Monofilament winding device

A winding device and monofilament technology, which is applied in the bundling of newly sprayed filaments, textiles and paper making, etc., can solve the problems of unsatisfactory length of rolled monofilaments, affecting the winding situation, etc., and achieves low friction resistance and reduced Small impact, not easy to strain or affect the effect of diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

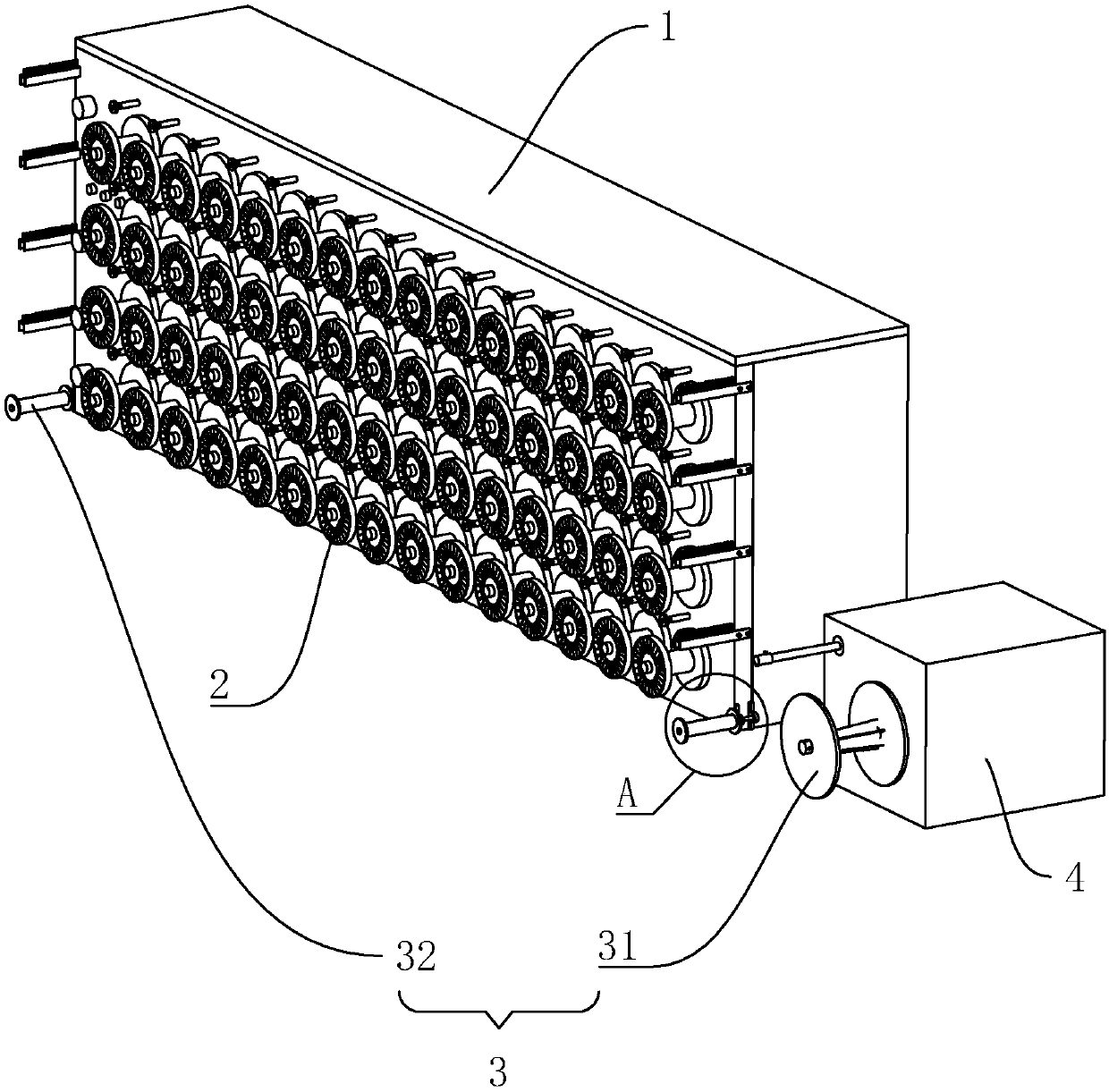

[0037] Embodiment 1: a kind of monofilament winding device, such as figure 1 As shown, it includes a rewinding panel 1, a number of rewinding rods protrude from the rewinding panel 1, the rewinding rods are perpendicular to the rewinding panel 1, and a rewinding roller 2 is set on the rewinding rod, and the rewinding roller 2 is set It is in the shape of an I-shaped wheel.

[0038] The winding rods are arranged in several rows on the winding panel 1, and the winding panel 1 is also provided with guide wheels, and the guide wheels are also provided with several rows, and a row of guide wheels is arranged between two adjacent rows of winding rollers 2 .

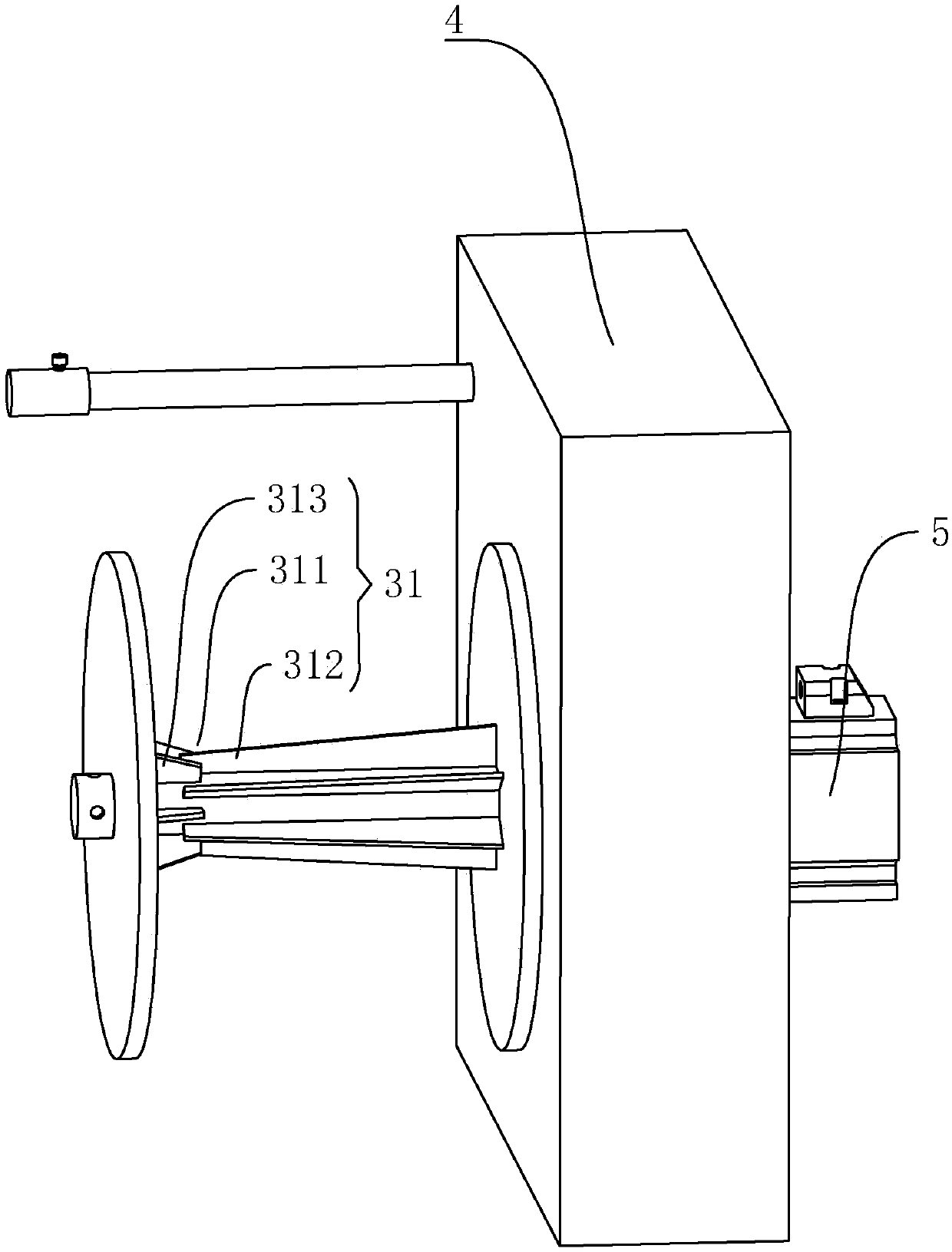

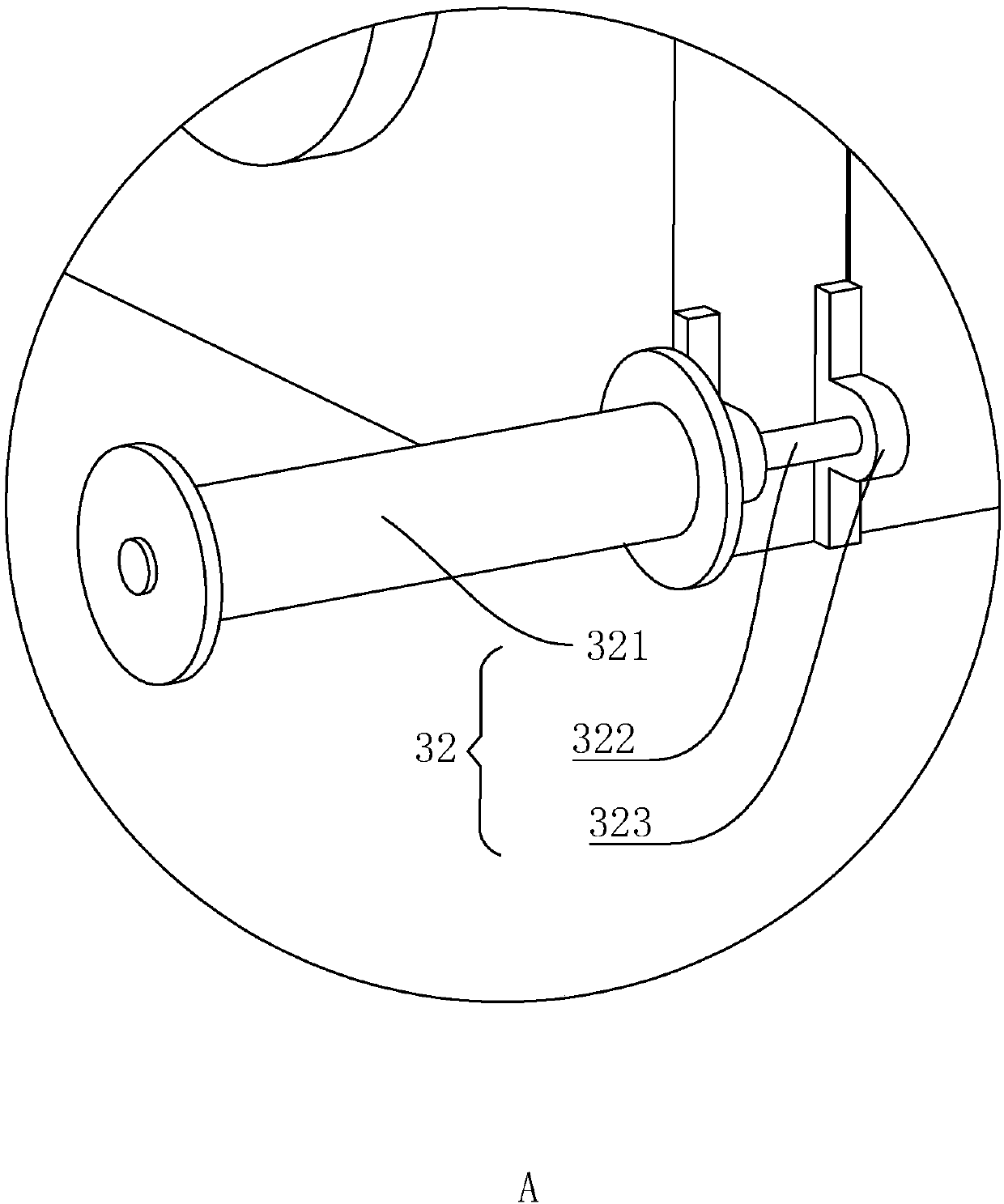

[0039] Such as figure 1 and 2 As shown, auxiliary rollers 3 are provided on both sides of the winding panel 1 , and the auxiliary rollers 3 include a driving roller 31 and a driven roller 32 . The driving roller 31 is located on the side of the winding panel 1 facing the advancing direction of the monofilament. The driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com