Automobile backdoor die

A technology for back doors and automobiles, which can be applied to household appliances, other household appliances, household components, etc., and can solve problems such as poor reliability and easy-to-strain products by core pulling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the drawings and specific embodiments.

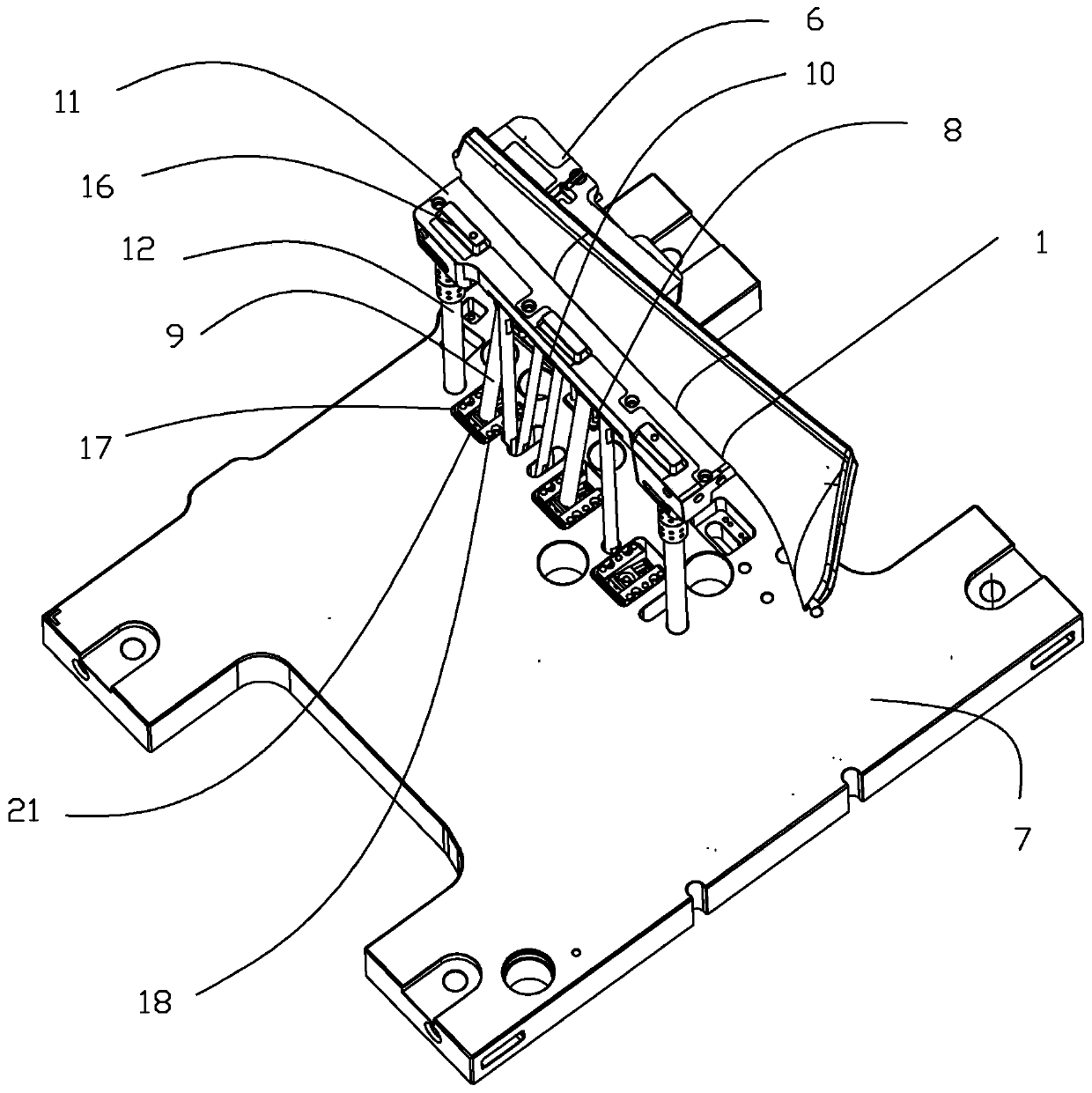

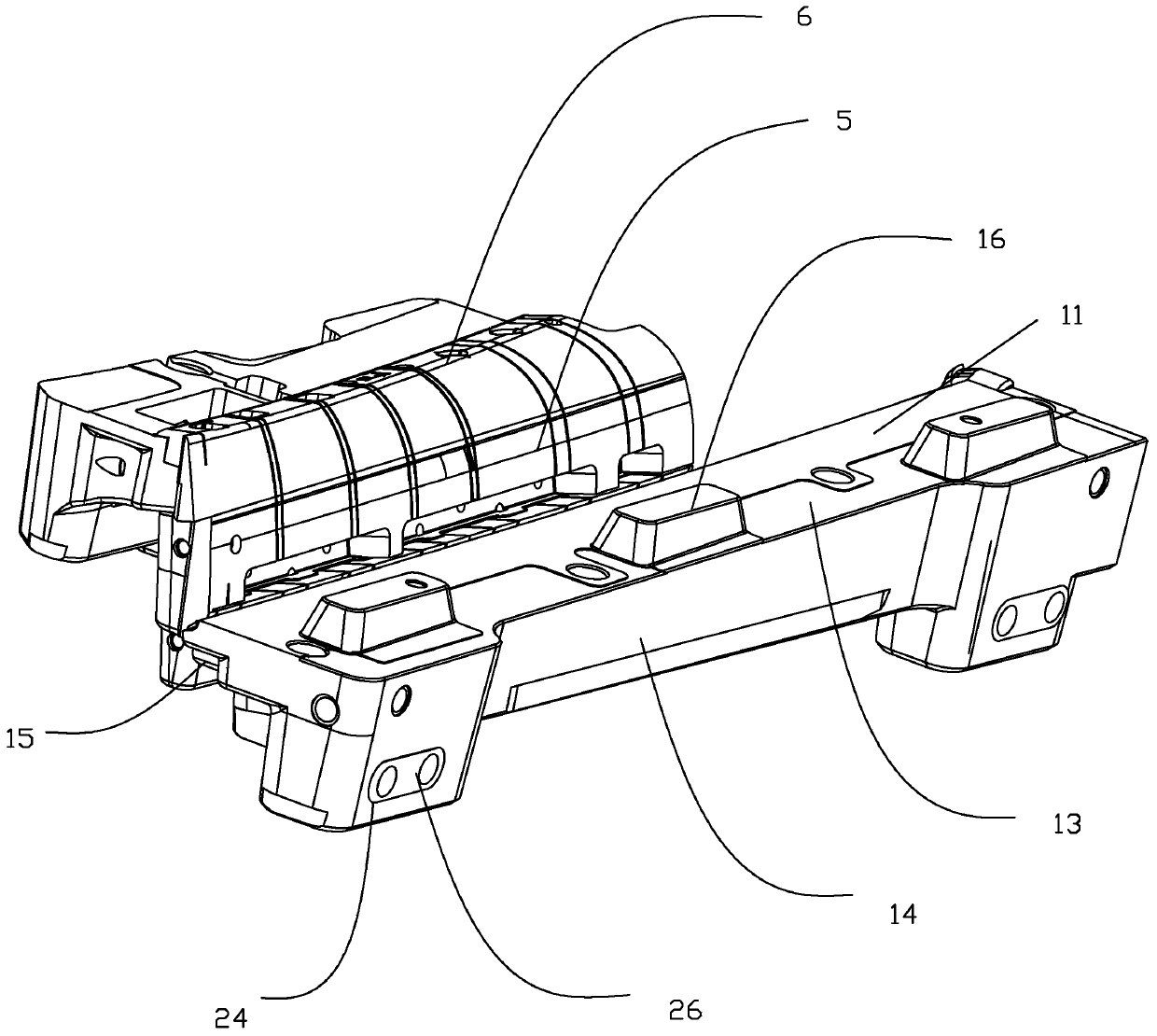

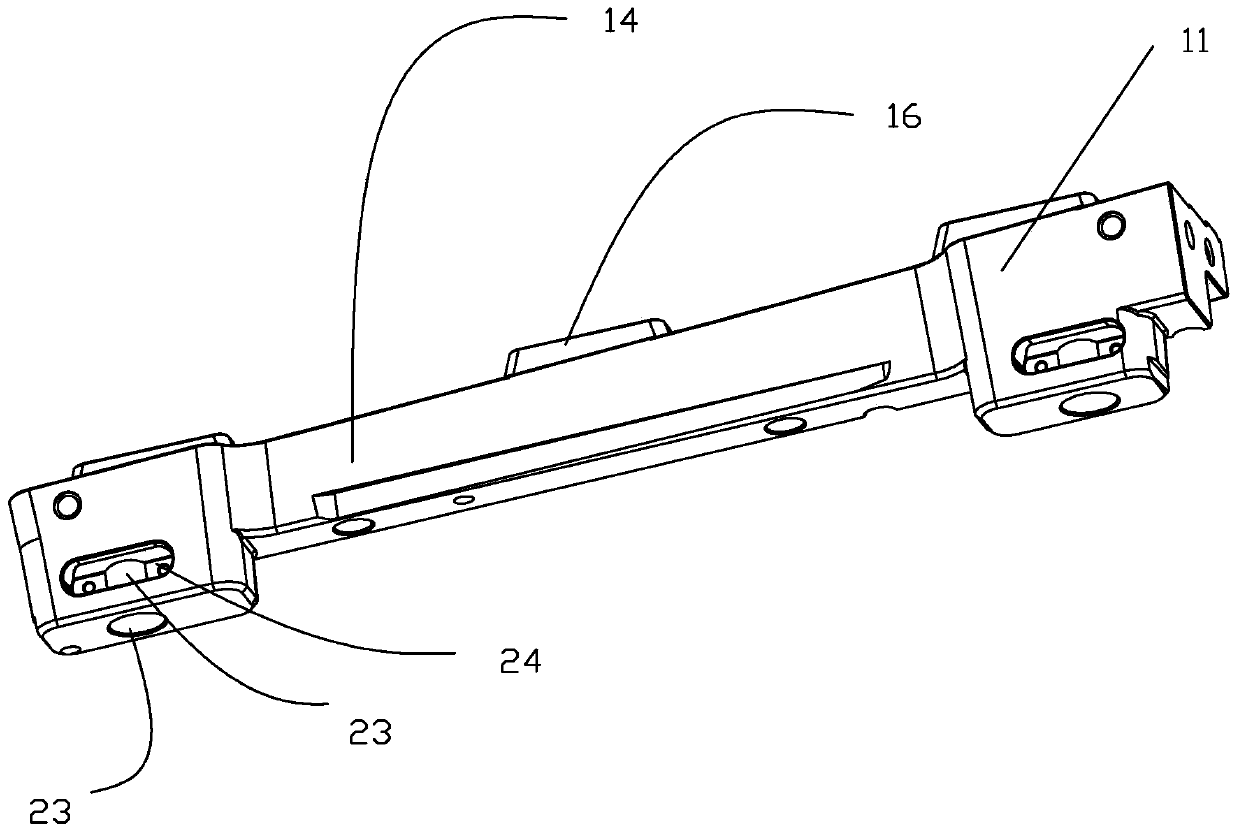

[0017] As shown in the figure, the present invention provides an automobile rear door mold, which includes a product 1, a thimble plate 7, an ejector rod 8 and an oblique guide rod 9. The lower surface of the product 1 is provided with an opening groove 2 and the opening groove 2 The front inner wall is provided with an inverted buckle 3, the top of the opening slot 2 is provided with a cross rib 4, the thimble plate 7 is located below the product 1, and it also includes a front inner wall for forming the opening groove 2 and an inverted buckle 3. The first mold core 5, the second mold core 6 and the ejector rod 10 for forming the rear inner wall of the open slot 2 and the cross rib 4, the upper end of the inclined guide rod 9 is pressed against the lower surface of the first mold core 5 , The lower end of the inclined guide rod 9 is set on the ejector plate 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com