Skewed slot stator iron core non-pull overlying device

A technology of skewed stator and iron core, which is applied in the manufacture of stator/rotor body, etc., which can solve the problems of difficult control and easy to damage the quality of the iron core, and achieve the effects of convenient operation, easy quality control, and guaranteed angle of the inclined slot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

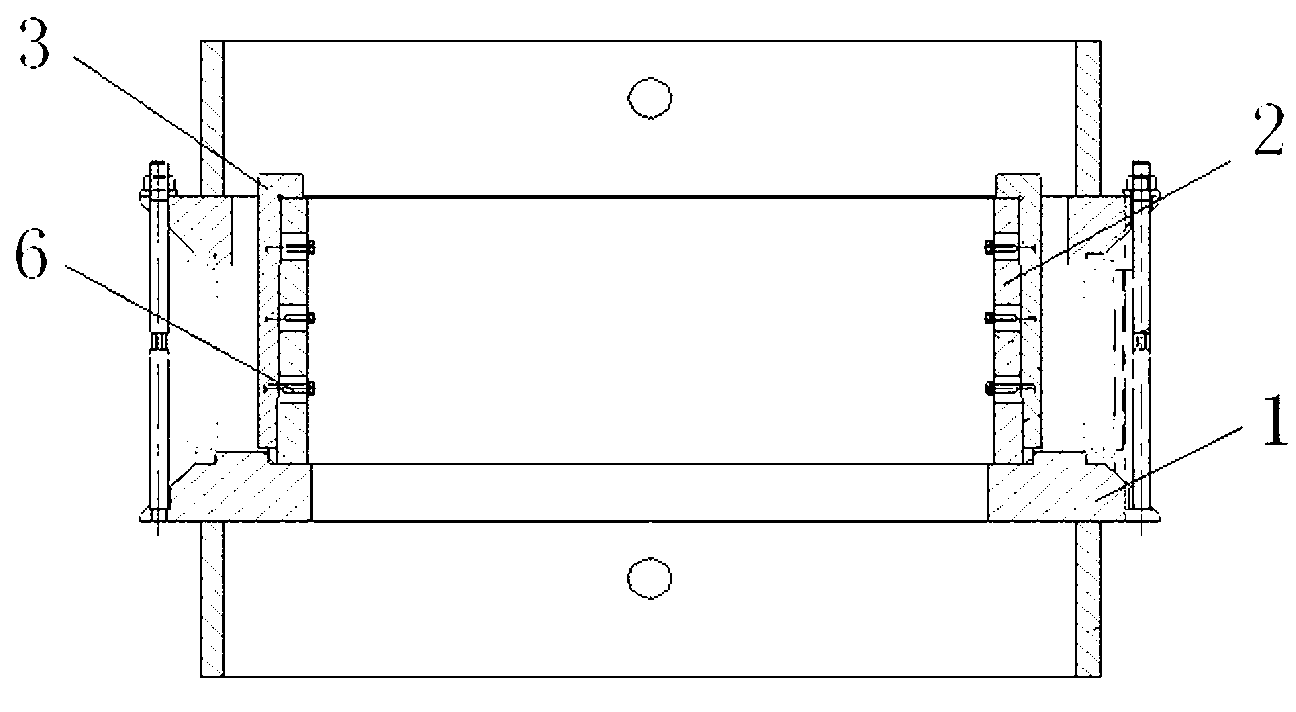

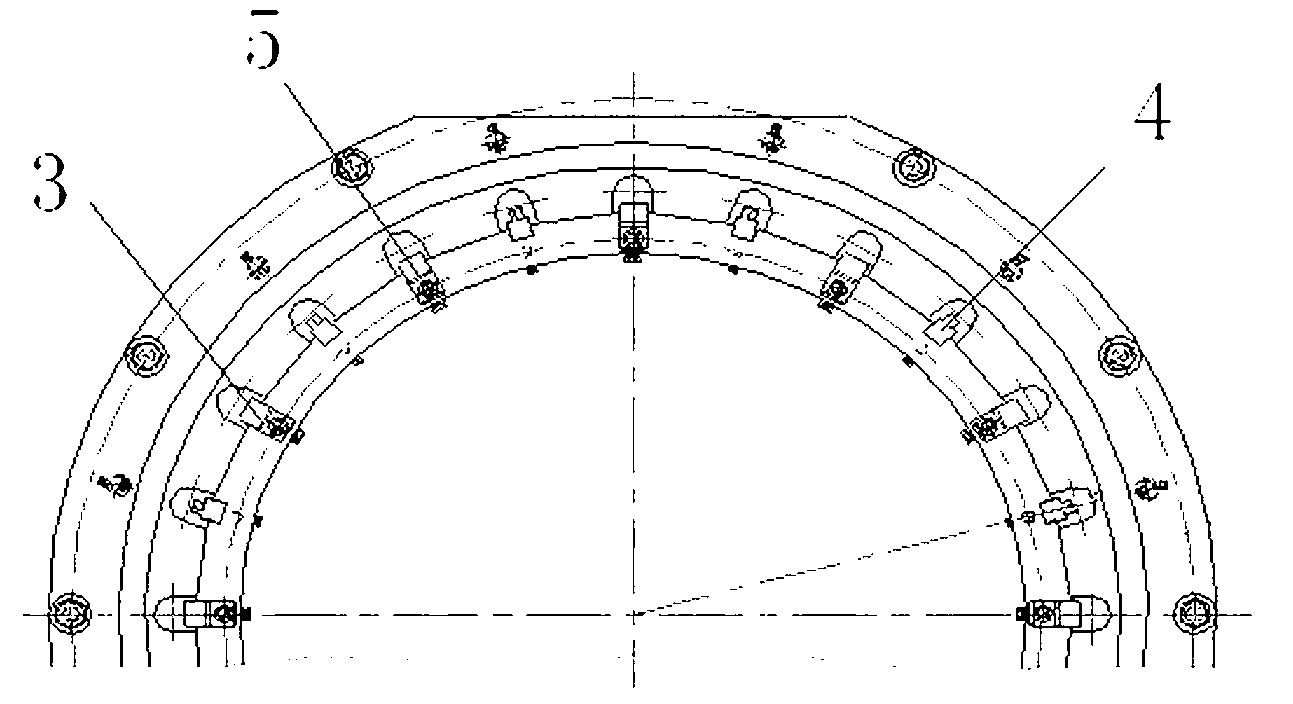

[0017] The non-strain stacking device for the inclined slot stator core includes a stacking base 1, on which a cylindrical core barrel 2 is arranged, and a number of vertical taper grooves are evenly distributed in the radial direction on the outer peripheral surface of the core barrel 2 , the taper groove is provided with an oblique wedge 3 and a positioning oblique key 4 matched with the gap at intervals, the upper end surface of the oblique wedge 3 is screwed with a top wire 5 whose lower end is in contact with the upper end surface of the core barrel 2, and the inner wall of the core barrel 2 is screwed with a The fastening bolt 6 fixed by the oblique wedge 3, and the outside of the positioning oblique key 4 is a helical structure matched with the oblique groove of the stator core.

[0018] In the specific implementation process, the diameter of the core barrel 2 is 40-50 mm smaller than the inner diameter of the iron core, and the taper of the taper groove is generally 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com