Material and method for manufacturing waterway controller

A controller and waterway technology, applied in the field of cleaners, can solve the problems of poor tensile performance, easy deformation, damage, etc., and achieve the effect of improved tensile performance and elasticity, not easy to break and strain, and good tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

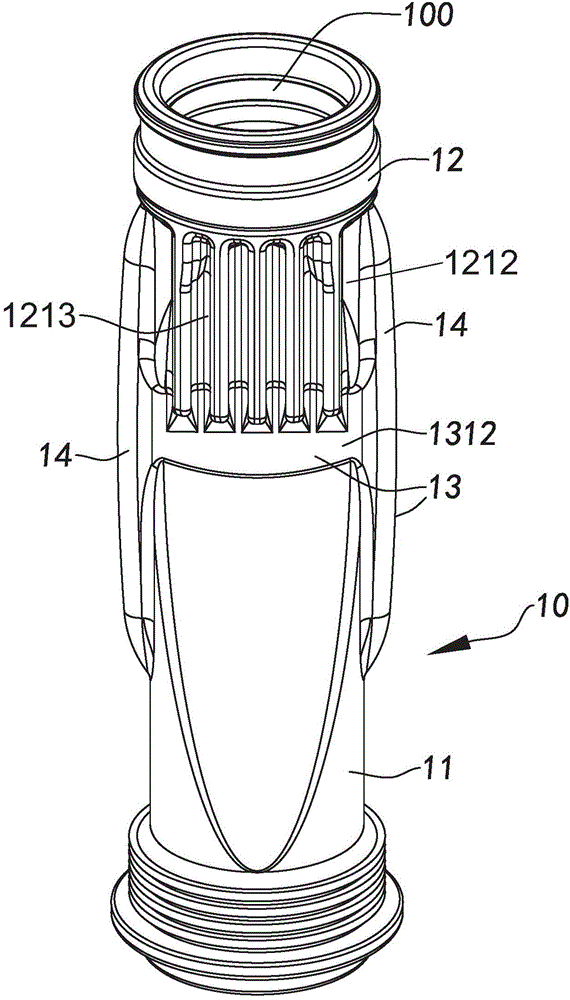

[0058] In this example, the raw materials used in the manufacture of waterway controllers provided by the present invention include silica gel, and one of reinforcing agents, release agents, vulcanizing agents, accelerators, active agents, anti-scorch agents, anti-aging agents and softeners or several. Preferably, the silica gel is gas phase silica gel.

[0059] The silica gel can withstand both high temperature and low temperature, and can be used in a wide temperature range. Its chemical and physical properties change little with temperature, and it has tear resistance, oxygen resistance and aging resistance, and good elasticity. Can vulcanize quickly.

[0060] The reinforcing agent can be white carbon black, because the smaller the particle size, the larger the specific surface area, the greater the surface activity, the higher the structure, the better the reinforcing effect, which can improve the wear resistance, strength and hardness of silica gel. The white carbon bla...

example 2

[0066] In this example, the raw materials used to manufacture the waterway controller provided by the present invention include styrene-butadiene rubber, and one or Various. Preferably, the raw material for manufacturing the waterway controller further includes ethylene-propylene rubber.

[0067] The styrene-butadiene rubber has good wear resistance, aging resistance and heat resistance, and is uniform in texture. The ethylene-propylene rubber has excellent ozone resistance, ultraviolet resistance, weather resistance and aging resistance, ranking first among general-purpose rubbers. Good chemical resistance, acid and alkali resistance, good impact elasticity, wide operating temperature range, the combination of the two, as a composite material, good elasticity, good fatigue resistance, good shock resistance, impact resistance, high tensile strength , good wear resistance.

[0068] The reinforcing agent is resin and precipitated carbon black, the vulcanizing agent is sulfur, ...

example 3

[0088] This example illustrates the manufacturing method of the present invention for manufacturing waterway controllers, wherein the raw materials used in this example manufacturing method include silica gel, preferably gas-phase method silica gel, and the auxiliary agents are respectively precipitation method white carbon black reinforcing agent, bis-pentasulfide Agent, vulcanization accelerator CZ, CTP anti-scorch agent, N-phenyl-β-naphthylamine anti-aging agent, zinc oxide active agent, polyethylene glycol mold release agent, dibutyl phthalate softener. The process steps for preparing the waterway controller in this example are:

[0089] (1) Raw materials are prepared, and the rubber is baked in a drying room at 60-70°C to make the raw rubber into small pieces.

[0090] (2) Masticating, plasticizing by means of mechanical stress and heat. The roller temperature of the plastic mixer is 30-40°C, and the time is about 15-20min. When it reaches above 120°C, continue to mastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com