Quick joint structure made of alloy steel material

A technology of joint structure and alloy steel, which is applied in the field of pipe joints, can solve the problems of easy straining, affecting the effect of quick extraction, and the difficulty of quick extraction of connecting cannula, so as to achieve the effect of convenient insertion and increase of the overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

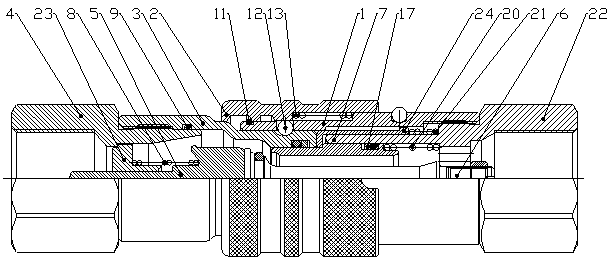

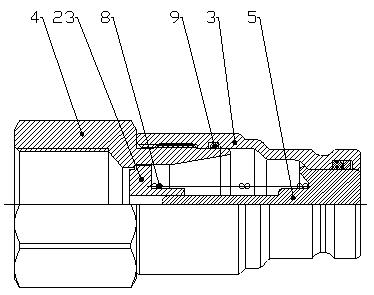

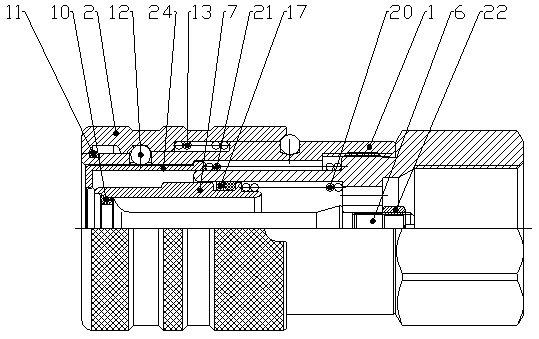

[0017] Such as Figure 1 to Figure 3 As shown, a quick joint structure made of alloy steel includes a housing 1, an outer ring 2, a plug 3, a housing joint body 4 and a sealing device, the plug 3 is set on the outside of the housing joint body 4, and the plug 3 and the An O-ring 9 is provided at the joint of the housing joint body 4;

[0018] The plug 3 extends into the inner cavity of the housing 1 and is slidingly connected with the housing 1. The material of the housing 1 and the plug 3 is 3Cr13 alloy steel. The inner cavity of the housing 1 is provided with a housing valve sleeve 7 and a housing valve core. 6 and the housing bushing 24, the housing bushing 24 is in sliding connection with the front end of the inner cavity of the housing 1, the outer wall of the housing valve sleeve 7 is provided with a limiting step, the front port of the housing valve sleeve 7 is connected to the housing The rod head of the valve core 6 is connected dynamically, the rod seat of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com