Wire clamping mechanism suitable for ultra-thin line spring wire

An ultra-fine wire and spring wire technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of being pulled, affecting the quality and efficiency of wire feeding, discounting, etc. , the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

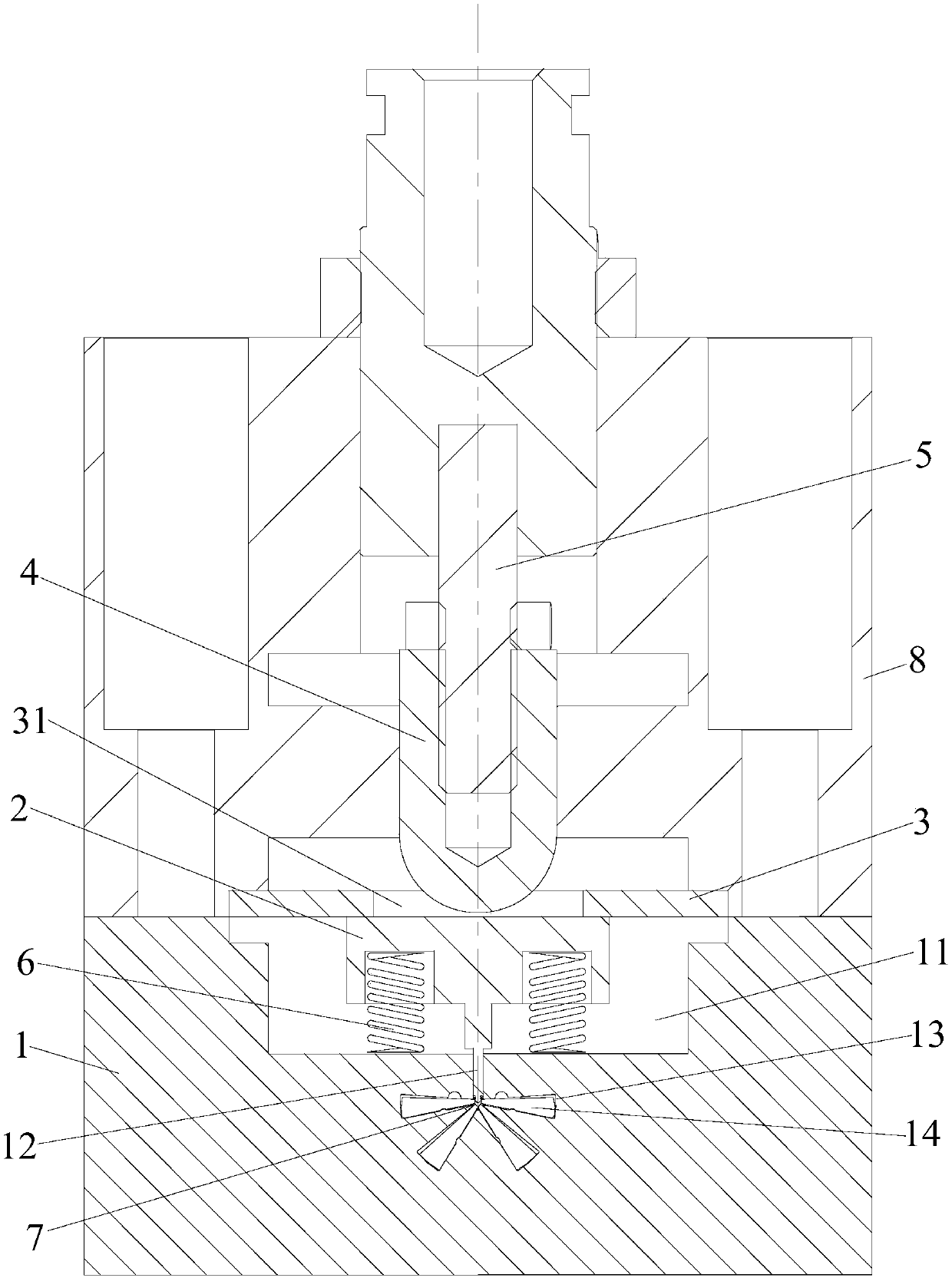

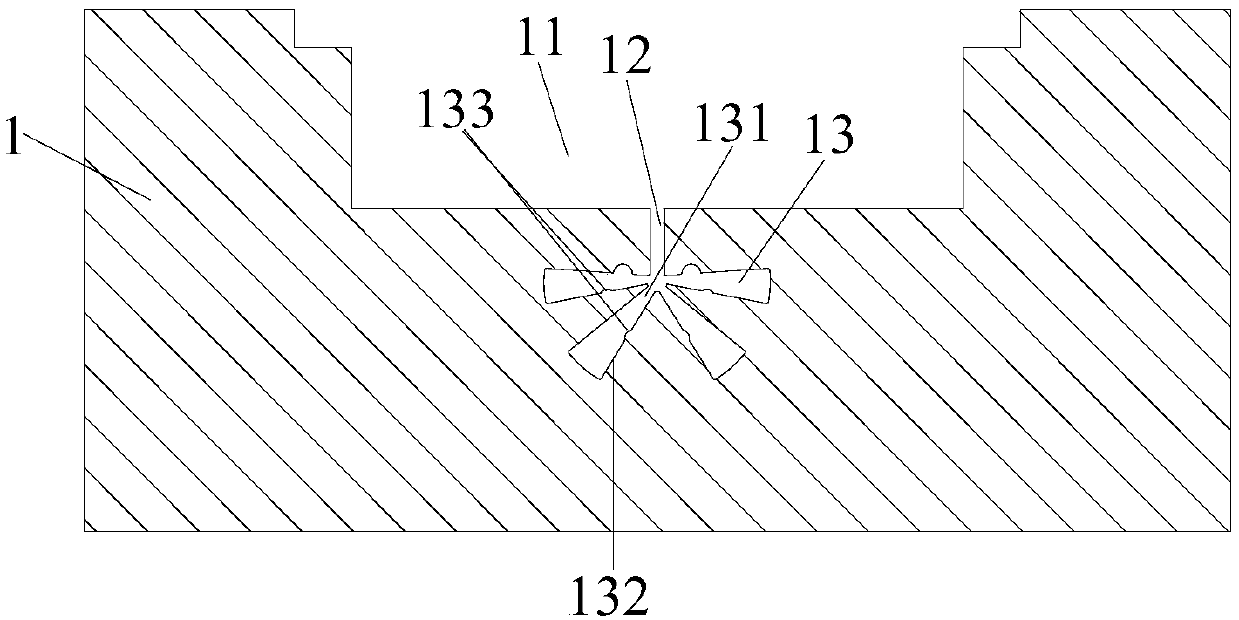

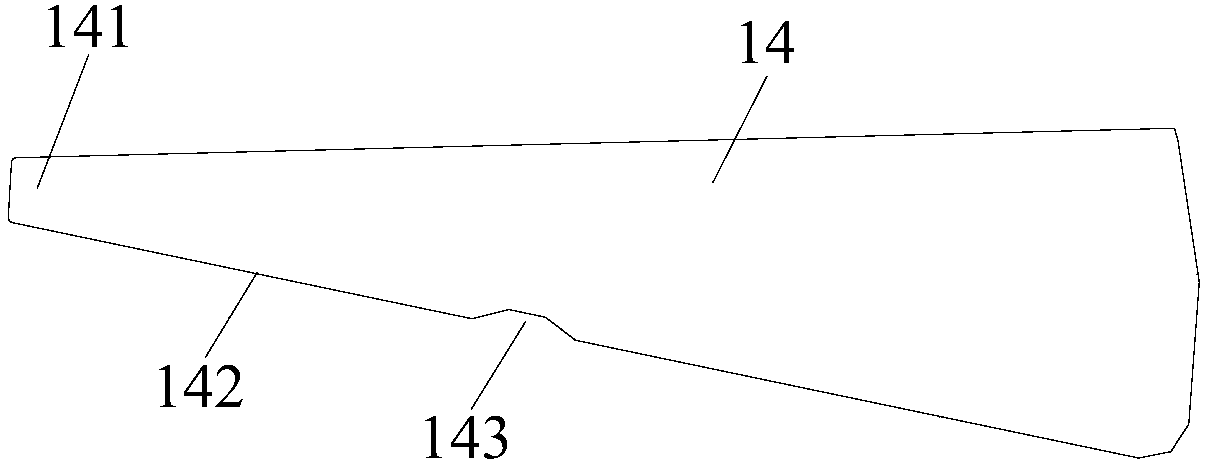

[0030] Please combine Figure 1 to Figure 8 As shown, this embodiment provides a clamping mechanism applicable to ultra-fine wire spring wire, including a base 1, a wire pressing member 2, a limiting member 3, a pressing member 4 and a power output member 5, the base 1 is provided with an opening groove 11 at the center, and an opening slot 12 is arranged at the center of the base below the opening groove 11, and the opening slot 12 communicates with the opening groove 11. The base below the slot 12 is provided with a plurality of cavities 13 centered on the lower end of the opening slot 12, uniformly radially distributed around, and left and right to form a center symmetry (the present embodiment takes 4 as an example, but Not limited to this), each cavity 13 is respectively provided with a movable piece 14 matching its respective shape, and each movable piece 14 has a movable gap in its corresponding cavity 13 and extends out of the cavity; The wire pressing part 2 is T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com