Patents

Literature

255results about How to "Easy to get stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

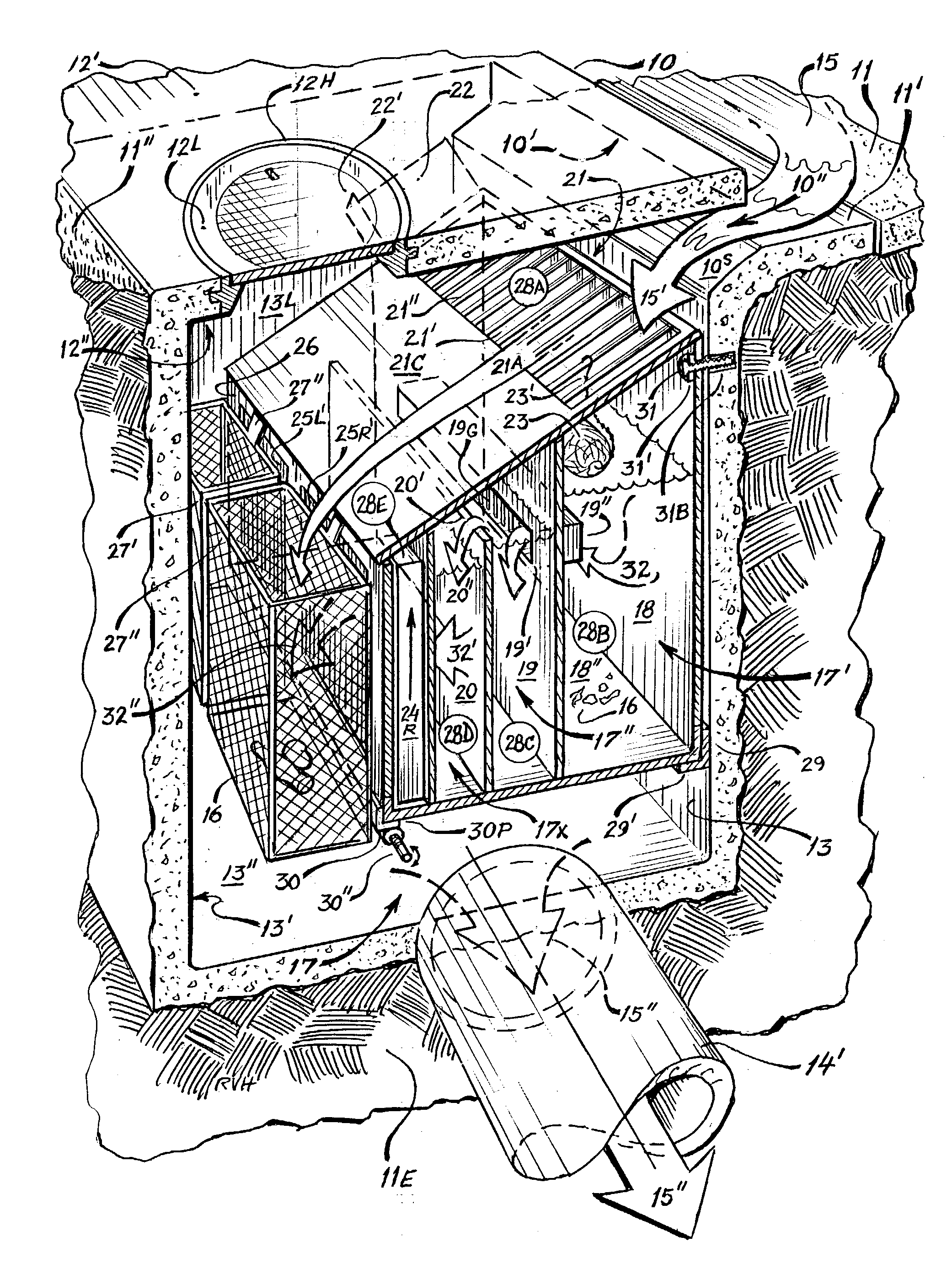

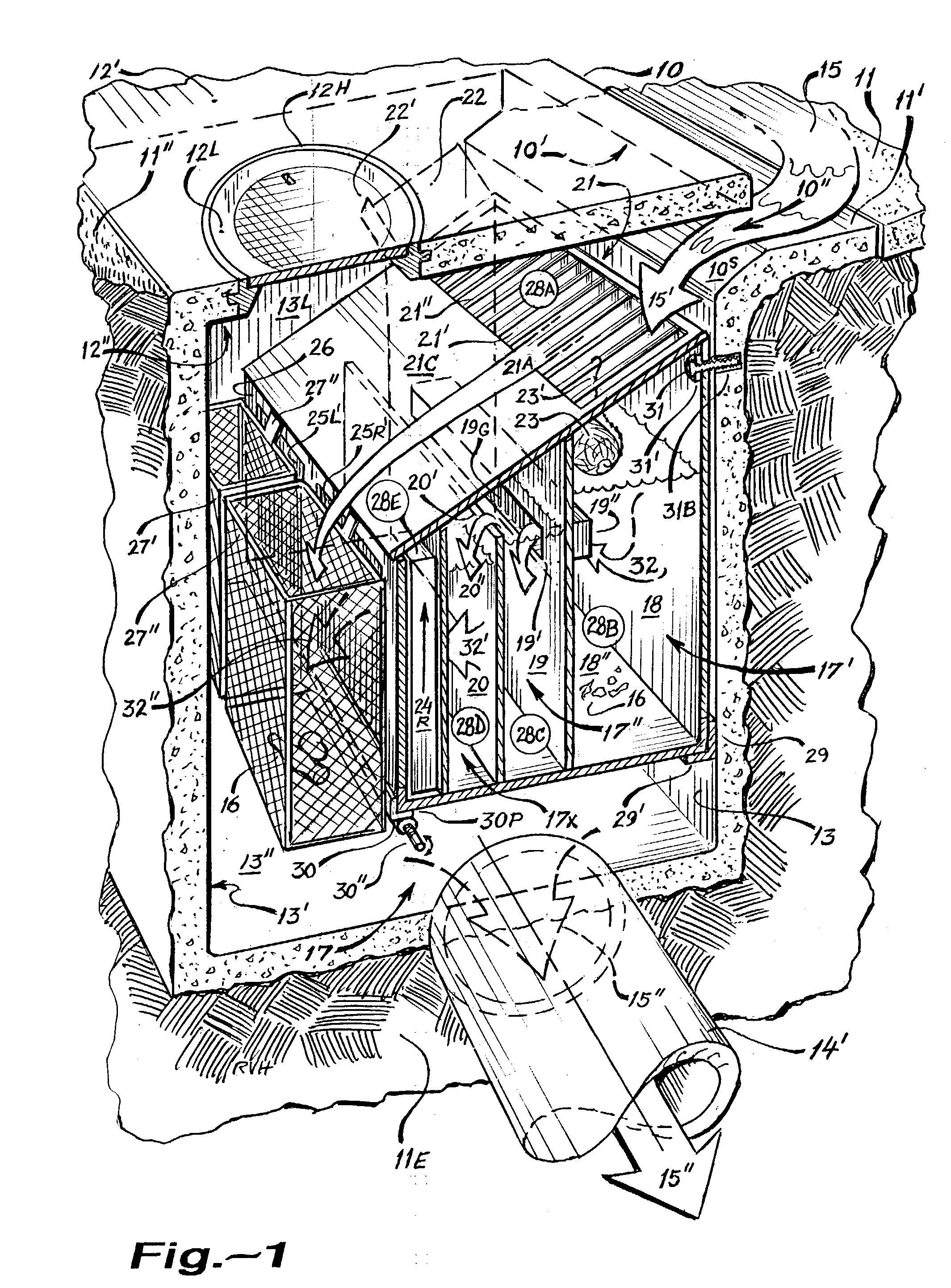

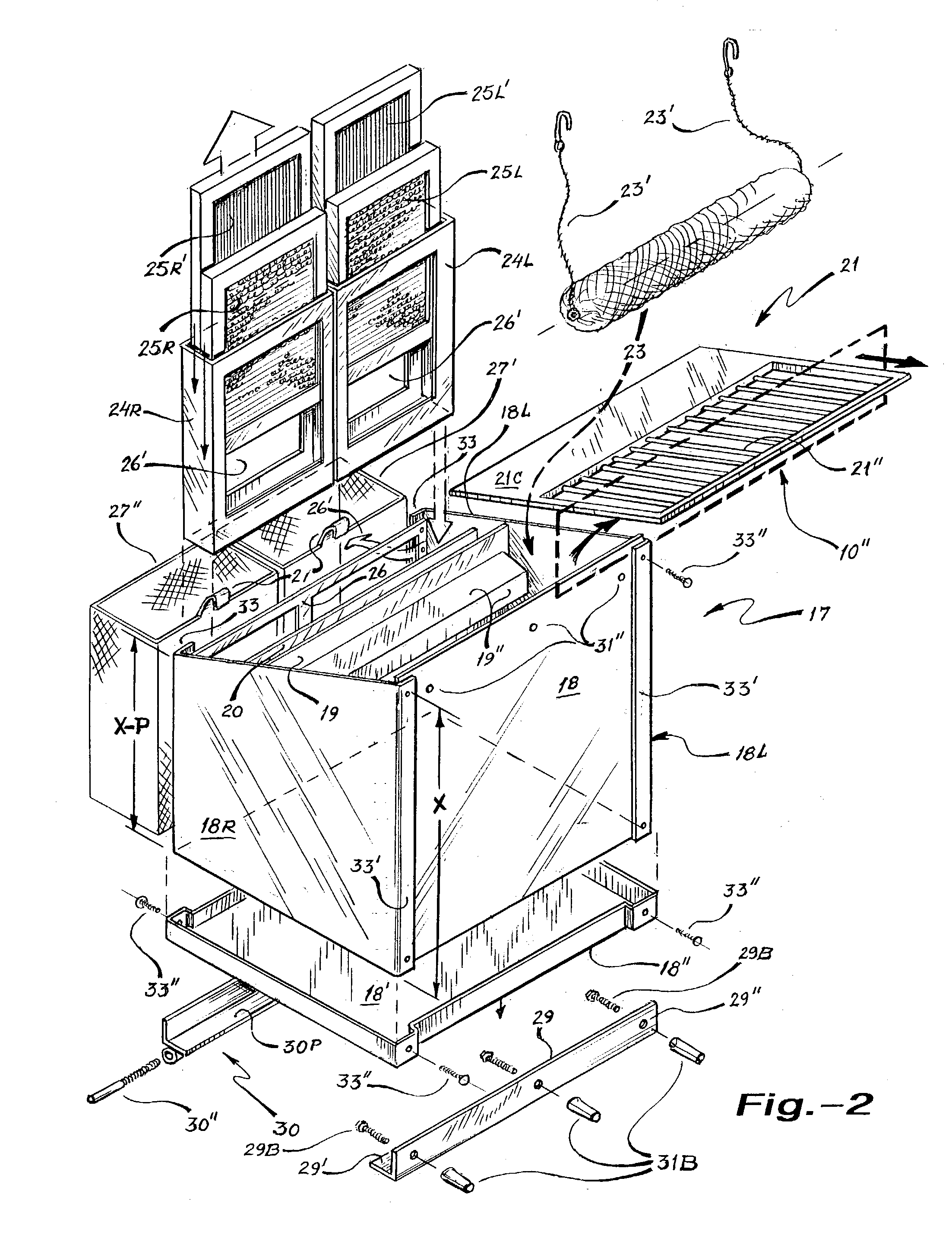

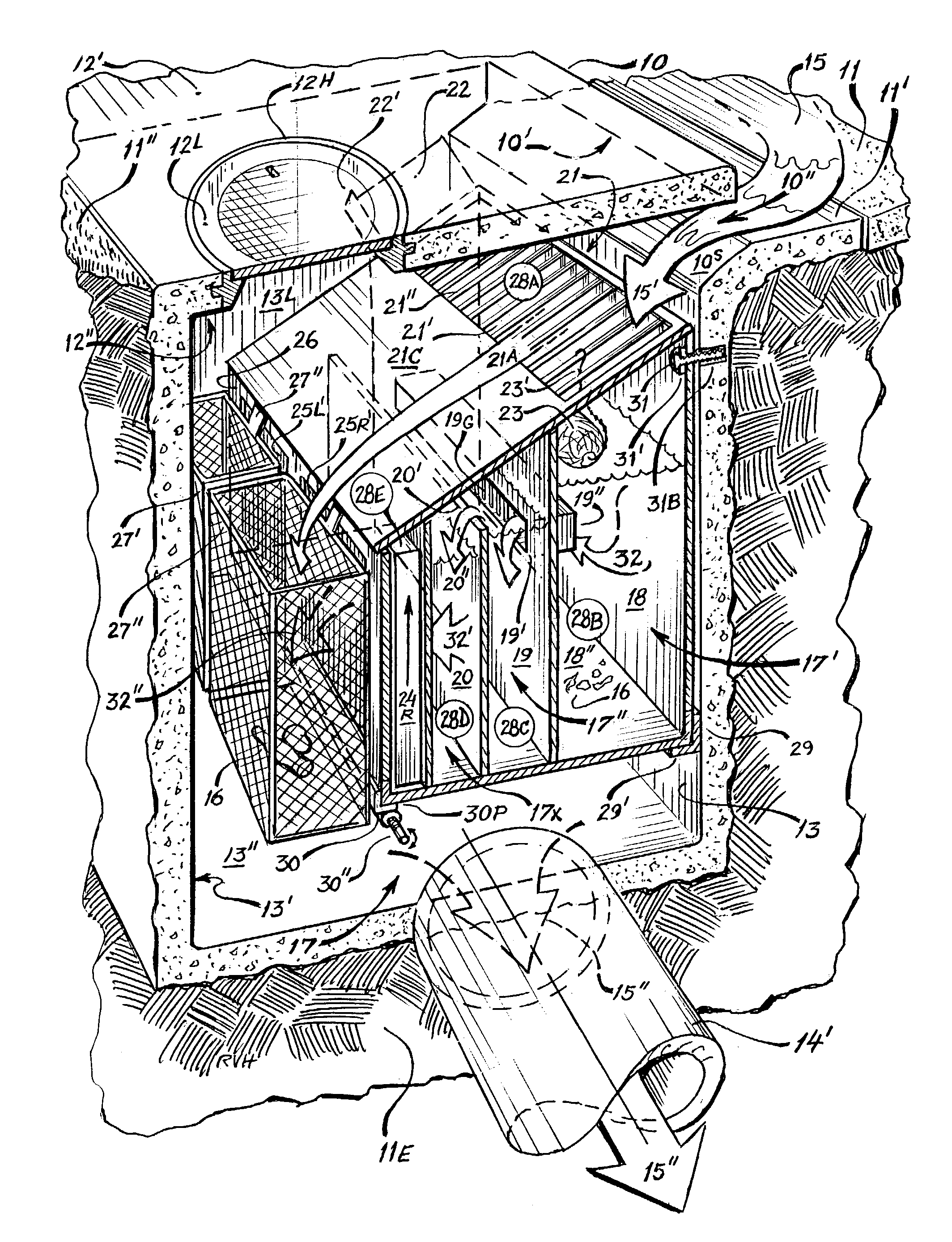

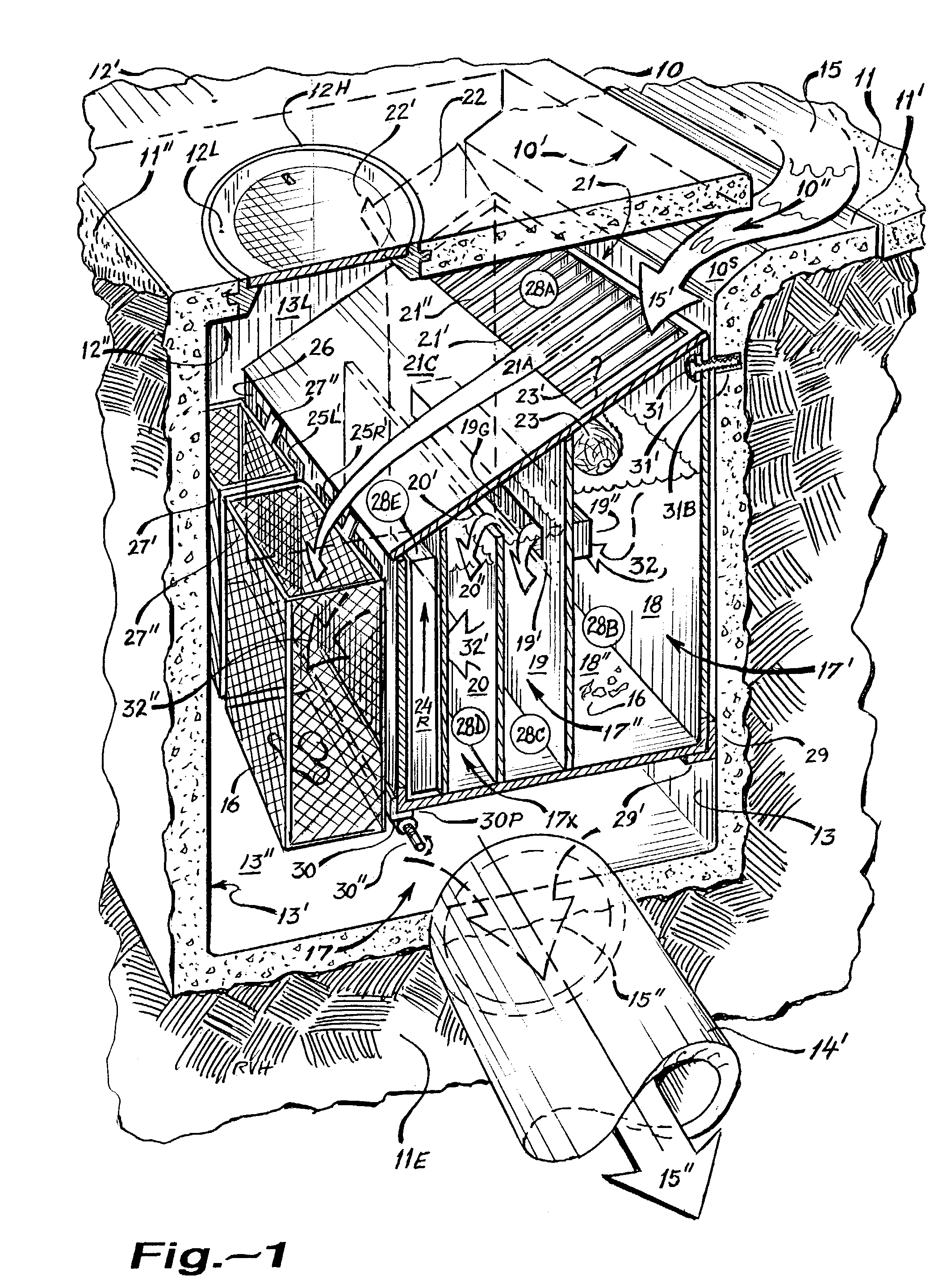

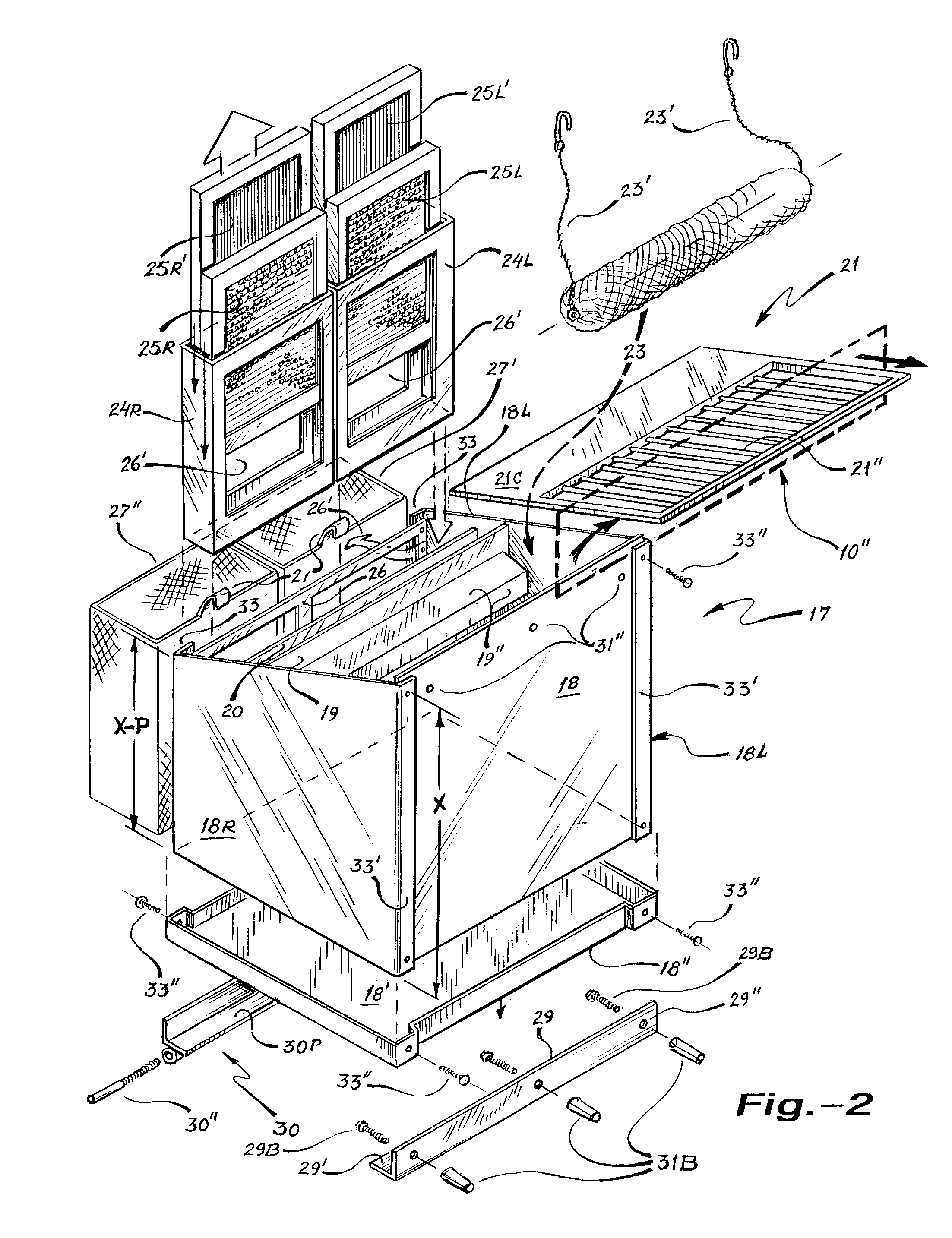

Stormdrain curb-inlet multi-stage filtration-unit

InactiveUS20040226869A1Easy to disassembleEasy accessGeneral water supply conservationPaving gutters/kerbsEnvironment of AlbaniaStorm

A hydraulic-permeation type environmental water-runoff filtration-system applicable to street curb-inlet type drainage-chambers, which generally cooperatively interconnect with street and parking-lot drains. The BLUEBAY-BMP(TM) pollution-trap provides advantage of community-tailored filtering stages, the preferred embodiment seting forth a convenient user-friendly prefabricated-kit assembly employing a basic build-in-place containment-housing which can be readily adapted to the studied needs of a given community,-without incuring alteration of existing sewer-stormdrains. The uniquely adaptative capability of the containment-housing enables selectively structuring multi-stages of filtration, which progressions address a variety of ecosystem-contaminants, ranging from basic street-refuse and floatable objects, to coarse sediment, finer silt, and comparatively minute albeit environmentally-hazardous petrochemicals, heavy-metals, phosphates, and nitrates;-all of which are readily retrieved from the apparatus confines via periodic maintenance for transfer to appropriate collection handling facilities.

Owner:STEWART D MCCLURE +3

Stormdrain curb-inlet multi-stage filtration-unit

InactiveUS7083721B2Easy to disassembleEasy accessGeneral water supply conservationPaving gutters/kerbsFiltrationPetrochemical

A hydraulic-permeation type environmental water-runoff filtration-system applicable to street curb-inlet type drainage-chambers, which generally cooperatively interconnect with street and parking-lot drains. The BLUEBAY-BMP™ pollution-trap provides advantage of community-tailored filtering stages, the preferred embodiment seting forth a convenient user-friendly prefabricated-kit assembly employing a basic build-in-place containment-housing which can be readily adapted to the studied needs of a given community,—without incuring alteration of existing sewer-stormdrains. The uniquely adaptative capability of the containment-housing enables selectively structuring multi-stages of filtration, which progressions address a variety of ecosystem-contaminants, ranging from basic street-refuse and floatable objects, to coarse sediment, finer silt, and comparatively minute albeit environmentally-hazardous petrochemicals, heavy-metals, phosphates, and nitrates;—all of which are readily retrieved from the apparatus confines via periodic maintenance for transfer to appropriate collection handling facilities.

Owner:STEWART D MCCLURE +3

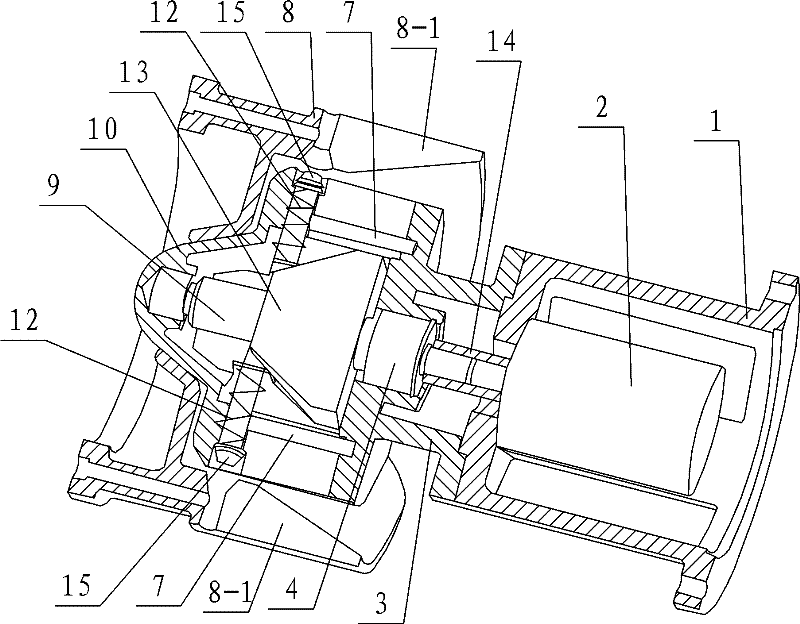

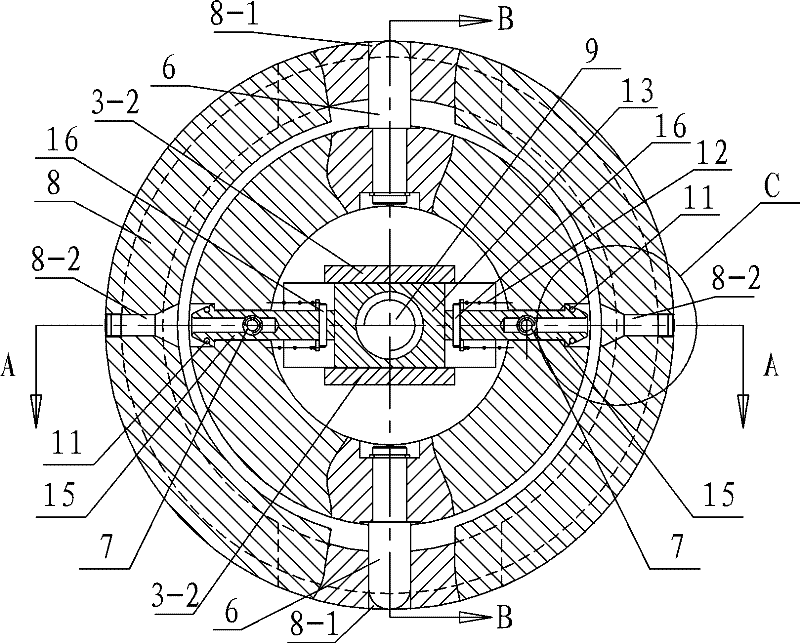

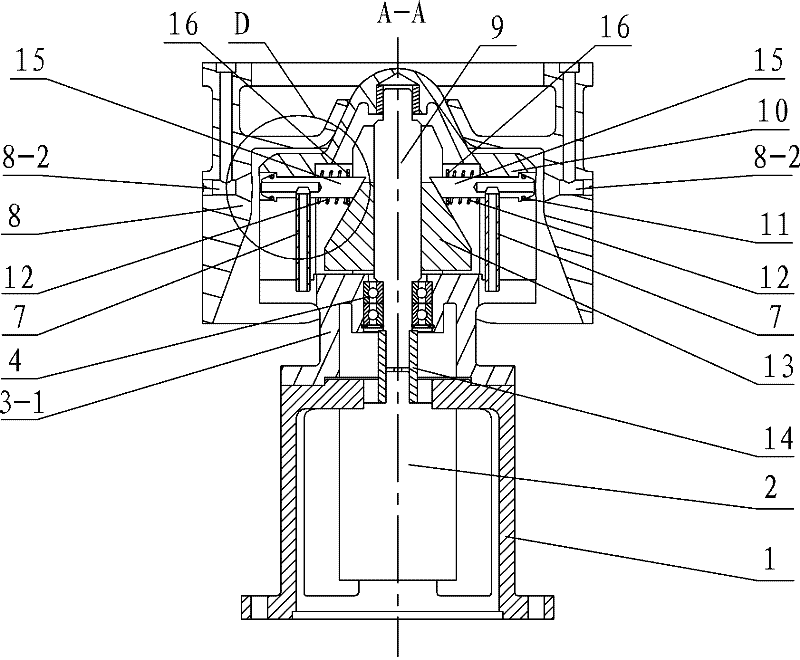

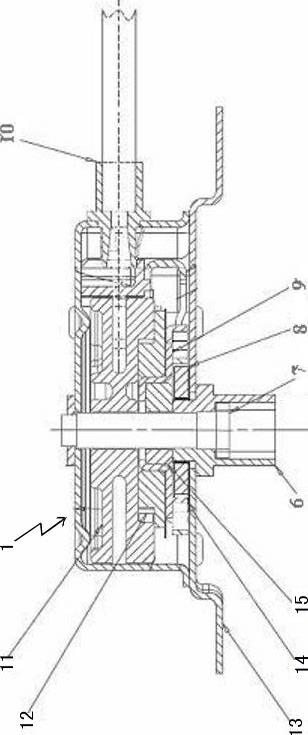

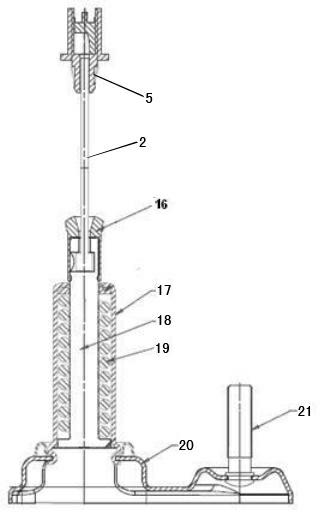

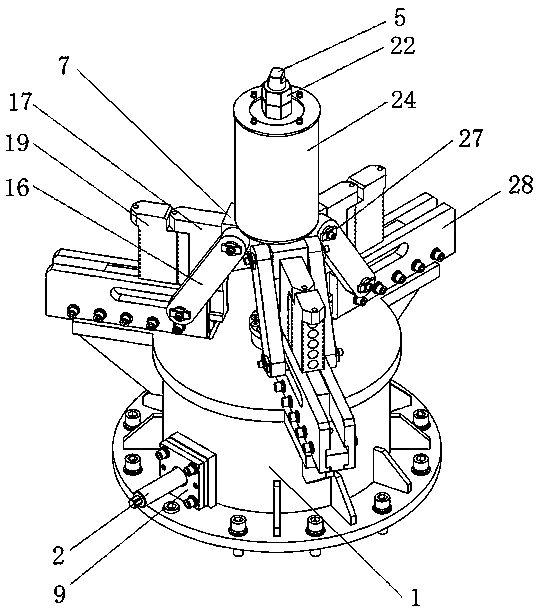

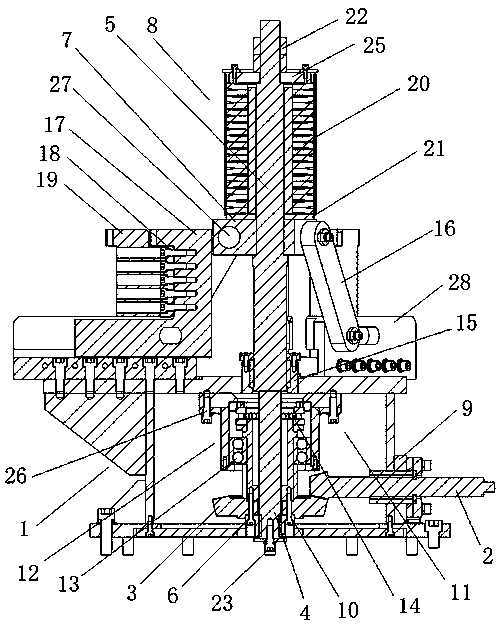

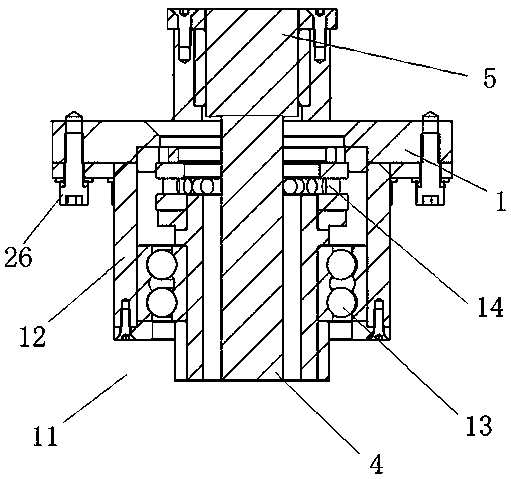

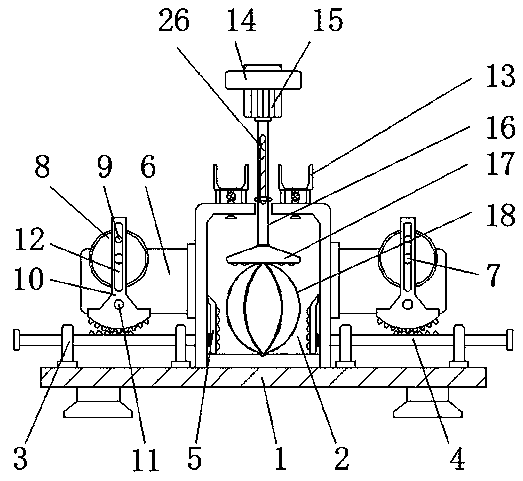

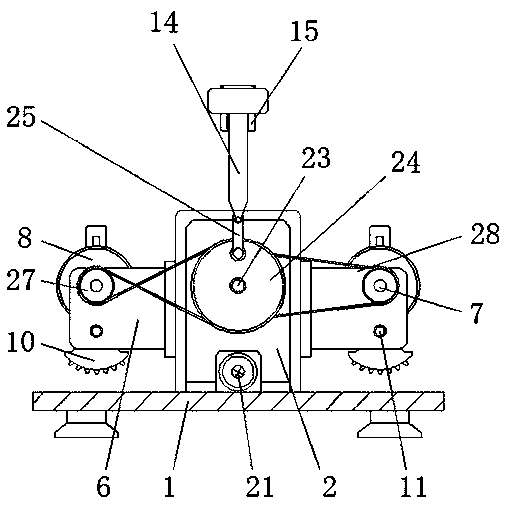

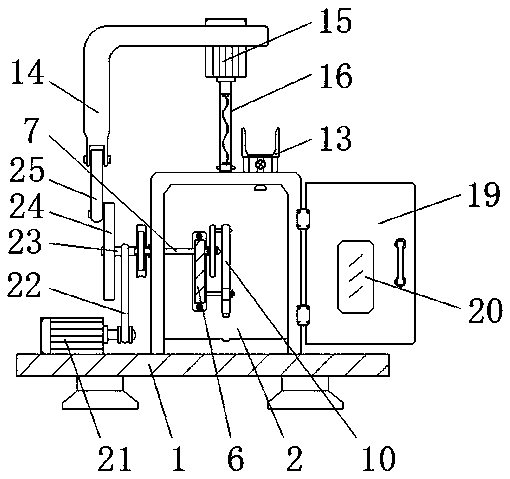

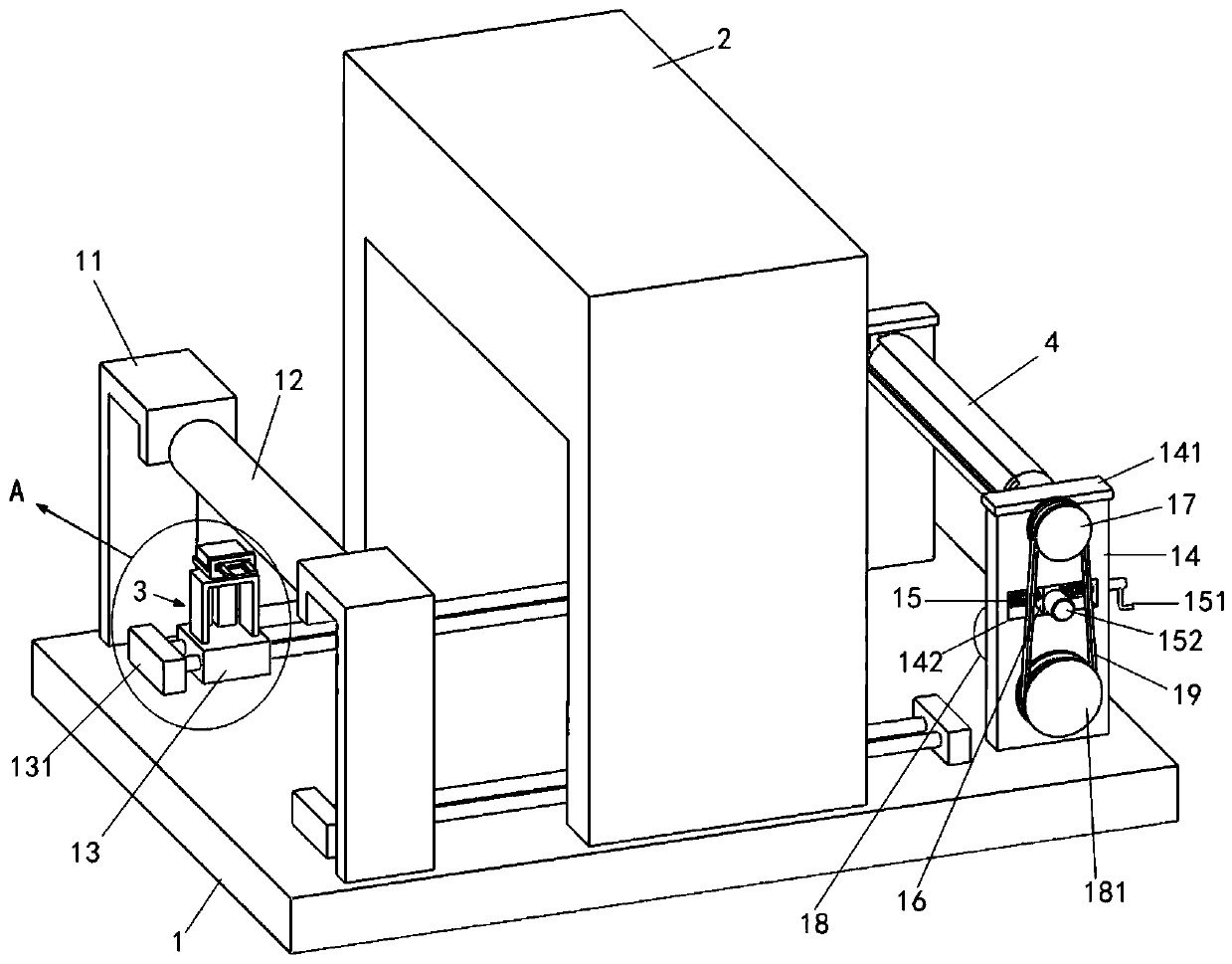

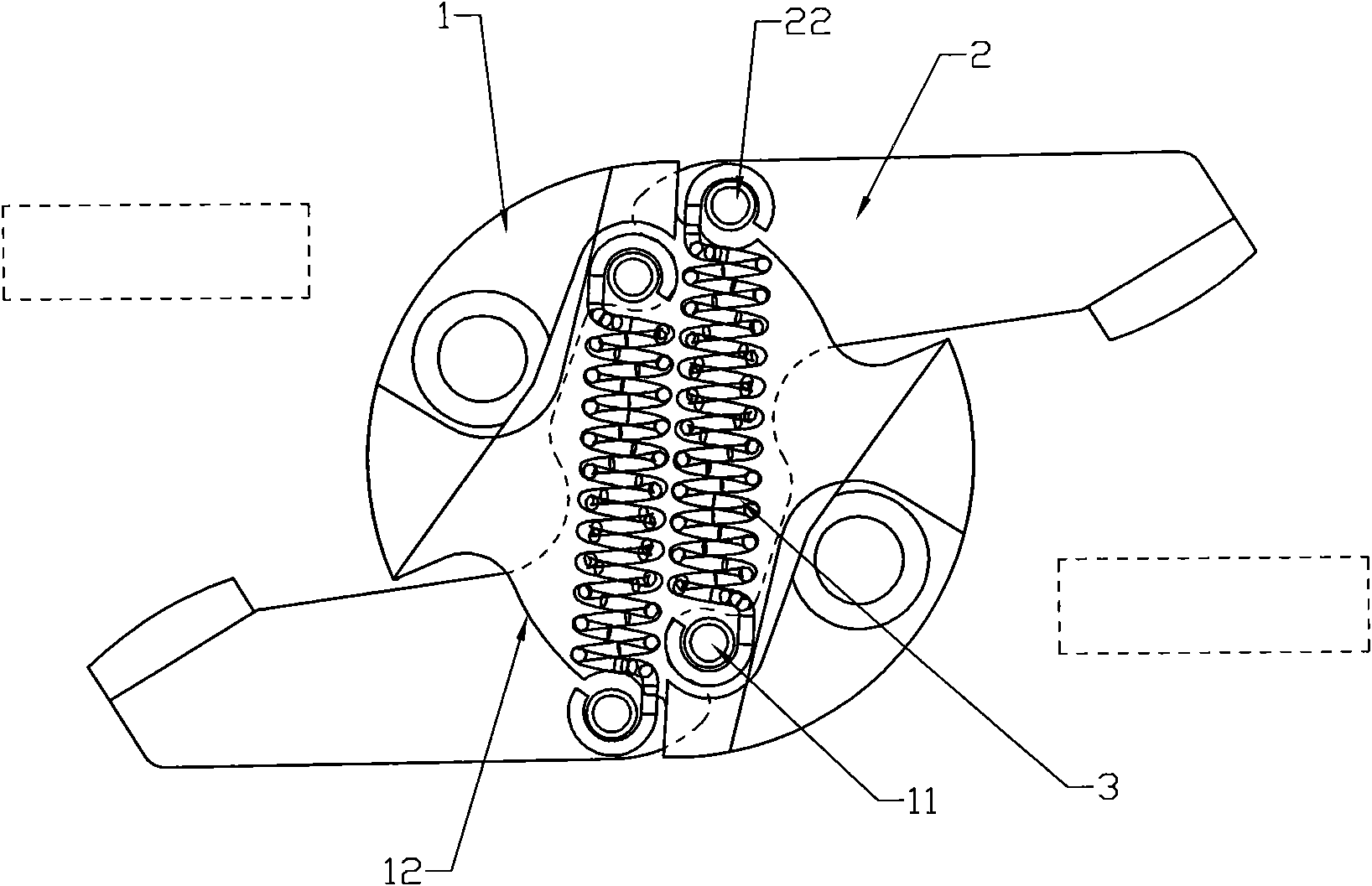

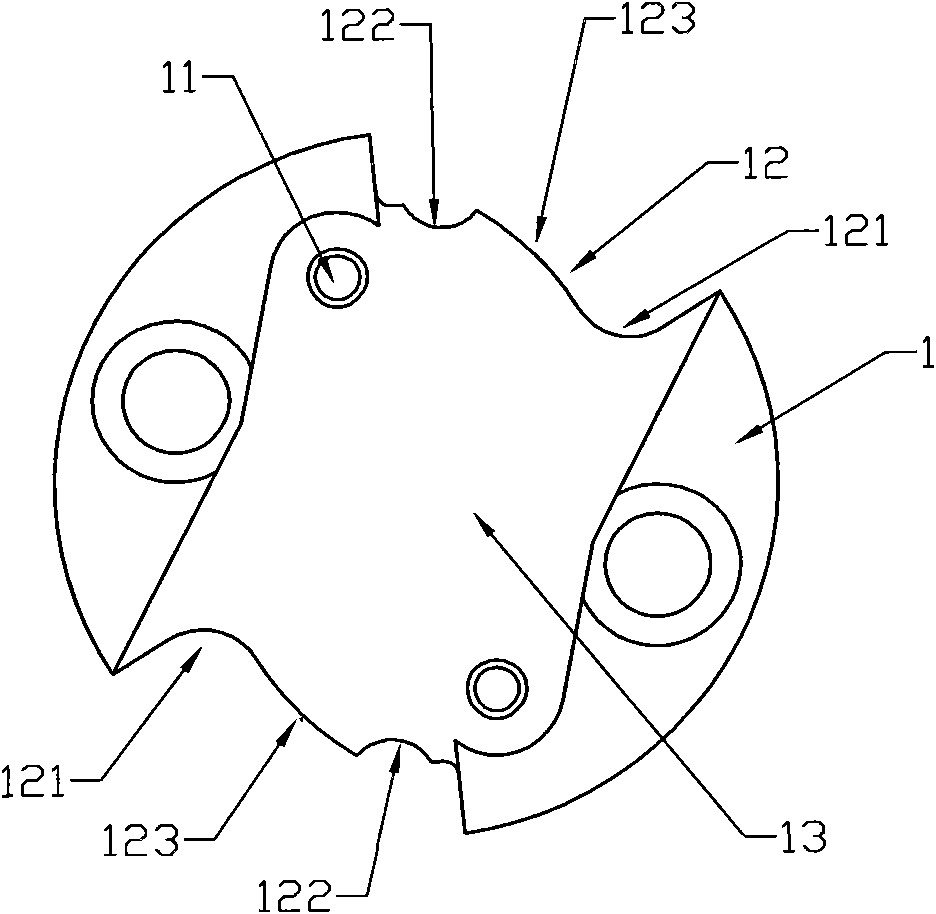

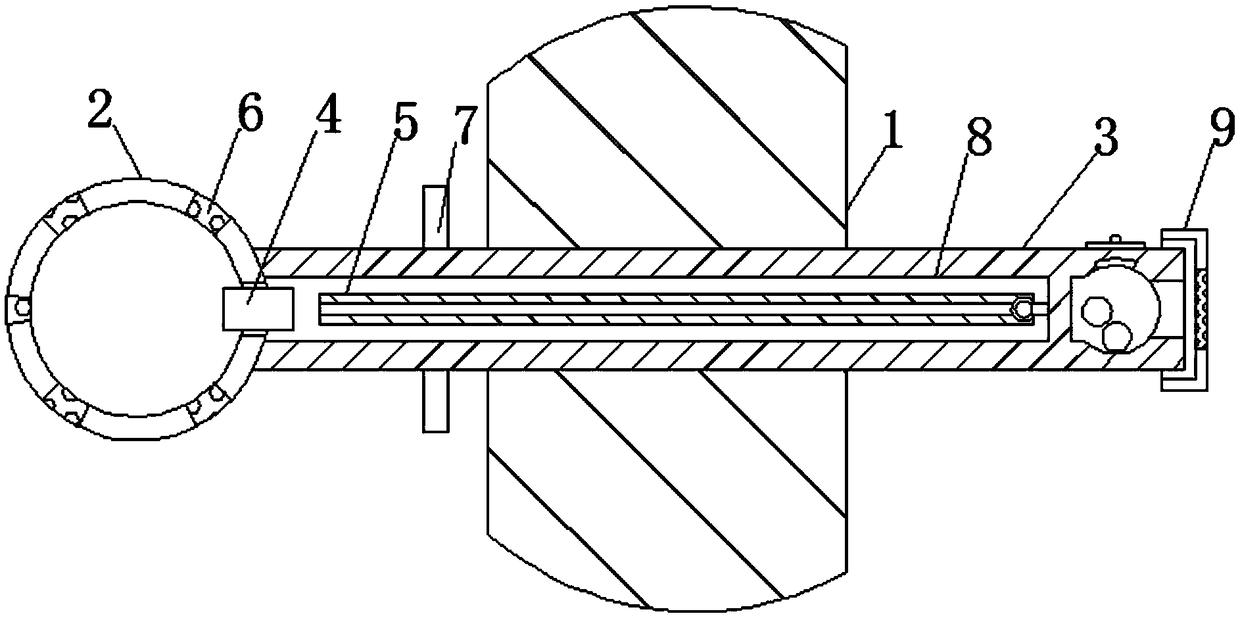

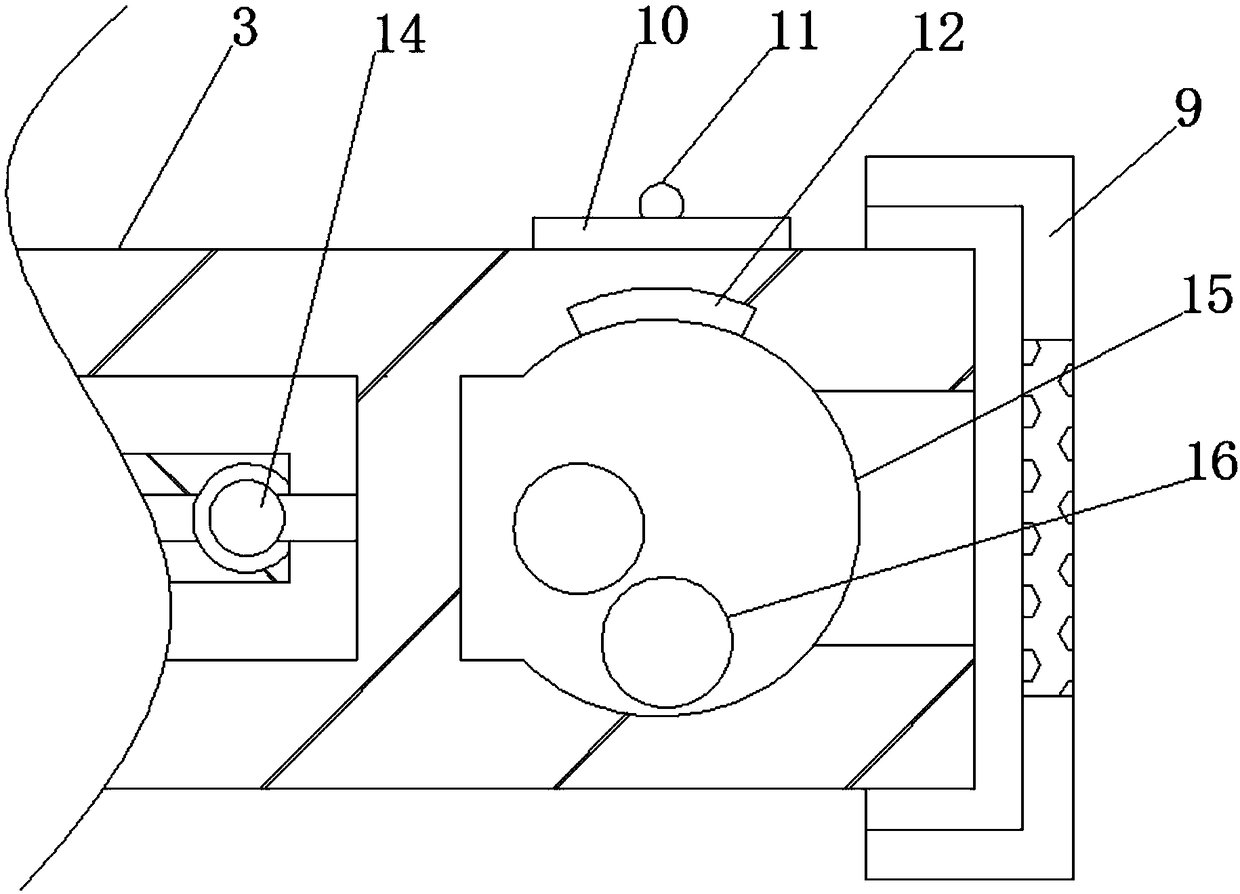

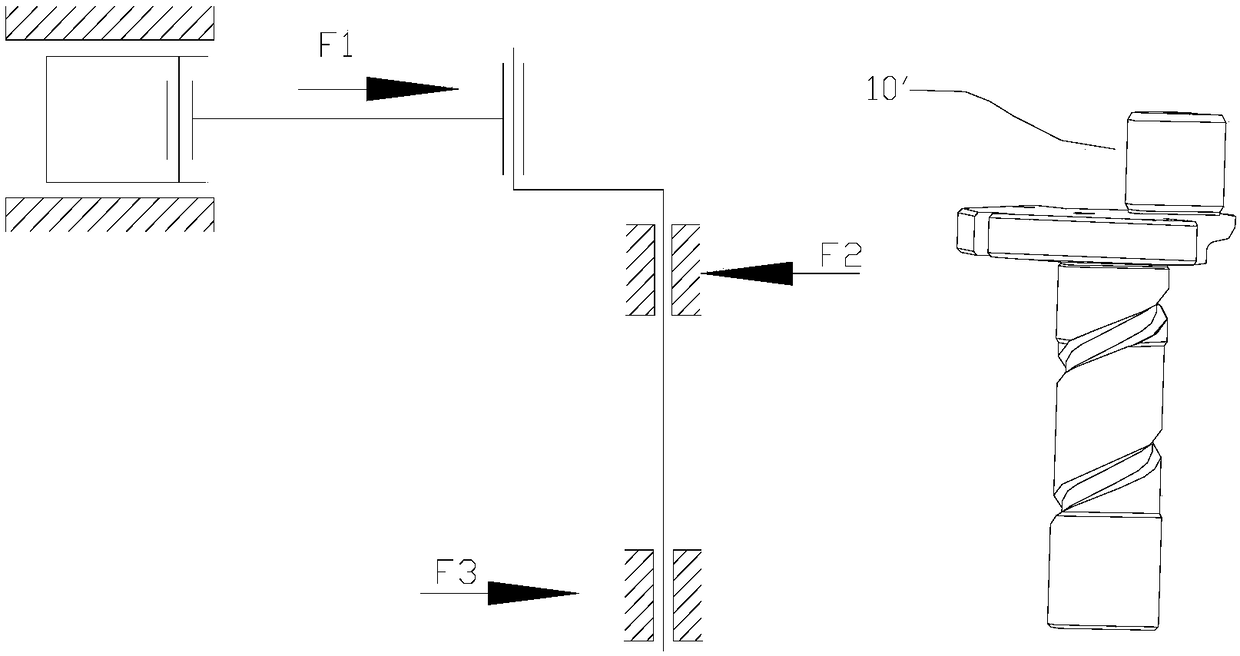

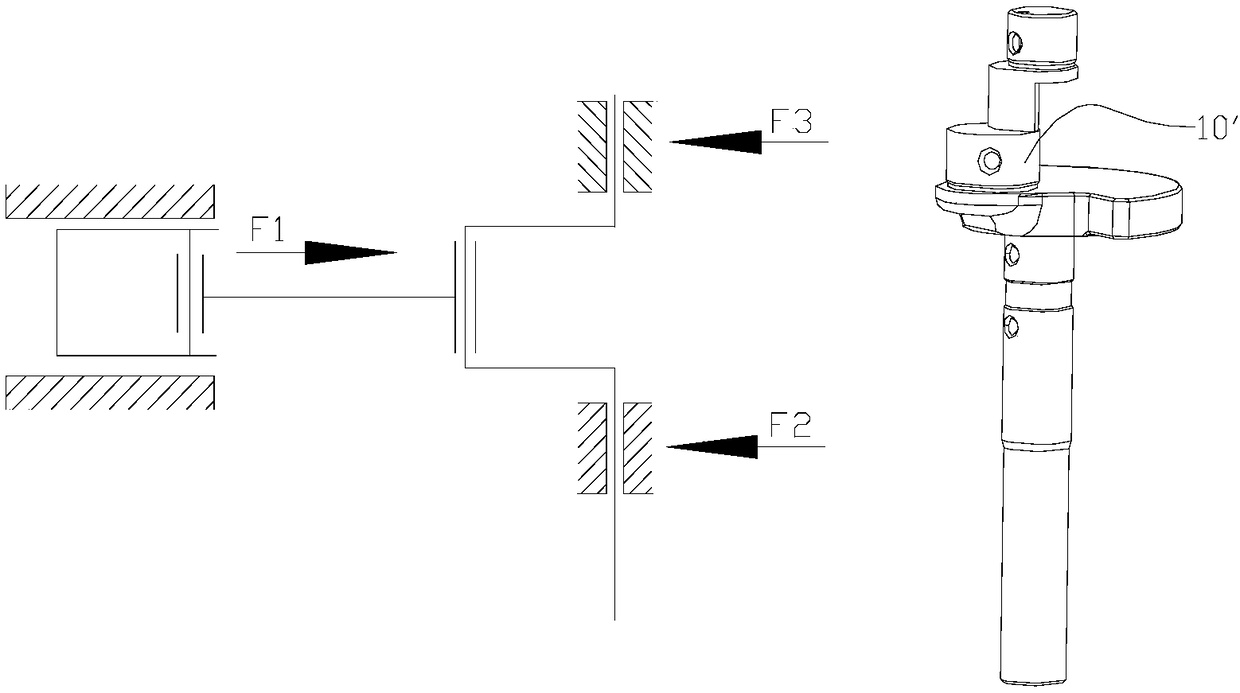

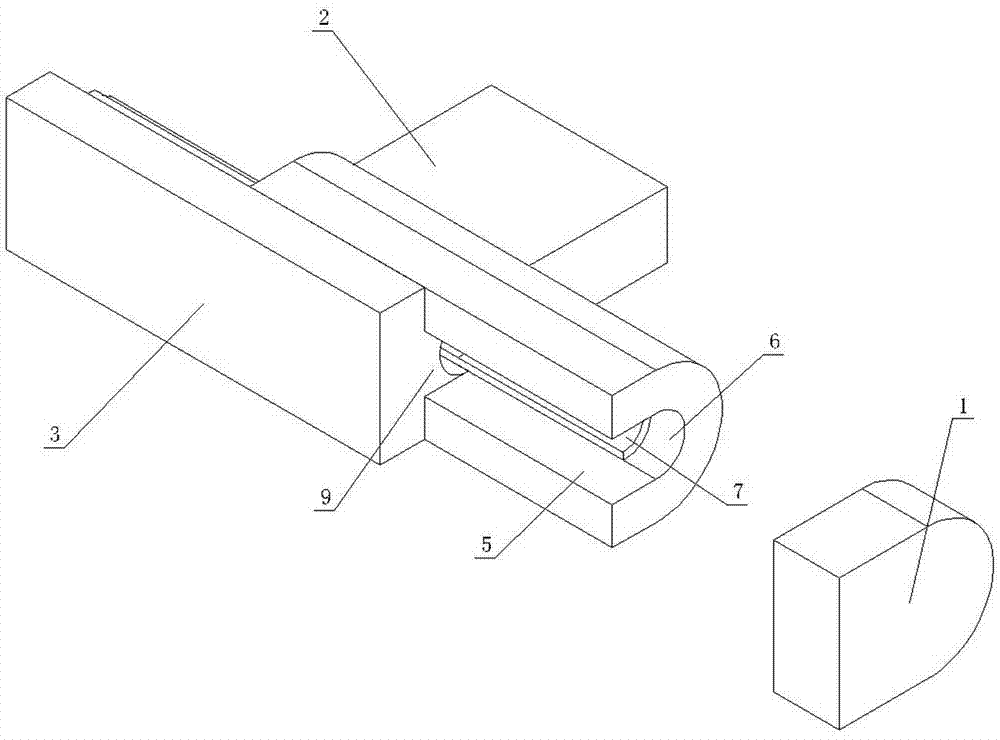

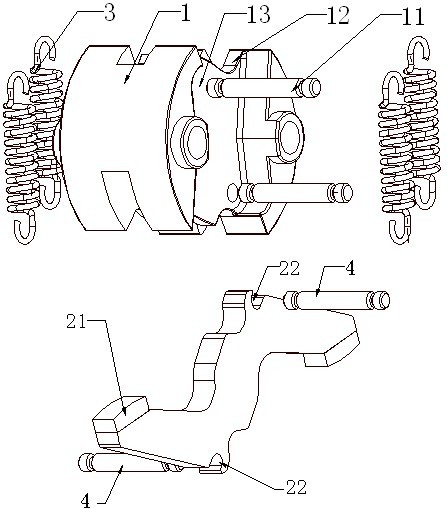

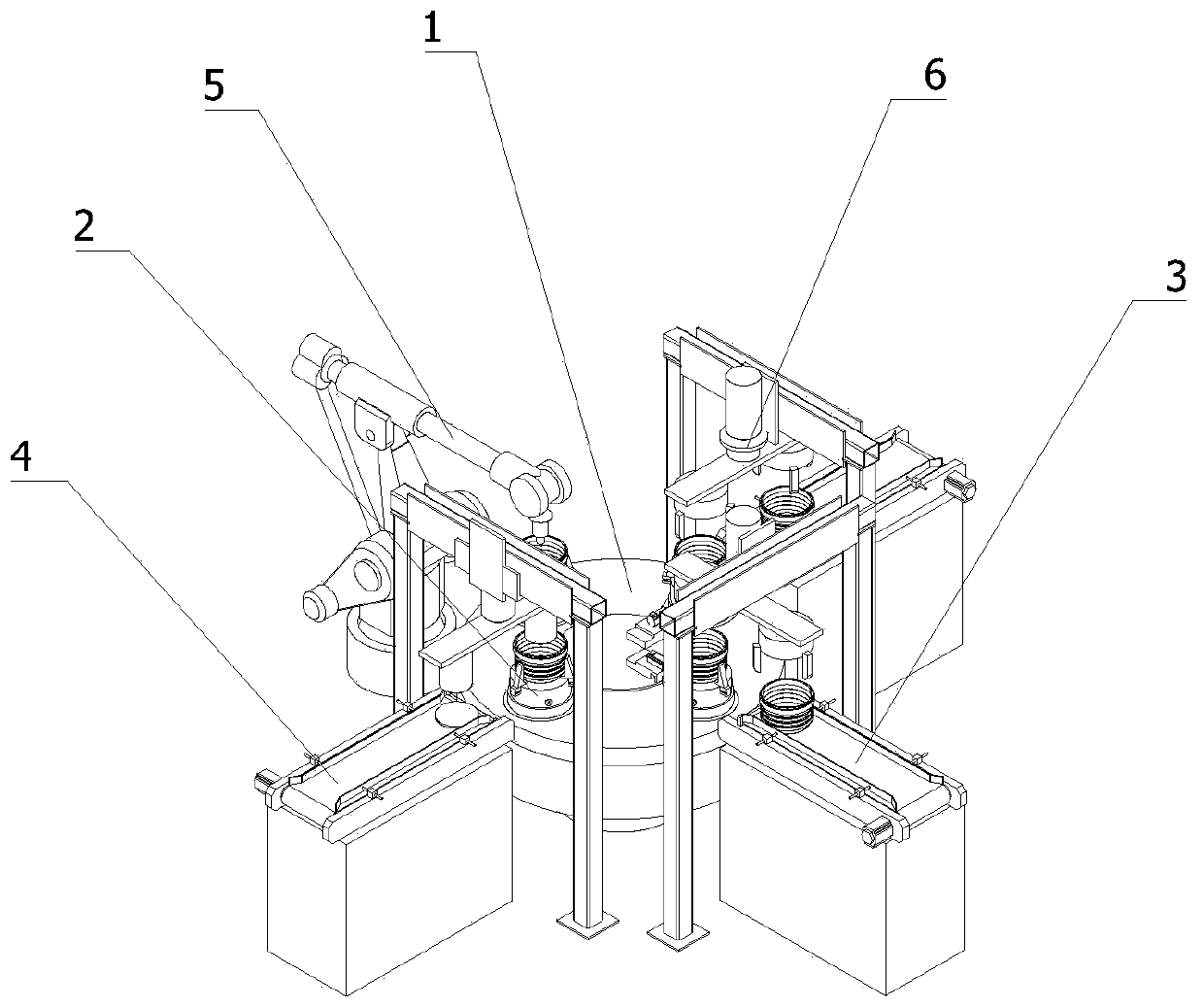

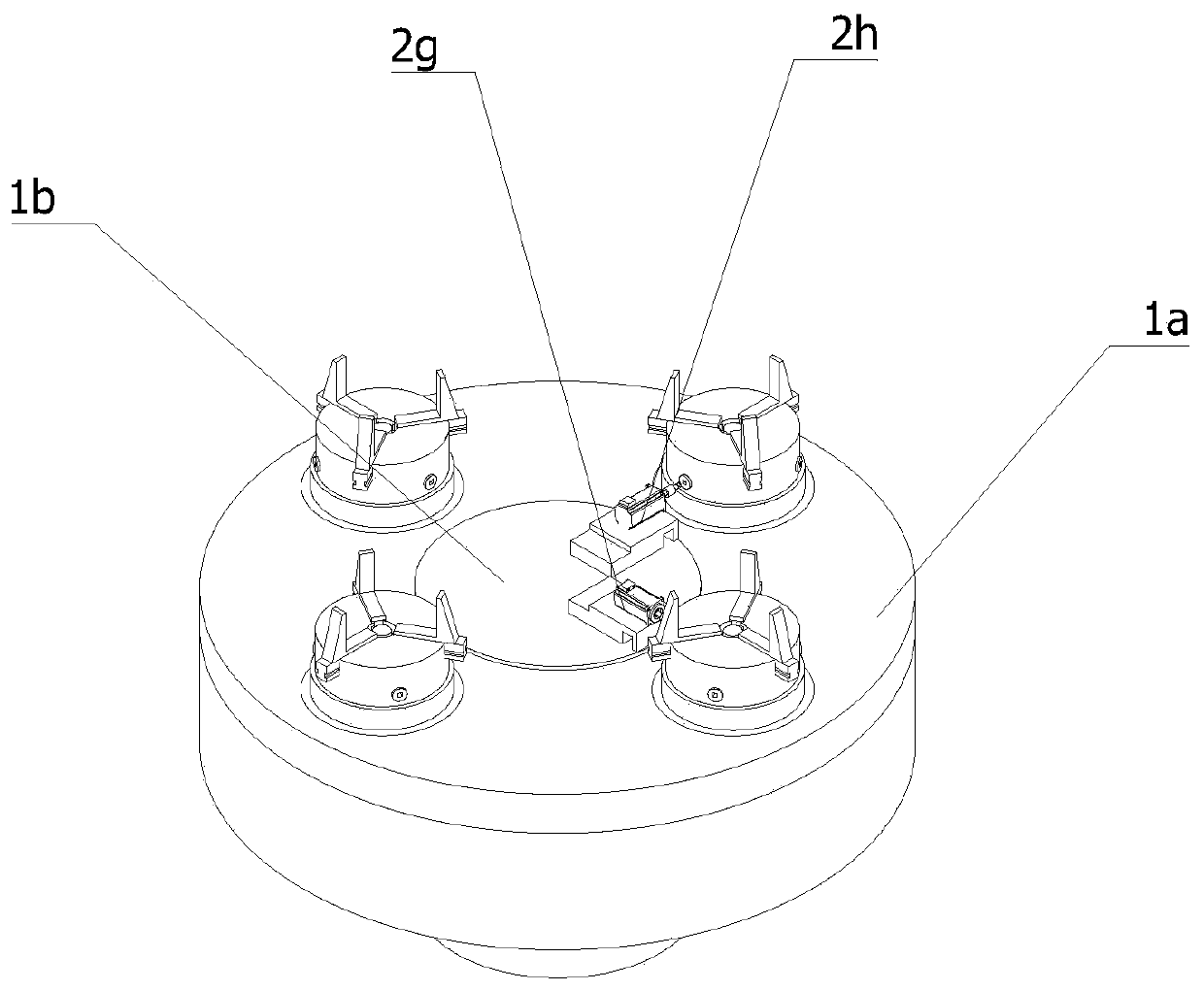

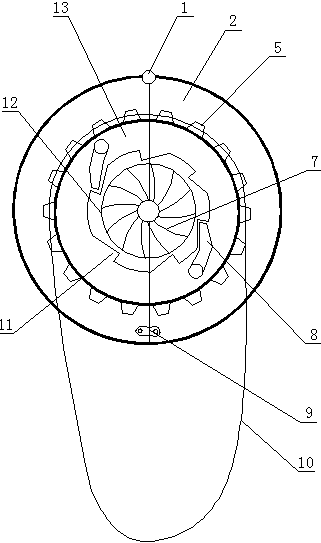

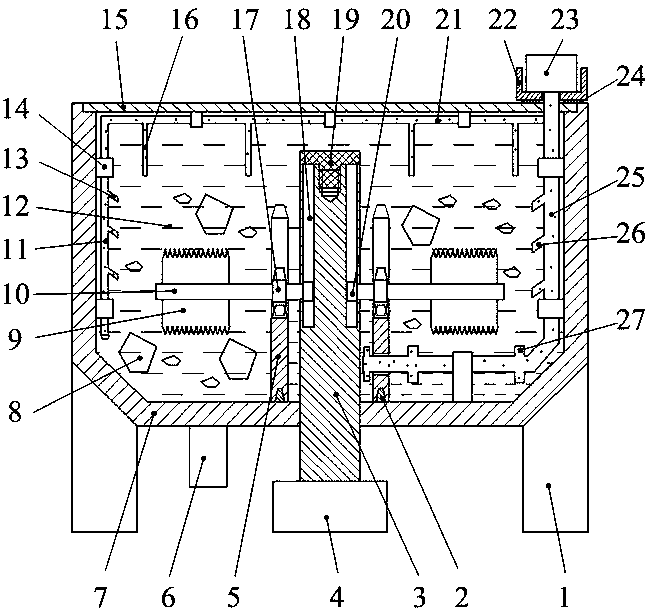

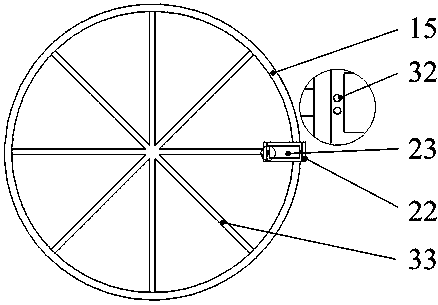

Gripping mechanism for replacing spatial on-orbit modules

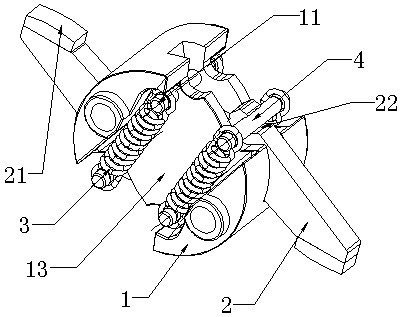

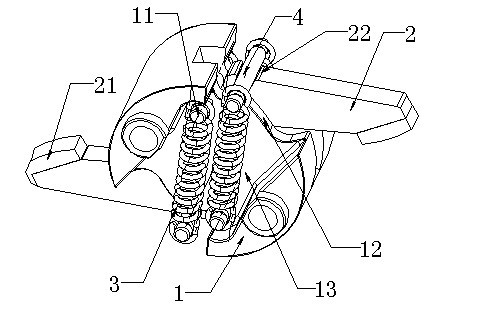

A gripping mechanism for replacing spatial on-orbit modules relates to a gripping mechanism for replacing spatial modules, and aims to solve problems that an existing gripping mechanism for replacing spatial on-orbit modules is complex in structure, single in function, large in volume, heavy in weight and low in positioning precision and is inflexible. A stepping motor is mounted in a driving rack, a transition plate is connected onto an upper end surface of the driving rack, a conical positioning piece is disposed on the upper end surface of the transition plate, a driven rack is covered on the outer portion of the conical positioning piece, two positioning columns arranged radially are symmetrically mounted on the lower portion of the conical positioning piece, the upper end of a screw is connected with the conical positioning piece in a threaded manner, a wedge-shaped slider is connected onto the screw, the lower end of the screw is connected with the stepping motor, second notches are arranged on the conical positioning piece, tubular columns are mounted on the tops of the second notches in a clamped manner, conveying pipes are communicated with counter bored holes of the tubular columns, inclined surfaces of the tubular columns are abutted to the wedge-shaped sliders, and a spring is arranged between each of catches and the conical positioning piece. The gripping mechanism is used for on-orbit module service for a spacecraft and on-orbit connecting tasks.

Owner:HARBIN INST OF TECH

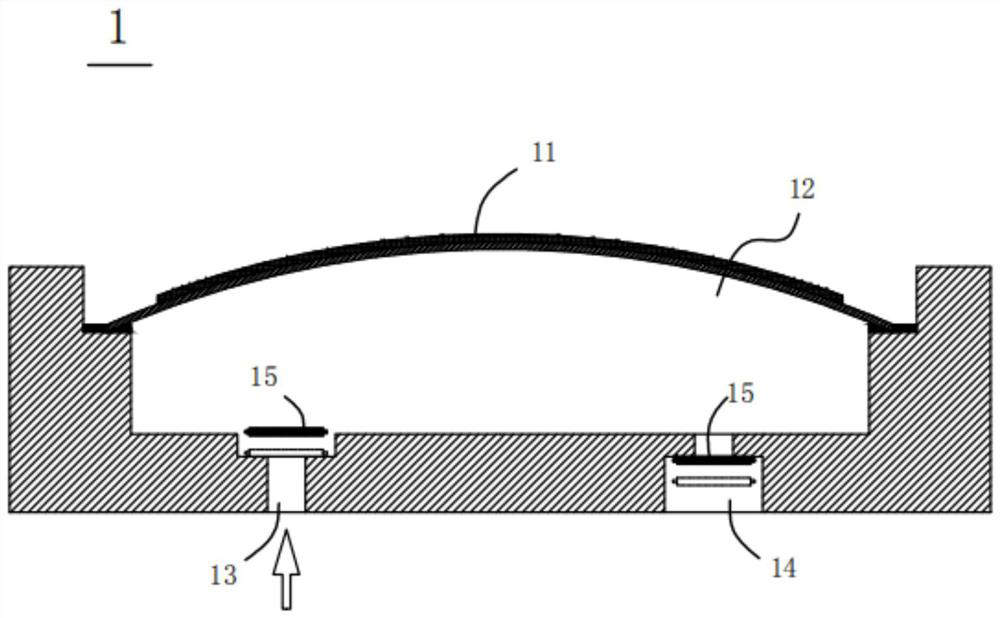

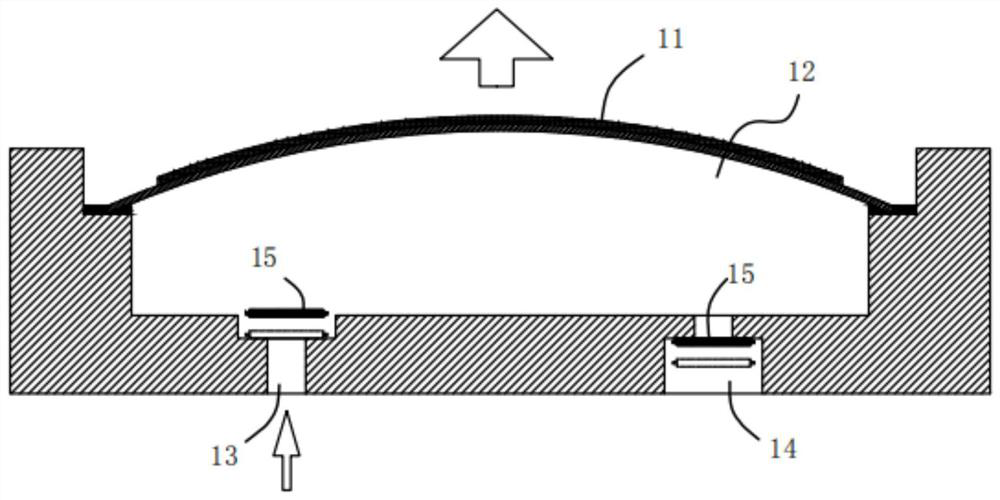

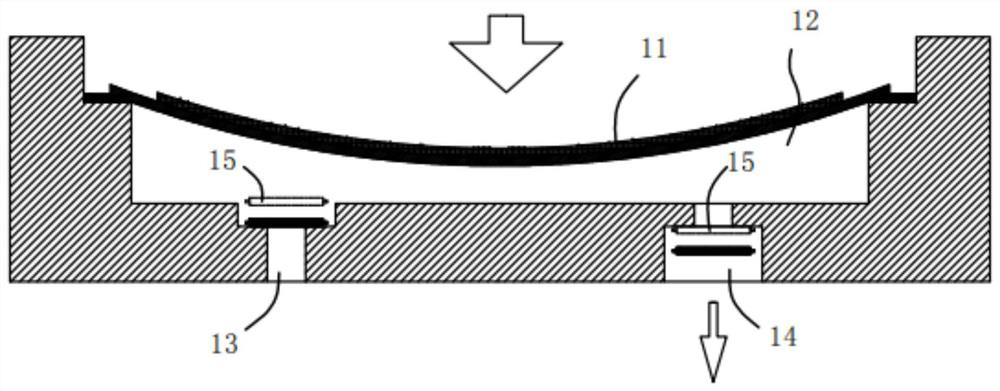

Liquid cooling heat dissipation module, liquid cooling heat dissipation system and electronic equipment

PendingCN111818770AEasy to get stuckAvoid tremorsSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsLiquid storage tank

The invention relates to the technical field of heat dissipation systems. A liquid cooling heat dissipation module comprises a heat dissipation module comprises a power pump and a pressure regulatingmodule, the power pump provides power for the heat dissipation loop; the pressure regulating module and the power pump are connected in a heat dissipation loop in series. During work, at the same moment, the sum of the pump cavity volume variation caused by the power pump and the pressure regulating cavity volume variation of the pressure regulating module approaches zero, so that the pressure inthe pipeline is in a balanced state, the problem of sudden stop of working medium circulation caused by clamping stagnation of a single power pump is solved, and meanwhile flow channel tremor is avoided. Meanwhile, due to the fact that a liquid storage tank is omitted, the problems that a traditional liquid cooling heat dissipation module is large in size and not high in integration degree are effectively solved, the size of a heat dissipation system is smaller, and miniaturization of products is facilitated.

Owner:常州威图流体科技有限公司

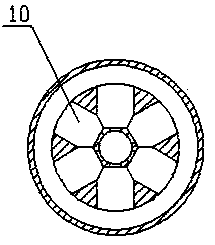

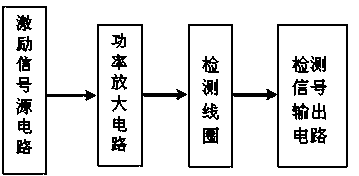

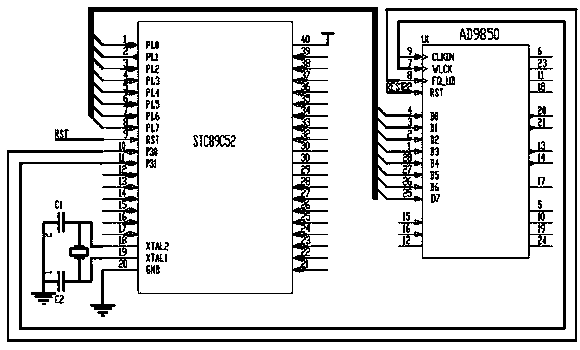

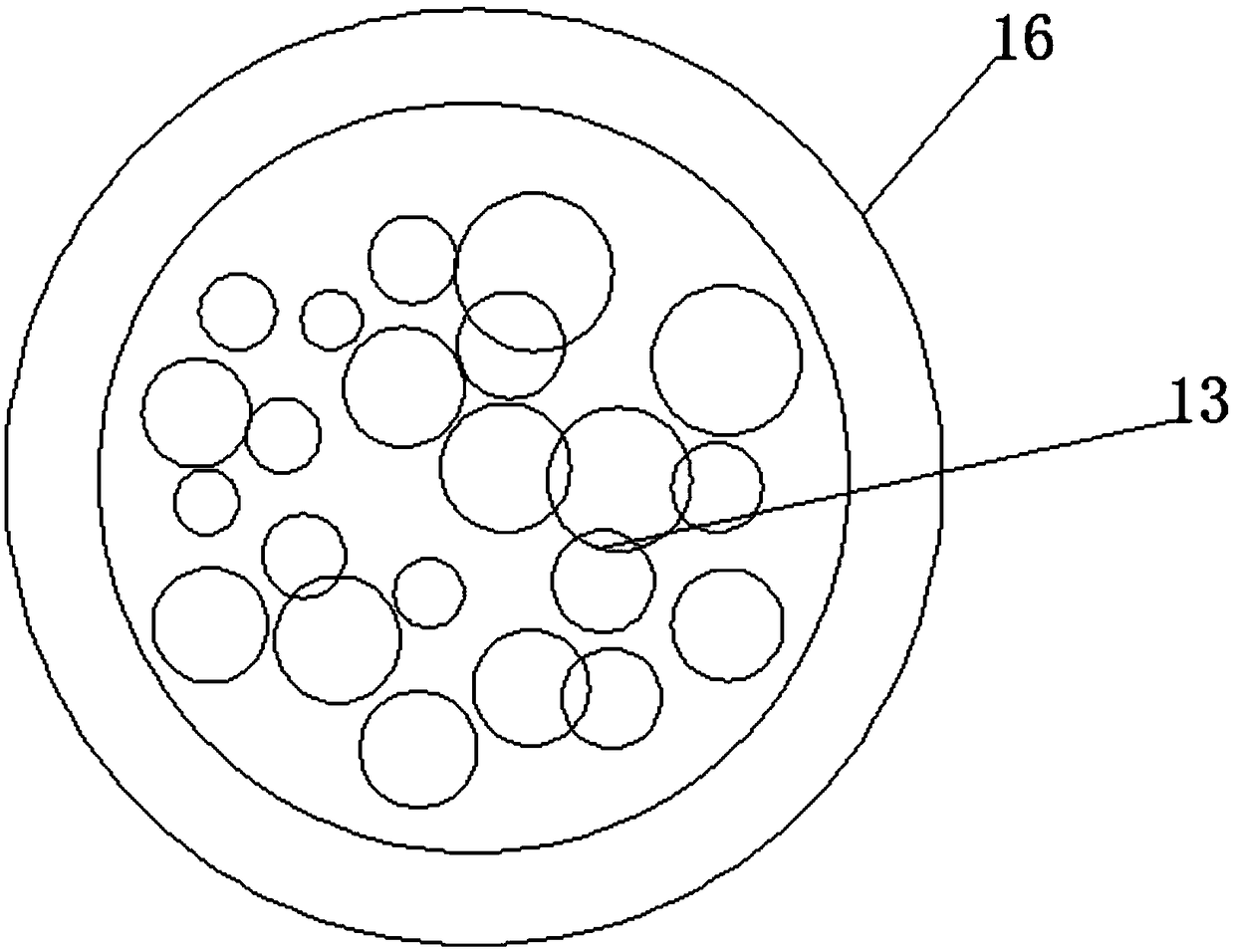

Eddy current non-contact multi-channel diameter detector in pipeline

ActiveCN103591883AHigh precisionImprove anti-interference abilityElectrical/magnetic solid deformation measurementElectrical/magnetic diameter measurementsElectricityCoupling

The invention discloses an eddy current non-contact multi-channel diameter detector in a pipeline. The detector comprises a tubular front detector warehouse, a computer warehouse and a battery warehouse. The detector is characterized in that the front detector warehouse, the computer warehouse and the battery warehouse are arranged in sequence, every two adjacent warehouses are connected through a coupler, and supporting wheels are evenly distributed at the outer side of each warehouse in the circumferential direction. A power leather cup is arranged at the axial front end of the front detector warehouse, an eddy current detection ring is arranged at the axial rear end of the front detector warehouse, and a three-channel eddy current sensor is at least arranged in the eddy current detection ring. A single chip microcomputer data processing unit is arranged in the computer warehouse, and a data storage device and a USB plug are also arranged in the computer warehouse. Eddy current detection signals are obtained through an eddy current detection circuit. A lithium battery and a positioning device are arranged in the battery warehouse, and a mileage wheel is arranged at the rear end of the battery warehouse. The eddy current non-contact multi-channel diameter detector is suitable for all pipelines, can solve the problems that the pipeline is easily blocked when the diameter of the large tapered pipeline is detected to the maximum degree, and calibration is not needed every time the detector is used.

Owner:SHENYANG ACAD OF INSTR SCI

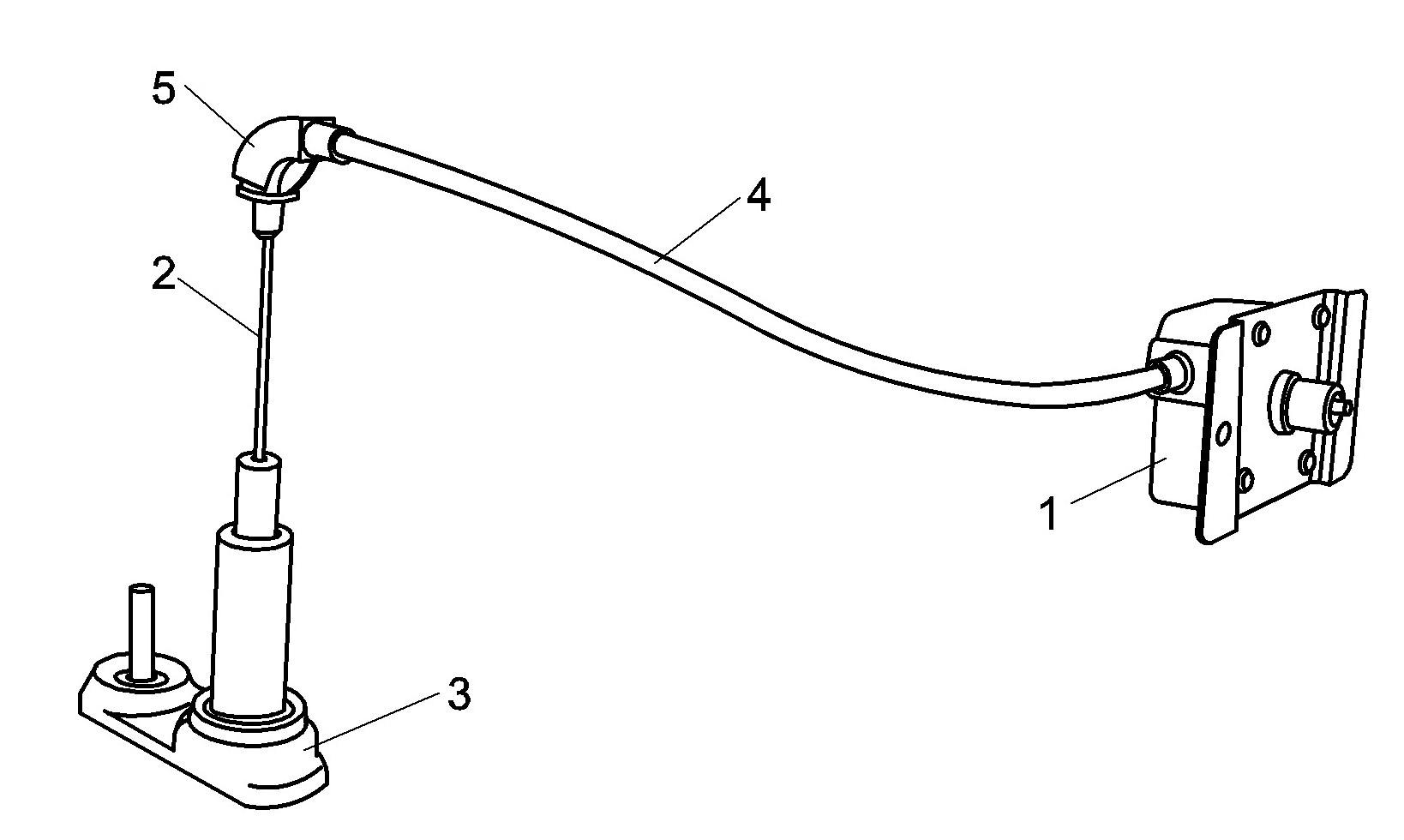

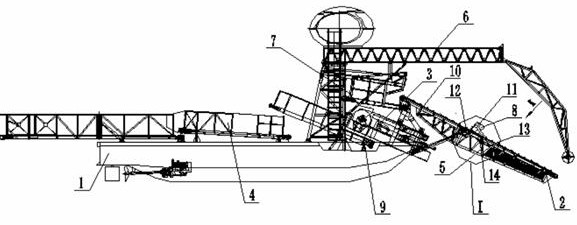

Vertical dock floating mooring device suitable for instantaneous amplitude variation of water level

InactiveCN102493398ALow movement resistanceAvoid stickingShipping equipmentPower stationMarine engineering

The invention discloses a vertical dock floating mooring device suitable for instantaneous amplitude variation of a water level. The device comprises a photon, running main wheels, lateral balancing wheels, an anchor pile and the like. The mooring device is arranged in a mooring chute of a vertical dock, and is connected with the dock into a whole. A ship goes up and down along the amplitude variation of the water level according to self buoyancy under the joint action of flow velocity force, ship mooring rope tension, fluctuating force and the like, and effectively avoids a blockage phenomenon in the running process by means of a spring balancing device. The mooring device is mainly suitable for vertical docks for riverways of which the water level is instantaneously varied, namely when the ship suddenly meets the instantaneous amplitude variation of the water level due to the peak regulation of an upstream power station in the process of mooring alongside for loading and unloading operation, the device can effectively float up and down with the water level, so that the influence of the variation of the water level on the loading and unloading operation can be reduced, and more importantly, a serious capsize accident caused by mooring rope rupture due to the variation of the water level can be avoided.

Owner:CHONGQING JIAOTONG UNIVERSITY

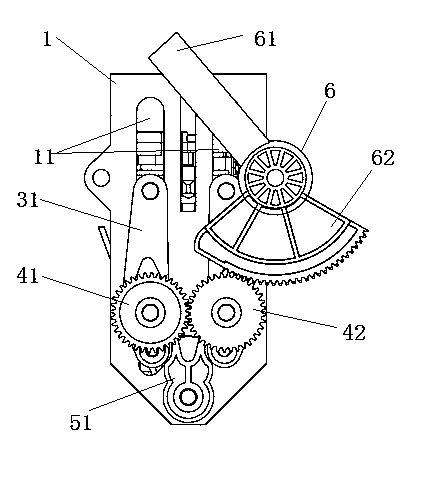

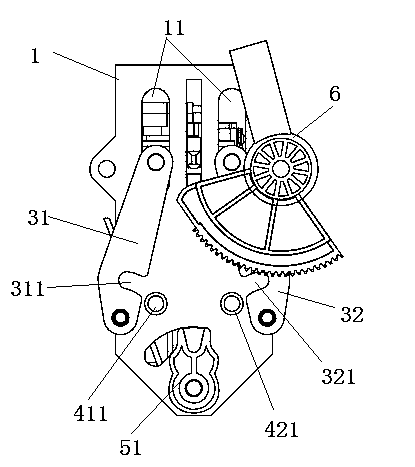

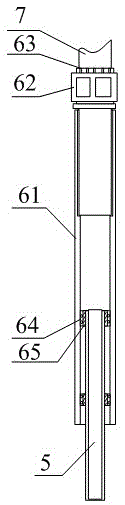

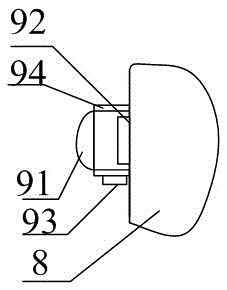

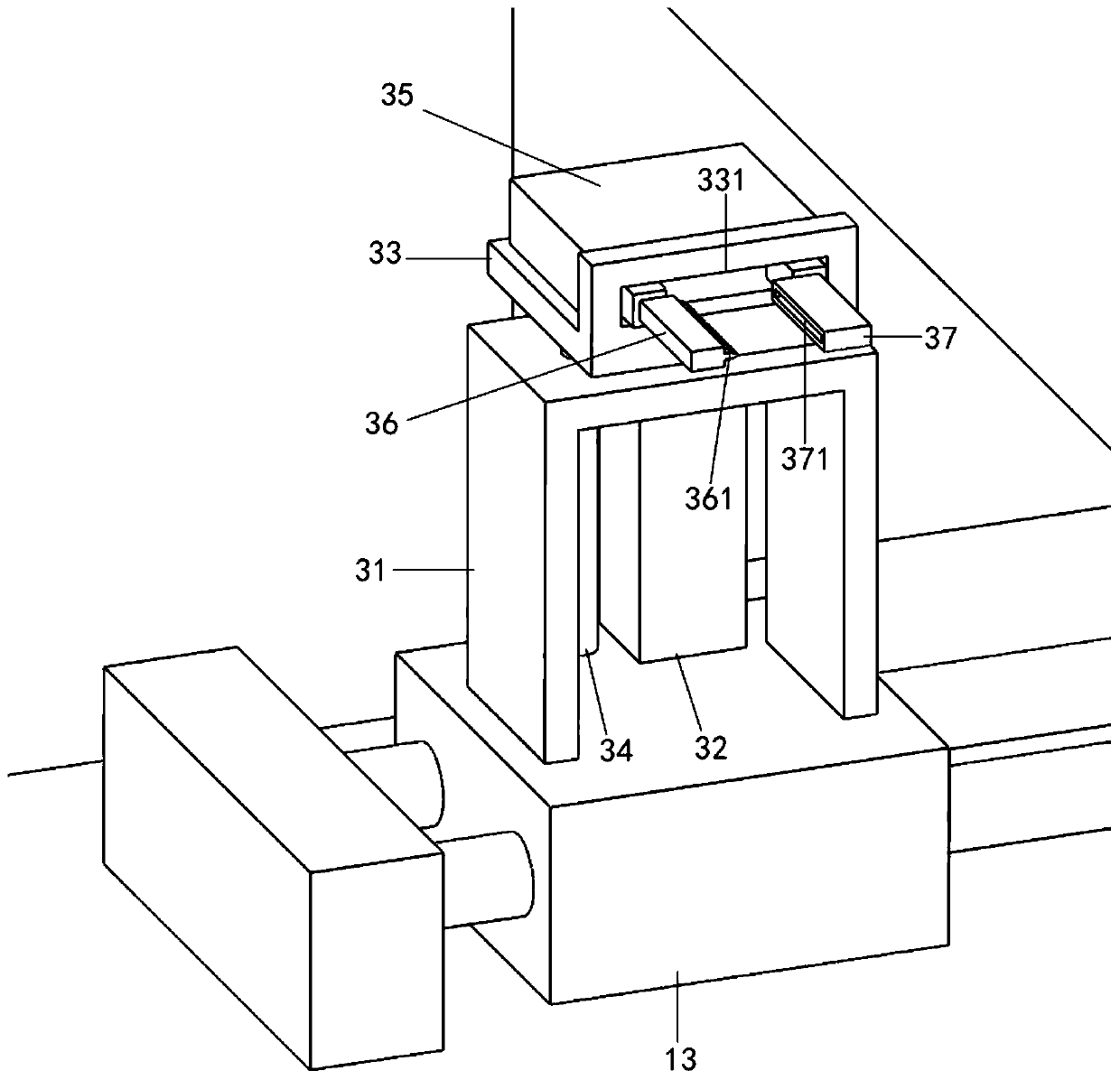

Spare tire fixing device

The invention relates to a spare tire fixing device which comprises a winch mechanism, a steel wire rope and a spare tire support mechanism, wherein the steel wire rope stretches into a shell from one side of the winch mechanism shell and is wound on a steel wire rope winch, the shrinkage and the extension of the steel wire rope can be realized through a mechanical motion of internal parts of the winch mechanism so as to finish the rise and the drop of a spare tire. The winch mechanism has a slip characteristic and gives a slip feedback to a user after the spare tire is well fixed, therefore, the damage to the winch mechanism caused by misoperation can be avoided. The spare tire support mechanism can be partially assembled and disassembled, which is convenient for assembling and disassembling the spare tire. The spare tire fixing device provided by the invention has the advantages of spare tire fixing reliability, transmission stability, operation portability and low noise and is superior to the traditional chain-type spare tire fixing device on performances in multiple aspects.

Owner:JIANGLING MOTORS

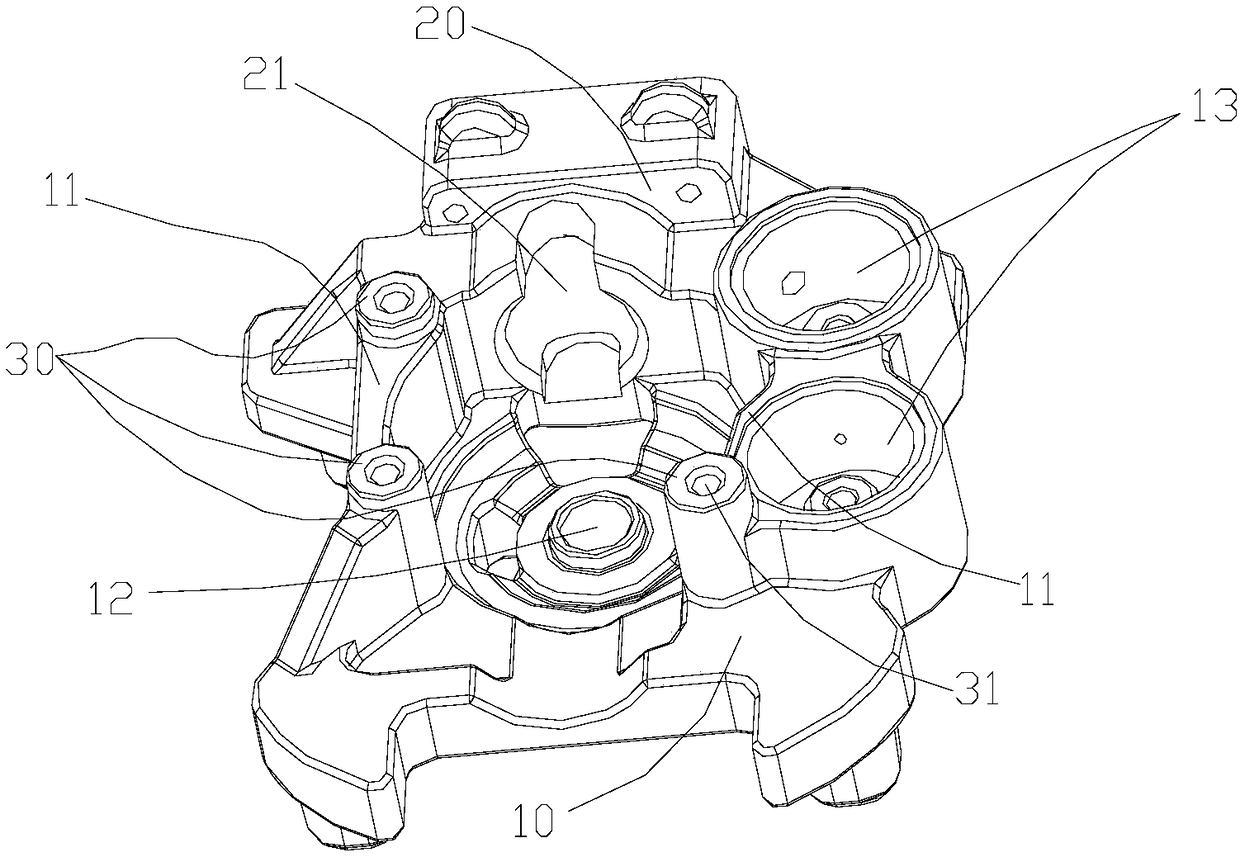

Three-claw inner support clamp assembly

PendingCN110216499AGuaranteed pressing forcePress firmlyPositioning apparatusMetal-working holdersHorizontal forceEngineering

The invention discloses a three-claw inner support clamp assembly. A supporting frame, a small bevel gear shaft, a large bevel gear, a first lead screw, a second lead screw, a lead screw nut, a connecting block and a disc spring are included. A fixing base with a middle opening is arranged on one side of the supporting frame. The small bevel gear shaft is in meshing transmission with the large bevel gear located at the center position of the supporting frame. The large bevel gear is in transmission connection with the lead screw nut through a first screw. The first lead screw and the second lead screw are fixedly connected and combined into an ejector rod lead screw. A guiding base is located above a bearing block, and rotation of the ejector rod lead screw is limited through cooperation of a guiding key in the guiding base and a key groove in the surface of the second lead screw. The rotating power of the small bevel gear shaft drives the large bevel gear to rotate through cooperationof the small bevel gear shaft and the large bevel gear, the lead screw nut connected with the large bevel gear drives the ejector rod lead screw to ascend and descend at the same time so that a sliding block can be driven to move in the horizontal direction, accordingly, axial force is further converted into horizontal force, and the function of workpiece pressing is achieved.

Owner:南京合信智能装备有限公司

Degradable alloy and application of degradable alloy serving as single-slip-type soluble bridge plug

The invention discloses a degradable alloy and application of the degradable alloy serving as a single-slip-type soluble bridge plug. The degradable alloy comprises the following components of 60-75%of Zn, 5-15% of Mg, 5-10% of Na, 1-5% of Fe, 0.1-0.5% of C, 0.5-2% of Si, 0.5-2% of Ni and inevitable impurities, wherein the sum of mass fractions of all the components is 100%. The degradable alloyis utilized to manufacture a tool for fracturing construction, the tool is automatically melted in a pit after completing a work task and can be completely degraded, the problems of liable clamping and plugging of a channel do not exist, the degrading time is controllable, and the sealing property and pressure-bearing property are excellent.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

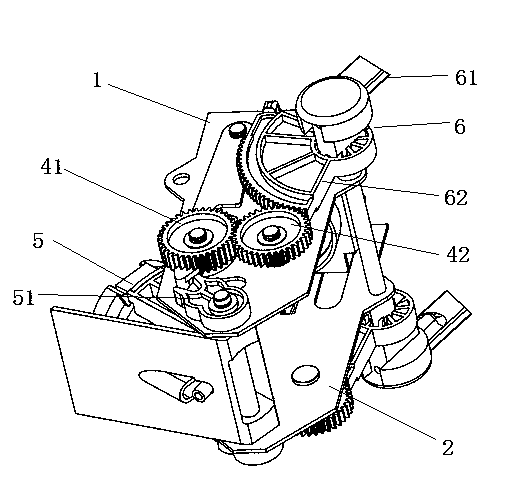

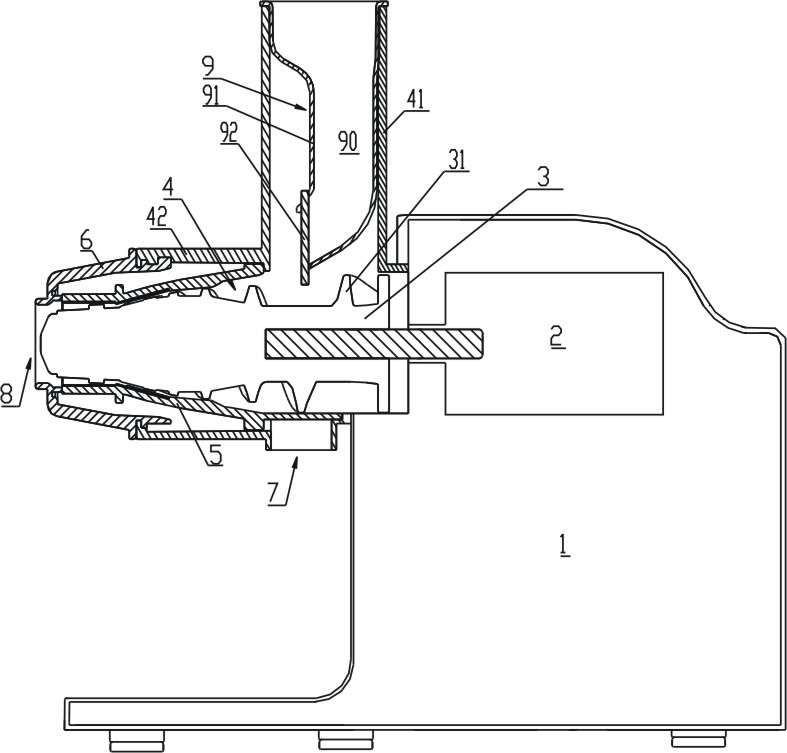

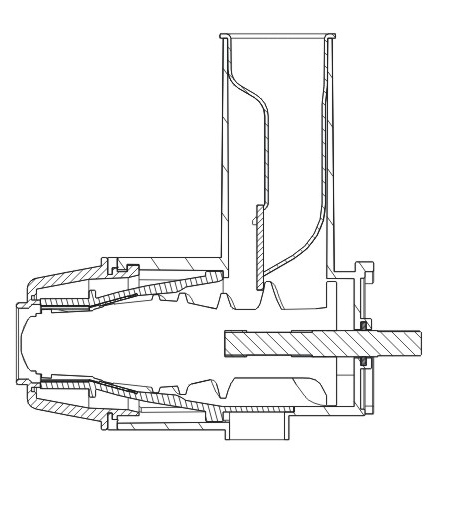

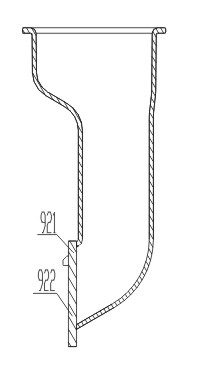

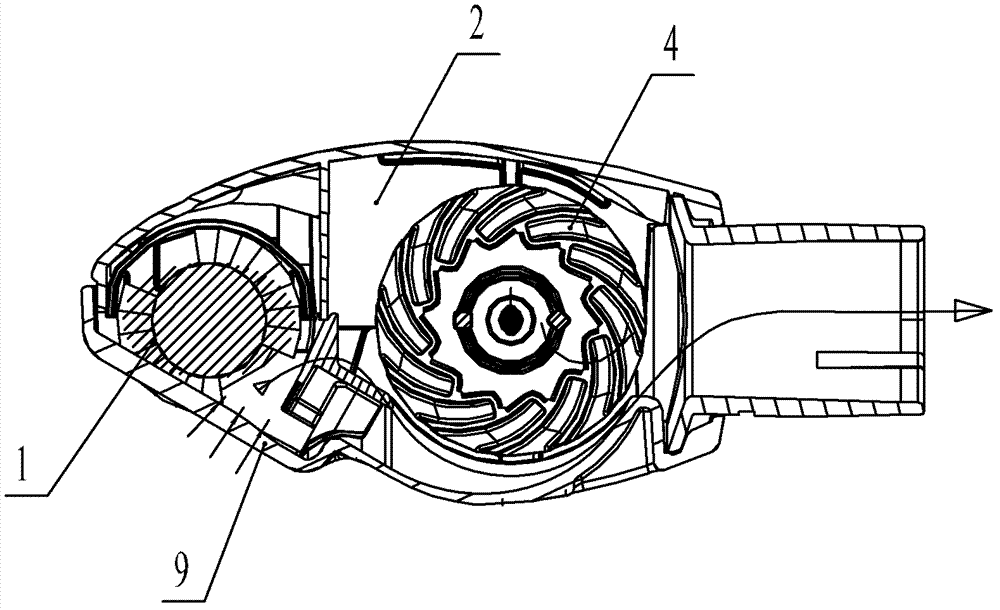

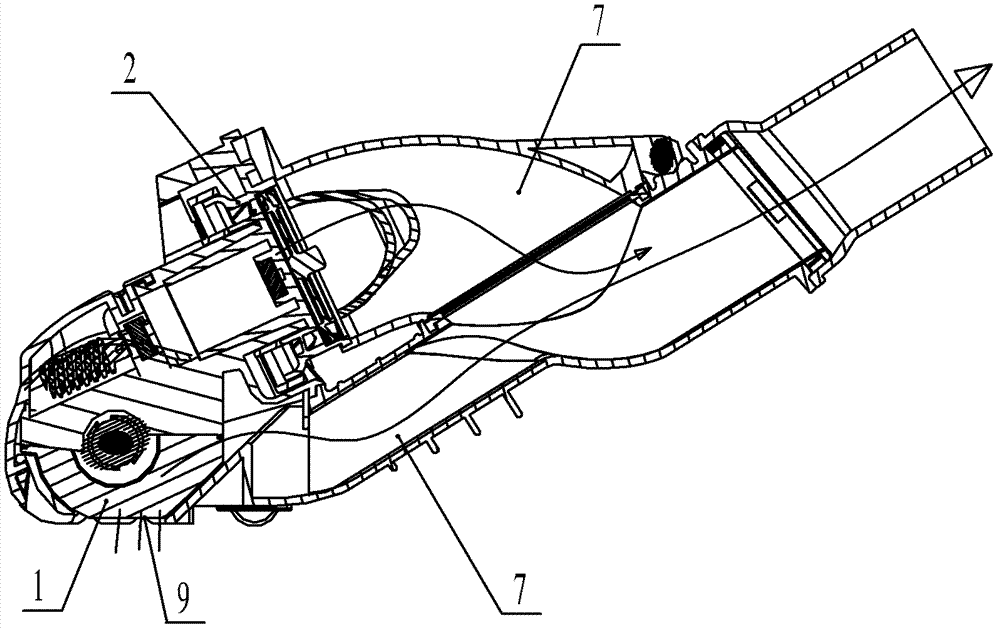

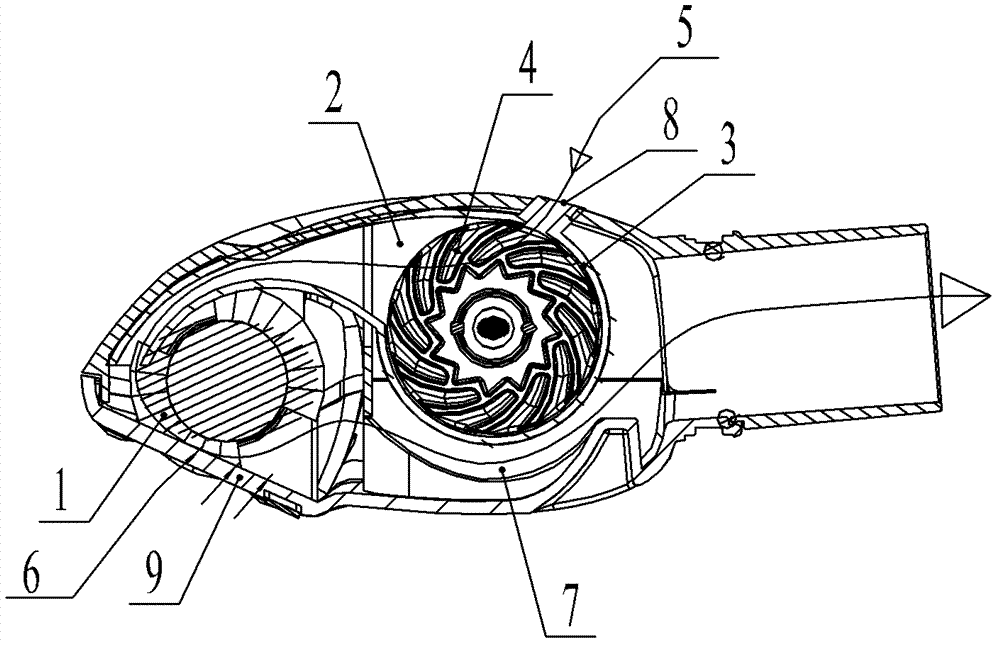

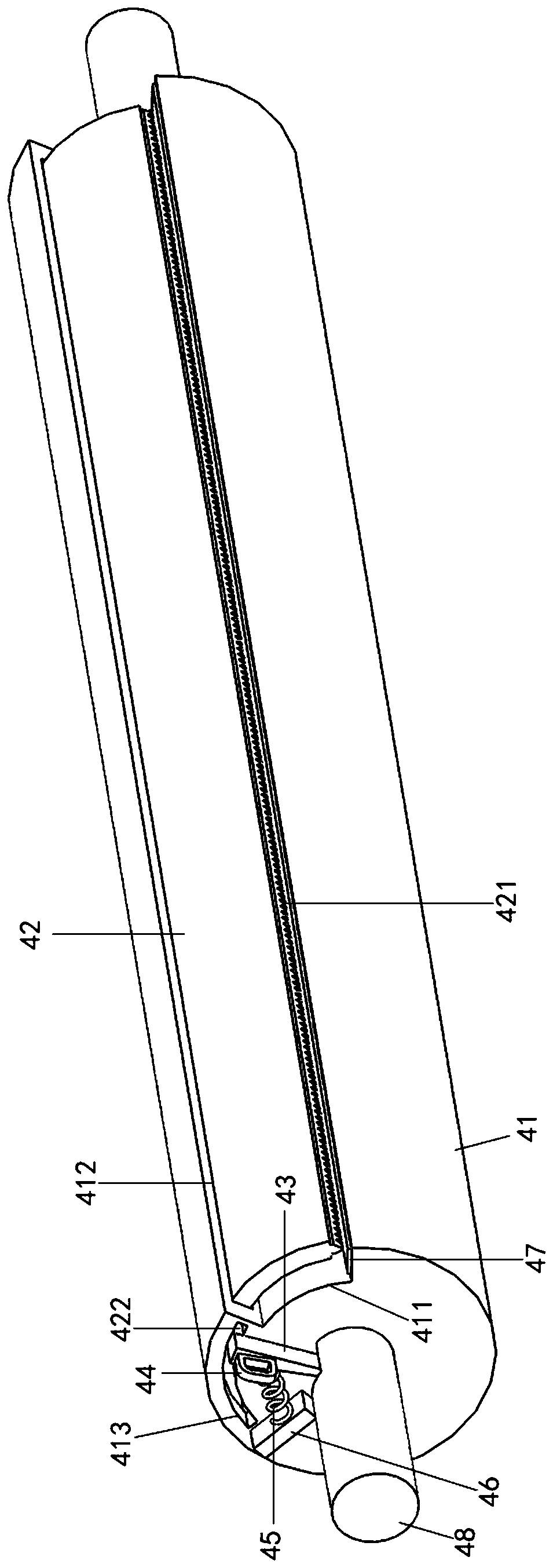

Coffee maker and brewing unit thereof

The invention provides a brewing unit of a coffee maker. The brewing unit comprises a first side wall and a second side wall opposite to the first side wall. A coffee pocket and a brewing head are arranged in space enclosed by the first side wall and the second side wall, the coffee pocket is used for accommodating coffee capsules or coffee cakes, the brewing head is used for squeezing the coffee capsules or coffee cakes, driving devices which are used for driving the brewing head to linearly move and simultaneously driving the coffee pocket to rotate are arranged on the first side wall and / or the second side wall, each driving device comprises a first gear, a second gear, a first driving arm, a second driving arm, a slide guide groove, a shifting shaft and a coffee pocket shifting rod, each first gear is meshed with the corresponding second gear, each first driving arm is connected with the brewing head and the corresponding first gear, each second driving arm is connected with the brewing head and the corresponding second gear, each slide guide groove is used for limiting the brewing head when the brewing head moves linearly, each shift shaft is arranged on the corresponding first gear or the corresponding second gear, and each coffee pocket shifting rod is coaxially connected with the coffee pocket and can accommodate the corresponding shifting shaft. The brewing unit has the advantages that the coffee capsules or coffee cakes can be placed in the coffee pocket conveniently, the brewing unit is simple in operation, and dead points cannot be formed easily.

Owner:MIDEA GRP CO LTD

Multi-functional distribution line rod top maintenance support bar

InactiveCN105610084AEasy to get stuckEasy to use at nightApparatus for overhead lines/cablesEngineeringMultiple function

The invention provides a multi-functional distribution line rod top maintenance support bar. The support bar comprises a rocking handle, a bevel gear 1, a bevel gear 2, a nut, a lead screw, an extension pipe, an insulation fulcrum bar, a U-shaped fork, an irradiation lamp, a pulley, a rotating shaft, a bearing 1, a gearbox, an end cap and a support seat. The rocking handle is fixedly connected to the bevel gear 1. An upper portion of the bevel gear 2 is fixedly connected to the nut. The lead screw and the nut are connected through a rectangular thread. The lead screw is provided with the extension pipe. An upper end of the extension pipe is connected to the insulation fulcrum bar. Through arranging the irradiation lamp, the extension pipe, the bevel gear 1 and the bevel gear 2, usage functions are perfect, a height adjusting amount is increased, the support bar is stable and reliable, night usage and operation are convenient, the support bar is easy to carry, a usage range is enlarged, and popularization and usage are convenient.

Owner:STATE GRID CORP OF CHINA +1

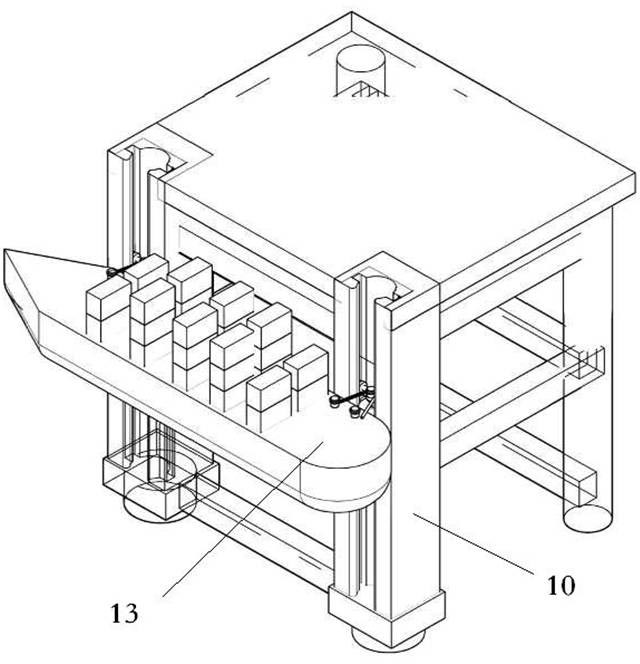

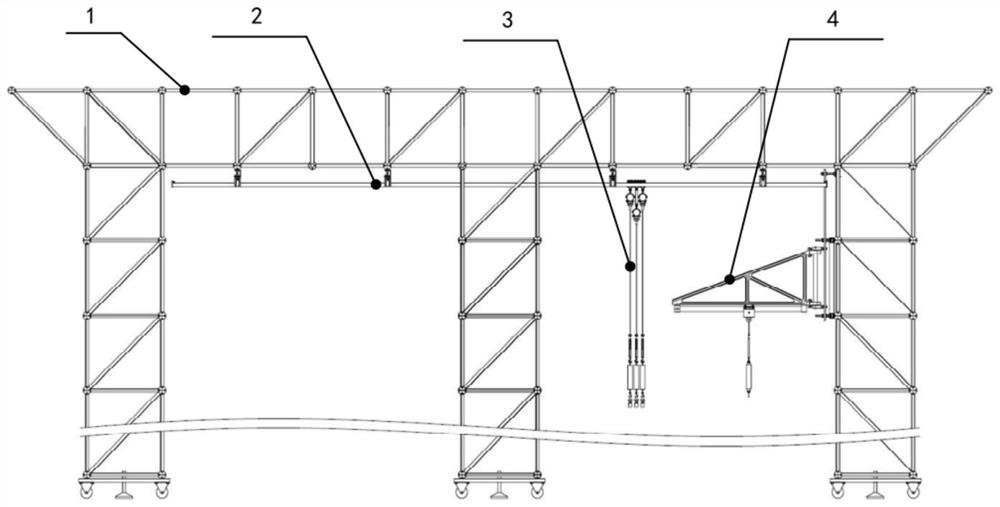

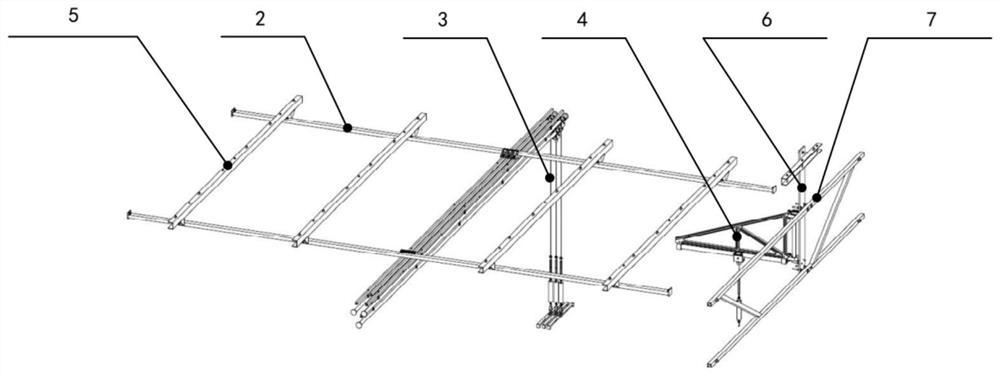

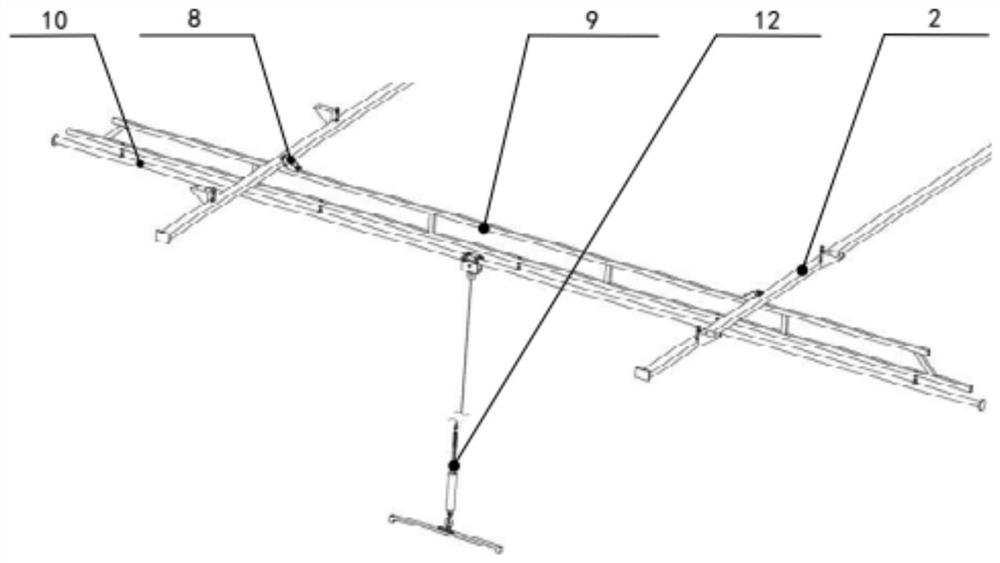

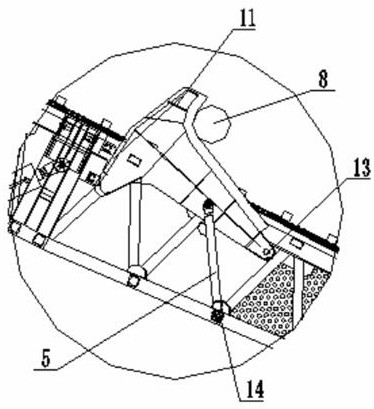

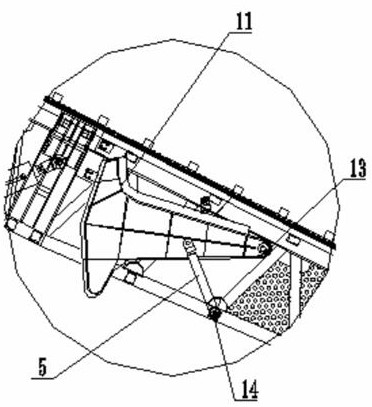

Gravity compensation device for step-by-step expansion type solar wing ground test

ActiveCN111674576AEasy to processHigh standardCosmonautic condition simulationsStructural engineeringMachine

The invention provides a gravity compensation device for a step-by-step expansion type solar wing ground test. The device comprises trusses, two sets of transverse guide rails, a plurality of sets ofsliding mechanisms and a swing mechanism. The two sets of transverse guide rails are installed on the upper portions of the trusses through a plurality of truss installation supports, the swing mechanisms are installed on the trusses, the multiple sets of sliding mechanisms cooperate with the two sets of transverse guide rails, and the section of each transverse guide rail is rectangular; each setof sliding mechanism comprises two transverse sliding frames, a longitudinal shaft support and a longitudinal shaft, the upper portions of the transverse sliding frames are erected on the transverseguide rails on the corresponding sides respectively and slide along the transverse guide rails of the transverse sliding frames, the swing mechanism and each longitudinal shaft are provided with a suspension assembly respectively, and the suspension assemblies slide along the longitudinal shafts and the swing mechanism. Therefore, problems that a long guide rail in a traditional large-range two-dimensional unfolding mechanism is difficult to machine, the guide rail machining and adjusting precision requirements are high, and the unfolding process is prone to being jammed are effectively solved, and the device is convenient to carry and has good economical efficiency and applicability.

Owner:CHANGGUANG SATELLITE TECH CO LTD

Convenient dough kneading device for food processing

InactiveCN109744278AEasy kneadingEasy to take outMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringFood processing

The invention discloses a convenient dough kneading device for food processing. The convenient dough kneading device comprises a base, a first motor and a second motor, wherein a dough kneading box isfixed above the base, fixing seats are fixed to the left side and the right side of the base, push rods are connected to the fixing seats and penetrate through the dough kneading box and is connectedwith a first kneading face plate, a fixing plate is fixed to the side surface of the dough kneading box, and a second groove is formed in the surface of a rotating shaft. A box door is connected to the dough kneading box, a second rotating wheel is fixed to the left side of the second connecting shaft, a connecting rod is connected to the second rotating wheel, a driven roller is fixed to the rear side of the first connecting shaft, a first spring is fixed in the rotating shaft, and a through hole is formed in the lower surface of the rotating shaft. The convenient dough kneading device for food processing can knead mixed dough, improve the dough kneading effect, and meanwhile a stirring steel wire can be retracted into the rotating shaft so that the kneaded dough can be taken out conveniently.

Owner:朱芙蓉

Multifunctional food processor capable of regulating feeding and feeding apparatus

ActiveCN101897551AAvoid stuck conditionsThe overall structure is simple and reliableKitchen equipmentMotor driveEngineering

Owner:JOYOUNG CO LTD

Pneumatic floor brush and vacuum cleaner thereof

The invention belongs to the technical field of household appliance manufacture and particularly relates to a pneumatic floor brush and a vacuum cleaner thereof. The pneumatic floor brush comprises a housing, a roll brush and a worm wheel, wherein the housing is provided with a roll brush chamber for accommodating the roll brush and a worm wheel chamber for accommodating the worm wheel; the worm wheel is used for driving the roll brush to rotate; dust airstream enters the roll brush chamber through a dust suction hole formed in the housing; clean airstream enters the worm wheel chamber through an air suction hole formed in the housing; a flow guide channel is formed between the roll brush chamber and the worm wheel chamber; the clean airstream flowing through the worm wheel chamber enters the roll brush chamber through the flow guide channel; and the roll brush is not coaxial with the worm wheel. According to the pneumatic floor brush, the problem of high possibility of worm wheel locking or low load capacity is solved, the clean airstream passing through the worm wheel is fully utilized, and the cleaning efficiency is improved.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

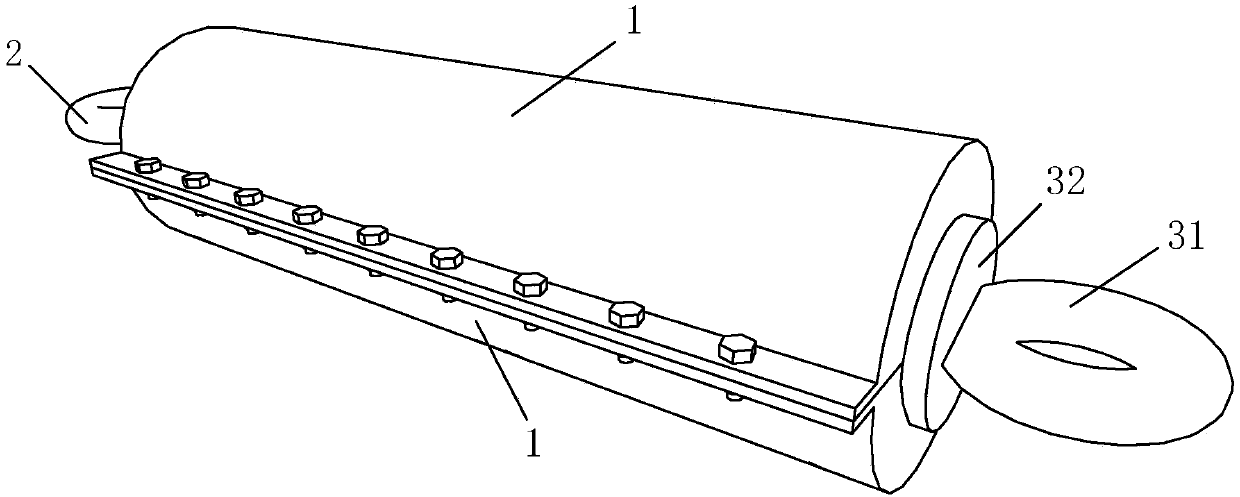

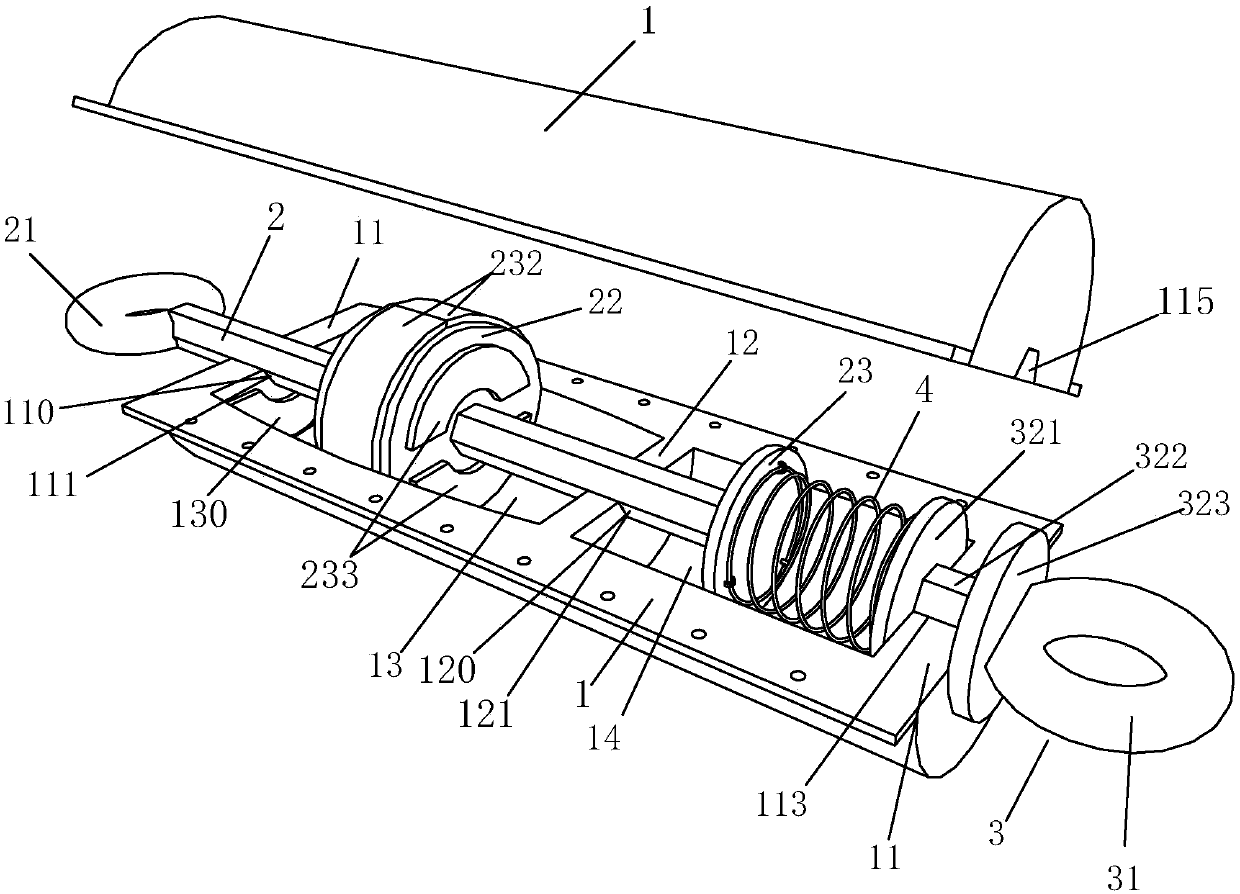

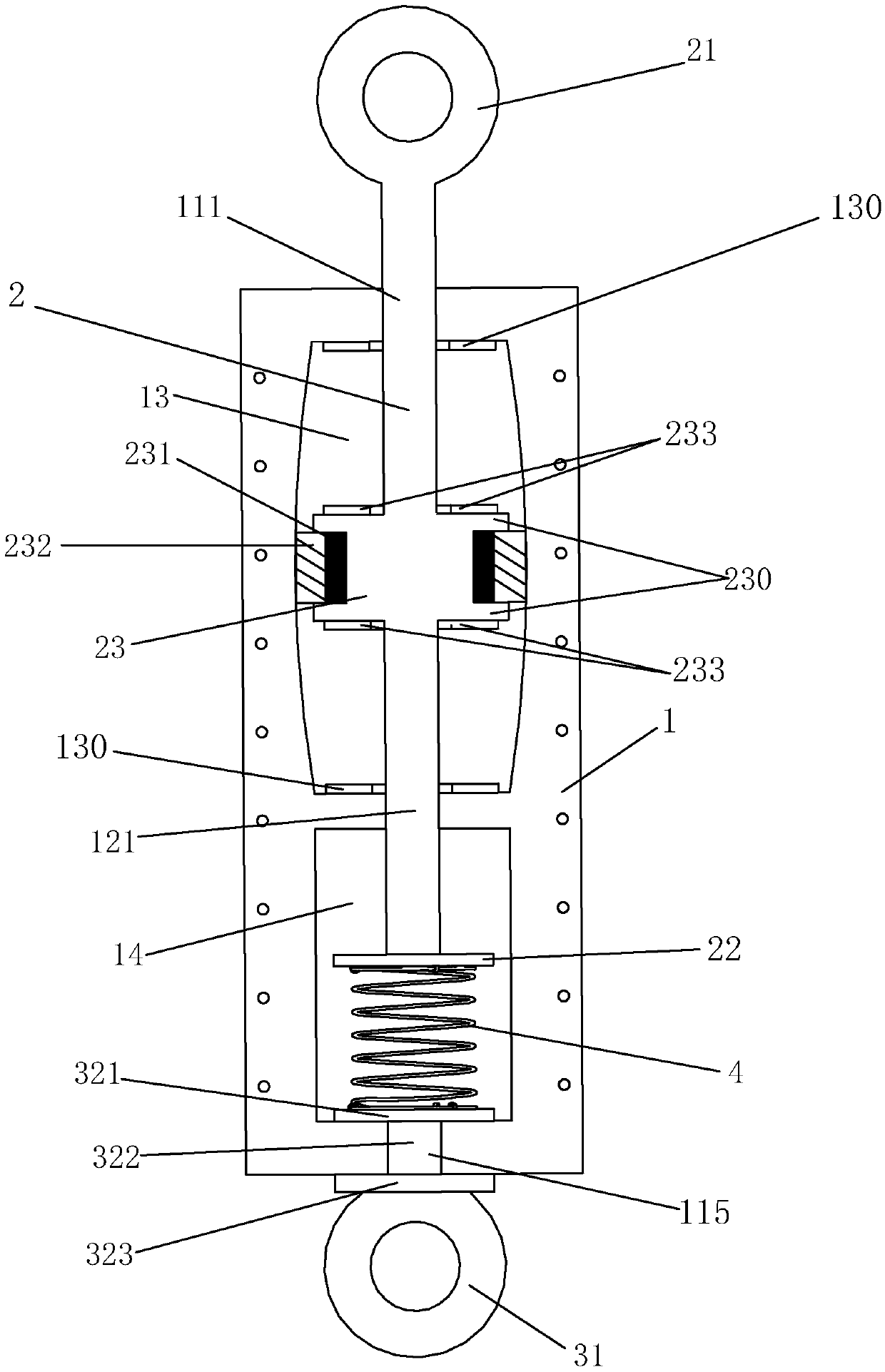

Assembled self-resetting variable friction damping device

PendingCN109519026AThe splicing and assembly method is simple and easyReduce manufacturing costProtective buildings/sheltersShock proofingPush pullEngineering

The invention discloses an assembled self-resetting variable friction damping device which comprises an outer cylinder tube, a push-pull rod, a hinge assembly and a spring which are detachably assembled by two half cylinders in axial symmetry. The assembled self-resetting variable friction damping device is simple and easy in assembly mode, solves the problem that the general damping device is inconvenient to disassemble and assemble and difficult to overhaul, reduces the manufacturing and overhaul cost to some extent, provides a new idea for development and has better application prospects.

Owner:HUAQIAO UNIVERSITY

Safety clamping and placing device for spinning cloth rolling

InactiveCN110371730AEasy to get stuckIncrease productivityWebs handlingEngineeringMechanical engineering

The invention discloses a safety clamping and placing device for spinning cloth rolling. The device comprises a base; rolled cloth, a machining device and a collecting roller device are arranged on the top surface of the base in sequence from front to back; a sliding cylinder is arranged under the rolled cloth; a clamping device is mounted on the sliding cylinder; the clamping device comprises a main mounting frame and a lifting bending frame; a finger cylinder is arranged on the top surface of a base plate of the lifting bending frame; the collecting roller device comprises a roller body; anarc gap is formed in the outer circular wall body of the roller body; an arc chute inwards extending is formed in one end of the arc gap; and an arc clamping plate is slidingly arranged in the arc chute. The device has the following advantages: a moving cylinder and the clamping device are arranged between two cloth rolling rollers; one end of cloth can be quickly clamped to shift to the cloth rolling roller at the collecting end; and a cloth fixing mechanism is arranged on the cloth rolling roller at the collecting end for convenient non-damage clamping of the cloth to greatly improve the production efficiency and the safety.

Owner:湖州浩方数码科技有限公司

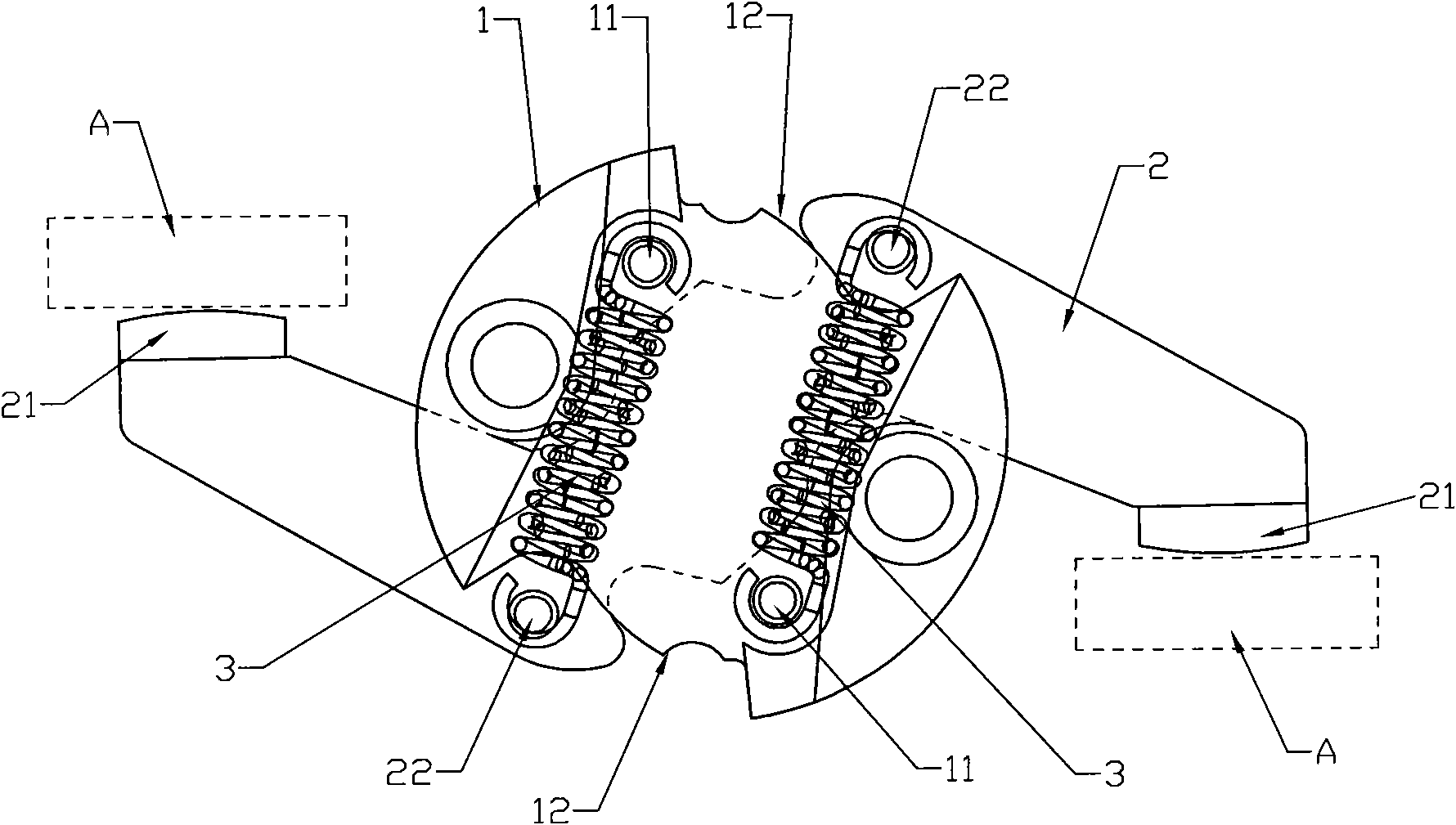

Rotating shaft clamping mechanism

InactiveCN101882546AEasy to installEasy to processContactsCircuit-breaking switch contactsLow voltage circuitsCam

The invention belongs to low-voltage electrical equipment, and relates to a rotating shaft clamping mechanism in a low-voltage circuit breaker. The rotating shaft clamping mechanism comprises a rotating shaft body and a moving contact terminal, wherein the moving contact terminal horizontally passes through an inner chamber of the rotating shaft body, can rotate around the centre of the rotating shaft body and is symmetrical about the centre; the front and rear ends of the moving contact terminal are provided with moving contacts corresponding to an upper fixed contact and a lower fixed contact on the circuit breaker respectively; the front and rear parts of the symmetrical centre of the moving contact terminal are fixed with a clamping pin extended out of the two sides respectively; the two ends of each clamping pin are towed by a pair of tension springs positioned outside the rotating shaft body; the fixed end of each tension spring is connected to corresponding fixed pins on the two outer sides of the rotating shaft body; the upper and lower edges of the rotating shaft body are provided with a section of cam surface respectively; each cam surface consists of two sunken sections and an arched section; the two sunken sections are positioned at the two ends of the cam surface, while the arched section is positioned on the middle part of the cam surface; and the clamping pins always cling to and are pressed on the corresponding cam surfaces under the action of the tension springs and can stay at the bottoms of the corresponding sunken sections. The rotating shaft clamping mechanism has the characteristics of simple structure, reliable motion and convenient manufacturing and mounting.

Owner:JIANGSU KAIFAN ELECTRICAL APPLIANCES

Corrugated carton damp-proof self-inspection packet and packing method thereof

InactiveCN109283175AIncrease usageReduce wasteMaterial analysis by observing effect on chemical indicatorComputer moduleCarton

The invention discloses a corrugated carton damp-proof self-inspection packet and a packing method thereof and belongs to the field of carton damp-proofing. The corrugated carton damp-proof self-inspection packet includes a self-inspection packet body, wherein a transparent detection rod is fixedly connected to interior of the self-inspection packet body and penetrates through the self-inspectionpacket body. A position limiting ring is fixedly connected to the outer end of the transparent detection rod and is located at the left side of the self-inspection packet body. An internal detection module and an external detection module are respectively arranged on the left and right ends of the transparent detection rod. The internal detection module includes a detection ball clamped with the transparent detection rod. A plurality of air holes are formed uniformly in the outer end of the detection ball. An internal detection groove is formed in the left end of the transparent detection rodand is communicated with one of the air holes. A transparent silica gel ball is fixedly connected to the inner wall of the internal detection groove. The self-inspection packet can simultaneously detect the dampness of internal and external environments of the corrugated carton. The self-inspection packet can be repeatedly used, thus increasing material utilization rate and reducing waste.

Owner:张起

Cylinder block and compressor

PendingCN108119340AEasy to get stuckReduce frictional power consumptionPositive displacement pump componentsPositive-displacement liquid enginesCylinder blockFastener

The invention provides a cylinder block and a compressor. The cylinder block comprises a flat plate seat, a lateral plate seat and support columns, wherein the flat plate seat is provided with a shafthole; the lateral plate seat is vertically arranged on the first side of the flat plate seat and provided with an air cylinder hole; the support columns are arranged on the flat plate seat, and a preset distance exists between each support column and the air cylinder hole. Due to the fact that the preset distance exists between each support column and the air cylinder hole, air cylinder hole deformation cannot occur easily during the screwing of fasteners for fixing a support plate when the support plate is mounted, the problem that a piston easily gets stuck in the air cylinder hole is solved, the friction power consumption of the compressor is lowered, and the mechanical efficiency of the compressor is increased.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

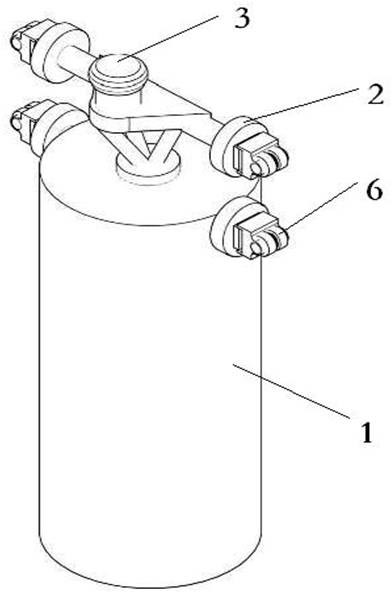

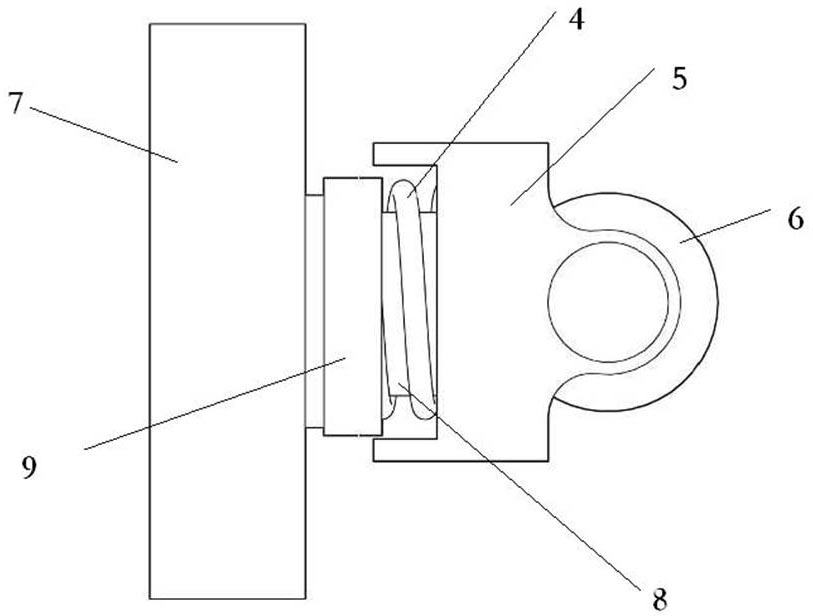

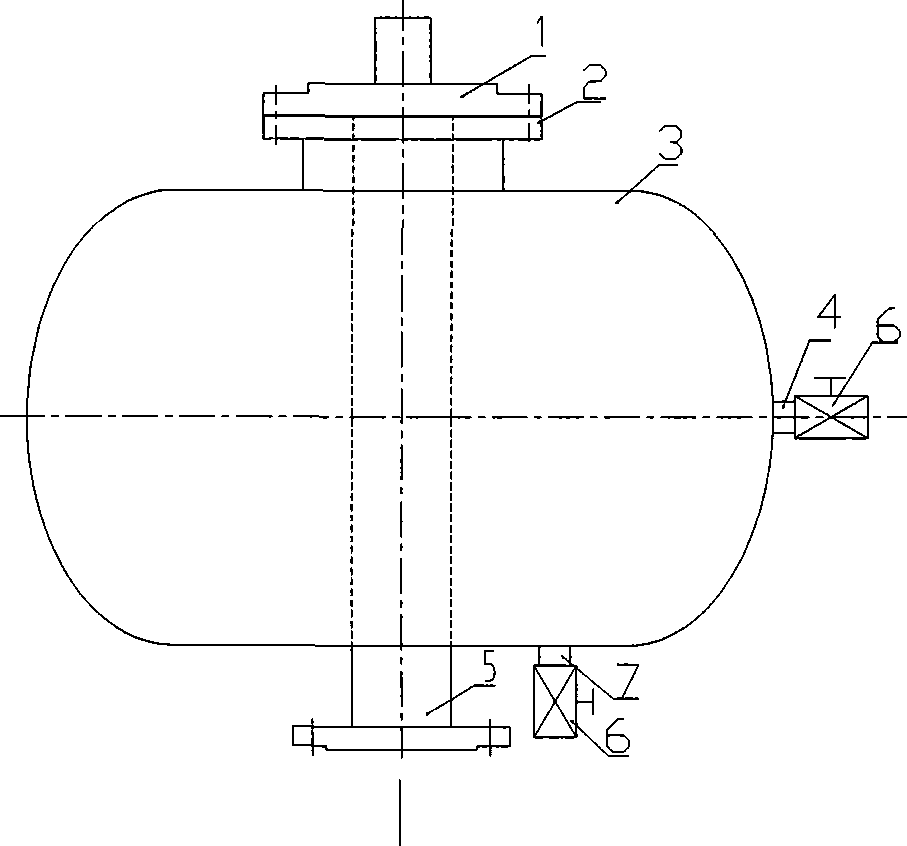

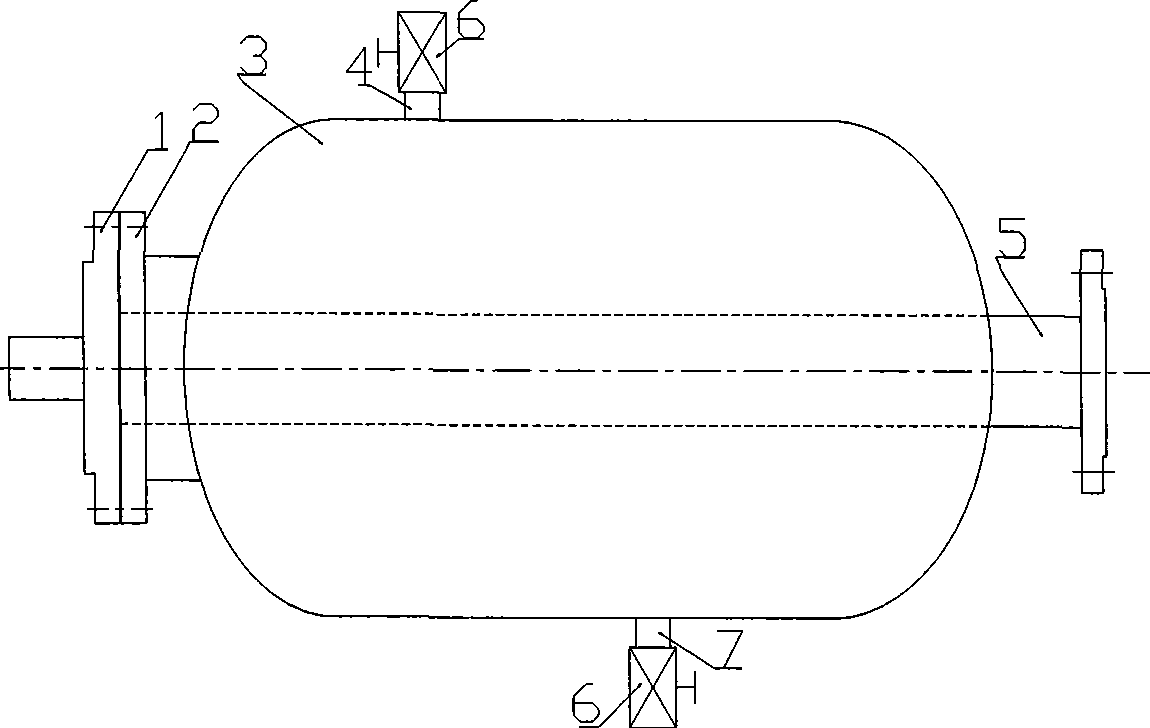

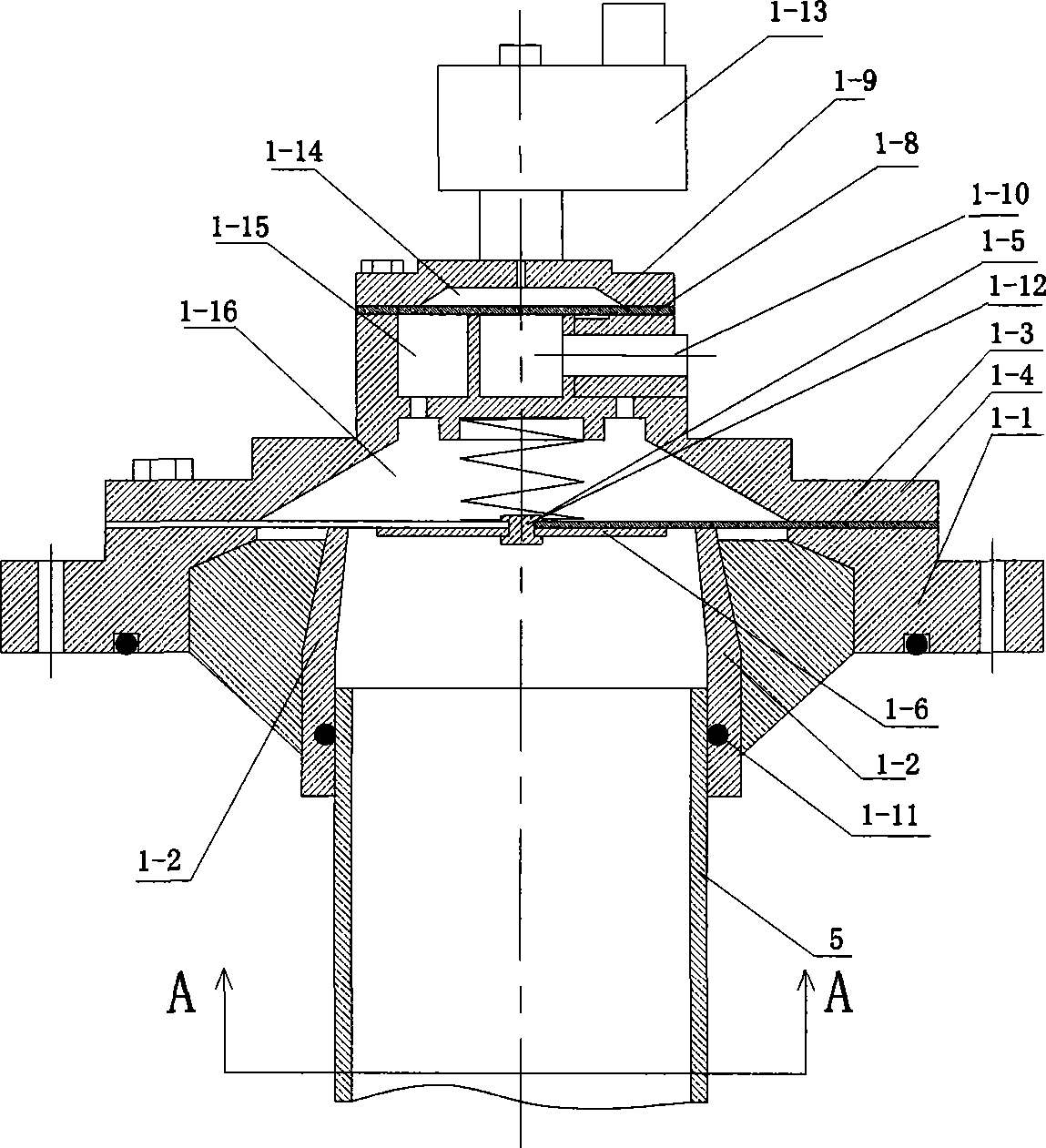

Submerged diaphragm type air cannon

The invention relates to a submerged diaphragm type air cannon which comprises an air storage tank, an air inlet pipe, a vent pipe and a connection flange which are arranged on the air storage tank. The submerged diaphragm type air cannon is characterized in that a submerged diaphragm valve is installed at the connection flange of the air storage tank; the vent pipe penetrates through a tank body and is connected with the diaphragm valve directly; and an elastic diaphragm is used for sealing an air inlet pipe nozzle of the vent pipe and controlling the vent pipe to exhaust. The working theory of the submerged diaphragm type air cannon is as follows: air enters into the air storage tank through the air inlet pipe; when the pressure in the tank reaches a set value, and the tank is required to be exhausted to impact material, the diaphragm valve is opened, and high-temperature air enters into the vent pipe through an annular air duct of a submerged pulse valve instantly and is ejected out through a vent pipe port to form a high-speed jet flow which impacts a material jammed position, so as to achieve the goals of dredging and cleaning. After the process is finished, the submerged diaphragm valve closes automatically. The air cannon has the advantages of enjoying simple structure, convenient installation, being capable of being repaired on line, causing no influence on production, being capable of realizing automatic control and continuous work and having long service life.

Owner:ZHENGZHOU OUYA AIR CANNON

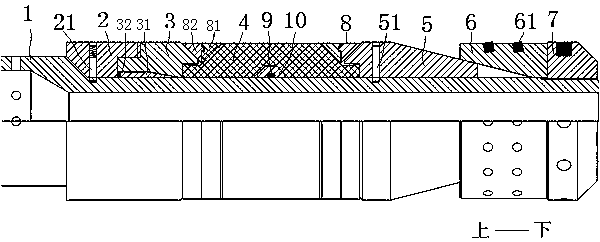

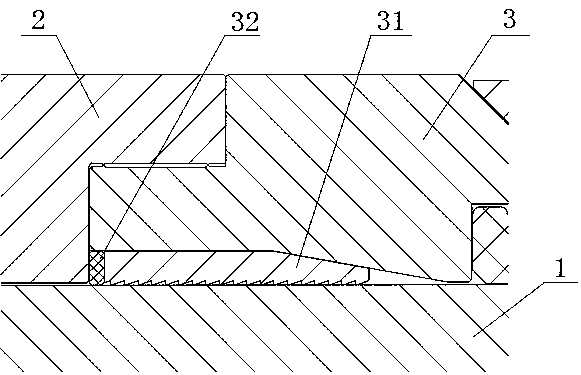

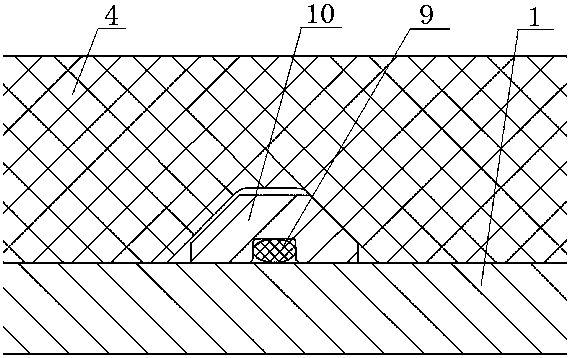

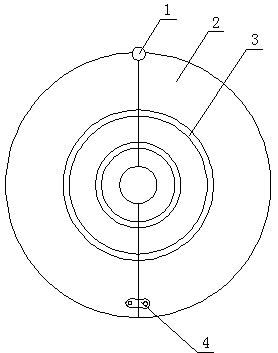

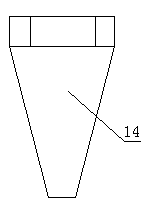

Die capable of continuously punching long screws

ActiveCN103495665AShort tripReduce energy consumptionShaping toolsStripping-off devicesPunchingEngineering

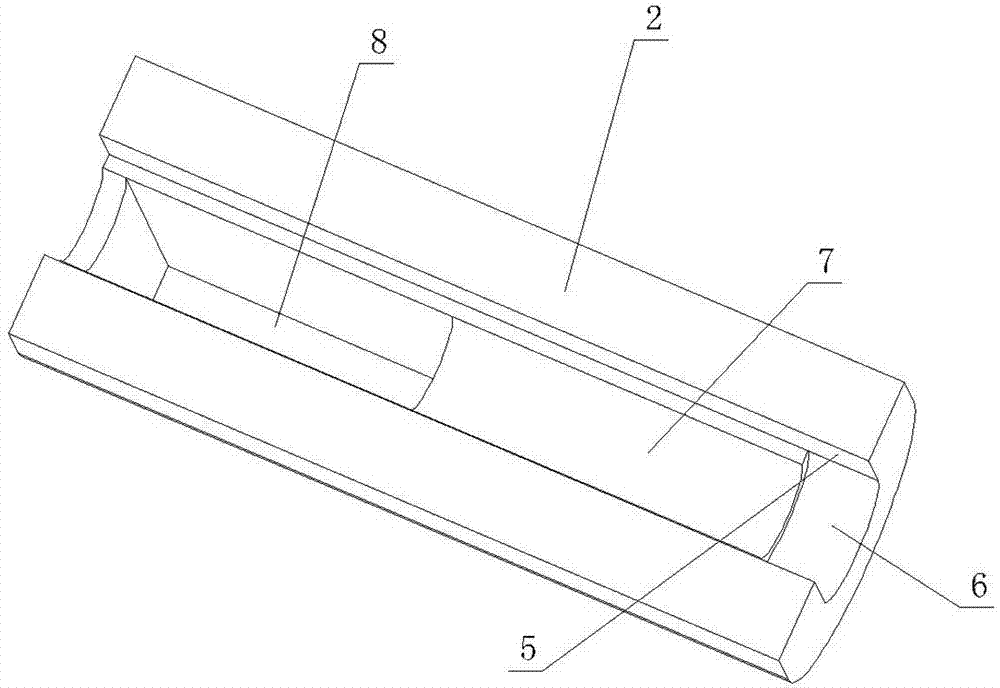

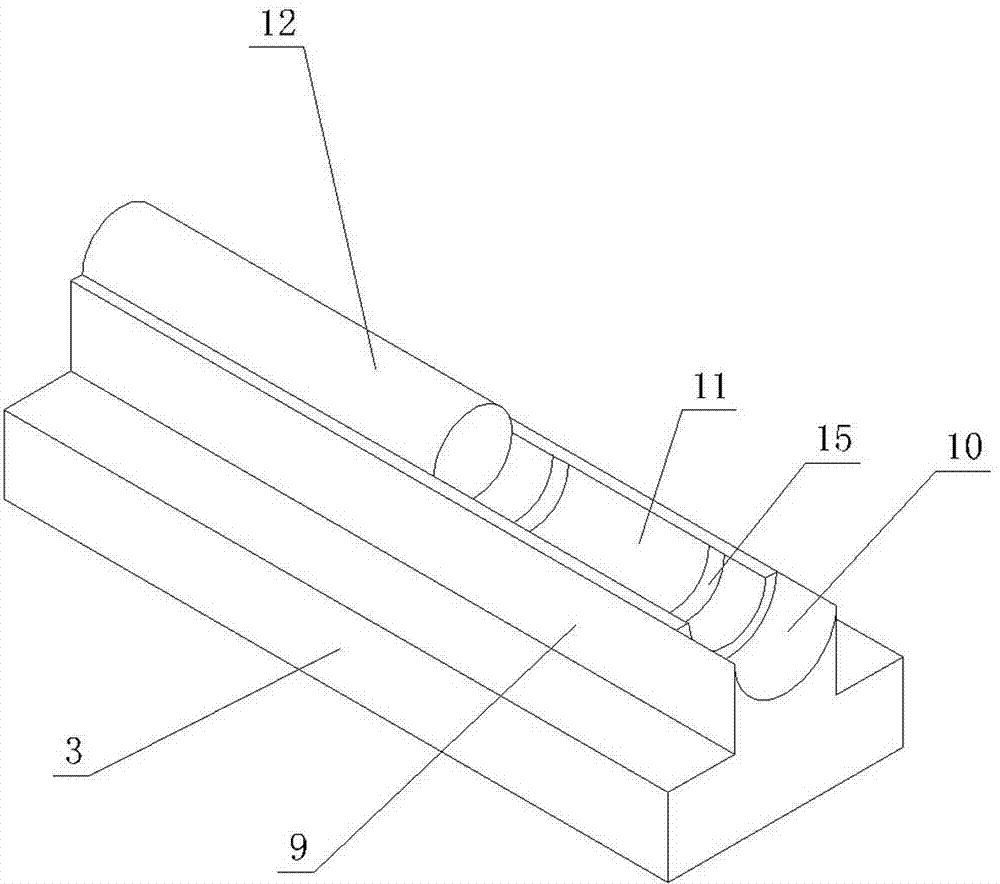

The invention discloses a die capable of continuously punching long screws. The die comprises a front punch (1), an upper die casing (2) and a lower die casing (3). A guide groove penetrating through the upper die casing (2) is arranged on the upper die casing (2), the guide groove is provided with a first upper semicircle groove (6) and a second upper semicircle groove (7), a vertical blanking channel (8) is formed in the upper die casing (2), the lower die casing (3) is provided with a guide protruded stripe, the guide protruded stripe is provided with a first lower semicircle groove (10) and a second lower semicircle groove (11), a long screw head cavity (13) is formed by the first upper semicircle groove (6), the first lower semicircle groove (10), a rear end face of the front punch (1) and an inner hexagonal protrusion (4), and a long screw rod cavity (14) is formed by the second upper semicircle groove (7), a second lower semicircle groove (11) and a blocking column (12). The die is short in die opening and closing stroke, prevents a round bar used for punching the long screws from being bent in a punching process, is high in speed, is high in efficiency and is convenient to demould.

Owner:JIANGSU HAOJIA STAINLESS STEEL STANDARD PARTS

Contactor falling-resistant device

InactiveCN102005314AEffective protectionEasy to installProtective switch detailsContact engagementsLow voltage circuitsEngineering

The invention belongs to low voltage electrical equipment, relating to a contactor falling-resistant device in a low-voltage circuit breaker. The contactor falling-resistant device comprises a spindle body and a moving contact, wherein the moving contact penetrates through the inner cavity of the spindle body from front to back and can rotate around the center of the spindle body; the moving contact is in central symmetry, the front and rear ends of the moving contact are respectively provided with a moving contact point which corresponds to fixed contact points at the upper and lower parts of the circuit breaker; the front and rear part of the centre of symmetry of the moving contact are respectively provided with a chute; each chute is internally provided with a bayonet lock which stretches out of the two sides; two ends of each bayonet lock are dragged by a pair of tension springs positioned outside the spindle body; the fixing ends of the tension springs are connected to fixing pins at two external sides of the spindle body; the upper and lower edges of the spindle body are respectively provided with a section of camming surface which is composed of two hollow sections at two ends and a hunch-up section in the middle; and the bayonet lock is always pressed on the camming surfaces under the action of the tension springs and can stay at the bottoms of the two hollow sections. The invention has simple structure and reliable action and is convenient to manufacture and install.

Owner:JIANGSU KAIFAN ELECTRICAL APPLIANCES

Oil box

InactiveCN101007299ANot easy to wearExtended service lifeLiquid surface applicatorsCoatingsGear wheelEngineering

An oiling edge box and preparation technology is used for oiling and coating edge of leather products. It includes oiling edge wheel and oiling edge box, oiling edge wheel mainly includes oiling wheel, center axis, bearings and plastic gaskets, and oiling edge box mainly includes box body and box cover. The oiling wheel is cylindrical and made of aluminum alloy material, its surface is equipped with gear deep groove. The components of the invention is relative independent and can be split to easy cleaning, and has long service life, high flexibility and efficiency and easy operation, it is simple and practical.

Owner:廖天文

Fishing and guiding device for decontamination robot

The invention relates to a fishing and guiding device for a decontamination robot. The fishing and guiding device comprises a floating body, wherein a fishing device is arranged on the floating body acrushing device is arranged below a discharge opening of the finishing device, a storing and unloading device is arranged below a discharge opening of the crushing device, a horizontal material transportation box is arranged above the crushing device, and supports A and B are arranged on two sides of the fishing device. The support A is hinged to one end of a baffle plate which clamps a long flotage, and a telescopic device which lifts the other end of the baffle plate is hinged to the support B. By adjusting the conveying direction of the long floatage, the fishing and guiding device can fish all relatively long floatages at one time automatically, so that follow-up collection of a storage box of decontamination equipment or crushing work of a crusher is facilitated.

Owner:SICHUAN ORIENT HYDROELECTRIC ENG

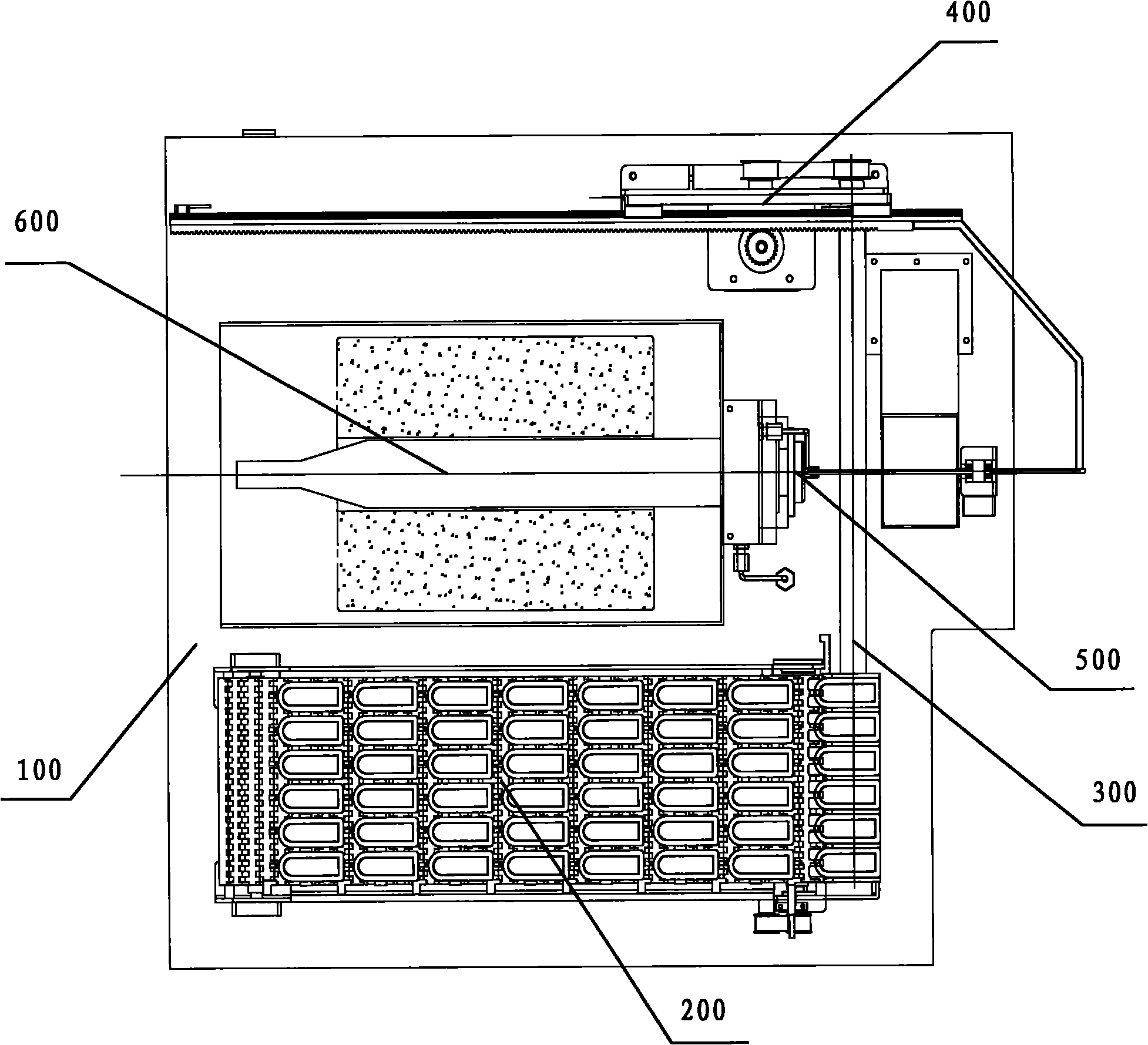

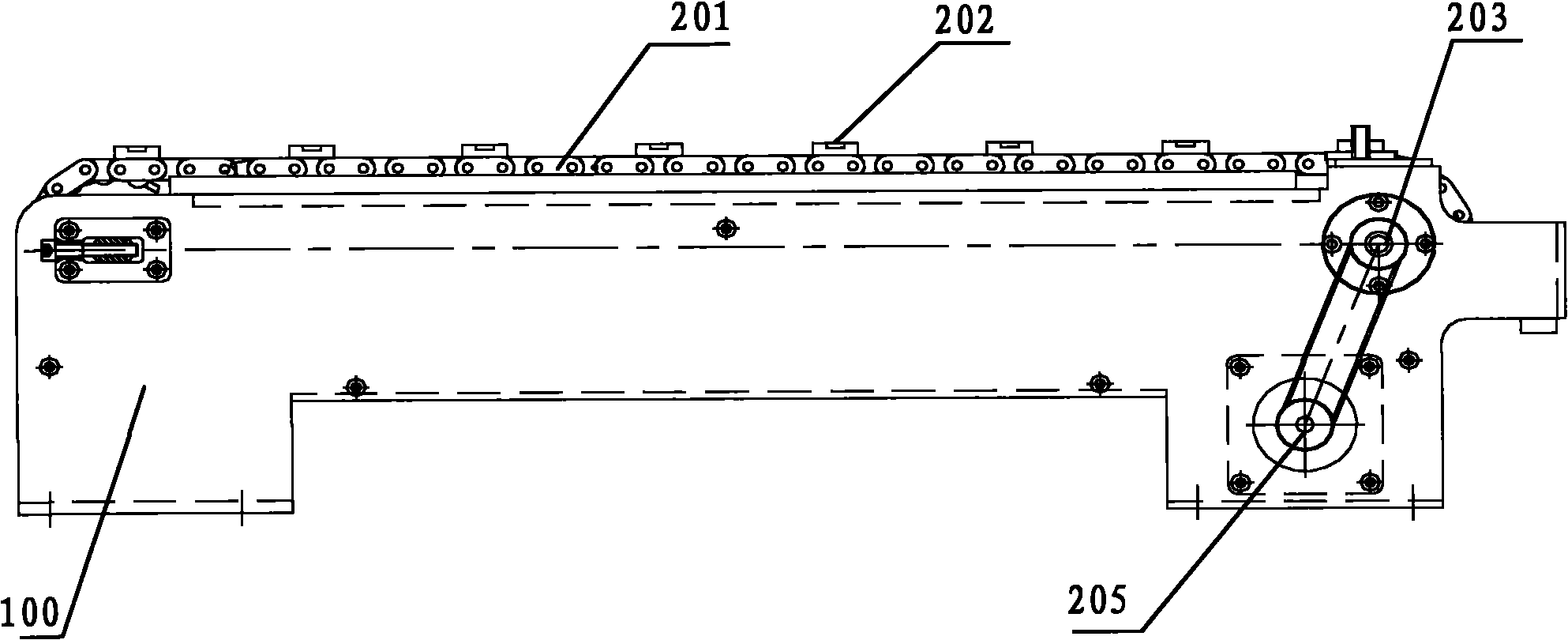

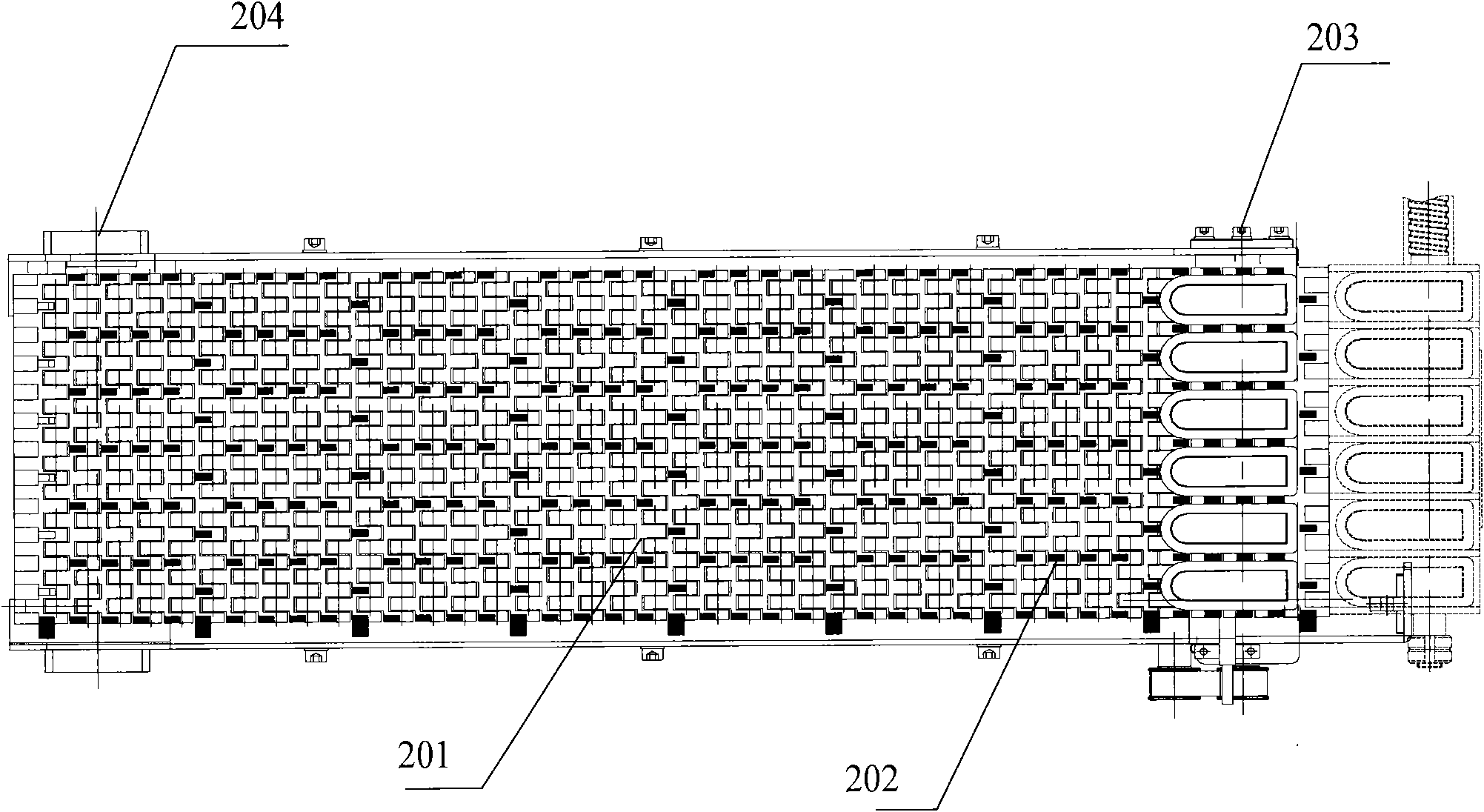

Automatic sample conveying device

InactiveCN101825643ARealize automatic transfer in batchesSimple structureMaterial analysis by optical meansAutomatic controlMechanical engineering

The invention discloses an automatic sample conveying device, which comprises a support frame, a mesh-belt conveying mechanism, a lead-screw conveying mechanism, a push rod mechanism and a furnace opening guide block, wherein the mesh-belt conveying mechanism is arranged on the support frame and is used for placing crucible pots and conveying the crucible pots in batches, the lead-screw conveyingmechanism is arranged on the support frame, and is used for conveying the crucible pots conveyed by the mesh-belt conveying mechanism to a stokehole, the push rod mechanism is arranged on the supportframe, is used for pushing the crucible pots conveyed to the stokehole by the lead-screw conveying mechanism into a furnace cavity, and can pull out the crucible pots out of the furnace cavity, and the furnace opening guide block is arranged at the stokehole and is used for making the push rod mechanism smooth push the crucible pots into the furnace cavity or smoothly pull out the crucible pots. The automatic sample conveying device can automatically control the sample conveyance in batches, the whole process is completely automatic without manual operation, and the labor can be saved. In addition, the conveyance precision is high, and the personal error is reduced.

Owner:CHANGSHA KAIYUAN INSTR

Automatic mounting spot welding machine for separation plate of drum brake

ActiveCN111168216AEasy to fall intoEasy to get stuckWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

The invention relates to the field spot welding production, in particular to an automatic mounting spot welding machine for a separation plate of a drum brake. The automatic mounting spot welding machine comprises an operation table, drum brake clamps, a drum brake feeding mechanism, a separation plate feeding mechanism, a spot welding mechanism and a finished product unloading mechanism. The operation table comprises a hollow rotary disc and a fixed disc, and the hollow rotary disc is coaxially and rotationally arranged on the fixed disc. The drum brake clamps are rotationally and evenly distributed on the fixed disc at four stations in the axial direction, and the drum brake feeding mechanism, the separation plate feeding mechanism, the spot welding mechanism and the finished product unloading mechanism are sequentially arranged on one sides of the four stations of the hollow rotary disc. According to the device, automatic feeding and welding can be carried out on the drum brake andthe separation plate, the work efficiency is high, and the labor cost is reduced.

Owner:FARINA JINAN WELDTEC & MACHINERY

Hard spiral deicing device for power transmission line cable

ActiveCN103490362AImprove securityEasy to connect and fixOverhead installationConvex structureEngineering

A hard spiral deicing device for a power transmission line cable comprises a shell, wherein the inside of the shell is provided with an annular guide rail or a guide groove, the shell comprises two symmetric half bodies, one end of one half body is hinged to one end of the other half body, the other end of one half body is connected with the other end of the other half body through a fixing mechanism, the guide rail or the guide groove is provided with a deicing wheel, the deicing wheel comprises two symmetric half wheel bodies, the outside of the deicing wheel is provided with a wheel tooth, the inside of the deicing wheel is provided with a cone-shaped cavity, the inner wall of the deicing wheel is provided with a convex structure, the wheel tooth is provided with a zipper, the two ends of the zipper penetrate through the shell and are movably connected, and the function of removing ice layers on power transmission lines is effectively achieved. Besides, the deicing wheel is movably connected with the shell through the guide rail or the guide groove and is very convenient to replace, a deicing wheel with a matched through hole can be selected according to cable models, and universality is strong.

Owner:STATE GRID CORP OF CHINA +1

Self-lifting rotary mixing and air flow impact type pulp breaking pulping equipment

InactiveCN108252139ARealize broken decompositionPlay a local stirring rolePaper recyclingRaw material divisionPulp and paper industryHigh pressure

The invention provides self-lifting rotary mixing and air flow impact type pulp breaking pulping equipment, which mainly comprises a pulp generating device consisting of a material cylinder and a cylinder cover, a self-lifting rotary mixing device, and an air flow impact pulp breaking device; the self-lifting rotary mixing device is composed of a gear cylinder, a spindle, a slide block, a cross rod, a gear and a flow disturbing plate; the air flow impact pulp breaking device is composed of a compressor, a branch pipe A, a branch pipe B and a branch pipe C; the self-lifting rotary mixing deviceand the air flow impact pulp breaking device are installed on the middle part and the inner wall of the pulp generating device. The pulping equipment is featured by that flow disturbing plate is rotated while vertically fluctuated and revolved to mix and pulp is broken by high pressure air impact. Through the gear cylinder and the flow disturbing plate of the self-lifting rotary mixing device, the all orientation mixing is realized; through the branch pipe A, the branch pipe B and the branch pipe C in the air flow impact pulp breaking device, the assistant impact breaking by air flow is realized.

Owner:UNIV OF JINAN

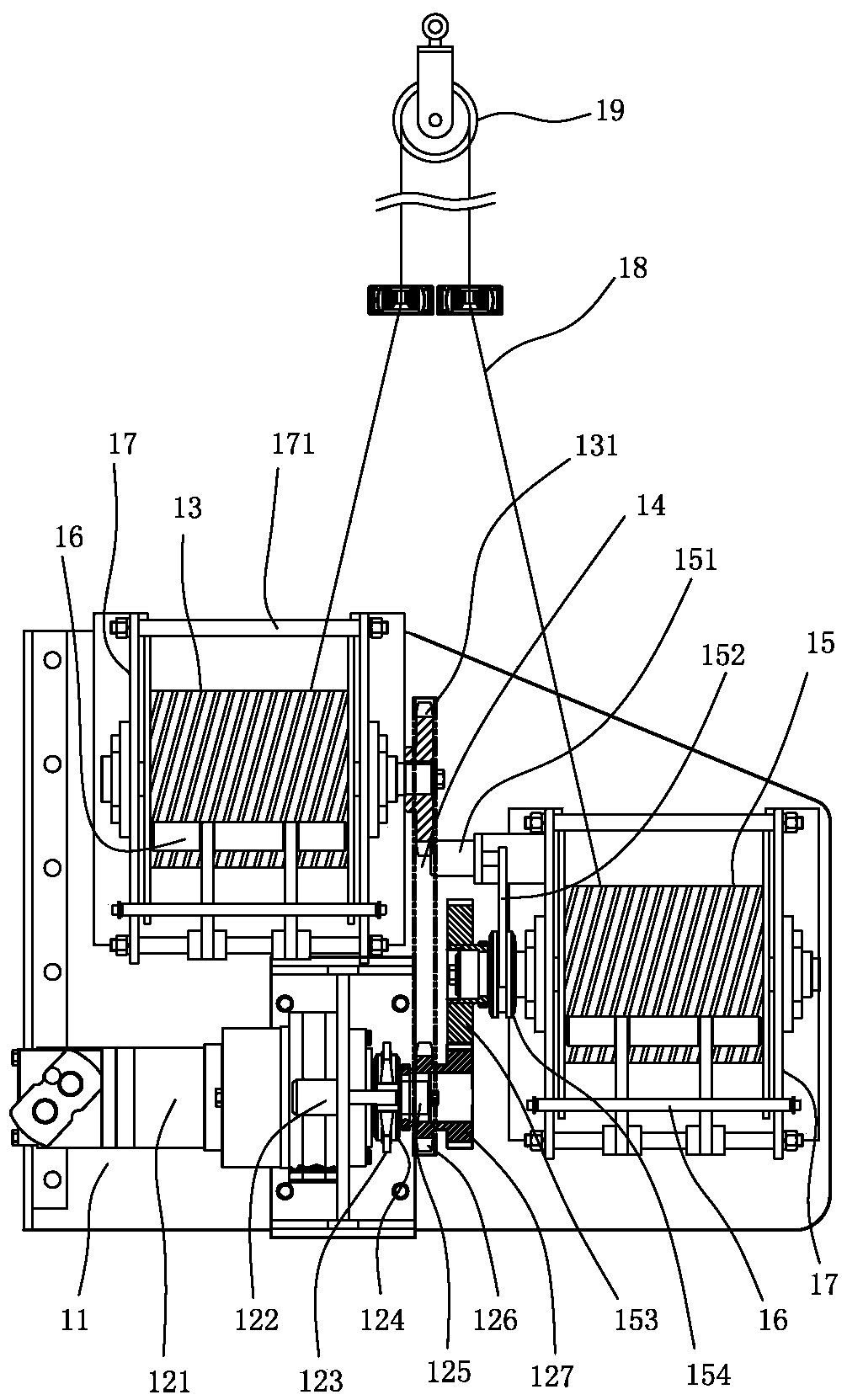

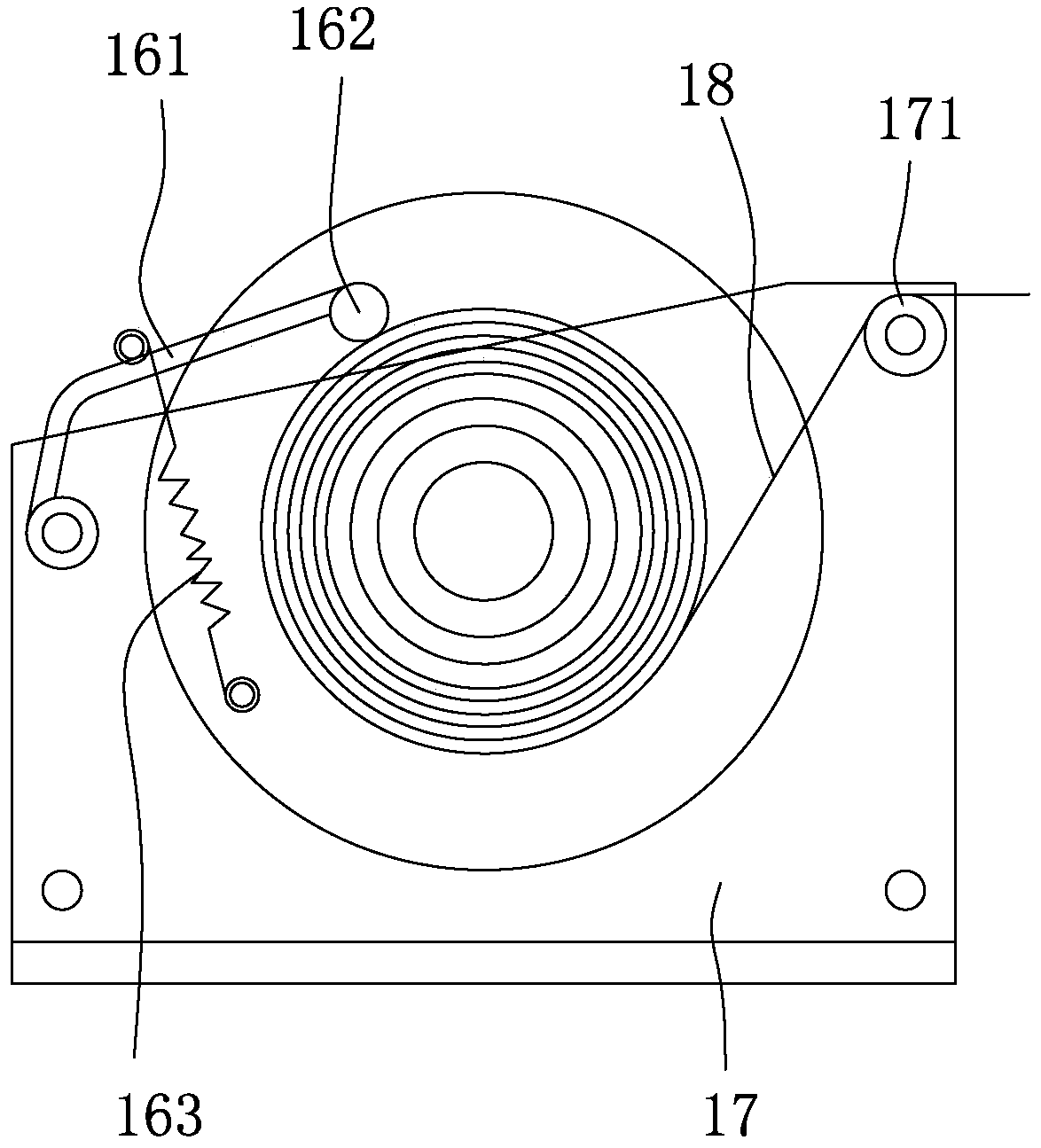

Bidirectional tractor

The invention provides a bidirectional tractor without the need of repeatedly pulling a steel wire rope by personnel. The bidirectional tractor comprises a rack, wherein an input shaft, a first drum, a second drum, the steel wire rope and a pulley are arranged on the rack; a first engagement sleeve and a first gear are arranged on the input shaft, and a first chain wheel is arranged on the first gear; a second chain wheel is arranged on a rotary shaft of the first drum, and the first chain wheel is connected with the second chain wheel through a chain; a second engagement sleeve and a second gear are arranged on a rotary shaft of the second drum, and the second gear is engaged with the first gear; and one end of the steel wire rope is fixed on the first drum, and the other end of the steel wire rope is fixed on the second drum around the pulley. According to the bidirectional tractor provided by the invention, the input shaft is capable of driving rotations with opposite rotation directions of the two drums simultaneously, the positive rotation and the reverse rotation of the input shaft drive the steel wire rope to carry out circulating travelling between the drums and the pulley, and materials are hung on the steel wire rope for being conveyed, thus a time of manually pulling the rope back to a material place is saved, the efficiency is increased, and the working intensity of the personnel is reduced.

Owner:泉州市劲力工程机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com