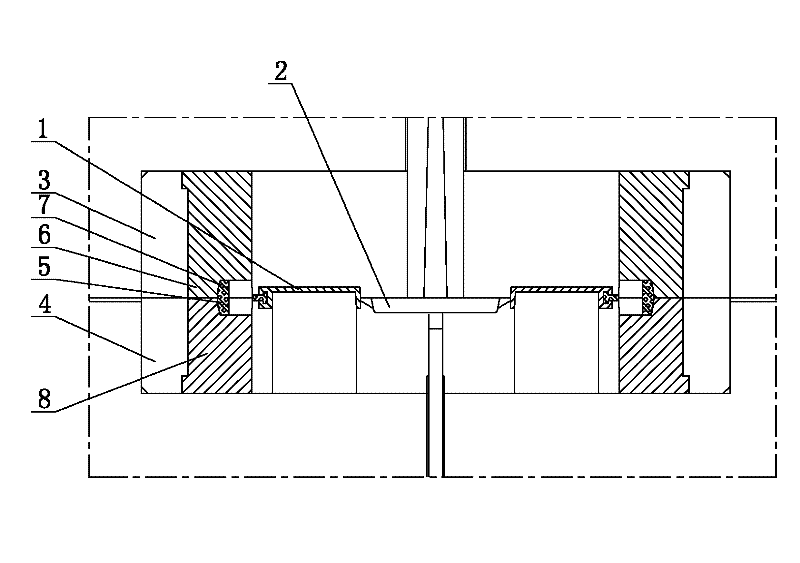

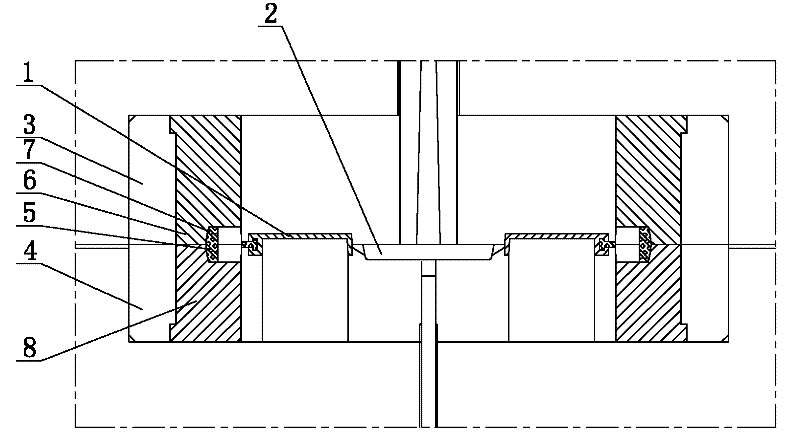

High-strength engineering machinery hydraulic cylinder

InactiveCN101655117AExtended service lifeSolve technical problems with short service lifeEngine sealsCylindersIntermediate frequencySteel ball

The invention discloses a high-strength engineering machinery hydraulic cylinder, which comprises a cylinder body. A piston rod and a guiding support ring are arranged in the cylinder body, a piston is arranged on the piston rod, and an oil inlet pipe interface and an oil return pipe interface are arranged on the cylinder body; the cylinder body is made of 27 SiMn alloy steel material, the pistonrod is made of SiCr-440 material, the surfaces of the cylinder body and the piston rod are quenched at intermediate frequency, and then the surface of the piston rod is plated with hard chromium and polished to Ra 0.08 mum; the piston consists of a floating buffer plunger piston and a floating buffer sleeve; the buffer plunger piston is limited by a steel ball; two lip-shaped seals are arranged onthe piston rod, and lubricant is filled between the two lip-shaped seals; two ends of the piston are provided with pollution-receiving rings of which thicknesses are 4 millimeters; and the guiding support ring is a DU composite material sliding bearing. The high-strength engineering machinery hydraulic cylinder solves the technical problem of short service life of the hydraulic cylinder in the prior art, can bear 30MPa high pressure when in use, and is an ideal engineering machinery hydraulic cylinder; and the surface of the hydraulic cylinder is not easy to be damaged.

Owner:SHANDONG ZHONGLI HYDRAULIC TECH

Structure of protecting appearances of metal inserts in mould

InactiveCN102328392AGood surface flexibilityReduce replacement costsCoatingsMetallurgyEngineering plastic

The invention provides a structure of protecting appearances of metal inserts in a mould, which is characterized in that the surfaces of the metal inserts are not easy to pull, mould cores are not easy to pull, and further, the production cost is low. The structure of protecting the appearances of the metal inserts in the mould comprises product mould cavities, a runner, a front mould core, a rear mould core and the metal inserts, wherein the runner is communicated with the product mould cavities, and the metal inserts are communicated with the product mould cavities. The structure of protecting the appearances of the metal inserts in the mould is characterized in that engineering plastic sleeves are respectively arranged between the outer surfaces of the metal inserts and the inner surfaces of the front mould core and the rear mould core; the outer surfaces of the metal inserts are fitted with mounting slots on the inner surfaces of the engineering plastic sleeves; and the outer surfaces of the engineering plastic sleeves are fitted with the inner surfaces of the front mould core and the rear mould core.

Owner:VANGUARD TECH WUXI

Method for manufacturing high manganese hot-dip galvanized steel sheet with excellent coatability and ultra-high strength, and high manganese hot-dip galvanized steel sheet manufactured by said method

ActiveUS20150329951A1High strengthHigh degreeHot-dipping/immersion processesPretreated surfacesUltimate tensile strengthImpurity

There are provided a method for manufacturing a high manganese hot-dip galvanized steel sheet having superior coatability and ultra-high strength, and a high manganese hot-dip galvanized steel sheet manufactured by the method. The method includes: cold rolling a hot-rolled steel sheet to form a cold-rolled steel sheet, the hot-rolled steel sheet including, by wt %, C: 0.3% to 1%, Mn: 8% to 25%, Si: 0.1% to 3%, Al: 0.01% to 8%, Cr: 0.1% to 2%, Ti: 0.01% to 0.2%, B: 0.0005% to 0.01%, Ni: 0.01% to 2%, Sn: 0.06% to 0.2%, and a balance of Fe and inevitable impurities; heating the cold-rolled steel sheet; cooling the heated steel sheet to, or maintaining the heated steel sheet; and performing a hot-dip galvanizing process on the cooled or temperature-maintained steel sheet by dipping the cooled or temperature-maintained steel sheet into a hot-dip galvanizing bath.

Owner:POHANG IRON & STEEL CO LTD

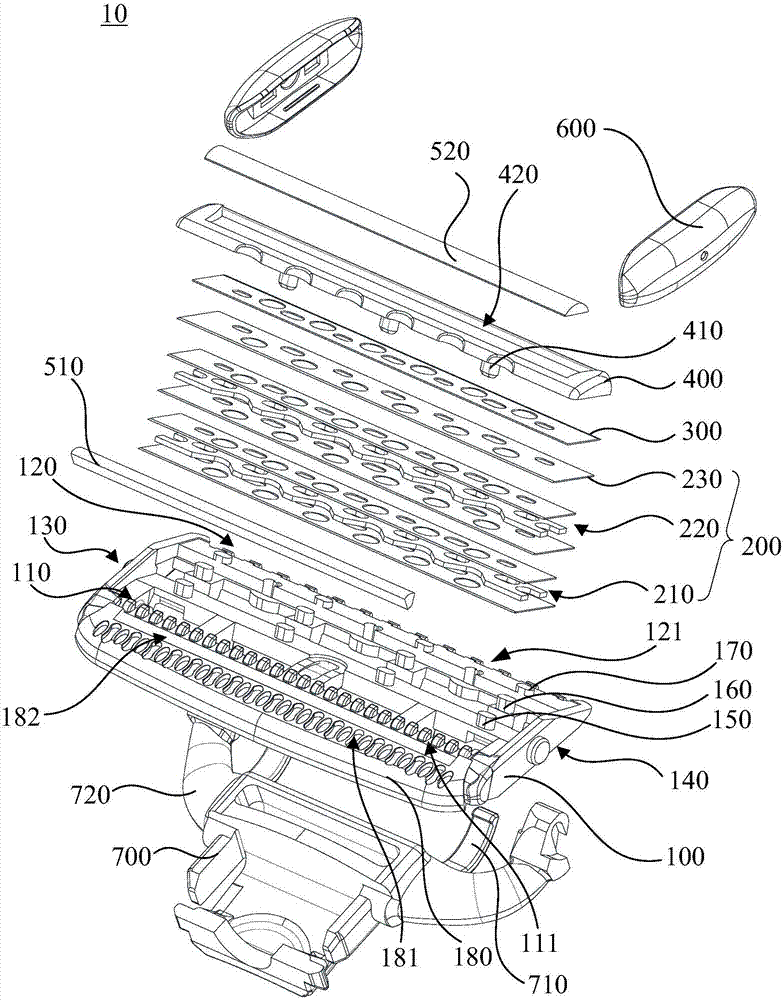

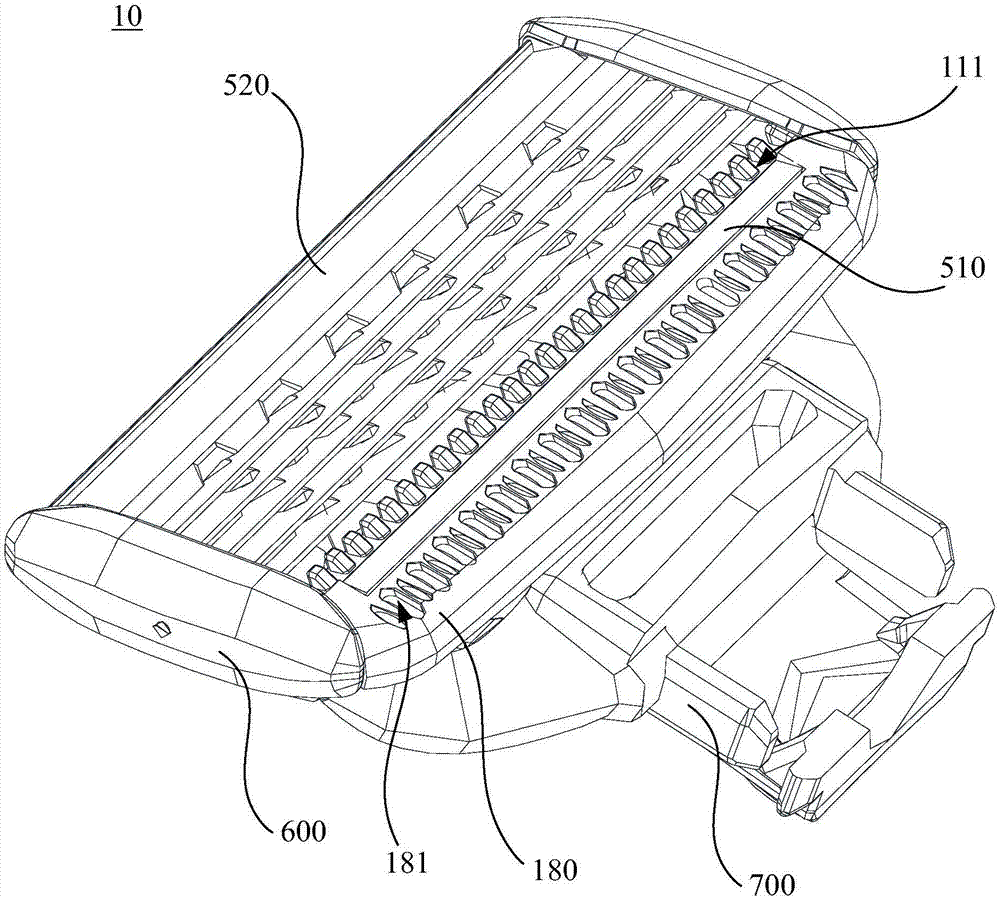

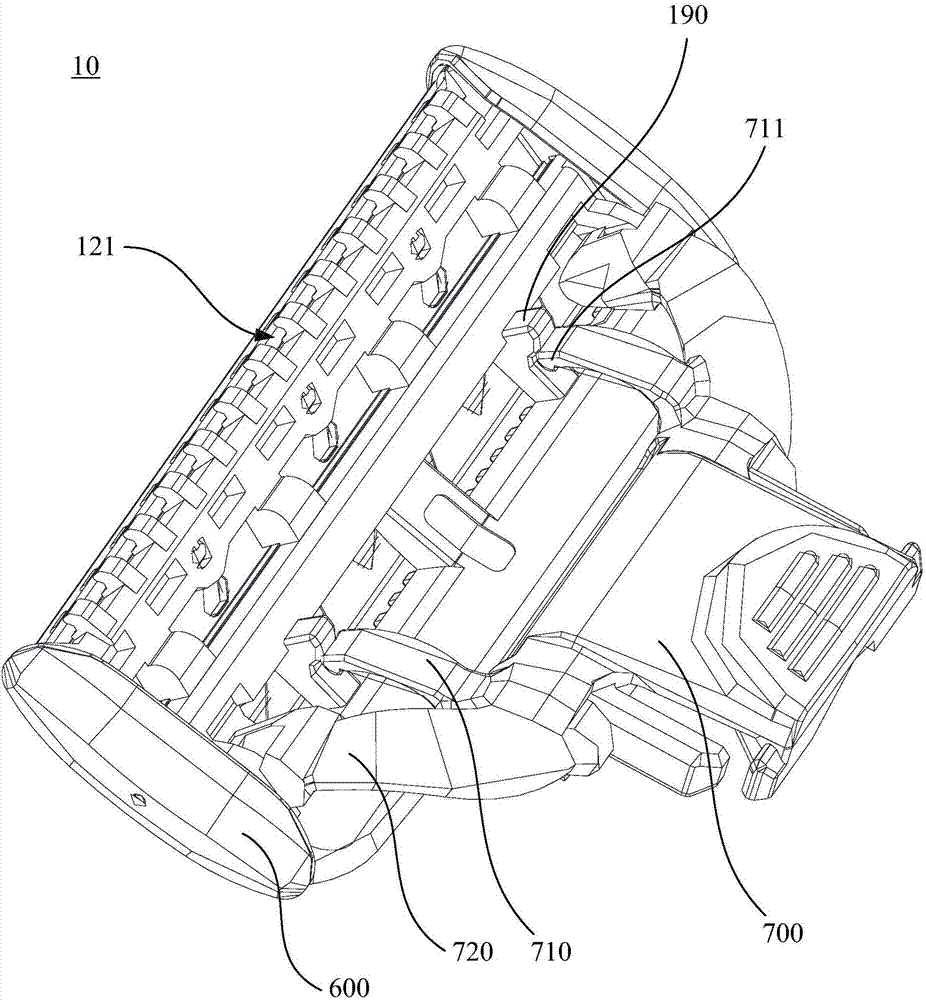

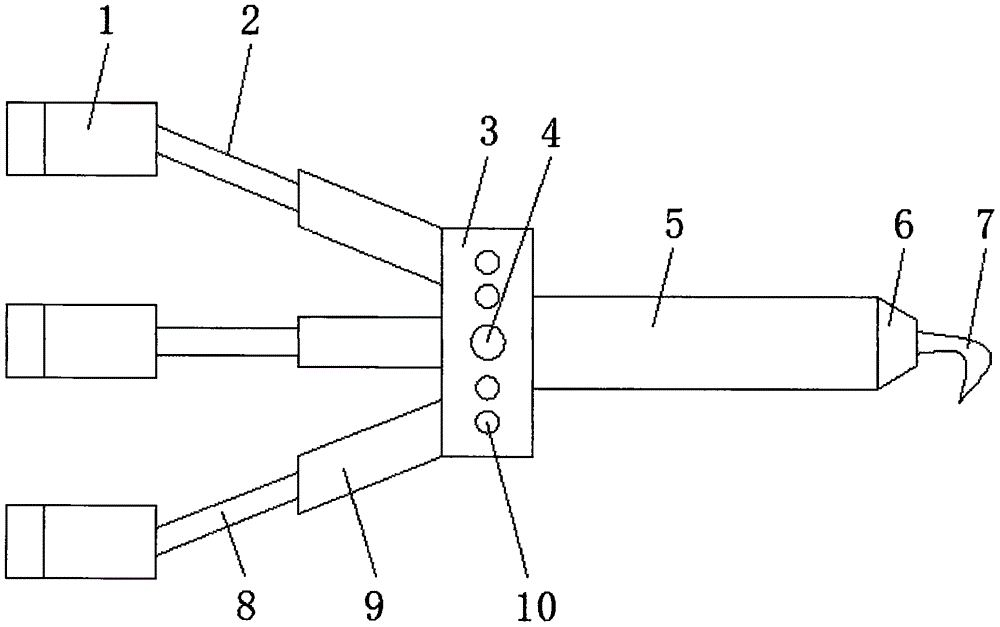

Shaver head with double lubricating strips

InactiveCN107953368APlay a protective effectPlay a moisturizing roleMetal working apparatusRazor stropRazor Blade

The invention discloses a shaver head with double lubricating strips. The shaver head with the double lubricating strips comprises a blade rack, a blade group and at least two lubricating strips, wherein the blade group is connected with the blade rack and extends to the direction of a second end of the blade rack along a first end of the blade rack; and the lubricating strips comprise a first lubricating strip arranged at the first end and a second lubricating strip arranged at the second end. When a user shaves, before being in contact with a blade, the skin of the user is in contact with the first lubricating strip, after meeting water, the lubricating strip releases lubricating liquid which has protecting and moistening effects on the skin, and thus the skin of the user cannot be hurteasily; and the second lubricating strip is arranged at the second end of the outer frame of the blade rack and is positioned on the top of the blade group, when meeting water, the second lubricatingstrip releases lubricating liquid which further protects and moistens the skin, hurt pain caused by repeated shaving is eliminated, and the use experience of the user is improved.

Owner:GUANGZHOU WEIDI COMMODITY CO LTD

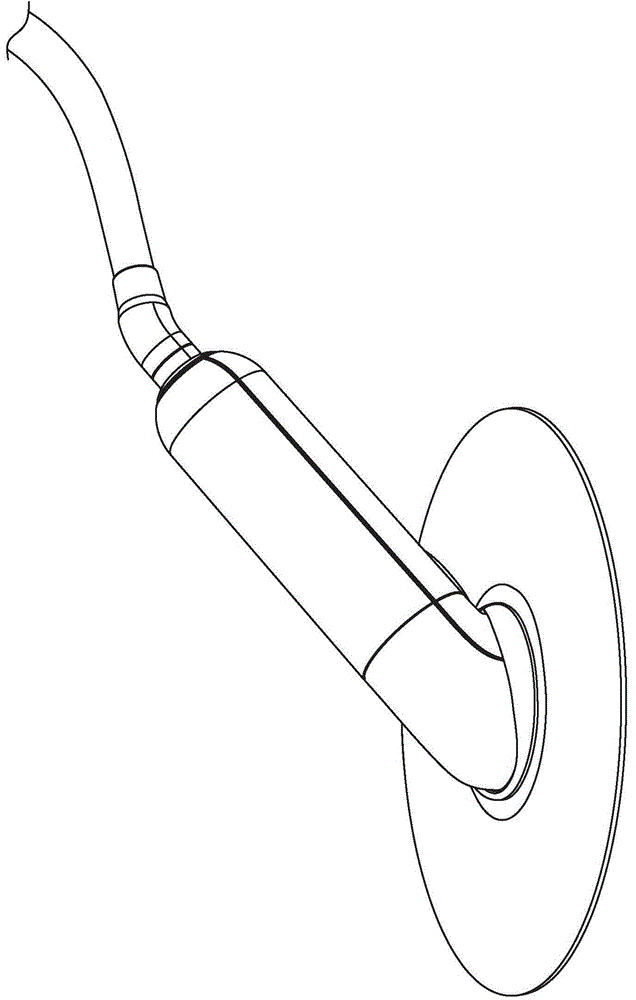

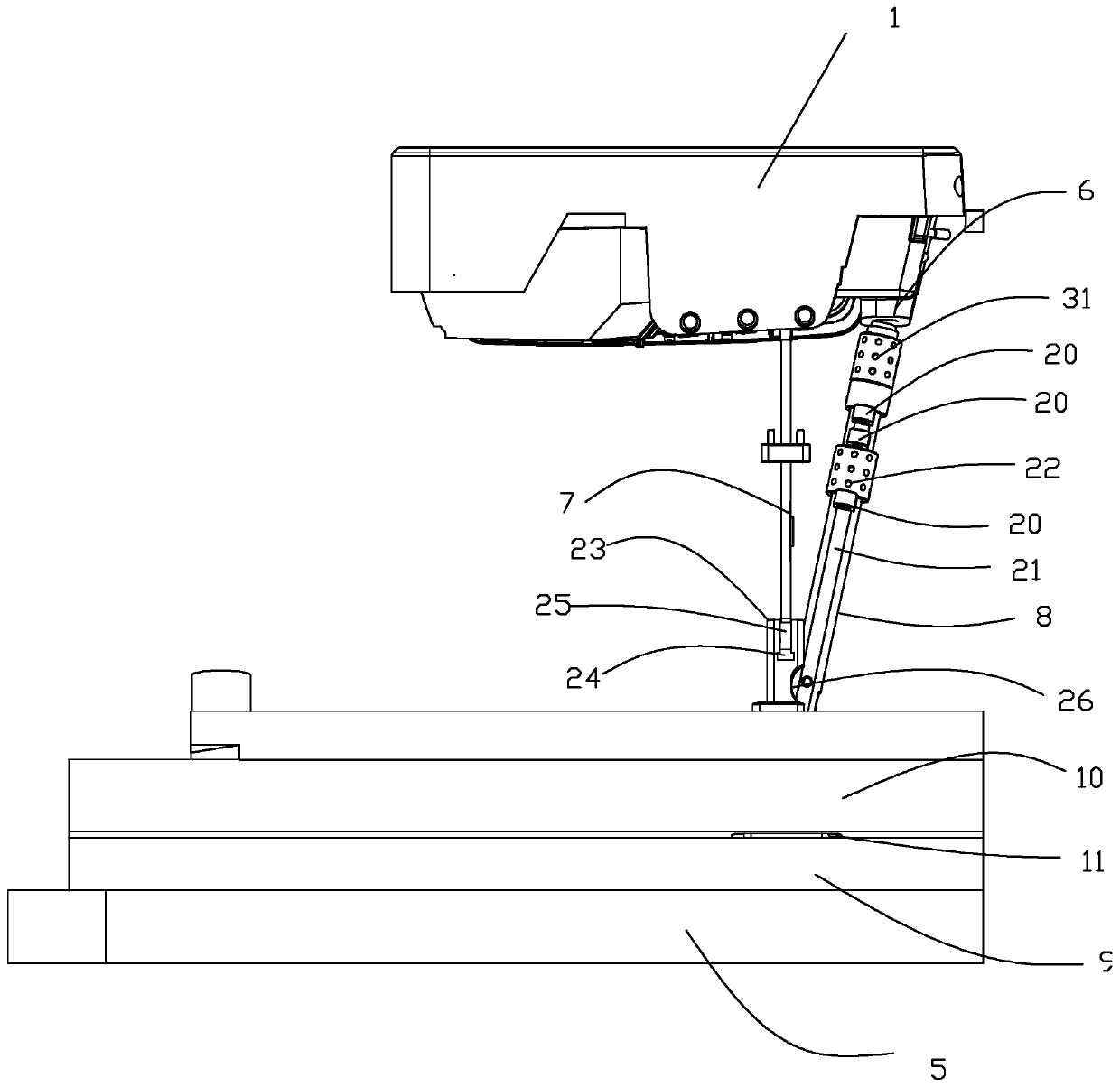

Surgical retractor device for hepatobiliary surgery

InactiveCN105919635AMeet the requirements of the surgical procedureNot easy to strainSurgeryEngineeringSurgical department

The invention discloses a surgical retractor device for hepatobiliary surgery. The surgical retractor device comprises a connecting device, an elastic connecting band, a telescopic bracket and a hook body, wherein a retractor is installed at the right end of the connecting device, and the left side of the connecting device is connected with the elastic connecting band; the left side of the elastic connecting band is connected with a connecting piece; the telescopic bracket is installed at the left end of the connecting piece; the hook body is installed at the left end of the telescopic bracket; the telescopic bracket consists of an extension bar and a fixing rod, and the extension bar is installed on the fixing rod in a nesting way. The surgical retractor device is smaller in whole structure, convenient to carry and ultra-thin in design; in an assisting process, the device can be flexibly operated by a user without being installed; the surgical retractor device can meet the requirements of a doctor during surgery; furthermore, the telescopic bracket is arranged, so that the size of the surgical retractor device can be adjusted; the surgical retractor device does not easily hurt the hand of a patient due to pulling by arranging the elastic connecting band.

Owner:刘毅

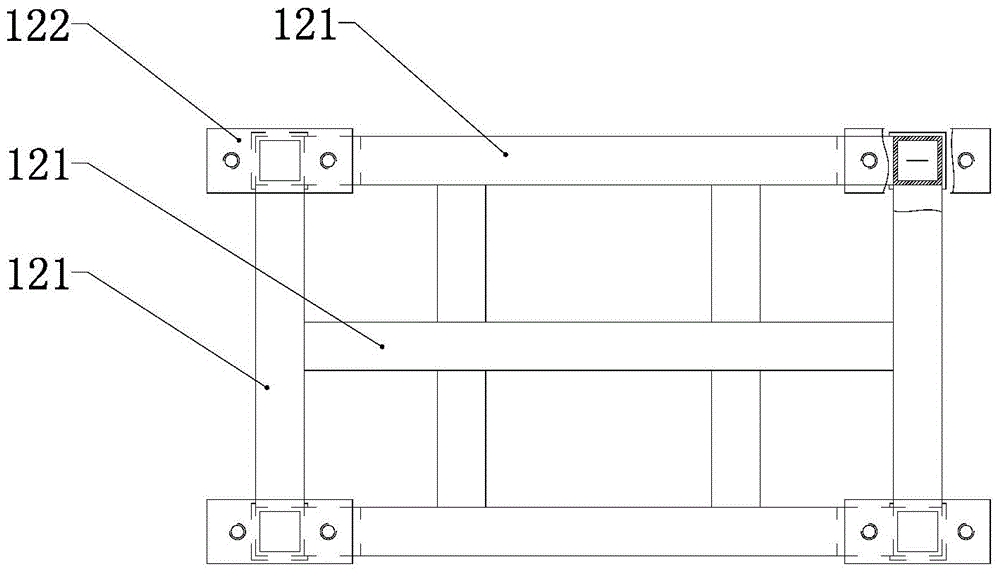

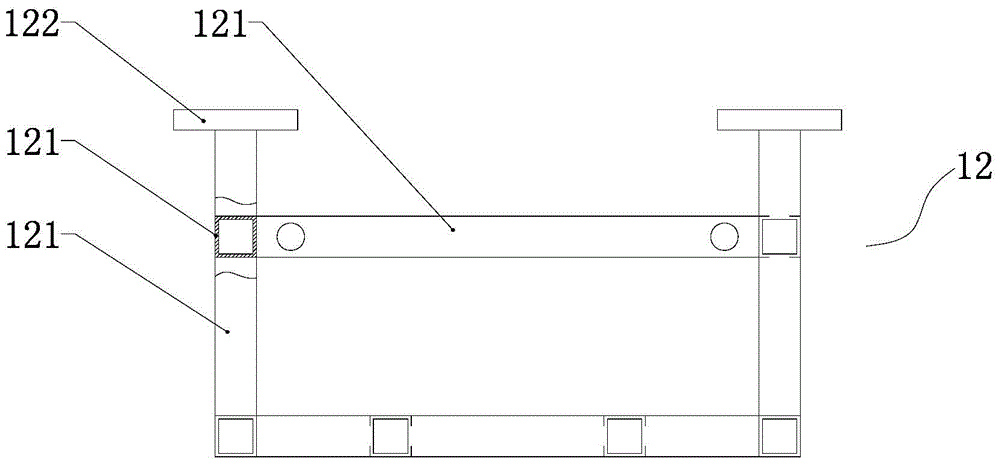

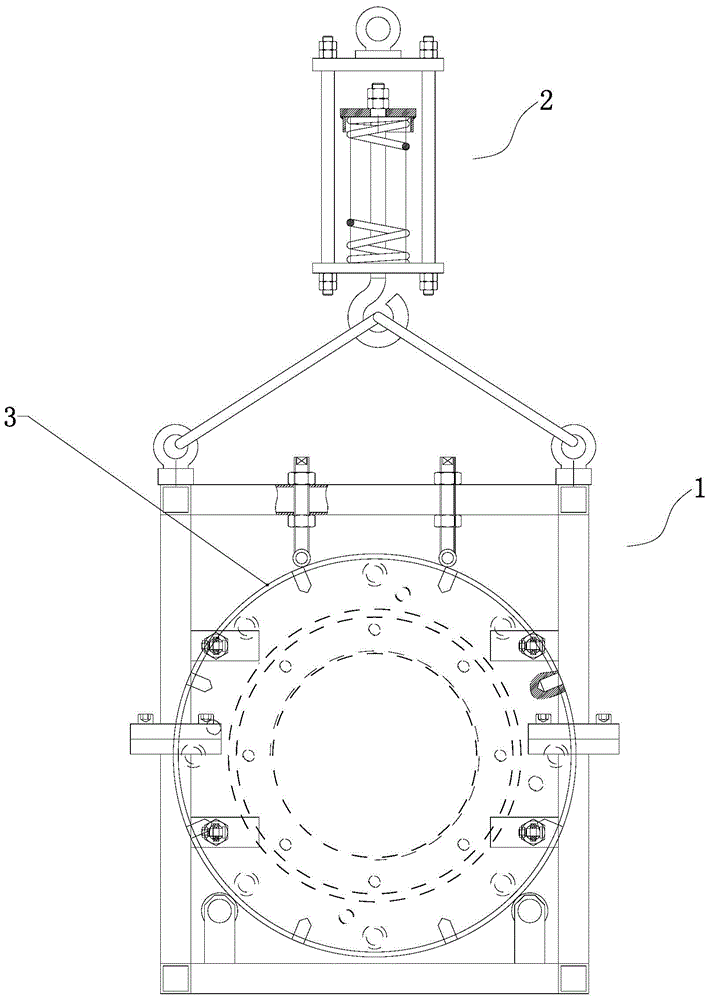

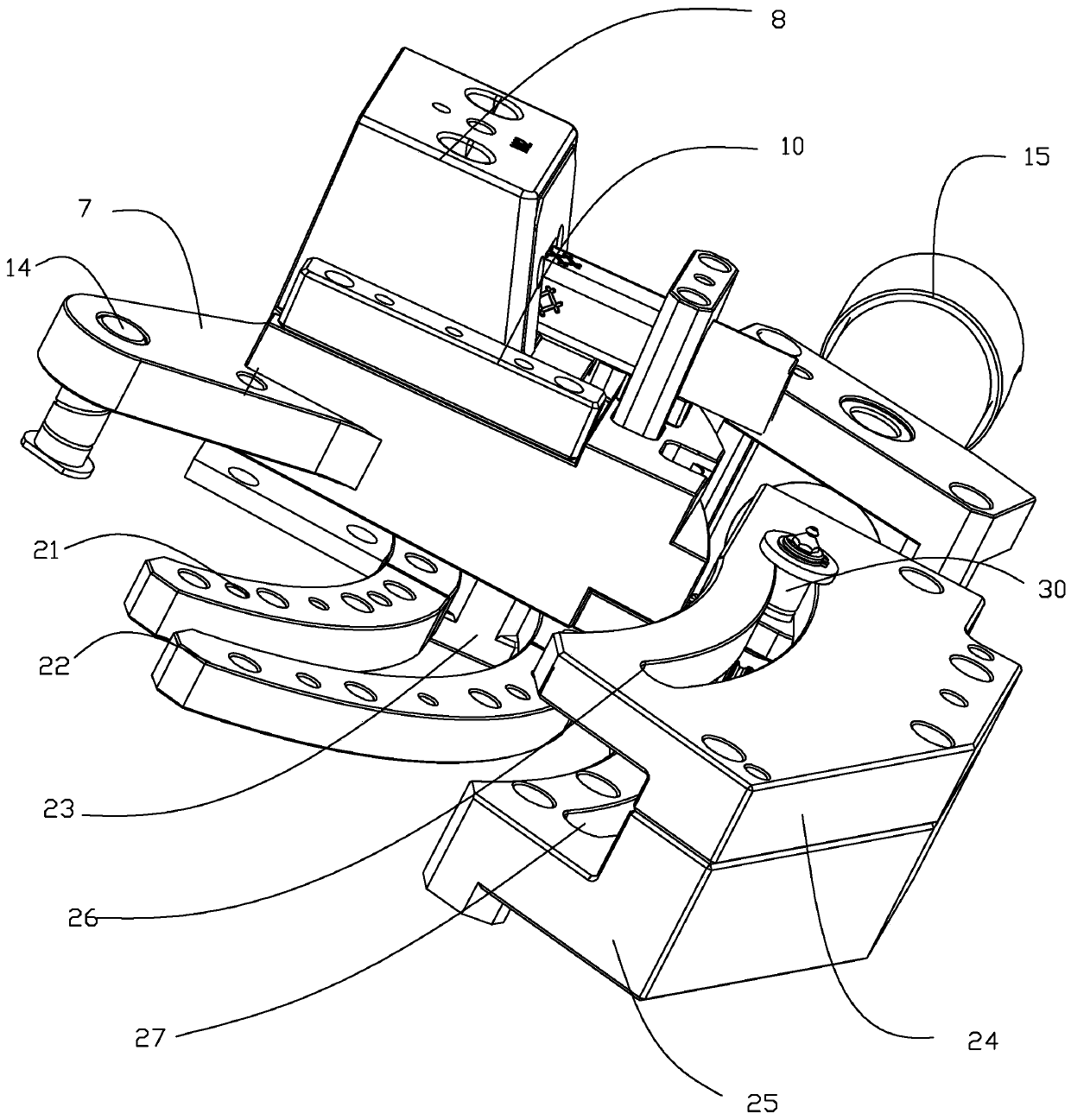

Horizontal large nut erector

The invention discloses a horizontal large nut erector. The horizontal large nut erector comprises a rotator and a buffer. The rotator is used for a large nut to be fixed in the rotator, and the large nut can freely rotate around the central axis of the large nut. The buffer is used for the rotator to hang below. The rotator is mainly formed by an upper bearer frame, a lower bearer frame, and a plurality of bearings. The buffer is mainly formed by an installation frame, a hook, and an elastic assembly. The rotator can make a large nut rotate freely in a vertical and stable manner in the rotator, and the buffer can make threads stress uniformly when the large nut is installed, and finally, screw-out and screw-in operation of the large nut are easily realized, and the threads cannot easily be scratched. The horizontal large nut erector effectively solves problems of increasing of friction forces and single-side stress of the large nut caused by gravity of the nut when the large nut is installed in a horizontal manner.

Owner:KEDA INDUSTRIAL GROUP CO LTD

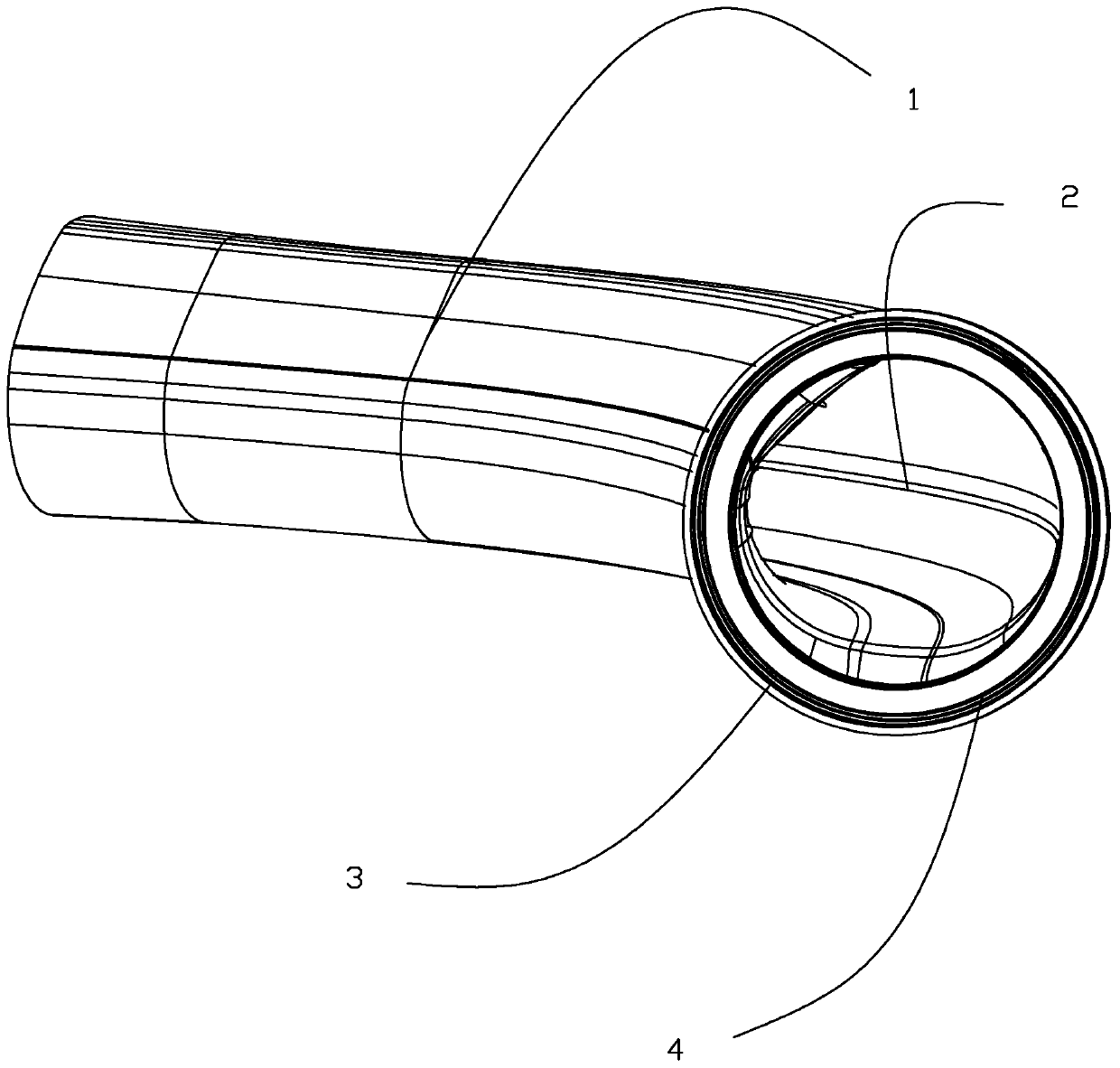

Automobile elbow pipe core-pulling mechanism

The invention discloses an automobile elbow pipe core-pulling mechanism which comprises a product and a lower mold plate. The product is located on the lower mold plate; an arc-shaped groove is formedin the product; an annular bulge is arranged at the front end of the product; a circular groove is formed in the annular bulge; the diameter of the circular groove is larger than the diameter of thearc-shaped groove; the circular groove communicates with the arc-shaped groove; a first insert core for forming the inner wall of the circular groove is arranged in the circular groove; and a second insert core for forming the inner wall of the arc-shaped groove is arranged in the arc-shaped groove. The automobile elbow pipe core-pulling mechanism further comprises a first-time linear core-pullingmechanism for core-pulling the circular groove, and a second-time arc core-pulling mechanism for core-pulling the arc-shaped groove, wherein the first insert core is connected with the second insertcore; and the second-time arc core-pulling mechanism is located on the lower mold plate. The invention provides the automobile elbow pipe core-pulling mechanism which is not easy to damage when beingpulled and has high reliability.

Owner:NINGBO FANGZHENG TOOL

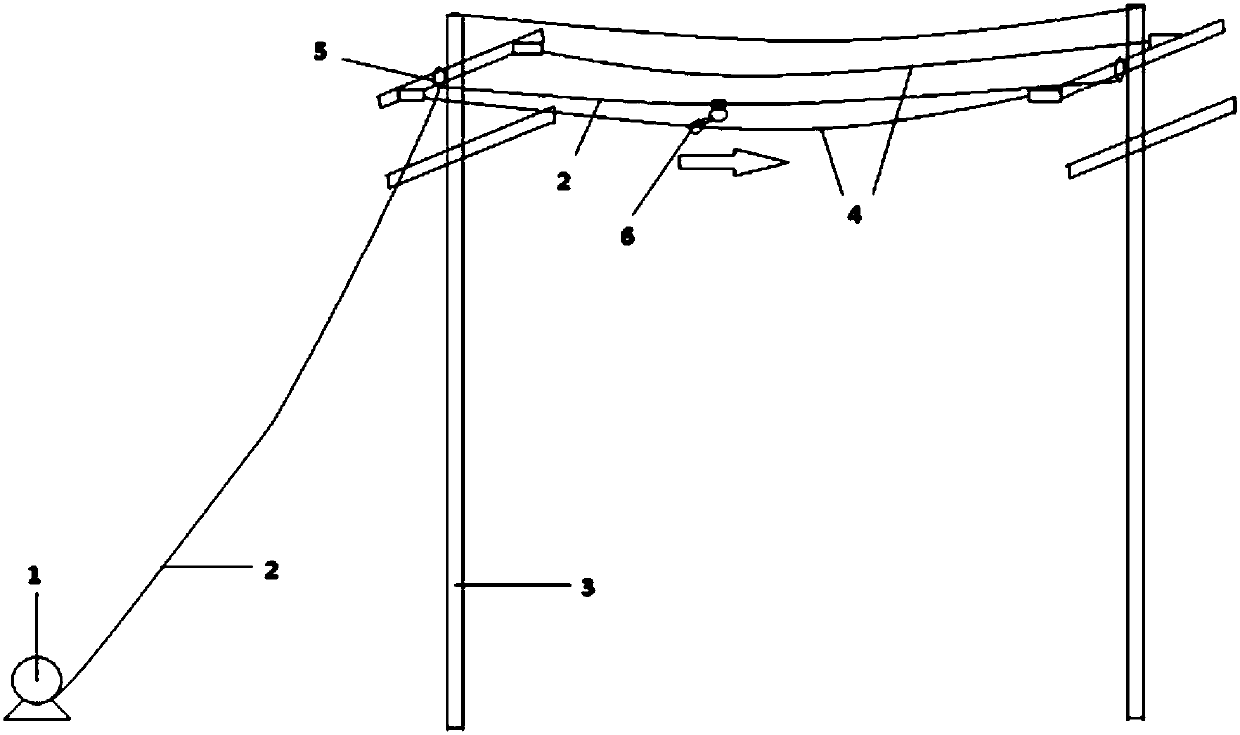

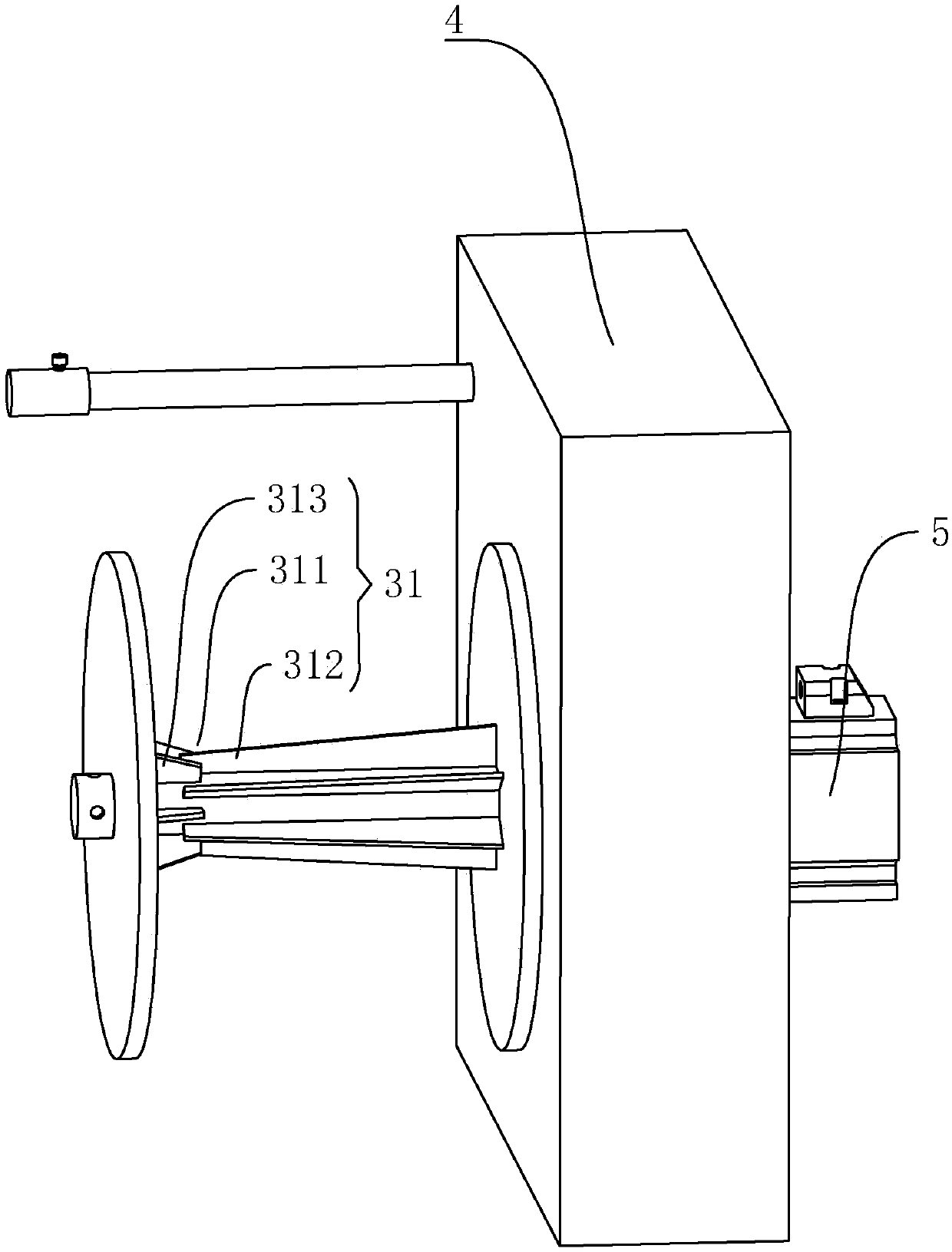

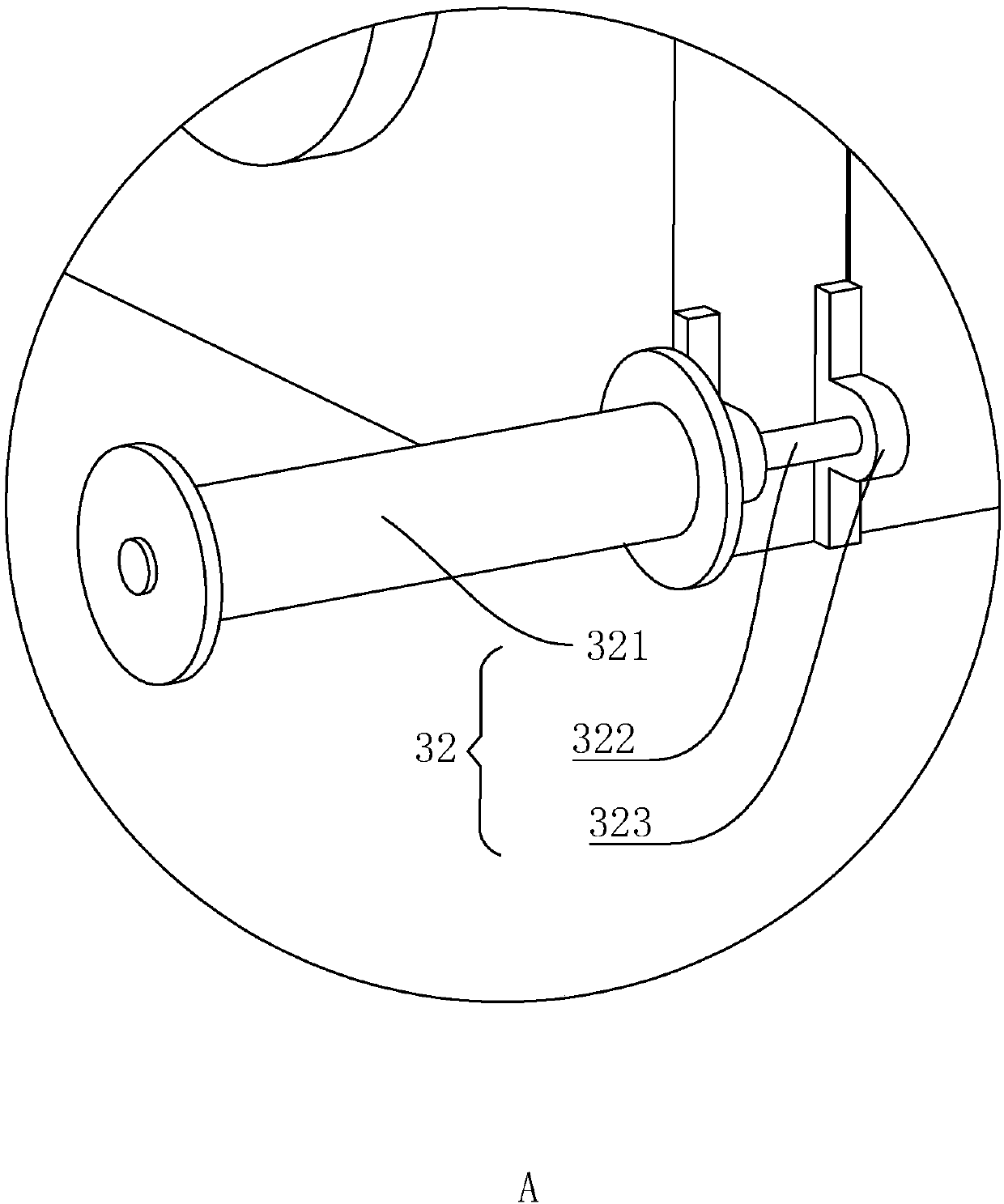

Power line intelligent cleaning device

InactiveCN106848924BNot easy to strainAvoid damageApparatus for overhead lines/cablesPower batteryMicrocomputer

The present invention discloses a transmission line intelligent cleaning device. The device comprises a winder, a cable and a cleaner. The coil is wound on the winder, and the cleaner is arranged on the cable; and the cleaner comprises a housing, a driven wheel, a rotation shaft, a drive wheel, a main rotation shaft, a single-chip microcomputer, a power battery, a motor, a rotary encoder, a flexible bracing piece, a cylinder, a cleaning brush and a balance weight. The cable is employed to delimit the path of the cleaner, the cleaner is driven by the motor, the motor drives the drive wheel on the main rotation shaft to rotate along the cable to realize automatic advance of the cleaner. The cleaning brush on the cleaner completes the cleaning of an overhead transmission line in the advance process. Workers only need to hang the cable on telegraph poles at two ends of a line and only need to assemble the device so as to very save labor force. The transmission line intelligent cleaning device is internally provided with the flexible bracing piece to adapt the changing of the distance of the cable and the transmission line through regulation of the length of the flexible bracing piece, is not easy to pull and damage the transmission line and is small in damaging of the transmission line.

Owner:ZHEJIANG UNIV

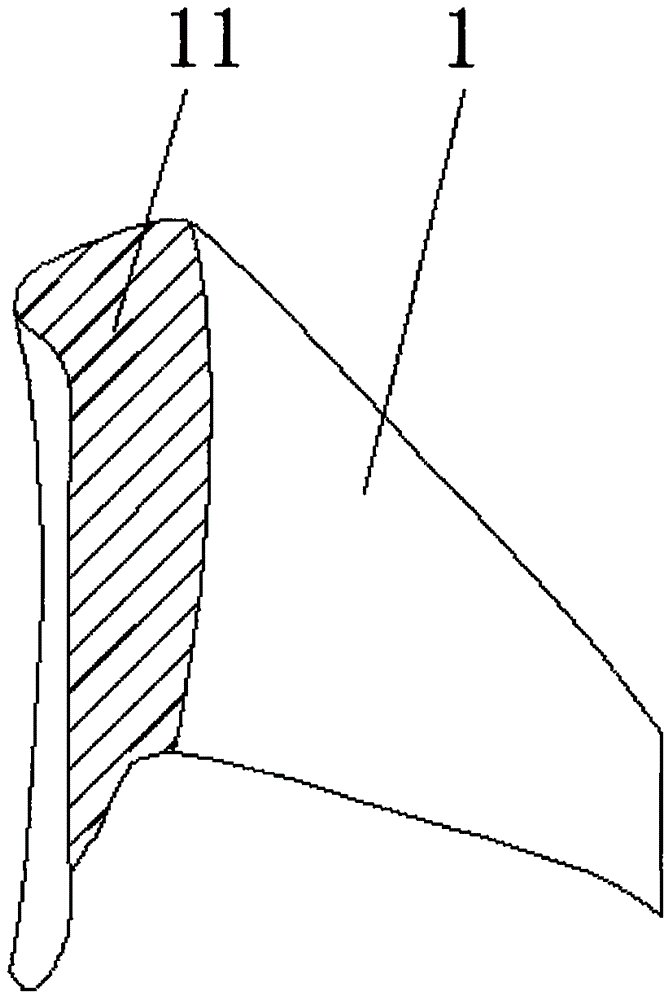

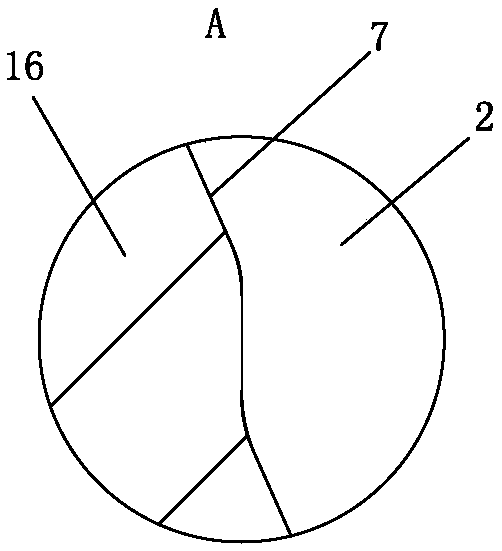

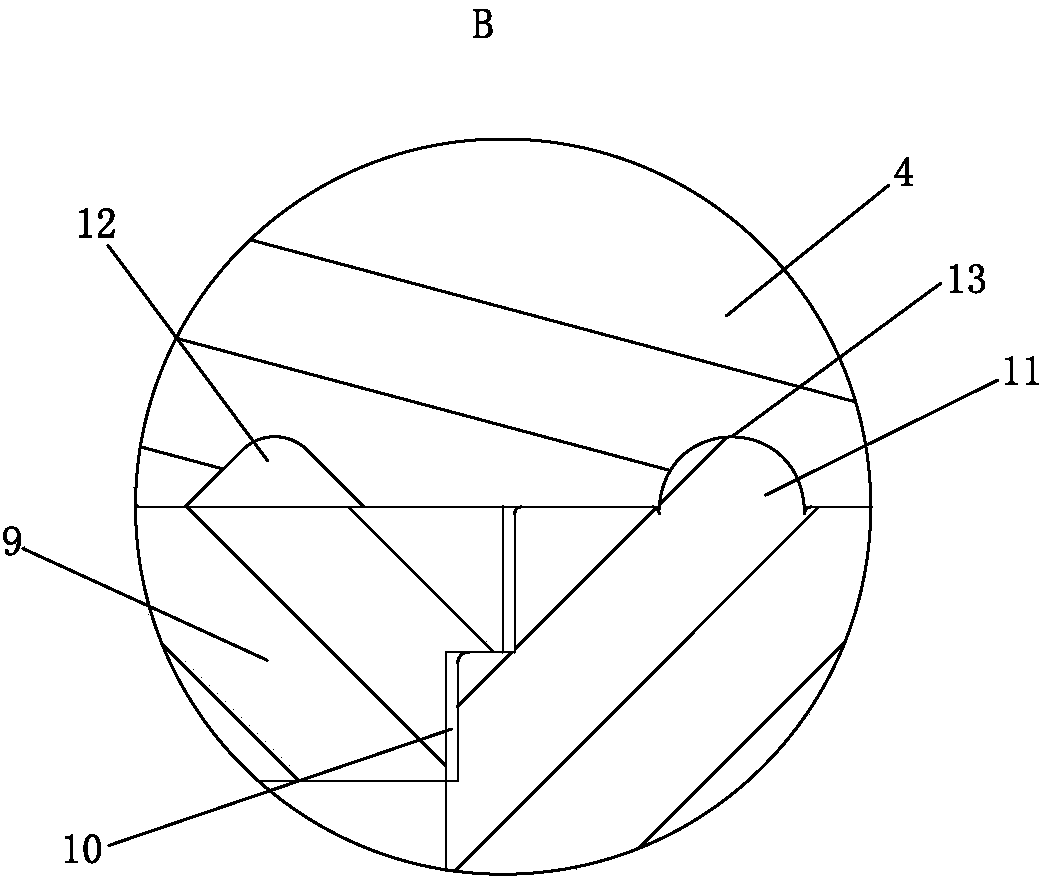

Mechanism used for separating product from fixed mould and capable of limiting slide block by adopting perpendicular locking surface for fixed mould and deep rib

The invention discloses a mechanism used for separating a product from a fixed mould and capable of limiting a slide block by adopting a perpendicular locking surface for the fixed mould and a deep rib. The mechanism comprises a mould cavity (1), an inclined guide post (3) arranged on the fixed mould (2) and the slide block (4) which is arranged on a movable mould in a sliding mode, wherein one end, close to the mould cavity (1), of the slide block (4) is a side wall, which corresponds to the mould cavity (1), of the deep rib, and is positioned above a position, which corresponds to the mouldcavity (1), of a product edge; height of one end, close to the mould cavity (1), of the slide block (4) is a value obtained by subtracting 1.0-3.5mm from height of the deep rib; a stroke limiting mechanism is arranged between the slide block (4) and the movable mould; an inclined hole (5) which is in sliding fit to the inclined guide post (3) is formed in the slide block (4); the inclined hole (5)is greater than the outer diameter of the inclined guide post (3); one end, away from the mould cavity (1), of the slide block is equipped with an inclined surface (6); and a pressing surface (7) which presses the slide block (4) when the pressing surface is matched with the inclined surface (6) for closing the mould is arranged on the fixed mould (2). Compared with the prior art, the mechanism has characteristics of being simple in structure, convenient to maintain and repair, and capable of increasing the product yield.

Owner:NINGBO FANGZHENG TOOL

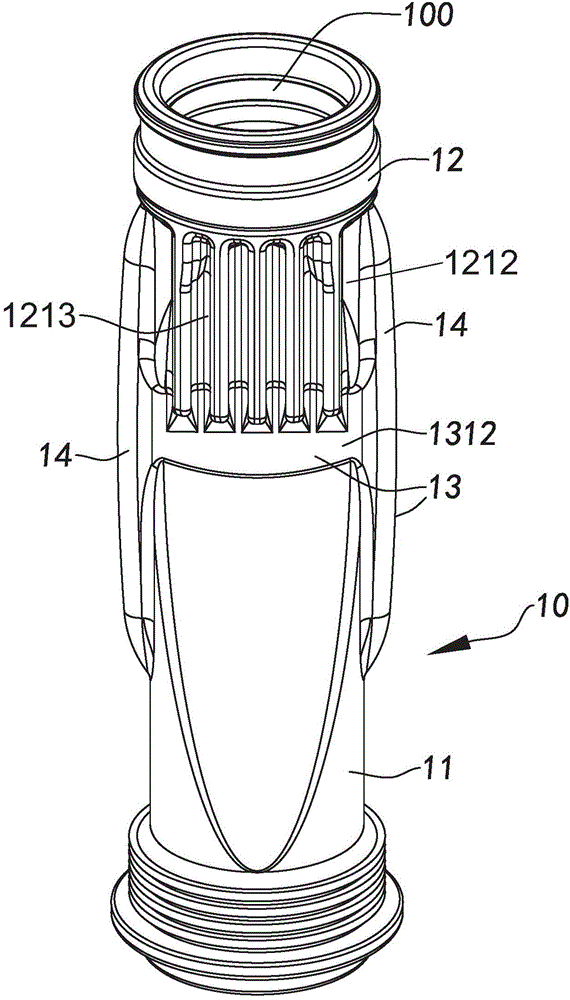

Material and method for manufacturing waterway controller

The utility model provides a cleaning device. The cleaning device comprises a water path controller and a capture assembly, wherein the water path controller forms a water flow passage, the capture assembly forms a first water inlet, the first water inlet is communicated with the water flow passage and the water path controller comprises an opening and closing part; when difference between external pressure and internal pressure applied to the opening and closing part is not smaller than a first preset value, the opening and closing part of the water path controller is closed to enable the water flow passage of the water path controller to be blocked; when the difference between the internal pressure and the external pressure applied to the opening and closing part is not smaller than a second preset value, the opening and closing part of the water path controller is opened to allow water to flow in the water flow passage of the water path controller; when the difference between the internal pressure and the external pressure applied to the opening and closing part is between the first preset value and the second preset value, the opening and closing part of the water path controller is kept in a natural state; the water path controller and a horizontal plane form an angle alpha and the magnitude of the angle alpha is 25-30 degrees.

Owner:宁波市镇海兴瑞橡塑科技有限公司

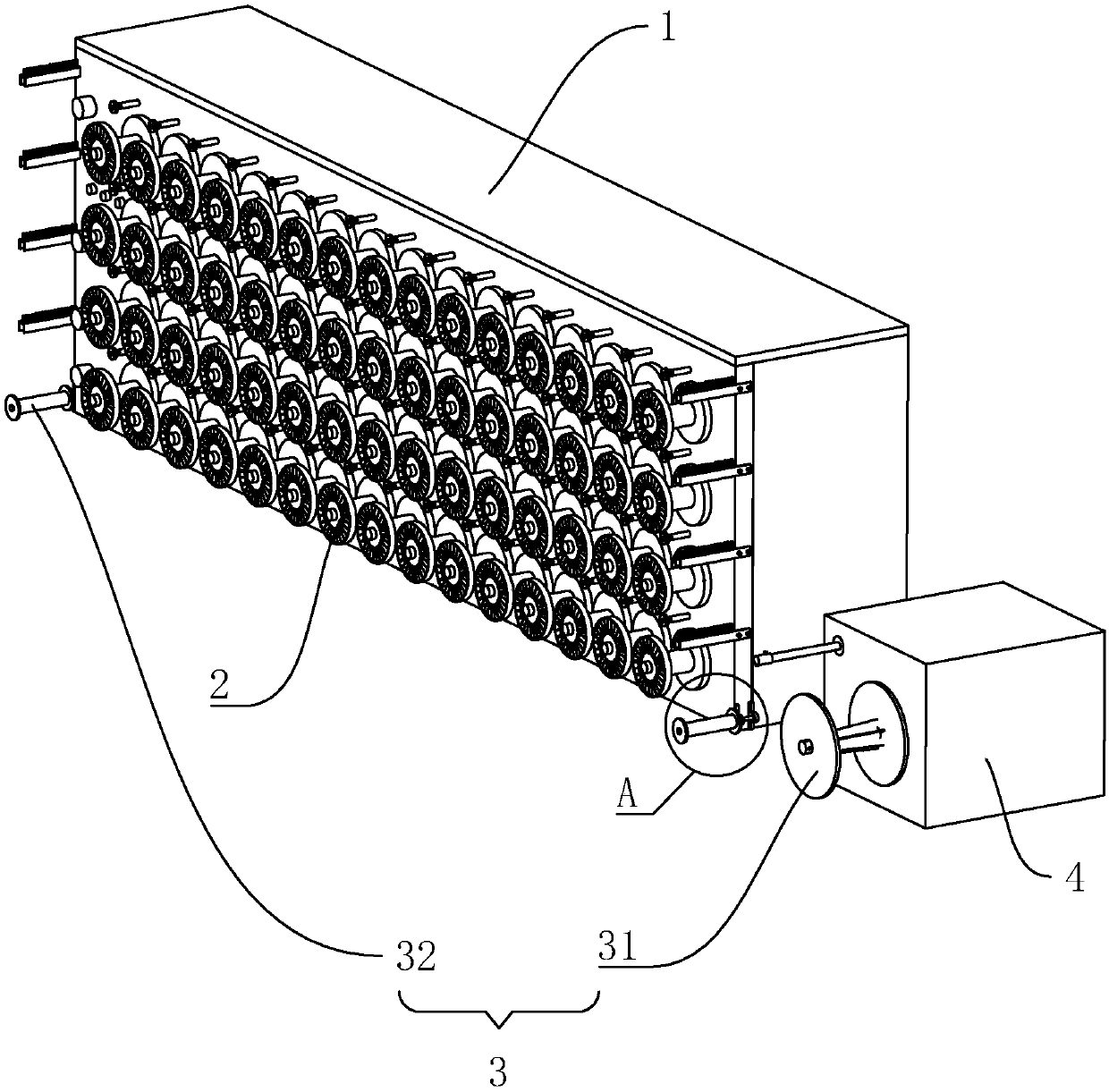

Monofilament winding device

ActiveCN107761180AReduce the impactNot easy to stickNew-spun product collectionConductor CoilSurface plate

The invention discloses a monofilament winding device. The monofilament winding device is characterized by comprising a winding panel, wherein a plurality of winding rollers are arranged on the winding panel; auxiliary rollers are arranged at one end in a monofilament forwarding direction of the winding panel and one end opposite to the monofilament forwarding direction of the winding panel; the auxiliary rollers comprise a driving roller and a driven roller; the driving roller is located at one end of the monofilament forwarding direction of the winding panel. By adopting the monofilament winding device disclosed by the invention, monofilaments are firstly overlapped on the driven roller in a winding process; one end of each monofilament is wound on the driving roller and the driving roller is used for winding and tensioning the monofilaments, so that the monofilaments do not easily fall onto the ground to be stuck with dust. When the monofilaments need to be wound on the winding rollers, one monofilament is cut off from the monofilaments wound on the driving roller and is wound on the winding roller. Which monofilament needs to be cut off is not appointed by the cutting-off manner so that the monofilament can be cut off randomly, and influences on winding are not caused.

Owner:浙江宝力特种丝业有限公司

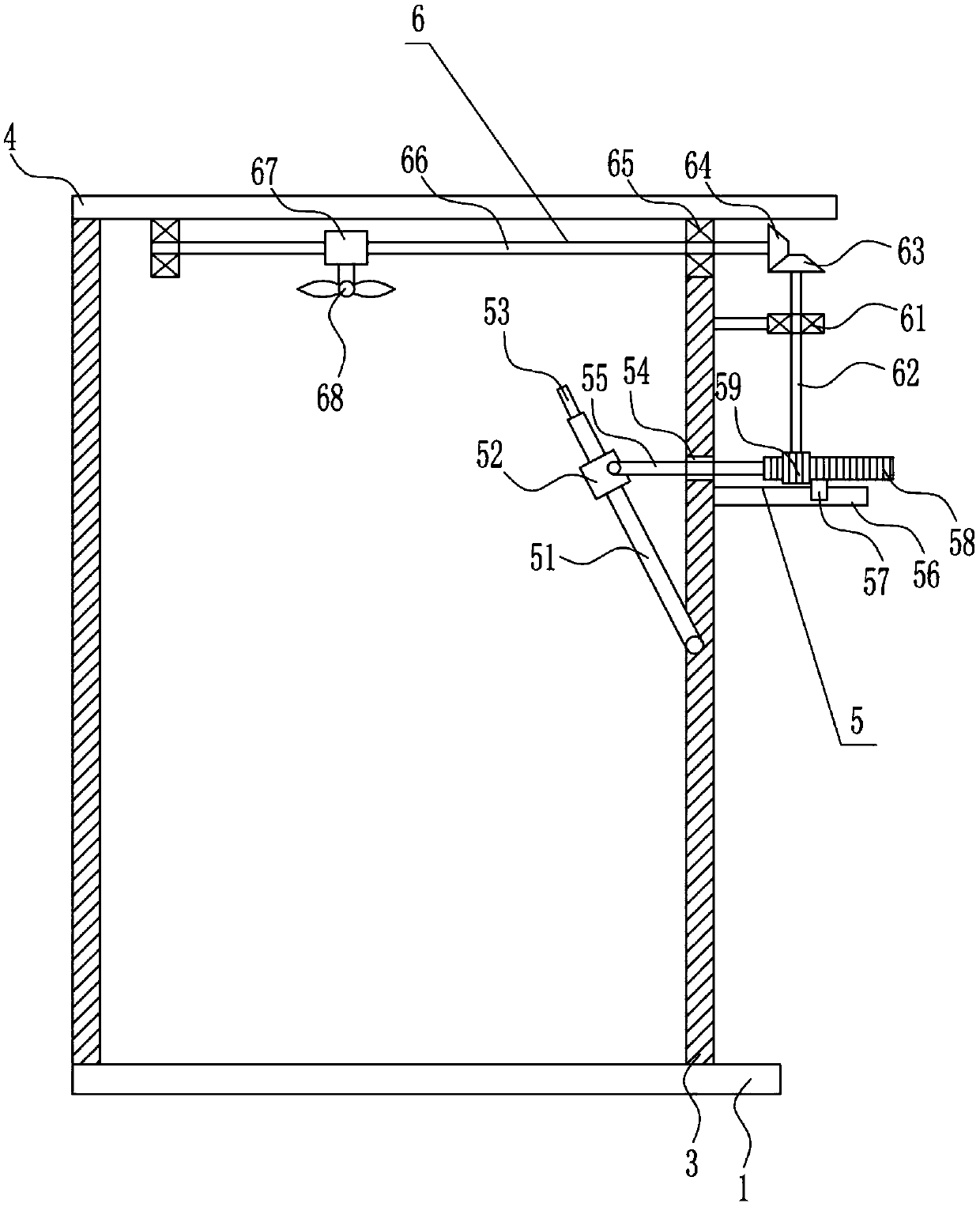

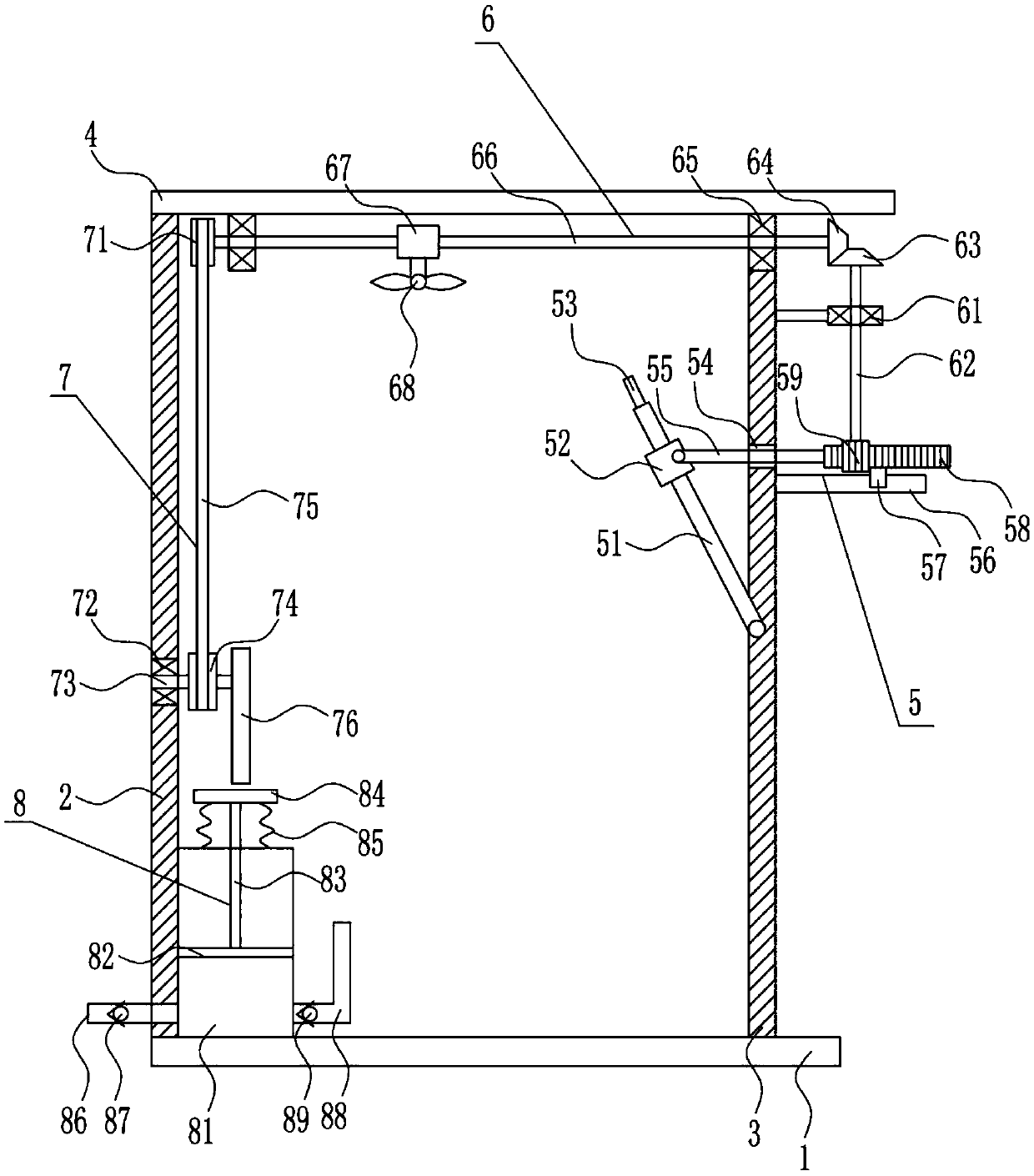

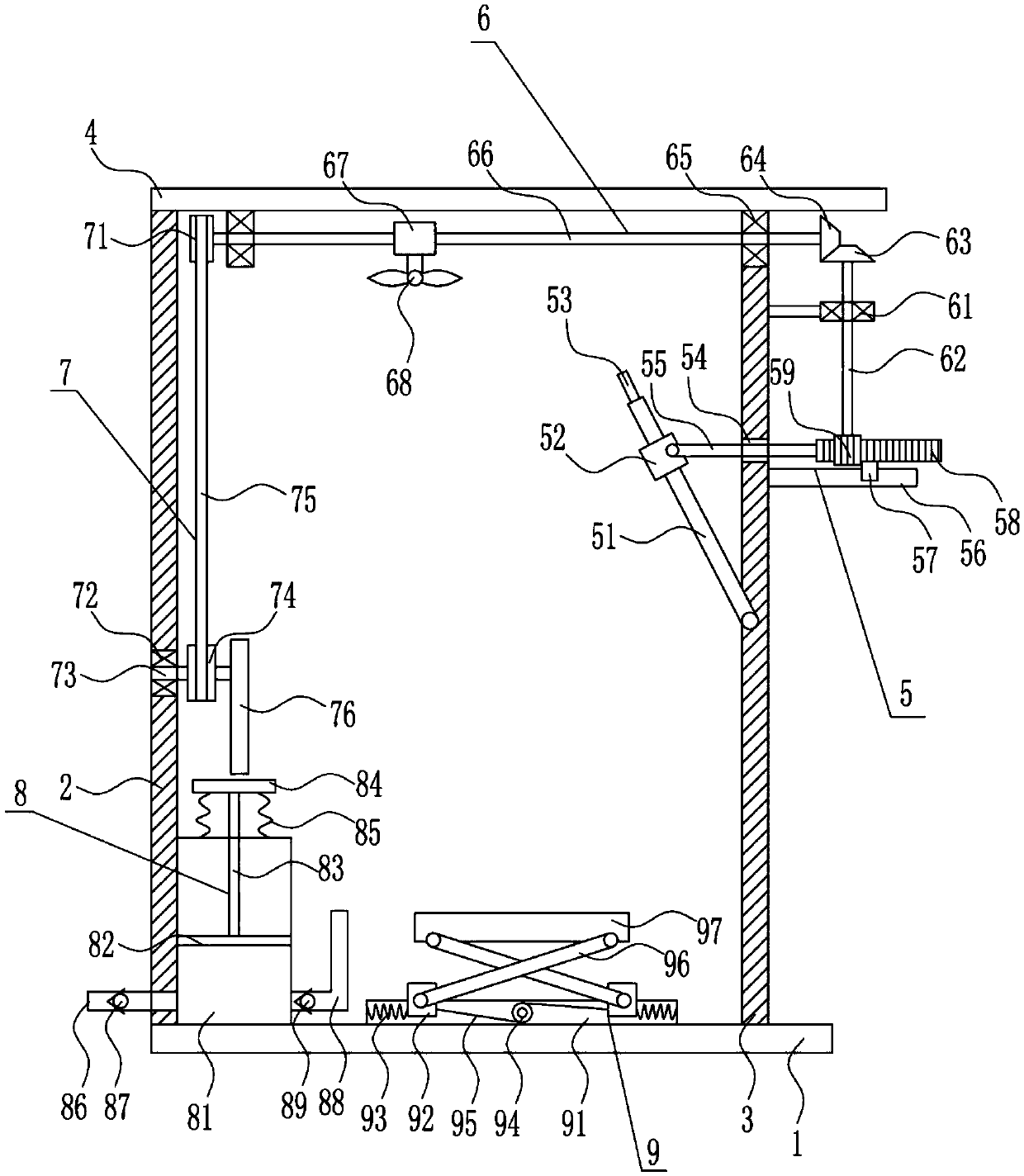

Arm exercise equipment for physical fitness

ActiveCN107670236BAchieve the effect of different exercisesImprove exercise effectMuscle exercising devicesArm exerciseEngineering

The invention relates to an arm exercising device, in particular to an arm exercising device for physical fitness. For solving the above technical problem, the arm exercising device for physical fitness comprises a base plate and the like. A left support is arranged on the left side of the top of the base plate, a right support is arranged on the right side of the top of the base plate, a top plate is arranged at the top of the left support and the top of the right support, an arm exercising mechanism is arranged at the upper portion of the right support, a blowing mechanism is arranged at thebottom of the top plate, and the blowing mechanism is connected with the arm exercising mechanism. The arm exercising device has the advantages of being good in exercising effect and adjustable, making a user not likely to be pulled and making the user feel cool during exercise. The blowing mechanism is driven to move left and right by the arm exercising mechanism for blowing air, the force produced during exercise is fully utilized, and the air in a whole space is kept fresh through gas exchange.

Owner:YANGZHOU QIAOXING SPORTS EQUIP

Automobile front door handle ejecting mechanism

ActiveCN110341143ANot easy to strainImprove reliabilityDomestic articlesMechanical engineeringDoor handle

The invention discloses an automobile front door handle ejecting mechanism. The automobile front door handle ejecting mechanism comprises a product, a lower moulding board, mould feet, a bottom plate,at least two ejector rods, an inclined guide rod and an ejector pin plate, wherein a groove is formed in the right side surface of the product; the side surface of the groove is an inclined surface;the top of the groove is equipped with an inverted buckle; a mould core which is used for simultaneously forming the side surfaces of the groove and the top of the groove is formed in the lower moulding board; the mould feet are positioned between the lower moulding board and the bottom plate; the upper surface of the bottom plate is equipped with a bump which is bulged out of the upper surface ofthe bottom plate; the upper surface of the bump and the upper surface of the ejector pin plate are inclined surfaces; the bump is positioned between the mould feet; the ejector pin plate is arrangedon the upper surface of the bump; the lower ends of the ejector rods are arranged on the ejector pin plates; the upper ends of the ejector rods pass through the lower moulding board to abut against the lower surface of the product; and the lower end of the inclined guide rod is arranged on the bottom plate. The invention provides the automobile front door handle ejecting mechanism which does not damage the product easily by pulling, and is high in reliability.

Owner:NINGBO FANGZHENG TOOL

Wood fringe template release agent

InactiveCN101418247APrevent infiltrationNot easy to strainBase-materialsCeramic shaping liningsSlurryMaterials science

The invention relates to a mould release agent for a wood stripe moulding board, which comprises the following raw materials in weight portion: 150 portions of regenerative lubricating oil and 1 to 1.2 portions of talcum powder. A method for preparing the mould release agent for the wood stripe moulding board comprises the following steps: weighing the regenerative lubricating oil and the talcum powder according to required weight portion and placing the regenerative lubricating oil and the talcum powder in a utensil; and stirring the weighed regenerative lubricating oil and the talcum powder at a temperate of between 15 and 30 DEG C to wet and disperse the mixture evenly, and dissolving and mixing the mixture to form a deposit-free white preparation. The method has the advantages that because the talcum powder has better antisticking effect and flow aid effect, the talcum powder can fill concave parts on the surface of wood grain after being mixed with the regenerative lubricating oil, so as to avoid the wood grain from permeating concrete during casting the concrete; at the same time, the talcum powder has hydrophilicity and is mutually merged with slurry in the concrete, the wood grain is shown on the concrete surface clearly after a mould is removed, and the concrete surface is not easily strained when a moulding board is removed; and the method has simple processes, low cost and wide application, and the template for smoothening a common surface can be repeatedly used for about 10 times without being painted anew.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Technique for coating cermet on inner and outer round surface of mechanical parts

The invention relates to a technique for coating metallic ceramic onto inner and outer circular surface of mechanical parts according to extrusion molding principle, which belongs to the field of mechanical machining. According to the extrusion molding principle in powdery metallurgy, metal ceramic solid micro powder and organic binder are uniformly melted into pasty, the metal ceramic in paste is uniformly coated onto the working surface by an injection coating machine, the working surface is compactly modeled by induction melting process, and organic binder is removed in the molding blank, and production of hydraulic cylinder metal ceramic coating is finally completed after grinding by a diamond wheel and polishing machining. Comparing with the prior art, the invention is high in surface rigidity, durable for corrosion, and abrasion resistant for the coating layer, so that the life of the hydraulic cylinder is prolonged. No substance harmful or toxic to human is generated, no air and environment pollution occurs during manufacturing process of hydraulic cylinder coated with metal ceramic or ceramic.

Owner:JIANGXI HUAWU HEAVY IND

Connection process for hand-made bag

The invention discloses a connection process for hand-made bags. The process is as below: cutting a whole leather into a front piece, a back piece, bound edges and connection leather strips; punching needed holes by a punching tool; fixing and positioning by glue, and using the connection leather strips to connect the front piece, back piece and bound edges, wherein the connection employs a route in the "8" shape to form wheat-like laces; arranging spring bones for supporting in the front piece and the back piece inside and between the connection leather strip; and finally sewing a zipper. The connections are connected by the connection leather strips, which are firm and not easy to sprain the leather ware; and the peripheral leather strips for protection are easy for replacement.

Owner:KAIHUI TECH CO LTD

Automobile backdoor die

The invention discloses an automobile backdoor die. The automobile backdoor die comprises a product, an ejector plate, an ejector rod, an inclined guide rod, a first mold core, a second mold core and an ejection rod, wherein an open groove is formed in the lower surface of the product, an inverted buckle is arranged on the front inner wall of the open groove, a cross rib position is arranged on the top of the open groove, the ejector plate is located below the product, the first mold core is used for forming the front inner wall of the open groove and the inverted buckle, the second mold core is used for forming the back inner wall of the open groove and the cross rib position, the upper end of the inclined guide rod is abutted with the lower surface of the first mold core, the lower end of the inclined guide rod is arranged on the ejector plate, the first mold core can be driven to disengage from the inverted buckle by the inclined guide rod, the upper end of the ejector rod is abutted with the lower surface of the second mold core, the lower end of the ejector rod is arranged on the ejector plate, the upper end of the ejection rod penetrates through the second mold core and then is abutted with the product, and the lower end of the ejection rod is arranged on the ejector plate. The invention provides the automobile backdoor die, which has the advantages of difficulty in pulling the product and high reliability.

Owner:NINGBO FANGZHENG TOOL

Wire clamping mechanism suitable for ultra-thin line spring wire

The invention discloses a wire clamping mechanism suitable for an ultra-thin line spring wire. The wire clamping mechanism comprises a base, a wire pressing piece, a limiting piece, an abutting pieceand a power output piece; the center of the base is provided with an opening groove and an opening insertion groove communicated with the opening groove, a plurality of cavities are formed below the opening insertion groove, a movable piece matched with each cavity in shape is arranged in each cavity, and each movable piece has a movement gap in the cavity corresponding to the movable piece and extends out of the cavity; and the wire pressing piece is in a T type, a wire pressing part is arranged at the lower portion and is inserted into the opening insertion groove, and the line spring wiresare arranged in gap formed by the wire pressing part and the movable pieces adjacent to the wire pressing part and gap formed between every two adjacent movable pieces in a penetrating manner. The power output piece drives the descending motion of the abutting piece, the wire pressing part can move downwards, the pressure is sequentially transmitted, and a closed pressure equivalent transmitting ring is formed, the line spring wire bears the balance pressure and is clamped synchronously, and clamping of the ultra-thin line spring wires can be achieved.

Owner:上海坤链连接器有限公司

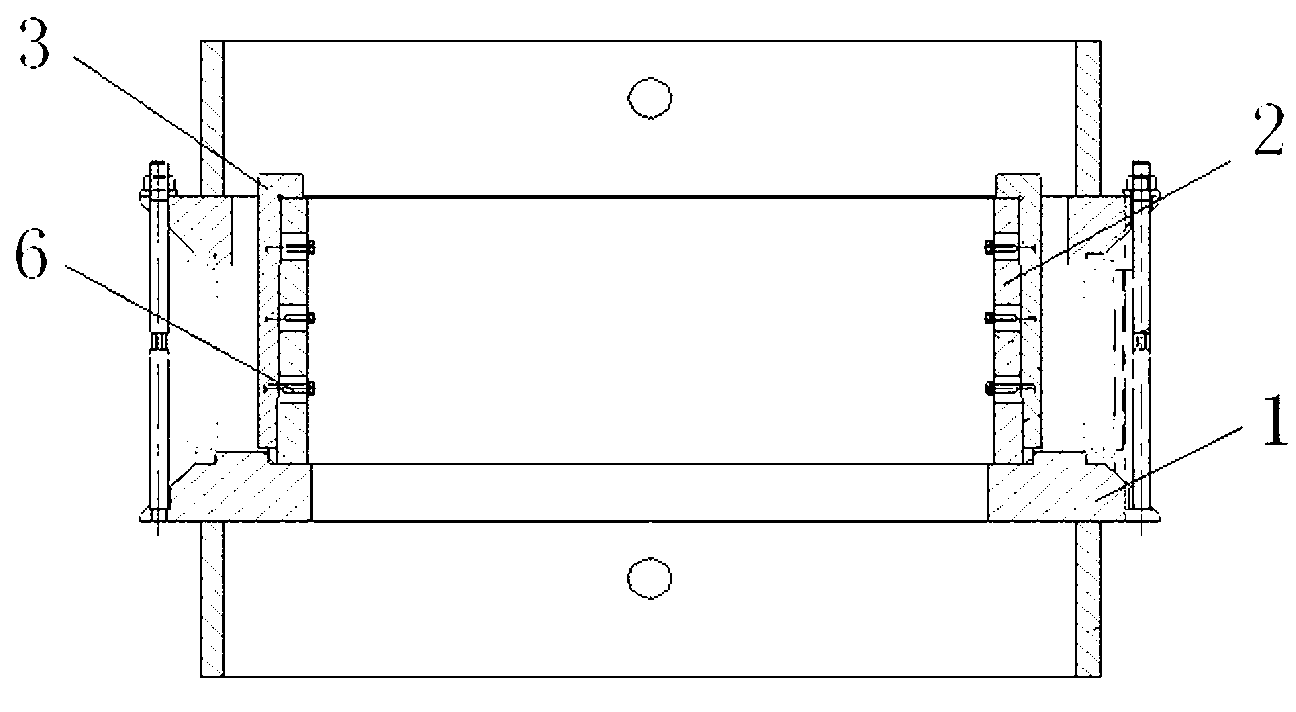

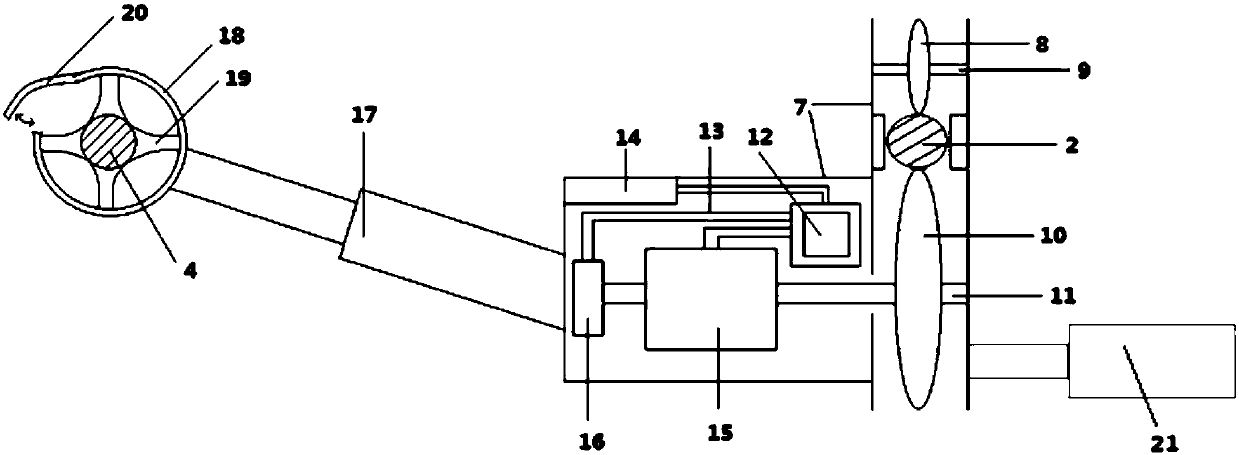

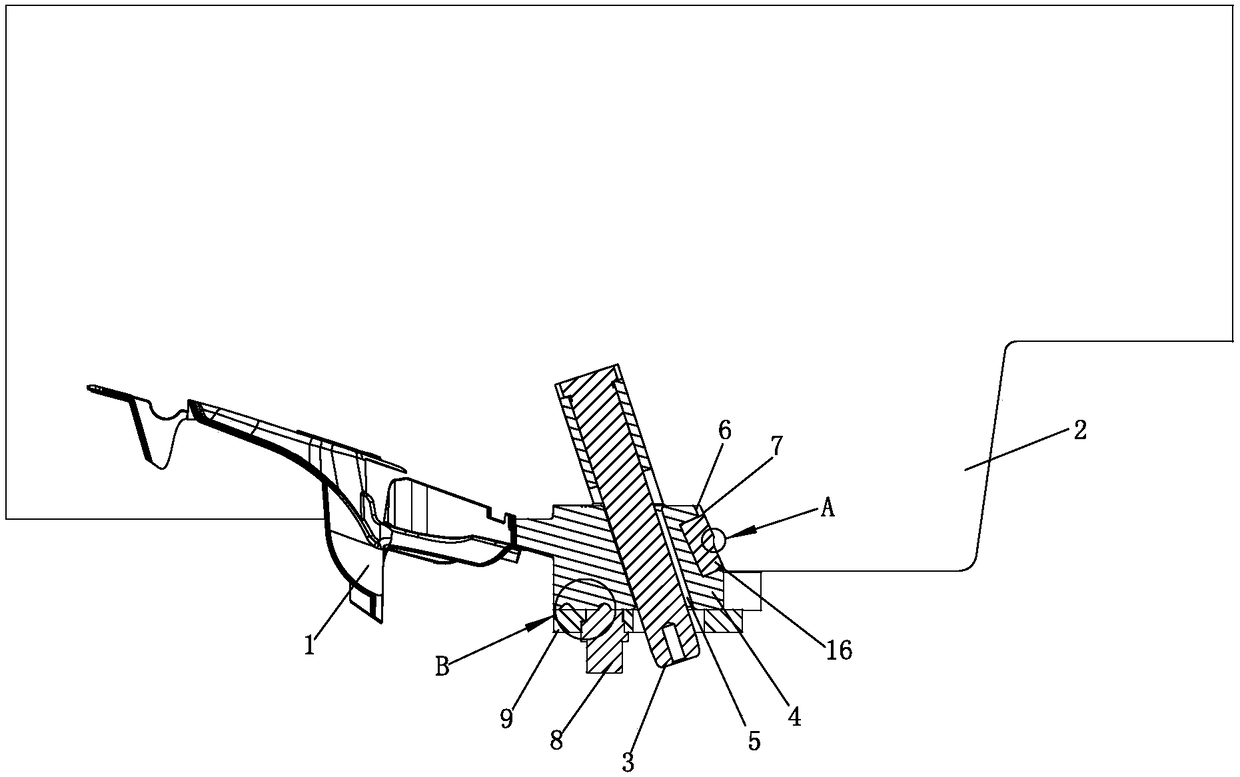

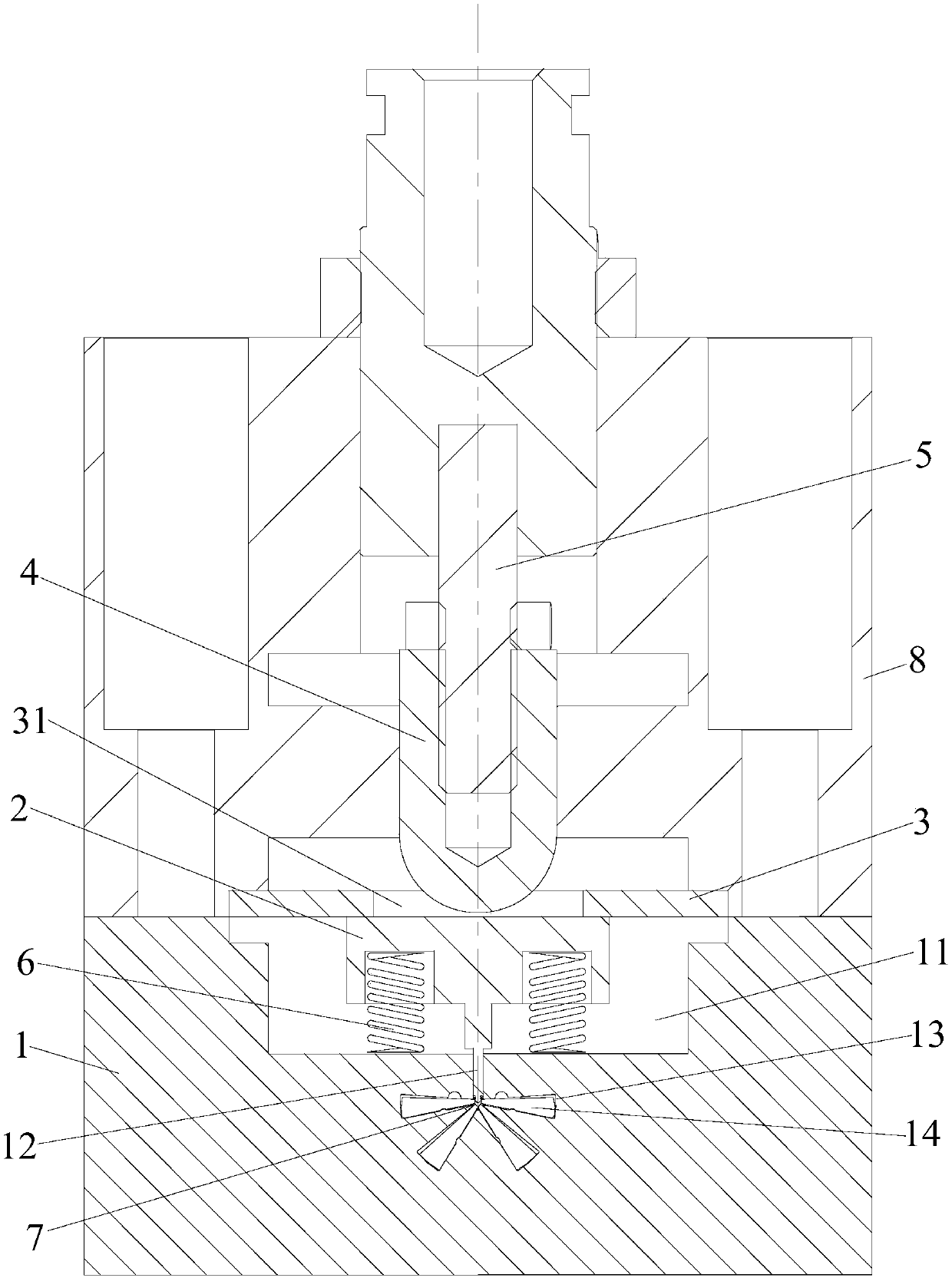

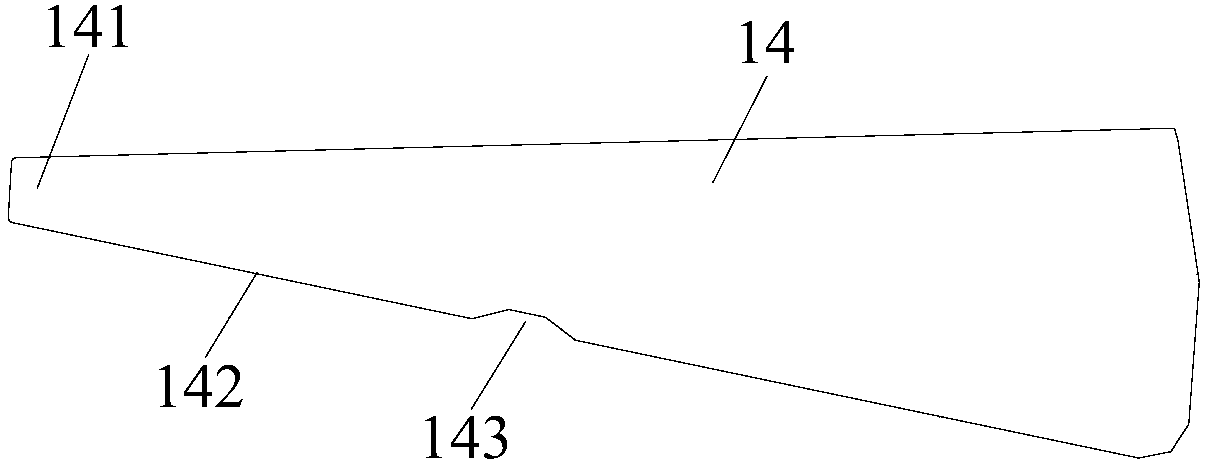

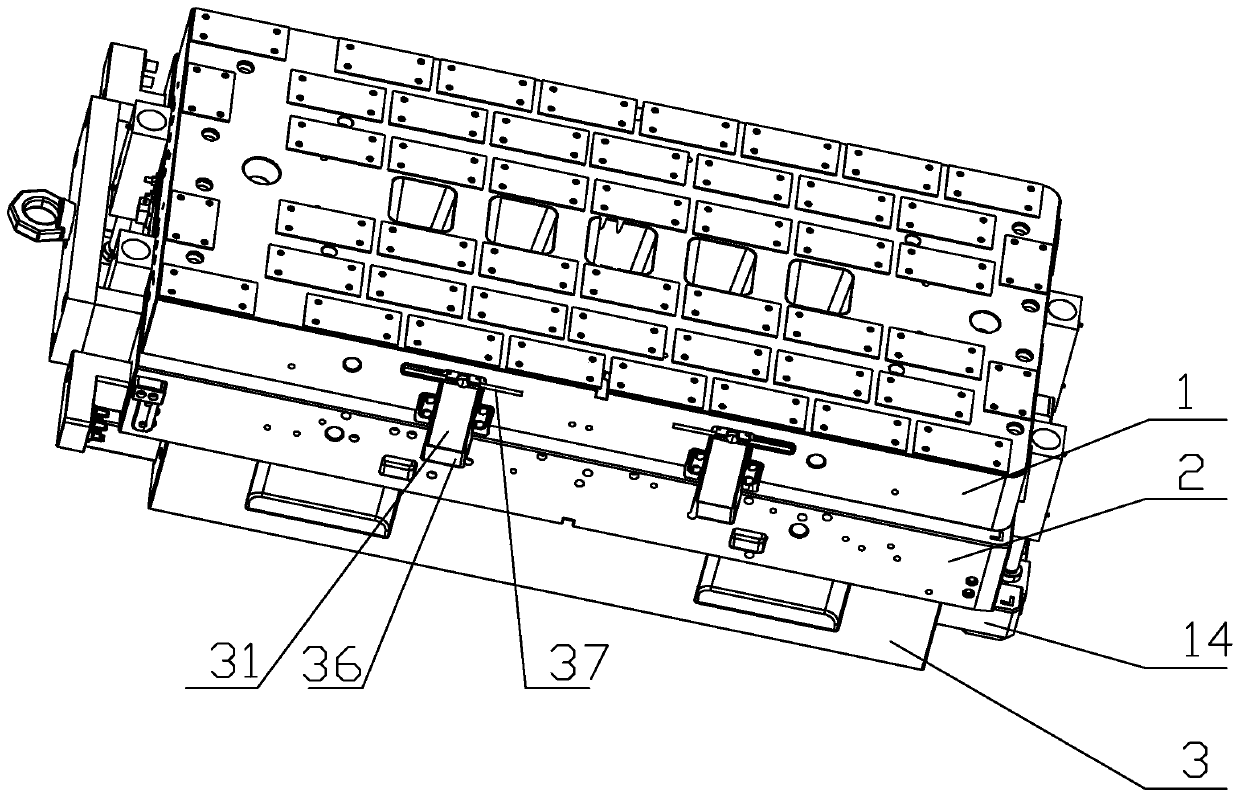

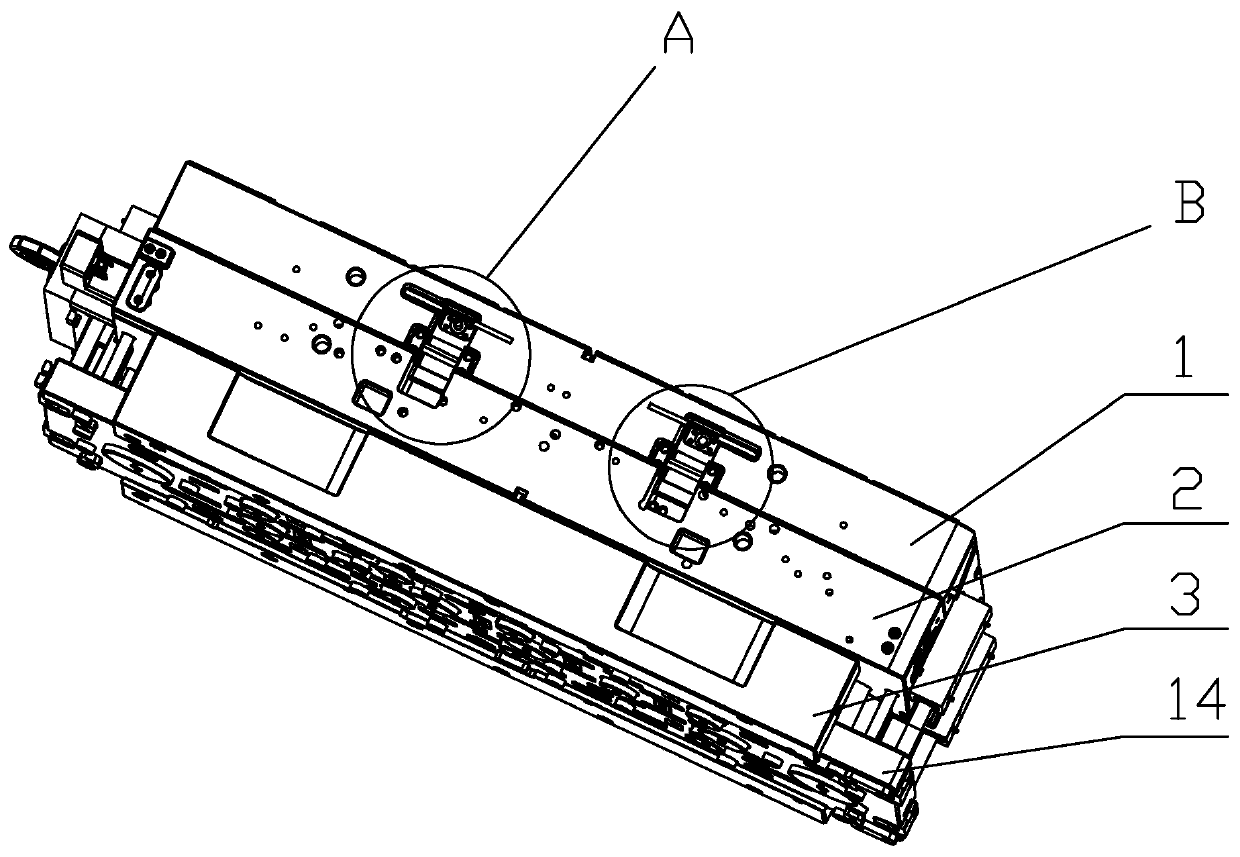

Injection mold for door scuff strips

The invention discloses a plastic injection mold for a rubbing strip of a car door. The plastic injection mold comprises an upper template (1), a lower template (2), a mold foot (3), a product (4), a pushing plate (14) and a sprue, wherein the lower template (2) is arranged on the mold foot (3) and positioned between the upper template (1) and the mold foot (3); the pushing plate (14) is matched with the interior of the mold foot (3) in a sliding manner; an upper mold cavity is formed in the lower surface of the upper template (1); a lower mold cavity is formed in the upper surface of the lower template (2); a cavity for forming the product (4) is formed between the upper mold cavity and the lower mold cavity; a plurality of first clamping grooves (5) are formed in the bottom surface of the product (4); and a bulge (6) and second clamping grooves (7) distributed on two sides of the bulge (6) are formed on the inner surface of the left side of the product (4). The plastic injection mold for the rubbing strip of the car door has low probability of straining the product, and is high in reliability and small in space occupation.

Owner:宁波如强模塑有限公司

A Wire Clamping Mechanism Applicable to Ultra-thin Wire Spring Wire

ActiveCN107650046BEnlarged activity spaceSynchronous balanced compressionWork holdersUltra fineEngineering

The invention discloses a wire clamping mechanism suitable for an ultra-thin line spring wire. The wire clamping mechanism comprises a base, a wire pressing piece, a limiting piece, an abutting pieceand a power output piece; the center of the base is provided with an opening groove and an opening insertion groove communicated with the opening groove, a plurality of cavities are formed below the opening insertion groove, a movable piece matched with each cavity in shape is arranged in each cavity, and each movable piece has a movement gap in the cavity corresponding to the movable piece and extends out of the cavity; and the wire pressing piece is in a T type, a wire pressing part is arranged at the lower portion and is inserted into the opening insertion groove, and the line spring wiresare arranged in gap formed by the wire pressing part and the movable pieces adjacent to the wire pressing part and gap formed between every two adjacent movable pieces in a penetrating manner. The power output piece drives the descending motion of the abutting piece, the wire pressing part can move downwards, the pressure is sequentially transmitted, and a closed pressure equivalent transmitting ring is formed, the line spring wire bears the balance pressure and is clamped synchronously, and clamping of the ultra-thin line spring wires can be achieved.

Owner:上海坤链连接器有限公司

Automobile rear door mold

ActiveCN110281480BNot easy to strainImprove reliabilityDomestic articlesBack doorManufacturing engineering

Owner:NINGBO FANGZHENG TOOL

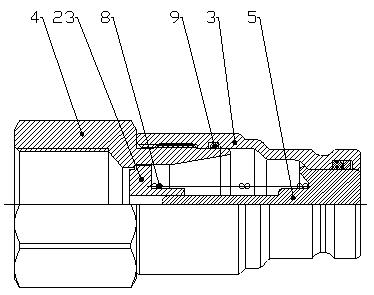

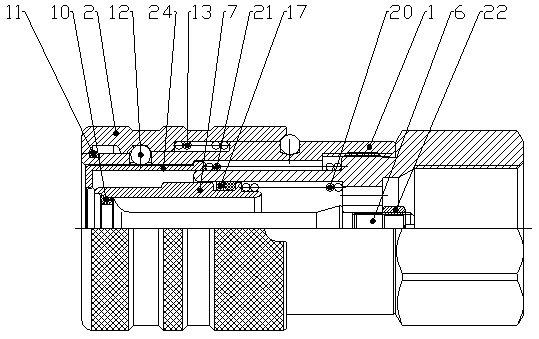

Quick joint structure made of alloy steel material

PendingCN111089210ANot easy to strainExtended service lifeCouplingsStructural engineeringWear resistance

The invention relates to a quick joint structure made of an alloy steel material. The quick joint structure made of the alloy steel material comprises a shell, an outer ring, a plug, a shell joint body and a sealing device; the plug stretches into an inner cavity of the shell and is in sliding connection with the shell; a shell valve sleeve, a shell valve core and a shell lining are arranged in the inner cavity of the shell; the shell lining is in limited sliding connection with the front end of the inner cavity of the shell; a limiting step is arranged on the outer sleeve wall of the shell valve sleeve; the front end port of the shell valve sleeve is dynamically connected with a rod head of the shell valve core correspondingly; a rod seat of the shell valve core is in positioning connection with a joint body; the front end port of the shell valve sleeve and the rod head of the shell valve core are in sliding connection with the shell lining; the shell and the plug are made of 3Cr13 alloy steel; and the 3Cr13 alloy steel has the characteristics of pressure resistance, wear resistance and the like, and the plug and shell are not liable to damage through pull when often moving, so that the whole service life of the joint body is prolonged.

Owner:JIANGXI AIKE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com