Non-hydraulic plate quenching device for steel belt continuous quenching and steel belt cooling method

A technology of a quenching device and a cooling method, applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problems such as the inability to improve the quenching efficiency of steel plates, the decrease of the thermal conductivity of the separated steel plates, and the slow cooling rate of the steel plates, etc. The effect of improving the finish and flatness, and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

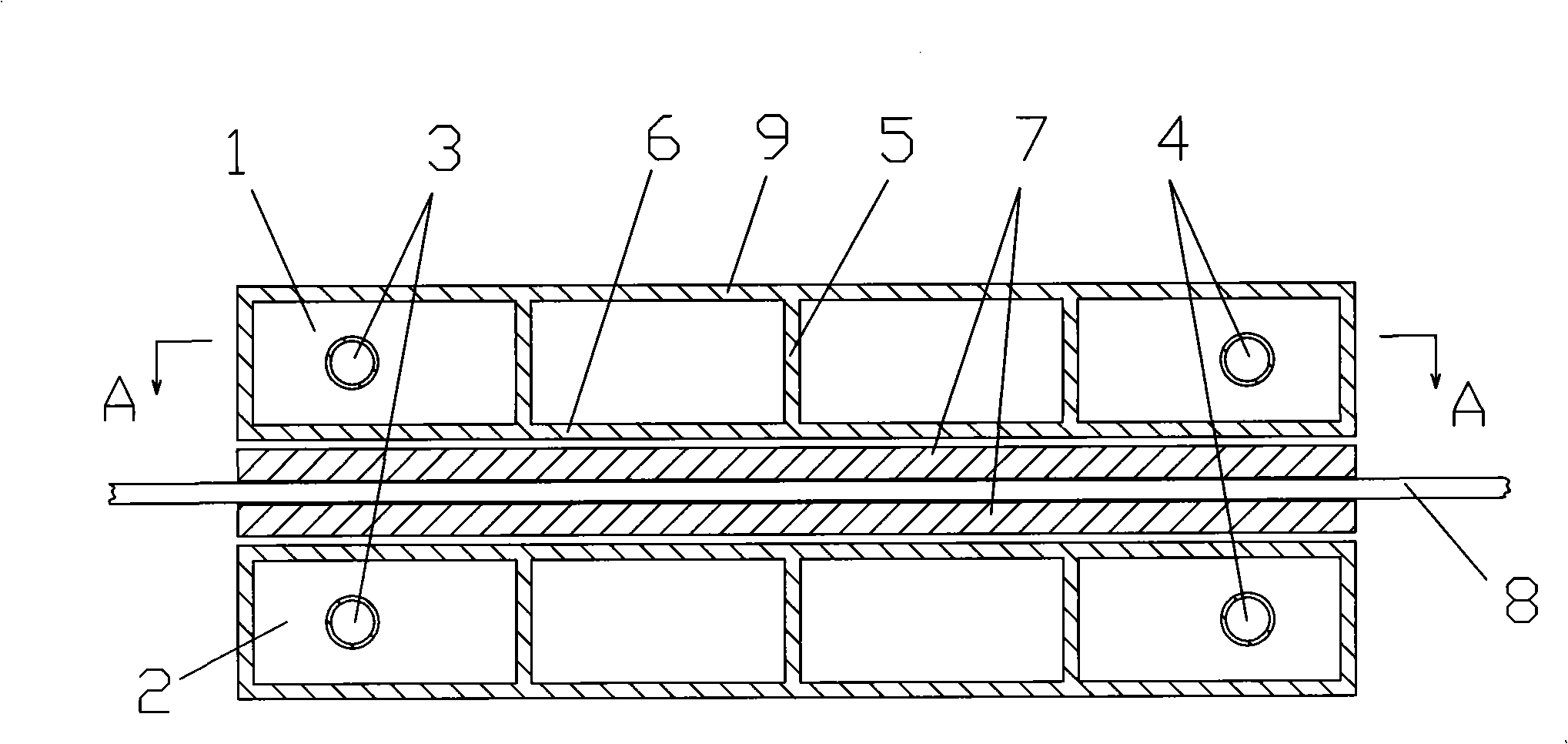

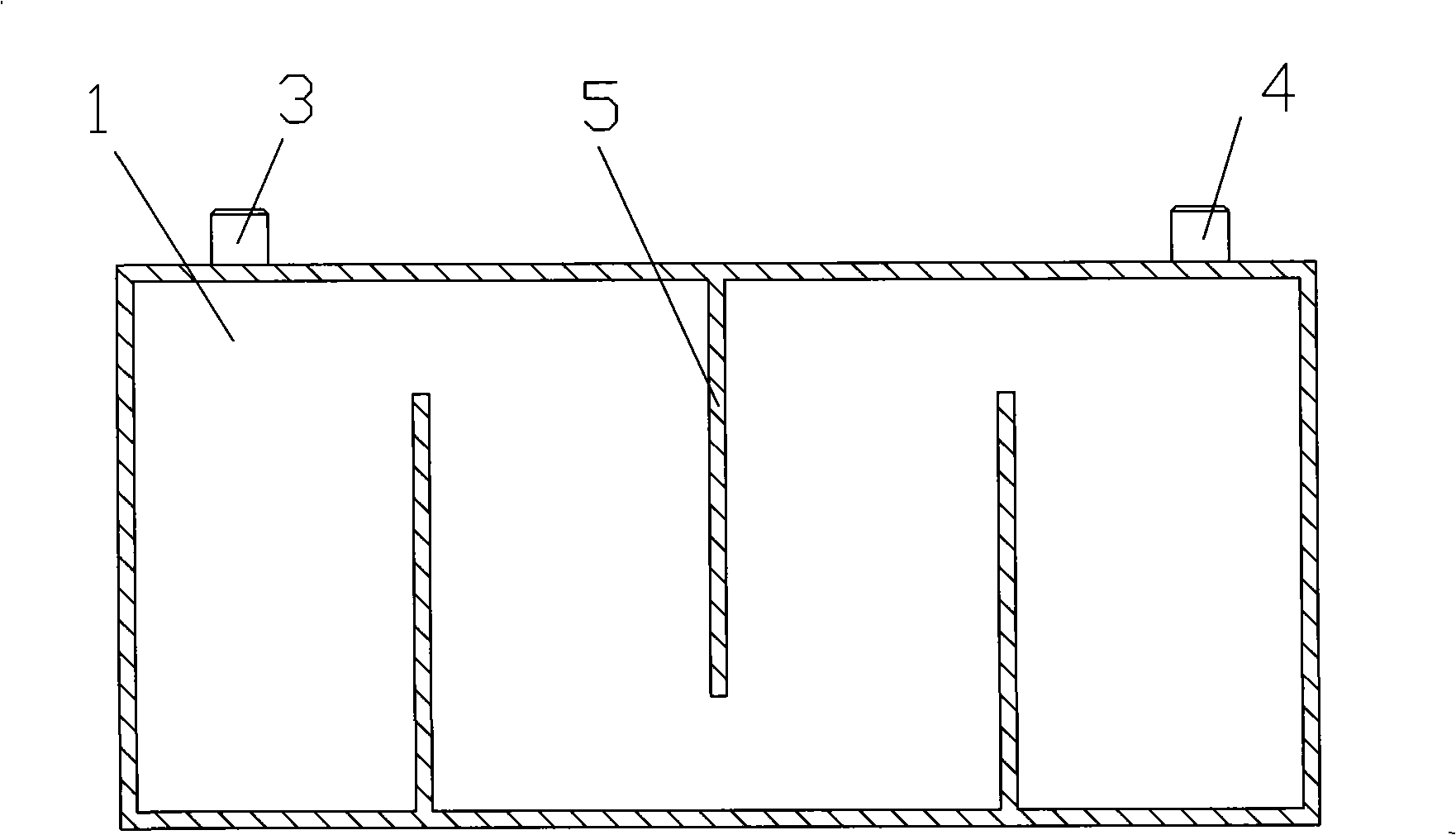

[0018] see figure 1 and figure 2 , the quenching device includes an upper water tank 1 and a lower water tank 2, and a continuously moving steel belt 8 passes between the two water tanks. The upper and lower water tanks 1 and 2 are respectively provided with a water inlet 4 and a water outlet 3. , 2 are respectively provided with three groups of water guide plates 5 for guiding the flow of water. Two water tanks are pressing plate 6 on one side close to the steel band, and the other side is loam cake 9, and water guide plate 5 is connected with pressing plate 6 and closely contacts, and is padded with protective plate 7 between pressing plate 6 and steel band 8.

[0019] The water deflectors 5 in the upper and lower water tanks 1 and 2 are usually arranged in three or five groups.

[0020] The protective plate 7 is made of materials with excellent thermal conductivity, small surface friction coefficient, high melting point, and deformability. Specifically, materials such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com