Liquid cooling heat dissipation module, liquid cooling heat dissipation system and electronic equipment

A technology for liquid cooling and heat dissipation of electronic equipment, which is applied to structural components of electrical equipment, cooling/ventilation/heating transformation, circuits, etc., and can solve the problem of low integration, single micro-pump easy to get stuck in the working medium circulation, and the volume of the cooling system Major and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

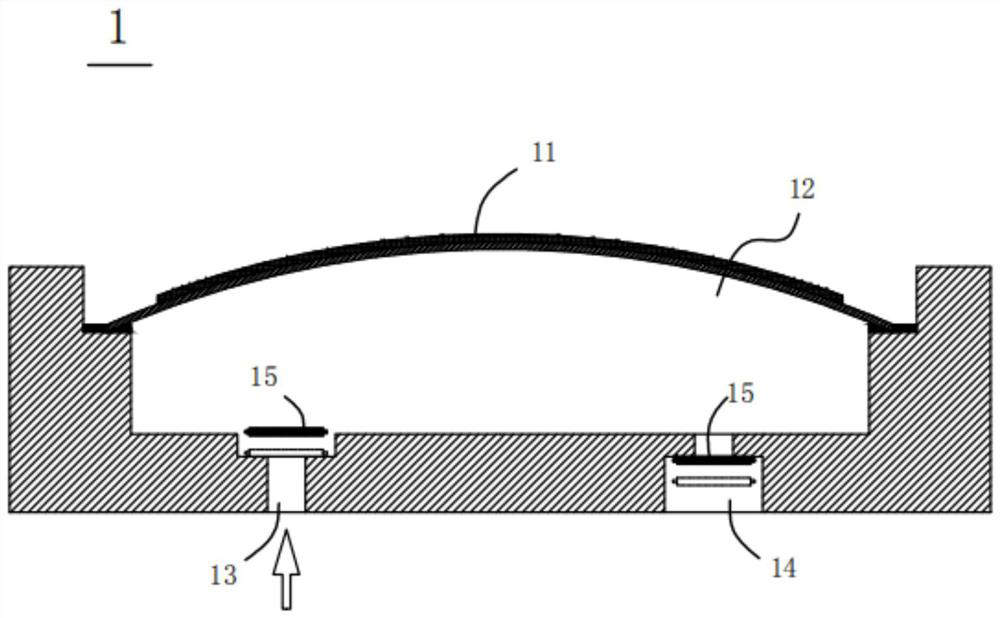

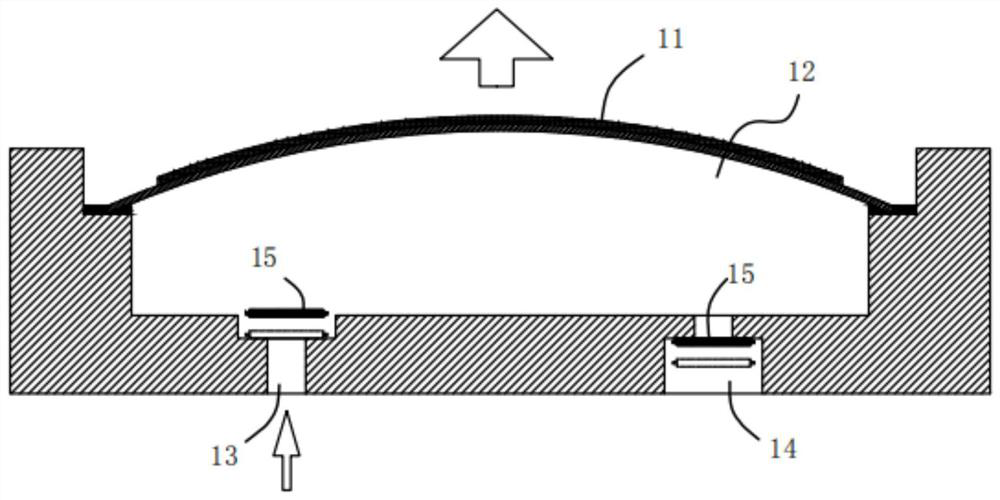

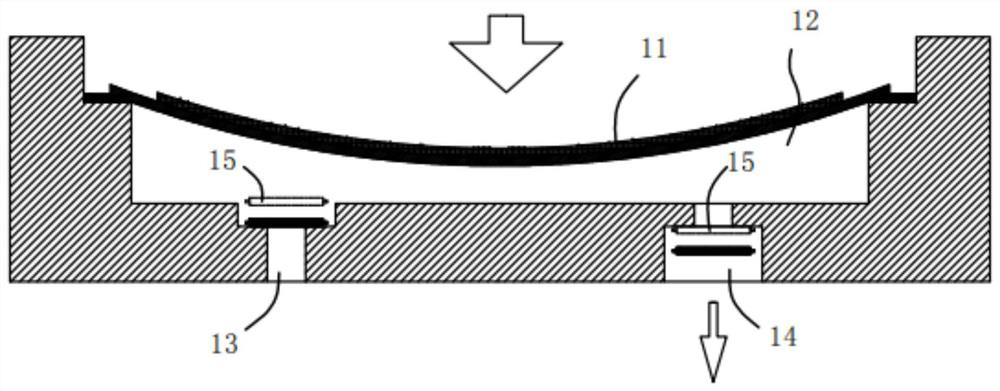

[0061] see Figure 1-4 , the liquid-cooled heat dissipation module provided in this embodiment includes a power pump 1 and a pressure regulating module 2. The power pump 1 provides power for the heat dissipation circuit, and the pressure regulation module 2 and the power pump 1 are connected in series on the heat dissipation circuit. When working, at the same time , the sum of the volume change of the pump chamber 12 caused by the power pump 1 and the volume change of the pressure regulating chamber of the pressure regulating module 2 approaches zero. Specifically, when the power pump 1 is in the suction range, the pressure regulating module 2 is in the discharge range , the fluid flows in one direction in the channel 3, and the volume increase of the pump chamber 12 of the power pump 1 is basically equal to the decrease of the volume of the pressure regulating module 2, so that the volume change of the pump chamber 12 caused by the power pump 1 The sum of the volume changes o...

Embodiment 2

[0071] Such as Figure 10 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the pressure regulating module 2 is an active pressure regulating structure, and the active pressure regulating structure includes a cavity 21a and an active plate 22a, and the cavity 21a Configured as the pressure regulating chamber, the chamber 21a communicates with the flow channel 3, and the part of the active plate 22a opposite to the chamber 21a can bend and vibrate, thereby driving the fluid in the chamber 21a to enter and exit. Its working principle is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0073] Such as Figure 11 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the pressure regulation module 2 is a passive pressure regulation structure, and the passive pressure regulation structure includes an elastic diaphragm 22b and an elastic chamber 21b, and the elastic diaphragm 22b is at least In the working state, it is formed into a curved structure, and the concave surface of the curved structure forms an elastic cavity 21b;

[0074] The elastic cavity 21b is configured as the pressure regulating cavity, and the elastic cavity 21b communicates with the flow channel 3 . In this way, the elastic cavity 21b can be adaptively changed along with the suction stroke and discharge stroke of the power pump 1 , thereby playing the role of balancing flow channel pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com